No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

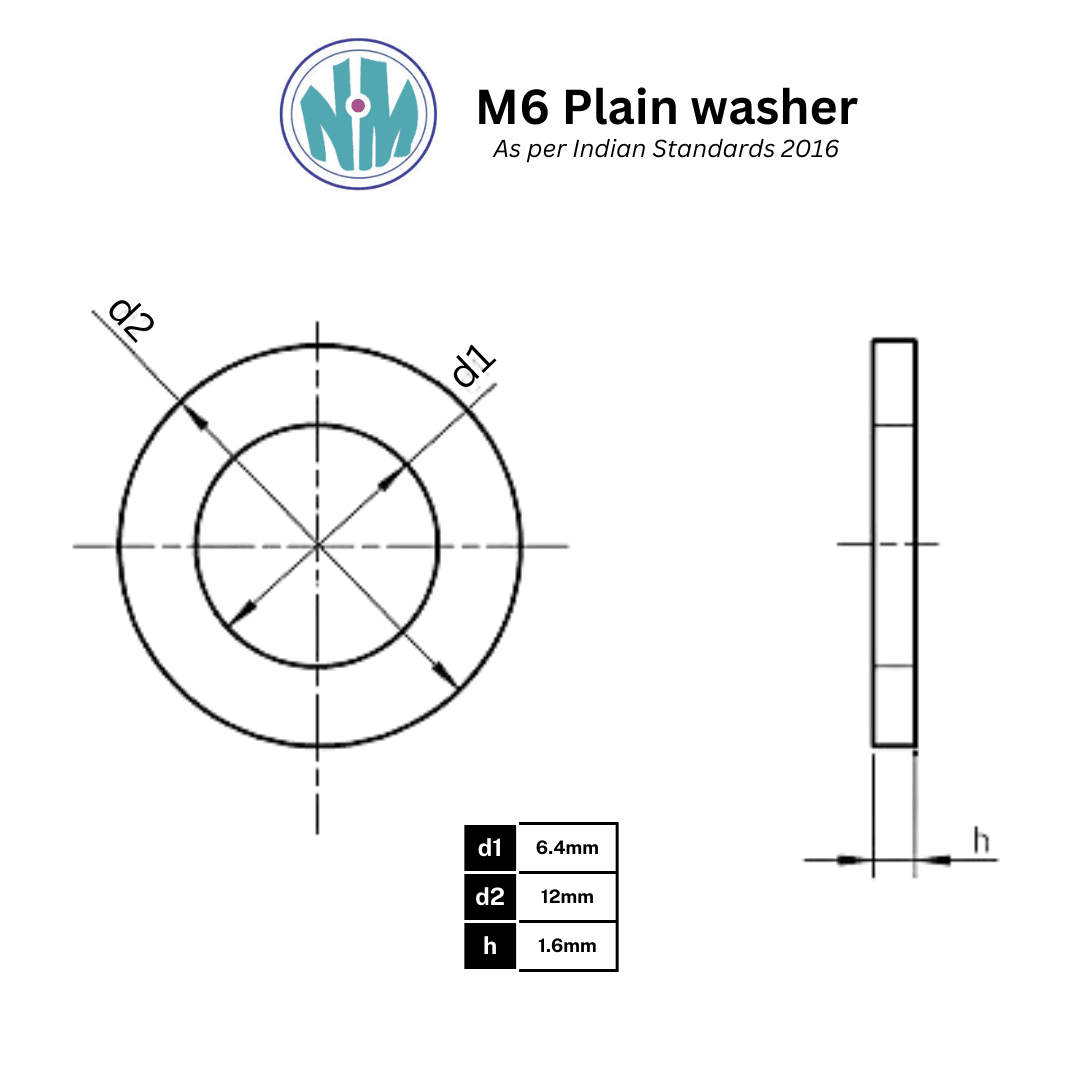

*Images shown for graphic representation. Not to scale.

M6 SS202 Plain Washers – Engineered for Reliability and Performance

Introduction

In the world of precision engineering and industrial fabrication, even the smallest components have a massive impact on the overall durability, stability, and performance of machinery. One such crucial yet often overlooked component is the washer. Washers play an essential role in load distribution, vibration dampening, and maintaining joint integrity.

Among the various washer types available in the market, industrial washers have gained significant popularity due to their optimal balance between performance and cost. These washers are crafted using SS202 stainless steel, making them both resilient and economical. Their widespread usage in automotive, construction, industrial machinery, electronics, and general fastening is a testament to their functional excellence.

As a trusted industrial fastener supplier, our company provides high-quality M6 SS202 Plain Washers that meet international standards and industry requirements. With in-house manufacturing, quality control processes, and customization capabilities, we are equipped to fulfill bulk and project-specific demands efficiently.

What Are M6 SS202 Plain Washers?

M6 SS202 Plain Washers are flat, circular discs with a centrally punched hole suitable for M6 fasteners (6mm inner diameter). Their primary function is to distribute the load of a bolt or screw evenly across the surface area, thus preventing damage and enhancing the stability of the joint.

These washers are commonly used where tightening torque needs to be distributed, especially over soft materials or thin surfaces that may otherwise deform. Additionally, they play a role in reducing friction between rotating parts and protecting surfaces from corrosion or paint wear.

Functional Highlights:

- Load Distribution: Helps prevent stress concentration by spreading the load across a broader surface area.

- Vibration Resistance: Acts as a buffer, reducing the chances of loosening due to vibrational impact.

- Surface Protection: Prevents surface scratches or dents that may occur from bolt tightening.

- Long-Term Joint Stability: Maintains torque consistency and reduces the need for frequent maintenance.

- Material Benefits: The use of SS202 ensures moderate corrosion resistance, making these washers suitable for indoor and lightly corrosive environments.

By incorporating M6 SS202 Plain Washers into your assembly, you ensure not only mechanical efficiency but also enhanced longevity and surface protection.

Material Details: Why SS202?

Composition:

SS202 stainless steel is part of the austenitic stainless steel family and contains higher manganese and lower nickel content compared to SS304 and SS316. This composition makes SS202 more affordable while still offering good mechanical properties.

Chemical Makeup:

- Chromium: 17-19%

- Nickel: 4-6%

- Manganese: 7.5-10%

- Carbon: 0.15% max

SS202 vs. SS304 vs. SS316:

| Property | SS202 | SS304 | SS316 |

|---|---|---|---|

| Cost | Low | Medium | High |

| Corrosion Resistance | Moderate | High | Very High |

| Strength | High | High | High |

| Weldability | Good | Excellent | Excellent |

| Applications | Indoor/general | Food, pharma | Marine, chemical |

Key Advantages of SS202:

- Cost-effective for general and light industrial use

- Good strength and hardness properties

- Suitable for mass production

- Offers fair corrosion resistance

SS202 is a perfect fit for producing M6 SS202 Plain Washers, combining strength, performance, and affordability in a single solution.

Manufacturing and Technical Specifications

The production of M6 SS202 Plain Washers involves a systematic process to ensure dimensional accuracy, durability, and consistency.

Manufacturing Process:

- Material Preparation: SS202 steel sheets are cut into strips or blanks.

- Punching: Precision machines punch the blanks into round shapes with M6 holes.

- Deburring: Sharp edges are smoothed to enhance safety and finish.

- Surface Treatment: Options include acid wash, passivation, or polishing.

- Inspection: Dimensional checks, hardness testing, and corrosion tests.

Technical Specifications Table:

| Parameter | Value |

| Inner Diameter | 6.4 mm |

| Outer Diameter | 12 mm |

| Thickness | 1.6 mm (typical) |

| Finish | Bright / Matte |

| Material | SS202 Stainless Steel |

| Shape | Round |

| Standard | IS 2016 / DIN 125 |

Our advanced CNC and stamping technologies ensure consistent quality across all batches of M6 SS202 Plain Washers.

Key Features

- Superior Load Distribution: Prevents localized stress and protects the underlying material by evenly dispersing the bolt or nut pressure over a larger surface area. This results in reduced wear and tear on the material and longer-lasting joints.

- Corrosion Resistance: The SS202 stainless steel composition ensures that these washers resist oxidation and corrosion in humid or moderately corrosive environments. This makes them ideal for applications where exposure to moisture or chemical agents is minimal but still a concern.

- Vibration Absorption: In dynamic environments, such as automotive or industrial machinery, these washers help absorb shock and vibration, minimizing the loosening of fasteners over time and ensuring structural integrity.

- Dimensional Accuracy: Manufactured with precision engineering standards, M6 SS202 Plain Washers are consistent in thickness, diameter, and hole alignment, ensuring a reliable fit in all M6 fastening applications.

- Versatility: Their standard sizing and stainless-steel construction make them suitable for a wide range of industries — from construction and manufacturing to electronics and DIY applications.

- Strength and Durability: Designed to handle high torque loads without bending or cracking, these washers maintain their structural integrity over long periods of use, even under stress.

- Reusable: Unlike plastic or soft-metal washers, M6 SS202 Plain Washers can be reused multiple times without compromising performance, making them a sustainable and cost-effective choice.

- Environmentally Friendly: Made from recyclable stainless steel, these washers contribute to sustainability and waste reduction in industrial operations.

- Customizable Finishes: Whether you need a matte, bright, or acid-passivated finish, these washers can be customized to match aesthetic or functional needs for your specific application.

- Cost Efficiency: Despite offering many high-performance features, M6 SS202 Plain Washers remain an affordable choice, providing significant savings without compromising on quality.

Applications & Use Cases

M6 SS202 Plain Washers are extensively used in various sectors due to their high functionality and adaptability. Their strength, reliability, and economic value make them indispensable in multiple settings.

Automotive Industry

Used in mounting brackets, engine components, suspension assemblies, and exhaust systems. Their vibration-resistant properties are ideal for dynamic load environments.

Construction Industry

Essential in joining metal frameworks, structural fasteners, and prefabricated modules. They offer added load distribution and surface protection on concrete, wood, or metal surfaces.

Industrial Machinery

Integrated into machines, production equipment, and factory tools. Helps maintain consistent torque levels and joint stability over long operating cycles.

Electronics & Electricals

Utilized in control panels, distribution boards, and circuit housings. They help avoid panel damage and short circuits by distributing torque evenly during fastener installation.

Furniture and Home Fixtures

Ideal for flat-pack furniture, fixtures, and interior installations. These washers prevent cracking or denting of wooden or polymer surfaces.

General Fastening and DIY Projects

Used in home improvement, plumbing, metalwork, and crafting applications. Their ease of use and availability make them perfect for everyday installations.

M6 SS202 Plain Washers demonstrate cross-industry value, from mechanical engineering to household setups, fulfilling the functional demands of both commercial and personal projects.

Why Choose the Best M6 SS202 Plain Washers Manufacturer

- ISO-Certified Production: Assures quality and compliance

- In-House Manufacturing: Control over production timelines and customization

- Bulk Customization: Specialized dimensions, thickness, and finishes

- Material Traceability: Every washer batch includes material test certificates

Trust a partner who offers not just products but solutions. Work with the best SS202 plain washers for industrial use supplier and experience unmatched reliability.

Installation Tips

Installing M6 SS202 Plain Washers correctly is essential to ensure the fasteners perform optimally and the joint remains secure over time. Here’s a comprehensive guide to best practices:

Step-by-Step Instructions:

- Prepare the Surface: Ensure the surfaces being joined are clean, dry, and free of contaminants such as oil or debris. A smooth, flat surface helps in achieving even washer contact.

- Align the Washer: Place the washer directly under the head of the bolt or nut, centering the M6 hole with the bolt shaft. For best results, use washers on both sides—under the bolt head and under the nut.

- Tighten with Torque Control: Use a torque wrench or calibrated tool to tighten the fastener to its recommended torque setting. This ensures even pressure distribution and prevents over-compression.

- Check for Washer Seating: After tightening, ensure the washer lies flat and is fully seated without bending or tilting. Misalignment can compromise the fastening system.

- Use Appropriate Coatings (if required): In outdoor or semi-corrosive environments, consider applying a protective coating over the washer assembly or use a pre-coated version.

- Avoid Mismatched Materials: Always pair SS202 washers with fasteners made from compatible materials to prevent galvanic corrosion.

- Regular Re-Tightening (if applicable): In high-vibration environments, schedule regular inspections and re-torque checks to maintain joint integrity.

Additional Tips:

- Avoid using damaged or bent washers.

- Store unused washers in a dry, protected space to prevent surface oxidation.

- For high-load applications, consider dual-washer systems or spring washers as supplements.

Proper installation not only enhances the effectiveness of M6 SS202 Plain Washers but also extends the lifespan of the entire fastening system.

Maintenance Guidelines

Proper maintenance of M6 SS202 Plain Washers is essential to ensure the longevity and performance of your fastening assemblies. While these washers are designed for durability, environmental factors and application-specific stresses can impact their lifespan. Below are best practices to follow:

1. Storage Recommendations

- Dry Environment: Always store washers in a dry, well-ventilated area away from moisture or chemical vapors to prevent surface oxidation.

- Packaging Integrity: Keep washers in their original sealed packaging until use to reduce exposure to air and contaminants.

- Avoid Mixing: Do not mix SS202 washers with carbon steel or other metal parts during storage to avoid cross-contamination and galvanic corrosion.

2. Inspection Frequency

- Visual Checks: Before each use, visually inspect washers for any signs of rust, pitting, warping, or discoloration.

- Routine Audit: Implement a regular inspection schedule (e.g., quarterly) for in-use applications, especially in high-vibration or outdoor settings.

3. Cleaning Methods

- Mild Cleaning Agents: Use warm water with a non-abrasive, pH-neutral cleaner to remove dirt or residues.

- Soft Brushes: Avoid steel wool or hard scrubbing tools; instead, use nylon brushes to preserve the washer’s surface.

- Dry Immediately: After washing, immediately dry washers thoroughly to prevent moisture accumulation.

4. When to Replace

- Signs of Deformation: Replace any washer that is bent, warped, or no longer sits flush against surfaces.

- Corrosion Presence: Any visible signs of corrosion or pitting indicate the need for replacement to maintain joint integrity.

- Torque Retention Issues: If a washer is contributing to bolt loosening, replace it even if no visible damage is present.

5. Lubrication and Protection (Optional)

- Anti-Seize Compounds: In high-friction or high-moisture applications, consider using anti-seize lubricant compatible with stainless steel.

- Protective Coatings: For added corrosion protection, a clear industrial coating can be applied to installed washers.

By adhering to these maintenance practices, users can maximize the lifespan and reliability of M6 SS202 Plain Washers in any application environment.

Case Study – Electrical Panel Manufacturing

A mid-sized manufacturer of electrical control panels was encountering repeated fastener-related failures in their enclosures. These issues emerged prominently in installations subjected to constant vibration, such as those in factory automation and heavy machinery environments. The washers they previously used were made of standard carbon steel, which failed to deliver the required load distribution and torque retention, leading to loosening of bolts and degradation of panel integrity.

Challenge:

- Frequent fastener loosening in vibration-prone installations

- Surface damage and deformation due to uneven pressure

- High number of customer complaints and service issues

Solution:

To resolve the reliability issues, the company transitioned to using M6 SS202 Plain Washers throughout their assembly lines. These washers were selected for their vibration resistance, dimensional consistency, and moderate corrosion resistance, all of which made them suitable for industrial-grade applications. The transition included a complete switch to SS202 washers for all M6 fastener points in critical units.

Execution:

- Procured 50,000+ M6 SS202 Plain Washers with certification and quality testing

- Conducted pilot runs across two assembly lines

- Adjusted torque settings and retrained technicians on updated fastening protocols

Results:

| Performance Metric | Before (Carbon Steel Washers) | After (M6 SS202 Plain Washers) |

|---|---|---|

| Monthly Fastener Failures | 10–12 | 1–2 |

| Rework Incidents | Frequent | Minimal |

| Assembly Line Throughput | 60 units/day | 72 units/day |

| Warranty Service Requests | High | Significantly Reduced |

Outcome:

The adoption of M6 SS202 Plain Washers led to a marked improvement in fastening reliability, panel durability, and assembly efficiency. The engineering team reported fewer disruptions, and the customer service department observed a notable drop in return and service cases. The washers have since been standardized in the company’s bill of materials for all future production batches.

Related Products or Variants

- Stainless Steel Flat Washers in M4–M48 sizes

- SS202 Washers with different coatings and finishes

- Metric & imperial-sized plain washers

- Custom die-punched variants

- Sample order kits for testing and prototyping

From everyday fastenings to mission-critical assemblies, M6 SS202 Plain Washers deliver long-lasting performance, economic value, and industry-trusted reliability. Backed by precision manufacturing and decades of fastener expertise, our washers are engineered to exceed expectations.

Get in touch with our sales team today to place a bulk order or request a sample pack.

Choose reliability. Choose quality. Choose M6 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

What are M6 SS202 Plain Washers used for?

They are used to distribute loads, reduce vibration, and prevent damage to surfaces in bolted joints.

Are these washers reusable?

Yes, provided they haven’t suffered from corrosion, deformation, or mechanical fatigue.

How corrosion-resistant is SS202?

SS202 provides moderate corrosion resistance suitable for indoor and mild environments.

Can I get these washers in custom sizes?

Yes, we offer full customization on dimensions, thickness, and surface finish.

Do they work with M6 bolts only?

They are optimized for M6 bolts, but can also be used in assemblies requiring similar internal diameters.

Are these washers magnetic?

SS202 is slightly magnetic, unlike SS304 or SS316.

What is the shelf life?

If stored properly, SS202 washers can last several years without any degradation.

Do you provide test certificates?

Yes, all our washers come with Material Test Certificates (MTCs).

Can these washers be used outdoors?

Only in non-aggressive environments. For marine or chemical use, SS316 is recommended.

How are these packed?

Standard packaging is in HDPE bags or boxes. Custom packaging available.

What’s the lead time for bulk orders?

Typically 7–15 working days depending on order volume and customizations.

How do I maintain them?

Wipe clean periodically, and store in dry conditions to prevent rust.

Are SS202 washers eco-friendly?

Yes, stainless steel is recyclable and reusable.

Do you offer sample orders?

Yes, we offer small sample kits for quality evaluation.

How do I place an order?

Reach out through our contact page or call our sales hotline. Bulk pricing available.

Why Choose Nafees Metal Industries

Our commitment to quality means every M6 SS202 Plain Washer is produced with meticulous care and precision. We use advanced manufacturing processes to maintain consistent dimensions and strength, batch after batch.

We know that reliability and cost matter, which is why we make it easy to buy bulk M6 stainless steel washers for large projects, or smaller quantities for routine maintenance. Backed by timely delivery, competitive pricing, and dedicated support, we aim to be your trusted supplier for all stainless steel washers and fastening needs.

✅ Order the Best M6 SS202 Plain Washers Today!

Discover the difference with Nafees Metal industries. Visit our manufacturing unit at Reay Road, Mumbai, or contact us online to secure your supply of M6 SS202 Plain Washers — the smart choice for durability, reliability, and long-term value.

M6 SS202 Plain Washers

26 people are viewing this product right now

₹0.43 Original price was: ₹0.43.₹0.36Current price is: ₹0.36. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M6

Inner Diameter (ID): 6.4 mm

Outer Diameter (OD): 12 mm

Thickness (t): 1.6 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M6 SS202 Plain Washers – Engineered for Reliability and Performance

Introduction

In the world of precision engineering and industrial fabrication, even the smallest components have a massive impact on the overall durability, stability, and performance of machinery. One such crucial yet often overlooked component is the washer. Washers play an essential role in load distribution, vibration dampening, and maintaining joint integrity.

Among the various washer types available in the market, industrial washers have gained significant popularity due to their optimal balance between performance and cost. These washers are crafted using SS202 stainless steel, making them both resilient and economical. Their widespread usage in automotive, construction, industrial machinery, electronics, and general fastening is a testament to their functional excellence.

As a trusted industrial fastener supplier, our company provides high-quality M6 SS202 Plain Washers that meet international standards and industry requirements. With in-house manufacturing, quality control processes, and customization capabilities, we are equipped to fulfill bulk and project-specific demands efficiently.

What Are M6 SS202 Plain Washers?

M6 SS202 Plain Washers are flat, circular discs with a centrally punched hole suitable for M6 fasteners (6mm inner diameter). Their primary function is to distribute the load of a bolt or screw evenly across the surface area, thus preventing damage and enhancing the stability of the joint.

These washers are commonly used where tightening torque needs to be distributed, especially over soft materials or thin surfaces that may otherwise deform. Additionally, they play a role in reducing friction between rotating parts and protecting surfaces from corrosion or paint wear.

Functional Highlights:

- Load Distribution: Helps prevent stress concentration by spreading the load across a broader surface area.

- Vibration Resistance: Acts as a buffer, reducing the chances of loosening due to vibrational impact.

- Surface Protection: Prevents surface scratches or dents that may occur from bolt tightening.

- Long-Term Joint Stability: Maintains torque consistency and reduces the need for frequent maintenance.

- Material Benefits: The use of SS202 ensures moderate corrosion resistance, making these washers suitable for indoor and lightly corrosive environments.

By incorporating M6 SS202 Plain Washers into your assembly, you ensure not only mechanical efficiency but also enhanced longevity and surface protection.

Material Details: Why SS202?

Composition:

SS202 stainless steel is part of the austenitic stainless steel family and contains higher manganese and lower nickel content compared to SS304 and SS316. This composition makes SS202 more affordable while still offering good mechanical properties.

Chemical Makeup:

- Chromium: 17-19%

- Nickel: 4-6%

- Manganese: 7.5-10%

- Carbon: 0.15% max

SS202 vs. SS304 vs. SS316:

| Property | SS202 | SS304 | SS316 |

|---|---|---|---|

| Cost | Low | Medium | High |

| Corrosion Resistance | Moderate | High | Very High |

| Strength | High | High | High |

| Weldability | Good | Excellent | Excellent |

| Applications | Indoor/general | Food, pharma | Marine, chemical |

Key Advantages of SS202:

- Cost-effective for general and light industrial use

- Good strength and hardness properties

- Suitable for mass production

- Offers fair corrosion resistance

SS202 is a perfect fit for producing M6 SS202 Plain Washers, combining strength, performance, and affordability in a single solution.

Manufacturing and Technical Specifications

The production of M6 SS202 Plain Washers involves a systematic process to ensure dimensional accuracy, durability, and consistency.

Manufacturing Process:

- Material Preparation: SS202 steel sheets are cut into strips or blanks.

- Punching: Precision machines punch the blanks into round shapes with M6 holes.

- Deburring: Sharp edges are smoothed to enhance safety and finish.

- Surface Treatment: Options include acid wash, passivation, or polishing.

- Inspection: Dimensional checks, hardness testing, and corrosion tests.

Technical Specifications Table:

| Parameter | Value |

| Inner Diameter | 6.4 mm |

| Outer Diameter | 12 mm |

| Thickness | 1.6 mm (typical) |

| Finish | Bright / Matte |

| Material | SS202 Stainless Steel |

| Shape | Round |

| Standard | IS 2016 / DIN 125 |

Our advanced CNC and stamping technologies ensure consistent quality across all batches of M6 SS202 Plain Washers.

Key Features

- Superior Load Distribution: Prevents localized stress and protects the underlying material by evenly dispersing the bolt or nut pressure over a larger surface area. This results in reduced wear and tear on the material and longer-lasting joints.

- Corrosion Resistance: The SS202 stainless steel composition ensures that these washers resist oxidation and corrosion in humid or moderately corrosive environments. This makes them ideal for applications where exposure to moisture or chemical agents is minimal but still a concern.

- Vibration Absorption: In dynamic environments, such as automotive or industrial machinery, these washers help absorb shock and vibration, minimizing the loosening of fasteners over time and ensuring structural integrity.

- Dimensional Accuracy: Manufactured with precision engineering standards, M6 SS202 Plain Washers are consistent in thickness, diameter, and hole alignment, ensuring a reliable fit in all M6 fastening applications.

- Versatility: Their standard sizing and stainless-steel construction make them suitable for a wide range of industries — from construction and manufacturing to electronics and DIY applications.

- Strength and Durability: Designed to handle high torque loads without bending or cracking, these washers maintain their structural integrity over long periods of use, even under stress.

- Reusable: Unlike plastic or soft-metal washers, M6 SS202 Plain Washers can be reused multiple times without compromising performance, making them a sustainable and cost-effective choice.

- Environmentally Friendly: Made from recyclable stainless steel, these washers contribute to sustainability and waste reduction in industrial operations.

- Customizable Finishes: Whether you need a matte, bright, or acid-passivated finish, these washers can be customized to match aesthetic or functional needs for your specific application.

- Cost Efficiency: Despite offering many high-performance features, M6 SS202 Plain Washers remain an affordable choice, providing significant savings without compromising on quality.

Applications & Use Cases

M6 SS202 Plain Washers are extensively used in various sectors due to their high functionality and adaptability. Their strength, reliability, and economic value make them indispensable in multiple settings.

Automotive Industry

Used in mounting brackets, engine components, suspension assemblies, and exhaust systems. Their vibration-resistant properties are ideal for dynamic load environments.

Construction Industry

Essential in joining metal frameworks, structural fasteners, and prefabricated modules. They offer added load distribution and surface protection on concrete, wood, or metal surfaces.

Industrial Machinery

Integrated into machines, production equipment, and factory tools. Helps maintain consistent torque levels and joint stability over long operating cycles.

Electronics & Electricals

Utilized in control panels, distribution boards, and circuit housings. They help avoid panel damage and short circuits by distributing torque evenly during fastener installation.

Furniture and Home Fixtures

Ideal for flat-pack furniture, fixtures, and interior installations. These washers prevent cracking or denting of wooden or polymer surfaces.

General Fastening and DIY Projects

Used in home improvement, plumbing, metalwork, and crafting applications. Their ease of use and availability make them perfect for everyday installations.

M6 SS202 Plain Washers demonstrate cross-industry value, from mechanical engineering to household setups, fulfilling the functional demands of both commercial and personal projects.

Why Choose the Best M6 SS202 Plain Washers Manufacturer

- ISO-Certified Production: Assures quality and compliance

- In-House Manufacturing: Control over production timelines and customization

- Bulk Customization: Specialized dimensions, thickness, and finishes

- Material Traceability: Every washer batch includes material test certificates

Trust a partner who offers not just products but solutions. Work with the best SS202 plain washers for industrial use supplier and experience unmatched reliability.

Installation Tips

Installing M6 SS202 Plain Washers correctly is essential to ensure the fasteners perform optimally and the joint remains secure over time. Here’s a comprehensive guide to best practices:

Step-by-Step Instructions:

- Prepare the Surface: Ensure the surfaces being joined are clean, dry, and free of contaminants such as oil or debris. A smooth, flat surface helps in achieving even washer contact.

- Align the Washer: Place the washer directly under the head of the bolt or nut, centering the M6 hole with the bolt shaft. For best results, use washers on both sides—under the bolt head and under the nut.

- Tighten with Torque Control: Use a torque wrench or calibrated tool to tighten the fastener to its recommended torque setting. This ensures even pressure distribution and prevents over-compression.

- Check for Washer Seating: After tightening, ensure the washer lies flat and is fully seated without bending or tilting. Misalignment can compromise the fastening system.

- Use Appropriate Coatings (if required): In outdoor or semi-corrosive environments, consider applying a protective coating over the washer assembly or use a pre-coated version.

- Avoid Mismatched Materials: Always pair SS202 washers with fasteners made from compatible materials to prevent galvanic corrosion.

- Regular Re-Tightening (if applicable): In high-vibration environments, schedule regular inspections and re-torque checks to maintain joint integrity.

Additional Tips:

- Avoid using damaged or bent washers.

- Store unused washers in a dry, protected space to prevent surface oxidation.

- For high-load applications, consider dual-washer systems or spring washers as supplements.

Proper installation not only enhances the effectiveness of M6 SS202 Plain Washers but also extends the lifespan of the entire fastening system.

Maintenance Guidelines

Proper maintenance of M6 SS202 Plain Washers is essential to ensure the longevity and performance of your fastening assemblies. While these washers are designed for durability, environmental factors and application-specific stresses can impact their lifespan. Below are best practices to follow:

1. Storage Recommendations

- Dry Environment: Always store washers in a dry, well-ventilated area away from moisture or chemical vapors to prevent surface oxidation.

- Packaging Integrity: Keep washers in their original sealed packaging until use to reduce exposure to air and contaminants.

- Avoid Mixing: Do not mix SS202 washers with carbon steel or other metal parts during storage to avoid cross-contamination and galvanic corrosion.

2. Inspection Frequency

- Visual Checks: Before each use, visually inspect washers for any signs of rust, pitting, warping, or discoloration.

- Routine Audit: Implement a regular inspection schedule (e.g., quarterly) for in-use applications, especially in high-vibration or outdoor settings.

3. Cleaning Methods

- Mild Cleaning Agents: Use warm water with a non-abrasive, pH-neutral cleaner to remove dirt or residues.

- Soft Brushes: Avoid steel wool or hard scrubbing tools; instead, use nylon brushes to preserve the washer’s surface.

- Dry Immediately: After washing, immediately dry washers thoroughly to prevent moisture accumulation.

4. When to Replace

- Signs of Deformation: Replace any washer that is bent, warped, or no longer sits flush against surfaces.

- Corrosion Presence: Any visible signs of corrosion or pitting indicate the need for replacement to maintain joint integrity.

- Torque Retention Issues: If a washer is contributing to bolt loosening, replace it even if no visible damage is present.

5. Lubrication and Protection (Optional)

- Anti-Seize Compounds: In high-friction or high-moisture applications, consider using anti-seize lubricant compatible with stainless steel.

- Protective Coatings: For added corrosion protection, a clear industrial coating can be applied to installed washers.

By adhering to these maintenance practices, users can maximize the lifespan and reliability of M6 SS202 Plain Washers in any application environment.

Case Study – Electrical Panel Manufacturing

A mid-sized manufacturer of electrical control panels was encountering repeated fastener-related failures in their enclosures. These issues emerged prominently in installations subjected to constant vibration, such as those in factory automation and heavy machinery environments. The washers they previously used were made of standard carbon steel, which failed to deliver the required load distribution and torque retention, leading to loosening of bolts and degradation of panel integrity.

Challenge:

- Frequent fastener loosening in vibration-prone installations

- Surface damage and deformation due to uneven pressure

- High number of customer complaints and service issues

Solution:

To resolve the reliability issues, the company transitioned to using M6 SS202 Plain Washers throughout their assembly lines. These washers were selected for their vibration resistance, dimensional consistency, and moderate corrosion resistance, all of which made them suitable for industrial-grade applications. The transition included a complete switch to SS202 washers for all M6 fastener points in critical units.

Execution:

- Procured 50,000+ M6 SS202 Plain Washers with certification and quality testing

- Conducted pilot runs across two assembly lines

- Adjusted torque settings and retrained technicians on updated fastening protocols

Results:

| Performance Metric | Before (Carbon Steel Washers) | After (M6 SS202 Plain Washers) |

|---|---|---|

| Monthly Fastener Failures | 10–12 | 1–2 |

| Rework Incidents | Frequent | Minimal |

| Assembly Line Throughput | 60 units/day | 72 units/day |

| Warranty Service Requests | High | Significantly Reduced |

Outcome:

The adoption of M6 SS202 Plain Washers led to a marked improvement in fastening reliability, panel durability, and assembly efficiency. The engineering team reported fewer disruptions, and the customer service department observed a notable drop in return and service cases. The washers have since been standardized in the company’s bill of materials for all future production batches.

Related Products or Variants

- Stainless Steel Flat Washers in M4–M48 sizes

- SS202 Washers with different coatings and finishes

- Metric & imperial-sized plain washers

- Custom die-punched variants

- Sample order kits for testing and prototyping

From everyday fastenings to mission-critical assemblies, M6 SS202 Plain Washers deliver long-lasting performance, economic value, and industry-trusted reliability. Backed by precision manufacturing and decades of fastener expertise, our washers are engineered to exceed expectations.

Get in touch with our sales team today to place a bulk order or request a sample pack.

Choose reliability. Choose quality. Choose M6 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

What are M6 SS202 Plain Washers used for?

They are used to distribute loads, reduce vibration, and prevent damage to surfaces in bolted joints.

Are these washers reusable?

Yes, provided they haven’t suffered from corrosion, deformation, or mechanical fatigue.

How corrosion-resistant is SS202?

SS202 provides moderate corrosion resistance suitable for indoor and mild environments.

Can I get these washers in custom sizes?

Yes, we offer full customization on dimensions, thickness, and surface finish.

Do they work with M6 bolts only?

They are optimized for M6 bolts, but can also be used in assemblies requiring similar internal diameters.

Are these washers magnetic?

SS202 is slightly magnetic, unlike SS304 or SS316.

What is the shelf life?

If stored properly, SS202 washers can last several years without any degradation.

Do you provide test certificates?

Yes, all our washers come with Material Test Certificates (MTCs).

Can these washers be used outdoors?

Only in non-aggressive environments. For marine or chemical use, SS316 is recommended.

How are these packed?

Standard packaging is in HDPE bags or boxes. Custom packaging available.

What’s the lead time for bulk orders?

Typically 7–15 working days depending on order volume and customizations.

How do I maintain them?

Wipe clean periodically, and store in dry conditions to prevent rust.

Are SS202 washers eco-friendly?

Yes, stainless steel is recyclable and reusable.

Do you offer sample orders?

Yes, we offer small sample kits for quality evaluation.

How do I place an order?

Reach out through our contact page or call our sales hotline. Bulk pricing available.

Why Choose Nafees Metal Industries

Our commitment to quality means every M6 SS202 Plain Washer is produced with meticulous care and precision. We use advanced manufacturing processes to maintain consistent dimensions and strength, batch after batch.

We know that reliability and cost matter, which is why we make it easy to buy bulk M6 stainless steel washers for large projects, or smaller quantities for routine maintenance. Backed by timely delivery, competitive pricing, and dedicated support, we aim to be your trusted supplier for all stainless steel washers and fastening needs.

✅ Order the Best M6 SS202 Plain Washers Today!

Discover the difference with Nafees Metal industries. Visit our manufacturing unit at Reay Road, Mumbai, or contact us online to secure your supply of M6 SS202 Plain Washers — the smart choice for durability, reliability, and long-term value.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch