No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M6 Mild Steel Plain Washers – Best M6 MS Flat Washers for Industrial Use

Introduction

When it comes to fastening components with consistent, repeatable strength, the smallest parts often make the biggest difference. M6 Mild Steel Plain Washers are a prime example: simple, reliable, and crucial for ensuring that bolts and nuts distribute their load evenly, protect surfaces, and keep assemblies tight under vibration and stress.

At Nafees Metal Industries, we’re trusted as the Best M6 MS Flat Washers for Industrial Use, thanks to our commitment to precision manufacturing, top-grade mild steel sourcing, and strict quality checks. Whether you work in automotive, construction, electrical, HVAC, or general fabrication, our M6 Mild Steel Plain Washers help you maintain the integrity and longevity of your products.

Read on for everything you need to know — including technical specs, detailed benefits, real-world applications, an expanded case study, practical installation and maintenance guidelines, and clear FAQs to help you Buy M6 Mild Steel Washers in Bulk with confidence.

Role of M6 Mild Steel Plain Washers in Industrial Applications

Fastening is about more than torque — it’s about durability and reliability under stress. Bolts and screws apply clamping force that can easily deform thin or soft materials if left unchecked. That’s where M6 Mild Steel Plain Washers step in: they spread the clamping force, protect the underlying surface, and act as a barrier against damage.

For M6 bolts — a common size in everything from metal frameworks to furniture, panels, and brackets — using plain washers is essential. They:

Prevent nuts and bolt heads from embedding into surfaces

Distribute loads evenly to maintain structural integrity

Reduce the risk of loosening from vibration

Protect painted or coated finishes from scratching

Add an extra layer of friction for better joint stability

In sectors like automotive, machinery, and building hardware, missing washers can lead to cracks, dents, or premature failure. That’s why OEMs, contractors, and repair shops rely on high-quality M6 Mild Steel Plain Washers as standard practice.

What Are M6 Mild Steel Plain Washers

A M6 Mild Steel Plain Washer is a flat, disc-shaped component with a central hole perfectly sized to fit an M6 bolt or screw. Simple as they look, they’re engineered to tight tolerances so that they slip on easily but stay snug under load.

How They Work

Imagine tightening an M6 bolt onto a powder-coated steel bracket. Without a washer, the bolt head bites directly into the coating — chipping it, causing local stress points, and increasing the chance of corrosion where the coating breaks. The washer acts like a shield, spreading the force and preserving the coating.

For layered materials — say, mounting metal brackets onto wooden frames — washers also help avoid pulling fasteners through the softer layer. This is especially valuable in assemblies that face dynamic loads, vibration, or thermal expansion.

So whether you’re bolting panels, brackets, or structural frames, M6 Mild Steel Plain Washers ensure every joint stays reliable and damage-free.

Material Details: Why Mild Steel Is the Perfect Choice

When selecting a washer material, you need a balance of strength, ductility, cost-effectiveness, and availability. That’s exactly why mild steel is the most trusted choice for general-purpose plain washers.

Advantages of Mild Steel Flat Washers

Strength & Ductility: Mild steel is strong enough to handle moderate loads without cracking or splitting, while its low carbon content makes it ductile enough to deform slightly under stress without losing shape.

Excellent Formability: It can be stamped and punched into consistent shapes with precise tolerances — ideal for mass production.

Cost-Effective: Compared to stainless steel or exotic alloys, mild steel is budget-friendly while delivering more than enough performance for indoor and low-corrosion settings.

Coating Options: Mild steel can be zinc plated, black oxidized, or phosphate coated for additional rust resistance when needed.

Recyclability: Eco-friendly manufacturing and easy to reclaim in the scrap stream.

For M6 fasteners, this makes mild steel the practical choice, delivering robust, reliable performance for a fraction of the price of stainless.

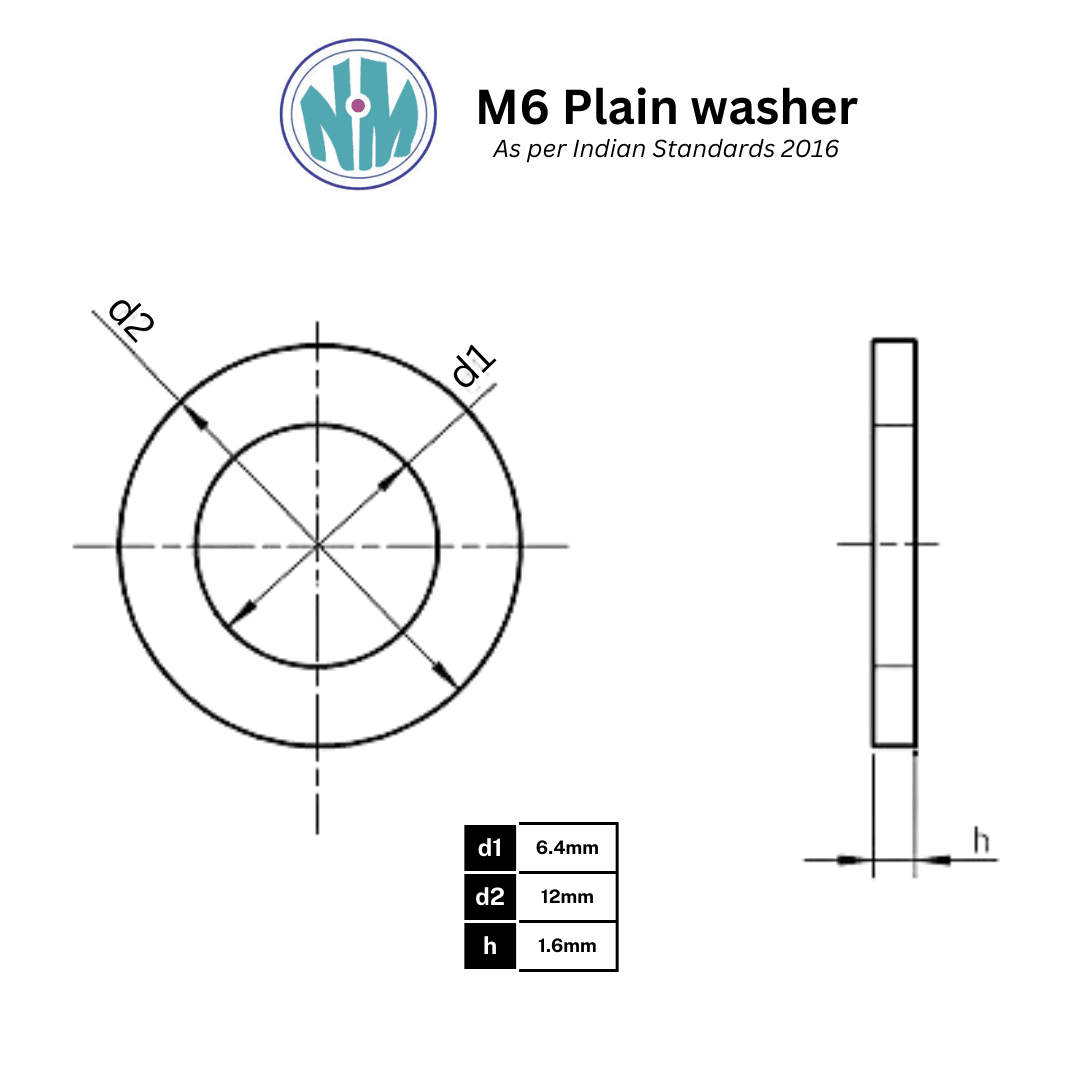

Manufacturing and Technical Specifications

Our M6 Mild Steel Plain Washers are made using modern CNC-controlled punching presses and rigorous inspection protocols to ensure every washer meets IS/ISO/DIN standards.

Manufacturing Process:

Raw mild steel sheets are tested for carbon content and consistency.

Washers are punched using high-speed stamping presses for exact inner and outer diameters.

Edges are deburred for safe handling and smooth seating.

Coating processes like zinc plating can be applied if specified.

Final inspection includes dimensional checks, thickness tests, and burr-free verification.

Typical Technical Specifications:

| Parameter | Specification |

|---|---|

| Inner Diameter | 6.4 mm (fits standard M6 bolts snugly) |

| Outer Diameter | 12–18 mm (depending on standard) |

| Thickness | 1.6–2 mm (per IS/ISO standard) |

| Finish | Plain, zinc plated, or phosphate coated |

| Material | Mild Steel |

| Shape | Flat round disc |

Key Features of M6 Mild Steel Plain Washers

Accurate Load Distribution

One of the main reasons to use M6 Mild Steel Plain Washers is their ability to spread the clamping force evenly. When an M6 bolt is tightened onto metal or wood without a washer, the force concentrates under the bolt head or nut. This can crush the material, deform it, or weaken the joint. A washer distributes the load across a larger surface area, maintaining the structural integrity of the assembly and preventing localized damage.

Surface Protection

Powder-coated, painted, or anodized surfaces need extra care. Direct fastener contact can scratch these finishes, opening up the base material to rust and ruining the product’s visual appeal. A washer acts as a sacrificial layer — taking the wear while protecting the surface below. In decorative or visible assemblies, this small detail keeps the final product looking clean and professional.

Resistance to Vibration

In machinery, furniture, and structures that move, vibration can gradually loosen bolts. Plain washers add friction and improve how a fastener grips the surface, helping resist this loosening effect. For example, in HVAC units or automotive panels that experience constant vibration, the right washer helps maintain tightness, reducing maintenance needs and the risk of unexpected failures.

Reusability and Durability

Our M6 Mild Steel Plain Washers are designed to withstand repeated tightening and loosening without significant deformation. This makes them cost-effective for fixtures that require periodic disassembly for cleaning, maintenance, or upgrades.

Compact and Versatile Design

The M6 size hits the sweet spot: strong enough for moderate loads, yet compact enough to fit tight spaces in control panels, enclosures, brackets, and furniture joints. Whether it’s an industrial panel or a household shelving unit, the washer does its job without adding bulk.

Affordability and Bulk Supply

Being able to Buy M6 Mild Steel Washers in Bulk means lower per-unit costs and consistent quality across your entire project — vital for contractors and OEMs who can’t afford delays or quality variation.

Applications of MS Washers Across Industries

Electrical Enclosures & Panels

Inside junction boxes, switchgear, or large control panels, M6 bolts and washers hold mounting plates, cable brackets, and component boards securely. The washer ensures that delicate metal sheets don’t warp under clamping loads.

Furniture & Fixtures

Shelving brackets, folding tables, and modular cabinets frequently use M6 bolts. Washers protect the powder-coated surfaces from scratching and ensure tight, rattle-free joints that hold up over time.

Automotive & Transport

In vehicles, M6 fasteners secure interior panels, brackets, and light fixtures. The washer provides a barrier that stops bolts from gouging softer panels, while also helping absorb vibration.

HVAC Systems & Ducting

Metal ducting, access panels, and mounting brackets often rely on M6 hardware. The washer prevents the bolt from tearing thin sheet metal flanges and helps maintain a tight seal.

Appliances & Consumer Goods

In appliances like air conditioners, washing machines, or small machinery, M6 fasteners plus washers hold everything in place, prevent scratches, and add friction that keeps components from shifting during operation.

DIY, Repair & Maintenance

Whether you’re fixing a gate hinge, assembling garden furniture, or mounting a handrail, M6 Mild Steel Plain Washers should be part of your toolkit. They protect surfaces, make joints last longer, and ensure the torque you apply actually holds up.

Case Study: Preventing Costly Ductwork Damage with M6 Mild Steel Plain Washers

Background

A leading HVAC contractor in Pune was awarded a large retrofitting project for a premium commercial building. The contract involved upgrading old HVAC ductwork, installing new insulated panels, and replacing hundreds of access panels and brackets to meet new safety and energy efficiency standards.

The contractor’s standard fastening setup for the project relied on M6 bolts for mounting lightweight access panels to galvanized steel ducts. At the time, they were using the bolts without washers, assuming that since the panels were light and the bolts small, there was no real need for additional hardware.

Problem

As installation progressed, the site team began noticing small but frequent issues:

When workers torqued the M6 bolts to ensure a tight seal, the bolt heads were deforming the thin galvanized sheet metal flanges around the mounting holes.

This caused tiny tears and cracks to develop in the duct walls, which later expanded under the stress of vibration when the HVAC units were switched on.

Air leaks developed around the access panels, which hurt system efficiency and caused rattling noises that the building management found unacceptable.

Within three months of handover, the contractor faced repeated complaints from the client about rattling panels and air leaks. Rework costs climbed as damaged duct sections had to be replaced entirely. It was clear that the problem stemmed from the localized stress of the bolt heads digging into thin sheet metal — a classic scenario where washers should have been used.

Solution

The contractor reached out to Nafees Metal Industries, explaining the issue. Our technical team immediately identified that using M6 Mild Steel Plain Washers would solve the problem by spreading the clamping force of the bolt heads over a larger surface area.

They requested a trial batch of zinc-plated M6 washers to match the mild moisture conditions inside the ducts and resist rusting over time. The washers were precision stamped, burr-free, and designed to fit snugly with standard M6 bolts.

A small test section of ducting was retrofitted with the washers and monitored for two weeks. Inspections found:

Zero flange deformation during re-tightening

No new cracks or air leaks

Significantly reduced vibration-related noise from loose panels

Implementation

Seeing these immediate improvements, the contractor rolled out M6 Mild Steel Plain Washers across the entire project. The installation team was trained on the updated process: for every M6 bolt securing an access panel, a washer was placed under the bolt head to protect the flange and spread the clamping load evenly.

No other tools or changes to the fastener type were needed — a testament to how easily a good washer can solve what seems like a complex problem.

Results

The results spoke for themselves:

90% reduction in service callbacks related to rattling panels and air leaks.

Savings of over ₹1.5 lakhs that would have otherwise been spent on duct repairs and panel replacements.

Faster installation — without the constant worry of over-torquing bolts and damaging the sheet metal, workers could work at normal speed.

A stronger, more energy-efficient HVAC system with improved customer satisfaction.

Client Testimonial

The site manager shared:

“Honestly, we underestimated what a small, inexpensive component like a washer could do. We were losing money on rework and complaints, all because of missing washers. Once we switched to your M6 Mild Steel Plain Washers, the panels fit tighter, the ducts held up better, and our entire quality rating went up.”

Key Takeaway

This case study is a powerful reminder: you can have the best bolts, panels, and ducts — but the right washer makes them work together without damage or extra cost.

In this retrofit project, M6 Mild Steel Plain Washers prevented localized stress damage, maintained the integrity of thin duct flanges, reduced rework, and ensured the building owner received a reliable, rattle-free HVAC system.

If you want the same peace of mind for your ducting, HVAC panels, furniture brackets, electrical enclosures, or any other M6 fastening application — never skip the washer. Trust Nafees Metal Industries for bulk supply of precision M6 Mild Steel Plain Washers, because we know the smallest parts can deliver the biggest savings.

Why Buy M6 Mild Steel Washers in Bulk

When you order from a trusted supplier like Nafees Metal Industries, buying in bulk means:

Volume discounts that lower your per-unit cost

Consistent quality from the same production batch

Custom packaging and labeling for organized storage

Fast turnaround and dedicated supply for large projects

Peace of mind that you’re getting the Best M6 MS Flat Washers for Industrial Use

Installation Tips

Always place a washer on both sides of a bolt (head and nut) if both touch soft or painted surfaces.

Clean surfaces to remove debris that could damage the finish.

Use torque wrenches to apply the correct clamping force without over-tightening.

Store extra washers in dry, sealed bins to prevent rust.

Maintenance Guidelines

Inspect washers during routine checks. Replace any that are warped or corroded.

Store bulk inventory in dry, ventilated areas.

Use coated washers for mild outdoor or humid environments.

Related Products

In addition to M6 Mild Steel Plain Washers, we also supply:

M4, M5, M8, and larger sizes

Spring washers and lock washers for anti-loosening

Stainless Steel Flat Washers for high-corrosion applications

Final Words

Protect every fastener, every surface, and your brand reputation with the reliability of M6 Mild Steel Plain Washers. We’re here to deliver consistent quality, competitive pricing, and a smooth supply experience so you can get the job done right.

FAQs

What are M6 Mild Steel Plain Washers used for?

They distribute bolt loads, protect surfaces, and add vibration resistance for M6 bolts.Are they reusable?

Yes — if not bent or corroded, they can be reused multiple times.Do you provide coated options?

Yes, we offer zinc and phosphate coatings.Are they good for outdoor use?

Yes, with appropriate coatings for mild weather exposure.What standards do you follow?

We follow IS, ISO, and DIN standards.Can you provide test certificates?

Yes, MTCs are available upon request.What industries use them most?

HVAC, furniture, automotive, electrical, and general construction.What’s the lead time for bulk orders?

Usually 7–14 working days.Can you supply samples?

Yes, we can send free samples for quality checks.How do I store them properly?

Keep them dry, sealed, and away from moisture.When should I replace a washer?

If you see warping, cracks, or heavy corrosion.Do you export?

Yes, we supply both domestic and international customers.Can I get custom dimensions?

Yes, custom sizes are available on request.Do you make other washer types?

Yes, we also make Spring Washers, Lock Washers, and Stainless Steel Flat Washers.Why choose Nafees Metal Industries?

We deliver reliable M6 Mild Steel Plain Washers, bulk supply, customization, and consistent quality every time.

Why Choose Nafees Metal Industries?

As a leading Best M6 MS Plain Washers manufacturer, Nafees Metal industries stands for quality, precision, and reliability. With state-of-the-art manufacturing facilities at Reay Road, Mumbai, and a skilled team, we ensure each batch meets exact industry standards. We supply to various industries and offer competitive rates, timely delivery, and full customer support.

If you want to Buy M6 Mild Steel Plain Washers in Bulk, choose a partner who understands your needs and guarantees consistent quality with every order. Trust Nafees Metal Industries for all your Mild Steel Washer requirements and experience hassle-free procurement backed by years of expertise.

M6 Mild Steel Plain Washers

10 people are viewing this product right now

₹0.22 Original price was: ₹0.22.₹0.18Current price is: ₹0.18. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M6

Inner Diameter (ID): 6.4 mm

Outer Diameter (OD): 12 mm

Thickness (t): 1.6 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M6 Mild Steel Plain Washers – Best M6 MS Flat Washers for Industrial Use

Introduction

When it comes to fastening components with consistent, repeatable strength, the smallest parts often make the biggest difference. M6 Mild Steel Plain Washers are a prime example: simple, reliable, and crucial for ensuring that bolts and nuts distribute their load evenly, protect surfaces, and keep assemblies tight under vibration and stress.

At Nafees Metal Industries, we’re trusted as the Best M6 MS Flat Washers for Industrial Use, thanks to our commitment to precision manufacturing, top-grade mild steel sourcing, and strict quality checks. Whether you work in automotive, construction, electrical, HVAC, or general fabrication, our M6 Mild Steel Plain Washers help you maintain the integrity and longevity of your products.

Read on for everything you need to know — including technical specs, detailed benefits, real-world applications, an expanded case study, practical installation and maintenance guidelines, and clear FAQs to help you Buy M6 Mild Steel Washers in Bulk with confidence.

Role of M6 Mild Steel Plain Washers in Industrial Applications

Fastening is about more than torque — it’s about durability and reliability under stress. Bolts and screws apply clamping force that can easily deform thin or soft materials if left unchecked. That’s where M6 Mild Steel Plain Washers step in: they spread the clamping force, protect the underlying surface, and act as a barrier against damage.

For M6 bolts — a common size in everything from metal frameworks to furniture, panels, and brackets — using plain washers is essential. They:

Prevent nuts and bolt heads from embedding into surfaces

Distribute loads evenly to maintain structural integrity

Reduce the risk of loosening from vibration

Protect painted or coated finishes from scratching

Add an extra layer of friction for better joint stability

In sectors like automotive, machinery, and building hardware, missing washers can lead to cracks, dents, or premature failure. That’s why OEMs, contractors, and repair shops rely on high-quality M6 Mild Steel Plain Washers as standard practice.

What Are M6 Mild Steel Plain Washers

A M6 Mild Steel Plain Washer is a flat, disc-shaped component with a central hole perfectly sized to fit an M6 bolt or screw. Simple as they look, they’re engineered to tight tolerances so that they slip on easily but stay snug under load.

How They Work

Imagine tightening an M6 bolt onto a powder-coated steel bracket. Without a washer, the bolt head bites directly into the coating — chipping it, causing local stress points, and increasing the chance of corrosion where the coating breaks. The washer acts like a shield, spreading the force and preserving the coating.

For layered materials — say, mounting metal brackets onto wooden frames — washers also help avoid pulling fasteners through the softer layer. This is especially valuable in assemblies that face dynamic loads, vibration, or thermal expansion.

So whether you’re bolting panels, brackets, or structural frames, M6 Mild Steel Plain Washers ensure every joint stays reliable and damage-free.

Material Details: Why Mild Steel Is the Perfect Choice

When selecting a washer material, you need a balance of strength, ductility, cost-effectiveness, and availability. That’s exactly why mild steel is the most trusted choice for general-purpose plain washers.

Advantages of Mild Steel Flat Washers

Strength & Ductility: Mild steel is strong enough to handle moderate loads without cracking or splitting, while its low carbon content makes it ductile enough to deform slightly under stress without losing shape.

Excellent Formability: It can be stamped and punched into consistent shapes with precise tolerances — ideal for mass production.

Cost-Effective: Compared to stainless steel or exotic alloys, mild steel is budget-friendly while delivering more than enough performance for indoor and low-corrosion settings.

Coating Options: Mild steel can be zinc plated, black oxidized, or phosphate coated for additional rust resistance when needed.

Recyclability: Eco-friendly manufacturing and easy to reclaim in the scrap stream.

For M6 fasteners, this makes mild steel the practical choice, delivering robust, reliable performance for a fraction of the price of stainless.

Manufacturing and Technical Specifications

Our M6 Mild Steel Plain Washers are made using modern CNC-controlled punching presses and rigorous inspection protocols to ensure every washer meets IS/ISO/DIN standards.

Manufacturing Process:

Raw mild steel sheets are tested for carbon content and consistency.

Washers are punched using high-speed stamping presses for exact inner and outer diameters.

Edges are deburred for safe handling and smooth seating.

Coating processes like zinc plating can be applied if specified.

Final inspection includes dimensional checks, thickness tests, and burr-free verification.

Typical Technical Specifications:

| Parameter | Specification |

|---|---|

| Inner Diameter | 6.4 mm (fits standard M6 bolts snugly) |

| Outer Diameter | 12–18 mm (depending on standard) |

| Thickness | 1.6–2 mm (per IS/ISO standard) |

| Finish | Plain, zinc plated, or phosphate coated |

| Material | Mild Steel |

| Shape | Flat round disc |

Key Features of M6 Mild Steel Plain Washers

Accurate Load Distribution

One of the main reasons to use M6 Mild Steel Plain Washers is their ability to spread the clamping force evenly. When an M6 bolt is tightened onto metal or wood without a washer, the force concentrates under the bolt head or nut. This can crush the material, deform it, or weaken the joint. A washer distributes the load across a larger surface area, maintaining the structural integrity of the assembly and preventing localized damage.

Surface Protection

Powder-coated, painted, or anodized surfaces need extra care. Direct fastener contact can scratch these finishes, opening up the base material to rust and ruining the product’s visual appeal. A washer acts as a sacrificial layer — taking the wear while protecting the surface below. In decorative or visible assemblies, this small detail keeps the final product looking clean and professional.

Resistance to Vibration

In machinery, furniture, and structures that move, vibration can gradually loosen bolts. Plain washers add friction and improve how a fastener grips the surface, helping resist this loosening effect. For example, in HVAC units or automotive panels that experience constant vibration, the right washer helps maintain tightness, reducing maintenance needs and the risk of unexpected failures.

Reusability and Durability

Our M6 Mild Steel Plain Washers are designed to withstand repeated tightening and loosening without significant deformation. This makes them cost-effective for fixtures that require periodic disassembly for cleaning, maintenance, or upgrades.

Compact and Versatile Design

The M6 size hits the sweet spot: strong enough for moderate loads, yet compact enough to fit tight spaces in control panels, enclosures, brackets, and furniture joints. Whether it’s an industrial panel or a household shelving unit, the washer does its job without adding bulk.

Affordability and Bulk Supply

Being able to Buy M6 Mild Steel Washers in Bulk means lower per-unit costs and consistent quality across your entire project — vital for contractors and OEMs who can’t afford delays or quality variation.

Applications of MS Washers Across Industries

Electrical Enclosures & Panels

Inside junction boxes, switchgear, or large control panels, M6 bolts and washers hold mounting plates, cable brackets, and component boards securely. The washer ensures that delicate metal sheets don’t warp under clamping loads.

Furniture & Fixtures

Shelving brackets, folding tables, and modular cabinets frequently use M6 bolts. Washers protect the powder-coated surfaces from scratching and ensure tight, rattle-free joints that hold up over time.

Automotive & Transport

In vehicles, M6 fasteners secure interior panels, brackets, and light fixtures. The washer provides a barrier that stops bolts from gouging softer panels, while also helping absorb vibration.

HVAC Systems & Ducting

Metal ducting, access panels, and mounting brackets often rely on M6 hardware. The washer prevents the bolt from tearing thin sheet metal flanges and helps maintain a tight seal.

Appliances & Consumer Goods

In appliances like air conditioners, washing machines, or small machinery, M6 fasteners plus washers hold everything in place, prevent scratches, and add friction that keeps components from shifting during operation.

DIY, Repair & Maintenance

Whether you’re fixing a gate hinge, assembling garden furniture, or mounting a handrail, M6 Mild Steel Plain Washers should be part of your toolkit. They protect surfaces, make joints last longer, and ensure the torque you apply actually holds up.

Case Study: Preventing Costly Ductwork Damage with M6 Mild Steel Plain Washers

Background

A leading HVAC contractor in Pune was awarded a large retrofitting project for a premium commercial building. The contract involved upgrading old HVAC ductwork, installing new insulated panels, and replacing hundreds of access panels and brackets to meet new safety and energy efficiency standards.

The contractor’s standard fastening setup for the project relied on M6 bolts for mounting lightweight access panels to galvanized steel ducts. At the time, they were using the bolts without washers, assuming that since the panels were light and the bolts small, there was no real need for additional hardware.

Problem

As installation progressed, the site team began noticing small but frequent issues:

When workers torqued the M6 bolts to ensure a tight seal, the bolt heads were deforming the thin galvanized sheet metal flanges around the mounting holes.

This caused tiny tears and cracks to develop in the duct walls, which later expanded under the stress of vibration when the HVAC units were switched on.

Air leaks developed around the access panels, which hurt system efficiency and caused rattling noises that the building management found unacceptable.

Within three months of handover, the contractor faced repeated complaints from the client about rattling panels and air leaks. Rework costs climbed as damaged duct sections had to be replaced entirely. It was clear that the problem stemmed from the localized stress of the bolt heads digging into thin sheet metal — a classic scenario where washers should have been used.

Solution

The contractor reached out to Nafees Metal Industries, explaining the issue. Our technical team immediately identified that using M6 Mild Steel Plain Washers would solve the problem by spreading the clamping force of the bolt heads over a larger surface area.

They requested a trial batch of zinc-plated M6 washers to match the mild moisture conditions inside the ducts and resist rusting over time. The washers were precision stamped, burr-free, and designed to fit snugly with standard M6 bolts.

A small test section of ducting was retrofitted with the washers and monitored for two weeks. Inspections found:

Zero flange deformation during re-tightening

No new cracks or air leaks

Significantly reduced vibration-related noise from loose panels

Implementation

Seeing these immediate improvements, the contractor rolled out M6 Mild Steel Plain Washers across the entire project. The installation team was trained on the updated process: for every M6 bolt securing an access panel, a washer was placed under the bolt head to protect the flange and spread the clamping load evenly.

No other tools or changes to the fastener type were needed — a testament to how easily a good washer can solve what seems like a complex problem.

Results

The results spoke for themselves:

90% reduction in service callbacks related to rattling panels and air leaks.

Savings of over ₹1.5 lakhs that would have otherwise been spent on duct repairs and panel replacements.

Faster installation — without the constant worry of over-torquing bolts and damaging the sheet metal, workers could work at normal speed.

A stronger, more energy-efficient HVAC system with improved customer satisfaction.

Client Testimonial

The site manager shared:

“Honestly, we underestimated what a small, inexpensive component like a washer could do. We were losing money on rework and complaints, all because of missing washers. Once we switched to your M6 Mild Steel Plain Washers, the panels fit tighter, the ducts held up better, and our entire quality rating went up.”

Key Takeaway

This case study is a powerful reminder: you can have the best bolts, panels, and ducts — but the right washer makes them work together without damage or extra cost.

In this retrofit project, M6 Mild Steel Plain Washers prevented localized stress damage, maintained the integrity of thin duct flanges, reduced rework, and ensured the building owner received a reliable, rattle-free HVAC system.

If you want the same peace of mind for your ducting, HVAC panels, furniture brackets, electrical enclosures, or any other M6 fastening application — never skip the washer. Trust Nafees Metal Industries for bulk supply of precision M6 Mild Steel Plain Washers, because we know the smallest parts can deliver the biggest savings.

Why Buy M6 Mild Steel Washers in Bulk

When you order from a trusted supplier like Nafees Metal Industries, buying in bulk means:

Volume discounts that lower your per-unit cost

Consistent quality from the same production batch

Custom packaging and labeling for organized storage

Fast turnaround and dedicated supply for large projects

Peace of mind that you’re getting the Best M6 MS Flat Washers for Industrial Use

Installation Tips

Always place a washer on both sides of a bolt (head and nut) if both touch soft or painted surfaces.

Clean surfaces to remove debris that could damage the finish.

Use torque wrenches to apply the correct clamping force without over-tightening.

Store extra washers in dry, sealed bins to prevent rust.

Maintenance Guidelines

Inspect washers during routine checks. Replace any that are warped or corroded.

Store bulk inventory in dry, ventilated areas.

Use coated washers for mild outdoor or humid environments.

Related Products

In addition to M6 Mild Steel Plain Washers, we also supply:

M4, M5, M8, and larger sizes

Spring washers and lock washers for anti-loosening

Stainless Steel Flat Washers for high-corrosion applications

Final Words

Protect every fastener, every surface, and your brand reputation with the reliability of M6 Mild Steel Plain Washers. We’re here to deliver consistent quality, competitive pricing, and a smooth supply experience so you can get the job done right.

FAQs

What are M6 Mild Steel Plain Washers used for?

They distribute bolt loads, protect surfaces, and add vibration resistance for M6 bolts.Are they reusable?

Yes — if not bent or corroded, they can be reused multiple times.Do you provide coated options?

Yes, we offer zinc and phosphate coatings.Are they good for outdoor use?

Yes, with appropriate coatings for mild weather exposure.What standards do you follow?

We follow IS, ISO, and DIN standards.Can you provide test certificates?

Yes, MTCs are available upon request.What industries use them most?

HVAC, furniture, automotive, electrical, and general construction.What’s the lead time for bulk orders?

Usually 7–14 working days.Can you supply samples?

Yes, we can send free samples for quality checks.How do I store them properly?

Keep them dry, sealed, and away from moisture.When should I replace a washer?

If you see warping, cracks, or heavy corrosion.Do you export?

Yes, we supply both domestic and international customers.Can I get custom dimensions?

Yes, custom sizes are available on request.Do you make other washer types?

Yes, we also make Spring Washers, Lock Washers, and Stainless Steel Flat Washers.Why choose Nafees Metal Industries?

We deliver reliable M6 Mild Steel Plain Washers, bulk supply, customization, and consistent quality every time.

Why Choose Nafees Metal Industries?

As a leading Best M6 MS Plain Washers manufacturer, Nafees Metal industries stands for quality, precision, and reliability. With state-of-the-art manufacturing facilities at Reay Road, Mumbai, and a skilled team, we ensure each batch meets exact industry standards. We supply to various industries and offer competitive rates, timely delivery, and full customer support.

If you want to Buy M6 Mild Steel Plain Washers in Bulk, choose a partner who understands your needs and guarantees consistent quality with every order. Trust Nafees Metal Industries for all your Mild Steel Washer requirements and experience hassle-free procurement backed by years of expertise.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch