No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M16 Mild Steel Plain Washers"

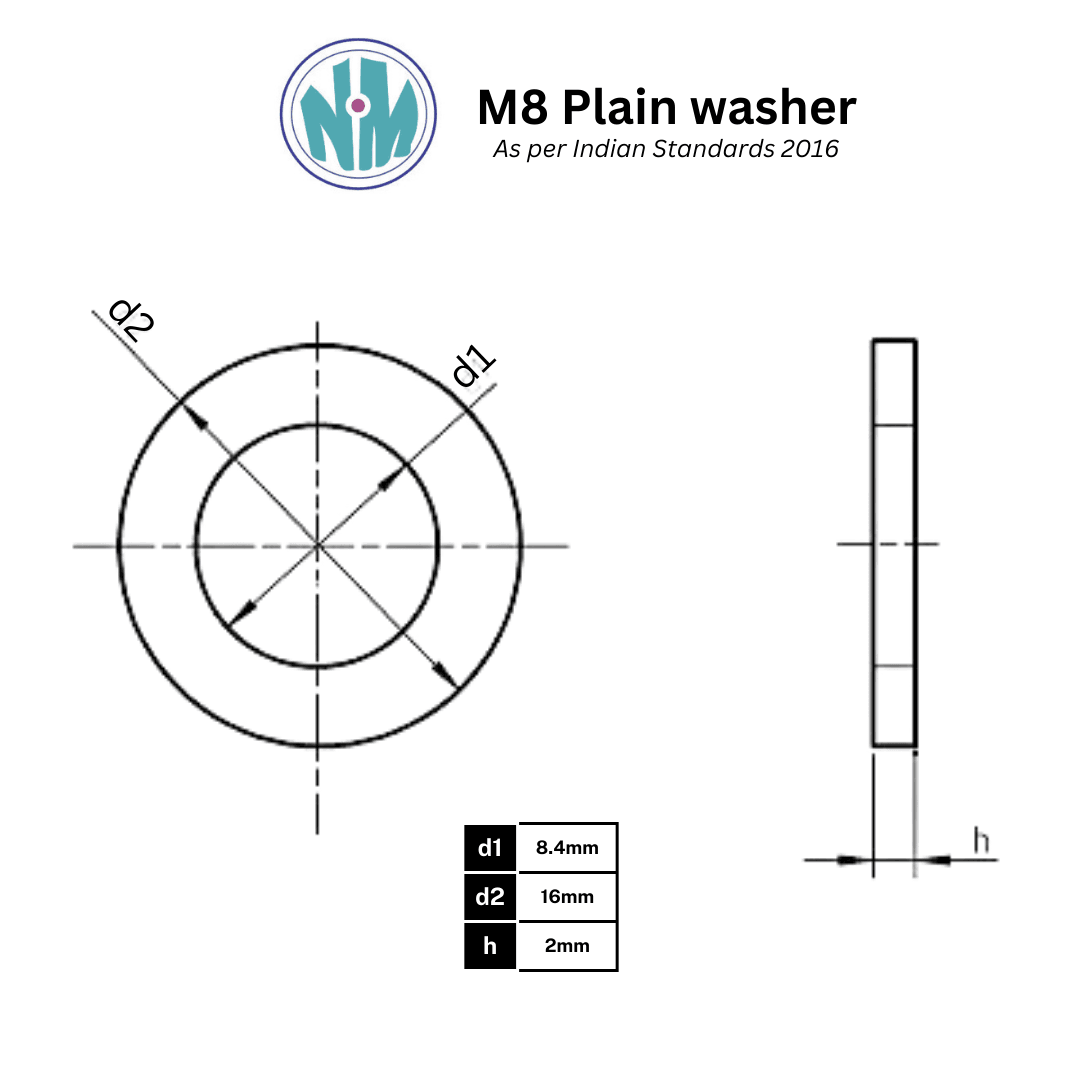

*Images shown for graphic representation. Not to scale.

M8 SS202 Plain Washers – Best Stainless Steel Washers for Industrial Use

M8 SS202 Plain Washers are precision-engineered flat washers crafted to provide even load distribution for M8-sized bolts or screws. These washers are crucial components in any mechanical or structural assembly where bolted joints are used. They are manufactured using premium-grade SS202 austenitic stainless steel, which offers excellent strength, moderate corrosion resistance, and durability at a cost-effective price point.

At Nafees Metal Industries, based in Mumbai, we take pride in being among the top stainless steel washer manufacturers in India. With advanced production capabilities and strict quality control, our M8 SS202 Plain Washers are trusted across diverse industrial applications, from automotive to electrical, infrastructure to fabrication.

Plain washers, though often considered simple hardware components, play a vital role in ensuring the structural stability and longevity of bolted joints. M8 SS202 Plain Washers are specifically designed to match M8 bolts or screws. Their primary function is to distribute the load evenly, reduce surface damage, and increase the bearing area. This helps prevent pull-through in softer materials and mitigates the loosening of fasteners due to vibration and dynamic loads.

The SS202 grade used in manufacturing these washers is a chromium-manganese-nickel stainless steel, providing a good balance of corrosion resistance, strength, and economic viability. It is particularly useful in environments where full marine-grade corrosion protection is not essential, thus lowering the overall cost of the assembly without compromising reliability.

As a leading Indian manufacturer of stainless steel plain washers (M8 SS202 Plain Washers), Nafees Metal Industries offers unmatched expertise in the production and supply of M8 SS202 Plain Washers. Our in-house toolroom, advanced power press machines, and trained workforce ensure we meet customer demands consistently—both in terms of volume and quality.

Technical Specifications

- Washer Type: Flat / Plain Washer

- Size: M8 (Internal Diameter – 8.4 mm approx., Outer Diameter – 16 mm approx.)

- Thickness: 1.6 mm (Customizable on order)

- Material: Austenitic Stainless Steel (SS202)

- Standard: DIN 125A, IS 2016

- Finish Options: Natural, Oiled, Bright Polish, Custom Finishes

- Manufacturing Method: Precision-stamped using high-tonnage power press machines

- Country of Origin: India

Key Features of M8 SS202 Plain Washers

Precision Fit for M8 Fasteners

These washers are engineered to perfectly complement M8 bolts and screws. With an inner diameter of approximately 8.4 mm, they provide an optimal fit that ensures even load distribution and a snug fastening, reducing the risk of bolt loosening or material deformation.Manufactured from SS202 Austenitic Stainless Steel

SS202 is a high-strength austenitic stainless steel that delivers excellent durability at a cost-effective price point. It offers moderate resistance to corrosion, making it ideal for general industrial and indoor environments. Its mechanical properties are well-suited for washers that require resilience under repeated use and high clamping loads.Excellent Load Distribution

These washers are flat and broad enough to spread the load exerted by the bolt head or nut over a larger surface area. This prevents indentation or damage to the base material—whether it’s metal, wood, or plastic—while maintaining joint integrity in both static and dynamic applications.Corrosion-Resistant Performance

While not as corrosion-resistant as SS304 or SS316, SS202 still performs well in mildly corrosive environments such as indoor industrial facilities or sheltered outdoor settings. This ensures reliable performance without rust formation under normal atmospheric conditions.Consistent Thickness and Dimensions

Every washer is produced with tight dimensional tolerances for thickness, inner diameter, and outer diameter. This uniformity is critical for applications requiring balanced load distribution and aesthetic finish, especially in OEM components and professional-grade assemblies.Non-Deforming Under Pressure

Thanks to the strength and hardness of SS202 steel, these washers maintain their shape under high clamping force. They resist warping, cracking, and deformation, even under pressure from impact wrenches or torque tools, ensuring consistent performance over time.Reusable in Multiple Cycles

Unlike spring or lock washers that lose elasticity over time, plain washers like these are reusable across multiple assembly and disassembly cycles, provided they remain undamaged. This helps reduce replacement costs in maintenance-heavy environments.Vibration Damping Support

While plain washers do not replace spring or lock washers in vibration-critical applications, they still help in reducing micro-movements between fastened parts. This slightly enhances joint reliability and prevents fasteners from embedding into the surface under vibration.Custom Thickness and Finishes Available

Standard thickness is around 1.6 mm, but Nafees Metal Industries also provides custom thickness options based on your load-bearing or space constraints. Available finishes include natural, oiled, and bright polish for improved appearance or added protection.Compatible with a Wide Range of Materials

These washers are suitable for use with metal, plastic, wood, or composite structures, ensuring universal application across sectors like fabrication, automotive, electrical, and construction.Power Press Precision Manufacturing

All M8 SS202 Plain Washers are produced using high-tonnage power press machines with in-house tooling. This ensures precision stamping, burr-free edges, and high production efficiency—ideal for bulk supply and export.Environmental and Cost Efficiency

SS202 offers a low-cost alternative to higher grades of stainless steel without compromising significantly on strength and corrosion resistance. This makes the product both economically and environmentally viable for non-critical industrial applications.Produced by an ISO-Certified Manufacturer

Manufactured at our ISO 9001:2015 certified facility, each washer undergoes rigorous quality checks for tensile strength, surface finish, burrs, and dimensional tolerance. This ensures consistent quality and traceability across every batch.Bulk Availability and OEM Support

Whether you require thousands or millions of washers, our scalable production setup ensures quick turnaround times, private-label branding, custom packaging, and export documentation support tailored to OEM needs.Made in India with Global Quality Standards

Proudly manufactured in Mumbai, these washers meet global standards like DIN 125A and IS 2016, making them suitable for domestic and international use across diverse industrial ecosystems.

Industrial Applications of M8 SS202 Plain Washers – Best SS202 plain washers for industrial use

M8 SS202 Plain Washers are known for their versatility and adaptability across various industries. Here are key areas where these washers are regularly used:

- Electrical Panel Assemblies

Prevent damage to mounting surfaces and ensure electrical insulation where needed. - Machinery and Equipment Manufacturing

Improve joint reliability in motor housing, machine frames, conveyor units, etc. - Construction and Civil Infrastructure

Used in metal frameworks, formwork, and modular assembly structures. - HVAC Installations

Maintain tight connections in ducts, vents, and pipe support systems. - Furniture & Modular Workstation Assembly

Adds to joint stability without marring visible surfaces. - Automotive Sector

Applied in bracket mounting, body parts, suspension assemblies, and non-critical structural areas. - Steel Fabrication and Tooling

Used in jigs, fixtures, dies, and general fabrication tasks for securing fasteners. - Appliance Manufacturing

Found in white goods, air conditioners, refrigerators, and other consumer appliances.

Why SS202 Stainless Steel?

Selecting the right material is crucial for the performance, longevity, and cost-efficiency of fastener components such as plain washers. SS202 stainless steel strikes a perfect balance between mechanical strength, corrosion resistance, and affordability—making it an ideal choice for manufacturing M8 plain washers. Here’s an in-depth look at why SS202 is the preferred material:

1. Excellent Strength-to-Cost Ratio

SS202 belongs to the 200 series of austenitic stainless steels and offers high tensile and yield strength at a significantly lower cost compared to grades like SS304 and SS316. This makes it the most economical choice for applications that don’t require extreme corrosion resistance but demand high mechanical durability.

2. Corrosion Resistance for Moderate Environments

While SS202 does not match the corrosion resistance of SS304 or marine-grade SS316, it still provides adequate resistance to rust, oxidation, and general corrosion in indoor or semi-protected environments. It performs well in low-moisture and industrial settings, where washers are not exposed to aggressive chemicals or saline air.

3. Excellent Mechanical Properties

SS202 offers a high degree of hardness and tensile strength, which is crucial for washers that bear compressive loads and are subjected to tightening forces from nuts and bolts. This prevents washers from deforming under pressure or repeated use, maintaining joint integrity over time.

Typical Yield Strength: 275 MPa

Tensile Strength: 515 MPa

Elongation: ≥ 40%

These values ensure that washers made from SS202 can withstand vibration, mechanical stress, and torque forces common in automotive, construction, and fabrication environments.

4. Magnetic Behavior for Specific Applications

Unlike fully non-magnetic SS304, SS202 can become slightly magnetic after cold working, which is often desirable in specific industries where magnetic pickup tools or magnetic detection is used for automation or assembly verification.

5. Ease of Fabrication and Stamping

SS202 stainless steel is known for its good formability, machinability, and punchability, making it ideal for high-speed washer production on power press machines. This leads to clean edge finishes, precise tolerances, and minimal material waste, improving production efficiency and quality.

6. Availability and Supply Stability

SS202 is readily available in India and international markets, ensuring smooth supply chains, especially for bulk orders or OEM projects. Its widespread use in the fastener and component manufacturing industries makes it a standard, reliable, and consistent material choice for plain washers.

7. Environmental & Cost Benefits

By choosing SS202 over higher alloy steels, manufacturers and end-users can lower material costs by up to 25–30% without compromising basic mechanical performance. Moreover, SS202 contains lower nickel content, making it more sustainable and less affected by volatile global nickel pricing.

8. Ideal for General-Purpose Industrial Applications

SS202 is the material of choice for industries like:

General engineering and fabrication

Electrical panels and enclosures

Light-duty automotive and two-wheeler parts

Machine assemblies

Domestic and commercial appliance installations

Furniture and interior hardware

Its cost-effective resilience makes it perfect for non-critical but high-volume washer applications.

SS202 stainless steel brings together durability, machinability, and affordability, making it the ideal material for M8 SS202 Plain Washers in high-volume, moderate-duty industrial and commercial applications. For buyers seeking a budget-friendly alternative to SS304 without compromising essential performance, SS202 stands out as a practical and proven solution.

Benefits of Choosing Nafees Metal Industries

- Advanced Manufacturing Setup: Equipped with power press machines, CNCs, and custom die-making units.

- Certified Quality Assurance: ISO 9001:2015 certified, with full inspection at each production stage.

- Flexible MOQ & Bulk Production: Efficient bulk order handling with short lead times.

- Customizability: Tailored dimensions, surface finishes, and packing.

- Logistics and Export Readiness: End-to-end export support with GST-compliant documentation and HS codes.

- Dedicated Client Support: Prompt response and post-sales assistance.

Whether you’re a small-scale fabricator or a global OEM, we deliver the same commitment to precision and quality.

M8 SS202 Plain Washers vs. Other Washer Types

| Specification | M8 SS202 Plain Washer | M8 Spring Washer | M8 Lock Washer |

|---|---|---|---|

| Load Distribution | Excellent | Fair | Fair |

| Reusability | High | Medium | Low |

| Surface Protection | High | Low | Low |

| Vibration Resistance | Medium | High | High |

| Cost | Low | Medium | Medium |

| Ideal Use | Load distribution | Anti-vibration | Anti-rotation |

For applications where vibration control is not a top priority, M8 plain washers offer the best value by providing protection, load balancing, and joint integrity.

Case Study: Enhancing Equipment Reliability with M8 SS202 Plain Washers in an Industrial Assembly Line

Industry: Heavy Equipment Manufacturing

Location: Maharashtra, India

Product Used: M8 SS202 Plain Washers

Application Area: Assembly of modular components in automated conveyor systems

Objective: Improve joint reliability, reduce fastener loosening due to vibration, and lower component replacement frequency

Background:

A well-known industrial equipment manufacturer was facing frequent maintenance shutdowns on their automated conveyor systems. These systems were responsible for transporting heavy parts across multiple assembly stations. Due to the intense vibrations and mechanical stress involved, the M8 fasteners securing several support structures were loosening over time, leading to misalignment, inefficiencies, and potential hazards.

Their existing washers (low-grade carbon steel) were deforming under torque, corroding over time, and failing to distribute the load evenly across the bolted joints. This prompted the engineering team to look for a stronger, cost-effective alternative that offered better surface protection, durability, and dimensional stability.

Solution Implementation:

After evaluating multiple washer materials and manufacturers, the client opted for M8 SS202 Plain Washers supplied by Nafees Metal Industries.

Key product specifications selected:

Washer Type: Plain Flat Washer

Material: Austenitic Stainless Steel – SS202

Finish: Oiled to prevent oxidation during storage

Dimensions: ID 8.4 mm, OD 16 mm, Thickness 1.6 mm

Standard: IS 2016 / DIN 125A

Testing: 100% dimension inspection and salt spray test for corrosion resistance

The washers were installed across 12 conveyor units using M8 bolts with specified torque ranges. Installation teams were instructed to replace all carbon steel washers with SS202 ones during routine shutdown maintenance.

Performance Results (Over 6 Months):

| Parameter | Before (Old Washers) | After (SS202 Washers) |

|---|---|---|

| Joint Loosening Incidents | 18/month | 2/month |

| Downtime Due to Re-tightening | Avg. 14 hours/month | < 2 hours/month |

| Corrosion/Rust Issues | Frequent | None observed |

| Washer Deformation Rate | 22% (after 3 months) | 0% (after 6 months) |

| Maintenance Cost (monthly avg.) | ₹ 48,000 | ₹ 6,500 |

Benefits Observed:

Improved Joint Integrity: The wider bearing surface of the M8 SS202 washers significantly reduced fastener loosening due to vibration and movement.

Increased Equipment Uptime: Drastic reduction in re-tightening and part misalignment led to increased uptime of the conveyor system.

Enhanced Safety: Reduced risk of structural instability and worker injury during operation.

Material Efficiency: M8 SS202 Plain Washers remained reusable and showed no signs of stress marks or corrosion.

Cost Savings: Over 85% reduction in maintenance-related costs within the first 6 months.

Client Feedback Summary:

While the client name is withheld due to confidentiality, the feedback received highlighted the following:

“Switching to SS202 stainless steel washers M8 SS202 Plain Washers from Nafees Metal Industries was a game-changer for our production line. We were skeptical about switching from the more expensive SS304, but the performance-to-cost ratio of SS202 exceeded expectations. Fewer shutdowns and reduced labor involvement have given our maintenance team a much-needed breather.”

Conclusion:

This case validates the effectiveness of M8 SS202 Plain Washers in demanding industrial applications involving mechanical stress, medium vibration, and the need for high reliability. It also reinforces the product’s position as a cost-effective yet high-performance alternative to premium stainless steel grades without compromising joint stability or corrosion resistance.

FAQs – M8 SS202 Plain Washers

- What are M8 SS202 Plain Washers used for? They are used to distribute the load of M8 bolts/screws over a wider area, minimizing surface wear and increasing the fastener’s lifespan.

- Are they suitable for outdoor use? Yes, in mild outdoor conditions. For highly corrosive environments, consider SS304 or SS316 alternatives.

- What standards do these washers meet? They comply with DIN 125A and IS 2016 standards for plain washers.

- Can I request a test certificate? Absolutely. We provide Material Test Certificates (MTC) upon order request.

- Is SS202 magnetic? It is slightly magnetic after cold working but this does not impact performance in most industrial uses.

- Do you offer customized washers? Yes. We can manufacture to custom thickness, ID, OD, and finishes based on your requirements.

- What is the standard washer thickness for M8? Our default is 1.6 mm, but thicknesses can be modified from 1 mm to 3 mm or more upon order.

- Can these be used in automotive assemblies? Definitely. They are commonly used in body panel fittings, engine brackets, and mounting hardware.

- Do you export these washers? Yes, we export M8 SS202 Plain Washers to the Middle East, Southeast Asia, Africa, and Europe.

- What are the packaging options? Polybags, corrugated boxes, and export cartons. Custom labeling and barcoding available.

- How do I place a bulk order? Contact us via our website or sales team with your specifications and quantity. We’ll share a quotation and timeline.

- Are these washers reusable? Yes, provided they are not damaged or corroded during use, they can be reused multiple times.

- Do you accept OEM branding or private labeling? Yes. We offer OEM/private-label services for large volume orders.

- What is your MOQ? Typically 5,000 pieces per size. For recurring clients, flexibility can be discussed.

- What finishes are available? We offer natural finish, oil coating, bright polish, and matte finishes.

M8 SS202 Plain Washers from Nafees Metal Industries combine affordability, durability, and industrial-grade performance in one compact product. Designed to offer superior load distribution and surface protection, they are ideal for manufacturers, contractors, and assemblers looking for cost-effective fastener solutions.

By choosing Nafees Metal Industries, you are partnering with a company that is not just a washer manufacturer—but a long-term collaborator dedicated to precision, integrity, and customer success.

Why Choose Nafees Metal Industries

When you choose Nafees Metal industries, you get more than just washers — you get a commitment to quality, precision, and unmatched service. Our M8 SS202 Plain Washers are produced using modern manufacturing processes, strict quality checks, and premium materials to ensure consistency in every batch.

We offer custom production sizes and competitive prices to suit small and bulk orders alike. If you’re looking to buy bulk M8 stainless steel washers, rest assured you’ll benefit from reliable delivery, fair pricing, and genuine technical support.

Order the Best M8 SS202 Plain Washers Today

Enhance your fastening systems with our M8 SS202 Plain Washers — the reliable choice for industrial and commercial use. Visit our manufacturing unit at Reay Road, Mumbai, or get in touch with our sales team to discuss your project requirements and place your next order for top-quality industrial washers.

M8 SS202 Plain Washers

24 people are viewing this product right now

₹0.82 Original price was: ₹0.82.₹0.68Current price is: ₹0.68. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M8

Inner Diameter (ID): 8.4 mm

Outer Diameter (OD): 16 mm

Thickness (t): 1.6 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:12 days

M8 SS202 Plain Washers – Best Stainless Steel Washers for Industrial Use

M8 SS202 Plain Washers are precision-engineered flat washers crafted to provide even load distribution for M8-sized bolts or screws. These washers are crucial components in any mechanical or structural assembly where bolted joints are used. They are manufactured using premium-grade SS202 austenitic stainless steel, which offers excellent strength, moderate corrosion resistance, and durability at a cost-effective price point.

At Nafees Metal Industries, based in Mumbai, we take pride in being among the top stainless steel washer manufacturers in India. With advanced production capabilities and strict quality control, our M8 SS202 Plain Washers are trusted across diverse industrial applications, from automotive to electrical, infrastructure to fabrication.

Plain washers, though often considered simple hardware components, play a vital role in ensuring the structural stability and longevity of bolted joints. M8 SS202 Plain Washers are specifically designed to match M8 bolts or screws. Their primary function is to distribute the load evenly, reduce surface damage, and increase the bearing area. This helps prevent pull-through in softer materials and mitigates the loosening of fasteners due to vibration and dynamic loads.

The SS202 grade used in manufacturing these washers is a chromium-manganese-nickel stainless steel, providing a good balance of corrosion resistance, strength, and economic viability. It is particularly useful in environments where full marine-grade corrosion protection is not essential, thus lowering the overall cost of the assembly without compromising reliability.

As a leading Indian manufacturer of stainless steel plain washers (M8 SS202 Plain Washers), Nafees Metal Industries offers unmatched expertise in the production and supply of M8 SS202 Plain Washers. Our in-house toolroom, advanced power press machines, and trained workforce ensure we meet customer demands consistently—both in terms of volume and quality.

Technical Specifications

- Washer Type: Flat / Plain Washer

- Size: M8 (Internal Diameter – 8.4 mm approx., Outer Diameter – 16 mm approx.)

- Thickness: 1.6 mm (Customizable on order)

- Material: Austenitic Stainless Steel (SS202)

- Standard: DIN 125A, IS 2016

- Finish Options: Natural, Oiled, Bright Polish, Custom Finishes

- Manufacturing Method: Precision-stamped using high-tonnage power press machines

- Country of Origin: India

Key Features of M8 SS202 Plain Washers

Precision Fit for M8 Fasteners

These washers are engineered to perfectly complement M8 bolts and screws. With an inner diameter of approximately 8.4 mm, they provide an optimal fit that ensures even load distribution and a snug fastening, reducing the risk of bolt loosening or material deformation.Manufactured from SS202 Austenitic Stainless Steel

SS202 is a high-strength austenitic stainless steel that delivers excellent durability at a cost-effective price point. It offers moderate resistance to corrosion, making it ideal for general industrial and indoor environments. Its mechanical properties are well-suited for washers that require resilience under repeated use and high clamping loads.Excellent Load Distribution

These washers are flat and broad enough to spread the load exerted by the bolt head or nut over a larger surface area. This prevents indentation or damage to the base material—whether it’s metal, wood, or plastic—while maintaining joint integrity in both static and dynamic applications.Corrosion-Resistant Performance

While not as corrosion-resistant as SS304 or SS316, SS202 still performs well in mildly corrosive environments such as indoor industrial facilities or sheltered outdoor settings. This ensures reliable performance without rust formation under normal atmospheric conditions.Consistent Thickness and Dimensions

Every washer is produced with tight dimensional tolerances for thickness, inner diameter, and outer diameter. This uniformity is critical for applications requiring balanced load distribution and aesthetic finish, especially in OEM components and professional-grade assemblies.Non-Deforming Under Pressure

Thanks to the strength and hardness of SS202 steel, these washers maintain their shape under high clamping force. They resist warping, cracking, and deformation, even under pressure from impact wrenches or torque tools, ensuring consistent performance over time.Reusable in Multiple Cycles

Unlike spring or lock washers that lose elasticity over time, plain washers like these are reusable across multiple assembly and disassembly cycles, provided they remain undamaged. This helps reduce replacement costs in maintenance-heavy environments.Vibration Damping Support

While plain washers do not replace spring or lock washers in vibration-critical applications, they still help in reducing micro-movements between fastened parts. This slightly enhances joint reliability and prevents fasteners from embedding into the surface under vibration.Custom Thickness and Finishes Available

Standard thickness is around 1.6 mm, but Nafees Metal Industries also provides custom thickness options based on your load-bearing or space constraints. Available finishes include natural, oiled, and bright polish for improved appearance or added protection.Compatible with a Wide Range of Materials

These washers are suitable for use with metal, plastic, wood, or composite structures, ensuring universal application across sectors like fabrication, automotive, electrical, and construction.Power Press Precision Manufacturing

All M8 SS202 Plain Washers are produced using high-tonnage power press machines with in-house tooling. This ensures precision stamping, burr-free edges, and high production efficiency—ideal for bulk supply and export.Environmental and Cost Efficiency

SS202 offers a low-cost alternative to higher grades of stainless steel without compromising significantly on strength and corrosion resistance. This makes the product both economically and environmentally viable for non-critical industrial applications.Produced by an ISO-Certified Manufacturer

Manufactured at our ISO 9001:2015 certified facility, each washer undergoes rigorous quality checks for tensile strength, surface finish, burrs, and dimensional tolerance. This ensures consistent quality and traceability across every batch.Bulk Availability and OEM Support

Whether you require thousands or millions of washers, our scalable production setup ensures quick turnaround times, private-label branding, custom packaging, and export documentation support tailored to OEM needs.Made in India with Global Quality Standards

Proudly manufactured in Mumbai, these washers meet global standards like DIN 125A and IS 2016, making them suitable for domestic and international use across diverse industrial ecosystems.

Industrial Applications of M8 SS202 Plain Washers – Best SS202 plain washers for industrial use

M8 SS202 Plain Washers are known for their versatility and adaptability across various industries. Here are key areas where these washers are regularly used:

- Electrical Panel Assemblies

Prevent damage to mounting surfaces and ensure electrical insulation where needed. - Machinery and Equipment Manufacturing

Improve joint reliability in motor housing, machine frames, conveyor units, etc. - Construction and Civil Infrastructure

Used in metal frameworks, formwork, and modular assembly structures. - HVAC Installations

Maintain tight connections in ducts, vents, and pipe support systems. - Furniture & Modular Workstation Assembly

Adds to joint stability without marring visible surfaces. - Automotive Sector

Applied in bracket mounting, body parts, suspension assemblies, and non-critical structural areas. - Steel Fabrication and Tooling

Used in jigs, fixtures, dies, and general fabrication tasks for securing fasteners. - Appliance Manufacturing

Found in white goods, air conditioners, refrigerators, and other consumer appliances.

Why SS202 Stainless Steel?

Selecting the right material is crucial for the performance, longevity, and cost-efficiency of fastener components such as plain washers. SS202 stainless steel strikes a perfect balance between mechanical strength, corrosion resistance, and affordability—making it an ideal choice for manufacturing M8 plain washers. Here’s an in-depth look at why SS202 is the preferred material:

1. Excellent Strength-to-Cost Ratio

SS202 belongs to the 200 series of austenitic stainless steels and offers high tensile and yield strength at a significantly lower cost compared to grades like SS304 and SS316. This makes it the most economical choice for applications that don’t require extreme corrosion resistance but demand high mechanical durability.

2. Corrosion Resistance for Moderate Environments

While SS202 does not match the corrosion resistance of SS304 or marine-grade SS316, it still provides adequate resistance to rust, oxidation, and general corrosion in indoor or semi-protected environments. It performs well in low-moisture and industrial settings, where washers are not exposed to aggressive chemicals or saline air.

3. Excellent Mechanical Properties

SS202 offers a high degree of hardness and tensile strength, which is crucial for washers that bear compressive loads and are subjected to tightening forces from nuts and bolts. This prevents washers from deforming under pressure or repeated use, maintaining joint integrity over time.

Typical Yield Strength: 275 MPa

Tensile Strength: 515 MPa

Elongation: ≥ 40%

These values ensure that washers made from SS202 can withstand vibration, mechanical stress, and torque forces common in automotive, construction, and fabrication environments.

4. Magnetic Behavior for Specific Applications

Unlike fully non-magnetic SS304, SS202 can become slightly magnetic after cold working, which is often desirable in specific industries where magnetic pickup tools or magnetic detection is used for automation or assembly verification.

5. Ease of Fabrication and Stamping

SS202 stainless steel is known for its good formability, machinability, and punchability, making it ideal for high-speed washer production on power press machines. This leads to clean edge finishes, precise tolerances, and minimal material waste, improving production efficiency and quality.

6. Availability and Supply Stability

SS202 is readily available in India and international markets, ensuring smooth supply chains, especially for bulk orders or OEM projects. Its widespread use in the fastener and component manufacturing industries makes it a standard, reliable, and consistent material choice for plain washers.

7. Environmental & Cost Benefits

By choosing SS202 over higher alloy steels, manufacturers and end-users can lower material costs by up to 25–30% without compromising basic mechanical performance. Moreover, SS202 contains lower nickel content, making it more sustainable and less affected by volatile global nickel pricing.

8. Ideal for General-Purpose Industrial Applications

SS202 is the material of choice for industries like:

General engineering and fabrication

Electrical panels and enclosures

Light-duty automotive and two-wheeler parts

Machine assemblies

Domestic and commercial appliance installations

Furniture and interior hardware

Its cost-effective resilience makes it perfect for non-critical but high-volume washer applications.

SS202 stainless steel brings together durability, machinability, and affordability, making it the ideal material for M8 SS202 Plain Washers in high-volume, moderate-duty industrial and commercial applications. For buyers seeking a budget-friendly alternative to SS304 without compromising essential performance, SS202 stands out as a practical and proven solution.

Benefits of Choosing Nafees Metal Industries

- Advanced Manufacturing Setup: Equipped with power press machines, CNCs, and custom die-making units.

- Certified Quality Assurance: ISO 9001:2015 certified, with full inspection at each production stage.

- Flexible MOQ & Bulk Production: Efficient bulk order handling with short lead times.

- Customizability: Tailored dimensions, surface finishes, and packing.

- Logistics and Export Readiness: End-to-end export support with GST-compliant documentation and HS codes.

- Dedicated Client Support: Prompt response and post-sales assistance.

Whether you’re a small-scale fabricator or a global OEM, we deliver the same commitment to precision and quality.

M8 SS202 Plain Washers vs. Other Washer Types

| Specification | M8 SS202 Plain Washer | M8 Spring Washer | M8 Lock Washer |

|---|---|---|---|

| Load Distribution | Excellent | Fair | Fair |

| Reusability | High | Medium | Low |

| Surface Protection | High | Low | Low |

| Vibration Resistance | Medium | High | High |

| Cost | Low | Medium | Medium |

| Ideal Use | Load distribution | Anti-vibration | Anti-rotation |

For applications where vibration control is not a top priority, M8 plain washers offer the best value by providing protection, load balancing, and joint integrity.

Case Study: Enhancing Equipment Reliability with M8 SS202 Plain Washers in an Industrial Assembly Line

Industry: Heavy Equipment Manufacturing

Location: Maharashtra, India

Product Used: M8 SS202 Plain Washers

Application Area: Assembly of modular components in automated conveyor systems

Objective: Improve joint reliability, reduce fastener loosening due to vibration, and lower component replacement frequency

Background:

A well-known industrial equipment manufacturer was facing frequent maintenance shutdowns on their automated conveyor systems. These systems were responsible for transporting heavy parts across multiple assembly stations. Due to the intense vibrations and mechanical stress involved, the M8 fasteners securing several support structures were loosening over time, leading to misalignment, inefficiencies, and potential hazards.

Their existing washers (low-grade carbon steel) were deforming under torque, corroding over time, and failing to distribute the load evenly across the bolted joints. This prompted the engineering team to look for a stronger, cost-effective alternative that offered better surface protection, durability, and dimensional stability.

Solution Implementation:

After evaluating multiple washer materials and manufacturers, the client opted for M8 SS202 Plain Washers supplied by Nafees Metal Industries.

Key product specifications selected:

Washer Type: Plain Flat Washer

Material: Austenitic Stainless Steel – SS202

Finish: Oiled to prevent oxidation during storage

Dimensions: ID 8.4 mm, OD 16 mm, Thickness 1.6 mm

Standard: IS 2016 / DIN 125A

Testing: 100% dimension inspection and salt spray test for corrosion resistance

The washers were installed across 12 conveyor units using M8 bolts with specified torque ranges. Installation teams were instructed to replace all carbon steel washers with SS202 ones during routine shutdown maintenance.

Performance Results (Over 6 Months):

| Parameter | Before (Old Washers) | After (SS202 Washers) |

|---|---|---|

| Joint Loosening Incidents | 18/month | 2/month |

| Downtime Due to Re-tightening | Avg. 14 hours/month | < 2 hours/month |

| Corrosion/Rust Issues | Frequent | None observed |

| Washer Deformation Rate | 22% (after 3 months) | 0% (after 6 months) |

| Maintenance Cost (monthly avg.) | ₹ 48,000 | ₹ 6,500 |

Benefits Observed:

Improved Joint Integrity: The wider bearing surface of the M8 SS202 washers significantly reduced fastener loosening due to vibration and movement.

Increased Equipment Uptime: Drastic reduction in re-tightening and part misalignment led to increased uptime of the conveyor system.

Enhanced Safety: Reduced risk of structural instability and worker injury during operation.

Material Efficiency: M8 SS202 Plain Washers remained reusable and showed no signs of stress marks or corrosion.

Cost Savings: Over 85% reduction in maintenance-related costs within the first 6 months.

Client Feedback Summary:

While the client name is withheld due to confidentiality, the feedback received highlighted the following:

“Switching to SS202 stainless steel washers M8 SS202 Plain Washers from Nafees Metal Industries was a game-changer for our production line. We were skeptical about switching from the more expensive SS304, but the performance-to-cost ratio of SS202 exceeded expectations. Fewer shutdowns and reduced labor involvement have given our maintenance team a much-needed breather.”

Conclusion:

This case validates the effectiveness of M8 SS202 Plain Washers in demanding industrial applications involving mechanical stress, medium vibration, and the need for high reliability. It also reinforces the product’s position as a cost-effective yet high-performance alternative to premium stainless steel grades without compromising joint stability or corrosion resistance.

FAQs – M8 SS202 Plain Washers

- What are M8 SS202 Plain Washers used for? They are used to distribute the load of M8 bolts/screws over a wider area, minimizing surface wear and increasing the fastener’s lifespan.

- Are they suitable for outdoor use? Yes, in mild outdoor conditions. For highly corrosive environments, consider SS304 or SS316 alternatives.

- What standards do these washers meet? They comply with DIN 125A and IS 2016 standards for plain washers.

- Can I request a test certificate? Absolutely. We provide Material Test Certificates (MTC) upon order request.

- Is SS202 magnetic? It is slightly magnetic after cold working but this does not impact performance in most industrial uses.

- Do you offer customized washers? Yes. We can manufacture to custom thickness, ID, OD, and finishes based on your requirements.

- What is the standard washer thickness for M8? Our default is 1.6 mm, but thicknesses can be modified from 1 mm to 3 mm or more upon order.

- Can these be used in automotive assemblies? Definitely. They are commonly used in body panel fittings, engine brackets, and mounting hardware.

- Do you export these washers? Yes, we export M8 SS202 Plain Washers to the Middle East, Southeast Asia, Africa, and Europe.

- What are the packaging options? Polybags, corrugated boxes, and export cartons. Custom labeling and barcoding available.

- How do I place a bulk order? Contact us via our website or sales team with your specifications and quantity. We’ll share a quotation and timeline.

- Are these washers reusable? Yes, provided they are not damaged or corroded during use, they can be reused multiple times.

- Do you accept OEM branding or private labeling? Yes. We offer OEM/private-label services for large volume orders.

- What is your MOQ? Typically 5,000 pieces per size. For recurring clients, flexibility can be discussed.

- What finishes are available? We offer natural finish, oil coating, bright polish, and matte finishes.

M8 SS202 Plain Washers from Nafees Metal Industries combine affordability, durability, and industrial-grade performance in one compact product. Designed to offer superior load distribution and surface protection, they are ideal for manufacturers, contractors, and assemblers looking for cost-effective fastener solutions.

By choosing Nafees Metal Industries, you are partnering with a company that is not just a washer manufacturer—but a long-term collaborator dedicated to precision, integrity, and customer success.

Why Choose Nafees Metal Industries

When you choose Nafees Metal industries, you get more than just washers — you get a commitment to quality, precision, and unmatched service. Our M8 SS202 Plain Washers are produced using modern manufacturing processes, strict quality checks, and premium materials to ensure consistency in every batch.

We offer custom production sizes and competitive prices to suit small and bulk orders alike. If you’re looking to buy bulk M8 stainless steel washers, rest assured you’ll benefit from reliable delivery, fair pricing, and genuine technical support.

Order the Best M8 SS202 Plain Washers Today

Enhance your fastening systems with our M8 SS202 Plain Washers — the reliable choice for industrial and commercial use. Visit our manufacturing unit at Reay Road, Mumbai, or get in touch with our sales team to discuss your project requirements and place your next order for top-quality industrial washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch