No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

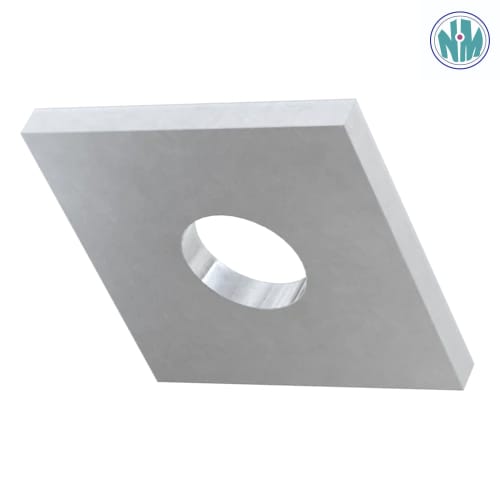

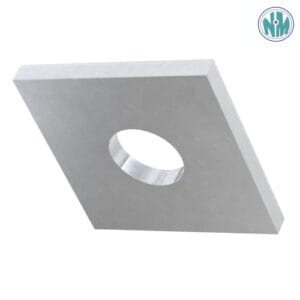

Square Washers – Heavy-Duty Stability for Industrial Applications

Square washers are essential fasteners used in a variety of high-load and structural applications. Unlike round washers, square washers offer a larger surface area, making them ideal for distributing the load evenly across structural joints. This reduces the chances of material deformation or bolt pull-through under stress. Nafees Metal Industries, located in Mumbai, is recognized as one of the best manufacturers of square washers in India, supplying bulk and custom options across multiple sectors.

Stainless Steel Washers for Corrosion Resistance

Our stainless steel washers in square shape offer superior performance in environments exposed to moisture, chemicals, and atmospheric agents. We manufacture these square washers using premium grades like SS202, SS304, and SS316, ensuring excellent resistance to corrosion, rust, and wear over time. These are ideal for marine, construction, and power sector applications where durability is non-negotiable.

What Are Square Washers?

Square washers are flat components with four equal-length sides and a central hole to accommodate bolts or screws. Their geometry ensures greater surface contact between the fastener and the material, making them especially useful when dealing with oversized holes or irregular surfaces. Due to their shape, square washers offer enhanced anti-rotation properties, which is critical in timber framing, structural steel assemblies, and seismic zones.

Key Features of Square Washers

1. Flat, Wide Surface for Maximum Load Distribution

The defining characteristic of square washers is their extended surface area compared to conventional round washers. This allows them to spread the load from bolts and nuts over a wider area, significantly reducing surface deformation or pull-through—especially when used on softer materials like wood or in oversized holes.

Benefit:

Ensures the pressure is evenly distributed, preventing material fatigue and enhancing joint longevity in heavy-duty assemblies.

2. Excellent Anti-Rotation Capability

The square geometry naturally resists turning, making these washers ideal for bolted connections where vibration or torque is present. This reduces loosening over time, especially in applications with dynamic loads or movement.

Benefit:

Improves joint stability in bridges, tunnels, marine environments, and heavy machinery by preventing bolt rotation under stress.

3. Available in Multiple Material Grades

Our square washers are manufactured in a wide range of materials including Stainless Steel (SS202, SS304, SS316), Mild Steel, Galvanized Iron, Aluminum, Brass, and Copper. Each material is selected based on its unique mechanical and environmental resistance properties.

Benefit:

Allows users to choose a washer that best suits their application—whether it’s corrosion resistance for marine use or high tensile strength for construction.

4. Corrosion and Rust Resistance

Especially with stainless steel variants like SS202 and SS316, our square washers offer excellent resistance to rust, moisture, and chemical exposure. This feature is crucial for outdoor use, high-humidity zones, or chemically aggressive environments.

Benefit:

Extends the life of the washer, minimizes maintenance needs, and prevents equipment failures in harsh weather or marine conditions.

5. High Dimensional Accuracy

We use precision machining and strict quality control during manufacturing, ensuring every washer conforms to exact dimensional standards. Our square washers feature consistent thickness, accurate hole placement, and burr-free edges.

Benefit:

Improves fitting accuracy, reduces alignment issues, and ensures compatibility with a wide variety of bolt and screw diameters.

6. Smooth, Burr-Free Edges

All washers are deburred during post-processing to eliminate sharp edges that could compromise safety or cause injury during installation. A smooth finish also helps prevent wear or scratching on the surfaces they’re applied to.

Benefit:

Enhances user safety, allows for seamless installation, and protects sensitive or coated surfaces from damage.

7. Customizable Dimensions and Finishes

Our in-house manufacturing allows us to offer complete customization for square washers—including hole size, outer dimensions, thickness, and surface finishes like zinc plating, black oxide, mirror polish, or sandblasting.

Benefit:

Ideal for clients needing tailor-made washers for niche applications such as designer constructions, heavy machinery, or branded assemblies.

8. Superior Load-Bearing Strength

Square washers are engineered to handle high axial and radial loads, especially in static or dynamic conditions. Their geometry allows for better weight transfer across the base material, reducing the likelihood of bolt fatigue or loosening.

Benefit:

Ensures reliable performance in infrastructure projects, MEP systems, and load-critical environments like cranes or turbines.

9. Supports Oversized Holes and Irregular Surfaces

In some assemblies, holes may be larger than standard or drilled into irregular materials. Square washers provide a broader base that helps anchor bolts securely even in such challenging conditions.

Benefit:

Minimizes the risk of fastener pull-through and supports structural safety in retrofitting or customized industrial setups.

10. Available in Ready Stock and Bulk Quantities

We maintain a large inventory of standard sizes—like 20mm, 25mm, 30mm, and 50mm—so you can quickly source washers without delay. Custom bulk orders are processed with fast turnaround times and precision quality.

Benefit:

Ideal for OEMs, distributors, and large infrastructure projects needing consistent, fast supply without compromising on quality.

Industrial Washers for Diverse Sectors

We manufacture industrial washers in square shape to meet the rigorous requirements of various sectors, including:

Construction and Infrastructure

Oil & Gas

Railways and Heavy Equipment

Wind and Solar Energy

Marine Structures

Agricultural Equipment

Telecom Infrastructure

Automotive and Defense

Whether it’s holding timber frames in place or securing machinery in high-vibration settings, our square washers perform reliably under pressure.

Applications of Square Washers

Square washers are widely recognized for their ability to offer enhanced load distribution and anti-rotation capabilities. Their unique design makes them indispensable in environments that demand mechanical stability, alignment precision, and long-term reliability. Below are the major industry applications of square washers, each supported by real-world use cases:

1. Construction and Structural Engineering

In construction, square washers are frequently used to reinforce bolted joints in concrete and timber framing. Their large surface area prevents bolts and nuts from sinking into soft materials, which is especially important in wooden structures.

Use case:

Used in foundation anchoring and column bases where the bolt holes are oversized, providing even load distribution and enhancing structural integrity.

2. Bridge and Infrastructure Projects – Square washers

Square washers play a vital role in high-load-bearing assemblies such as bridges, flyovers, and public infrastructure. They help stabilize structural members during vibrations and heavy traffic conditions.

Use case:

Utilized in beam-to-column connections and expansion joints to prevent rotation and minimize bolt wear in high-vibration zones.

3. Railways and Heavy Equipment Manufacturing

In railway tracks, locomotives, and industrial machinery, square washers serve as reliable fasteners that resist loosening due to constant movement, torque, and high-pressure environments.

Use case:

Used under track bolts to ensure bolts remain tightly fastened even under repeated rail vibration and dynamic loading.

4. Wind and Solar Energy Installations

Square washers are preferred in renewable energy infrastructure for their ability to resist corrosion and maintain joint stability under fluctuating wind or thermal loads.

Use case:

Installed in solar panel mounting systems and wind turbine foundations to provide a secure base against environmental stress and dynamic load conditions.

5. Marine and Offshore Applications

Given their enhanced anti-rotational stability and corrosion resistance (especially in stainless steel grades), square washers are commonly used in shipbuilding, ports, and oil rigs.

Use case:

Used to secure deck components, railing systems, and offshore structural joints where exposure to saltwater is constant.

6. Tunneling and Mining Operations

Mining environments involve heavy machinery and dynamic underground operations. Square washers help stabilize bolted joints in mining equipment and support frames.

Use case:

Used in the assembly of rock bolting systems and tunnel lining structures where strength and resistance to deformation are critical.

7. Telecom Towers and Transmission Lines

Square washers are ideal for electrical installations where fasteners must remain stable under wind loads and environmental changes.

Use case:

Used in tower bolting and grounding systems to ensure electrical continuity and mechanical rigidity.

8. Seismic Zone Construction

In regions prone to earthquakes, square washers are integral in reducing rotational slippage of bolts in structural members.

Use case:

Installed in shear walls and brace frames in commercial and residential buildings in seismic zones to enhance vibration resistance.

9. Timber Framing and Wooden Architecture

Due to their flat and broad profile, square washers distribute the load over a larger wooden surface area, making them ideal for preserving the integrity of timber.

Use case:

Used in gazebos, wooden bridges, and heavy timber trusses to prevent bolt embedment into wood and ensure joint longevity.

10. Agricultural and Earthmoving Equipment

In rugged terrains and heavy-duty operations, square washers hold bolts securely and prevent assembly failures in large machinery.

Use case:

Applied in plows, tillers, and tractors where vibration, soil impact, and movement demand robust fastening solutions.

11. OEM (Original Equipment Manufacturer) Assemblies

OEMs across sectors use square washers in product designs requiring both mechanical strength and dimensional precision.

Use case:

Used in custom machinery, HVAC systems, and industrial frameworks where part integrity must be maintained through repetitive operation cycles.

Buy Bulk Square Washers at Competitive Prices

You can now buy bulk square washers directly from our website: https://nafeesmetalindustries.com. We offer:

Discounted rates for large orders

Custom labeling and packaging

Delivery across India and selected global locations

Consistent inventory with quick dispatch timelines

Whether you’re a construction contractor or a distributor, we ensure a hassle-free ordering experience with the ability to scale based on your project demands.

Why Choose Square Washers from Nafees Metal Industries?

We are one of the best manufacturers of square washers in India, and here’s why:

Advanced Manufacturing Setup: Precision power presses and inspection systems ensure dimensional accuracy.

Quality Assurance: All batches are tested for load-bearing, hardness, and corrosion resistance.

Custom Production: We cater to small and large-scale customized orders across dimensions and finishes.

Bulk Availability: Always ready stock of common square washer sizes like 20mm, 25mm, 30mm, and 50mm.

Expert Support: Guidance from our technical team to select the right washer for your application.

At Nafees Metal industries, quality and precision are at the core of our manufacturing process. Every batch is produced with meticulous attention to detail, ensuring they meet the highest industry standards. We offer competitive pricing, flexible order quantities, and quick delivery for all your fastening needs — whether you want a small order or plan to buy bulk square washers online.

Our commitment to customer satisfaction and premium industrial washers makes us your trusted partner in fastening solutions.

Material Grades Offered

We manufacture square washers in a wide range of materials:

Stainless Steel (SS202, SS304, SS316) – for corrosion and high-strength use

Mild Steel (MS) – for cost-effective load-bearing applications

Galvanized Iron – for outdoor and structural projects

Copper & Brass – for aesthetic or electrical conductivity-based needs

Aluminum – for lightweight, non-corrosive assemblies

Customization Options

Our team provides fully customized washer solutions to meet your project-specific load, surface area, and appearance requirements. Customizable parameters include:

Inner and outer diameter

Thickness from 1mm to 10mm+

Hole shape and alignment

Surface coating or finish

Edge treatment (deburring, polishing)

Every square washer is manufactured under strict tolerances to ensure reliability and functionality.

Real-World Case Study: Enhancing Structural Stability with Custom Square Washers

A leading infrastructure development company in India approached Nafees Metal Industries for a solution to a recurring issue they were facing during the construction of a large public bridge project. The challenge revolved around the consistent loosening of bolts in their structural assemblies due to heavy vibrations, dynamic loads, and exposure to extreme weather conditions.

The Challenge

The bridge project involved fastening heavy steel plates and support beams across expansion joints and cantilever sections. The client was using traditional round washers with high-tension bolts, but the assemblies frequently suffered from bolt loosening, fastener pull-through, and surface deformation. The round washers failed to provide adequate grip and load distribution, especially in areas with oversized drilled holes and irregular steel surfaces.

Nafees Metal Industries’ Solution

After a detailed assessment of the construction drawings and on-site challenges, our engineering team recommended the use of custom-manufactured square washers with the following specifications:

Material: Stainless Steel 316 for maximum corrosion resistance in a marine-influenced environment

Dimensions: 50mm x 50mm with a central 14mm hole and 6mm thickness

Surface Finish: Shot-blasted and passivated for enhanced durability and anti-corrosion performance

Customization: Tight tolerance control to ensure flush installation with load-bearing steel structures

These square washers were designed to offer superior anti-rotation performance and a larger surface area, enabling effective load distribution even on oversized and irregular holes.

The Result

Upon installation, the square washers from Nafees Metal Industries significantly improved the performance of the bolted joints:

Bolt stability improved by over 40%, reducing the need for re-tightening

Surface wear and deformation were virtually eliminated

Assembly time was reduced due to ease of alignment and faster installation

Structural safety was enhanced, with vibration-induced loosening no longer being a problem

The client reported zero washer-related issues in post-installation audits over a 12-month observation period—even in high-stress zones like expansion joints and cantilevered sections.

Ongoing Partnership

Impressed by the results, the company placed repeat bulk orders for their other infrastructure projects, including metro rail support structures and highway overpass systems. Our team continues to provide them with customized square washers in different sizes and finishes, tailored to their evolving requirements.

This case study demonstrates how the right choice of square washers can directly impact structural safety, reduce maintenance costs, and improve long-term reliability in demanding industrial environments.

Frequently Asked Questions (FAQs)

1. What is the primary use of square washers?

To provide even load distribution and prevent rotation of bolts or nuts.

2. How are square washers different from round washers?

Square washers have better anti-rotation properties and a larger contact surface.

3. Are stainless steel square washers corrosion-resistant?

Yes, especially in SS316 or SS304 grades.

4. Can I buy bulk square washers?

Yes, bulk purchases can be made via our website with customized pricing.

5. Are square washers reusable?

If not deformed or corroded, they can be reused.

6. What sizes are available?

Standard sizes like 20mm, 25mm, 30mm, and custom dimensions are available.

7. Can square washers be used with timber?

Yes, they’re ideal for wooden structures to avoid fastener pull-through.

8. Are test certificates provided?

Yes, including Mill Test Certificates (MTC) and quality inspection documents.

9. Do you export square washers?

Yes, to the UAE, Africa, Southeast Asia, and other regions.

10. What is the typical lead time?

5–7 working days for custom orders, immediate dispatch for stock items.

11. Which materials are available?

Stainless steel, mild steel, galvanized iron, brass, copper, and aluminum.

12. Are they compatible with seismic applications?

Yes, their shape and strength are ideal for such conditions.

13. Can I customize the coating or finish?

Absolutely—zinc, black oxide, hot-dip, or plain finishes are available.

14. Will square washers damage the surface?

No, in fact, they reduce surface deformation by evenly spreading the load.

15. Why are you considered the best manufacturer?

Because of our consistency, quality, custom capabilities, and fast deliveries.

Contact Us Today for Best Square Washers

Choose the best square washers for heavy-duty use and get the strength and durability you need for your assemblies. Visit our manufacturing unit at Reay Road, Mumbai, or contact us for customized orders and bulk inquiries.

Be the first to review “Square Washers” Cancel reply

Square Washers

18 people are viewing this product right now

₹1.20 /per piece

Square Washers

We have this product in all sizes & all metals as per your requirements.

To share your requirements contact us by using the Call us?or Request Quote?option below.

Pricing will be based on the customization.

Estimated Delivery:14 days

Square Washers – Heavy-Duty Stability for Industrial Applications

Square washers are essential fasteners used in a variety of high-load and structural applications. Unlike round washers, square washers offer a larger surface area, making them ideal for distributing the load evenly across structural joints. This reduces the chances of material deformation or bolt pull-through under stress. Nafees Metal Industries, located in Mumbai, is recognized as one of the best manufacturers of square washers in India, supplying bulk and custom options across multiple sectors.

Stainless Steel Washers for Corrosion Resistance

Our stainless steel washers in square shape offer superior performance in environments exposed to moisture, chemicals, and atmospheric agents. We manufacture these square washers using premium grades like SS202, SS304, and SS316, ensuring excellent resistance to corrosion, rust, and wear over time. These are ideal for marine, construction, and power sector applications where durability is non-negotiable.

What Are Square Washers?

Square washers are flat components with four equal-length sides and a central hole to accommodate bolts or screws. Their geometry ensures greater surface contact between the fastener and the material, making them especially useful when dealing with oversized holes or irregular surfaces. Due to their shape, square washers offer enhanced anti-rotation properties, which is critical in timber framing, structural steel assemblies, and seismic zones.

Key Features of Square Washers

1. Flat, Wide Surface for Maximum Load Distribution

The defining characteristic of square washers is their extended surface area compared to conventional round washers. This allows them to spread the load from bolts and nuts over a wider area, significantly reducing surface deformation or pull-through—especially when used on softer materials like wood or in oversized holes.

Benefit:

Ensures the pressure is evenly distributed, preventing material fatigue and enhancing joint longevity in heavy-duty assemblies.

2. Excellent Anti-Rotation Capability

The square geometry naturally resists turning, making these washers ideal for bolted connections where vibration or torque is present. This reduces loosening over time, especially in applications with dynamic loads or movement.

Benefit:

Improves joint stability in bridges, tunnels, marine environments, and heavy machinery by preventing bolt rotation under stress.

3. Available in Multiple Material Grades

Our square washers are manufactured in a wide range of materials including Stainless Steel (SS202, SS304, SS316), Mild Steel, Galvanized Iron, Aluminum, Brass, and Copper. Each material is selected based on its unique mechanical and environmental resistance properties.

Benefit:

Allows users to choose a washer that best suits their application—whether it’s corrosion resistance for marine use or high tensile strength for construction.

4. Corrosion and Rust Resistance

Especially with stainless steel variants like SS202 and SS316, our square washers offer excellent resistance to rust, moisture, and chemical exposure. This feature is crucial for outdoor use, high-humidity zones, or chemically aggressive environments.

Benefit:

Extends the life of the washer, minimizes maintenance needs, and prevents equipment failures in harsh weather or marine conditions.

5. High Dimensional Accuracy

We use precision machining and strict quality control during manufacturing, ensuring every washer conforms to exact dimensional standards. Our square washers feature consistent thickness, accurate hole placement, and burr-free edges.

Benefit:

Improves fitting accuracy, reduces alignment issues, and ensures compatibility with a wide variety of bolt and screw diameters.

6. Smooth, Burr-Free Edges

All washers are deburred during post-processing to eliminate sharp edges that could compromise safety or cause injury during installation. A smooth finish also helps prevent wear or scratching on the surfaces they’re applied to.

Benefit:

Enhances user safety, allows for seamless installation, and protects sensitive or coated surfaces from damage.

7. Customizable Dimensions and Finishes

Our in-house manufacturing allows us to offer complete customization for square washers—including hole size, outer dimensions, thickness, and surface finishes like zinc plating, black oxide, mirror polish, or sandblasting.

Benefit:

Ideal for clients needing tailor-made washers for niche applications such as designer constructions, heavy machinery, or branded assemblies.

8. Superior Load-Bearing Strength

Square washers are engineered to handle high axial and radial loads, especially in static or dynamic conditions. Their geometry allows for better weight transfer across the base material, reducing the likelihood of bolt fatigue or loosening.

Benefit:

Ensures reliable performance in infrastructure projects, MEP systems, and load-critical environments like cranes or turbines.

9. Supports Oversized Holes and Irregular Surfaces

In some assemblies, holes may be larger than standard or drilled into irregular materials. Square washers provide a broader base that helps anchor bolts securely even in such challenging conditions.

Benefit:

Minimizes the risk of fastener pull-through and supports structural safety in retrofitting or customized industrial setups.

10. Available in Ready Stock and Bulk Quantities

We maintain a large inventory of standard sizes—like 20mm, 25mm, 30mm, and 50mm—so you can quickly source washers without delay. Custom bulk orders are processed with fast turnaround times and precision quality.

Benefit:

Ideal for OEMs, distributors, and large infrastructure projects needing consistent, fast supply without compromising on quality.

Industrial Washers for Diverse Sectors

We manufacture industrial washers in square shape to meet the rigorous requirements of various sectors, including:

Construction and Infrastructure

Oil & Gas

Railways and Heavy Equipment

Wind and Solar Energy

Marine Structures

Agricultural Equipment

Telecom Infrastructure

Automotive and Defense

Whether it’s holding timber frames in place or securing machinery in high-vibration settings, our square washers perform reliably under pressure.

Applications of Square Washers

Square washers are widely recognized for their ability to offer enhanced load distribution and anti-rotation capabilities. Their unique design makes them indispensable in environments that demand mechanical stability, alignment precision, and long-term reliability. Below are the major industry applications of square washers, each supported by real-world use cases:

1. Construction and Structural Engineering

In construction, square washers are frequently used to reinforce bolted joints in concrete and timber framing. Their large surface area prevents bolts and nuts from sinking into soft materials, which is especially important in wooden structures.

Use case:

Used in foundation anchoring and column bases where the bolt holes are oversized, providing even load distribution and enhancing structural integrity.

2. Bridge and Infrastructure Projects – Square washers

Square washers play a vital role in high-load-bearing assemblies such as bridges, flyovers, and public infrastructure. They help stabilize structural members during vibrations and heavy traffic conditions.

Use case:

Utilized in beam-to-column connections and expansion joints to prevent rotation and minimize bolt wear in high-vibration zones.

3. Railways and Heavy Equipment Manufacturing

In railway tracks, locomotives, and industrial machinery, square washers serve as reliable fasteners that resist loosening due to constant movement, torque, and high-pressure environments.

Use case:

Used under track bolts to ensure bolts remain tightly fastened even under repeated rail vibration and dynamic loading.

4. Wind and Solar Energy Installations

Square washers are preferred in renewable energy infrastructure for their ability to resist corrosion and maintain joint stability under fluctuating wind or thermal loads.

Use case:

Installed in solar panel mounting systems and wind turbine foundations to provide a secure base against environmental stress and dynamic load conditions.

5. Marine and Offshore Applications

Given their enhanced anti-rotational stability and corrosion resistance (especially in stainless steel grades), square washers are commonly used in shipbuilding, ports, and oil rigs.

Use case:

Used to secure deck components, railing systems, and offshore structural joints where exposure to saltwater is constant.

6. Tunneling and Mining Operations

Mining environments involve heavy machinery and dynamic underground operations. Square washers help stabilize bolted joints in mining equipment and support frames.

Use case:

Used in the assembly of rock bolting systems and tunnel lining structures where strength and resistance to deformation are critical.

7. Telecom Towers and Transmission Lines

Square washers are ideal for electrical installations where fasteners must remain stable under wind loads and environmental changes.

Use case:

Used in tower bolting and grounding systems to ensure electrical continuity and mechanical rigidity.

8. Seismic Zone Construction

In regions prone to earthquakes, square washers are integral in reducing rotational slippage of bolts in structural members.

Use case:

Installed in shear walls and brace frames in commercial and residential buildings in seismic zones to enhance vibration resistance.

9. Timber Framing and Wooden Architecture

Due to their flat and broad profile, square washers distribute the load over a larger wooden surface area, making them ideal for preserving the integrity of timber.

Use case:

Used in gazebos, wooden bridges, and heavy timber trusses to prevent bolt embedment into wood and ensure joint longevity.

10. Agricultural and Earthmoving Equipment

In rugged terrains and heavy-duty operations, square washers hold bolts securely and prevent assembly failures in large machinery.

Use case:

Applied in plows, tillers, and tractors where vibration, soil impact, and movement demand robust fastening solutions.

11. OEM (Original Equipment Manufacturer) Assemblies

OEMs across sectors use square washers in product designs requiring both mechanical strength and dimensional precision.

Use case:

Used in custom machinery, HVAC systems, and industrial frameworks where part integrity must be maintained through repetitive operation cycles.

Buy Bulk Square Washers at Competitive Prices

You can now buy bulk square washers directly from our website: https://nafeesmetalindustries.com. We offer:

Discounted rates for large orders

Custom labeling and packaging

Delivery across India and selected global locations

Consistent inventory with quick dispatch timelines

Whether you’re a construction contractor or a distributor, we ensure a hassle-free ordering experience with the ability to scale based on your project demands.

Why Choose Square Washers from Nafees Metal Industries?

We are one of the best manufacturers of square washers in India, and here’s why:

Advanced Manufacturing Setup: Precision power presses and inspection systems ensure dimensional accuracy.

Quality Assurance: All batches are tested for load-bearing, hardness, and corrosion resistance.

Custom Production: We cater to small and large-scale customized orders across dimensions and finishes.

Bulk Availability: Always ready stock of common square washer sizes like 20mm, 25mm, 30mm, and 50mm.

Expert Support: Guidance from our technical team to select the right washer for your application.

At Nafees Metal industries, quality and precision are at the core of our manufacturing process. Every batch is produced with meticulous attention to detail, ensuring they meet the highest industry standards. We offer competitive pricing, flexible order quantities, and quick delivery for all your fastening needs — whether you want a small order or plan to buy bulk square washers online.

Our commitment to customer satisfaction and premium industrial washers makes us your trusted partner in fastening solutions.

Material Grades Offered

We manufacture square washers in a wide range of materials:

Stainless Steel (SS202, SS304, SS316) – for corrosion and high-strength use

Mild Steel (MS) – for cost-effective load-bearing applications

Galvanized Iron – for outdoor and structural projects

Copper & Brass – for aesthetic or electrical conductivity-based needs

Aluminum – for lightweight, non-corrosive assemblies

Customization Options

Our team provides fully customized washer solutions to meet your project-specific load, surface area, and appearance requirements. Customizable parameters include:

Inner and outer diameter

Thickness from 1mm to 10mm+

Hole shape and alignment

Surface coating or finish

Edge treatment (deburring, polishing)

Every square washer is manufactured under strict tolerances to ensure reliability and functionality.

Real-World Case Study: Enhancing Structural Stability with Custom Square Washers

A leading infrastructure development company in India approached Nafees Metal Industries for a solution to a recurring issue they were facing during the construction of a large public bridge project. The challenge revolved around the consistent loosening of bolts in their structural assemblies due to heavy vibrations, dynamic loads, and exposure to extreme weather conditions.

The Challenge

The bridge project involved fastening heavy steel plates and support beams across expansion joints and cantilever sections. The client was using traditional round washers with high-tension bolts, but the assemblies frequently suffered from bolt loosening, fastener pull-through, and surface deformation. The round washers failed to provide adequate grip and load distribution, especially in areas with oversized drilled holes and irregular steel surfaces.

Nafees Metal Industries’ Solution

After a detailed assessment of the construction drawings and on-site challenges, our engineering team recommended the use of custom-manufactured square washers with the following specifications:

Material: Stainless Steel 316 for maximum corrosion resistance in a marine-influenced environment

Dimensions: 50mm x 50mm with a central 14mm hole and 6mm thickness

Surface Finish: Shot-blasted and passivated for enhanced durability and anti-corrosion performance

Customization: Tight tolerance control to ensure flush installation with load-bearing steel structures

These square washers were designed to offer superior anti-rotation performance and a larger surface area, enabling effective load distribution even on oversized and irregular holes.

The Result

Upon installation, the square washers from Nafees Metal Industries significantly improved the performance of the bolted joints:

Bolt stability improved by over 40%, reducing the need for re-tightening

Surface wear and deformation were virtually eliminated

Assembly time was reduced due to ease of alignment and faster installation

Structural safety was enhanced, with vibration-induced loosening no longer being a problem

The client reported zero washer-related issues in post-installation audits over a 12-month observation period—even in high-stress zones like expansion joints and cantilevered sections.

Ongoing Partnership

Impressed by the results, the company placed repeat bulk orders for their other infrastructure projects, including metro rail support structures and highway overpass systems. Our team continues to provide them with customized square washers in different sizes and finishes, tailored to their evolving requirements.

This case study demonstrates how the right choice of square washers can directly impact structural safety, reduce maintenance costs, and improve long-term reliability in demanding industrial environments.

Frequently Asked Questions (FAQs)

1. What is the primary use of square washers?

To provide even load distribution and prevent rotation of bolts or nuts.

2. How are square washers different from round washers?

Square washers have better anti-rotation properties and a larger contact surface.

3. Are stainless steel square washers corrosion-resistant?

Yes, especially in SS316 or SS304 grades.

4. Can I buy bulk square washers?

Yes, bulk purchases can be made via our website with customized pricing.

5. Are square washers reusable?

If not deformed or corroded, they can be reused.

6. What sizes are available?

Standard sizes like 20mm, 25mm, 30mm, and custom dimensions are available.

7. Can square washers be used with timber?

Yes, they’re ideal for wooden structures to avoid fastener pull-through.

8. Are test certificates provided?

Yes, including Mill Test Certificates (MTC) and quality inspection documents.

9. Do you export square washers?

Yes, to the UAE, Africa, Southeast Asia, and other regions.

10. What is the typical lead time?

5–7 working days for custom orders, immediate dispatch for stock items.

11. Which materials are available?

Stainless steel, mild steel, galvanized iron, brass, copper, and aluminum.

12. Are they compatible with seismic applications?

Yes, their shape and strength are ideal for such conditions.

13. Can I customize the coating or finish?

Absolutely—zinc, black oxide, hot-dip, or plain finishes are available.

14. Will square washers damage the surface?

No, in fact, they reduce surface deformation by evenly spreading the load.

15. Why are you considered the best manufacturer?

Because of our consistency, quality, custom capabilities, and fast deliveries.

Contact Us Today for Best Square Washers

Choose the best square washers for heavy-duty use and get the strength and durability you need for your assemblies. Visit our manufacturing unit at Reay Road, Mumbai, or contact us for customized orders and bulk inquiries.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

Reviews

There are no reviews yet.

Be the first to review “Square Washers” Cancel reply

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Square Washers, Washers

Got Questions?

Feel free to

Get in touch

Reviews

There are no reviews yet.