No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M5 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M8 Mild Steel Plain Washers – Best M8 MS Flat Washers Manufacturer

Introduction

In every industrial fastening solution, the smallest parts can often be the unsung heroes. That’s exactly the case with M8 Mild Steel Plain Washers — simple yet vital flat discs that make all the difference in how a bolted joint performs over time. From preventing surface damage and distributing load evenly to ensuring a stable joint that resists vibration, these washers play a crucial role across industries.

At Nafees Metal Industries, we understand that high-volume assembly lines, contractors, and OEMs rely on consistent, high-quality washers. That’s why we’re trusted as the Best M8 MS Flat Washers Manufacturer, supplying bulk quantities that help our clients meet deadlines, maintain structural integrity, and deliver products that last.

Whether you’re an engineer, procurement head, or maintenance manager, this guide will show you why using M8 Mild Steel Plain Washers isn’t just good practice — it’s an investment in long-term reliability.

Role of M8 Mild Steel Plain Washers in Industrial Applications

Fasteners like bolts and nuts apply clamping force to hold components together, but that force is highly concentrated. For M8 bolts, which are widely used for medium-duty connections, that load can deform softer materials, chip coatings, or weaken the joint if not handled properly. That’s where M8 Mild Steel Plain Washers come in.

By placing a washer under the bolt head or nut, you:

Distribute load evenly over a larger surface area

Prevent embedding or crushing of the material beneath

Protect surface finishes from scratches or dents

Reduce vibration loosening

Maintain bolt torque more reliably

Extend the lifespan of the entire assembly

From structural brackets to heavy-duty machinery, these simple, cost-effective components keep your fasteners working as intended — saving you money on rework and replacements.

What Are M8 Mild Steel Plain Washers

A M8 Mild Steel Plain Washer is a flat, round disc with a precise inner hole that fits an M8 bolt snugly. Its job is to spread the pressure applied by the bolt or nut across a broader area, preventing damage to the parts being joined.

Consider a painted metal bracket. Tightening an M8 bolt directly onto it can chip the paint, exposing the metal to corrosion. Add a washer, and the pressure is spread more evenly, protecting both the coating and the material underneath.

For layered assemblies, like mounting metal panels onto wood or plastic frames, washers also prevent fasteners from pulling through the softer layer. That’s why industries like automotive, furniture, electrical, and construction always stock M8 Mild Steel Plain Washers for secure and damage-free fastening.

Material Details: Why Mild Steel Flat Washers Are Reliable

When it comes to manufacturing washers for general-purpose industrial use, mild steel remains the top choice. Here’s why:

Strength & Formability:

Mild steel strikes the perfect balance between strength and ductility. It’s strong enough to resist deformation under load yet flexible enough to handle slight bending without cracking — ideal for flat washers that need to spread force but not fracture under torque.

Cost-Effective:

Compared to stainless or specialty alloys, mild steel is more affordable. This makes it practical for bulk use in medium-load applications where extreme corrosion resistance isn’t needed.

Versatility:

Mild steel can be easily punched into precise shapes and sizes with minimal wastage. It’s also easy to plate or coat, so it can be adapted for different working environments.

Sustainability:

Mild steel is fully recyclable, helping industries meet their sustainability goals while reducing costs.

By choosing Mild Steel Flat Washers, you get all the performance your project needs at a reasonable price — without compromising on quality.

Manufacturing and Technical Specifications

At Nafees Metal Industries, our production process for M8 Mild Steel Plain Washers combines modern CNC punching with rigorous quality checks to deliver consistent dimensions and finishes.

Manufacturing Process Includes:

Sourcing mild steel sheets from certified mills

Punching washers to exact dimensions for snug bolt fit

Deburring edges for safe handling and smooth seating

Applying optional protective coatings (zinc, black oxide, etc.)

Visual and dimensional inspections before final packing

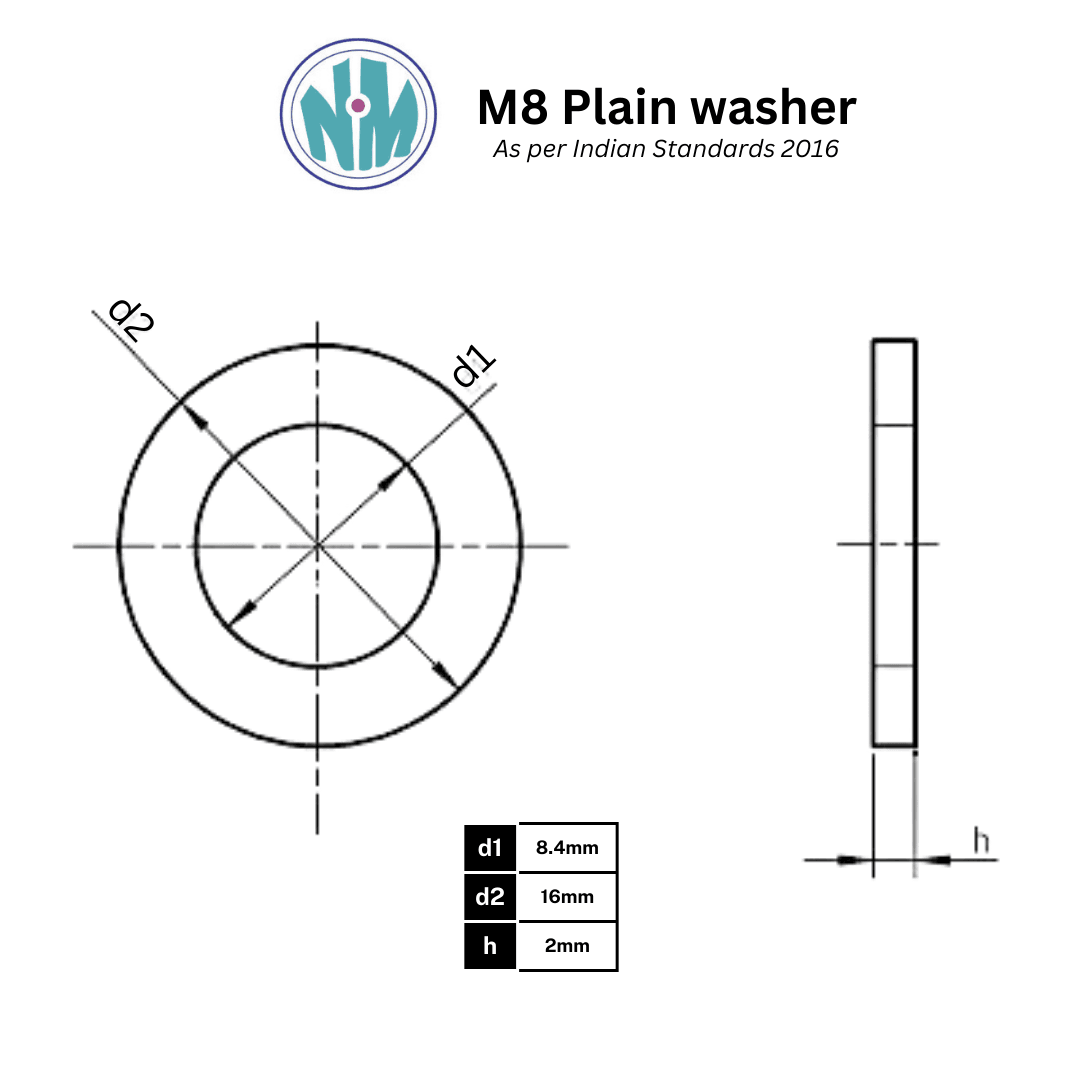

Typical Specs for M8 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | ~8.4 mm (for standard M8 bolt clearance) |

| Outer Diameter | ~16–24 mm depending on standard |

| Thickness | 1.6–2.5 mm |

| Finish | Plain or coated (zinc, phosphate, black oxide) |

| Material | Mild Steel |

| Shape | Flat round disc |

When you Buy M8 Mild Steel Plain Washers in Bulk from us, you can rest assured each washer meets IS/ISO/DIN standards and undergoes batch-level inspections to ensure consistent performance.

Key Features of M8 Mild Steel Plain Washers

Accurate Load Distribution

One of the biggest advantages of using M8 Mild Steel Plain Washers is the way they evenly spread the bolt’s clamping force. For an M8 bolt, this is especially important in sheet metal, aluminum panels, or softer substrates. Without a washer, the bolt head can bite into the material, causing dents, cracks, or pull-through failures. The washer spreads this load, preventing costly damage.

Surface Protection

Painted, coated, or anodized surfaces add beauty and corrosion resistance — but they’re vulnerable to scratches. A washer acts as a buffer between the fastener and the surface, preserving the finish and protecting the underlying material from rust.

Vibration Resistance

In mechanical systems that operate under vibration — HVAC units, industrial machinery, or vehicles — bolts can work themselves loose over time. Plain washers add friction to the joint, minimizing loosening. Combined with lock washers or thread-locking compounds, they deliver even greater security.

Reusable and Durable

Our M8 Mild Steel Plain Washers are built to last. You can remove and reinstall them multiple times during maintenance cycles without losing shape, making them a practical and cost-effective solution for projects that need periodic disassembly.

Custom Finishes Available

Depending on the working environment, mild steel washers can be supplied plain or with protective coatings to resist mild corrosion and wear.

Cost-Effective for Large Projects

Whether you’re running a large assembly line or managing multiple job sites, using a standard washer size like M8 reduces inventory complexity and brings down costs. That’s why smart buyers Buy M8 Mild Steel Plain Washers in Bulk — it just makes sense.

Applications of M8 Mild Steel Plain Washers

Automotive Sector

In vehicles, M8 fasteners are common for mounting engine covers, brackets, and interior panels. Using M8 Mild Steel Plain Washers here prevents bolt heads from digging into sheet metal or plastic panels, reducing the risk of vibrations causing rattles over time.

HVAC Ducting and Mounting

M8 washers are a staple in HVAC projects for mounting duct supports, brackets, and panels. They prevent thin metal flanges from tearing under torque, especially in high-vibration installations.

Electrical Enclosures

Switchgear cabinets, control panels, and junction boxes often rely on M8 hardware to hold busbars, mounting plates, or cable trays. Washers keep the bolt heads from damaging enclosures and ensure the bolts stay tight.

Construction & Infrastructure

From mounting rails to guard rails and structural brackets, M8 bolts and washers provide reliable connections that last. They help prevent damage to galvanized or painted steel parts, ensuring corrosion protection remains intact.

Furniture & Fixtures

In metal furniture frames, display racks, or shelving systems, M8 Mild Steel Plain Washers protect finishes and ensure tight, stable joints that won’t loosen easily.

Industrial Equipment

For conveyors, machine frames, or process equipment, these washers add an extra layer of reliability to bolted joints that see dynamic loads and thermal cycling.

DIY & Maintenance

Homeowners and small businesses often keep MS Flat Washers in stock for repairs — from gates and fences to tool benches and fixtures.

Case Study: How M8 Mild Steel Plain Washers Reduced Downtime and Saved ₹2.5 Lakhs in a Conveyor System Upgrade

Background

One of our long-standing clients, a mid-sized food processing company in Gujarat, recently expanded its production line to meet rising demand. As part of the expansion, they installed a new 80-meter conveyor system to move packaged goods between stations efficiently.

The conveyor structure involved dozens of support brackets fixed to mild steel uprights using M8 bolts. To save time and reduce upfront costs, the installation contractor skipped using washers, assuming the bolts alone would provide sufficient clamping force.

Problem

Within just three months of commissioning, operators began noticing unusual vibrations and rattling noises along sections of the conveyor line. On closer inspection, the maintenance team found that:

The direct contact of M8 bolt heads with the painted mild steel uprights was causing the paint layer to crack and flake off under torque.

Without M8 Mild Steel Plain Washers, the concentrated bolt pressure was denting the upright brackets and deforming the thin metal flanges.

As a result, the bolts gradually lost their hold due to constant vibration and thermal cycling inside the processing unit.

Misaligned brackets began to tilt under load, causing the conveyor belt to mis-track, which led to multiple unplanned shutdowns and expensive product jams.

Not only did this create production bottlenecks, but it also forced the maintenance crew to replace bent brackets and retighten bolts every few weeks — increasing downtime and labor costs.

Solution

Frustrated by recurring failures, the plant’s operations manager reached out to Nafees Metal Industries for an urgent fix. After understanding the entire scenario, our technical team immediately recommended the addition of M8 Mild Steel Plain Washers to each fastener assembly.

Our engineers explained that the washers would:

✅ Spread the bolt’s clamping force over a larger area, preventing local deformation of the bracket flanges.

✅ Protect the painted surface under the bolt head, keeping the protective coating intact and resisting corrosion.

✅ Add friction under the bolt head to reduce loosening from vibration.

✅ Maintain bolt tension more consistently over long production cycles.

Recognizing the severity of the problem, we expedited the production and supplied a bulk lot of M8 Mild Steel Plain Washers with a bright zinc-plated finish to suit the factory’s moderately humid environment.

Implementation

To test the fix, the maintenance team retrofitted M8 Mild Steel Plain Washers on a 10-meter section of the conveyor line first. The reinstallation took minimal time: the crew simply removed each bolt, slid on a washer, and retightened it to the specified torque.

After monitoring for three weeks, they reported:

No visible bracket dents or paint damage.

No bolt loosening, even during peak production hours.

A significant drop in rattling noise levels from the conveyor structure.

Encouraged by this result, the company rolled out the washer solution across the entire conveyor length and updated their installation SOP to include washers in all future support brackets.

Results

The simple addition of M8 Mild Steel Plain Washers produced measurable, lasting improvements:

✅ Zero bracket replacements needed in the six months following the retrofit.

✅ The maintenance team cut unplanned shutdowns by over 70%, boosting production output.

✅ The company estimated savings of over ₹2.5 lakhs in avoided repairs, parts, and labor costs — a huge ROI considering the negligible upfront cost of bulk washers.

✅ Long-term, the conveyor system now runs quieter and more reliably, with better alignment and less vibration-induced wear and tear.

Client Testimonial

The plant’s senior maintenance engineer shared this feedback:

“When we started seeing cracks and misalignment so soon after commissioning, it was frustrating — every shutdown cost us production hours. Adding M8 Mild Steel Plain Washers from Nafees Metal Industries was a game changer. Such a small part, yet it solved a big problem. Now, every support bracket holds firm, there’s no paint damage, and our conveyor system works smoothly with minimal maintenance.”

Key Takeaway

This project highlights how even the most robust bolts can underperform if they’re not supported by the right washer. The M8 Mild Steel Plain Washers provided a crucial layer of protection and stability, ensuring that the fasteners delivered consistent clamping force without damaging the structural integrity of the brackets.

For any industry dealing with dynamic loads, vibration, or sensitive finishes — whether it’s food processing, packaging, automotive, or infrastructure — investing in quality M8 Mild Steel Plain Washers is a proven way to extend equipment lifespan and cut maintenance costs.

How This Applies to You

If your projects involve bolted joints on painted or thin sheet metal, structural brackets, machinery frames, or conveyor systems — don’t underestimate the impact of washers. By adding M8 Mild Steel Plain Washers, you:

✔ Prevent surface damage and local deformation.

✔ Maintain bolt tension longer.

✔ Reduce vibration-induced failures.

✔ Save big on rework, part replacement, and downtime.

✔ Deliver a higher-quality, longer-lasting finished product to your clients.

At Nafees Metal Industries, we’re proud to be your trusted partner for high-quality, bulk-supply M8 Mild Steel Plain Washers. Let us help you secure every bolt with confidence — because it’s the small details that protect your biggest investments.

Why Choose the Best M8 MS Flat Washers Manufacturer

When quality, bulk consistency, and technical support matter, Nafees Metal Industries stands out as the Best M8 MS Flat Washers Manufacturer. Here’s why:

In-house production with strict ISO-aligned QC

Proven batch consistency for large orders

Custom sizes, finishes, and packaging

Fast lead times and reliable dispatch

Technical support to help you choose the right washer for your job

Installation Tips

Always place a washer under both the bolt head and nut if both contact the material surface.

Don’t overtighten; use torque wrenches to achieve the specified clamping force.

For coated washers, handle gently to avoid scratching the protective layer.

Maintenance Guidelines

Inspect periodically during scheduled maintenance.

Replace any washers showing signs of deformation or corrosion.

Store in sealed bins in a dry place to prevent rust.

Related Products

Need more than just M8 Mild Steel Plain Washers? We also supply:

Spring and lock washers for anti-vibration

Stainless Steel Flat Washers for high-corrosion environments

Custom punched washers for special projects

Final Words

Never underestimate the power of a simple washer. Our M8 Mild Steel Plain Washers protect your projects, save you money on rework, and give you confidence in every bolted connection. That’s the Nafees Metal Industries promise.

FAQs

What are M8 Mild Steel Plain Washers used for?

To distribute bolt loads, protect surfaces, and resist vibration.Are they reusable?

Yes, if they’re not bent or corroded.Can you supply coated washers?

Yes — zinc, phosphate, or black oxide.Are they suitable for outdoor use?

Yes, if coated for mild weather.Do you follow IS/ISO/DIN standards?

Absolutely.Do you provide test certificates?

Yes, on request.Can you supply other sizes?

Yes, we have M4 to M40 in mild and stainless steel.Do you offer bulk pricing?

Yes, with volume discounts.What’s your lead time?

Usually 7–14 days for bulk orders.Do you ship internationally?

Yes.Can I get free samples?

Of course.What is the MOQ?

We’re flexible, just ask.How do I store them?

Keep them dry and sealed.Can you do custom packaging?

Yes.Why choose Nafees Metal Industries?

For consistency, quality, and trusted bulk supply.

Why Choose Nafees Metal Industries?

When you choose Nafees Metal industries, you’re partnering with one of the Best M8 Mild Steel Plain Washers Manufacturers in India. Our washers are produced using the latest manufacturing technology, ensuring precise tolerances, durable finishes, and consistent quality across every batch.

Whether you need a small lot for urgent maintenance work or wish to Buy M8 Mild Steel Plain Washers in Bulk for large-scale production, we offer competitive pricing, flexible customization, and prompt delivery. Our dedicated team is committed to your satisfaction and ready to assist you with tailored solutions for all your industrial washer needs.

Visit Us Today

Explore our range of Mild Steel Flat Washers and place your bulk orders with complete confidence. Visit our state-of-the-art manufacturing facility at Reay Road, Mumbai , or get in touch with our team to discuss your specific requirements.

M8 Mild Steel Plain Washers

10 people are viewing this product right now

₹0.41 Original price was: ₹0.41.₹0.34Current price is: ₹0.34. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M8

Inner Diameter (ID): 8.4 mm

Outer Diameter (OD): 16 mm

Thickness (t): 1.6 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M8 Mild Steel Plain Washers – Best M8 MS Flat Washers Manufacturer

Introduction

In every industrial fastening solution, the smallest parts can often be the unsung heroes. That’s exactly the case with M8 Mild Steel Plain Washers — simple yet vital flat discs that make all the difference in how a bolted joint performs over time. From preventing surface damage and distributing load evenly to ensuring a stable joint that resists vibration, these washers play a crucial role across industries.

At Nafees Metal Industries, we understand that high-volume assembly lines, contractors, and OEMs rely on consistent, high-quality washers. That’s why we’re trusted as the Best M8 MS Flat Washers Manufacturer, supplying bulk quantities that help our clients meet deadlines, maintain structural integrity, and deliver products that last.

Whether you’re an engineer, procurement head, or maintenance manager, this guide will show you why using M8 Mild Steel Plain Washers isn’t just good practice — it’s an investment in long-term reliability.

Role of M8 Mild Steel Plain Washers in Industrial Applications

Fasteners like bolts and nuts apply clamping force to hold components together, but that force is highly concentrated. For M8 bolts, which are widely used for medium-duty connections, that load can deform softer materials, chip coatings, or weaken the joint if not handled properly. That’s where M8 Mild Steel Plain Washers come in.

By placing a washer under the bolt head or nut, you:

Distribute load evenly over a larger surface area

Prevent embedding or crushing of the material beneath

Protect surface finishes from scratches or dents

Reduce vibration loosening

Maintain bolt torque more reliably

Extend the lifespan of the entire assembly

From structural brackets to heavy-duty machinery, these simple, cost-effective components keep your fasteners working as intended — saving you money on rework and replacements.

What Are M8 Mild Steel Plain Washers

A M8 Mild Steel Plain Washer is a flat, round disc with a precise inner hole that fits an M8 bolt snugly. Its job is to spread the pressure applied by the bolt or nut across a broader area, preventing damage to the parts being joined.

Consider a painted metal bracket. Tightening an M8 bolt directly onto it can chip the paint, exposing the metal to corrosion. Add a washer, and the pressure is spread more evenly, protecting both the coating and the material underneath.

For layered assemblies, like mounting metal panels onto wood or plastic frames, washers also prevent fasteners from pulling through the softer layer. That’s why industries like automotive, furniture, electrical, and construction always stock M8 Mild Steel Plain Washers for secure and damage-free fastening.

Material Details: Why Mild Steel Flat Washers Are Reliable

When it comes to manufacturing washers for general-purpose industrial use, mild steel remains the top choice. Here’s why:

Strength & Formability:

Mild steel strikes the perfect balance between strength and ductility. It’s strong enough to resist deformation under load yet flexible enough to handle slight bending without cracking — ideal for flat washers that need to spread force but not fracture under torque.

Cost-Effective:

Compared to stainless or specialty alloys, mild steel is more affordable. This makes it practical for bulk use in medium-load applications where extreme corrosion resistance isn’t needed.

Versatility:

Mild steel can be easily punched into precise shapes and sizes with minimal wastage. It’s also easy to plate or coat, so it can be adapted for different working environments.

Sustainability:

Mild steel is fully recyclable, helping industries meet their sustainability goals while reducing costs.

By choosing Mild Steel Flat Washers, you get all the performance your project needs at a reasonable price — without compromising on quality.

Manufacturing and Technical Specifications

At Nafees Metal Industries, our production process for M8 Mild Steel Plain Washers combines modern CNC punching with rigorous quality checks to deliver consistent dimensions and finishes.

Manufacturing Process Includes:

Sourcing mild steel sheets from certified mills

Punching washers to exact dimensions for snug bolt fit

Deburring edges for safe handling and smooth seating

Applying optional protective coatings (zinc, black oxide, etc.)

Visual and dimensional inspections before final packing

Typical Specs for M8 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | ~8.4 mm (for standard M8 bolt clearance) |

| Outer Diameter | ~16–24 mm depending on standard |

| Thickness | 1.6–2.5 mm |

| Finish | Plain or coated (zinc, phosphate, black oxide) |

| Material | Mild Steel |

| Shape | Flat round disc |

When you Buy M8 Mild Steel Plain Washers in Bulk from us, you can rest assured each washer meets IS/ISO/DIN standards and undergoes batch-level inspections to ensure consistent performance.

Key Features of M8 Mild Steel Plain Washers

Accurate Load Distribution

One of the biggest advantages of using M8 Mild Steel Plain Washers is the way they evenly spread the bolt’s clamping force. For an M8 bolt, this is especially important in sheet metal, aluminum panels, or softer substrates. Without a washer, the bolt head can bite into the material, causing dents, cracks, or pull-through failures. The washer spreads this load, preventing costly damage.

Surface Protection

Painted, coated, or anodized surfaces add beauty and corrosion resistance — but they’re vulnerable to scratches. A washer acts as a buffer between the fastener and the surface, preserving the finish and protecting the underlying material from rust.

Vibration Resistance

In mechanical systems that operate under vibration — HVAC units, industrial machinery, or vehicles — bolts can work themselves loose over time. Plain washers add friction to the joint, minimizing loosening. Combined with lock washers or thread-locking compounds, they deliver even greater security.

Reusable and Durable

Our M8 Mild Steel Plain Washers are built to last. You can remove and reinstall them multiple times during maintenance cycles without losing shape, making them a practical and cost-effective solution for projects that need periodic disassembly.

Custom Finishes Available

Depending on the working environment, mild steel washers can be supplied plain or with protective coatings to resist mild corrosion and wear.

Cost-Effective for Large Projects

Whether you’re running a large assembly line or managing multiple job sites, using a standard washer size like M8 reduces inventory complexity and brings down costs. That’s why smart buyers Buy M8 Mild Steel Plain Washers in Bulk — it just makes sense.

Applications of M8 Mild Steel Plain Washers

Automotive Sector

In vehicles, M8 fasteners are common for mounting engine covers, brackets, and interior panels. Using M8 Mild Steel Plain Washers here prevents bolt heads from digging into sheet metal or plastic panels, reducing the risk of vibrations causing rattles over time.

HVAC Ducting and Mounting

M8 washers are a staple in HVAC projects for mounting duct supports, brackets, and panels. They prevent thin metal flanges from tearing under torque, especially in high-vibration installations.

Electrical Enclosures

Switchgear cabinets, control panels, and junction boxes often rely on M8 hardware to hold busbars, mounting plates, or cable trays. Washers keep the bolt heads from damaging enclosures and ensure the bolts stay tight.

Construction & Infrastructure

From mounting rails to guard rails and structural brackets, M8 bolts and washers provide reliable connections that last. They help prevent damage to galvanized or painted steel parts, ensuring corrosion protection remains intact.

Furniture & Fixtures

In metal furniture frames, display racks, or shelving systems, M8 Mild Steel Plain Washers protect finishes and ensure tight, stable joints that won’t loosen easily.

Industrial Equipment

For conveyors, machine frames, or process equipment, these washers add an extra layer of reliability to bolted joints that see dynamic loads and thermal cycling.

DIY & Maintenance

Homeowners and small businesses often keep MS Flat Washers in stock for repairs — from gates and fences to tool benches and fixtures.

Case Study: How M8 Mild Steel Plain Washers Reduced Downtime and Saved ₹2.5 Lakhs in a Conveyor System Upgrade

Background

One of our long-standing clients, a mid-sized food processing company in Gujarat, recently expanded its production line to meet rising demand. As part of the expansion, they installed a new 80-meter conveyor system to move packaged goods between stations efficiently.

The conveyor structure involved dozens of support brackets fixed to mild steel uprights using M8 bolts. To save time and reduce upfront costs, the installation contractor skipped using washers, assuming the bolts alone would provide sufficient clamping force.

Problem

Within just three months of commissioning, operators began noticing unusual vibrations and rattling noises along sections of the conveyor line. On closer inspection, the maintenance team found that:

The direct contact of M8 bolt heads with the painted mild steel uprights was causing the paint layer to crack and flake off under torque.

Without M8 Mild Steel Plain Washers, the concentrated bolt pressure was denting the upright brackets and deforming the thin metal flanges.

As a result, the bolts gradually lost their hold due to constant vibration and thermal cycling inside the processing unit.

Misaligned brackets began to tilt under load, causing the conveyor belt to mis-track, which led to multiple unplanned shutdowns and expensive product jams.

Not only did this create production bottlenecks, but it also forced the maintenance crew to replace bent brackets and retighten bolts every few weeks — increasing downtime and labor costs.

Solution

Frustrated by recurring failures, the plant’s operations manager reached out to Nafees Metal Industries for an urgent fix. After understanding the entire scenario, our technical team immediately recommended the addition of M8 Mild Steel Plain Washers to each fastener assembly.

Our engineers explained that the washers would:

✅ Spread the bolt’s clamping force over a larger area, preventing local deformation of the bracket flanges.

✅ Protect the painted surface under the bolt head, keeping the protective coating intact and resisting corrosion.

✅ Add friction under the bolt head to reduce loosening from vibration.

✅ Maintain bolt tension more consistently over long production cycles.

Recognizing the severity of the problem, we expedited the production and supplied a bulk lot of M8 Mild Steel Plain Washers with a bright zinc-plated finish to suit the factory’s moderately humid environment.

Implementation

To test the fix, the maintenance team retrofitted M8 Mild Steel Plain Washers on a 10-meter section of the conveyor line first. The reinstallation took minimal time: the crew simply removed each bolt, slid on a washer, and retightened it to the specified torque.

After monitoring for three weeks, they reported:

No visible bracket dents or paint damage.

No bolt loosening, even during peak production hours.

A significant drop in rattling noise levels from the conveyor structure.

Encouraged by this result, the company rolled out the washer solution across the entire conveyor length and updated their installation SOP to include washers in all future support brackets.

Results

The simple addition of M8 Mild Steel Plain Washers produced measurable, lasting improvements:

✅ Zero bracket replacements needed in the six months following the retrofit.

✅ The maintenance team cut unplanned shutdowns by over 70%, boosting production output.

✅ The company estimated savings of over ₹2.5 lakhs in avoided repairs, parts, and labor costs — a huge ROI considering the negligible upfront cost of bulk washers.

✅ Long-term, the conveyor system now runs quieter and more reliably, with better alignment and less vibration-induced wear and tear.

Client Testimonial

The plant’s senior maintenance engineer shared this feedback:

“When we started seeing cracks and misalignment so soon after commissioning, it was frustrating — every shutdown cost us production hours. Adding M8 Mild Steel Plain Washers from Nafees Metal Industries was a game changer. Such a small part, yet it solved a big problem. Now, every support bracket holds firm, there’s no paint damage, and our conveyor system works smoothly with minimal maintenance.”

Key Takeaway

This project highlights how even the most robust bolts can underperform if they’re not supported by the right washer. The M8 Mild Steel Plain Washers provided a crucial layer of protection and stability, ensuring that the fasteners delivered consistent clamping force without damaging the structural integrity of the brackets.

For any industry dealing with dynamic loads, vibration, or sensitive finishes — whether it’s food processing, packaging, automotive, or infrastructure — investing in quality M8 Mild Steel Plain Washers is a proven way to extend equipment lifespan and cut maintenance costs.

How This Applies to You

If your projects involve bolted joints on painted or thin sheet metal, structural brackets, machinery frames, or conveyor systems — don’t underestimate the impact of washers. By adding M8 Mild Steel Plain Washers, you:

✔ Prevent surface damage and local deformation.

✔ Maintain bolt tension longer.

✔ Reduce vibration-induced failures.

✔ Save big on rework, part replacement, and downtime.

✔ Deliver a higher-quality, longer-lasting finished product to your clients.

At Nafees Metal Industries, we’re proud to be your trusted partner for high-quality, bulk-supply M8 Mild Steel Plain Washers. Let us help you secure every bolt with confidence — because it’s the small details that protect your biggest investments.

Why Choose the Best M8 MS Flat Washers Manufacturer

When quality, bulk consistency, and technical support matter, Nafees Metal Industries stands out as the Best M8 MS Flat Washers Manufacturer. Here’s why:

In-house production with strict ISO-aligned QC

Proven batch consistency for large orders

Custom sizes, finishes, and packaging

Fast lead times and reliable dispatch

Technical support to help you choose the right washer for your job

Installation Tips

Always place a washer under both the bolt head and nut if both contact the material surface.

Don’t overtighten; use torque wrenches to achieve the specified clamping force.

For coated washers, handle gently to avoid scratching the protective layer.

Maintenance Guidelines

Inspect periodically during scheduled maintenance.

Replace any washers showing signs of deformation or corrosion.

Store in sealed bins in a dry place to prevent rust.

Related Products

Need more than just M8 Mild Steel Plain Washers? We also supply:

Spring and lock washers for anti-vibration

Stainless Steel Flat Washers for high-corrosion environments

Custom punched washers for special projects

Final Words

Never underestimate the power of a simple washer. Our M8 Mild Steel Plain Washers protect your projects, save you money on rework, and give you confidence in every bolted connection. That’s the Nafees Metal Industries promise.

FAQs

What are M8 Mild Steel Plain Washers used for?

To distribute bolt loads, protect surfaces, and resist vibration.Are they reusable?

Yes, if they’re not bent or corroded.Can you supply coated washers?

Yes — zinc, phosphate, or black oxide.Are they suitable for outdoor use?

Yes, if coated for mild weather.Do you follow IS/ISO/DIN standards?

Absolutely.Do you provide test certificates?

Yes, on request.Can you supply other sizes?

Yes, we have M4 to M40 in mild and stainless steel.Do you offer bulk pricing?

Yes, with volume discounts.What’s your lead time?

Usually 7–14 days for bulk orders.Do you ship internationally?

Yes.Can I get free samples?

Of course.What is the MOQ?

We’re flexible, just ask.How do I store them?

Keep them dry and sealed.Can you do custom packaging?

Yes.Why choose Nafees Metal Industries?

For consistency, quality, and trusted bulk supply.

Why Choose Nafees Metal Industries?

When you choose Nafees Metal industries, you’re partnering with one of the Best M8 Mild Steel Plain Washers Manufacturers in India. Our washers are produced using the latest manufacturing technology, ensuring precise tolerances, durable finishes, and consistent quality across every batch.

Whether you need a small lot for urgent maintenance work or wish to Buy M8 Mild Steel Plain Washers in Bulk for large-scale production, we offer competitive pricing, flexible customization, and prompt delivery. Our dedicated team is committed to your satisfaction and ready to assist you with tailored solutions for all your industrial washer needs.

Visit Us Today

Explore our range of Mild Steel Flat Washers and place your bulk orders with complete confidence. Visit our state-of-the-art manufacturing facility at Reay Road, Mumbai , or get in touch with our team to discuss your specific requirements.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch