No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

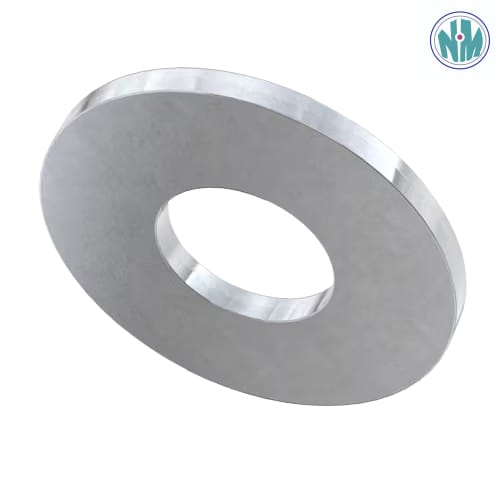

*Images shown for graphic representation. Not to scale.

Introduction

In industrial applications, even the smallest components can make a significant difference in performance and reliability. Among these, machined washers play a pivotal role. They may appear minor, but they are essential for ensuring stability, load distribution, and the longevity of bolted assemblies. Unlike standard washers, machined washers are manufactured with precision to meet high industrial standards, making them indispensable in engineering applications where exact tolerances are critical.

Industries such as automotive, aerospace, oil & gas, construction, and heavy machinery heavily rely on machined washers to ensure that bolts, nuts, and fasteners perform reliably under stress. By providing consistent thickness, smooth surfaces, and structural strength, machined washers prevent equipment failure, reduce maintenance costs, and enhance overall efficiency.

In this comprehensive guide, we will explore every aspect of machined washers — from types, materials, and manufacturing processes to their applications, advantages, and frequently asked questions. By the end of this guide, you’ll have a complete understanding of why these seemingly small components are crucial for industrial excellence.

What Are Machined Washers?

Machined washers are specialized fastener components designed to provide precise load distribution, protection, and stability in mechanical assemblies. Unlike traditional stamped washers, which are punched or pressed from metal sheets, machined washers are manufactured through precision machining processes. This ensures exact dimensions, smooth edges, uniform thickness, and superior strength, making them ideal for high-performance and critical industrial applications.

Key Features of Machined Washers:

Precision Dimensions – Machined washers are produced with tight tolerances, ensuring a perfect fit between nuts, bolts, and mating surfaces.

Smooth Surface Finish – The machining process eliminates rough edges, reducing friction and wear during assembly.

Enhanced Durability – Made from high-quality metals like stainless steel, carbon steel, brass, or specialized alloys, machined washers withstand extreme stress, pressure, and temperature conditions.

Consistency – Each washer is identical in size and shape, which is essential for repetitive industrial processes where uniformity is critical.

Versatility – They can be used in applications ranging from automotive engines to aerospace assemblies, marine equipment, and heavy construction machinery.

Why They Are Important

Machined washers are more than just supportive components—they protect the integrity of mechanical systems. They prevent damage to surfaces, distribute loads evenly, and minimize the risk of loosening under vibration. This makes them indispensable for industries where precision and reliability are non-negotiable.

For buyers seeking high-quality solutions, precision machined washers are often preferred over standard washers due to their superior performance and long-term cost-effectiveness.

Why Choose Machined Washers Over Standard Washers?

While standard washers are commonly used in everyday applications, machined washers offer significant advantages that make them indispensable in industrial and high-precision environments. Here’s why choosing machined washers over conventional washers can make a real difference:

1. Dimensional Accuracy

Machined washers are produced with tight tolerances, ensuring that each washer has the exact inner and outer diameter, thickness, and flatness required. In contrast, stamped washers can have slight variations that may lead to uneven load distribution or improper fitting. For applications such as automotive engines, aerospace assemblies, or industrial machinery, precision matters—and machined washers deliver it consistently.

2. Superior Strength and Durability

Due to the manufacturing process and the use of high-quality metals, machined washers have enhanced mechanical strength. They can withstand high pressure, heavy loads, and extreme operational environments without deforming or losing functionality. Standard washers, on the other hand, may bend or fail under heavy stress.

3. Smooth Surface Finish

Machined washers have polished and smooth surfaces, which reduce friction, wear, and the risk of corrosion when in contact with bolts or nuts. This not only extends the life of the washer but also protects the surfaces of the components they support.

4. Consistency in Production

One of the critical advantages of machined washers is uniformity. Each washer is identical to the next, which is vital for repetitive industrial processes. This consistency ensures predictable performance in critical assemblies, something that standard washers may not reliably provide.

5. Resistance to Loosening

Vibration is a common cause of loosening in mechanical assemblies. Machined washers are designed to maintain their structural integrity under vibration and dynamic loads, preventing nuts and bolts from loosening over time.

6. Long-Term Cost Efficiency

Though initially more expensive than stamped washers, machined washers offer long-term savings due to their durability, reduced maintenance needs, and enhanced performance. In critical industries, this cost efficiency translates into fewer production delays and longer equipment life.

Applications where this matters:

Automotive engines and transmissions

Aerospace and defense equipment

Industrial machinery and robotics

Oil & gas pipelines

Heavy construction equipment

In summary, machined washers are not just a premium alternative—they are a necessary choice for industries where precision, reliability, and longevity are critical.

Manufacturing Process of Machined Washers

The manufacturing of machined washers is a precise and methodical process designed to ensure that each washer meets strict industrial standards. Unlike standard stamped washers, which are simply cut from metal sheets, machined washers undergo advanced machining and finishing processes that enhance their durability, accuracy, and performance.

Step 1: Material Selection

The first and most critical step in producing machined washers is selecting the right material. Common materials include:

Stainless Steel – Offers corrosion resistance and strength, ideal for industrial and marine applications.

Carbon Steel – Provides high tensile strength for heavy-duty usage.

Brass and Copper – Used in electrical and decorative applications.

Special Alloys – Customized for extreme temperature or chemical resistance.

The choice of material depends on the application, load requirements, and environmental conditions.

Step 2: CNC Machining

After selecting the material, washers are cut and shaped using CNC (Computer Numerical Control) machines. CNC machining ensures:

Exact dimensions and tolerances

Smooth edges and surfaces

Consistent thickness across all washers

This precision is what differentiates machined washers from regular stamped washers.

Step 3: Heat Treatment

Depending on the material and application, washers may undergo heat treatment processes such as annealing or quenching. Heat treatment enhances:

Mechanical strength

Hardness

Resistance to wear and deformation

Step 4: Surface Finishing

Surface finishing improves the washer’s performance and longevity. Techniques include:

Grinding and Polishing – For smooth, burr-free surfaces.

Plating or Coating – For corrosion resistance (e.g., zinc plating, nickel coating).

Passivation – Common for stainless steel to enhance corrosion resistance.

Step 5: Quality Inspection

Quality control is a critical step. Each batch of machined washers is inspected for:

Dimensional accuracy (inner and outer diameter, thickness)

Surface finish quality

Hardness and tensile strength

Compliance with industrial standards (DIN, ISO, ASTM)

Only washers that pass rigorous inspection are approved for shipment, ensuring that customers receive high-quality, reliable components.

Advantages of the Machining Process

Precision – CNC machining ensures washers fit perfectly in critical applications.

Durability – Heat treatment and high-quality materials increase lifespan.

Consistency – Every washer in a batch is identical, ensuring reliable performance.

Versatility – Allows for custom designs and specifications.

In short, the manufacturing process of machined washers guarantees high performance, making them suitable for demanding industrial applications where reliability is non-negotiable.

Applications of Machined Washers

Machined washers are essential components in a wide range of industrial and mechanical applications. Their precision, strength, and durability make them indispensable wherever reliability and load distribution are critical. Here’s a detailed look at the major applications of machined washers:

1. Aerospace Industry

In aerospace applications, even the smallest component can impact performance and safety. Machined washers are used in aircraft engines, landing gear assemblies, and structural components to:

Distribute loads evenly

Prevent loosening of fasteners under vibration

Enhance reliability in high-stress environments

Their precision and durability make them a preferred choice for aerospace engineers.

2. Automotive Industry

Automobiles rely on countless fasteners for engines, transmissions, suspensions, and chassis components. Machined washers provide:

Perfect fit for critical bolted connections

Resistance to wear, heat, and vibration

Protection of surfaces from damage

From passenger vehicles to heavy trucks, these washers ensure long-lasting performance.

3. Oil & Gas Industry

Machined washers are widely used in oil and gas pipelines, drilling equipment, and refineries. They help:

Maintain structural integrity under high pressure

Prevent loosening in vibrating machinery

Resist corrosion in harsh environments

High-quality machined washers are essential for safety and reliability in this demanding sector.

4. Construction and Heavy Machinery

In construction equipment, bridges, cranes, and industrial machinery, machined washers:

Distribute heavy loads efficiently

Protect bolts from bending or breaking

Ensure stable and secure assemblies

Their durability reduces maintenance and replacement costs in large-scale projects.

5. Electronics and Electrical Applications

Smaller machined washers are used in electronics and electrical assemblies for:

Insulating components

Providing precise spacing

Preventing surface damage during assembly

Materials like brass or copper washers are common in these applications.

6. Marine Industry

In marine applications, corrosion-resistant machined washers (usually stainless steel) are critical for:

Securing fasteners in boats and offshore equipment

Withstanding saltwater exposure and harsh weather conditions

Maintaining long-term performance without frequent replacements

Summary

The versatility of machined washers makes them suitable for nearly every industrial sector. From aerospace and automotive to oil & gas, construction, electronics, and marine applications, they provide essential benefits in load distribution, reliability, and durability.

Types of Machined Washers

Machined washers come in various types, each designed for specific industrial applications. Understanding the types of washers helps in selecting the right one for your assembly needs. Below is a detailed overview:

1. Flat Machined Washers

Flat washers are the most common type of machined washer. They have a uniform thickness and smooth surfaces that distribute loads evenly across a fastened joint.

Applications:

Automotive assemblies

Machinery connections

Structural components

Benefits: Provide stability, prevent surface damage, and maintain bolt tension.

2. Thrust Washers

Thrust washers are designed to handle axial loads in rotating assemblies. They prevent wear and reduce friction between moving parts.

Applications:

Gearboxes

Rotating shafts

Industrial machinery

Benefits: Reduce wear, improve efficiency, and extend component life.

3. Belleville (Disc) Washers

Belleville washers, also known as disc springs, are conical washers that provide a spring-like action under load.

Applications:

High-tension bolted joints

Vibration-prone assemblies

Heavy machinery

Benefits: Maintain tension, absorb shocks, and prevent loosening due to vibration.

4. Spherical Washers

Spherical washers compensate for misalignment between the bolt and the surface. They are ideal for assemblies where flatness cannot be guaranteed.

Applications:

Engine mounts

Heavy construction equipment

Aerospace structures

Benefits: Ensure uniform load distribution even on uneven surfaces, preventing stress concentration.

5. Custom Machined Washers

Custom washers are manufactured to meet specific requirements, including unique dimensions, materials, or load capacities.

Applications:

Specialized industrial machinery

Aerospace and defense

High-precision engineering projects

Benefits: Tailored to exact specifications, ensuring optimal performance in unique applications.

Summary

Selecting the right type of machined washer is crucial for ensuring optimal performance and longevity. Whether it’s a flat washer for general use or a Belleville washer for high-tension applications, choosing the correct type reduces maintenance, enhances safety, and improves the efficiency of mechanical systems.

Key Advantages of Using Machined Washers

Machined washers offer a range of advantages that make them essential components in industrial and mechanical assemblies. Their precision engineering ensures reliability, durability, and performance across various applications. Here’s a detailed look at the key benefits:

1. High Strength for Heavy Loads

Machined washers are manufactured from high-quality metals and alloys, making them capable of handling heavy loads without deforming. They are ideal for applications where standard washers might fail under pressure, such as in construction equipment, industrial machinery, and automotive engines.

2. Perfect Fit and Alignment

The precision machining process ensures that each washer has exact dimensions and tolerances. This guarantees a perfect fit between nuts, bolts, and surfaces, reducing misalignment and enhancing the stability of the assembly.

3. Resistance to Vibration and Loosening

Vibration is a common issue in machinery and automotive applications. Machined washers maintain their structural integrity under dynamic conditions, preventing nuts and bolts from loosening over time. This reduces maintenance and improves the safety of mechanical systems.

4. Corrosion Resistance

Washers made from stainless steel or coated alloys are highly resistant to corrosion. This makes machined washers suitable for harsh environments, including marine, chemical, and oil & gas industries, where exposure to moisture and chemicals is common.

5. Extended Service Life

The combination of high-quality materials, precision manufacturing, and surface finishing ensures that machined washers have a longer lifespan than standard washers. This reduces downtime and replacement costs in industrial operations.

6. Versatility Across Industries

Machined washers are versatile components used in aerospace, automotive, construction, oil & gas, electronics, and marine industries. Their ability to meet demanding specifications makes them an essential choice for engineers and industrial buyers.

7. Cost-Effectiveness in the Long Run

While machined washers may have a higher initial cost than stamped washers, their durability, precision, and reduced maintenance requirements make them a cost-effective solution over time. Industries save money by avoiding frequent replacements and ensuring uninterrupted operations.

Machined Washers Manufacturers in India

India has emerged as a global hub for high-quality machined washers manufacturing, offering competitive prices, advanced technology, and reliable supply chains. For industries seeking precision components, partnering with machined washers manufacturers in India provides several advantages.

Why India is a Preferred Destination for Machined Washers

Advanced Manufacturing Facilities

Indian manufacturers use CNC machining, precision grinding, and advanced finishing techniques to produce washers that meet international quality standards such as DIN, ISO, and ASTM.Wide Material Range

Manufacturers in India offer machined washers in a variety of materials including stainless steel, carbon steel, brass, copper, and specialized alloys. This variety ensures compatibility with diverse industrial applications.Customization Capabilities

Indian manufacturers can produce custom machined washers tailored to specific dimensions, tolerances, and load requirements. This flexibility is crucial for industries with unique or high-precision needs.Cost-Effective Solutions

Due to lower labor and operational costs, sourcing from India often results in high-quality washers at competitive prices, making bulk procurement economically viable.Export-Ready Supply Chains

Many Indian manufacturers have experience exporting to global markets including the USA, Europe, Middle East, and Asia-Pacific. They ensure timely delivery, proper packaging, and compliance with international shipping standards.

Key Industries Served

Automotive and aerospace

Oil & gas and petrochemicals

Construction and heavy machinery

Electronics and electrical assemblies

Marine and shipbuilding

Choosing the Right Manufacturer

When selecting machined washers manufacturers in India, consider:

Quality certifications and standards compliance

Track record with domestic and international clients

Capability to produce custom sizes and materials

Capacity for bulk production and timely delivery

How to Buy Machined Washers in Bulk

For industrial buyers, sourcing machined washers in bulk requires careful planning to ensure quality, consistency, and cost-effectiveness. Bulk procurement is common in industries such as automotive, aerospace, construction, and heavy machinery, where large volumes are needed for assembly lines and maintenance operations.

Steps to Buy Machined Washers in Bulk

Identify Requirements

Determine the exact specifications you need:Material: Stainless steel, carbon steel, brass, or alloys

Size and Dimensions: Inner diameter, outer diameter, thickness

Type: Flat, Belleville, thrust, spherical, or custom washers

Quantity: Estimate based on production or maintenance requirements

Choose a Reliable Supplier

Look for manufacturers or distributors who:Offer precision machined washers with tight tolerances

Have certifications (ISO, DIN, ASTM)

Can supply consistent quality in bulk

Request Samples

Before committing to large quantities, request samples to inspect:Dimensional accuracy

Surface finish

Material quality

Overall performance

Compare Prices and Delivery Terms

Evaluate multiple suppliers to ensure competitive pricing without compromising quality. Check:Bulk pricing discounts

Minimum order quantity (MOQ)

Shipping and delivery timelines

Finalize Customization (if needed)

If your application requires unique dimensions, tolerances, or finishes, confirm that the supplier can meet your specifications. Custom machined washers are common for critical applications.Place Bulk Order

Once the supplier is verified and samples approved, place your bulk order. Ensure a clear agreement on:Quality assurance and inspection

Packaging and labeling

After-sales support

Advantages of Buying in Bulk

Cost Savings – Reduced unit cost per washer

Consistent Supply – Ensures uninterrupted operations

Better Supplier Relationship – Large orders often lead to priority service

Customization Opportunities – Easier to request tailored specifications for repeated orders

Best Machined Washers for Industrial Use

When it comes to industrial applications, choosing the best machined washers for industrial use is crucial to ensure safety, reliability, and long-term performance. The right washer enhances the integrity of bolted joints, distributes loads evenly, and withstands extreme operational conditions.

Factors to Consider

Material Selection

Stainless Steel – Offers excellent corrosion resistance and durability, ideal for marine, chemical, and outdoor environments.

Carbon Steel – Provides high tensile strength, suitable for heavy machinery and structural applications.

Brass or Copper – Common in electrical and decorative applications due to conductivity and aesthetic appeal.

Special Alloys – For high-temperature, high-pressure, or chemically aggressive environments.

Dimensional Accuracy

The best machined washers have precise inner and outer diameters, thickness, and flatness to ensure a perfect fit. This minimizes the risk of misalignment, wear, or uneven load distribution.Load-Bearing Capacity

Industrial applications often involve heavy loads. Choose washers that are engineered to handle axial and radial forces without deformation.Surface Finish and Treatment

A polished or coated surface enhances performance by reducing friction, preventing corrosion, and extending service life. Treatments like zinc plating, nickel coating, or passivation are common for industrial-grade washers.Type of Washer

Depending on the application, select the appropriate type:Flat washers for general load distribution

Belleville washers for tensioning and vibration resistance

Thrust washers for rotary assemblies

Spherical washers for misalignment compensation

Supplier Reliability

Purchase from trusted manufacturers who provide quality certifications, consistent supply, and customization options if needed.

Recommended Applications

Automotive and Aerospace – Precision-engineered washers for engine assemblies, transmissions, and structural components.

Heavy Machinery and Construction – High-strength washers for cranes, bridges, and industrial equipment.

Oil & Gas – Corrosion-resistant washers for pipelines, drilling rigs, and high-pressure systems.

Electronics and Electrical – Conductive or insulating washers for precise spacing and component protection.

Future of Machined Washers in Global Industry

The demand for machined washers is expected to grow steadily across global industries due to increasing reliance on precision engineering, automation, and heavy-duty machinery. As industries become more sophisticated, the need for components that offer accuracy, durability, and reliability is more critical than ever.

Key Trends Driving Growth

Advancements in Manufacturing Technology

Modern CNC machining, laser cutting, and precision grinding techniques are enabling manufacturers to produce washers with extremely tight tolerances and superior surface finishes. This allows for higher-quality precision machined washers that meet stringent industrial standards.Growth in Industrial Automation

Automated assembly lines require washers with consistent quality and exact dimensions to ensure seamless integration. The use of machined washers reduces errors, enhances efficiency, and supports robotic assembly in automotive, electronics, and aerospace industries.Material Innovations

Research in advanced alloys, composite materials, and surface coatings is improving the performance of machined washer, allowing them to withstand higher temperatures, pressures, and corrosive environments.Sustainability and Longevity

Industries are increasingly focusing on reducing maintenance costs and minimizing waste. High-quality machined washer offer long-term durability, reducing replacements and supporting sustainable industrial practices.Customization and Specialized Applications

The demand for custom machined washers is rising as industries require washers tailored to specific dimensions, load capacities, and environmental conditions. Manufacturers are adapting by offering bespoke solutions that meet precise engineering needs.

Emerging Applications

Renewable Energy – Wind turbines and solar panel structures require durable and precise washers.

Aerospace & Defense – High-performance machined washers are critical for structural and mechanical assemblies.

Medical Devices – Precision washers are used in surgical and diagnostic equipment.

Summary

The future of machined washer is closely tied to technological advancements, industrial automation, and demand for high-performance materials. As industries continue to evolve, precision machined washer will remain an essential component in maintaining reliability, efficiency, and safety across critical applications worldwide.

FAQs About Machined Washers

What are machined washers?

Machined washers are precision-manufactured flat rings used to distribute loads, protect surfaces, and enhance the stability of bolted joints in industrial applications.How are machined washers different from standard washers?

Unlike stamped washers, machined washers are produced through CNC machining, offering superior dimensional accuracy, smooth surfaces, and enhanced strength.What materials are used for machined washers?

Common materials include stainless steel, carbon steel, brass, copper, and specialized alloys, depending on the application requirements.Where are machined washers commonly used?

They are widely used in aerospace, automotive, oil & gas, construction, electronics, and marine industries for critical assemblies.Can I buy machined washers in bulk?

Yes, bulk orders of machined washers are available from trusted manufacturers, often with discounts and custom specifications.What are precision washers?

Precision machined washers are high-accuracy washers produced with tight tolerances, ensuring perfect fit and uniform load distribution.Why should I choose machined washer over stamped washers?

Machined washers offer better strength, durability, resistance to vibration, and precise dimensions, making them ideal for industrial and heavy-duty applications.Who are the leading machined washer manufacturers in India?

Several Indian manufacturers specialize in high-quality machined washer, offering both standard and custom options for domestic and international markets.What is the best type of machined washer for industrial use?

The best machined washers for industrial use depend on the application but typically include stainless steel flat washers, Belleville washers, and thrust washers for heavy-duty and vibration-prone environments.Can machined washer resist corrosion?

Yes, washers made from stainless steel or coated with protective finishes are highly resistant to corrosion, making them suitable for marine, chemical, and outdoor applications.Are custom machined washer available?

Yes, many manufacturers provide custom machined washers tailored to specific dimensions, materials, tolerances, and surface finishes.How do I select the right machined washer for my application?

Consider the material, load-bearing capacity, type, size, surface finish, and manufacturer reliability to choose the most suitable machined washers.What are the advantages of buying machined washers in bulk?

Bulk purchasing offers cost savings, consistent supply, priority service from suppliers, and the ability to request customized washers for recurring industrial needs.What standards do machined washers comply with?

High-quality washers typically comply with international standards like DIN, ISO, and ASTM, ensuring reliability and consistency.Where can I buy the best machined washers for industrial use?

The best machined washers for industrial use can be sourced from reputable manufacturers in India and globally, offering certified, high-precision washers suitable for demanding applications.

Why Choose Nafees Metal Industries

At Nafees Metal industries, we prioritize quality, precision, and customer satisfaction. Our Machine Washers are manufactured using the latest technology and highest-grade materials, ensuring they meet the rigorous demands of various industries. We offer competitive pricing, timely delivery, and excellent customer support, making us the preferred choice for all your washer needs at Reay Road, Mumbai.

Be the first to review “Machined Washers” Cancel reply

Machined Washers

17 people are viewing this product right now

₹1.20 /per piece

Machine Washers

We have this product in all sizes following ISO 2016 standard.

To order this product please contact us my Calling us or using Request Quote button below.

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

Introduction

In industrial applications, even the smallest components can make a significant difference in performance and reliability. Among these, machined washers play a pivotal role. They may appear minor, but they are essential for ensuring stability, load distribution, and the longevity of bolted assemblies. Unlike standard washers, machined washers are manufactured with precision to meet high industrial standards, making them indispensable in engineering applications where exact tolerances are critical.

Industries such as automotive, aerospace, oil & gas, construction, and heavy machinery heavily rely on machined washers to ensure that bolts, nuts, and fasteners perform reliably under stress. By providing consistent thickness, smooth surfaces, and structural strength, machined washers prevent equipment failure, reduce maintenance costs, and enhance overall efficiency.

In this comprehensive guide, we will explore every aspect of machined washers — from types, materials, and manufacturing processes to their applications, advantages, and frequently asked questions. By the end of this guide, you’ll have a complete understanding of why these seemingly small components are crucial for industrial excellence.

What Are Machined Washers?

Machined washers are specialized fastener components designed to provide precise load distribution, protection, and stability in mechanical assemblies. Unlike traditional stamped washers, which are punched or pressed from metal sheets, machined washers are manufactured through precision machining processes. This ensures exact dimensions, smooth edges, uniform thickness, and superior strength, making them ideal for high-performance and critical industrial applications.

Key Features of Machined Washers:

Precision Dimensions – Machined washers are produced with tight tolerances, ensuring a perfect fit between nuts, bolts, and mating surfaces.

Smooth Surface Finish – The machining process eliminates rough edges, reducing friction and wear during assembly.

Enhanced Durability – Made from high-quality metals like stainless steel, carbon steel, brass, or specialized alloys, machined washers withstand extreme stress, pressure, and temperature conditions.

Consistency – Each washer is identical in size and shape, which is essential for repetitive industrial processes where uniformity is critical.

Versatility – They can be used in applications ranging from automotive engines to aerospace assemblies, marine equipment, and heavy construction machinery.

Why They Are Important

Machined washers are more than just supportive components—they protect the integrity of mechanical systems. They prevent damage to surfaces, distribute loads evenly, and minimize the risk of loosening under vibration. This makes them indispensable for industries where precision and reliability are non-negotiable.

For buyers seeking high-quality solutions, precision machined washers are often preferred over standard washers due to their superior performance and long-term cost-effectiveness.

Why Choose Machined Washers Over Standard Washers?

While standard washers are commonly used in everyday applications, machined washers offer significant advantages that make them indispensable in industrial and high-precision environments. Here’s why choosing machined washers over conventional washers can make a real difference:

1. Dimensional Accuracy

Machined washers are produced with tight tolerances, ensuring that each washer has the exact inner and outer diameter, thickness, and flatness required. In contrast, stamped washers can have slight variations that may lead to uneven load distribution or improper fitting. For applications such as automotive engines, aerospace assemblies, or industrial machinery, precision matters—and machined washers deliver it consistently.

2. Superior Strength and Durability

Due to the manufacturing process and the use of high-quality metals, machined washers have enhanced mechanical strength. They can withstand high pressure, heavy loads, and extreme operational environments without deforming or losing functionality. Standard washers, on the other hand, may bend or fail under heavy stress.

3. Smooth Surface Finish

Machined washers have polished and smooth surfaces, which reduce friction, wear, and the risk of corrosion when in contact with bolts or nuts. This not only extends the life of the washer but also protects the surfaces of the components they support.

4. Consistency in Production

One of the critical advantages of machined washers is uniformity. Each washer is identical to the next, which is vital for repetitive industrial processes. This consistency ensures predictable performance in critical assemblies, something that standard washers may not reliably provide.

5. Resistance to Loosening

Vibration is a common cause of loosening in mechanical assemblies. Machined washers are designed to maintain their structural integrity under vibration and dynamic loads, preventing nuts and bolts from loosening over time.

6. Long-Term Cost Efficiency

Though initially more expensive than stamped washers, machined washers offer long-term savings due to their durability, reduced maintenance needs, and enhanced performance. In critical industries, this cost efficiency translates into fewer production delays and longer equipment life.

Applications where this matters:

Automotive engines and transmissions

Aerospace and defense equipment

Industrial machinery and robotics

Oil & gas pipelines

Heavy construction equipment

In summary, machined washers are not just a premium alternative—they are a necessary choice for industries where precision, reliability, and longevity are critical.

Manufacturing Process of Machined Washers

The manufacturing of machined washers is a precise and methodical process designed to ensure that each washer meets strict industrial standards. Unlike standard stamped washers, which are simply cut from metal sheets, machined washers undergo advanced machining and finishing processes that enhance their durability, accuracy, and performance.

Step 1: Material Selection

The first and most critical step in producing machined washers is selecting the right material. Common materials include:

Stainless Steel – Offers corrosion resistance and strength, ideal for industrial and marine applications.

Carbon Steel – Provides high tensile strength for heavy-duty usage.

Brass and Copper – Used in electrical and decorative applications.

Special Alloys – Customized for extreme temperature or chemical resistance.

The choice of material depends on the application, load requirements, and environmental conditions.

Step 2: CNC Machining

After selecting the material, washers are cut and shaped using CNC (Computer Numerical Control) machines. CNC machining ensures:

Exact dimensions and tolerances

Smooth edges and surfaces

Consistent thickness across all washers

This precision is what differentiates machined washers from regular stamped washers.

Step 3: Heat Treatment

Depending on the material and application, washers may undergo heat treatment processes such as annealing or quenching. Heat treatment enhances:

Mechanical strength

Hardness

Resistance to wear and deformation

Step 4: Surface Finishing

Surface finishing improves the washer’s performance and longevity. Techniques include:

Grinding and Polishing – For smooth, burr-free surfaces.

Plating or Coating – For corrosion resistance (e.g., zinc plating, nickel coating).

Passivation – Common for stainless steel to enhance corrosion resistance.

Step 5: Quality Inspection

Quality control is a critical step. Each batch of machined washers is inspected for:

Dimensional accuracy (inner and outer diameter, thickness)

Surface finish quality

Hardness and tensile strength

Compliance with industrial standards (DIN, ISO, ASTM)

Only washers that pass rigorous inspection are approved for shipment, ensuring that customers receive high-quality, reliable components.

Advantages of the Machining Process

Precision – CNC machining ensures washers fit perfectly in critical applications.

Durability – Heat treatment and high-quality materials increase lifespan.

Consistency – Every washer in a batch is identical, ensuring reliable performance.

Versatility – Allows for custom designs and specifications.

In short, the manufacturing process of machined washers guarantees high performance, making them suitable for demanding industrial applications where reliability is non-negotiable.

Applications of Machined Washers

Machined washers are essential components in a wide range of industrial and mechanical applications. Their precision, strength, and durability make them indispensable wherever reliability and load distribution are critical. Here’s a detailed look at the major applications of machined washers:

1. Aerospace Industry

In aerospace applications, even the smallest component can impact performance and safety. Machined washers are used in aircraft engines, landing gear assemblies, and structural components to:

Distribute loads evenly

Prevent loosening of fasteners under vibration

Enhance reliability in high-stress environments

Their precision and durability make them a preferred choice for aerospace engineers.

2. Automotive Industry

Automobiles rely on countless fasteners for engines, transmissions, suspensions, and chassis components. Machined washers provide:

Perfect fit for critical bolted connections

Resistance to wear, heat, and vibration

Protection of surfaces from damage

From passenger vehicles to heavy trucks, these washers ensure long-lasting performance.

3. Oil & Gas Industry

Machined washers are widely used in oil and gas pipelines, drilling equipment, and refineries. They help:

Maintain structural integrity under high pressure

Prevent loosening in vibrating machinery

Resist corrosion in harsh environments

High-quality machined washers are essential for safety and reliability in this demanding sector.

4. Construction and Heavy Machinery

In construction equipment, bridges, cranes, and industrial machinery, machined washers:

Distribute heavy loads efficiently

Protect bolts from bending or breaking

Ensure stable and secure assemblies

Their durability reduces maintenance and replacement costs in large-scale projects.

5. Electronics and Electrical Applications

Smaller machined washers are used in electronics and electrical assemblies for:

Insulating components

Providing precise spacing

Preventing surface damage during assembly

Materials like brass or copper washers are common in these applications.

6. Marine Industry

In marine applications, corrosion-resistant machined washers (usually stainless steel) are critical for:

Securing fasteners in boats and offshore equipment

Withstanding saltwater exposure and harsh weather conditions

Maintaining long-term performance without frequent replacements

Summary

The versatility of machined washers makes them suitable for nearly every industrial sector. From aerospace and automotive to oil & gas, construction, electronics, and marine applications, they provide essential benefits in load distribution, reliability, and durability.

Types of Machined Washers

Machined washers come in various types, each designed for specific industrial applications. Understanding the types of washers helps in selecting the right one for your assembly needs. Below is a detailed overview:

1. Flat Machined Washers

Flat washers are the most common type of machined washer. They have a uniform thickness and smooth surfaces that distribute loads evenly across a fastened joint.

Applications:

Automotive assemblies

Machinery connections

Structural components

Benefits: Provide stability, prevent surface damage, and maintain bolt tension.

2. Thrust Washers

Thrust washers are designed to handle axial loads in rotating assemblies. They prevent wear and reduce friction between moving parts.

Applications:

Gearboxes

Rotating shafts

Industrial machinery

Benefits: Reduce wear, improve efficiency, and extend component life.

3. Belleville (Disc) Washers

Belleville washers, also known as disc springs, are conical washers that provide a spring-like action under load.

Applications:

High-tension bolted joints

Vibration-prone assemblies

Heavy machinery

Benefits: Maintain tension, absorb shocks, and prevent loosening due to vibration.

4. Spherical Washers

Spherical washers compensate for misalignment between the bolt and the surface. They are ideal for assemblies where flatness cannot be guaranteed.

Applications:

Engine mounts

Heavy construction equipment

Aerospace structures

Benefits: Ensure uniform load distribution even on uneven surfaces, preventing stress concentration.

5. Custom Machined Washers

Custom washers are manufactured to meet specific requirements, including unique dimensions, materials, or load capacities.

Applications:

Specialized industrial machinery

Aerospace and defense

High-precision engineering projects

Benefits: Tailored to exact specifications, ensuring optimal performance in unique applications.

Summary

Selecting the right type of machined washer is crucial for ensuring optimal performance and longevity. Whether it’s a flat washer for general use or a Belleville washer for high-tension applications, choosing the correct type reduces maintenance, enhances safety, and improves the efficiency of mechanical systems.

Key Advantages of Using Machined Washers

Machined washers offer a range of advantages that make them essential components in industrial and mechanical assemblies. Their precision engineering ensures reliability, durability, and performance across various applications. Here’s a detailed look at the key benefits:

1. High Strength for Heavy Loads

Machined washers are manufactured from high-quality metals and alloys, making them capable of handling heavy loads without deforming. They are ideal for applications where standard washers might fail under pressure, such as in construction equipment, industrial machinery, and automotive engines.

2. Perfect Fit and Alignment

The precision machining process ensures that each washer has exact dimensions and tolerances. This guarantees a perfect fit between nuts, bolts, and surfaces, reducing misalignment and enhancing the stability of the assembly.

3. Resistance to Vibration and Loosening

Vibration is a common issue in machinery and automotive applications. Machined washers maintain their structural integrity under dynamic conditions, preventing nuts and bolts from loosening over time. This reduces maintenance and improves the safety of mechanical systems.

4. Corrosion Resistance

Washers made from stainless steel or coated alloys are highly resistant to corrosion. This makes machined washers suitable for harsh environments, including marine, chemical, and oil & gas industries, where exposure to moisture and chemicals is common.

5. Extended Service Life

The combination of high-quality materials, precision manufacturing, and surface finishing ensures that machined washers have a longer lifespan than standard washers. This reduces downtime and replacement costs in industrial operations.

6. Versatility Across Industries

Machined washers are versatile components used in aerospace, automotive, construction, oil & gas, electronics, and marine industries. Their ability to meet demanding specifications makes them an essential choice for engineers and industrial buyers.

7. Cost-Effectiveness in the Long Run

While machined washers may have a higher initial cost than stamped washers, their durability, precision, and reduced maintenance requirements make them a cost-effective solution over time. Industries save money by avoiding frequent replacements and ensuring uninterrupted operations.

Machined Washers Manufacturers in India

India has emerged as a global hub for high-quality machined washers manufacturing, offering competitive prices, advanced technology, and reliable supply chains. For industries seeking precision components, partnering with machined washers manufacturers in India provides several advantages.

Why India is a Preferred Destination for Machined Washers

Advanced Manufacturing Facilities

Indian manufacturers use CNC machining, precision grinding, and advanced finishing techniques to produce washers that meet international quality standards such as DIN, ISO, and ASTM.Wide Material Range

Manufacturers in India offer machined washers in a variety of materials including stainless steel, carbon steel, brass, copper, and specialized alloys. This variety ensures compatibility with diverse industrial applications.Customization Capabilities

Indian manufacturers can produce custom machined washers tailored to specific dimensions, tolerances, and load requirements. This flexibility is crucial for industries with unique or high-precision needs.Cost-Effective Solutions

Due to lower labor and operational costs, sourcing from India often results in high-quality washers at competitive prices, making bulk procurement economically viable.Export-Ready Supply Chains

Many Indian manufacturers have experience exporting to global markets including the USA, Europe, Middle East, and Asia-Pacific. They ensure timely delivery, proper packaging, and compliance with international shipping standards.

Key Industries Served

Automotive and aerospace

Oil & gas and petrochemicals

Construction and heavy machinery

Electronics and electrical assemblies

Marine and shipbuilding

Choosing the Right Manufacturer

When selecting machined washers manufacturers in India, consider:

Quality certifications and standards compliance

Track record with domestic and international clients

Capability to produce custom sizes and materials

Capacity for bulk production and timely delivery

How to Buy Machined Washers in Bulk

For industrial buyers, sourcing machined washers in bulk requires careful planning to ensure quality, consistency, and cost-effectiveness. Bulk procurement is common in industries such as automotive, aerospace, construction, and heavy machinery, where large volumes are needed for assembly lines and maintenance operations.

Steps to Buy Machined Washers in Bulk

Identify Requirements

Determine the exact specifications you need:Material: Stainless steel, carbon steel, brass, or alloys

Size and Dimensions: Inner diameter, outer diameter, thickness

Type: Flat, Belleville, thrust, spherical, or custom washers

Quantity: Estimate based on production or maintenance requirements

Choose a Reliable Supplier

Look for manufacturers or distributors who:Offer precision machined washers with tight tolerances

Have certifications (ISO, DIN, ASTM)

Can supply consistent quality in bulk

Request Samples

Before committing to large quantities, request samples to inspect:Dimensional accuracy

Surface finish

Material quality

Overall performance

Compare Prices and Delivery Terms

Evaluate multiple suppliers to ensure competitive pricing without compromising quality. Check:Bulk pricing discounts

Minimum order quantity (MOQ)

Shipping and delivery timelines

Finalize Customization (if needed)

If your application requires unique dimensions, tolerances, or finishes, confirm that the supplier can meet your specifications. Custom machined washers are common for critical applications.Place Bulk Order

Once the supplier is verified and samples approved, place your bulk order. Ensure a clear agreement on:Quality assurance and inspection

Packaging and labeling

After-sales support

Advantages of Buying in Bulk

Cost Savings – Reduced unit cost per washer

Consistent Supply – Ensures uninterrupted operations

Better Supplier Relationship – Large orders often lead to priority service

Customization Opportunities – Easier to request tailored specifications for repeated orders

Best Machined Washers for Industrial Use

When it comes to industrial applications, choosing the best machined washers for industrial use is crucial to ensure safety, reliability, and long-term performance. The right washer enhances the integrity of bolted joints, distributes loads evenly, and withstands extreme operational conditions.

Factors to Consider

Material Selection

Stainless Steel – Offers excellent corrosion resistance and durability, ideal for marine, chemical, and outdoor environments.

Carbon Steel – Provides high tensile strength, suitable for heavy machinery and structural applications.

Brass or Copper – Common in electrical and decorative applications due to conductivity and aesthetic appeal.

Special Alloys – For high-temperature, high-pressure, or chemically aggressive environments.

Dimensional Accuracy

The best machined washers have precise inner and outer diameters, thickness, and flatness to ensure a perfect fit. This minimizes the risk of misalignment, wear, or uneven load distribution.Load-Bearing Capacity

Industrial applications often involve heavy loads. Choose washers that are engineered to handle axial and radial forces without deformation.Surface Finish and Treatment

A polished or coated surface enhances performance by reducing friction, preventing corrosion, and extending service life. Treatments like zinc plating, nickel coating, or passivation are common for industrial-grade washers.Type of Washer

Depending on the application, select the appropriate type:Flat washers for general load distribution

Belleville washers for tensioning and vibration resistance

Thrust washers for rotary assemblies

Spherical washers for misalignment compensation

Supplier Reliability

Purchase from trusted manufacturers who provide quality certifications, consistent supply, and customization options if needed.

Recommended Applications

Automotive and Aerospace – Precision-engineered washers for engine assemblies, transmissions, and structural components.

Heavy Machinery and Construction – High-strength washers for cranes, bridges, and industrial equipment.

Oil & Gas – Corrosion-resistant washers for pipelines, drilling rigs, and high-pressure systems.

Electronics and Electrical – Conductive or insulating washers for precise spacing and component protection.

Future of Machined Washers in Global Industry

The demand for machined washers is expected to grow steadily across global industries due to increasing reliance on precision engineering, automation, and heavy-duty machinery. As industries become more sophisticated, the need for components that offer accuracy, durability, and reliability is more critical than ever.

Key Trends Driving Growth

Advancements in Manufacturing Technology

Modern CNC machining, laser cutting, and precision grinding techniques are enabling manufacturers to produce washers with extremely tight tolerances and superior surface finishes. This allows for higher-quality precision machined washers that meet stringent industrial standards.Growth in Industrial Automation

Automated assembly lines require washers with consistent quality and exact dimensions to ensure seamless integration. The use of machined washers reduces errors, enhances efficiency, and supports robotic assembly in automotive, electronics, and aerospace industries.Material Innovations

Research in advanced alloys, composite materials, and surface coatings is improving the performance of machined washer, allowing them to withstand higher temperatures, pressures, and corrosive environments.Sustainability and Longevity

Industries are increasingly focusing on reducing maintenance costs and minimizing waste. High-quality machined washer offer long-term durability, reducing replacements and supporting sustainable industrial practices.Customization and Specialized Applications

The demand for custom machined washers is rising as industries require washers tailored to specific dimensions, load capacities, and environmental conditions. Manufacturers are adapting by offering bespoke solutions that meet precise engineering needs.

Emerging Applications

Renewable Energy – Wind turbines and solar panel structures require durable and precise washers.

Aerospace & Defense – High-performance machined washers are critical for structural and mechanical assemblies.

Medical Devices – Precision washers are used in surgical and diagnostic equipment.

Summary

The future of machined washer is closely tied to technological advancements, industrial automation, and demand for high-performance materials. As industries continue to evolve, precision machined washer will remain an essential component in maintaining reliability, efficiency, and safety across critical applications worldwide.

FAQs About Machined Washers

What are machined washers?

Machined washers are precision-manufactured flat rings used to distribute loads, protect surfaces, and enhance the stability of bolted joints in industrial applications.How are machined washers different from standard washers?

Unlike stamped washers, machined washers are produced through CNC machining, offering superior dimensional accuracy, smooth surfaces, and enhanced strength.What materials are used for machined washers?

Common materials include stainless steel, carbon steel, brass, copper, and specialized alloys, depending on the application requirements.Where are machined washers commonly used?

They are widely used in aerospace, automotive, oil & gas, construction, electronics, and marine industries for critical assemblies.Can I buy machined washers in bulk?

Yes, bulk orders of machined washers are available from trusted manufacturers, often with discounts and custom specifications.What are precision washers?

Precision machined washers are high-accuracy washers produced with tight tolerances, ensuring perfect fit and uniform load distribution.Why should I choose machined washer over stamped washers?

Machined washers offer better strength, durability, resistance to vibration, and precise dimensions, making them ideal for industrial and heavy-duty applications.Who are the leading machined washer manufacturers in India?

Several Indian manufacturers specialize in high-quality machined washer, offering both standard and custom options for domestic and international markets.What is the best type of machined washer for industrial use?

The best machined washers for industrial use depend on the application but typically include stainless steel flat washers, Belleville washers, and thrust washers for heavy-duty and vibration-prone environments.Can machined washer resist corrosion?

Yes, washers made from stainless steel or coated with protective finishes are highly resistant to corrosion, making them suitable for marine, chemical, and outdoor applications.Are custom machined washer available?

Yes, many manufacturers provide custom machined washers tailored to specific dimensions, materials, tolerances, and surface finishes.How do I select the right machined washer for my application?

Consider the material, load-bearing capacity, type, size, surface finish, and manufacturer reliability to choose the most suitable machined washers.What are the advantages of buying machined washers in bulk?

Bulk purchasing offers cost savings, consistent supply, priority service from suppliers, and the ability to request customized washers for recurring industrial needs.What standards do machined washers comply with?

High-quality washers typically comply with international standards like DIN, ISO, and ASTM, ensuring reliability and consistency.Where can I buy the best machined washers for industrial use?

The best machined washers for industrial use can be sourced from reputable manufacturers in India and globally, offering certified, high-precision washers suitable for demanding applications.

Why Choose Nafees Metal Industries

At Nafees Metal industries, we prioritize quality, precision, and customer satisfaction. Our Machine Washers are manufactured using the latest technology and highest-grade materials, ensuring they meet the rigorous demands of various industries. We offer competitive pricing, timely delivery, and excellent customer support, making us the preferred choice for all your washer needs at Reay Road, Mumbai.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

Reviews

There are no reviews yet.

Be the first to review “Machined Washers” Cancel reply

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Machine Washers, Washers

Got Questions?

Feel free to

Get in touch

Reviews

There are no reviews yet.