No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M39 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M6 Copper Plain Washer – High-Conductivity Flat Washers for Precision Fastening Applications

Nafees Metal Industries proudly presents the M6 Copper Plain Washer, a high-quality fastening component designed for superior conductivity, exceptional corrosion resistance, and effective load distribution. Manufactured at our advanced facility in Mumbai, these copper washers are engineered to deliver reliable performance in electrical, automotive, HVAC, and heavy-duty mechanical assemblies.

As one of the best copper washer manufacturers in India, we specialize in crafting precision-engineered washers that comply with global standards. Our M6 copper plain washers are widely used for grounding, sealing, and fastening tasks where electrical conductivity and durability are crucial. With optimized tolerances and surface finish, these washers serve as a reliable solution for professionals who demand consistent results in both industrial and commercial applications.

Whether you are working with battery terminals, circuit assemblies, or hydraulic fittings, the M6 copper plain washer is your go-to solution for a robust and stable fastening system. With options for customized thickness, coating, and bulk packaging, we are fully equipped to fulfill small to large-volume requirements across India and worldwide.

What is M6 Copper Plain Washer?

M6 Copper Plain Washer is a flat, circular disc with a center hole precisely sized to fit M6 bolts or screws (6 mm in diameter). These washers are designed to distribute the load of a threaded fastener more evenly across the surface, prevent damage to the assembled parts, reduce friction during tightening, and improve the longevity of the fastening joint. Made from pure or high-grade copper, these washers also offer excellent electrical and thermal conductivity, making them ideal for electrical assemblies and high-heat environments.

At Nafees Metal Industries, every M6 copper plain washer is manufactured under strict quality standards to ensure accurate inner and outer diameters, uniform thickness, and a smooth surface finish. They are particularly favored in situations where both mechanical performance and electrical contact are required, such as grounding terminals, automotive battery connections, electronic circuit boards, and HVAC units.

Due to copper’s natural resistance to corrosion and its superior ability to conduct electricity, the M6 copper plain washer is also commonly used in sensitive equipment where long-term reliability is essential. It plays a dual role: acting as a mechanical buffer and ensuring electrical continuity or grounding in circuits.

We offer copper flat washer M6 size in a variety of finishes—plain (uncoated), tin-plated, or oxidized—depending on your application requirements. These washers meet relevant standards such as DIN 125, DIN 7603A, or custom tolerances as specified by OEMs.

Whether you’re an electrical contractor, HVAC installer, auto technician, or industrial OEM, our flat washer copper products guarantee quality and consistency across every unit. We supply bulk quantities to distributors, manufacturers, and assembly lines across India and international markets.

Why Choose Copper for M6 Plain Washers?

Copper is one of the most preferred materials for flat washers due to its unique combination of mechanical strength, chemical stability, and exceptional electrical and thermal conductivity. When it comes to small fasteners like the M6 copper plain washer, copper offers a set of advantages that make it ideal for both general-purpose and high-performance industrial applications.

Here’s why copper is the ideal choice for M6 plain washers:

1. Excellent Electrical Conductivity

The primary reason copper is chosen for washers—especially in electrical systems—is its unmatched ability to conduct electricity. The M6 copper plain washer ensures minimal resistance in grounding applications and provides a consistent electrical path in terminal connections and PCB assemblies.

2. Superior Corrosion Resistance

Copper naturally forms a protective oxide layer that prevents it from rusting. This makes our M6 copper plain washers highly suitable for use in moist, corrosive, or outdoor environments—including marine and HVAC installations. Compared to steel, copper lasts longer without degrading in chemically exposed applications.

3. High Thermal Conductivity

Copper’s ability to dissipate heat makes it ideal for use in heat-sensitive or high-temperature applications, such as electrical enclosures or automotive parts near the engine. The M6 copper plain washer helps in minimizing heat buildup at fastening points, reducing the risk of thermal stress.

4. Ductility and Malleability

Copper washers can compress slightly under pressure without cracking, which helps in creating a better seal in assemblies like brake lines, oil filters, or hydraulic systems. This is particularly important for copper flat washer M6 size, which is often used in fluid sealing and vibration-prone applications.

5. Eco-Friendly & Recyclable

Copper is 100% recyclable without loss of quality. At Nafees Metal Industries, we adopt environmentally responsible manufacturing practices, ensuring that our M6 copper plain washers not only perform well but also contribute toward sustainable engineering and green procurement goals.

6. Versatile Finishing Options

We offer plain, tin-plated, or oxide-treated M6 copper washers based on customer-specific use cases. Whether you need improved surface conductivity or better corrosion resistance, our washers are adaptable to diverse needs.

In summary, copper is not just a metal—it’s a performance material. Our M6 copper plain washer combines material science with precision engineering to deliver a product that exceeds expectations across mechanical, electrical, and chemical performance criteria.

How Are M6 Copper Plain Washers Manufactured?

At Nafees Metal Industries, we follow a stringent, ISO-compliant manufacturing process to produce high-quality M6 copper plain washers that meet both domestic and international standards. Our manufacturing unit in Mumbai is equipped with advanced power press machines, precision stamping dies, and automated inspection systems that ensure consistency in every washer produced.

Here’s a step-by-step breakdown of how our M6 copper plain washers are made:

1. Raw Material Selection

We source high-grade electrolytic copper sheets or coils with certified purity levels to ensure excellent conductivity and corrosion resistance. Only copper that meets our strict metallurgical and dimensional criteria is used to manufacture our M6 copper plain washers.

2. Cold Stamping (Punching Process)

Using hydraulic or mechanical power press machines, copper sheets are cold-stamped with precision tooling to create perfectly round washers with an inner diameter (ID) of ~6.4 mm to fit M6 bolts. The M6 copper plain washer is designed to match industry-standard dimensions such as DIN 125, DIN 7603A, or IS 2016.

3. Deburring and Edge Finishing

After stamping, the washers go through a deburring process where sharp edges and burrs are removed. This step ensures smooth surface contact, which is especially important in electrical applications where poor contact can lead to overheating or failure.

4. Surface Treatment (Optional)

Depending on the application and customer requirements, the M6 copper plain washer can undergo various surface treatments such as:

Tin plating – for improved corrosion resistance and solderability

Oxidation or passivation – for a non-reflective, corrosion-resistant finish

Plain finish – with polished copper surface for maximum conductivity

5. Quality Inspection

Every batch of M6 copper plain washers is tested for dimensional accuracy, thickness uniformity, surface smoothness, and electrical conductivity. We use micrometers, calipers, concentricity gauges, and visual inspection systems to guarantee that only defect-free washers leave our premises.

6. Customization and Packaging

We offer tailored thickness (typically 1.0–1.5 mm), ID/OD ratios, and finishing options based on your specifications. Washers are packed in:

Bulk poly bags or corrugated cartons

Custom-labeled boxes for OEMs

Export-grade packaging with documentation and HS codes for international shipments

Our focus on precision engineering, bulk readiness, and finish customization makes us the go-to choice for best copper washer manufacturers in India—especially for clients requiring copper flat washer M6 size in volume with consistent quality.

Key Features of M6 Copper Plain Washers

At Nafees Metal Industries, we take pride in delivering M6 copper plain washers that combine superior design, material purity, and manufacturing precision. Our washers are not just components—they are high-performance solutions tailored for demanding electrical, mechanical, and sealing applications.

Below are the key features that make our M6 copper plain washers the preferred choice for industrial and commercial use:

1. Precision Fitment

Every M6 copper plain washer is manufactured to fit snugly with standard M6 bolts and screws (6 mm). This ensures reliable load distribution, proper clamping force, and minimal movement under vibration or thermal expansion.

2. High Conductivity Copper Material

Crafted from premium-grade copper, these washers ensure low electrical resistance and superior conductivity. Ideal for grounding, power transmission, and electrical contact applications.

3. Effective Load Distribution

The M6 copper plain washer acts as a buffer between the fastener and the substrate, preventing surface damage, wear, and stress concentration during tightening. This extends the lifespan of assemblies, especially in electronic and automotive setups.

4. Corrosion Resistance

Thanks to the natural corrosion-resistant properties of copper, our washers perform well in environments prone to moisture, oxidation, or chemical exposure. For enhanced durability, we also offer tin-plated or oxidized finishes.

5. Customizable Dimensions

Need a specific thickness or outer diameter? Our washers can be customized to meet DIN, ISO, or unique OEM requirements, making them ideal for specialized applications in industrial assemblies and maintenance.

6. Smooth Surface and Burr-Free Edges

Each M6 copper plain washer is deburred and polished to ensure smooth edges, which prevent scratching or damage to sensitive components during assembly. This also aids in achieving better electrical contact.

7. Mechanical and Thermal Stability

Copper’s malleability allows the washer to compress slightly for a tighter seal without cracking. These properties make it ideal for use in high-vibration or high-temperature environments.

8. Wide Application Compatibility

Whether used in automotive electronics, HVAC systems, battery terminals, or circuit boards, our flat washer copper delivers consistent results and long-term performance.

9. Made in India with Global Standards

Manufactured at our Mumbai facility, our washers comply with standards like DIN 125, DIN 7603A, and IS 2016. We are proud contributors to the Make in India initiative and deliver quality that rivals global competitors.

10. Bulk Supply and Custom Packaging

Available in large volumes with quick delivery, we offer flexible packaging options such as bulk poly bags, labeled boxes, and export-ready cartons to suit distributors, OEMs, and contractors.

These features position our M6 copper plain washer range as the most reliable and cost-effective choice across industrial sectors. Whether your application is electrical, thermal, or sealing-critical, you can count on us to deliver quality without compromise.

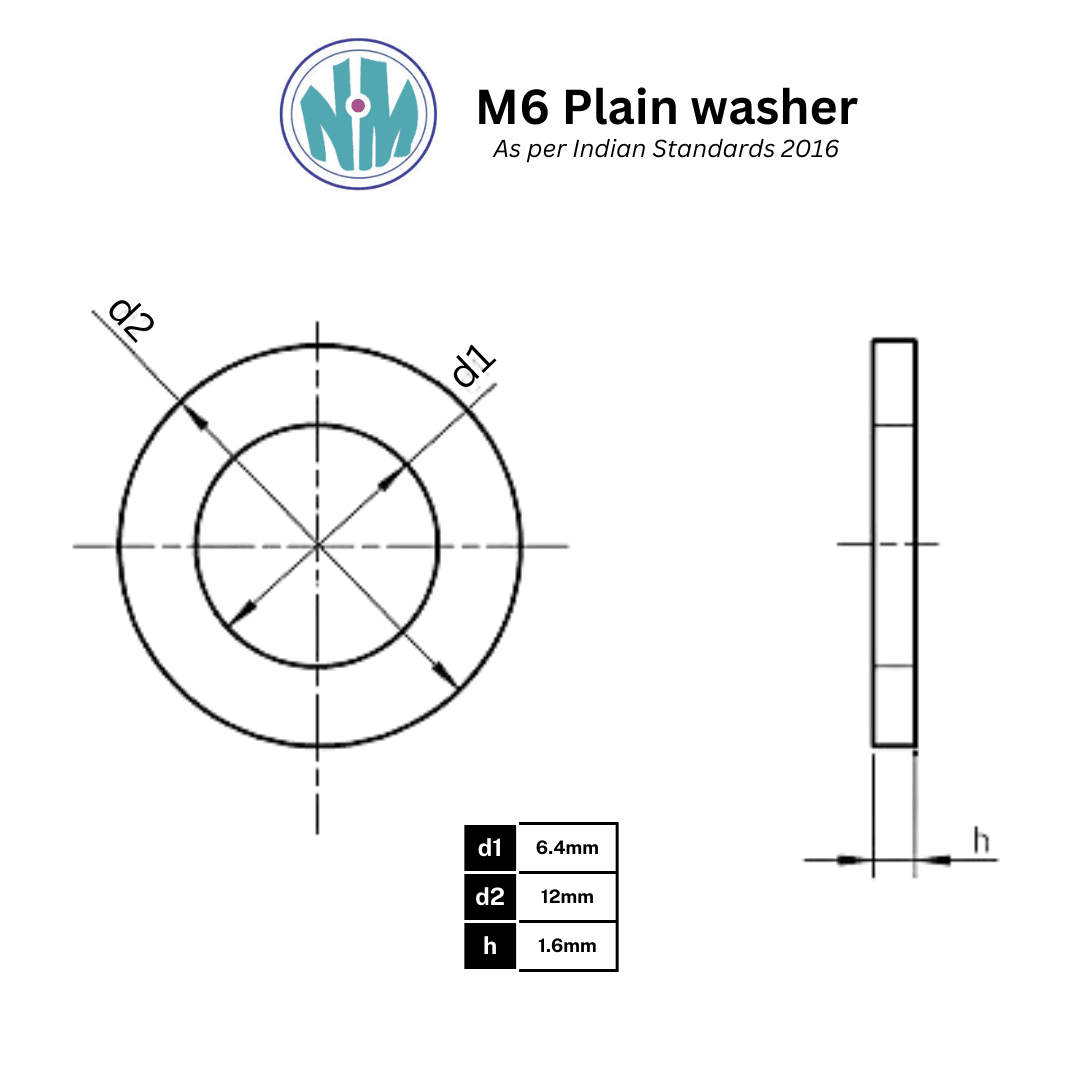

Technical Specifications of M6 Copper Plain Washer

At Nafees Metal Industries, we ensure that every M6 copper plain washer meets precise engineering and dimensional standards for superior fit, durability, and performance. Below are the detailed technical specifications of our product:

| Property | Specification |

|---|---|

| Product Name | M6 Copper Plain Washer |

| Material | High-Grade Copper (99% Purity or as per customer specification) |

| Inner Diameter (ID) | Approximately 6.4 mm (Fits standard M6 bolts and screws) |

| Outer Diameter (OD) | Standard: 12 mm to 18 mm (Customizable based on application) |

| Thickness | Standard: 1.0 mm to 1.5 mm (Custom thickness available on request) |

| Surface Finish | Plain / Tin-Plated / Oxidized (Optional based on corrosion or conductivity needs) |

| Hardness | Soft Annealed or Half-Hard (as required) |

| Conductivity | Excellent (Ideal for electrical grounding and contact applications) |

| Temperature Range | -40°C to +200°C (Suitable for high-heat applications) |

| Corrosion Resistance | High – Natural Copper Resistance; Enhanced with Plating |

| Standard Compliance | DIN 125 / DIN 7603A / IS 2016 / Custom Dimensions |

| Application Category | Electrical, Mechanical, Automotive, HVAC, Sealing, Fastening Systems |

| Packaging | Bulk Poly Bags / Small Pack Boxes / Export-Grade Cartons |

| Manufacturing Location | Mumbai, Maharashtra, India |

| HS Code | 74153300 (Used for copper washers in export documentation) |

Our in-house engineering team can also develop custom tooling and dies for non-standard copper washer sizes and tolerances. Each M6 copper plain washer is batch-coded and inspected under strict ISO-compliant processes to maintain traceability and performance assurance.

These specifications ensure that our washers meet the mechanical, electrical, and environmental requirements of both Indian and global customers.

Applications of M6 Copper Plain Washers

The M6 copper plain washer is widely recognized for its dual-purpose performance in mechanical fastening and electrical conductivity. Its design, material properties, and precise dimensions make it suitable across diverse industries. At Nafees Metal Industries, we manufacture these washers to cater to a broad range of applications, ensuring consistent results even under demanding conditions.

Here are the primary application areas of the M6 copper flat washer:

1. Electrical Terminals and Grounding Systems

Copper’s high electrical conductivity makes the M6 copper plain washer a perfect fit for grounding applications, terminal lugs, and switchgear panels. It ensures consistent current flow and reduces resistance in live connections.

2. Automotive and Battery Assemblies

Used in automotive battery terminals, sensor connections, and electronic modules, the Copper flat washer metric size M6 provides stable fastening while withstanding engine heat and vibration. It also prevents galvanic corrosion between dissimilar metals.

3. Printed Circuit Boards (PCBs)

In sensitive electronic systems, copper washers act as a buffer and a grounding medium. The M6 copper washer prevents stress on circuit boards during tightening and maintains stable contact in electronic assemblies.

4. HVAC Equipment and Compressors

For air conditioning units, heat pumps, and industrial compressors, these washers help ensure secure assembly of copper tubing, electrical enclosures, and vibration-prone joints.

5. Hydraulic and Pneumatic Systems

The flat washer copper type is widely used in sealing hydraulic fittings, fuel lines, and brake systems to avoid leaks. Its malleability ensures tight sealing in high-pressure systems.

6. Solar and Renewable Energy Installations

In solar panels and renewable setups, copper washers play a role in conductive mounting and grounding. Our M6 copper plain washer ensures corrosion resistance and long-term performance under outdoor exposure.

7. Aerospace and Marine Applications

Due to its corrosion resistance, copper is the preferred material in marine environments and aerospace components. The M6 copper Flat washer helps secure fixtures while resisting saltwater or humid exposure.

8. Consumer Electronics and Appliances

From laptops and televisions to fans and mixers, our M6 copper plain washers are integrated in internal assemblies for grounding, vibration absorption, and proper load distribution.

9. Industrial Machinery and Control Panels

In heavy-duty machinery, control units, and automation panels, copper washers prevent spark generation, ensure stable clamping force, and protect against wear caused by vibrations.

10. Maintenance, Repair & Overhaul (MRO)

They are commonly included in fastener kits, servicing toolkits, and emergency repair units for on-site use by engineers, technicians, and mechanics.

With such broad usage across multiple industries, the M6 copper Flat washer is not just a small part—it is a crucial component in ensuring safety, stability, and functionality in critical applications.

Advantages of Using M6 Copper Plain Washers

Choosing the right washer is essential to ensuring reliable mechanical joints and long-term performance, especially in electrical and corrosive environments. The M6 copper plain washer stands out due to its excellent material properties, precision fit, and versatile usage. At Nafees Metal Industries, our washers are crafted to deliver consistent performance, making us one of the best copper washer manufacturers in India.

Here are the key advantages of using M6 copper washers:

1. Superior Electrical Conductivity

Copper is the second-best conductor of electricity after silver. This makes the M6 copper washer ideal for grounding, power transmission, and maintaining electrical continuity in sensitive devices.

2. Uniform Load Distribution

These washers help evenly distribute the pressure of bolts and screws, reducing the risk of surface damage or material deformation during tightening. They are especially useful in delicate assemblies like electronics or soft metal surfaces.

3. Excellent Corrosion Resistance

Copper forms a natural oxide layer that protects against corrosion. Whether in humid, coastal, or chemically exposed environments, the M6 copper plain washer maintains its integrity and performance.

4. Thermal Stability in High-Heat Applications

With a high melting point and excellent heat dissipation capacity, copper washers withstand elevated temperatures. Ideal for engine parts, electrical enclosures, or HVAC systems where heat is a concern.

5. Tight Sealing Capability

Due to copper’s ductility, these washers conform to mating surfaces, creating a tight seal. This makes the flat washer copper type a preferred choice in hydraulic, pneumatic, and brake line applications.

6. Versatility Across Industries

From automotive to aerospace, electronics to solar, and HVAC to industrial machinery, the M6 copper plain washer serves a wide array of sectors thanks to its mechanical strength and conductive properties.

7. Compatible with a Variety of Coatings and Finishes

We offer plain, tin-plated, or oxidized versions of our M6 copper plain washers to meet specific application needs—whether it’s solderability, enhanced corrosion resistance, or anti-reflective requirements.

8. Cost-Effective Long-Term Performance

Though copper is costlier than mild steel, its durability, conductivity, and corrosion resistance translate into long-term value. These washers reduce the risk of failure, downtime, and maintenance in critical applications.

9. Eco-Friendly and Recyclable

Copper is 100% recyclable, making these washers an environmentally responsible choice. We also ensure sustainable manufacturing practices at our facility in Mumbai.

10. Bulk Availability with Customization Options

As a manufacturer, we offer large-volume supplies with flexible customization in thickness, diameter, and packaging, ensuring OEMs, distributors, and contractors receive precisely what they need.

These advantages make our M6 copper plain washers a trusted choice in high-performance and high-reliability applications across India and globally.

FAQs for M6 Copper Plain Washers

What is an M6 copper plain washer?

An M6 copper plain washer is a flat, circular component with a 6mm inner diameter, commonly used to distribute load and improve conductivity in mechanical and electrical assemblies.What are the applications of M6 copper washers?

M6 copper washers are widely used in automotive, electrical, plumbing, and HVAC systems for grounding, sealing, and reducing galvanic corrosion.Is copper a good material for plain washers?

Yes, copper is highly conductive, corrosion-resistant, and malleable, making it ideal for washers used in electrical and industrial environments.Where can I buy high-quality M6 copper plain washers?

You can purchase premium-grade M6 copper plain washers from Nafees Metal Industries, a trusted manufacturer and supplier with bulk order facilities.What is the outer diameter and thickness of an M6 copper washer?

Standard dimensions may vary, but typically an M6 copper washer has an outer diameter of 12 mm to 14 mm and a thickness of 1 mm to 2 mm. Custom sizes are also available on request.Are M6 copper washers suitable for electrical grounding?

Yes, copper’s excellent electrical conductivity makes M6 copper washers ideal for grounding applications in electrical panels and circuits.Can I use M6 copper washers in plumbing systems?

Yes, copper washers are commonly used in plumbing for sealing joints, especially in high-pressure systems or where corrosion resistance is critical.Do you offer bulk orders or custom manufacturing?

Yes, Nafees Metal Industries offers custom manufacturing and bulk supply of M6 copper plain washers tailored to your industrial requirements.How do M6 copper washers differ from stainless steel washers?

Unlike stainless steel, copper washers offer better electrical and thermal conductivity and are softer, making them suitable for sealing and vibration damping.What standards or grades are followed for M6 copper washers?

Our M6 copper washers are manufactured as per IS, DIN, and international standards to ensure dimensional accuracy and performance.Are copper plain washers reusable?

Copper washers can be reused in non-critical applications; however, for best performance, especially in sealing or high-temperature use, replacement is recommended.Do you provide certification or test reports with the washers?

Yes, upon request, we provide material test certificates (MTC), RoHS compliance, and other quality documentation with all our washer products.Can M6 copper washers handle high temperatures?

Yes, copper washers can withstand temperatures up to 400°C, making them ideal for use in engines, heating systems, and industrial furnaces.What is the minimum order quantity (MOQ) for M6 copper plain washers?

The MOQ depends on the size and finish, but we offer flexible ordering options for both small and bulk quantities.How soon can I get delivery for M6 copper plain washers?

Delivery times range from 2 to 7 days depending on order size and location. For urgent orders, we offer express dispatch options.

M6 Copper Plain Washers (DIN 125)

27 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M6

Inner Diameter (ID): 6.4 mm

Outer Diameter (OD): 12 mm

Thickness (t): 1.6 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:12 days

M6 Copper Plain Washer – High-Conductivity Flat Washers for Precision Fastening Applications

Nafees Metal Industries proudly presents the M6 Copper Plain Washer, a high-quality fastening component designed for superior conductivity, exceptional corrosion resistance, and effective load distribution. Manufactured at our advanced facility in Mumbai, these copper washers are engineered to deliver reliable performance in electrical, automotive, HVAC, and heavy-duty mechanical assemblies.

As one of the best copper washer manufacturers in India, we specialize in crafting precision-engineered washers that comply with global standards. Our M6 copper plain washers are widely used for grounding, sealing, and fastening tasks where electrical conductivity and durability are crucial. With optimized tolerances and surface finish, these washers serve as a reliable solution for professionals who demand consistent results in both industrial and commercial applications.

Whether you are working with battery terminals, circuit assemblies, or hydraulic fittings, the M6 copper plain washer is your go-to solution for a robust and stable fastening system. With options for customized thickness, coating, and bulk packaging, we are fully equipped to fulfill small to large-volume requirements across India and worldwide.

What is M6 Copper Plain Washer?

M6 Copper Plain Washer is a flat, circular disc with a center hole precisely sized to fit M6 bolts or screws (6 mm in diameter). These washers are designed to distribute the load of a threaded fastener more evenly across the surface, prevent damage to the assembled parts, reduce friction during tightening, and improve the longevity of the fastening joint. Made from pure or high-grade copper, these washers also offer excellent electrical and thermal conductivity, making them ideal for electrical assemblies and high-heat environments.

At Nafees Metal Industries, every M6 copper plain washer is manufactured under strict quality standards to ensure accurate inner and outer diameters, uniform thickness, and a smooth surface finish. They are particularly favored in situations where both mechanical performance and electrical contact are required, such as grounding terminals, automotive battery connections, electronic circuit boards, and HVAC units.

Due to copper’s natural resistance to corrosion and its superior ability to conduct electricity, the M6 copper plain washer is also commonly used in sensitive equipment where long-term reliability is essential. It plays a dual role: acting as a mechanical buffer and ensuring electrical continuity or grounding in circuits.

We offer copper flat washer M6 size in a variety of finishes—plain (uncoated), tin-plated, or oxidized—depending on your application requirements. These washers meet relevant standards such as DIN 125, DIN 7603A, or custom tolerances as specified by OEMs.

Whether you’re an electrical contractor, HVAC installer, auto technician, or industrial OEM, our flat washer copper products guarantee quality and consistency across every unit. We supply bulk quantities to distributors, manufacturers, and assembly lines across India and international markets.

Why Choose Copper for M6 Plain Washers?

Copper is one of the most preferred materials for flat washers due to its unique combination of mechanical strength, chemical stability, and exceptional electrical and thermal conductivity. When it comes to small fasteners like the M6 copper plain washer, copper offers a set of advantages that make it ideal for both general-purpose and high-performance industrial applications.

Here’s why copper is the ideal choice for M6 plain washers:

1. Excellent Electrical Conductivity

The primary reason copper is chosen for washers—especially in electrical systems—is its unmatched ability to conduct electricity. The M6 copper plain washer ensures minimal resistance in grounding applications and provides a consistent electrical path in terminal connections and PCB assemblies.

2. Superior Corrosion Resistance

Copper naturally forms a protective oxide layer that prevents it from rusting. This makes our M6 copper plain washers highly suitable for use in moist, corrosive, or outdoor environments—including marine and HVAC installations. Compared to steel, copper lasts longer without degrading in chemically exposed applications.

3. High Thermal Conductivity

Copper’s ability to dissipate heat makes it ideal for use in heat-sensitive or high-temperature applications, such as electrical enclosures or automotive parts near the engine. The M6 copper plain washer helps in minimizing heat buildup at fastening points, reducing the risk of thermal stress.

4. Ductility and Malleability

Copper washers can compress slightly under pressure without cracking, which helps in creating a better seal in assemblies like brake lines, oil filters, or hydraulic systems. This is particularly important for copper flat washer M6 size, which is often used in fluid sealing and vibration-prone applications.

5. Eco-Friendly & Recyclable

Copper is 100% recyclable without loss of quality. At Nafees Metal Industries, we adopt environmentally responsible manufacturing practices, ensuring that our M6 copper plain washers not only perform well but also contribute toward sustainable engineering and green procurement goals.

6. Versatile Finishing Options

We offer plain, tin-plated, or oxide-treated M6 copper washers based on customer-specific use cases. Whether you need improved surface conductivity or better corrosion resistance, our washers are adaptable to diverse needs.

In summary, copper is not just a metal—it’s a performance material. Our M6 copper plain washer combines material science with precision engineering to deliver a product that exceeds expectations across mechanical, electrical, and chemical performance criteria.

How Are M6 Copper Plain Washers Manufactured?

At Nafees Metal Industries, we follow a stringent, ISO-compliant manufacturing process to produce high-quality M6 copper plain washers that meet both domestic and international standards. Our manufacturing unit in Mumbai is equipped with advanced power press machines, precision stamping dies, and automated inspection systems that ensure consistency in every washer produced.

Here’s a step-by-step breakdown of how our M6 copper plain washers are made:

1. Raw Material Selection

We source high-grade electrolytic copper sheets or coils with certified purity levels to ensure excellent conductivity and corrosion resistance. Only copper that meets our strict metallurgical and dimensional criteria is used to manufacture our M6 copper plain washers.

2. Cold Stamping (Punching Process)

Using hydraulic or mechanical power press machines, copper sheets are cold-stamped with precision tooling to create perfectly round washers with an inner diameter (ID) of ~6.4 mm to fit M6 bolts. The M6 copper plain washer is designed to match industry-standard dimensions such as DIN 125, DIN 7603A, or IS 2016.

3. Deburring and Edge Finishing

After stamping, the washers go through a deburring process where sharp edges and burrs are removed. This step ensures smooth surface contact, which is especially important in electrical applications where poor contact can lead to overheating or failure.

4. Surface Treatment (Optional)

Depending on the application and customer requirements, the M6 copper plain washer can undergo various surface treatments such as:

Tin plating – for improved corrosion resistance and solderability

Oxidation or passivation – for a non-reflective, corrosion-resistant finish

Plain finish – with polished copper surface for maximum conductivity

5. Quality Inspection

Every batch of M6 copper plain washers is tested for dimensional accuracy, thickness uniformity, surface smoothness, and electrical conductivity. We use micrometers, calipers, concentricity gauges, and visual inspection systems to guarantee that only defect-free washers leave our premises.

6. Customization and Packaging

We offer tailored thickness (typically 1.0–1.5 mm), ID/OD ratios, and finishing options based on your specifications. Washers are packed in:

Bulk poly bags or corrugated cartons

Custom-labeled boxes for OEMs

Export-grade packaging with documentation and HS codes for international shipments

Our focus on precision engineering, bulk readiness, and finish customization makes us the go-to choice for best copper washer manufacturers in India—especially for clients requiring copper flat washer M6 size in volume with consistent quality.

Key Features of M6 Copper Plain Washers

At Nafees Metal Industries, we take pride in delivering M6 copper plain washers that combine superior design, material purity, and manufacturing precision. Our washers are not just components—they are high-performance solutions tailored for demanding electrical, mechanical, and sealing applications.

Below are the key features that make our M6 copper plain washers the preferred choice for industrial and commercial use:

1. Precision Fitment

Every M6 copper plain washer is manufactured to fit snugly with standard M6 bolts and screws (6 mm). This ensures reliable load distribution, proper clamping force, and minimal movement under vibration or thermal expansion.

2. High Conductivity Copper Material

Crafted from premium-grade copper, these washers ensure low electrical resistance and superior conductivity. Ideal for grounding, power transmission, and electrical contact applications.

3. Effective Load Distribution

The M6 copper plain washer acts as a buffer between the fastener and the substrate, preventing surface damage, wear, and stress concentration during tightening. This extends the lifespan of assemblies, especially in electronic and automotive setups.

4. Corrosion Resistance

Thanks to the natural corrosion-resistant properties of copper, our washers perform well in environments prone to moisture, oxidation, or chemical exposure. For enhanced durability, we also offer tin-plated or oxidized finishes.

5. Customizable Dimensions

Need a specific thickness or outer diameter? Our washers can be customized to meet DIN, ISO, or unique OEM requirements, making them ideal for specialized applications in industrial assemblies and maintenance.

6. Smooth Surface and Burr-Free Edges

Each M6 copper plain washer is deburred and polished to ensure smooth edges, which prevent scratching or damage to sensitive components during assembly. This also aids in achieving better electrical contact.

7. Mechanical and Thermal Stability

Copper’s malleability allows the washer to compress slightly for a tighter seal without cracking. These properties make it ideal for use in high-vibration or high-temperature environments.

8. Wide Application Compatibility

Whether used in automotive electronics, HVAC systems, battery terminals, or circuit boards, our flat washer copper delivers consistent results and long-term performance.

9. Made in India with Global Standards

Manufactured at our Mumbai facility, our washers comply with standards like DIN 125, DIN 7603A, and IS 2016. We are proud contributors to the Make in India initiative and deliver quality that rivals global competitors.

10. Bulk Supply and Custom Packaging

Available in large volumes with quick delivery, we offer flexible packaging options such as bulk poly bags, labeled boxes, and export-ready cartons to suit distributors, OEMs, and contractors.

These features position our M6 copper plain washer range as the most reliable and cost-effective choice across industrial sectors. Whether your application is electrical, thermal, or sealing-critical, you can count on us to deliver quality without compromise.

Technical Specifications of M6 Copper Plain Washer

At Nafees Metal Industries, we ensure that every M6 copper plain washer meets precise engineering and dimensional standards for superior fit, durability, and performance. Below are the detailed technical specifications of our product:

| Property | Specification |

|---|---|

| Product Name | M6 Copper Plain Washer |

| Material | High-Grade Copper (99% Purity or as per customer specification) |

| Inner Diameter (ID) | Approximately 6.4 mm (Fits standard M6 bolts and screws) |

| Outer Diameter (OD) | Standard: 12 mm to 18 mm (Customizable based on application) |

| Thickness | Standard: 1.0 mm to 1.5 mm (Custom thickness available on request) |

| Surface Finish | Plain / Tin-Plated / Oxidized (Optional based on corrosion or conductivity needs) |

| Hardness | Soft Annealed or Half-Hard (as required) |

| Conductivity | Excellent (Ideal for electrical grounding and contact applications) |

| Temperature Range | -40°C to +200°C (Suitable for high-heat applications) |

| Corrosion Resistance | High – Natural Copper Resistance; Enhanced with Plating |

| Standard Compliance | DIN 125 / DIN 7603A / IS 2016 / Custom Dimensions |

| Application Category | Electrical, Mechanical, Automotive, HVAC, Sealing, Fastening Systems |

| Packaging | Bulk Poly Bags / Small Pack Boxes / Export-Grade Cartons |

| Manufacturing Location | Mumbai, Maharashtra, India |

| HS Code | 74153300 (Used for copper washers in export documentation) |

Our in-house engineering team can also develop custom tooling and dies for non-standard copper washer sizes and tolerances. Each M6 copper plain washer is batch-coded and inspected under strict ISO-compliant processes to maintain traceability and performance assurance.

These specifications ensure that our washers meet the mechanical, electrical, and environmental requirements of both Indian and global customers.

Applications of M6 Copper Plain Washers

The M6 copper plain washer is widely recognized for its dual-purpose performance in mechanical fastening and electrical conductivity. Its design, material properties, and precise dimensions make it suitable across diverse industries. At Nafees Metal Industries, we manufacture these washers to cater to a broad range of applications, ensuring consistent results even under demanding conditions.

Here are the primary application areas of the M6 copper flat washer:

1. Electrical Terminals and Grounding Systems

Copper’s high electrical conductivity makes the M6 copper plain washer a perfect fit for grounding applications, terminal lugs, and switchgear panels. It ensures consistent current flow and reduces resistance in live connections.

2. Automotive and Battery Assemblies

Used in automotive battery terminals, sensor connections, and electronic modules, the Copper flat washer metric size M6 provides stable fastening while withstanding engine heat and vibration. It also prevents galvanic corrosion between dissimilar metals.

3. Printed Circuit Boards (PCBs)

In sensitive electronic systems, copper washers act as a buffer and a grounding medium. The M6 copper washer prevents stress on circuit boards during tightening and maintains stable contact in electronic assemblies.

4. HVAC Equipment and Compressors

For air conditioning units, heat pumps, and industrial compressors, these washers help ensure secure assembly of copper tubing, electrical enclosures, and vibration-prone joints.

5. Hydraulic and Pneumatic Systems

The flat washer copper type is widely used in sealing hydraulic fittings, fuel lines, and brake systems to avoid leaks. Its malleability ensures tight sealing in high-pressure systems.

6. Solar and Renewable Energy Installations

In solar panels and renewable setups, copper washers play a role in conductive mounting and grounding. Our M6 copper plain washer ensures corrosion resistance and long-term performance under outdoor exposure.

7. Aerospace and Marine Applications

Due to its corrosion resistance, copper is the preferred material in marine environments and aerospace components. The M6 copper Flat washer helps secure fixtures while resisting saltwater or humid exposure.

8. Consumer Electronics and Appliances

From laptops and televisions to fans and mixers, our M6 copper plain washers are integrated in internal assemblies for grounding, vibration absorption, and proper load distribution.

9. Industrial Machinery and Control Panels

In heavy-duty machinery, control units, and automation panels, copper washers prevent spark generation, ensure stable clamping force, and protect against wear caused by vibrations.

10. Maintenance, Repair & Overhaul (MRO)

They are commonly included in fastener kits, servicing toolkits, and emergency repair units for on-site use by engineers, technicians, and mechanics.

With such broad usage across multiple industries, the M6 copper Flat washer is not just a small part—it is a crucial component in ensuring safety, stability, and functionality in critical applications.

Advantages of Using M6 Copper Plain Washers

Choosing the right washer is essential to ensuring reliable mechanical joints and long-term performance, especially in electrical and corrosive environments. The M6 copper plain washer stands out due to its excellent material properties, precision fit, and versatile usage. At Nafees Metal Industries, our washers are crafted to deliver consistent performance, making us one of the best copper washer manufacturers in India.

Here are the key advantages of using M6 copper washers:

1. Superior Electrical Conductivity

Copper is the second-best conductor of electricity after silver. This makes the M6 copper washer ideal for grounding, power transmission, and maintaining electrical continuity in sensitive devices.

2. Uniform Load Distribution

These washers help evenly distribute the pressure of bolts and screws, reducing the risk of surface damage or material deformation during tightening. They are especially useful in delicate assemblies like electronics or soft metal surfaces.

3. Excellent Corrosion Resistance

Copper forms a natural oxide layer that protects against corrosion. Whether in humid, coastal, or chemically exposed environments, the M6 copper plain washer maintains its integrity and performance.

4. Thermal Stability in High-Heat Applications

With a high melting point and excellent heat dissipation capacity, copper washers withstand elevated temperatures. Ideal for engine parts, electrical enclosures, or HVAC systems where heat is a concern.

5. Tight Sealing Capability

Due to copper’s ductility, these washers conform to mating surfaces, creating a tight seal. This makes the flat washer copper type a preferred choice in hydraulic, pneumatic, and brake line applications.

6. Versatility Across Industries

From automotive to aerospace, electronics to solar, and HVAC to industrial machinery, the M6 copper plain washer serves a wide array of sectors thanks to its mechanical strength and conductive properties.

7. Compatible with a Variety of Coatings and Finishes

We offer plain, tin-plated, or oxidized versions of our M6 copper plain washers to meet specific application needs—whether it’s solderability, enhanced corrosion resistance, or anti-reflective requirements.

8. Cost-Effective Long-Term Performance

Though copper is costlier than mild steel, its durability, conductivity, and corrosion resistance translate into long-term value. These washers reduce the risk of failure, downtime, and maintenance in critical applications.

9. Eco-Friendly and Recyclable

Copper is 100% recyclable, making these washers an environmentally responsible choice. We also ensure sustainable manufacturing practices at our facility in Mumbai.

10. Bulk Availability with Customization Options

As a manufacturer, we offer large-volume supplies with flexible customization in thickness, diameter, and packaging, ensuring OEMs, distributors, and contractors receive precisely what they need.

These advantages make our M6 copper plain washers a trusted choice in high-performance and high-reliability applications across India and globally.

FAQs for M6 Copper Plain Washers

What is an M6 copper plain washer?

An M6 copper plain washer is a flat, circular component with a 6mm inner diameter, commonly used to distribute load and improve conductivity in mechanical and electrical assemblies.What are the applications of M6 copper washers?

M6 copper washers are widely used in automotive, electrical, plumbing, and HVAC systems for grounding, sealing, and reducing galvanic corrosion.Is copper a good material for plain washers?

Yes, copper is highly conductive, corrosion-resistant, and malleable, making it ideal for washers used in electrical and industrial environments.Where can I buy high-quality M6 copper plain washers?

You can purchase premium-grade M6 copper plain washers from Nafees Metal Industries, a trusted manufacturer and supplier with bulk order facilities.What is the outer diameter and thickness of an M6 copper washer?

Standard dimensions may vary, but typically an M6 copper washer has an outer diameter of 12 mm to 14 mm and a thickness of 1 mm to 2 mm. Custom sizes are also available on request.Are M6 copper washers suitable for electrical grounding?

Yes, copper’s excellent electrical conductivity makes M6 copper washers ideal for grounding applications in electrical panels and circuits.Can I use M6 copper washers in plumbing systems?

Yes, copper washers are commonly used in plumbing for sealing joints, especially in high-pressure systems or where corrosion resistance is critical.Do you offer bulk orders or custom manufacturing?

Yes, Nafees Metal Industries offers custom manufacturing and bulk supply of M6 copper plain washers tailored to your industrial requirements.How do M6 copper washers differ from stainless steel washers?

Unlike stainless steel, copper washers offer better electrical and thermal conductivity and are softer, making them suitable for sealing and vibration damping.What standards or grades are followed for M6 copper washers?

Our M6 copper washers are manufactured as per IS, DIN, and international standards to ensure dimensional accuracy and performance.Are copper plain washers reusable?

Copper washers can be reused in non-critical applications; however, for best performance, especially in sealing or high-temperature use, replacement is recommended.Do you provide certification or test reports with the washers?

Yes, upon request, we provide material test certificates (MTC), RoHS compliance, and other quality documentation with all our washer products.Can M6 copper washers handle high temperatures?

Yes, copper washers can withstand temperatures up to 400°C, making them ideal for use in engines, heating systems, and industrial furnaces.What is the minimum order quantity (MOQ) for M6 copper plain washers?

The MOQ depends on the size and finish, but we offer flexible ordering options for both small and bulk quantities.How soon can I get delivery for M6 copper plain washers?

Delivery times range from 2 to 7 days depending on order size and location. For urgent orders, we offer express dispatch options.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch