No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M5 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M5 Copper Plain Washers – Best Copper Flat Washers for Corrosion-Resistant Hydraulic and Electrical Applications

Nafees Metal Industries proudly presents M5 copper plain washers, engineered for precision, performance, and reliability. As one of the top copper washer manufacturers in India, our company has earned a reputation for delivering washers that meet stringent industrial standards while offering superior sealing, conductivity, and corrosion resistance. These M5 copper plain washers are designed to work seamlessly in a wide range of demanding environments such as hydraulic systems, electrical assemblies, and high-temperature mechanical setups.

With exacting attention to quality, our Mumbai-based production unit manufactures these washers in compliance with global standards like DIN 125 and ISO 7089. Whether you’re an OEM, maintenance service provider, or procurement manager, these M5 copper plain washers offer a robust and cost-effective solution for industrial and commercial applications.

Used extensively in automotive electronics, electrical switchboards, heavy-duty pumps, solar panel grounding, and high-pressure sealing, M5 copper plain washers serve as critical components where fastening efficiency and durability are non-negotiable. We ensure each washer is dimensionally accurate, mechanically reliable, and capable of withstanding corrosion, moisture, heat, and vibration.

Thanks to their non-magnetic and spark-resistant properties, M5 copper plain washers are also widely trusted in environments where safety is paramount—such as oil & gas units, control panels, and power distribution networks. Being thin yet strong, they are ideal for installations where compactness and conductivity must go hand-in-hand.

As a leading manufacturer and supplier, Nafees Metal Industries guarantees that our M5 copper plain washers will exceed expectations for both performance and product life. For industries seeking an efficient way to improve load distribution and avoid surface damage while enhancing sealing performance, these M5 copper plain washers are a proven choice.

In the following sections, we’ll dive deeper into their specifications, manufacturing process, key benefits, use cases, and real-world impact. Whether you’re looking for industrial copper flat washer corrosion-resistant solutions or lightweight alternatives for compact devices, M5 copper plain washers from Nafees Metal Industries deliver unmatched versatility.

What Are M5 Copper Plain Washers?

M5 copper plain washers are circular, flat disc components with a central hole precisely sized to fit M5 bolts or screws (5 mm diameter). Their primary function is to evenly distribute the load of a threaded fastener during tightening, thereby minimizing surface wear, preventing bolt pull-through, and enhancing the overall strength and safety of the joint. These washers also help in absorbing vibrations and maintaining assembly integrity, especially in sensitive or high-vibration environments.

At Nafees Metal Industries, our M5 copper plain washers are manufactured from high-purity copper sheets and punched with extreme precision to ensure a consistent inner diameter (approx. 5.3 mm) and outer diameter as per industry standards. Each washer undergoes deburring and finishing to remove sharp edges, making them safe and efficient to use in fast-paced production environments.

Being made of copper, these M5 copper plain washers offer excellent thermal and electrical conductivity, which makes them ideal for electrical panels, battery connections, alternators, and grounding systems. Their non-ferrous and non-magnetic nature makes them especially valuable in electronics, where magnetic interference is a concern.

These washers also function exceptionally well in hydraulic and plumbing systems, providing a secure and leak-resistant seal. When used in high-pressure environments, M5 copper plain washers adapt to the mating surface and fill irregularities due to copper’s malleability, thereby ensuring a tighter, more reliable seal.

All our M5 copper plain washers comply with copper plain washer DIN 125 size M5 specifications, which means their dimensions and tolerances align with global norms. This allows users to easily replace or integrate them into existing assemblies without the need for additional customization.

Whether you’re assembling control boxes, sealing hydraulic fittings, or grounding electrical panels, M5 copper plain washers ensure long-lasting fastening performance with minimal maintenance. Their adaptability across industries—from automotive and electronics to renewable energy and aerospace—makes them one of the most versatile washer types in our product line.

When reliability, safety, and high-performance sealing are essential, M5 copper plain washers from Nafees Metal Industries provide the right balance of durability, conductivity, and affordability.

Why Choose Copper for M5 Washers?

Copper is one of the most trusted materials in the fastening and sealing industry due to its unmatched balance of physical, mechanical, and chemical properties. When it comes to manufacturing high-performance M5 copper plain washers, copper stands out for several key reasons that make it ideal for electrical, mechanical, and hydraulic applications.

Firstly, M5 copper plain washers offer superior electrical conductivity, which is essential for applications involving current transmission or grounding. Unlike steel or other alloys, copper ensures a low-resistance path for electricity, making these washers perfect for use in power systems, battery terminals, PCB mounts, and renewable energy setups.

Secondly, copper is naturally corrosion-resistant. This makes M5 copper plain washers particularly suited for harsh environments where exposure to moisture, chemicals, or atmospheric elements could otherwise degrade performance. The use of M5 copper plain washers helps in prolonging the lifespan of assemblies and reduces maintenance needs over time.

Another significant advantage is copper’s high malleability and ductility. This property allows M5 copper plain washers to deform slightly under pressure, conforming tightly to uneven surfaces, and creating a more effective seal—especially important in fluid systems and vibration-prone environments. In fact, they are often chosen as the ideal copper sealing washer M5 hydraulic fittings in both industrial and automotive applications.

Copper also exhibits excellent thermal conductivity, which makes M5 copper plain washers suitable for use in high-temperature environments like engine compartments, electrical motors, and industrial furnaces. They help dissipate heat efficiently, protecting surrounding components and ensuring system stability.

Further, copper’s non-magnetic and spark-resistant nature is another reason industries prefer M5 copper plain washers in sensitive areas like explosive environments, electronic enclosures, or cleanroom equipment where magnetic interference and flammability concerns exist.

When manufactured according to specifications such as M5 copper flat washer metric series DIN 125, these washers offer consistent fit and functionality. Their compatibility with global standards ensures interchangeability and easy integration into production lines.

In summary, the selection of copper is not just about conductivity or corrosion resistance—it’s about performance, reliability, and long-term value. At Nafees Metal Industries, we ensure that our M5 copper plain washers are made from the highest quality copper to meet the demands of today’s advanced mechanical and electrical systems.

Manufacturing Process of M5 Copper Plain Washers

At Nafees Metal Industries, we follow a precise and quality-focused process to manufacture our M5 copper plain washers, ensuring every unit meets international standards like DIN 125, IS 2016, and ISO 7089. With a dedicated facility in Mumbai and a team of experienced technicians, we take pride in being one of the top copper washer manufacturers in India, delivering bulk orders with consistent quality and customization.

The manufacturing journey of our M5 copper plain washers begins with the selection of high-purity electrolytic copper sheets, known for their excellent conductivity, malleability, and corrosion resistance. We source only certified raw materials to ensure that the final washers perform optimally across all applications.

Once the copper sheets are selected, they undergo the following stages:

Precision Punching

Using CNC-controlled machines and high-tonnage hydraulic presses, the copper sheets are stamped into discs matching the inner and outer diameter standards of M5 copper plain washers. The inner hole is approximately 5.3 mm, ensuring a snug fit with M5 bolts and screws.Trimming & Deburring

After stamping, the washers pass through trimming stations where sharp edges or burrs are removed. This process ensures the M5 copper plain washers have smooth edges, which are essential for safe handling, especially in high-speed assembly lines.Annealing (Optional)

For applications requiring greater pliability, such as sealing, the washers may be annealed. This heat treatment softens the copper, allowing the M5 copper plain washers to better conform to mating surfaces and function as effective seals.Surface Finishing

Depending on client requirements, washers may be left with a natural finish or treated further. Available options include polishing, electro-tinning, or oxidization protection. Each M5 copper plain washer is cleaned thoroughly to remove oils or residues from the punching process.Quality Control and Dimensional Testing

Before packing, our in-house quality control team inspects each batch of M5 copper plain washers using calipers, go/no-go gauges, and micrometers. Tests are conducted to ensure correct thickness, concentricity, inner diameter, and finish. This ensures our washers not only meet but often exceed expectations.Custom Packaging and Labeling

Depending on the order size and client specifications, we offer various packaging solutions—from bulk polybags and corrugated cartons to labeled and barcoded retail packs. Our packaging ensures the M5 copper plain washers remain protected during transportation and are easy to stock.

Thanks to our streamlined production process and commitment to excellence, we are capable of supplying thousands of M5 copper plain washers daily to industries across India and abroad. Whether you need washers for electrical panels, sealing hydraulic joints, or industrial machinery, we deliver consistent, reliable, and cost-effective washer solutions.

Key Features of M5 Copper Plain Washers

At Nafees Metal Industries, our M5 copper plain washers are engineered with performance, precision, and reliability at the core. Designed to meet global industrial standards and optimized for both sealing and fastening applications, these washers are a trusted component across various sectors including electrical, mechanical, plumbing, and hydraulic systems.

Below are the most important features that make our M5 copper plain washers a top choice for OEMs, engineers, and procurement specialists:

Precision Fit for M5 Fasteners

Our M5 copper plain washers are manufactured with tight tolerances and dimensionally accurate inner diameters (approx. 5.3 mm), ensuring a perfect fit with all standard M5 bolts, screws, and studs. This precision eliminates fastener play and improves load transfer.High Electrical and Thermal Conductivity

Due to their copper composition, these washers provide excellent current conduction and heat dissipation. That’s why M5 copper plain washers are widely used in battery terminals, circuit protection, and power control units.Exceptional Corrosion Resistance

These washers are inherently resistant to rust and degradation from moisture, salt, and industrial chemicals. Their long service life makes them ideal for indoor and moderately exposed environments. As a result, they qualify as industrial copper flat washer corrosion-resistant.Vibration Dampening & Surface Protection

The malleability of copper allows M5 copper plain washers to slightly compress under load, acting as a buffer against mechanical vibrations. This protects the mating surface from wear and enhances the overall joint integrity.DIN 125 Standard Compliance

All our washers comply with M5 copper flat washer metric series DIN 125, ensuring compatibility across global mechanical and electrical systems.Smooth Edges and Uniform Thickness

Each washer is deburred and finished to provide a smooth, safe edge and uniform thickness. This not only facilitates safe handling but also guarantees consistent performance during assembly.Available in Multiple Finishes

Depending on client needs, M5 copper plain washers can be supplied in natural, annealed, or electro-tinned finishes. These finishes enhance surface conductivity and oxidation resistance.Custom Sizing and Bulk Availability

As one of India’s leading copper washer manufacturers, we offer custom ID, OD, and thickness configurations for specialized applications. Whether you need 10,000 or 1,00,000 pieces, we have the manufacturing capacity to deliver.Non-Magnetic and Spark-Resistant

Perfect for use in sensitive environments such as electronics, fuel systems, or explosion-prone areas, M5 copper plain washers prevent static buildup and electrical interference.Eco-Friendly and Recyclable

Copper is a 100% recyclable material, making M5 copper plain washers a sustainable choice for environmentally conscious industries.

Each of these features reflects our commitment to delivering washers that are not just functionally effective but also cost-efficient and long-lasting.

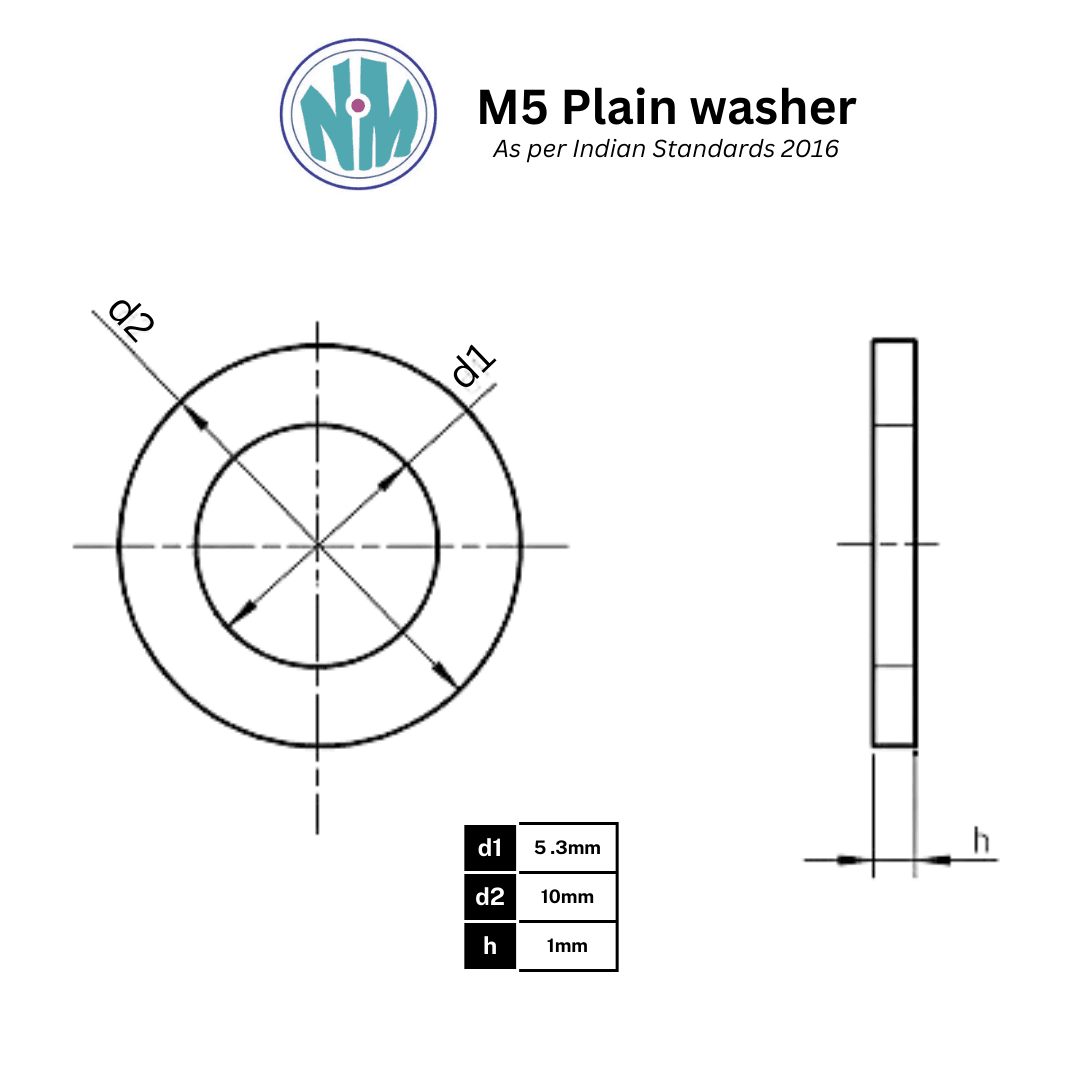

Technical Specifications

Our M5 copper plain washers are manufactured to precise technical standards to meet a wide variety of industrial applications. Whether you’re sourcing for electrical, hydraulic, or mechanical assemblies, these washers provide reliable performance backed by measurable quality parameters.

Each of our M5 copper plain washers undergoes stringent quality control checks for dimensional accuracy, surface finish, and material integrity. Manufactured as per DIN 125 specifications, they are perfectly compatible with standard M5 bolts and screws used globally.

Below are the detailed technical specifications for our M5 copper plain washers:

| Property | Specification |

|---|---|

| Product Name | M5 Copper Plain Washer |

| Material | 99.9% Pure Electrolytic Copper |

| Inner Diameter (ID) | Approx. 5.3 mm (fits standard M5 bolts/screws) |

| Outer Diameter (OD) | As per DIN 125 standard (custom OD available upon request) |

| Thickness | 0.5 mm to 1.0 mm (standard), customizable based on application requirements |

| Standard Compliance | DIN 125 / IS 2016 / ISO 7089 |

| Surface Finish | Plain, Annealed, or Electro-Tinned |

| Hardness | Typically Soft Annealed (custom hardness upon request) |

| Tensile Strength | Maintains mechanical integrity under fastening torque |

| Conductivity | High electrical and thermal conductivity (up to 100% IACS) |

| Packaging Options | Bulk polybags, shrink wrap, labeled cartons, or customized branding available |

| Application Category | Electrical Assemblies, Hydraulic Sealing, Mechanical Fastening Systems |

| Origin | Proudly Manufactured in India (Mumbai Facility) |

These specifications reflect the commitment of Nafees Metal Industries to provide durable, high-quality, and standard-compliant M5 copper plain washers for professional applications.

If your project requires copper plain washer DIN 125 size M5 compatibility, or you are searching for a copper sealing washer M5 hydraulic fittings that delivers consistent sealing and current transmission, our product meets all the necessary engineering standards.

Whether used for vibration dampening, electrical grounding, pressure sealing, or corrosion resistance, M5 copper plain washers provide a dependable solution supported by measurable specifications.

Applications of M5 Copper Plain Washers

M5 copper plain washers are engineered to serve a wide spectrum of applications across diverse industries, owing to their excellent electrical conductivity, sealing capability, and corrosion resistance. Whether it’s a high-voltage electrical panel or a precision hydraulic fitting, these washers offer critical support for reliability, safety, and long-term performance.

1. Electrical & Electronic Equipment

One of the most common uses of M5 copper plain washers is in electrical enclosures and devices, where their superior conductivity ensures low resistance contact. They are often used in circuit boards, battery terminals, grounding setups, and junction boxes. The M5 copper flat washer metric series DIN 125 ensures compatibility with global hardware, streamlining assembly across OEMs and panel builders.

2. Hydraulic and Pneumatic Systems

As copper sealing washer M5 hydraulic fittings, these washers offer an excellent seal under pressure, preventing fluid leakage in hydraulic pipelines, valves, and compression fittings. Their malleability allows them to compress and form a tight seal between uneven surfaces, reducing the risk of leaks in high-pressure systems.

3. Automotive and Aerospace

In vehicles and aerospace components, M5 copper plain washers are used for both mechanical spacing and heat dissipation. Their non-sparking nature and resistance to vibration-induced loosening make them suitable for engines, fuel systems, and electronic modules.

4. Industrial and Machinery Assembly

Many mechanical assemblies in industrial plants rely on industrial copper flat washer corrosion-resistant components like these washers. They prevent galvanic corrosion between dissimilar metals, distribute fastening pressure evenly, and protect surfaces during high-load fastening applications.

5. Renewable Energy Systems

Solar and wind energy systems benefit from the electrical and thermal conductivity of M5 copper plain washers. They ensure efficient energy flow in panel connections, battery packs, and inverter terminals while maintaining structural integrity in outdoor conditions.

6. Telecommunication Equipment

These washers play a crucial role in high-frequency electronic assemblies by maintaining stable grounding and shielding to prevent electromagnetic interference (EMI).

7. Marine and Coastal Installations

Due to their resistance to moisture and salt-induced corrosion, M5 copper plain washers are often deployed in marine-grade equipment and coastal infrastructure where longevity and reliability are paramount.

Whether you’re an OEM, a repair technician, or an industrial contractor, you can trust M5 copper plain washers from Nafees Metal Industries for critical performance in your assemblies. These washers are ideal wherever durability, conductivity, and corrosion resistance are required in compact fastening solutions.

Why Choose Nafees Metal Industries for M5 Copper Plain Washers

When it comes to sourcing M5 copper plain washers, choosing the right manufacturer is crucial for quality, consistency, and long-term reliability. At Nafees Metal Industries, we bring decades of experience, precision manufacturing, and unmatched service to the table—making us one of India’s most trusted suppliers of copper washer solutions.

Precision Engineering with Global Standards

Every M5 copper plain washer produced at our state-of-the-art facility in Mumbai adheres to copper plain washer DIN 125 size M5 standards. This ensures global compatibility and dependable performance across mechanical and electrical assemblies. Our precision tooling, combined with stringent quality controls, delivers washers with uniform thickness, burr-free edges, and exact dimensional tolerances.

High-Purity Raw Material

We use only premium-grade copper sheets that offer excellent conductivity, thermal resistance, and anti-corrosion properties. This allows our M5 copper flat washer metric series DIN 125 products to be suitable for high-performance environments like electric power systems, hydraulic circuits, and industrial machines.

Advanced Manufacturing Capabilities

Our Mumbai-based facility is equipped with modern power press machines, hydraulic cutters, and inspection systems. We manufacture in bulk while maintaining dimensional accuracy and surface finish quality. Whether you’re ordering 500 pieces or 5 lakh units, every M5 copper plain washer meets the same exacting standard.

Tailored Solutions for Diverse Industries

From OEMs in the automotive sector to marine equipment installers, we serve customers across India and the UAE. Need a copper sealing washer M5 hydraulic fittings solution or an industrial copper flat washer corrosion resistant variant? We can offer custom sizes, packaging, and delivery schedules tailored to your project’s requirements.

Trusted by Engineers and Procurement Teams

With thousands of successful orders delivered across industries—electronics, renewable energy, aerospace, and heavy machinery—M5 copper plain washers from Nafees Metal Industries are trusted for consistent performance and long-term durability.

Commitment to On-Time Delivery

Our robust supply chain and stock management system ensure that you never face delays. We are capable of fulfilling bulk orders with short lead times, helping you meet production timelines without compromise.

Choose Nafees Metal Industries as your reliable partner for M5 copper plain washers—and benefit from quality craftsmanship, industry expertise, and professional support at every step.

For inquiries or bulk orders, connect with us today and experience why hundreds of manufacturers and suppliers trust us with their washer requirements.

Frequently Asked Questions (FAQs)

What is the primary use of M5 copper plain washers?

They distribute load and offer excellent electrical and corrosion resistance in fastening applications.Do these washers comply with any standards?

Yes, they follow DIN 125, IS 2016, and ISO 7089 guidelines.Are they suitable for outdoor use?

Yes, copper’s corrosion resistance makes them ideal for both indoor and outdoor use.Can M5 copper plain washers be used for electrical grounding?

Absolutely. Copper’s conductivity makes these washers perfect for grounding.What is the ID and OD of these washers?

Inner diameter is approx. 5.3 mm; outer diameter varies per DIN 125 standards.What finish options are available?

Natural copper finish, electro-tinned, or custom finishes upon request.Do you offer custom sizes or thicknesses?

Yes, we manufacture based on client specifications in bulk quantities.Is there a minimum order quantity (MOQ)?

MOQ varies by packaging and customization, typically starting at 5,000 pcs.Where are these washers manufactured?

They are proudly made in our Mumbai-based facility.Are these washers suitable for hydraulic fittings?

Yes, they are compatible with copper sealing washer M5 hydraulic fittings.Can I buy these in small quantities?

Yes, we offer flexible packaging options for both small and bulk orders.Are certificates provided for exports?

Yes, we provide all documentation including test certificates and MSDS.What is the lead time for large orders?

Typically 5–7 working days, depending on customization and volume.Do you offer samples for quality evaluation?

Yes, samples are available upon request.Are these washers recyclable?

Yes, copper washers are 100% recyclable and environmentally friendly.

M5 Copper Plain washers (DIN 125)

19 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M5

Inner Diameter (ID): 5.3 mm

Outer Diameter (OD): 10 mm

Thickness (t): 1 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:12 days

M5 Copper Plain Washers – Best Copper Flat Washers for Corrosion-Resistant Hydraulic and Electrical Applications

Nafees Metal Industries proudly presents M5 copper plain washers, engineered for precision, performance, and reliability. As one of the top copper washer manufacturers in India, our company has earned a reputation for delivering washers that meet stringent industrial standards while offering superior sealing, conductivity, and corrosion resistance. These M5 copper plain washers are designed to work seamlessly in a wide range of demanding environments such as hydraulic systems, electrical assemblies, and high-temperature mechanical setups.

With exacting attention to quality, our Mumbai-based production unit manufactures these washers in compliance with global standards like DIN 125 and ISO 7089. Whether you’re an OEM, maintenance service provider, or procurement manager, these M5 copper plain washers offer a robust and cost-effective solution for industrial and commercial applications.

Used extensively in automotive electronics, electrical switchboards, heavy-duty pumps, solar panel grounding, and high-pressure sealing, M5 copper plain washers serve as critical components where fastening efficiency and durability are non-negotiable. We ensure each washer is dimensionally accurate, mechanically reliable, and capable of withstanding corrosion, moisture, heat, and vibration.

Thanks to their non-magnetic and spark-resistant properties, M5 copper plain washers are also widely trusted in environments where safety is paramount—such as oil & gas units, control panels, and power distribution networks. Being thin yet strong, they are ideal for installations where compactness and conductivity must go hand-in-hand.

As a leading manufacturer and supplier, Nafees Metal Industries guarantees that our M5 copper plain washers will exceed expectations for both performance and product life. For industries seeking an efficient way to improve load distribution and avoid surface damage while enhancing sealing performance, these M5 copper plain washers are a proven choice.

In the following sections, we’ll dive deeper into their specifications, manufacturing process, key benefits, use cases, and real-world impact. Whether you’re looking for industrial copper flat washer corrosion-resistant solutions or lightweight alternatives for compact devices, M5 copper plain washers from Nafees Metal Industries deliver unmatched versatility.

What Are M5 Copper Plain Washers?

M5 copper plain washers are circular, flat disc components with a central hole precisely sized to fit M5 bolts or screws (5 mm diameter). Their primary function is to evenly distribute the load of a threaded fastener during tightening, thereby minimizing surface wear, preventing bolt pull-through, and enhancing the overall strength and safety of the joint. These washers also help in absorbing vibrations and maintaining assembly integrity, especially in sensitive or high-vibration environments.

At Nafees Metal Industries, our M5 copper plain washers are manufactured from high-purity copper sheets and punched with extreme precision to ensure a consistent inner diameter (approx. 5.3 mm) and outer diameter as per industry standards. Each washer undergoes deburring and finishing to remove sharp edges, making them safe and efficient to use in fast-paced production environments.

Being made of copper, these M5 copper plain washers offer excellent thermal and electrical conductivity, which makes them ideal for electrical panels, battery connections, alternators, and grounding systems. Their non-ferrous and non-magnetic nature makes them especially valuable in electronics, where magnetic interference is a concern.

These washers also function exceptionally well in hydraulic and plumbing systems, providing a secure and leak-resistant seal. When used in high-pressure environments, M5 copper plain washers adapt to the mating surface and fill irregularities due to copper’s malleability, thereby ensuring a tighter, more reliable seal.

All our M5 copper plain washers comply with copper plain washer DIN 125 size M5 specifications, which means their dimensions and tolerances align with global norms. This allows users to easily replace or integrate them into existing assemblies without the need for additional customization.

Whether you’re assembling control boxes, sealing hydraulic fittings, or grounding electrical panels, M5 copper plain washers ensure long-lasting fastening performance with minimal maintenance. Their adaptability across industries—from automotive and electronics to renewable energy and aerospace—makes them one of the most versatile washer types in our product line.

When reliability, safety, and high-performance sealing are essential, M5 copper plain washers from Nafees Metal Industries provide the right balance of durability, conductivity, and affordability.

Why Choose Copper for M5 Washers?

Copper is one of the most trusted materials in the fastening and sealing industry due to its unmatched balance of physical, mechanical, and chemical properties. When it comes to manufacturing high-performance M5 copper plain washers, copper stands out for several key reasons that make it ideal for electrical, mechanical, and hydraulic applications.

Firstly, M5 copper plain washers offer superior electrical conductivity, which is essential for applications involving current transmission or grounding. Unlike steel or other alloys, copper ensures a low-resistance path for electricity, making these washers perfect for use in power systems, battery terminals, PCB mounts, and renewable energy setups.

Secondly, copper is naturally corrosion-resistant. This makes M5 copper plain washers particularly suited for harsh environments where exposure to moisture, chemicals, or atmospheric elements could otherwise degrade performance. The use of M5 copper plain washers helps in prolonging the lifespan of assemblies and reduces maintenance needs over time.

Another significant advantage is copper’s high malleability and ductility. This property allows M5 copper plain washers to deform slightly under pressure, conforming tightly to uneven surfaces, and creating a more effective seal—especially important in fluid systems and vibration-prone environments. In fact, they are often chosen as the ideal copper sealing washer M5 hydraulic fittings in both industrial and automotive applications.

Copper also exhibits excellent thermal conductivity, which makes M5 copper plain washers suitable for use in high-temperature environments like engine compartments, electrical motors, and industrial furnaces. They help dissipate heat efficiently, protecting surrounding components and ensuring system stability.

Further, copper’s non-magnetic and spark-resistant nature is another reason industries prefer M5 copper plain washers in sensitive areas like explosive environments, electronic enclosures, or cleanroom equipment where magnetic interference and flammability concerns exist.

When manufactured according to specifications such as M5 copper flat washer metric series DIN 125, these washers offer consistent fit and functionality. Their compatibility with global standards ensures interchangeability and easy integration into production lines.

In summary, the selection of copper is not just about conductivity or corrosion resistance—it’s about performance, reliability, and long-term value. At Nafees Metal Industries, we ensure that our M5 copper plain washers are made from the highest quality copper to meet the demands of today’s advanced mechanical and electrical systems.

Manufacturing Process of M5 Copper Plain Washers

At Nafees Metal Industries, we follow a precise and quality-focused process to manufacture our M5 copper plain washers, ensuring every unit meets international standards like DIN 125, IS 2016, and ISO 7089. With a dedicated facility in Mumbai and a team of experienced technicians, we take pride in being one of the top copper washer manufacturers in India, delivering bulk orders with consistent quality and customization.

The manufacturing journey of our M5 copper plain washers begins with the selection of high-purity electrolytic copper sheets, known for their excellent conductivity, malleability, and corrosion resistance. We source only certified raw materials to ensure that the final washers perform optimally across all applications.

Once the copper sheets are selected, they undergo the following stages:

Precision Punching

Using CNC-controlled machines and high-tonnage hydraulic presses, the copper sheets are stamped into discs matching the inner and outer diameter standards of M5 copper plain washers. The inner hole is approximately 5.3 mm, ensuring a snug fit with M5 bolts and screws.Trimming & Deburring

After stamping, the washers pass through trimming stations where sharp edges or burrs are removed. This process ensures the M5 copper plain washers have smooth edges, which are essential for safe handling, especially in high-speed assembly lines.Annealing (Optional)

For applications requiring greater pliability, such as sealing, the washers may be annealed. This heat treatment softens the copper, allowing the M5 copper plain washers to better conform to mating surfaces and function as effective seals.Surface Finishing

Depending on client requirements, washers may be left with a natural finish or treated further. Available options include polishing, electro-tinning, or oxidization protection. Each M5 copper plain washer is cleaned thoroughly to remove oils or residues from the punching process.Quality Control and Dimensional Testing

Before packing, our in-house quality control team inspects each batch of M5 copper plain washers using calipers, go/no-go gauges, and micrometers. Tests are conducted to ensure correct thickness, concentricity, inner diameter, and finish. This ensures our washers not only meet but often exceed expectations.Custom Packaging and Labeling

Depending on the order size and client specifications, we offer various packaging solutions—from bulk polybags and corrugated cartons to labeled and barcoded retail packs. Our packaging ensures the M5 copper plain washers remain protected during transportation and are easy to stock.

Thanks to our streamlined production process and commitment to excellence, we are capable of supplying thousands of M5 copper plain washers daily to industries across India and abroad. Whether you need washers for electrical panels, sealing hydraulic joints, or industrial machinery, we deliver consistent, reliable, and cost-effective washer solutions.

Key Features of M5 Copper Plain Washers

At Nafees Metal Industries, our M5 copper plain washers are engineered with performance, precision, and reliability at the core. Designed to meet global industrial standards and optimized for both sealing and fastening applications, these washers are a trusted component across various sectors including electrical, mechanical, plumbing, and hydraulic systems.

Below are the most important features that make our M5 copper plain washers a top choice for OEMs, engineers, and procurement specialists:

Precision Fit for M5 Fasteners

Our M5 copper plain washers are manufactured with tight tolerances and dimensionally accurate inner diameters (approx. 5.3 mm), ensuring a perfect fit with all standard M5 bolts, screws, and studs. This precision eliminates fastener play and improves load transfer.High Electrical and Thermal Conductivity

Due to their copper composition, these washers provide excellent current conduction and heat dissipation. That’s why M5 copper plain washers are widely used in battery terminals, circuit protection, and power control units.Exceptional Corrosion Resistance

These washers are inherently resistant to rust and degradation from moisture, salt, and industrial chemicals. Their long service life makes them ideal for indoor and moderately exposed environments. As a result, they qualify as industrial copper flat washer corrosion-resistant.Vibration Dampening & Surface Protection

The malleability of copper allows M5 copper plain washers to slightly compress under load, acting as a buffer against mechanical vibrations. This protects the mating surface from wear and enhances the overall joint integrity.DIN 125 Standard Compliance

All our washers comply with M5 copper flat washer metric series DIN 125, ensuring compatibility across global mechanical and electrical systems.Smooth Edges and Uniform Thickness

Each washer is deburred and finished to provide a smooth, safe edge and uniform thickness. This not only facilitates safe handling but also guarantees consistent performance during assembly.Available in Multiple Finishes

Depending on client needs, M5 copper plain washers can be supplied in natural, annealed, or electro-tinned finishes. These finishes enhance surface conductivity and oxidation resistance.Custom Sizing and Bulk Availability

As one of India’s leading copper washer manufacturers, we offer custom ID, OD, and thickness configurations for specialized applications. Whether you need 10,000 or 1,00,000 pieces, we have the manufacturing capacity to deliver.Non-Magnetic and Spark-Resistant

Perfect for use in sensitive environments such as electronics, fuel systems, or explosion-prone areas, M5 copper plain washers prevent static buildup and electrical interference.Eco-Friendly and Recyclable

Copper is a 100% recyclable material, making M5 copper plain washers a sustainable choice for environmentally conscious industries.

Each of these features reflects our commitment to delivering washers that are not just functionally effective but also cost-efficient and long-lasting.

Technical Specifications

Our M5 copper plain washers are manufactured to precise technical standards to meet a wide variety of industrial applications. Whether you’re sourcing for electrical, hydraulic, or mechanical assemblies, these washers provide reliable performance backed by measurable quality parameters.

Each of our M5 copper plain washers undergoes stringent quality control checks for dimensional accuracy, surface finish, and material integrity. Manufactured as per DIN 125 specifications, they are perfectly compatible with standard M5 bolts and screws used globally.

Below are the detailed technical specifications for our M5 copper plain washers:

| Property | Specification |

|---|---|

| Product Name | M5 Copper Plain Washer |

| Material | 99.9% Pure Electrolytic Copper |

| Inner Diameter (ID) | Approx. 5.3 mm (fits standard M5 bolts/screws) |

| Outer Diameter (OD) | As per DIN 125 standard (custom OD available upon request) |

| Thickness | 0.5 mm to 1.0 mm (standard), customizable based on application requirements |

| Standard Compliance | DIN 125 / IS 2016 / ISO 7089 |

| Surface Finish | Plain, Annealed, or Electro-Tinned |

| Hardness | Typically Soft Annealed (custom hardness upon request) |

| Tensile Strength | Maintains mechanical integrity under fastening torque |

| Conductivity | High electrical and thermal conductivity (up to 100% IACS) |

| Packaging Options | Bulk polybags, shrink wrap, labeled cartons, or customized branding available |

| Application Category | Electrical Assemblies, Hydraulic Sealing, Mechanical Fastening Systems |

| Origin | Proudly Manufactured in India (Mumbai Facility) |

These specifications reflect the commitment of Nafees Metal Industries to provide durable, high-quality, and standard-compliant M5 copper plain washers for professional applications.

If your project requires copper plain washer DIN 125 size M5 compatibility, or you are searching for a copper sealing washer M5 hydraulic fittings that delivers consistent sealing and current transmission, our product meets all the necessary engineering standards.

Whether used for vibration dampening, electrical grounding, pressure sealing, or corrosion resistance, M5 copper plain washers provide a dependable solution supported by measurable specifications.

Applications of M5 Copper Plain Washers

M5 copper plain washers are engineered to serve a wide spectrum of applications across diverse industries, owing to their excellent electrical conductivity, sealing capability, and corrosion resistance. Whether it’s a high-voltage electrical panel or a precision hydraulic fitting, these washers offer critical support for reliability, safety, and long-term performance.

1. Electrical & Electronic Equipment

One of the most common uses of M5 copper plain washers is in electrical enclosures and devices, where their superior conductivity ensures low resistance contact. They are often used in circuit boards, battery terminals, grounding setups, and junction boxes. The M5 copper flat washer metric series DIN 125 ensures compatibility with global hardware, streamlining assembly across OEMs and panel builders.

2. Hydraulic and Pneumatic Systems

As copper sealing washer M5 hydraulic fittings, these washers offer an excellent seal under pressure, preventing fluid leakage in hydraulic pipelines, valves, and compression fittings. Their malleability allows them to compress and form a tight seal between uneven surfaces, reducing the risk of leaks in high-pressure systems.

3. Automotive and Aerospace

In vehicles and aerospace components, M5 copper plain washers are used for both mechanical spacing and heat dissipation. Their non-sparking nature and resistance to vibration-induced loosening make them suitable for engines, fuel systems, and electronic modules.

4. Industrial and Machinery Assembly

Many mechanical assemblies in industrial plants rely on industrial copper flat washer corrosion-resistant components like these washers. They prevent galvanic corrosion between dissimilar metals, distribute fastening pressure evenly, and protect surfaces during high-load fastening applications.

5. Renewable Energy Systems

Solar and wind energy systems benefit from the electrical and thermal conductivity of M5 copper plain washers. They ensure efficient energy flow in panel connections, battery packs, and inverter terminals while maintaining structural integrity in outdoor conditions.

6. Telecommunication Equipment

These washers play a crucial role in high-frequency electronic assemblies by maintaining stable grounding and shielding to prevent electromagnetic interference (EMI).

7. Marine and Coastal Installations

Due to their resistance to moisture and salt-induced corrosion, M5 copper plain washers are often deployed in marine-grade equipment and coastal infrastructure where longevity and reliability are paramount.

Whether you’re an OEM, a repair technician, or an industrial contractor, you can trust M5 copper plain washers from Nafees Metal Industries for critical performance in your assemblies. These washers are ideal wherever durability, conductivity, and corrosion resistance are required in compact fastening solutions.

Why Choose Nafees Metal Industries for M5 Copper Plain Washers

When it comes to sourcing M5 copper plain washers, choosing the right manufacturer is crucial for quality, consistency, and long-term reliability. At Nafees Metal Industries, we bring decades of experience, precision manufacturing, and unmatched service to the table—making us one of India’s most trusted suppliers of copper washer solutions.

Precision Engineering with Global Standards

Every M5 copper plain washer produced at our state-of-the-art facility in Mumbai adheres to copper plain washer DIN 125 size M5 standards. This ensures global compatibility and dependable performance across mechanical and electrical assemblies. Our precision tooling, combined with stringent quality controls, delivers washers with uniform thickness, burr-free edges, and exact dimensional tolerances.

High-Purity Raw Material

We use only premium-grade copper sheets that offer excellent conductivity, thermal resistance, and anti-corrosion properties. This allows our M5 copper flat washer metric series DIN 125 products to be suitable for high-performance environments like electric power systems, hydraulic circuits, and industrial machines.

Advanced Manufacturing Capabilities

Our Mumbai-based facility is equipped with modern power press machines, hydraulic cutters, and inspection systems. We manufacture in bulk while maintaining dimensional accuracy and surface finish quality. Whether you’re ordering 500 pieces or 5 lakh units, every M5 copper plain washer meets the same exacting standard.

Tailored Solutions for Diverse Industries

From OEMs in the automotive sector to marine equipment installers, we serve customers across India and the UAE. Need a copper sealing washer M5 hydraulic fittings solution or an industrial copper flat washer corrosion resistant variant? We can offer custom sizes, packaging, and delivery schedules tailored to your project’s requirements.

Trusted by Engineers and Procurement Teams

With thousands of successful orders delivered across industries—electronics, renewable energy, aerospace, and heavy machinery—M5 copper plain washers from Nafees Metal Industries are trusted for consistent performance and long-term durability.

Commitment to On-Time Delivery

Our robust supply chain and stock management system ensure that you never face delays. We are capable of fulfilling bulk orders with short lead times, helping you meet production timelines without compromise.

Choose Nafees Metal Industries as your reliable partner for M5 copper plain washers—and benefit from quality craftsmanship, industry expertise, and professional support at every step.

For inquiries or bulk orders, connect with us today and experience why hundreds of manufacturers and suppliers trust us with their washer requirements.

Frequently Asked Questions (FAQs)

What is the primary use of M5 copper plain washers?

They distribute load and offer excellent electrical and corrosion resistance in fastening applications.Do these washers comply with any standards?

Yes, they follow DIN 125, IS 2016, and ISO 7089 guidelines.Are they suitable for outdoor use?

Yes, copper’s corrosion resistance makes them ideal for both indoor and outdoor use.Can M5 copper plain washers be used for electrical grounding?

Absolutely. Copper’s conductivity makes these washers perfect for grounding.What is the ID and OD of these washers?

Inner diameter is approx. 5.3 mm; outer diameter varies per DIN 125 standards.What finish options are available?

Natural copper finish, electro-tinned, or custom finishes upon request.Do you offer custom sizes or thicknesses?

Yes, we manufacture based on client specifications in bulk quantities.Is there a minimum order quantity (MOQ)?

MOQ varies by packaging and customization, typically starting at 5,000 pcs.Where are these washers manufactured?

They are proudly made in our Mumbai-based facility.Are these washers suitable for hydraulic fittings?

Yes, they are compatible with copper sealing washer M5 hydraulic fittings.Can I buy these in small quantities?

Yes, we offer flexible packaging options for both small and bulk orders.Are certificates provided for exports?

Yes, we provide all documentation including test certificates and MSDS.What is the lead time for large orders?

Typically 5–7 working days, depending on customization and volume.Do you offer samples for quality evaluation?

Yes, samples are available upon request.Are these washers recyclable?

Yes, copper washers are 100% recyclable and environmentally friendly.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch