No products in the cart.

Washer for Pipeline Joints – Best Washer for High-Pressure Pipeline Connections

Pipelines form the backbone of fluid and gas distribution in industries, residential systems, and large-scale infrastructure projects. While their functionality often draws the most attention, the smaller components—like washers—play a crucial role in maintaining system integrity. One such component is the washer for pipeline joints.

In this blog, we explore the essential role of washers in pipeline systems, the types best suited for such applications, and why Nafees Metal Industries should be your trusted supplier.

Understanding the Purpose of Washers in Pipeline Joints

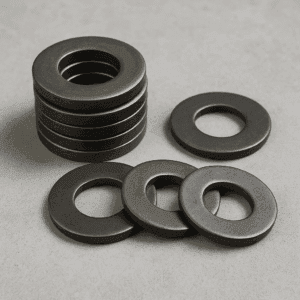

Washers are thin plates, often disk-shaped, that distribute load, seal gaps, and prevent leakage in pipeline systems. When pipelines are joined, especially in high-pressure or temperature-sensitive environments, washers act as reliable buffers between flanges, fittings, or bolts.

Sealing washers ensure that no fluid escapes from the joint. This is critical for industries dealing with chemicals, petroleum, water supply, and steam systems.

Key Benefits of Using Pipe Washers for Pipeline Joints

Leak Prevention: Washers form a tight seal that prevents the escape of liquids or gases.

Load Distribution: They evenly distribute the tightening force of bolts, reducing wear.

Shock Absorption: In high-vibration settings, washers help minimize damage to pipeline joints.

Durability Enhancement: They protect the joints from rust, corrosion, and heat exposure.

Choosing the Best Washer for High-Pressure Pipeline Joints

When selecting a washer for pipeline joints, it’s crucial to consider:

Material: Stainless steel, copper, and rubberized washers are common for pipelines.

Size: The washer must match the bolt and flange diameter.

Type: Options include plain flat washers, sealing washers, and bonded washers depending on the pressure and fluid nature.

For high-pressure pipelines, metal-sealing washers are often the most effective. They withstand extreme stress and temperatures, ensuring a long-lasting connection.

Applications of Washers in Pipeline Systems

Oil and Gas Pipelines: Require robust sealing due to the high flammability of contents.

Water Supply Networks: Must prevent leaks to avoid wastage and damage.

Industrial Steam Lines: Need washers that can handle both high heat and vibration.

Plumbing Systems: Use washers for flexible pipe fittings and faucets to avoid drips.

If you’re wondering where to buy washers for plumbing pipelines, Nafees Metal Industries provides a wide variety of pipeline washers customized to your needs.

Why Nafees Metal Industries?

At Nafees Metal Industries, we understand that washers are more than just hardware accessories. Our expertise ensures:

Consistent Quality: Each washer is manufactured with precision to meet international standards.

Wide Selection: From sealing to plain washers, find everything under one roof.

Custom Sizes & Finishes: Get washers that perfectly suit your pipeline requirements.

Fast Delivery & Bulk Supply: We handle orders of all sizes with efficiency.

How to Choose the Right Washer for Your Pipeline System

Determine Pressure & Temperature Levels: Select washers that can resist these conditions.

Measure Dimensions Accurately: Use calipers for bolt and flange sizing.

Check for Corrosion Resistance: Particularly for outdoor and underground pipelines.

Confirm Compatibility with Pipe Material: Ensure the washer’s material complements your pipe to avoid galvanic corrosion.

FAQs About Washers for Pipeline Joints

Q1: Are metal washers better than rubber washers for pipelines?

Metal washers are ideal for high-pressure systems, while rubber washers are great for low-pressure or flexible pipeline connections.

Q2: Can I reuse washers in plumbing systems?

While some metal washers can be reused, it is generally recommended to replace washers during maintenance to avoid potential leaks.

Q3: What industries use washers in their pipeline joints?

Industries include oil & gas, water treatment, food processing, pharmaceuticals, and HVAC.

Conclusion

Using the right washer for pipeline joints ensures long-term efficiency, safety, and cost savings. Whether you’re sealing a high-pressure pipeline or upgrading plumbing lines, washers serve as silent heroes in any fluid transport system.

Ready to upgrade your pipeline connections? Explore our collection of premium sealing washers and pipe washers crafted for industrial performance.

Tags: best washer for high-pressure pipeline joints, industrial sealing solutions, pipe washers, plumbing pipeline washer, sealing washers, washer for pipeline joints

Related posts

Introduction In the world of heavy-duty machinery and critical equipment, every component counts — especially the small ones like washers. While they may seem insignificant,... Continue reading

Introduction Industrial machinery and high-heat environments demand components that won’t fail under pressure—and that’s where high-temperature washers come into play. Built to endure extreme heat... Continue reading

Leave a reply