No products in the cart.

Spring Steel Washers – Best Heavy-Duty Washers for Load-Bearing Applications

Introduction

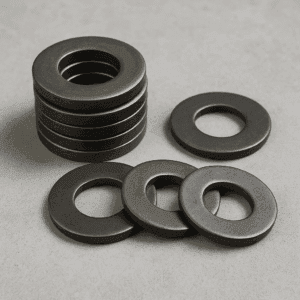

When it comes to durability, resilience, and long-term reliability, spring steel washers stand at the forefront of heavy-duty industrial fastening solutions. These specially designed washers are manufactured using high-tensile spring steel, known for its elasticity and ability to retain shape under extreme mechanical stress. Whether it’s for high-load machinery, vibration resistance, or secure fastening, spring steel washers are the go-to choice.

In this blog, we will explore the significance of spring steel washers, their properties, applications, and why they are considered among the best heavy-duty washers for load-bearing fasteners applications.

What Are Spring Steel Washers?

Spring steel washers are flat or curved metal components made from high-carbon or alloyed spring steel materials. These washers are designed to maintain tension and provide a preload between fastened surfaces, especially under dynamic or cyclic loads. Their key function lies in absorbing shock and maintaining assembly tension even when subjected to load variations.

Key Properties of Spring Steel Washers

High Tensile Strength

Spring steel washers exhibit exceptional tensile strength, making them suitable for high-load environments. They are often used in machinery where consistent pressure and alignment are vital.Elasticity

Their spring-like nature allows them to return to their original shape after compression, which aids in preventing loosening in joints exposed to vibration or dynamic movement.Corrosion Resistance

When coated or made from alloy variants, these washers offer good corrosion resistance, extending their life span even in challenging conditions.Fatigue Resistance

Due to their durable composition, spring steel washers are highly resistant to fatigue and wear, making them reliable for long-term usage.

Applications of Spring Steel Washers

Because of their strength and flexibility, spring steel washers find applications in a wide range of industries:

Automotive – Used in suspension systems, engines, and brake assemblies.

Heavy Machinery – Ideal for agricultural, construction, and mining equipment.

Railway and Aerospace – Used in joints that require vibration damping and load maintenance.

Manufacturing Equipment – Ensures stable and reliable fastening in machines with moving parts.

Why Choose Spring Steel Washers Over Other Types?

When comparing spring steel washers to other types, the edge lies in their load-bearing capabilities and elasticity. Unlike standard flat washers that only distribute load, spring steel variants actively maintain pressure and prevent loosening in critical assemblies.

These washers are especially effective when used with bolts in applications where vibrations are common, helping maintain torque over time and reducing the need for frequent maintenance.

How to Select the Right Spring Steel Washer?

Load Requirement

Determine the maximum load the washer must support to avoid deformation.Environmental Conditions

Choose coated or stainless variants if the washer will be exposed to moisture, chemicals, or salt air.Dimensions

Ensure the washer’s inner and outer diameters match the bolt or screw size for a snug fit.Type of Washer

Depending on your application, choose from Belleville, wave, curved, or disc spring types.

Advantages of Using Spring Steel Washers in Load-Bearing Applications

Maintains consistent clamping force

Minimizes bolt loosening from vibration

Increases safety in mechanical joints

Reduces maintenance downtime

Supports high axial and radial loads

Where to Buy the Best Spring Steel Washers for Machinery?

At Nafees Metal Industries, we manufacture a premium range of spring steel washers designed for demanding industrial use. Our washers are available in various sizes and finishes and can be customized to meet your specific requirements.

If you’re looking to buy spring steel washers in bulk, we offer competitive prices with assured quality and delivery. Our washers are tested for tensile strength, corrosion resistance, and dimensional accuracy to ensure top-tier performance.

Conclusion

From automotive giants to precision engineering plants, spring steel washers are a crucial part of load-bearing and vibration-sensitive assemblies. Their durability, flexibility, and shock absorption capabilities make them a staple in industries that demand reliability.

If you’re planning your next project or upgrading your inventory of fasteners, spring steel washers are a smart investment.

Tags: best spring washers, heavy duty washers, Industrial Washers, load-bearing fasteners, machinery fasteners, spring steel washers

Related posts

Introduction When it comes to assembling heavy-duty structures, every small detail matters. One of the most crucial yet often overlooked components is the thick flat... Continue reading

Introduction When it comes to withstanding extreme loads and maintaining structural integrity, not all washers are created equal. High strength washers are engineered for the... Continue reading

When it comes to demanding industrial or structural applications, the smallest components often play the biggest roles. One such unsung hero in the world of... Continue reading

In the realm of industrial fasteners, one component silently shoulders immense responsibility — the heavy-duty flat washer. These simple yet powerful circular discs are crucial... Continue reading

In high-pressure industrial settings where joints are constantly exposed to stress, motion, or vibration, using standard flat washers simply won’t do the job. That’s where... Continue reading

One comment on “Spring Steel Washers – Best Heavy-Duty Washers for Load-Bearing Applications”

vorbelutrioperbir

I appreciate, cause I found exactly what I was looking for. You’ve ended my four day long hunt! God Bless you man. Have a great day. Bye