No products in the cart.

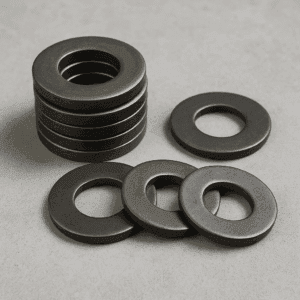

Spring Washers – The Unsung Heroes of Secure & Vibration-Resistant Fastening

When it comes to secure fastening in high-motion, high-load environments, spring washers play a vital role. They might be small, but they prevent costly failures, reduce maintenance, and increase the lifespan of machinery and infrastructure.

At Nafees Metal Industries, we manufacture high-performance spring washers that are widely used across sectors like automotive, construction, energy, and heavy machinery. If you’re searching for the best spring washers for vibration resistance, this blog is your go-to guide.

What Are Spring Washers?

These are also known as split or locking washers, are mechanical components designed to resist loosening caused by vibration and dynamic loads. They offer axial flexibility, allowing them to absorb shocks and maintain clamping force.Unlike plain washers that simply distribute load, spring washers create tension in the assembly, holding bolts and nuts tightly even in challenging conditions.

Key Benefits

Vibration Resistance: Prevent loosening in high-motion environments

Load Distribution: Help maintain consistent torque and prevent damage to joints

Compact Size: Easy to install without occupying extra space

Reusable: Depending on use, can be reused in maintenance cycles

Cost-Effective Safety: Reduce risk of fastener failure or machine downtime

Whether it’s for a fast-moving vehicle or a rotating turbine, a locking washer like the spring washer ensures reliability under pressure.

Types of Spring Washers We Manufacture

At Nafees Metal Industries, we offer a wide range of spring washers made from materials like stainless steel, carbon steel, and alloy steel—customized for diverse load conditions.

Split Spring Washers

The most common type—split at one point and bent into a helical shape. When compressed, they act like a spring, applying continuous pressure on the joint.

Ideal For: Construction, automotive assembly, electrical panels.

Conical (Belleville) Spring Washers

Cone-shaped washers designed for high-load applications with limited axial space. They provide a high spring constant.

Used In: Power plants, marine assemblies, oil rigs.

Dome and Wave Spring Washers

These provide uniform pressure over a wide area, making them excellent for delicate materials or assemblies where space is tight.

Ideal For: Electronics, medical equipment, and compact mechanical assemblies.

Where Are They Used

High-tension washers like spring washers are a crucial component in industries that experience high levels of shock, vibration, and thermal expansion. These include:

- Automotive and railways

- Aerospace and defense

- Construction machinery

- Wind and solar power installations

- Pumps, compressors, and heavy-duty engines

- Even household appliances that run on motors often rely on these washers to ensure their longevity.

Material Grades We Offer

Depending on the application, we offer spring washers in:

| Material | Best Used For |

|---|---|

| Carbon Steel | General-purpose indoor applications |

| Stainless Steel 304 | High corrosion resistance, outdoor & marine use |

| Stainless Steel 316 | Superior performance in chemical industries |

| Phosphor Bronze | Electrical conductivity & anti-sparking uses |

Our washers comply with international standards and are tested for hardness, dimensional accuracy, and corrosion resistance.

Buy Spring Washers in Bulk for Industrial Use

Looking to secure your operations with reliable fasteners? You can now buy spring washers in bulk for industrial use directly from our website.

We support:

High-volume orders with consistent quality

Custom sizes, thicknesses, and load ratings

OEM partnerships and white-label packaging

Pan-India shipping with fast turnaround

All washers are manufactured in-house at Nafees Metal Industries using advanced CNC machines and power presses to ensure precision at scale.

Why Our Spring Washers Are the Best Choice

If you’re searching for the best spring washers for vibration resistance, here’s why we’re a preferred supplier for hundreds of clients:

Manufacturing Excellence: State-of-the-art machinery and skilled technicians

Custom Engineering: We create washers as per your drawings or load requirements

Bulk Capacity: High-volume production ready for pan-India and export delivery

Trusted Quality: 100% quality-checked before dispatch

Client-Centric Service: We’re responsive, reliable, and relationship-focused

With decades of experience in washer manufacturing, we understand the unique needs of industries where fastener performance can make or break operations.

Pro Tip: When to Replace a Spring Washer

Over time, even the best spring washer may lose its tension due to fatigue or stress. It’s important to inspect them regularly during maintenance. Replace spring washers if you notice:

- Flattening of the washer

- Loss of elasticity

- Visible cracks or deformation

- Excessive rust (especially in non-stainless variants)

Preventative replacement ensures uninterrupted performance and safety.

Nafees Metal Industries – Your Partner in Precision Engineering

As India’s trusted manufacturer of industrial washers, we take pride in delivering components that drive reliability, safety, and efficiency. Our products are not just washers—they’re part of your success story.

Whether you’re fastening a highway bridge or a precision motor, spring washers from Nafees Metal Industries will hold things together—literally and figuratively.

Difference between Plain, Flat, Punched & Machined Washers

What is the difference between plain washers, machined washers and flat washers? Washers are often used interchangeably, but they have slight differences. Plain washers are...

Read MoreThe Ultimate Guide to Plain Washers: Dimensions, Uses, Types & More

When delving into the world of fasteners, plain washers manufacturers often take center stage as unassuming yet critical components. Whether you’re assembling machinery, securing structural...

Read MoreSpring Steel Washers – Best Heavy-Duty Washers for Load-Bearing Applications

Introduction When it comes to durability, resilience, and long-term reliability, spring steel washers stand at the forefront of heavy-duty industrial fastening solutions. These specially designed...

Read MoreStainless Steel Washers – Strength, Durability & Corrosion-resistant washers for Every Industry

In the fast-paced world of industrial manufacturing, Stainless steel washers the smallest components often make the biggest difference. Washers, though seemingly simple, are essential for...

Read MoreSpring Washers – The Unsung Heroes of Secure & Vibration-Resistant Fastening

When it comes to secure fastening in high-motion, high-load environments, spring washers play a vital role. They might be small, but they prevent costly failures,...

Read MoreHeavy Duty Washers – Essential for Structural Fastening and High Load Applications

Heavy duty washers are used in engineering, construction, and heavy machinery, every component must be designed to withstand extreme stress. These washers are built not...

Read MoreTags: Buy Washers in Bulk, High-Tension Washers, Industrial Washers, Locking Washers, Nafees Metal Industries, Spring Washers, stainless steel washers, Vibration Resistant Fasteners, Washer Manufacturer in India

Related posts

Introduction Fastening heavy equipment, large structures, or critical machinery demands more than just strong bolts or nuts. The often-underestimated heroes behind reliable connections are Large... Continue reading

Introduction When it comes to assembling machinery that must endure high stress and heavy loads, ordinary washers are simply not enough. High strength flat washers... Continue reading

Introduction In the fast-paced world of mechanical engineering and construction, achieving perfect fastening without damaging surfaces or compromising bolt tension is crucial. One tiny yet... Continue reading

In industrial and engineering applications, the importance of a strong fastening solution cannot be overstated. Among the specialized washer types, dome washers stand out as... Continue reading

Washers play an essential role in the fastening industry, especially when it comes to maintaining structural integrity and reducing friction between components. Among the most... Continue reading

One comment on “Spring Washers – The Unsung Heroes of Secure & Vibration-Resistant Fastening”

vorbelutrioperbir

Hi my friend! I wish to say that this post is awesome, great written and come with almost all important infos. I’d like to look more posts like this .