No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M16 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M8 Copper Plain Washers – High-Conductivity Washers for Precision Fastening Applications

At Nafees Metal Industries, we specialize in delivering high-precision fastening components, and our M8 copper plain washer is a testament to this commitment. Manufactured with premium-grade copper, this washer offers outstanding thermal and electrical conductivity, making it ideal for electrical, plumbing, automotive, and mechanical applications.

As one of the best copper washer manufacturers in India, we design each M8 copper plain washer to exact international standards for dimensional accuracy, surface finish, and durability. Whether you’re working with high-performance electrical systems or sensitive mechanical assemblies, our washers provide the reliability and performance you need.

Each M8 copper plain washer from Nafees Metal Industries ensures stable load distribution, corrosion resistance, and superior conductivity—making it the first choice for industries requiring high-quality copper washers. With our Mumbai-based facility equipped for high-volume production, we cater to bulk orders while maintaining consistent quality across batches.

What Are M8 Copper Plain Washers?

An M8 copper plain washer is a circular flat washer with a central hole designed to accommodate M8-sized bolts or screws (8 mm in diameter). Its core function is to evenly distribute the load of a fastener, thereby preventing surface damage, loosening, and wear to the materials being joined.

What sets the M8 copper plain washer apart is its high electrical and thermal conductivity, corrosion resistance, and malleability. These properties make it especially valuable in industries where precision, conductivity, and anti-corrosion features are non-negotiable—such as electronics, plumbing, HVAC systems, and automotive assembly lines.

Crafted from solid copper, each M8 copper plain washer is designed to:

Prevent direct contact between the fastener and the base material

Spread the load over a larger surface area

Protect the surface finish of the connected components

Support conductivity in applications where electrical flow is required

Being a copper flat washer M8 size, it is non-magnetic, resistant to extreme temperatures, and provides a tight seal, especially under vibration-prone environments. That’s why industries across India and overseas trust Nafees Metal Industries as their reliable source for machined washer components and bulk supplies of copper washers.

Why Copper for M8 Washers?

Choosing copper as the base material for washers brings a range of performance advantages, especially when compared to conventional materials like mild steel or aluminum. An M8 copper plain washer offers a unique combination of strength, corrosion resistance, and conductivity—making it an ideal choice for both mechanical and electrical applications.

Here are key reasons why copper is the preferred material for M8 plain washers:

1. Excellent Electrical Conductivity

Copper is one of the best electrical conductors among industrial metals. An M8 copper plain washer facilitates uninterrupted current flow in electrical and grounding systems, which is vital for safety and performance.

2. Superior Thermal Conductivity

In applications where heat dissipation is required, copper outperforms other metals. These washers are ideal for use in systems exposed to high temperatures or requiring thermal stability.

3. Natural Corrosion Resistance

Copper forms a protective oxide layer when exposed to air, protecting it from corrosion in many environments. Our M8 copper plain washer can be used confidently in plumbing, HVAC, and marine applications without the fear of rust or degradation.

4. Ductility and Malleability

Copper’s ability to deform without cracking ensures each washer conforms snugly during fastening. This provides better sealing, especially in dynamic or vibration-sensitive environments.

5. Non-Magnetic Properties

The non-magnetic nature of copper makes the M8 copper plain washer suitable for sensitive applications, including MRI machines, telecom equipment, and precision electronics.

6. Environmentally Sustainable

Copper is 100% recyclable without loss of performance, making our M8 copper plain washer an eco-friendly choice for forward-thinking industries.

Whether you require a copper washer for conductivity, sealing, or structural support, Nafees Metal Industries ensures that every washer we manufacture delivers performance, durability, and reliability. We are proud to be one of the best copper washer manufacturers in India, known for quality materials and customer-focused solutions.

How Are M8 Copper Plain Washers Manufactured?

At Nafees Metal Industries, every M8 copper plain washer is crafted with precision and care to meet international engineering standards. Our production process combines advanced machinery, skilled manpower, and strict quality controls to ensure each washer performs reliably in its intended application.

Here’s a step-by-step overview of how our M8 copper plain washers are manufactured:

1. Raw Material Sourcing

We procure high-purity industrial-grade copper sheets that are tested for conductivity, tensile strength, and corrosion resistance. These sheets form the base of every M8 copper plain washer we produce.

2. Precision Blanking & Punching

Using CNC-controlled punch presses, washers are cut (blanked) to the exact outer diameter, and then punched to create the precise 8.4 mm inner diameter—ideal for M8 bolts or screws. Our process ensures consistency across thousands of units.

3. Deburring & Edge Smoothing

The punched washers undergo vibratory deburring and edge-smoothing to eliminate sharp edges and surface irregularities. This is critical for ensuring safe handling and accurate fitment of the M8 copper plain washer.

4. Annealing (Optional)

If required, washers are heat-treated (annealed) to increase ductility and ensure flexibility in sealing or vibration-prone applications.

5. Surface Finishing

Each M8 copper plain washer is either left in its raw copper finish or lightly polished based on application needs. We can also offer customized coatings if required.

6. Dimensional & Conductivity Testing

Each production batch is tested for:

Inner and outer diameter (as per IS/DIN/ISO standards)

Thickness tolerance

Flatness and roundness

Electrical conductivity (on request)

7. Packaging & Dispatch

Washers are carefully packed in moisture-resistant polybags or corrugated boxes. Bulk buyers can opt for custom packaging and labeling as per their procurement standards.

Our in-house quality control team ensures that every M8 copper plain washer leaving our Mumbai-based facility meets exact technical specifications and is ready for immediate use across various industries.

As one of the best copper washer manufacturers in India, we take pride in producing machined washers that meet the highest standards of quality, consistency, and value.

Key Features of M8 Copper Plain Washers

The M8 copper plain washer is engineered to provide optimum performance in a wide range of industrial and technical environments. Whether you’re dealing with high-temperature conditions, electrical applications, or mechanical systems, this washer delivers reliable functionality and long-term durability.

Below are the key features that make our M8 copper plain washers stand out:

1. Precision Fit for M8 Bolts and Screws

Designed with a central hole diameter of approximately 8.4 mm, each M8 copper plain washer ensures an exact and snug fit with M8 fasteners. This prevents wobble, enhances load distribution, and improves fastening security.

2. Superior Electrical and Thermal Conductivity

Copper is unmatched in its ability to conduct electricity and dissipate heat. These properties make the M8 copper plain washer essential in grounding systems, electrical terminals, and thermal applications.

3. Anti-Corrosive Properties

Our washers resist rust and corrosion naturally due to the protective oxide layer that forms on copper surfaces. This ensures a long service life even in humid or chemically exposed environments.

4. Uniform Thickness and Smooth Surface

Every M8 copper plain washer is manufactured with controlled thickness and a polished finish. This helps reduce friction during fastening and ensures smooth engagement with adjoining surfaces.

5. Vibration Dampening

Thanks to copper’s inherent softness and malleability, these washers can absorb minor vibrations and reduce loosening in dynamic assemblies, such as automotive engines or industrial equipment.

6. Non-Magnetic and Non-Sparking

Copper is a non-magnetic and non-sparking metal, making these washers suitable for use in sensitive environments such as electronics, medical devices, and flammable zones.

7. Available in Bulk and Custom Packaging

Our M8 copper plain washers are available for bulk procurement with the option of tailored packaging, labeling, and delivery schedules to suit OEMs, distributors, and resellers.

8. Fully Compliant with Industry Standards

All washers comply with applicable dimensions and tolerances as per IS 2016 / DIN 125 / ISO 7089 standards. This ensures compatibility and interchangeability with other standard fasteners.

9. Made in India with Global Standards

Manufactured at our Mumbai facility using advanced power press machines and QC-tested procedures, our washers represent the quality and reliability of India’s leading copper washer manufacturer.

10. Ready Stock and Short Lead Times

We maintain consistent inventory levels of M8 copper plain washers to fulfill urgent or high-volume requirements swiftly across India and globally.

When you choose Nafees Metal Industries, you are investing in high-quality, precision-made copper washers trusted by engineers and manufacturers across industries. We’re proud to be among the best copper washer manufacturers in India, offering unmatched value and performance.

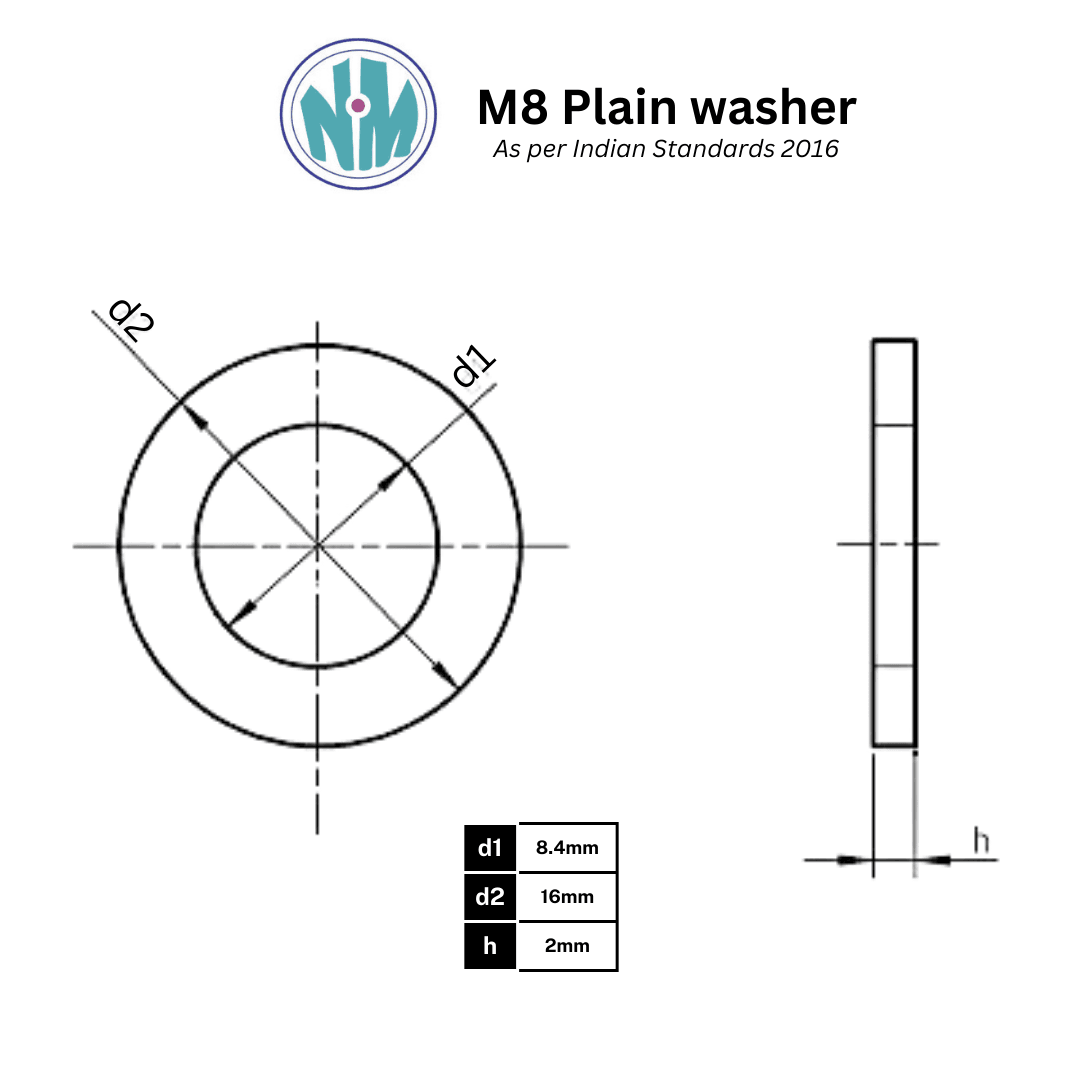

Technical Specifications of M8 Copper Plain Washers

At Nafees Metal Industries, we understand the importance of precision in fastening applications. That’s why each M8 copper plain washer we produce conforms to globally recognized quality and dimensional standards. Below is a detailed overview of the technical specifications:

| Property | Specification |

|---|---|

| Product Name | M8 Copper Plain Washer |

| Material | Commercially Pure Copper (99% min. Cu content) |

| Inner Diameter (ID) | Approx. 8.4 mm (suitable for M8 bolts/screws) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 |

| Thickness | 1.0 mm – 2.0 mm (standard); customizable on request |

| Washer Type | Flat / Plain Washer |

| Surface Finish | Natural Copper Finish / Lightly Polished |

| Hardness | Soft to Medium (Annealed or Work-Hardened as required) |

| Conductivity | High electrical and thermal conductivity |

| Corrosion Resistance | Naturally corrosion-resistant (non-ferrous) |

| Magnetism | Non-magnetic |

| Flammability | Non-sparking; safe for explosive or flammable environments |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Manufacturing Process | Cold-stamped or CNC-machined from solid copper sheets |

| Packaging Options | Bulk polybags / Boxes / Customized Packaging |

| MOQ (Minimum Order Quantity) | As per client requirement |

| Application Category | Electrical, Mechanical, Plumbing, Automotive, HVAC |

| Country of Origin | India |

Every M8 copper plain washer undergoes rigorous testing for dimensional accuracy, surface finish, and performance. As one of the leading copper washer manufacturers in India, we assure strict adherence to technical standards, whether for domestic use or international exports.

We also accommodate custom orders for different copper washer sizes, surface finishes, or hardness grades to match the specific needs of our clients. Whether you’re an OEM, wholesaler, or industrial buyer, our flexible manufacturing capabilities and fast delivery timelines ensure you receive exactly what you need—on time and in budget.

Applications of M8 Copper Plain Washers

The M8 copper plain washer is a versatile and essential fastening component used across a wide range of industries. Due to its superior conductivity, anti-corrosion properties, and mechanical stability, this washer is favored in both electrical and mechanical environments where reliability is non-negotiable.

Here’s a breakdown of key applications where the M8 copper plain washer excels:

1. Electrical Grounding Systems

In electrical panels, terminals, and cable lug assemblies, M8 copper plain washers ensure optimal conductivity and secure fastening. Their high conductivity helps maintain stable current flow and reduces resistance across joints.

2. Automotive & Engine Assemblies

These washers are ideal for vibration-prone environments such as engine compartments and exhaust systems. They offer a stable seal and prevent fastener loosening under thermal expansion and movement.

3. Plumbing & HVAC Installations

Due to copper’s natural corrosion resistance and sealing ability, M8 copper plain washers are widely used in pipe flanges, valves, and heating system fittings, especially in systems where galvanic corrosion must be avoided.

4. Renewable Energy Systems

Used in solar panels, wind turbines, and battery assemblies, these washers maintain conductivity and resist weathering over long service periods, ensuring minimal maintenance and maximum efficiency.

5. Electrical & Electronic Equipment

From printed circuit boards (PCBs) to switchgear cabinets, the M8 copper plain washer helps secure components while maintaining electrical integrity. It’s particularly useful in applications requiring EMI/RFI shielding.

6. Aerospace & Defense

The non-sparking, non-magnetic nature of copper makes these washers safe for use in explosive or sensitive electromagnetic environments where safety and precision are critical.

7. Marine & Offshore Equipment

In shipbuilding and offshore oil platforms, where salty, humid conditions prevail, M8 copper plain washers are chosen for their corrosion resistance and sealing performance.

8. Power Distribution Systems

They are extensively used in substations, battery banks, and transmission systems to ensure safe and reliable connectivity between high-voltage equipment.

9. Manufacturing and Assembly Lines

Industrial machinery often incorporates copper washers to ensure clean, tight, and safe bolting, especially in temperature-sensitive or conductive environments.

10. Custom Equipment & Prototype Development

OEMs and R&D labs use M8 copper flat washers during prototyping to ensure material reliability and performance under various stress conditions.

Because of their excellent material properties and dimensional accuracy, our M8 copper plain washers have become a staple in industries where both performance and longevity are crucial. Whether you need a copper washer for its conductivity, vibration resistance, or sealing properties, Nafees Metal Industries is your trusted source.

We proudly serve clients across sectors and are recognized among the best copper washer manufacturers in India for delivering quality that meets global standards.

Advantages of Using M8 Copper Washers

When selecting the ideal washer for mechanical or electrical applications, copper stands out as a premium material. The copper washer offers several unmatched advantages that make it a preferred choice across industries. At Nafees Metal Industries, we focus on delivering washers that combine performance, durability, and value.

Here are the key benefits of using our M8 copper plain washers:

1. Excellent Load Distribution

Each M8 copper plain washer evenly spreads the load of the fastener over a wider surface area. This reduces stress concentration on the material underneath and prevents deformation or damage to softer components.

2. High Electrical and Thermal Conductivity

Copper’s superior conductivity ensures optimal current flow in electrical assemblies and rapid heat dissipation in high-temperature environments. This makes the washer ideal for grounding, terminals, and thermal control systems.

3. Superior Corrosion Resistance

Unlike steel washers that require plating to resist rust, copper naturally forms a protective oxide layer. Our M8 copper flat washers perform reliably in humid, marine, and chemically exposed environments without degrading.

4. Non-Magnetic and Non-Sparking

Copper does not interfere with magnetic fields and doesn’t create sparks, making it a safe choice for explosive environments or sensitive electronic equipment.

5. Thermal Stability

Even under high thermal loads, these washers retain their structural integrity. This makes the M8 copper washer suitable for use in engines, power plants, and high-temperature installations.

6. Vibration Absorption

Copper’s malleability helps absorb shock and vibrations, reducing the chances of fastener loosening over time. This enhances long-term joint integrity in machines and moving systems.

7. Machinability and Customization

Copper is easy to machine, allowing us to produce machined washers in precise sizes and thicknesses to match client-specific requirements.

8. Easy Handling and Installation

Our M8 copper flat washers come with smooth edges, clean finishes, and consistent thickness—making them easy to use on assembly lines or during maintenance work.

9. Sustainable and Recyclable

Copper is 100% recyclable without loss in quality. Choosing copper washers reflects a sustainable and eco-conscious approach to industrial material usage.

10. Trusted by Professionals Across India

As one of the best copper washer manufacturers in India, Nafees Metal Industries has earned the trust of thousands of buyers across automotive, electrical, marine, and heavy machinery sectors. Our washers consistently meet performance expectations under the toughest conditions.

Whether you require them in bulk for industrial applications or as part of a specialized system, our M8 copper washers deliver the strength, reliability, and conductivity you expect from a premium fastening component.

Buy M8 Copper Plain Washers in Bulk – Best Copper Washer Manufacturer in India

If you’re sourcing high-quality, precision-made M8 copper flat washers for your business, look no further than Nafees Metal Industries—India’s trusted partner in industrial-grade washer manufacturing.

As one of the best copper washer manufacturers in India, we specialize in meeting the needs of OEMs, distributors, industrial suppliers, and government contractors who demand consistency, performance, and value.

Here’s why you should source your M8 copper washer requirements from us:

1. Bulk Manufacturing Capability

Our advanced production unit in Mumbai is equipped with high-speed power press machines and CNC-controlled systems that allow us to manufacture M8 copper flat washers in large volumes while maintaining consistent dimensions and finish.

2. Competitive Pricing for Bulk Orders

With raw material sourcing in bulk and streamlined operations, we offer the most competitive prices in the market—without compromising on quality. We cater to high-volume procurement requirements across India and for export markets.

3. Custom Coating and Finish Options

Depending on your application, we provide natural polished finish, or custom coatings on request. From annealed finishes for flexibility to harder surfaces for load-bearing, we tailor your M8 copper washer order to your needs.

4. Fast Lead Times & Nationwide Delivery

We maintain ready stock for standard sizes like copper flat washer M8 size, allowing us to process and dispatch bulk orders quickly. Our logistics partners ensure timely delivery across India, including remote industrial zones.

5. Export-Ready Documentation

For international clients, we provide full export support, including test certificates, packing lists, HS codes, invoices, and country-of-origin documentation for seamless customs clearance.

6. Dedicated Customer Support

Our technical team works closely with buyers to understand project specifications and recommend the most appropriate copper washer solution. We offer responsive service from inquiry to delivery.

7. Custom Labeling and Packaging

We offer customized packaging options for distributors and resellers. Washers can be packed in polybags, cartons, or labeled with your branding or item codes.

8. Made in India – Trusted Globally

All our M8 copper plain washers are proudly manufactured in India, in full compliance with IS and DIN standards. Our reputation for quality has helped us build lasting relationships with clients across multiple sectors.

Whether you’re assembling electrical equipment, developing industrial machinery, or supplying components to key industries, partnering with Nafees Metal Industries ensures you receive machined washers that exceed expectations.

To place a bulk order or request a sample of our M8 copper plain washer, visit www.nafeesmetalindustries.com or get in touch with our sales team.

Case Study – Solving Electrical Fastening Issues with M8 Copper Washers

A leading electrical panel manufacturer in Pune faced recurring issues with arcing and surface damage around fastener points during high-voltage operations. Their existing hardware lacked conductivity and could not maintain proper grounding, leading to performance drops and costly maintenance downtime.

The company decided to test copper washers of 8 mm inner diameter across multiple units. Within weeks, they observed the following improvements:

Stable electrical grounding that reduced system resistance by over 20%

Reduced arcing and thermal hotspots, thanks to copper’s high conductivity

Increased component lifespan, as the washers protected mating surfaces from damage

Minimal loosening under vibration, enhancing reliability in mission-critical applications

These measurable improvements led the manufacturer to adopt copper washers for all their high-current terminals. Since implementation, their service complaints have reduced by over 40%.

This case study highlights how industries can benefit from switching to better fastener accessories, especially in environments where conductivity, sealing, and corrosion resistance are essential.

Different Applications of M8 Copper Washers in Industrial Settings

Copper washers with an 8 mm inner diameter are widely used across industries due to their exceptional thermal and electrical properties. These flat rings serve critical roles beyond just spacing or load distribution — they enhance performance, safety, and durability in demanding environments.

1. Automotive Industry

In engines and braking systems, these washers are commonly installed in oil drain plugs, fuel systems, and banjo bolt assemblies. Their malleability ensures a tight seal, even under high-pressure and high-temperature conditions, preventing leaks and improving safety.

2. Electrical and Electronics

Owing to copper’s high conductivity, these washers are used in switchboards, earthing terminals, and high-voltage electrical systems. They ensure consistent grounding, reduce electrical resistance, and help prevent arcing between fastened metal surfaces.

3. HVAC and Refrigeration Systems

Technicians use them in refrigeration compressors and HVAC connections where thermal expansion and contraction are common. Their ability to maintain a seal under fluctuating temperatures makes them ideal for such applications.

4. Plumbing and Fluid Handling

In pipe fittings and hydraulic systems, they act as crush washers that ensure leak-proof seals. Their corrosion resistance makes them ideal for contact with water and chemicals.

5. Renewable Energy Sector

Solar panel installations and wind turbines require reliable electrical conductivity and corrosion resistance. Copper washers are integrated into panel mounting systems and electrical junctions to enhance longevity and efficiency.

From aerospace engineering to marine applications, these small but vital components provide unmatched value, especially where performance and reliability are non-negotiable.

Why Nafees Metal Industries is the Trusted Supplier for M8 Copper Washers

At Nafees Metal Industries, we are committed to delivering washers that combine material excellence with dimensional precision. Our M8 copper washers are manufactured under stringent quality control systems, using high-grade copper sourced from verified suppliers. This ensures that every piece we produce meets industrial performance standards and endures the demands of real-world usage.

1. Precision Manufacturing

Each washer is produced using advanced CNC and power press machines to ensure consistent sizing and flatness. This guarantees optimal fitment and sealing performance, particularly in critical applications like automotive, electrical, and plumbing systems.

2. High Conductivity and Corrosion Resistance

We use copper that exhibits excellent electrical conductivity and natural resistance to corrosion. This makes our washers suitable for both conductive applications and long-term exposure to moisture or chemicals, with minimal risk of degradation.

3. Bulk Availability and Customization

Whether you’re looking for standard M8 dimensions or need washers with specific thickness or surface treatments, we offer full customization to meet your exact project requirements. Our capacity supports both small-scale and bulk industrial orders.

4. Strict Quality Inspection

Every washer undergoes dimensional checks and surface inspection before packaging. This multi-step process ensures zero defects and full compliance with client specifications.

5. Client-Centric Approach

Our team focuses on timely deliveries, transparent communication, and consistent after-sales support. With an increasing number of returning customers and long-term B2B relationships, we’ve built a reputation for reliability and professionalism.

When you choose Nafees Metal Industries, you’re not just buying a washer — you’re investing in performance, consistency, and service that lasts.

Applications of M8 Copper Plain Washers in Different Industries

M8 copper plain washers are highly sought-after components across a wide range of industries due to their excellent thermal and electrical conductivity, corrosion resistance, and ability to distribute load effectively. These washers are particularly valuable where electrical insulation, conductivity, or non-sparking properties are critical.

1. Electrical and Electronics Industry

Copper’s high electrical conductivity makes M8 washers ideal for use in:

Printed Circuit Boards (PCBs) – Providing stable contact and insulation between components.

Switchgear Assemblies – Preventing arc faults and supporting secure terminations.

Grounding Systems – Used in earthing applications to ensure continuity and conductivity.

2. Automotive Sector

Battery Terminals and Alternators – Copper washers ensure optimal current flow and corrosion resistance.

Radiators and Engines – Serve as thermal dissipation washers in assemblies exposed to heat.

Fuel Systems – Often used as sealing washers in fuel injectors and brake lines due to their soft sealing properties.

3. Aerospace and Aviation

Avionics Systems – Ensure reliable current transmission with minimal resistance.

Engine and Cabin Assemblies – Lightweight yet conductive, ideal for precision applications where reliability is crucial.

4. Telecommunications

Tower Installations – Copper washers are used in grounding, surge protection, and signal clarity systems.

Network Infrastructure – Support stable mounting of signal processors and transmission hardware.

5. Renewable Energy Systems

Solar Panel Installations – Used in connections for inverters and grounding systems.

Wind Turbines – For lightning protection and static dissipation systems in rotating parts.

6. Marine and Chemical Industries

Shipbuilding and Offshore Equipment – Corrosion resistance to seawater and chemical exposure.

Chemical Plants – Serve as isolation washers in corrosive processing units.

7. General Engineering & Machinery

Heavy Machinery – Used in motor housings, gearboxes, and structural assemblies.

Pumps and Compressors – Offer leak-proof sealing and vibration absorption.

The combination of mechanical strength and superior conductivity makes M8 copper plain washers a critical component in both heavy-duty and precision-based industries. Their versatility ensures compatibility with various fasteners and materials.

Frequently Asked Questions (FAQs) – M8 Copper Plain Washers

1. What is the primary use of M8 copper plain washers?

M8 copper plain washers are used to evenly distribute load and prevent damage to surfaces in bolted or screwed joints. Their conductive properties also make them ideal for electrical and thermal applications.

2. What is the outer diameter and thickness of an M8 copper plain washer?

Standard M8 copper washers typically have an inner diameter of 8.4 mm, an outer diameter of around 16 mm, and a thickness of approximately 1.5 mm. However, sizes can be customized as per project requirements.

3. Are M8 copper washers suitable for high-temperature applications?

Yes, copper washers are heat-resistant and perform well in high-temperature environments, making them suitable for use in engines, boilers, and electrical setups.

4. Can M8 copper washers be used for electrical grounding?

Absolutely. Due to their high conductivity, copper washers are commonly used in electrical grounding and bonding applications.

5. Do these washers corrode easily?

Copper washers offer excellent corrosion resistance, especially in dry or moderately moist environments. For extreme conditions, additional surface treatments may be applied.

6. Are your M8 copper washers RoHS compliant?

Yes, all washers manufactured by Nafees Metal Industries comply with RoHS (Restriction of Hazardous Substances) standards, ensuring they are safe for electronic and electrical applications.

7. Can I order M8 copper washers in bulk?

Yes, we supply bulk quantities for industrial and commercial use. We also cater to customized bulk orders with specific dimensions and tolerances.

8. Do copper washers deform under pressure?

Copper is a soft metal, so it offers a slight degree of compressibility. This makes it useful for applications that require tight sealing, such as hydraulic fittings or fuel lines.

9. What standards do your M8 copper plain washers comply with?

Our washers comply with relevant DIN and ISO standards, ensuring reliable performance and dimensional consistency.

10. Can I get a test certificate with my order?

Yes, we provide mill test certificates, raw material reports, and dimensional inspection reports on request.

11. What is the minimum order quantity (MOQ) for M8 copper washers?

The MOQ depends on the order type (standard or custom). Please contact our sales team for the best quotation and minimum order terms.

12. Are these washers recyclable?

Yes, copper is 100% recyclable. Our washers are manufactured using environmentally responsible practices and can be fully recycled at the end of their service life.

13. Can I request a sample before placing a large order?

Yes, we offer samples upon request to ensure our product meets your application needs and quality standards.

14. Do you export M8 copper washers internationally?

Yes, we serve clients across various countries and ensure seamless international shipping with proper packaging and documentation support.

15. How do I get in touch for a quote or consultation?

You can reach out through our website’s contact form, call our sales helpline, or email us directly. Our team will respond promptly with detailed assistance and quotations.

M8 Copper Plain Washers (DIN 125)

27 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M8

Inner Diameter (ID): 8.4 mm

Outer Diameter (OD): 16 mm

Thickness (t): 1.6 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:12 days

M8 Copper Plain Washers – High-Conductivity Washers for Precision Fastening Applications

At Nafees Metal Industries, we specialize in delivering high-precision fastening components, and our M8 copper plain washer is a testament to this commitment. Manufactured with premium-grade copper, this washer offers outstanding thermal and electrical conductivity, making it ideal for electrical, plumbing, automotive, and mechanical applications.

As one of the best copper washer manufacturers in India, we design each M8 copper plain washer to exact international standards for dimensional accuracy, surface finish, and durability. Whether you’re working with high-performance electrical systems or sensitive mechanical assemblies, our washers provide the reliability and performance you need.

Each M8 copper plain washer from Nafees Metal Industries ensures stable load distribution, corrosion resistance, and superior conductivity—making it the first choice for industries requiring high-quality copper washers. With our Mumbai-based facility equipped for high-volume production, we cater to bulk orders while maintaining consistent quality across batches.

What Are M8 Copper Plain Washers?

An M8 copper plain washer is a circular flat washer with a central hole designed to accommodate M8-sized bolts or screws (8 mm in diameter). Its core function is to evenly distribute the load of a fastener, thereby preventing surface damage, loosening, and wear to the materials being joined.

What sets the M8 copper plain washer apart is its high electrical and thermal conductivity, corrosion resistance, and malleability. These properties make it especially valuable in industries where precision, conductivity, and anti-corrosion features are non-negotiable—such as electronics, plumbing, HVAC systems, and automotive assembly lines.

Crafted from solid copper, each M8 copper plain washer is designed to:

Prevent direct contact between the fastener and the base material

Spread the load over a larger surface area

Protect the surface finish of the connected components

Support conductivity in applications where electrical flow is required

Being a copper flat washer M8 size, it is non-magnetic, resistant to extreme temperatures, and provides a tight seal, especially under vibration-prone environments. That’s why industries across India and overseas trust Nafees Metal Industries as their reliable source for machined washer components and bulk supplies of copper washers.

Why Copper for M8 Washers?

Choosing copper as the base material for washers brings a range of performance advantages, especially when compared to conventional materials like mild steel or aluminum. An M8 copper plain washer offers a unique combination of strength, corrosion resistance, and conductivity—making it an ideal choice for both mechanical and electrical applications.

Here are key reasons why copper is the preferred material for M8 plain washers:

1. Excellent Electrical Conductivity

Copper is one of the best electrical conductors among industrial metals. An M8 copper plain washer facilitates uninterrupted current flow in electrical and grounding systems, which is vital for safety and performance.

2. Superior Thermal Conductivity

In applications where heat dissipation is required, copper outperforms other metals. These washers are ideal for use in systems exposed to high temperatures or requiring thermal stability.

3. Natural Corrosion Resistance

Copper forms a protective oxide layer when exposed to air, protecting it from corrosion in many environments. Our M8 copper plain washer can be used confidently in plumbing, HVAC, and marine applications without the fear of rust or degradation.

4. Ductility and Malleability

Copper’s ability to deform without cracking ensures each washer conforms snugly during fastening. This provides better sealing, especially in dynamic or vibration-sensitive environments.

5. Non-Magnetic Properties

The non-magnetic nature of copper makes the M8 copper plain washer suitable for sensitive applications, including MRI machines, telecom equipment, and precision electronics.

6. Environmentally Sustainable

Copper is 100% recyclable without loss of performance, making our M8 copper plain washer an eco-friendly choice for forward-thinking industries.

Whether you require a copper washer for conductivity, sealing, or structural support, Nafees Metal Industries ensures that every washer we manufacture delivers performance, durability, and reliability. We are proud to be one of the best copper washer manufacturers in India, known for quality materials and customer-focused solutions.

How Are M8 Copper Plain Washers Manufactured?

At Nafees Metal Industries, every M8 copper plain washer is crafted with precision and care to meet international engineering standards. Our production process combines advanced machinery, skilled manpower, and strict quality controls to ensure each washer performs reliably in its intended application.

Here’s a step-by-step overview of how our M8 copper plain washers are manufactured:

1. Raw Material Sourcing

We procure high-purity industrial-grade copper sheets that are tested for conductivity, tensile strength, and corrosion resistance. These sheets form the base of every M8 copper plain washer we produce.

2. Precision Blanking & Punching

Using CNC-controlled punch presses, washers are cut (blanked) to the exact outer diameter, and then punched to create the precise 8.4 mm inner diameter—ideal for M8 bolts or screws. Our process ensures consistency across thousands of units.

3. Deburring & Edge Smoothing

The punched washers undergo vibratory deburring and edge-smoothing to eliminate sharp edges and surface irregularities. This is critical for ensuring safe handling and accurate fitment of the M8 copper plain washer.

4. Annealing (Optional)

If required, washers are heat-treated (annealed) to increase ductility and ensure flexibility in sealing or vibration-prone applications.

5. Surface Finishing

Each M8 copper plain washer is either left in its raw copper finish or lightly polished based on application needs. We can also offer customized coatings if required.

6. Dimensional & Conductivity Testing

Each production batch is tested for:

Inner and outer diameter (as per IS/DIN/ISO standards)

Thickness tolerance

Flatness and roundness

Electrical conductivity (on request)

7. Packaging & Dispatch

Washers are carefully packed in moisture-resistant polybags or corrugated boxes. Bulk buyers can opt for custom packaging and labeling as per their procurement standards.

Our in-house quality control team ensures that every M8 copper plain washer leaving our Mumbai-based facility meets exact technical specifications and is ready for immediate use across various industries.

As one of the best copper washer manufacturers in India, we take pride in producing machined washers that meet the highest standards of quality, consistency, and value.

Key Features of M8 Copper Plain Washers

The M8 copper plain washer is engineered to provide optimum performance in a wide range of industrial and technical environments. Whether you’re dealing with high-temperature conditions, electrical applications, or mechanical systems, this washer delivers reliable functionality and long-term durability.

Below are the key features that make our M8 copper plain washers stand out:

1. Precision Fit for M8 Bolts and Screws

Designed with a central hole diameter of approximately 8.4 mm, each M8 copper plain washer ensures an exact and snug fit with M8 fasteners. This prevents wobble, enhances load distribution, and improves fastening security.

2. Superior Electrical and Thermal Conductivity

Copper is unmatched in its ability to conduct electricity and dissipate heat. These properties make the M8 copper plain washer essential in grounding systems, electrical terminals, and thermal applications.

3. Anti-Corrosive Properties

Our washers resist rust and corrosion naturally due to the protective oxide layer that forms on copper surfaces. This ensures a long service life even in humid or chemically exposed environments.

4. Uniform Thickness and Smooth Surface

Every M8 copper plain washer is manufactured with controlled thickness and a polished finish. This helps reduce friction during fastening and ensures smooth engagement with adjoining surfaces.

5. Vibration Dampening

Thanks to copper’s inherent softness and malleability, these washers can absorb minor vibrations and reduce loosening in dynamic assemblies, such as automotive engines or industrial equipment.

6. Non-Magnetic and Non-Sparking

Copper is a non-magnetic and non-sparking metal, making these washers suitable for use in sensitive environments such as electronics, medical devices, and flammable zones.

7. Available in Bulk and Custom Packaging

Our M8 copper plain washers are available for bulk procurement with the option of tailored packaging, labeling, and delivery schedules to suit OEMs, distributors, and resellers.

8. Fully Compliant with Industry Standards

All washers comply with applicable dimensions and tolerances as per IS 2016 / DIN 125 / ISO 7089 standards. This ensures compatibility and interchangeability with other standard fasteners.

9. Made in India with Global Standards

Manufactured at our Mumbai facility using advanced power press machines and QC-tested procedures, our washers represent the quality and reliability of India’s leading copper washer manufacturer.

10. Ready Stock and Short Lead Times

We maintain consistent inventory levels of M8 copper plain washers to fulfill urgent or high-volume requirements swiftly across India and globally.

When you choose Nafees Metal Industries, you are investing in high-quality, precision-made copper washers trusted by engineers and manufacturers across industries. We’re proud to be among the best copper washer manufacturers in India, offering unmatched value and performance.

Technical Specifications of M8 Copper Plain Washers

At Nafees Metal Industries, we understand the importance of precision in fastening applications. That’s why each M8 copper plain washer we produce conforms to globally recognized quality and dimensional standards. Below is a detailed overview of the technical specifications:

| Property | Specification |

|---|---|

| Product Name | M8 Copper Plain Washer |

| Material | Commercially Pure Copper (99% min. Cu content) |

| Inner Diameter (ID) | Approx. 8.4 mm (suitable for M8 bolts/screws) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 |

| Thickness | 1.0 mm – 2.0 mm (standard); customizable on request |

| Washer Type | Flat / Plain Washer |

| Surface Finish | Natural Copper Finish / Lightly Polished |

| Hardness | Soft to Medium (Annealed or Work-Hardened as required) |

| Conductivity | High electrical and thermal conductivity |

| Corrosion Resistance | Naturally corrosion-resistant (non-ferrous) |

| Magnetism | Non-magnetic |

| Flammability | Non-sparking; safe for explosive or flammable environments |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Manufacturing Process | Cold-stamped or CNC-machined from solid copper sheets |

| Packaging Options | Bulk polybags / Boxes / Customized Packaging |

| MOQ (Minimum Order Quantity) | As per client requirement |

| Application Category | Electrical, Mechanical, Plumbing, Automotive, HVAC |

| Country of Origin | India |

Every M8 copper plain washer undergoes rigorous testing for dimensional accuracy, surface finish, and performance. As one of the leading copper washer manufacturers in India, we assure strict adherence to technical standards, whether for domestic use or international exports.

We also accommodate custom orders for different copper washer sizes, surface finishes, or hardness grades to match the specific needs of our clients. Whether you’re an OEM, wholesaler, or industrial buyer, our flexible manufacturing capabilities and fast delivery timelines ensure you receive exactly what you need—on time and in budget.

Applications of M8 Copper Plain Washers

The M8 copper plain washer is a versatile and essential fastening component used across a wide range of industries. Due to its superior conductivity, anti-corrosion properties, and mechanical stability, this washer is favored in both electrical and mechanical environments where reliability is non-negotiable.

Here’s a breakdown of key applications where the M8 copper plain washer excels:

1. Electrical Grounding Systems

In electrical panels, terminals, and cable lug assemblies, M8 copper plain washers ensure optimal conductivity and secure fastening. Their high conductivity helps maintain stable current flow and reduces resistance across joints.

2. Automotive & Engine Assemblies

These washers are ideal for vibration-prone environments such as engine compartments and exhaust systems. They offer a stable seal and prevent fastener loosening under thermal expansion and movement.

3. Plumbing & HVAC Installations

Due to copper’s natural corrosion resistance and sealing ability, M8 copper plain washers are widely used in pipe flanges, valves, and heating system fittings, especially in systems where galvanic corrosion must be avoided.

4. Renewable Energy Systems

Used in solar panels, wind turbines, and battery assemblies, these washers maintain conductivity and resist weathering over long service periods, ensuring minimal maintenance and maximum efficiency.

5. Electrical & Electronic Equipment

From printed circuit boards (PCBs) to switchgear cabinets, the M8 copper plain washer helps secure components while maintaining electrical integrity. It’s particularly useful in applications requiring EMI/RFI shielding.

6. Aerospace & Defense

The non-sparking, non-magnetic nature of copper makes these washers safe for use in explosive or sensitive electromagnetic environments where safety and precision are critical.

7. Marine & Offshore Equipment

In shipbuilding and offshore oil platforms, where salty, humid conditions prevail, M8 copper plain washers are chosen for their corrosion resistance and sealing performance.

8. Power Distribution Systems

They are extensively used in substations, battery banks, and transmission systems to ensure safe and reliable connectivity between high-voltage equipment.

9. Manufacturing and Assembly Lines

Industrial machinery often incorporates copper washers to ensure clean, tight, and safe bolting, especially in temperature-sensitive or conductive environments.

10. Custom Equipment & Prototype Development

OEMs and R&D labs use M8 copper flat washers during prototyping to ensure material reliability and performance under various stress conditions.

Because of their excellent material properties and dimensional accuracy, our M8 copper plain washers have become a staple in industries where both performance and longevity are crucial. Whether you need a copper washer for its conductivity, vibration resistance, or sealing properties, Nafees Metal Industries is your trusted source.

We proudly serve clients across sectors and are recognized among the best copper washer manufacturers in India for delivering quality that meets global standards.

Advantages of Using M8 Copper Washers

When selecting the ideal washer for mechanical or electrical applications, copper stands out as a premium material. The copper washer offers several unmatched advantages that make it a preferred choice across industries. At Nafees Metal Industries, we focus on delivering washers that combine performance, durability, and value.

Here are the key benefits of using our M8 copper plain washers:

1. Excellent Load Distribution

Each M8 copper plain washer evenly spreads the load of the fastener over a wider surface area. This reduces stress concentration on the material underneath and prevents deformation or damage to softer components.

2. High Electrical and Thermal Conductivity

Copper’s superior conductivity ensures optimal current flow in electrical assemblies and rapid heat dissipation in high-temperature environments. This makes the washer ideal for grounding, terminals, and thermal control systems.

3. Superior Corrosion Resistance

Unlike steel washers that require plating to resist rust, copper naturally forms a protective oxide layer. Our M8 copper flat washers perform reliably in humid, marine, and chemically exposed environments without degrading.

4. Non-Magnetic and Non-Sparking

Copper does not interfere with magnetic fields and doesn’t create sparks, making it a safe choice for explosive environments or sensitive electronic equipment.

5. Thermal Stability

Even under high thermal loads, these washers retain their structural integrity. This makes the M8 copper washer suitable for use in engines, power plants, and high-temperature installations.

6. Vibration Absorption

Copper’s malleability helps absorb shock and vibrations, reducing the chances of fastener loosening over time. This enhances long-term joint integrity in machines and moving systems.

7. Machinability and Customization

Copper is easy to machine, allowing us to produce machined washers in precise sizes and thicknesses to match client-specific requirements.

8. Easy Handling and Installation

Our M8 copper flat washers come with smooth edges, clean finishes, and consistent thickness—making them easy to use on assembly lines or during maintenance work.

9. Sustainable and Recyclable

Copper is 100% recyclable without loss in quality. Choosing copper washers reflects a sustainable and eco-conscious approach to industrial material usage.

10. Trusted by Professionals Across India

As one of the best copper washer manufacturers in India, Nafees Metal Industries has earned the trust of thousands of buyers across automotive, electrical, marine, and heavy machinery sectors. Our washers consistently meet performance expectations under the toughest conditions.

Whether you require them in bulk for industrial applications or as part of a specialized system, our M8 copper washers deliver the strength, reliability, and conductivity you expect from a premium fastening component.

Buy M8 Copper Plain Washers in Bulk – Best Copper Washer Manufacturer in India

If you’re sourcing high-quality, precision-made M8 copper flat washers for your business, look no further than Nafees Metal Industries—India’s trusted partner in industrial-grade washer manufacturing.

As one of the best copper washer manufacturers in India, we specialize in meeting the needs of OEMs, distributors, industrial suppliers, and government contractors who demand consistency, performance, and value.

Here’s why you should source your M8 copper washer requirements from us:

1. Bulk Manufacturing Capability

Our advanced production unit in Mumbai is equipped with high-speed power press machines and CNC-controlled systems that allow us to manufacture M8 copper flat washers in large volumes while maintaining consistent dimensions and finish.

2. Competitive Pricing for Bulk Orders

With raw material sourcing in bulk and streamlined operations, we offer the most competitive prices in the market—without compromising on quality. We cater to high-volume procurement requirements across India and for export markets.

3. Custom Coating and Finish Options

Depending on your application, we provide natural polished finish, or custom coatings on request. From annealed finishes for flexibility to harder surfaces for load-bearing, we tailor your M8 copper washer order to your needs.

4. Fast Lead Times & Nationwide Delivery

We maintain ready stock for standard sizes like copper flat washer M8 size, allowing us to process and dispatch bulk orders quickly. Our logistics partners ensure timely delivery across India, including remote industrial zones.

5. Export-Ready Documentation

For international clients, we provide full export support, including test certificates, packing lists, HS codes, invoices, and country-of-origin documentation for seamless customs clearance.

6. Dedicated Customer Support

Our technical team works closely with buyers to understand project specifications and recommend the most appropriate copper washer solution. We offer responsive service from inquiry to delivery.

7. Custom Labeling and Packaging

We offer customized packaging options for distributors and resellers. Washers can be packed in polybags, cartons, or labeled with your branding or item codes.

8. Made in India – Trusted Globally

All our M8 copper plain washers are proudly manufactured in India, in full compliance with IS and DIN standards. Our reputation for quality has helped us build lasting relationships with clients across multiple sectors.

Whether you’re assembling electrical equipment, developing industrial machinery, or supplying components to key industries, partnering with Nafees Metal Industries ensures you receive machined washers that exceed expectations.

To place a bulk order or request a sample of our M8 copper plain washer, visit www.nafeesmetalindustries.com or get in touch with our sales team.

Case Study – Solving Electrical Fastening Issues with M8 Copper Washers

A leading electrical panel manufacturer in Pune faced recurring issues with arcing and surface damage around fastener points during high-voltage operations. Their existing hardware lacked conductivity and could not maintain proper grounding, leading to performance drops and costly maintenance downtime.

The company decided to test copper washers of 8 mm inner diameter across multiple units. Within weeks, they observed the following improvements:

Stable electrical grounding that reduced system resistance by over 20%

Reduced arcing and thermal hotspots, thanks to copper’s high conductivity

Increased component lifespan, as the washers protected mating surfaces from damage

Minimal loosening under vibration, enhancing reliability in mission-critical applications

These measurable improvements led the manufacturer to adopt copper washers for all their high-current terminals. Since implementation, their service complaints have reduced by over 40%.

This case study highlights how industries can benefit from switching to better fastener accessories, especially in environments where conductivity, sealing, and corrosion resistance are essential.

Different Applications of M8 Copper Washers in Industrial Settings

Copper washers with an 8 mm inner diameter are widely used across industries due to their exceptional thermal and electrical properties. These flat rings serve critical roles beyond just spacing or load distribution — they enhance performance, safety, and durability in demanding environments.

1. Automotive Industry

In engines and braking systems, these washers are commonly installed in oil drain plugs, fuel systems, and banjo bolt assemblies. Their malleability ensures a tight seal, even under high-pressure and high-temperature conditions, preventing leaks and improving safety.

2. Electrical and Electronics

Owing to copper’s high conductivity, these washers are used in switchboards, earthing terminals, and high-voltage electrical systems. They ensure consistent grounding, reduce electrical resistance, and help prevent arcing between fastened metal surfaces.

3. HVAC and Refrigeration Systems

Technicians use them in refrigeration compressors and HVAC connections where thermal expansion and contraction are common. Their ability to maintain a seal under fluctuating temperatures makes them ideal for such applications.

4. Plumbing and Fluid Handling

In pipe fittings and hydraulic systems, they act as crush washers that ensure leak-proof seals. Their corrosion resistance makes them ideal for contact with water and chemicals.

5. Renewable Energy Sector

Solar panel installations and wind turbines require reliable electrical conductivity and corrosion resistance. Copper washers are integrated into panel mounting systems and electrical junctions to enhance longevity and efficiency.

From aerospace engineering to marine applications, these small but vital components provide unmatched value, especially where performance and reliability are non-negotiable.

Why Nafees Metal Industries is the Trusted Supplier for M8 Copper Washers

At Nafees Metal Industries, we are committed to delivering washers that combine material excellence with dimensional precision. Our M8 copper washers are manufactured under stringent quality control systems, using high-grade copper sourced from verified suppliers. This ensures that every piece we produce meets industrial performance standards and endures the demands of real-world usage.

1. Precision Manufacturing

Each washer is produced using advanced CNC and power press machines to ensure consistent sizing and flatness. This guarantees optimal fitment and sealing performance, particularly in critical applications like automotive, electrical, and plumbing systems.

2. High Conductivity and Corrosion Resistance

We use copper that exhibits excellent electrical conductivity and natural resistance to corrosion. This makes our washers suitable for both conductive applications and long-term exposure to moisture or chemicals, with minimal risk of degradation.

3. Bulk Availability and Customization

Whether you’re looking for standard M8 dimensions or need washers with specific thickness or surface treatments, we offer full customization to meet your exact project requirements. Our capacity supports both small-scale and bulk industrial orders.

4. Strict Quality Inspection

Every washer undergoes dimensional checks and surface inspection before packaging. This multi-step process ensures zero defects and full compliance with client specifications.

5. Client-Centric Approach

Our team focuses on timely deliveries, transparent communication, and consistent after-sales support. With an increasing number of returning customers and long-term B2B relationships, we’ve built a reputation for reliability and professionalism.

When you choose Nafees Metal Industries, you’re not just buying a washer — you’re investing in performance, consistency, and service that lasts.

Applications of M8 Copper Plain Washers in Different Industries

M8 copper plain washers are highly sought-after components across a wide range of industries due to their excellent thermal and electrical conductivity, corrosion resistance, and ability to distribute load effectively. These washers are particularly valuable where electrical insulation, conductivity, or non-sparking properties are critical.

1. Electrical and Electronics Industry

Copper’s high electrical conductivity makes M8 washers ideal for use in:

Printed Circuit Boards (PCBs) – Providing stable contact and insulation between components.

Switchgear Assemblies – Preventing arc faults and supporting secure terminations.

Grounding Systems – Used in earthing applications to ensure continuity and conductivity.

2. Automotive Sector

Battery Terminals and Alternators – Copper washers ensure optimal current flow and corrosion resistance.

Radiators and Engines – Serve as thermal dissipation washers in assemblies exposed to heat.

Fuel Systems – Often used as sealing washers in fuel injectors and brake lines due to their soft sealing properties.

3. Aerospace and Aviation

Avionics Systems – Ensure reliable current transmission with minimal resistance.

Engine and Cabin Assemblies – Lightweight yet conductive, ideal for precision applications where reliability is crucial.

4. Telecommunications

Tower Installations – Copper washers are used in grounding, surge protection, and signal clarity systems.

Network Infrastructure – Support stable mounting of signal processors and transmission hardware.

5. Renewable Energy Systems

Solar Panel Installations – Used in connections for inverters and grounding systems.

Wind Turbines – For lightning protection and static dissipation systems in rotating parts.

6. Marine and Chemical Industries

Shipbuilding and Offshore Equipment – Corrosion resistance to seawater and chemical exposure.

Chemical Plants – Serve as isolation washers in corrosive processing units.

7. General Engineering & Machinery

Heavy Machinery – Used in motor housings, gearboxes, and structural assemblies.

Pumps and Compressors – Offer leak-proof sealing and vibration absorption.

The combination of mechanical strength and superior conductivity makes M8 copper plain washers a critical component in both heavy-duty and precision-based industries. Their versatility ensures compatibility with various fasteners and materials.

Frequently Asked Questions (FAQs) – M8 Copper Plain Washers

1. What is the primary use of M8 copper plain washers?

M8 copper plain washers are used to evenly distribute load and prevent damage to surfaces in bolted or screwed joints. Their conductive properties also make them ideal for electrical and thermal applications.

2. What is the outer diameter and thickness of an M8 copper plain washer?

Standard M8 copper washers typically have an inner diameter of 8.4 mm, an outer diameter of around 16 mm, and a thickness of approximately 1.5 mm. However, sizes can be customized as per project requirements.

3. Are M8 copper washers suitable for high-temperature applications?

Yes, copper washers are heat-resistant and perform well in high-temperature environments, making them suitable for use in engines, boilers, and electrical setups.

4. Can M8 copper washers be used for electrical grounding?

Absolutely. Due to their high conductivity, copper washers are commonly used in electrical grounding and bonding applications.

5. Do these washers corrode easily?

Copper washers offer excellent corrosion resistance, especially in dry or moderately moist environments. For extreme conditions, additional surface treatments may be applied.

6. Are your M8 copper washers RoHS compliant?

Yes, all washers manufactured by Nafees Metal Industries comply with RoHS (Restriction of Hazardous Substances) standards, ensuring they are safe for electronic and electrical applications.

7. Can I order M8 copper washers in bulk?

Yes, we supply bulk quantities for industrial and commercial use. We also cater to customized bulk orders with specific dimensions and tolerances.

8. Do copper washers deform under pressure?

Copper is a soft metal, so it offers a slight degree of compressibility. This makes it useful for applications that require tight sealing, such as hydraulic fittings or fuel lines.

9. What standards do your M8 copper plain washers comply with?

Our washers comply with relevant DIN and ISO standards, ensuring reliable performance and dimensional consistency.

10. Can I get a test certificate with my order?

Yes, we provide mill test certificates, raw material reports, and dimensional inspection reports on request.

11. What is the minimum order quantity (MOQ) for M8 copper washers?

The MOQ depends on the order type (standard or custom). Please contact our sales team for the best quotation and minimum order terms.

12. Are these washers recyclable?

Yes, copper is 100% recyclable. Our washers are manufactured using environmentally responsible practices and can be fully recycled at the end of their service life.

13. Can I request a sample before placing a large order?

Yes, we offer samples upon request to ensure our product meets your application needs and quality standards.

14. Do you export M8 copper washers internationally?

Yes, we serve clients across various countries and ensure seamless international shipping with proper packaging and documentation support.

15. How do I get in touch for a quote or consultation?

You can reach out through our website’s contact form, call our sales helpline, or email us directly. Our team will respond promptly with detailed assistance and quotations.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch