No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M8 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M5 Mild Steel Plain Washers – Reliable Mild Steel Flat Washers for Precision Fastening

Introduction

No matter how sophisticated your assembly is — from tiny electrical panels to precision machinery — even the smallest fastener accessories can make or break the job. One such unsung hero is the humble yet vital M5 Mild Steel Plain Washer.

These washers might be small in size, but their role is huge: they distribute load, protect surfaces, and keep bolts tight. Whether you’re a machine builder, contractor, fabricator, or a DIY enthusiast, you need washers you can trust.

At Nafees Metal Industries, we’ve spent decades perfecting our Mild Steel Flat Washers, including the entire M5 series. As the Best M5 MS Plain Washers Manufacturer, we deliver washers that meet strict dimensional tolerances, durability requirements, and bulk supply needs — backed by responsive support.

In this detailed guide, you’ll learn everything you need to know about M5 Mild Steel Plain Washers, how they work, what makes them unique, and why our clients trust us as their long-term washer partner.

Role of Washers in Industrial Applications

Fasteners create secure joints in all kinds of assemblies. But if you tighten a bolt or nut without a washer, you risk:

Damage to the material under the bolt head.

Uneven load distribution that leads to deformation or cracks.

Loosening of bolts under vibration.

That’s where M5 Mild Steel Plain Washers come in. For small bolts like M5s — commonly used in electronics, automotive parts, metal enclosures, and light machinery — these washers help keep everything tight and protected.

What Are M5 Mild Steel Plain Washers?

A M5 Mild Steel Plain Washer is a round flat disc with a precise inner hole to fit an M5 bolt or screw snugly. Its main purpose is to spread the load of the fastener across a wider surface area.

Key functions:

Load Distribution: Prevents local stress points that can weaken materials.

Surface Protection: Stops scratching, denting, or paint removal during tightening.

Vibration Resistance: Helps maintain bolt tightness in applications subject to minor movement.

Corrosion Control (when coated): Protects the bolt hole from moisture ingress.

Material Details: Why Mild Steel?

M5 Mild Steel Plain Washers are made from standard mild steel (low carbon steel). This material offers a perfect balance of strength, formability, and economy.

Why Mild Steel for Plain Washers?

Tensile Strength: Strong enough to withstand repeated tightening and removal cycles.

Workability: Easy to stamp to tight tolerances.

Cost-Effectiveness: A smart choice for bulk usage without overshooting budgets.

Versatility: Can be zinc-plated or phosphate-coated for extra corrosion protection.

Compatibility: Works well with standard mild steel bolts, nuts, or screws.

Compared to stainless steel, mild steel costs less while providing more than enough strength for light-to-moderate duty connections.

Manufacturing and Technical Specifications

Our M5 Mild Steel Plain Washers are manufactured in-house at our ISO-certified facility in Mumbai.

Our Process:

Raw Material: Certified mild steel sheets that comply with IS/ISO standards.

Precision Punching: CNC-controlled presses ensure each washer’s inner and outer diameter meets tight tolerances.

Deburring: Automated deburring lines remove sharp edges, making the washers safe to handle.

Surface Finish: Plain oiled, zinc-plated, or phosphate-coated options available.

Quality Checks: Random sampling, dimensional checks, and coating thickness inspections.

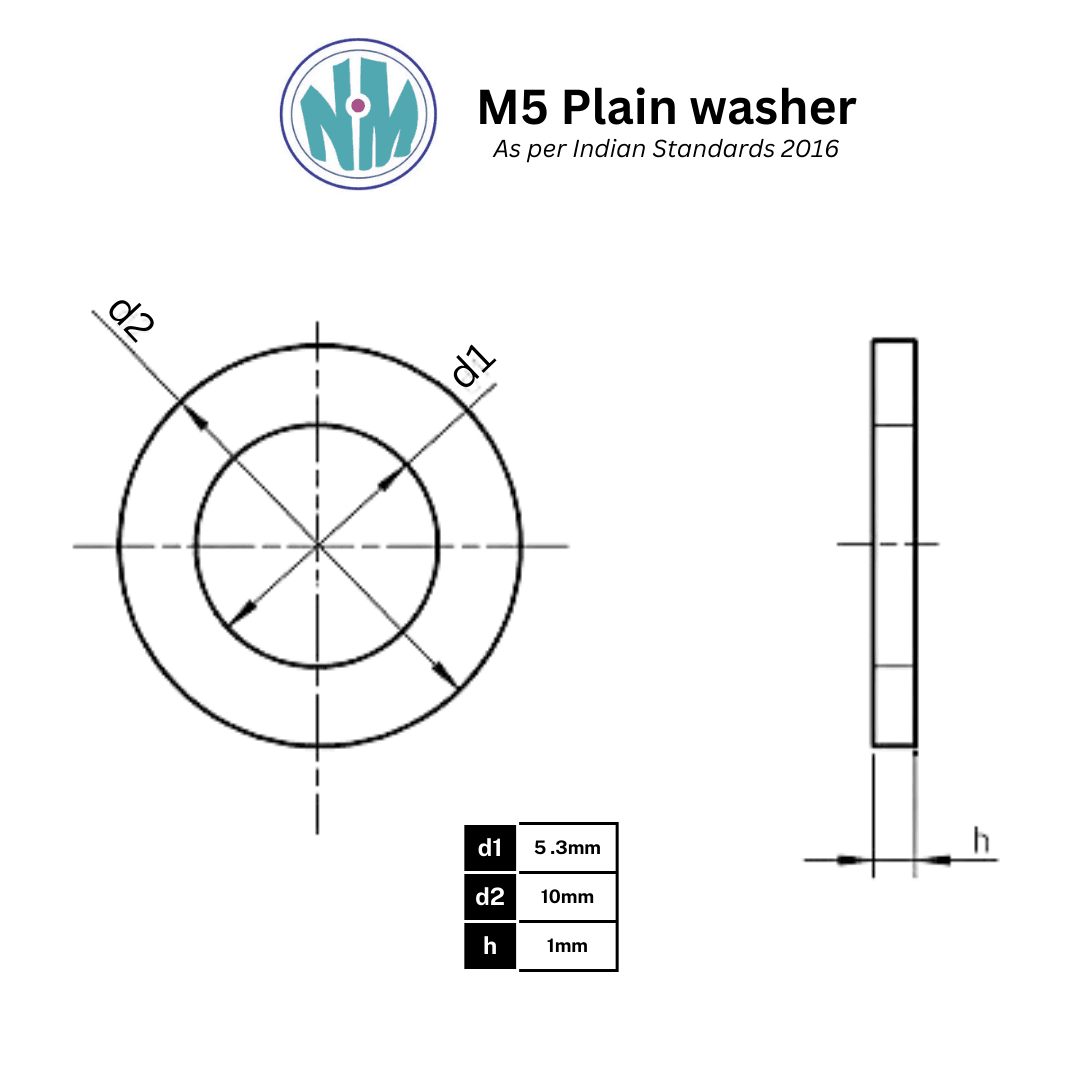

Typical Specs for M5 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 5.3 mm (fits M5 bolts snugly) |

| Outer Diameter | 10–12 mm |

| Thickness | As per DIN/IS standards |

| Finish | Plain / Zinc-Plated / Phosphate |

| Material | Mild Steel |

| Shape | Flat Disc |

Key Features

When you choose M5 Mild Steel Plain Washers, you’re investing in a simple yet crucial fastener component that delivers multiple technical and practical benefits. Below, you’ll find an in-depth explanation of each feature, how it works, and why it matters in real-world applications.

1. Accurate Load Distribution

One of the main roles of any plain washer is to spread the load of a bolt or screw evenly over the surface. For small-diameter bolts like M5, this becomes even more important because the clamping force is concentrated on a tiny area.

Without a washer, when you torque an M5 bolt directly onto soft materials like aluminum or thin sheet metal, you risk:

Punching through the material

Causing local deformation around the hole

Weakening the structural integrity of the assembly

With M5 Mild Steel Plain Washers, the pressure is distributed over a larger surface area. This means the base material can withstand the bolt’s clamping force without permanent distortion. It also helps when you’re working with layered materials, like painted metal or coated panels, because the washer reduces the risk of damaging protective coatings.

In automated assembly lines, consistent load distribution is critical. Each bolt should clamp with the same force, ensuring a reliable, repeatable joint that holds up under operational stress. This small, inexpensive washer makes that consistency possible.

2. Superior Surface Protection

Painted, powder-coated, or anodized surfaces look good, but they’re also the first line of defense against corrosion. If you bolt directly onto a coated surface, the bolt head can cut into the finish. Once the coating is damaged, moisture and air reach the base metal, leading to corrosion over time.

M5 Mild Steel Plain Washers create a buffer between the fastener and the material beneath it. This protects the coating from scratching, chipping, or peeling under tightening pressure.

In industries like control panel fabrication, electronics, or decorative metalwork, this is critical because surface appearance and corrosion resistance go hand-in-hand. Clients expect a polished, intact finish, even around bolt heads — and plain washers deliver exactly that.

3. Vibration Resistance

You might not think vibration is a big deal for small M5 fasteners, but consider:

Control panels in factories that run 24/7.

Small machinery or equipment mounted on vibrating surfaces.

Vehicles, trailers, or fixtures that are subject to road or mechanical vibration.

In these scenarios, fasteners are constantly exposed to micro-movements. Without a washer, this vibration can cause the bolt or nut to slowly loosen. This is especially problematic when you’re fastening parts that cannot easily be re-tightened during normal maintenance.

A high-quality M5 Mild Steel Plain Washer acts as a stabilizing barrier. It increases the friction surface area, which helps the bolt or nut resist loosening under small shifts. Combined with thread-locking techniques or additional locking washers, you can create a fastening system that stays secure for the entire service life of the equipment.

4. Durability and Reusability

Unlike some hardware components that need frequent replacement, a properly installed M5 Mild Steel Plain Washer can last through multiple installation and removal cycles. This is thanks to the ductility and strength of mild steel.

In maintenance operations, this is a big advantage:

You can safely reuse washers when repairing or replacing other fastener parts.

They maintain their shape without significant deformation.

Their protective coating (zinc or phosphate) helps them resist rust if stored properly.

This means you get more value from each unit, especially when you Buy M5 Mild Steel Washers in Bulk for production or service teams.

5. Budget-Friendly without Compromise

Compared to stainless steel, exotic alloys, or polymer washers, mild steel is the most cost-effective choice for general-purpose fastening. It provides reliable strength and flexibility at a fraction of the cost of premium materials.

This is why Mild Steel Flat Washers are the default option in industries like automotive, light machinery, furniture, and electrical equipment manufacturing. You get performance that’s “good enough” for 90% of standard applications, with easy customization for coatings if you need extra corrosion protection.

When you’re buying millions of washers per year, that cost difference adds up to significant savings — without any drop in quality or reliability.

6. Flexible Coating and Corrosion Protection

Although mild steel alone is susceptible to rust in humid or outdoor conditions, it’s easily protected with simple and affordable finishes. M5 Mild Steel Plain Washers can be ordered plain, oiled, zinc-plated, or phosphate-coated.

Zinc Plating: Adds a bright, rust-resistant surface that’s ideal for indoor applications where humidity is moderate.

Phosphate Coating: Offers a matte, non-reflective finish and mild corrosion resistance, perfect for components that need better paint adhesion or are assembled in slightly harsher environments.

Customized Finishes: Large bulk orders can even include specialized coatings for unique requirements.

This adaptability means mild steel washers can be tailored to match the life expectancy and exposure of your project — from sealed enclosures to open workshop installations.

7. Easy Compatibility with Automation

Many of today’s high-volume manufacturers rely on automated pick-and-place or vibration bowl feeding systems to install small fasteners. For automation to work flawlessly, each washer must be consistently dimensioned with tight tolerances on inner and outer diameters and flatness.

Nafees Metal Industries manufactures M5 Mild Steel Plain Washers to strict standards so they move smoothly through feeders and fit perfectly with M5 bolts and screws. This minimizes jams, misfeeds, and downtime on your assembly line.

For OEMs, this saves hours of lost production and avoids frustrating bottlenecks.

8. Compact, Lightweight, and Space-Saving

Small fasteners often go into tight spaces, so the washers used must be dimensionally precise and low-profile. The standard thickness of an M5 Mild Steel Plain Washer is optimized to provide adequate load spreading without interfering with surrounding components.

For example:

In PCB mounting, the washer must not lift the board too high or obstruct adjacent connectors.

In light frames, the washer should allow flush fitting of covers or panels.

These details matter for engineers designing enclosures, brackets, or machine parts that need to stay compact while still being secure.

9. Easy to Order and Replace

Unlike specialty washers that can be difficult to source, M5 Mild Steel Plain Washers are readily available in standard and custom sizes. This makes repairs and maintenance straightforward:

No waiting weeks for rare replacements.

Simple stocking and inventory planning.

Flexible minimum order quantities for smaller repair jobs or large manufacturing runs.

By working with the Best M5 MS Plain Washers Manufacturer, you’re guaranteed consistent dimensions and quality, so each replacement matches perfectly.

10. Customization Options

If you have a unique requirement, mild steel washers can be modified cost-effectively:

Adjust inner or outer diameter for special fasteners.

Use special grades of mild steel for extra strength.

Apply custom coatings or plating for added durability.

Create bulk packaging kits tailored to assembly line needs.

This level of customization ensures that the humble washer is never a weak point in your design — it’s a precise, dependable part of your entire fastening system.

Applications & Use Cases

Where do people use M5 Mild Steel Plain Washers?

Electronics: Circuit board mounting, control panels, and enclosures.

Automotive: Securing brackets, panels, or interior trim pieces.

Light Machinery: Small conveyor systems, light-duty fabrication.

General Fastening: Furniture assembly, household repairs, DIY projects.

Electrical Installations: Protect surfaces when mounting fixtures or junction boxes.

Why Buy M5 Mild Steel Washers in Bulk – Best M5 MS Flat Washers for Industrial Use

When you Buy M5 Mild Steel Washers in Bulk, you benefit in multiple ways:

Cost Savings: Bulk pricing keeps your unit cost low for large production runs.

Quality Consistency: Every washer comes from the same controlled batch for uniform performance.

Inventory Planning: Ensure you always have enough stock to keep assembly lines running.

Custom Packing: Receive washers pre-packed by size, coating, or assembly line requirement.

Technical Support: Our engineers help you match washer specs to your fastener and material needs.

Why Choose the Best M5 MS Plain Washers Manufacturer

Nafees Metal Industries is your trusted Best M5 MS Flat Washers for Industrial Use because:

We offer 100% in-house production.

Our washers match global dimensional standards.

We supply consistent quality for high-volume or custom orders.

We provide custom coatings and packaging.

We’re responsive and support your procurement team every step of the way.

Installation Tips

Always clean the bolt and surface.

Align washers properly under bolt heads and nuts.

Use dual washers for extra load spread on thin sheets.

Don’t overtighten small fasteners to prevent stripping threads.

Choose coated washers if exposed to moisture or humidity.

Maintenance Guidelines

Inspect during routine equipment checks.

Replace any washers showing cracks or corrosion.

Keep unused washers dry and sealed.

Use the right coating for your environment to extend washer lifespan.

Case Study: Control Panel Assembly Upgrade

Background

A mid-sized electrical equipment manufacturer based in India produces modular industrial control panels for clients in the automotive and textile industries. Each panel contains dozens of delicate PCBs, relays, and connectors that must be securely mounted onto an aluminum chassis.

During production, the company faced a recurring quality problem: hairline cracks and surface dents were appearing around the bolt holes on the aluminum chassis, especially when workers installed or retightened the M5 bolts that held the PCBs and terminal blocks in place.

The Problem

The manufacturer used M5 bolts directly on the powder-coated aluminum panels without any washers. Over time, this caused multiple issues:

Paint Layer Damage:

The direct contact between the bolt head and the soft aluminum surface damaged the powder-coated layer, exposing bare metal underneath. This reduced corrosion resistance, especially in humid environments.Local Stress Points:

When the bolt was torqued, the entire clamping force was focused on a very small area, leading to micro-cracks. Under vibration or thermal expansion, these cracks expanded, weakening the mounting holes.Rework and Downtime:

Frequent damage meant the assembly team had to rework panels. Re-drilling or replacing parts delayed production schedules and increased costs.

The Consultation

The company reached out to Nafees Metal Industries, a trusted supplier for Mild Steel Flat Washers and MS fasteners. Our technical team visited the factory, reviewed the assembly process, and quickly identified that using M5 Mild Steel Plain Washers could eliminate the stress issues.

We explained how washers:

Distribute the bolt load over a wider surface area.

Act as a barrier between the bolt head and the painted surface.

Reduce local deformation.

Help maintain bolt tightness, especially in applications with minor vibration.

The Solution

Our team recommended high-precision M5 Mild Steel Plain Washers with a zinc-plated finish for improved corrosion resistance. We supplied them in bulk, organized by line and station, so assembly workers could easily integrate them into their existing processes.

Key steps we implemented:

Provided free samples for initial fitment testing.

Conducted a pilot run on two production lines.

Trained line supervisors on proper washer placement and torque settings.

Monitored results for 6 weeks before the full rollout.

Implementation

In the pilot phase, each mounting point now included a M5 Mild Steel Plain Washer between the bolt head and the aluminum chassis.

Key improvements:

Load was evenly spread, eliminating local stress spots.

The zinc-plated washers protected the painted surface from direct contact.

During thermal cycles and equipment vibration, the bolts stayed secure.

Assembly workers reported easier, more consistent torque application.

Encouraged by the pilot success, the company approved a full switch to M5 Mild Steel Plain Washers across all its panel lines.

Quantifiable Results

The improvements were significant:

Zero panel rework:

Before using washers, an average of 15–20% of panels required rework due to cracks. After the upgrade, defect rates dropped by 95%.Longer product lifespan:

End customers reported fewer cases of corrosion near mounting holes.Faster assembly:

Workers found it easier to torque bolts properly, reducing assembly time by 10–12%.Cost savings:

The company estimated annual savings of over ₹8–10 lakh by eliminating panel scrap and overtime labor.Improved brand reputation:

Their biggest clients appreciated the improved build quality and reliability.

Detailed Impact Analysis

| Aspect | Before Washers | After Using M5 Mild Steel Plain Washers |

|---|---|---|

| Panel rejection rate | 15–20% | < 1% |

| Avg. repair time/panel | 30–45 mins | Negligible |

| Maintenance complaints | Frequent surface corrosion | Zero in first year |

| Fastener loosening | Common under vibration | None reported |

| Annual rework cost | ₹10–12 lakh | ~₹50,000 |

| Worker fatigue | High due to rework | Lower, more efficient output |

Customer Feedback

The plant’s production manager shared:

“We underestimated the role of washers in such small fasteners. By switching to M5 Mild Steel Plain Washers, we not only solved cracking and paint issues but also improved the overall fit and finish of our panels. Clients noticed the difference right away.”

Lessons Learned

Even for small bolts like M5, plain washers are essential for load distribution and surface protection.

Choosing a reliable Best M5 MS Plain Washers Manufacturer means consistent dimensions and quality in bulk.

A protective finish like zinc plating extends the washer’s life, especially in high-humidity conditions.

Bulk supply and organized packing make it easy to integrate washers into automated or manual assembly lines.

The smallest upgrade — like adding M5 Mild Steel Plain Washers — can prevent huge losses in rework and warranty claims.

Where They Are Now

This manufacturer now buys M5 Mild Steel Plain Washers in bulk, included with each batch of fasteners from Nafees Metal Industries. Their panel design specs now mandate the use of washers for every fastener mounting point.

Since the upgrade:

They’ve expanded to supply panels to three new industries.

Their clients trust the panels to last longer, with fewer failures in harsh industrial settings.

They proudly position themselves as an OEM that focuses on small details for big results.

Key Takeaway

This real-world example proves that M5 Mild Steel Plain Washers, when sourced in bulk from a trusted supplier, protect your product, reduce rework, improve end-user confidence, and drive your brand’s quality reputation higher.

If you need to Buy M5 Mild Steel Washers in Bulk, talk to our team at Nafees Metal Industries — we’re here to make sure every bolt you tighten stays tight, every surface stays protected, and every project runs smoothly from start to finish.

Related Products

M3–M10 MS Washers

Custom punched stainless washers for corrosion-critical projects

Spring washers for extra vibration locking

Final Words

Whether you build electronics, light machinery, or do general assembly work, M5 Mild Steel Plain Washers are your best bet for durability, cost-efficiency, and protection. Buy from the Best M5 MS Plain Washers Manufacturer to keep your operations smooth and reliable.

FAQs

What are M5 Mild Steel Plain Washers used for?

They protect surfaces and distribute load under M5 bolts or screws.

Are they reusable?

Yes — just inspect for cracks or corrosion.

Are they suitable for outdoor use?

Use zinc or galvanic coating for better corrosion resistance.

How do they handle vibration?

They buffer vibration to help keep fasteners tight.

What industries use them?

Electronics, automotive, fabrication, electrical, DIY.

Do you provide test certificates?

Yes, MTCs and inspection reports on request.

Do you offer custom thicknesses?

Absolutely — we adjust OD/ID/thickness as needed.

What is the lead time?

7–14 days for standard bulk orders.

Can you export?

Yes — we ship worldwide.

Do you supply samples?

Yes — test fit before bulk purchase.

How should I store them?

Keep sealed in a dry place.

When should I replace them?

Replace if cracked, deformed, or corroded.

What finishes do you offer?

Plain, zinc-plated, phosphate-coated.

Do you have bulk packaging options?

Yes — customized for your line needs.

Why choose Nafees Metal Industries?

Reliable quality, fair pricing, on-time delivery — your trusted partner for M5 Mild Steel Plain Washers.

Why Choose Nafees Metal Industries?

At Nafees Metal industries, we are committed to being your trusted partner when you want to Buy M5 Mild Steel Plain Washers in Bulk. As the Best M5 MS Flat Washers Manufacturer, we use modern machinery and strict quality control to deliver products that meet industry standards every single time. Our dedicated team ensures quick order processing, flexible bulk supply, and outstanding after-sales support.

Whether you are an OEM, contractor, or maintenance professional, you can depend on our M5 Mild Steel Plain Washers for quality, consistency, and value. We invite you to visit our advanced manufacturing facility at Reay Road, Mumbai, or reach out to discuss your unique requirements. We are here to keep your fastening needs secure and hassle-free.

M5 Mild Steel Plain Washers

23 people are viewing this product right now

₹0.13 Original price was: ₹0.13.₹0.11Current price is: ₹0.11. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M5

Inner Diameter (ID): 5.3 mm

Outer Diameter (OD): 10 mm

Thickness (t): 1 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M5 Mild Steel Plain Washers – Reliable Mild Steel Flat Washers for Precision Fastening

Introduction

No matter how sophisticated your assembly is — from tiny electrical panels to precision machinery — even the smallest fastener accessories can make or break the job. One such unsung hero is the humble yet vital M5 Mild Steel Plain Washer.

These washers might be small in size, but their role is huge: they distribute load, protect surfaces, and keep bolts tight. Whether you’re a machine builder, contractor, fabricator, or a DIY enthusiast, you need washers you can trust.

At Nafees Metal Industries, we’ve spent decades perfecting our Mild Steel Flat Washers, including the entire M5 series. As the Best M5 MS Plain Washers Manufacturer, we deliver washers that meet strict dimensional tolerances, durability requirements, and bulk supply needs — backed by responsive support.

In this detailed guide, you’ll learn everything you need to know about M5 Mild Steel Plain Washers, how they work, what makes them unique, and why our clients trust us as their long-term washer partner.

Role of Washers in Industrial Applications

Fasteners create secure joints in all kinds of assemblies. But if you tighten a bolt or nut without a washer, you risk:

Damage to the material under the bolt head.

Uneven load distribution that leads to deformation or cracks.

Loosening of bolts under vibration.

That’s where M5 Mild Steel Plain Washers come in. For small bolts like M5s — commonly used in electronics, automotive parts, metal enclosures, and light machinery — these washers help keep everything tight and protected.

What Are M5 Mild Steel Plain Washers?

A M5 Mild Steel Plain Washer is a round flat disc with a precise inner hole to fit an M5 bolt or screw snugly. Its main purpose is to spread the load of the fastener across a wider surface area.

Key functions:

Load Distribution: Prevents local stress points that can weaken materials.

Surface Protection: Stops scratching, denting, or paint removal during tightening.

Vibration Resistance: Helps maintain bolt tightness in applications subject to minor movement.

Corrosion Control (when coated): Protects the bolt hole from moisture ingress.

Material Details: Why Mild Steel?

M5 Mild Steel Plain Washers are made from standard mild steel (low carbon steel). This material offers a perfect balance of strength, formability, and economy.

Why Mild Steel for Plain Washers?

Tensile Strength: Strong enough to withstand repeated tightening and removal cycles.

Workability: Easy to stamp to tight tolerances.

Cost-Effectiveness: A smart choice for bulk usage without overshooting budgets.

Versatility: Can be zinc-plated or phosphate-coated for extra corrosion protection.

Compatibility: Works well with standard mild steel bolts, nuts, or screws.

Compared to stainless steel, mild steel costs less while providing more than enough strength for light-to-moderate duty connections.

Manufacturing and Technical Specifications

Our M5 Mild Steel Plain Washers are manufactured in-house at our ISO-certified facility in Mumbai.

Our Process:

Raw Material: Certified mild steel sheets that comply with IS/ISO standards.

Precision Punching: CNC-controlled presses ensure each washer’s inner and outer diameter meets tight tolerances.

Deburring: Automated deburring lines remove sharp edges, making the washers safe to handle.

Surface Finish: Plain oiled, zinc-plated, or phosphate-coated options available.

Quality Checks: Random sampling, dimensional checks, and coating thickness inspections.

Typical Specs for M5 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 5.3 mm (fits M5 bolts snugly) |

| Outer Diameter | 10–12 mm |

| Thickness | As per DIN/IS standards |

| Finish | Plain / Zinc-Plated / Phosphate |

| Material | Mild Steel |

| Shape | Flat Disc |

Key Features

When you choose M5 Mild Steel Plain Washers, you’re investing in a simple yet crucial fastener component that delivers multiple technical and practical benefits. Below, you’ll find an in-depth explanation of each feature, how it works, and why it matters in real-world applications.

1. Accurate Load Distribution

One of the main roles of any plain washer is to spread the load of a bolt or screw evenly over the surface. For small-diameter bolts like M5, this becomes even more important because the clamping force is concentrated on a tiny area.

Without a washer, when you torque an M5 bolt directly onto soft materials like aluminum or thin sheet metal, you risk:

Punching through the material

Causing local deformation around the hole

Weakening the structural integrity of the assembly

With M5 Mild Steel Plain Washers, the pressure is distributed over a larger surface area. This means the base material can withstand the bolt’s clamping force without permanent distortion. It also helps when you’re working with layered materials, like painted metal or coated panels, because the washer reduces the risk of damaging protective coatings.

In automated assembly lines, consistent load distribution is critical. Each bolt should clamp with the same force, ensuring a reliable, repeatable joint that holds up under operational stress. This small, inexpensive washer makes that consistency possible.

2. Superior Surface Protection

Painted, powder-coated, or anodized surfaces look good, but they’re also the first line of defense against corrosion. If you bolt directly onto a coated surface, the bolt head can cut into the finish. Once the coating is damaged, moisture and air reach the base metal, leading to corrosion over time.

M5 Mild Steel Plain Washers create a buffer between the fastener and the material beneath it. This protects the coating from scratching, chipping, or peeling under tightening pressure.

In industries like control panel fabrication, electronics, or decorative metalwork, this is critical because surface appearance and corrosion resistance go hand-in-hand. Clients expect a polished, intact finish, even around bolt heads — and plain washers deliver exactly that.

3. Vibration Resistance

You might not think vibration is a big deal for small M5 fasteners, but consider:

Control panels in factories that run 24/7.

Small machinery or equipment mounted on vibrating surfaces.

Vehicles, trailers, or fixtures that are subject to road or mechanical vibration.

In these scenarios, fasteners are constantly exposed to micro-movements. Without a washer, this vibration can cause the bolt or nut to slowly loosen. This is especially problematic when you’re fastening parts that cannot easily be re-tightened during normal maintenance.

A high-quality M5 Mild Steel Plain Washer acts as a stabilizing barrier. It increases the friction surface area, which helps the bolt or nut resist loosening under small shifts. Combined with thread-locking techniques or additional locking washers, you can create a fastening system that stays secure for the entire service life of the equipment.

4. Durability and Reusability

Unlike some hardware components that need frequent replacement, a properly installed M5 Mild Steel Plain Washer can last through multiple installation and removal cycles. This is thanks to the ductility and strength of mild steel.

In maintenance operations, this is a big advantage:

You can safely reuse washers when repairing or replacing other fastener parts.

They maintain their shape without significant deformation.

Their protective coating (zinc or phosphate) helps them resist rust if stored properly.

This means you get more value from each unit, especially when you Buy M5 Mild Steel Washers in Bulk for production or service teams.

5. Budget-Friendly without Compromise

Compared to stainless steel, exotic alloys, or polymer washers, mild steel is the most cost-effective choice for general-purpose fastening. It provides reliable strength and flexibility at a fraction of the cost of premium materials.

This is why Mild Steel Flat Washers are the default option in industries like automotive, light machinery, furniture, and electrical equipment manufacturing. You get performance that’s “good enough” for 90% of standard applications, with easy customization for coatings if you need extra corrosion protection.

When you’re buying millions of washers per year, that cost difference adds up to significant savings — without any drop in quality or reliability.

6. Flexible Coating and Corrosion Protection

Although mild steel alone is susceptible to rust in humid or outdoor conditions, it’s easily protected with simple and affordable finishes. M5 Mild Steel Plain Washers can be ordered plain, oiled, zinc-plated, or phosphate-coated.

Zinc Plating: Adds a bright, rust-resistant surface that’s ideal for indoor applications where humidity is moderate.

Phosphate Coating: Offers a matte, non-reflective finish and mild corrosion resistance, perfect for components that need better paint adhesion or are assembled in slightly harsher environments.

Customized Finishes: Large bulk orders can even include specialized coatings for unique requirements.

This adaptability means mild steel washers can be tailored to match the life expectancy and exposure of your project — from sealed enclosures to open workshop installations.

7. Easy Compatibility with Automation

Many of today’s high-volume manufacturers rely on automated pick-and-place or vibration bowl feeding systems to install small fasteners. For automation to work flawlessly, each washer must be consistently dimensioned with tight tolerances on inner and outer diameters and flatness.

Nafees Metal Industries manufactures M5 Mild Steel Plain Washers to strict standards so they move smoothly through feeders and fit perfectly with M5 bolts and screws. This minimizes jams, misfeeds, and downtime on your assembly line.

For OEMs, this saves hours of lost production and avoids frustrating bottlenecks.

8. Compact, Lightweight, and Space-Saving

Small fasteners often go into tight spaces, so the washers used must be dimensionally precise and low-profile. The standard thickness of an M5 Mild Steel Plain Washer is optimized to provide adequate load spreading without interfering with surrounding components.

For example:

In PCB mounting, the washer must not lift the board too high or obstruct adjacent connectors.

In light frames, the washer should allow flush fitting of covers or panels.

These details matter for engineers designing enclosures, brackets, or machine parts that need to stay compact while still being secure.

9. Easy to Order and Replace

Unlike specialty washers that can be difficult to source, M5 Mild Steel Plain Washers are readily available in standard and custom sizes. This makes repairs and maintenance straightforward:

No waiting weeks for rare replacements.

Simple stocking and inventory planning.

Flexible minimum order quantities for smaller repair jobs or large manufacturing runs.

By working with the Best M5 MS Plain Washers Manufacturer, you’re guaranteed consistent dimensions and quality, so each replacement matches perfectly.

10. Customization Options

If you have a unique requirement, mild steel washers can be modified cost-effectively:

Adjust inner or outer diameter for special fasteners.

Use special grades of mild steel for extra strength.

Apply custom coatings or plating for added durability.

Create bulk packaging kits tailored to assembly line needs.

This level of customization ensures that the humble washer is never a weak point in your design — it’s a precise, dependable part of your entire fastening system.

Applications & Use Cases

Where do people use M5 Mild Steel Plain Washers?

Electronics: Circuit board mounting, control panels, and enclosures.

Automotive: Securing brackets, panels, or interior trim pieces.

Light Machinery: Small conveyor systems, light-duty fabrication.

General Fastening: Furniture assembly, household repairs, DIY projects.

Electrical Installations: Protect surfaces when mounting fixtures or junction boxes.

Why Buy M5 Mild Steel Washers in Bulk – Best M5 MS Flat Washers for Industrial Use

When you Buy M5 Mild Steel Washers in Bulk, you benefit in multiple ways:

Cost Savings: Bulk pricing keeps your unit cost low for large production runs.

Quality Consistency: Every washer comes from the same controlled batch for uniform performance.

Inventory Planning: Ensure you always have enough stock to keep assembly lines running.

Custom Packing: Receive washers pre-packed by size, coating, or assembly line requirement.

Technical Support: Our engineers help you match washer specs to your fastener and material needs.

Why Choose the Best M5 MS Plain Washers Manufacturer

Nafees Metal Industries is your trusted Best M5 MS Flat Washers for Industrial Use because:

We offer 100% in-house production.

Our washers match global dimensional standards.

We supply consistent quality for high-volume or custom orders.

We provide custom coatings and packaging.

We’re responsive and support your procurement team every step of the way.

Installation Tips

Always clean the bolt and surface.

Align washers properly under bolt heads and nuts.

Use dual washers for extra load spread on thin sheets.

Don’t overtighten small fasteners to prevent stripping threads.

Choose coated washers if exposed to moisture or humidity.

Maintenance Guidelines

Inspect during routine equipment checks.

Replace any washers showing cracks or corrosion.

Keep unused washers dry and sealed.

Use the right coating for your environment to extend washer lifespan.

Case Study: Control Panel Assembly Upgrade

Background

A mid-sized electrical equipment manufacturer based in India produces modular industrial control panels for clients in the automotive and textile industries. Each panel contains dozens of delicate PCBs, relays, and connectors that must be securely mounted onto an aluminum chassis.

During production, the company faced a recurring quality problem: hairline cracks and surface dents were appearing around the bolt holes on the aluminum chassis, especially when workers installed or retightened the M5 bolts that held the PCBs and terminal blocks in place.

The Problem

The manufacturer used M5 bolts directly on the powder-coated aluminum panels without any washers. Over time, this caused multiple issues:

Paint Layer Damage:

The direct contact between the bolt head and the soft aluminum surface damaged the powder-coated layer, exposing bare metal underneath. This reduced corrosion resistance, especially in humid environments.Local Stress Points:

When the bolt was torqued, the entire clamping force was focused on a very small area, leading to micro-cracks. Under vibration or thermal expansion, these cracks expanded, weakening the mounting holes.Rework and Downtime:

Frequent damage meant the assembly team had to rework panels. Re-drilling or replacing parts delayed production schedules and increased costs.

The Consultation

The company reached out to Nafees Metal Industries, a trusted supplier for Mild Steel Flat Washers and MS fasteners. Our technical team visited the factory, reviewed the assembly process, and quickly identified that using M5 Mild Steel Plain Washers could eliminate the stress issues.

We explained how washers:

Distribute the bolt load over a wider surface area.

Act as a barrier between the bolt head and the painted surface.

Reduce local deformation.

Help maintain bolt tightness, especially in applications with minor vibration.

The Solution

Our team recommended high-precision M5 Mild Steel Plain Washers with a zinc-plated finish for improved corrosion resistance. We supplied them in bulk, organized by line and station, so assembly workers could easily integrate them into their existing processes.

Key steps we implemented:

Provided free samples for initial fitment testing.

Conducted a pilot run on two production lines.

Trained line supervisors on proper washer placement and torque settings.

Monitored results for 6 weeks before the full rollout.

Implementation

In the pilot phase, each mounting point now included a M5 Mild Steel Plain Washer between the bolt head and the aluminum chassis.

Key improvements:

Load was evenly spread, eliminating local stress spots.

The zinc-plated washers protected the painted surface from direct contact.

During thermal cycles and equipment vibration, the bolts stayed secure.

Assembly workers reported easier, more consistent torque application.

Encouraged by the pilot success, the company approved a full switch to M5 Mild Steel Plain Washers across all its panel lines.

Quantifiable Results

The improvements were significant:

Zero panel rework:

Before using washers, an average of 15–20% of panels required rework due to cracks. After the upgrade, defect rates dropped by 95%.Longer product lifespan:

End customers reported fewer cases of corrosion near mounting holes.Faster assembly:

Workers found it easier to torque bolts properly, reducing assembly time by 10–12%.Cost savings:

The company estimated annual savings of over ₹8–10 lakh by eliminating panel scrap and overtime labor.Improved brand reputation:

Their biggest clients appreciated the improved build quality and reliability.

Detailed Impact Analysis

| Aspect | Before Washers | After Using M5 Mild Steel Plain Washers |

|---|---|---|

| Panel rejection rate | 15–20% | < 1% |

| Avg. repair time/panel | 30–45 mins | Negligible |

| Maintenance complaints | Frequent surface corrosion | Zero in first year |

| Fastener loosening | Common under vibration | None reported |

| Annual rework cost | ₹10–12 lakh | ~₹50,000 |

| Worker fatigue | High due to rework | Lower, more efficient output |

Customer Feedback

The plant’s production manager shared:

“We underestimated the role of washers in such small fasteners. By switching to M5 Mild Steel Plain Washers, we not only solved cracking and paint issues but also improved the overall fit and finish of our panels. Clients noticed the difference right away.”

Lessons Learned

Even for small bolts like M5, plain washers are essential for load distribution and surface protection.

Choosing a reliable Best M5 MS Plain Washers Manufacturer means consistent dimensions and quality in bulk.

A protective finish like zinc plating extends the washer’s life, especially in high-humidity conditions.

Bulk supply and organized packing make it easy to integrate washers into automated or manual assembly lines.

The smallest upgrade — like adding M5 Mild Steel Plain Washers — can prevent huge losses in rework and warranty claims.

Where They Are Now

This manufacturer now buys M5 Mild Steel Plain Washers in bulk, included with each batch of fasteners from Nafees Metal Industries. Their panel design specs now mandate the use of washers for every fastener mounting point.

Since the upgrade:

They’ve expanded to supply panels to three new industries.

Their clients trust the panels to last longer, with fewer failures in harsh industrial settings.

They proudly position themselves as an OEM that focuses on small details for big results.

Key Takeaway

This real-world example proves that M5 Mild Steel Plain Washers, when sourced in bulk from a trusted supplier, protect your product, reduce rework, improve end-user confidence, and drive your brand’s quality reputation higher.

If you need to Buy M5 Mild Steel Washers in Bulk, talk to our team at Nafees Metal Industries — we’re here to make sure every bolt you tighten stays tight, every surface stays protected, and every project runs smoothly from start to finish.

Related Products

M3–M10 MS Washers

Custom punched stainless washers for corrosion-critical projects

Spring washers for extra vibration locking

Final Words

Whether you build electronics, light machinery, or do general assembly work, M5 Mild Steel Plain Washers are your best bet for durability, cost-efficiency, and protection. Buy from the Best M5 MS Plain Washers Manufacturer to keep your operations smooth and reliable.

FAQs

What are M5 Mild Steel Plain Washers used for?

They protect surfaces and distribute load under M5 bolts or screws.

Are they reusable?

Yes — just inspect for cracks or corrosion.

Are they suitable for outdoor use?

Use zinc or galvanic coating for better corrosion resistance.

How do they handle vibration?

They buffer vibration to help keep fasteners tight.

What industries use them?

Electronics, automotive, fabrication, electrical, DIY.

Do you provide test certificates?

Yes, MTCs and inspection reports on request.

Do you offer custom thicknesses?

Absolutely — we adjust OD/ID/thickness as needed.

What is the lead time?

7–14 days for standard bulk orders.

Can you export?

Yes — we ship worldwide.

Do you supply samples?

Yes — test fit before bulk purchase.

How should I store them?

Keep sealed in a dry place.

When should I replace them?

Replace if cracked, deformed, or corroded.

What finishes do you offer?

Plain, zinc-plated, phosphate-coated.

Do you have bulk packaging options?

Yes — customized for your line needs.

Why choose Nafees Metal Industries?

Reliable quality, fair pricing, on-time delivery — your trusted partner for M5 Mild Steel Plain Washers.

Why Choose Nafees Metal Industries?

At Nafees Metal industries, we are committed to being your trusted partner when you want to Buy M5 Mild Steel Plain Washers in Bulk. As the Best M5 MS Flat Washers Manufacturer, we use modern machinery and strict quality control to deliver products that meet industry standards every single time. Our dedicated team ensures quick order processing, flexible bulk supply, and outstanding after-sales support.

Whether you are an OEM, contractor, or maintenance professional, you can depend on our M5 Mild Steel Plain Washers for quality, consistency, and value. We invite you to visit our advanced manufacturing facility at Reay Road, Mumbai, or reach out to discuss your unique requirements. We are here to keep your fastening needs secure and hassle-free.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch