No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

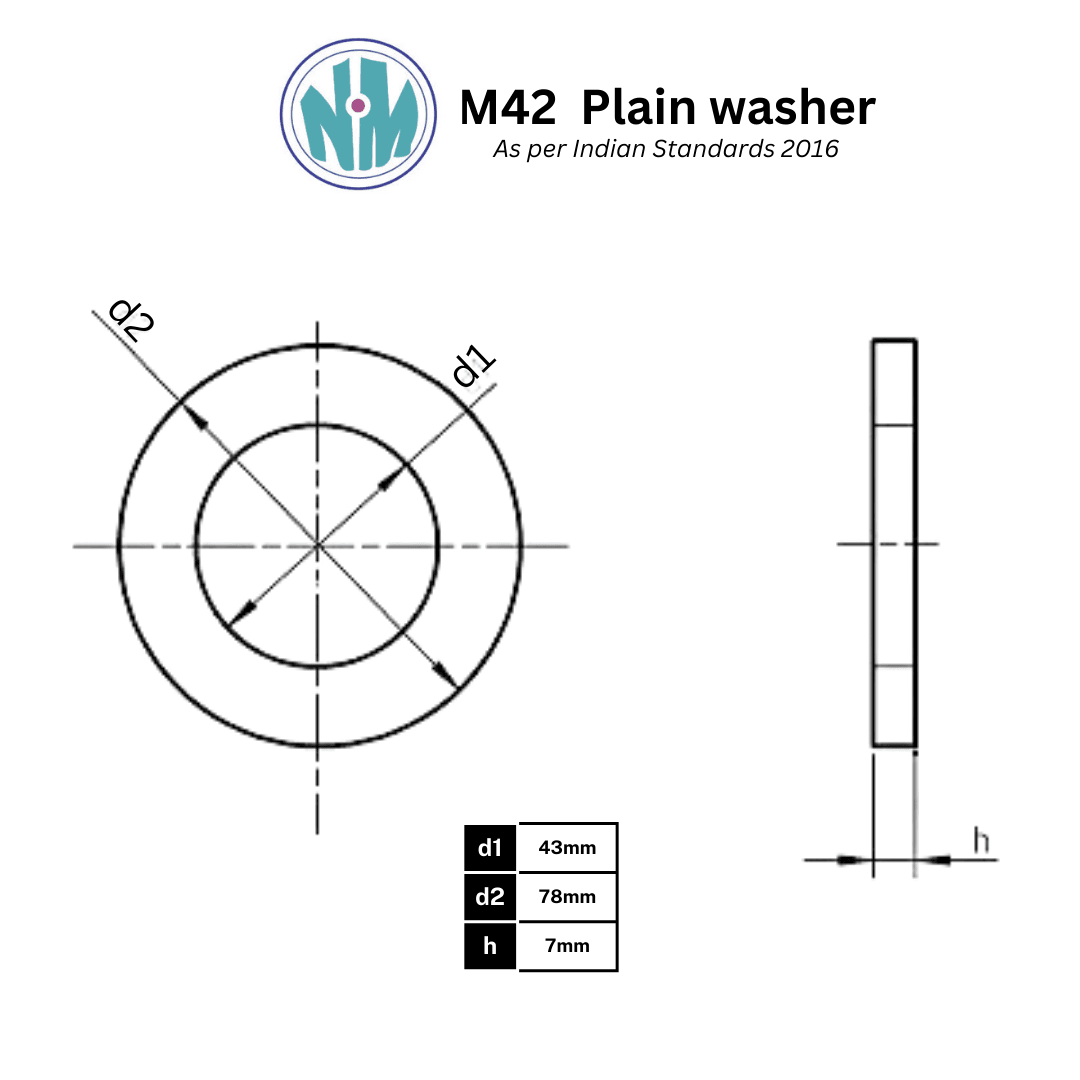

*Images shown for graphic representation. Not to scale.

M40 SS202 Plain Washers – Built for Maximum Strength in Heavy-Duty Applications

Introduction

In the world of engineering and industrial manufacturing, every component plays a vital role in the overall strength, performance, and safety of an assembly. Among these, washers are often overlooked due to their small size—yet they are indispensable in ensuring the durability and reliability of fastening systems. When it comes to heavy-duty applications involving high-pressure, vibration, or load-bearing operations, the choice of washer becomes even more critical.

M40 SS202 Plain Washers represent the perfect combination of precision engineering, high-grade material, and practical utility. These washers are specifically designed to fit M40 bolts and screws, offering a stable interface between fasteners and the materials they secure. Crafted from SS202 stainless steel, a cost-effective yet robust alloy, these washers bring together the advantages of corrosion resistance, structural strength, and affordability. Their plain, flat design allows for even load distribution, preventing surface damage, deformation, and joint failure—common issues in high-stress environments.

At Nafees Metal Industries, we understand that a washer is more than just a spacer—it’s a crucial part of the integrity of your assembly. That’s why our M40 SS202 Plain Washers are manufactured to the highest quality standards using advanced CNC technology, thorough inspection processes, and customized finishing options. Whether you’re in the automotive, construction, marine, or machinery sector, these washers ensure consistent, reliable performance even under the most demanding conditions.

This guide will walk you through everything you need to know about M40 SS202 Plain Washers—from their construction and material benefits to real-world applications, technical specifications, and installation best practices. If you’re looking for an efficient, high-quality fastening solution, you’ll quickly see why M40 SS202 Plain Washers should be your go-to choice.

What Are M40 SS202 Plain Washers?

M40 SS202 Plain Washers are flat, circular components with a central hole precisely engineered to accommodate M40 bolts or screws. They serve several critical purposes:

Distributing clamping forces across a wider area

Preventing damage to surfaces

Reducing the risk of fastener loosening due to vibration or pressure

Improving the longevity of the assembly

Made from SS202 stainless steel, these washers are ideal for high-load applications where durability, rust resistance, and cost-efficiency are required.

Why SS202? Material Properties That Matter

SS202 stainless steel is an austenitic grade with a chromium-manganese-nickel composition that provides a unique balance between strength, machinability, and corrosion resistance—at a lower cost than SS304 or SS316.

Key Benefits:

Corrosion Resistance: Resists rust and oxidation in indoor and outdoor environments

Strength: Excellent tensile strength suitable for heavy-duty usage

Affordability: A more cost-effective alternative without compromising on performance

Formability: Easy to shape and machine, leading to tighter tolerances and consistency

These advantages make SS202 the ideal material for M40 SS202 Plain Washers, allowing them to withstand stress while maintaining surface integrity. While it may not offer the same corrosion resistance as SS304 or SS316, SS202 remains a highly capable material for most indoor and outdoor applications, particularly when used with protective coatings like zinc or passivation. This makes M40 SS202 Plain Washers suitable for both general-purpose and high-stress environments where budget and performance must be balanced.

Specifications and Manufacturing Excellence

At Nafees Metal Industries, we follow a rigorous manufacturing process to ensure quality and consistency in every batch of M40 SS202 Plain Washers.

High-Precision Stainless Steel Flat Washers by Nafees Metal Industries

| Attribute | Specification |

|---|---|

| Product Name | M40 SS202 Plain Washers |

| Material | SS202 Stainless Steel |

| Inner Diameter | Precisely machined to fit M40 bolts |

| Outer Diameter | Standard per IS/DIN specs for load spread |

| Thickness | Optimized for heavy-duty clamping |

| Surface Finish | Plain finish (custom coatings available) |

| Shape | Flat round disc with central hole |

Each washer is CNC-cut, deburred, thermally treated (if required), and inspected for:

Dimensional accuracy

Surface flatness

Mechanical integrity

Key Features of M40 SS202 Plain Washers

Here’s why M40 SS202 Plain Washers are preferred in industrial-grade applications:

✅ Uniform Load Distribution: Reduces deformation and prolongs the life of joints

✅ Anti-Loosening Performance: Prevents fasteners from backing out in high-vibration setups

✅ Surface Protection: Protects mating surfaces from scoring, indentation, or cracking

✅ Corrosion Resistance: Ideal for outdoor and humid conditions

✅ Customizable Finishes: Available with zinc, nickel, or passivation coating

✅ Universal Fitment: Compatible with all standard M40 bolts and nuts

M40 SS202 Plain Washers are flat, circular metallic discs with a central hole engineered to snugly fit M40 bolts or screws. As the name suggests, these washers belong to the “plain washer” category—meaning they have a smooth, flat profile without serrations, ridges, or spring-like properties. Their primary function is to act as a barrier and load distributor between the bolt head (or nut) and the surface of the material being fastened.

But their role goes far beyond simple separation.

Here’s what makes M40 SS202 Plain Washers a critical component in any fastening system:

✅ Load Distribution

When a bolt is tightened without a washer, the pressure is concentrated in a small area, which can deform softer materials such as wood, plastic, or even mild steel. M40 SS202 Plain Washers spread this load over a wider surface area, significantly reducing the risk of indentation, cracking, or material fatigue. This makes them essential for applications involving delicate surfaces or components that endure repetitive stress.

✅ Prevention of Fastener Loosening

Vibration is the enemy of any bolted joint. In machinery, vehicles, or structures that experience movement, bolts can gradually loosen over time. When placed between the fastener and the joint surface, M40 SS202 Plain Washers act as a stabilizing layer, helping maintain clamping force and reducing micro-movement that leads to loosening.

✅ Protection of Components

They also serve as a physical buffer, preventing damage to finished surfaces, painted materials, or critical electrical components during bolt installation. Without washers, bolt heads can gouge or score surfaces, weakening the material and compromising the integrity of the joint.

✅ Enhanced Longevity of Assemblies

By reducing friction, stress, and movement at the joint interface, M40 SS202 Plain Washers contribute to the long-term stability and safety of mechanical systems. They are particularly useful in assemblies that are expected to perform for decades, such as structural frameworks or heavy equipment.

✅ Compatibility with M40 Fasteners

These washers are specifically dimensioned to match M40 bolts, which are large-diameter fasteners used in heavy-duty applications. The inner diameter is precision-machined to allow easy fitment, while the outer diameter and thickness are optimized to ensure maximum load dispersion and structural support.

Why Buy M40 SS202 Plain Washers in Bulk?

For industrial-scale operations, choosing to Buy M40 SS202 Plain Washers in Bulk has multiple benefits:

💰 Volume Pricing: Lower cost per unit

📦 Packaging Customization: Pre-labeled cartons for easy logistics

⏱️ Availability: Minimize downtime with large inventory at your site

🛠️ Consistency: Get washers from the same production batch for uniform performance

Whether you need 10,000 or 1,000,000 pieces, we ensure fast dispatch and batch traceability.

Why Choose the Best M40 SS202 Plain Washers Manufacturer?

Here’s why Nafees Metal Industries is recognized as the Best M40 SS202 Plain Washers manufacturer in India:

✅ ISO-Certified Production Standards

✅ In-House Manufacturing

✅ CNC-Controlled Precision

✅ Bulk and Custom Orders Handled Seamlessly

✅ Custom Coatings & Sizes Available

✅ Technical Documentation & Certification on Request

✅ Export-Ready Packaging

✅ Nationwide & International Dispatch

We don’t just make washers—we engineer fastening solutions tailored to your industrial needs.

Installation Tips for M40 SS202 Plain Washers

To ensure proper functionality:

🔩 Use Matched Fasteners: Always pair M40 washers with M40 bolts/nuts

🧼 Clean Before Installation: Avoid dirt, oils, and metal flakes

🔧 Use Even Torque: Prevent uneven compression or stress

⚙️ Double-Sided Use: Place a washer under both bolt head and nut for optimal force spread

🧰 Secure in Stacks: For oversized holes, use multiple washers to improve load sharing

Maintenance Guidelines

M40 SS202 Plain Washers are low-maintenance, but periodic checks are beneficial:

🔍 Inspect for corrosion or deformation every 6–12 months

💦 Clean with soap water; avoid strong acids unless passivated

🗃️ Store in dry, moisture-free packaging

🛠️ Replace if damaged or bent due to overtightening or impact

Case Study: Coastal Bridge Reinforcement Project – Gujarat, India

Client: A leading government-approved infrastructure contractor

Project: Coastal bridge reinforcement and structural bolt replacement across Gujarat’s monsoon-prone highway corridor

Washer Used: M40 SS202 Plain Washers

Order Volume: 75,000 pieces

Requirement: High-load-bearing washers with anti-corrosion properties, suitable for long-term coastal exposure

Delivered By: Nafees Metal Industries – Best M40 SS202 Plain Washers Manufacturer

Background & Challenge

The client, a top-tier infrastructure development firm, was awarded a multi-year contract to reinforce and expand a 7-kilometer coastal bridge stretch in Gujarat, which connects critical highways and coastal ports. The region is known for:

Intense humidity and salt-laden air

High wind speeds during monsoon

Heavy vehicular traffic, including container trucks

The project involved replacing corroded fasteners and washers on steel girders, handrails, and base anchor plates. A key concern was ensuring long-term structural integrity without recurring maintenance—especially in the exposed marine environment where rust and material fatigue pose a serious threat.

The client had previously used standard carbon steel washers, which had failed prematurely due to rust, warping, and bolt loosening. They needed a robust, corrosion-resistant, high-tolerance solution that would extend structural life by at least 15–20 years.

Why M40 SS202 Plain Washers Were Chosen

Nafees Metal Industries proposed a tailored solution using our high-precision M40 SS202 Plain Washers, enhanced with a protective zinc coating for marine-grade performance.

The decision was based on several key factors:

✅ Material Strength: SS202 stainless steel offered the tensile strength and ductility needed to withstand dynamic vehicle loads and wind pressure

✅ Corrosion Resistance: Even without coating, SS202 performs better than mild steel in coastal areas. The additional zinc layer provided dual protection

✅ Perfect Fit: Our washers were CNC-cut with ±0.05 mm tolerance to match M40 bolts, ensuring zero lateral play

✅ Bulk Availability: Nafees Metal Industries was able to meet the urgent supply timeline with 75,000 washers delivered in batches

✅ Test Certification: Salt spray test certificates and mechanical test reports were provided for each batch, ensuring accountability and compliance

Customizations Provided

To meet the specific demands of the project, the following customizations were made:

| Feature | Customization Applied |

|---|---|

| Coating | Zinc electroplating with passivation finish |

| Packaging | Phase-wise installation packs with weatherproof labeling |

| Batch Coding | Laser-etched codes for traceability |

| Tensile Testing | Third-party verification via NABL-accredited lab |

| Documentation | Full compliance with IS and ASTM standards |

Implementation Process

Pre-Supply Fitment Check

Sample M40 SS202 Plain Washers were sent to the contractor for test fitment. The washers were tested onsite with their existing bolts and anchor assemblies.Batch-wise Production & Delivery

To align with the bridge’s reinforcement schedule, washers were supplied in five separate shipments. Each batch was individually labeled by bridge section and use-case.Field Training Provided

Our technical team conducted virtual sessions to train the site engineers and workers on:Correct torque application

Washer installation under marine-grade bolts

Visual inspection criteria during assembly

Post-Installation Monitoring

The client continued monitoring washer performance during the first two monsoons. No slippage, rusting, or washer failure was reported.

Results After 24 Months

| Performance Metric | Result |

|---|---|

| Structural Integrity | No bolt loosening or washer deformation |

| Corrosion Resistance | Zero rust or pitting despite constant salt air exposure |

| Installation Efficiency | Reduced assembly time by 15% due to washer standardization |

| Maintenance Cost Savings | Estimated ₹7.5 lakhs saved in post-project replacements |

| Client Satisfaction | Project extended to include another bridge section using same washer specs |

Key Takeaway

This project illustrates how the right choice of hardware—particularly M40 SS202 Plain Washers—can dramatically improve structural safety, reduce lifetime maintenance, and optimize installation workflows. In corrosion-prone, high-load environments, these washers act as silent protectors of infrastructure integrity.

By trusting the Best M40 SS202 Plain Washers manufacturer, the client not only solved a current problem but laid the groundwork for scalable, reliable fastening solutions in future infrastructure projects.

Related Products You Might Need

SS202 Washers in other metric sizes

Stainless Steel Flat Washers with passivation

M39 / M42 plain and spring washers

Coated and color-coded variants

Custom laser-marked batches

How to Order

Submit your size, quantity, and finish preferences. We’ll offer a fast quote and sampling if needed. Our team also assists with technical specs, drawings, and international delivery compliance.

Final Words

When you’re working on a project that requires precision fastening, you cannot afford weak links. M40 SS202 Plain Washers provide that reliable foundation—resisting corrosion, distributing loads, and staying in place under pressure.

Backed by Nafees Metal Industries’ commitment to quality, they are your go-to solution for performance and peace of mind. So whether you’re building infrastructure, machines, or vehicles—don’t settle. Choose M40 SS202 Plain Washers made with purpose.

FAQs – M40 SS202 Plain Washers

Q1: Are M40 SS202 Plain Washers suitable for outdoor use?

Yes, especially when combined with a protective coating like zinc. SS202 offers good corrosion resistance in moderate conditions.

Q2: Can I get M40 SS202 Plain Washers in custom sizes?

Absolutely. We manufacture custom diameters and thicknesses based on your project needs.

Q3: What’s the default surface finish on these washers?

They come with a plain stainless finish. We also offer zinc, nickel, or passivation coatings upon request.

Q4: Are these washers reusable?

Yes—if undamaged and rust-free. Always inspect before reinstallation.

Q5: What certifications do you provide?

Mill Test Certificates (MTC), third-party inspection reports, and compliance with IS/DIN standards are available.

Q6: Do you ship internationally?

Yes, we export worldwide and comply with all packaging and documentation standards.

Q7: Are these magnetic?

SS202 is partially magnetic, but this doesn’t affect performance in general industrial use.

Q8: Can they be used with spring washers?

Yes. Combine with spring or lock washers for added anti-vibration protection.

Q9: What is the lead time for bulk orders?

Standard stock ships within 3–5 days. Custom orders may take 2–3 weeks depending on specs.

Q10: Are these suitable for food-grade applications?

No. Use SS304 or SS316 for food or sanitary environments.

Q11: How thick are M40 SS202 Plain Washers?

Thickness varies based on IS standards or client request—typically 4 to 6 mm.

Q12: Can I get branded or labeled packaging?

Yes. We offer private labeling, QR-coded cartons, and moisture-sealed bulk boxes.

Q13: Are you the original manufacturer or reseller?

We are an in-house manufacturer with CNC precision control—no middlemen involved.

Q14: Do you offer trial samples?

Yes. Samples are available on request for evaluation before bulk purchase.

Q15: Why choose Nafees Metal Industries over others?

We combine ISO-certified production, fast delivery, custom engineering, and proven reliability. That’s why we’re the Best M40 SS202 Plain Washers manufacturer.

Why Choose Nafees Metal Industries?

At Nafees Metal industries, we pride ourselves on producing high-quality M40 SS202 Plain Washers made from premium SS202 Stainless Steel. Our washers are engineered to meet the rigorous demands of various industries, offering top-notch durability, corrosion resistance, and reliable performance. We ensure competitive pricing, quick delivery, and outstanding customer support to meet all your fastening needs.

Best M40 SS202 Plain Washers manufacturer for dependable and high-performance fastening solutions. For more information or to visit our manufacturing unit, come to Reay Road, Mumbai, where we offer a full range of fastening products and custom solutions for all your industrial needs.

M40 SS202 Plain Washers

21 people are viewing this product right now

₹47.40 Original price was: ₹47.40.₹39.50Current price is: ₹39.50. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M40

Inner Diameter (ID): 42.5 mm

Outer Diameter (OD): 80 mm

Thickness (t): 5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M40 SS202 Plain Washers – Built for Maximum Strength in Heavy-Duty Applications

Introduction

In the world of engineering and industrial manufacturing, every component plays a vital role in the overall strength, performance, and safety of an assembly. Among these, washers are often overlooked due to their small size—yet they are indispensable in ensuring the durability and reliability of fastening systems. When it comes to heavy-duty applications involving high-pressure, vibration, or load-bearing operations, the choice of washer becomes even more critical.

M40 SS202 Plain Washers represent the perfect combination of precision engineering, high-grade material, and practical utility. These washers are specifically designed to fit M40 bolts and screws, offering a stable interface between fasteners and the materials they secure. Crafted from SS202 stainless steel, a cost-effective yet robust alloy, these washers bring together the advantages of corrosion resistance, structural strength, and affordability. Their plain, flat design allows for even load distribution, preventing surface damage, deformation, and joint failure—common issues in high-stress environments.

At Nafees Metal Industries, we understand that a washer is more than just a spacer—it’s a crucial part of the integrity of your assembly. That’s why our M40 SS202 Plain Washers are manufactured to the highest quality standards using advanced CNC technology, thorough inspection processes, and customized finishing options. Whether you’re in the automotive, construction, marine, or machinery sector, these washers ensure consistent, reliable performance even under the most demanding conditions.

This guide will walk you through everything you need to know about M40 SS202 Plain Washers—from their construction and material benefits to real-world applications, technical specifications, and installation best practices. If you’re looking for an efficient, high-quality fastening solution, you’ll quickly see why M40 SS202 Plain Washers should be your go-to choice.

What Are M40 SS202 Plain Washers?

M40 SS202 Plain Washers are flat, circular components with a central hole precisely engineered to accommodate M40 bolts or screws. They serve several critical purposes:

Distributing clamping forces across a wider area

Preventing damage to surfaces

Reducing the risk of fastener loosening due to vibration or pressure

Improving the longevity of the assembly

Made from SS202 stainless steel, these washers are ideal for high-load applications where durability, rust resistance, and cost-efficiency are required.

Why SS202? Material Properties That Matter

SS202 stainless steel is an austenitic grade with a chromium-manganese-nickel composition that provides a unique balance between strength, machinability, and corrosion resistance—at a lower cost than SS304 or SS316.

Key Benefits:

Corrosion Resistance: Resists rust and oxidation in indoor and outdoor environments

Strength: Excellent tensile strength suitable for heavy-duty usage

Affordability: A more cost-effective alternative without compromising on performance

Formability: Easy to shape and machine, leading to tighter tolerances and consistency

These advantages make SS202 the ideal material for M40 SS202 Plain Washers, allowing them to withstand stress while maintaining surface integrity. While it may not offer the same corrosion resistance as SS304 or SS316, SS202 remains a highly capable material for most indoor and outdoor applications, particularly when used with protective coatings like zinc or passivation. This makes M40 SS202 Plain Washers suitable for both general-purpose and high-stress environments where budget and performance must be balanced.

Specifications and Manufacturing Excellence

At Nafees Metal Industries, we follow a rigorous manufacturing process to ensure quality and consistency in every batch of M40 SS202 Plain Washers.

High-Precision Stainless Steel Flat Washers by Nafees Metal Industries

| Attribute | Specification |

|---|---|

| Product Name | M40 SS202 Plain Washers |

| Material | SS202 Stainless Steel |

| Inner Diameter | Precisely machined to fit M40 bolts |

| Outer Diameter | Standard per IS/DIN specs for load spread |

| Thickness | Optimized for heavy-duty clamping |

| Surface Finish | Plain finish (custom coatings available) |

| Shape | Flat round disc with central hole |

Each washer is CNC-cut, deburred, thermally treated (if required), and inspected for:

Dimensional accuracy

Surface flatness

Mechanical integrity

Key Features of M40 SS202 Plain Washers

Here’s why M40 SS202 Plain Washers are preferred in industrial-grade applications:

✅ Uniform Load Distribution: Reduces deformation and prolongs the life of joints

✅ Anti-Loosening Performance: Prevents fasteners from backing out in high-vibration setups

✅ Surface Protection: Protects mating surfaces from scoring, indentation, or cracking

✅ Corrosion Resistance: Ideal for outdoor and humid conditions

✅ Customizable Finishes: Available with zinc, nickel, or passivation coating

✅ Universal Fitment: Compatible with all standard M40 bolts and nuts

M40 SS202 Plain Washers are flat, circular metallic discs with a central hole engineered to snugly fit M40 bolts or screws. As the name suggests, these washers belong to the “plain washer” category—meaning they have a smooth, flat profile without serrations, ridges, or spring-like properties. Their primary function is to act as a barrier and load distributor between the bolt head (or nut) and the surface of the material being fastened.

But their role goes far beyond simple separation.

Here’s what makes M40 SS202 Plain Washers a critical component in any fastening system:

✅ Load Distribution

When a bolt is tightened without a washer, the pressure is concentrated in a small area, which can deform softer materials such as wood, plastic, or even mild steel. M40 SS202 Plain Washers spread this load over a wider surface area, significantly reducing the risk of indentation, cracking, or material fatigue. This makes them essential for applications involving delicate surfaces or components that endure repetitive stress.

✅ Prevention of Fastener Loosening

Vibration is the enemy of any bolted joint. In machinery, vehicles, or structures that experience movement, bolts can gradually loosen over time. When placed between the fastener and the joint surface, M40 SS202 Plain Washers act as a stabilizing layer, helping maintain clamping force and reducing micro-movement that leads to loosening.

✅ Protection of Components

They also serve as a physical buffer, preventing damage to finished surfaces, painted materials, or critical electrical components during bolt installation. Without washers, bolt heads can gouge or score surfaces, weakening the material and compromising the integrity of the joint.

✅ Enhanced Longevity of Assemblies

By reducing friction, stress, and movement at the joint interface, M40 SS202 Plain Washers contribute to the long-term stability and safety of mechanical systems. They are particularly useful in assemblies that are expected to perform for decades, such as structural frameworks or heavy equipment.

✅ Compatibility with M40 Fasteners

These washers are specifically dimensioned to match M40 bolts, which are large-diameter fasteners used in heavy-duty applications. The inner diameter is precision-machined to allow easy fitment, while the outer diameter and thickness are optimized to ensure maximum load dispersion and structural support.

Why Buy M40 SS202 Plain Washers in Bulk?

For industrial-scale operations, choosing to Buy M40 SS202 Plain Washers in Bulk has multiple benefits:

💰 Volume Pricing: Lower cost per unit

📦 Packaging Customization: Pre-labeled cartons for easy logistics

⏱️ Availability: Minimize downtime with large inventory at your site

🛠️ Consistency: Get washers from the same production batch for uniform performance

Whether you need 10,000 or 1,000,000 pieces, we ensure fast dispatch and batch traceability.

Why Choose the Best M40 SS202 Plain Washers Manufacturer?

Here’s why Nafees Metal Industries is recognized as the Best M40 SS202 Plain Washers manufacturer in India:

✅ ISO-Certified Production Standards

✅ In-House Manufacturing

✅ CNC-Controlled Precision

✅ Bulk and Custom Orders Handled Seamlessly

✅ Custom Coatings & Sizes Available

✅ Technical Documentation & Certification on Request

✅ Export-Ready Packaging

✅ Nationwide & International Dispatch

We don’t just make washers—we engineer fastening solutions tailored to your industrial needs.

Installation Tips for M40 SS202 Plain Washers

To ensure proper functionality:

🔩 Use Matched Fasteners: Always pair M40 washers with M40 bolts/nuts

🧼 Clean Before Installation: Avoid dirt, oils, and metal flakes

🔧 Use Even Torque: Prevent uneven compression or stress

⚙️ Double-Sided Use: Place a washer under both bolt head and nut for optimal force spread

🧰 Secure in Stacks: For oversized holes, use multiple washers to improve load sharing

Maintenance Guidelines

M40 SS202 Plain Washers are low-maintenance, but periodic checks are beneficial:

🔍 Inspect for corrosion or deformation every 6–12 months

💦 Clean with soap water; avoid strong acids unless passivated

🗃️ Store in dry, moisture-free packaging

🛠️ Replace if damaged or bent due to overtightening or impact

Case Study: Coastal Bridge Reinforcement Project – Gujarat, India

Client: A leading government-approved infrastructure contractor

Project: Coastal bridge reinforcement and structural bolt replacement across Gujarat’s monsoon-prone highway corridor

Washer Used: M40 SS202 Plain Washers

Order Volume: 75,000 pieces

Requirement: High-load-bearing washers with anti-corrosion properties, suitable for long-term coastal exposure

Delivered By: Nafees Metal Industries – Best M40 SS202 Plain Washers Manufacturer

Background & Challenge

The client, a top-tier infrastructure development firm, was awarded a multi-year contract to reinforce and expand a 7-kilometer coastal bridge stretch in Gujarat, which connects critical highways and coastal ports. The region is known for:

Intense humidity and salt-laden air

High wind speeds during monsoon

Heavy vehicular traffic, including container trucks

The project involved replacing corroded fasteners and washers on steel girders, handrails, and base anchor plates. A key concern was ensuring long-term structural integrity without recurring maintenance—especially in the exposed marine environment where rust and material fatigue pose a serious threat.

The client had previously used standard carbon steel washers, which had failed prematurely due to rust, warping, and bolt loosening. They needed a robust, corrosion-resistant, high-tolerance solution that would extend structural life by at least 15–20 years.

Why M40 SS202 Plain Washers Were Chosen

Nafees Metal Industries proposed a tailored solution using our high-precision M40 SS202 Plain Washers, enhanced with a protective zinc coating for marine-grade performance.

The decision was based on several key factors:

✅ Material Strength: SS202 stainless steel offered the tensile strength and ductility needed to withstand dynamic vehicle loads and wind pressure

✅ Corrosion Resistance: Even without coating, SS202 performs better than mild steel in coastal areas. The additional zinc layer provided dual protection

✅ Perfect Fit: Our washers were CNC-cut with ±0.05 mm tolerance to match M40 bolts, ensuring zero lateral play

✅ Bulk Availability: Nafees Metal Industries was able to meet the urgent supply timeline with 75,000 washers delivered in batches

✅ Test Certification: Salt spray test certificates and mechanical test reports were provided for each batch, ensuring accountability and compliance

Customizations Provided

To meet the specific demands of the project, the following customizations were made:

| Feature | Customization Applied |

|---|---|

| Coating | Zinc electroplating with passivation finish |

| Packaging | Phase-wise installation packs with weatherproof labeling |

| Batch Coding | Laser-etched codes for traceability |

| Tensile Testing | Third-party verification via NABL-accredited lab |

| Documentation | Full compliance with IS and ASTM standards |

Implementation Process

Pre-Supply Fitment Check

Sample M40 SS202 Plain Washers were sent to the contractor for test fitment. The washers were tested onsite with their existing bolts and anchor assemblies.Batch-wise Production & Delivery

To align with the bridge’s reinforcement schedule, washers were supplied in five separate shipments. Each batch was individually labeled by bridge section and use-case.Field Training Provided

Our technical team conducted virtual sessions to train the site engineers and workers on:Correct torque application

Washer installation under marine-grade bolts

Visual inspection criteria during assembly

Post-Installation Monitoring

The client continued monitoring washer performance during the first two monsoons. No slippage, rusting, or washer failure was reported.

Results After 24 Months

| Performance Metric | Result |

|---|---|

| Structural Integrity | No bolt loosening or washer deformation |

| Corrosion Resistance | Zero rust or pitting despite constant salt air exposure |

| Installation Efficiency | Reduced assembly time by 15% due to washer standardization |

| Maintenance Cost Savings | Estimated ₹7.5 lakhs saved in post-project replacements |

| Client Satisfaction | Project extended to include another bridge section using same washer specs |

Key Takeaway

This project illustrates how the right choice of hardware—particularly M40 SS202 Plain Washers—can dramatically improve structural safety, reduce lifetime maintenance, and optimize installation workflows. In corrosion-prone, high-load environments, these washers act as silent protectors of infrastructure integrity.

By trusting the Best M40 SS202 Plain Washers manufacturer, the client not only solved a current problem but laid the groundwork for scalable, reliable fastening solutions in future infrastructure projects.

Related Products You Might Need

SS202 Washers in other metric sizes

Stainless Steel Flat Washers with passivation

M39 / M42 plain and spring washers

Coated and color-coded variants

Custom laser-marked batches

How to Order

Submit your size, quantity, and finish preferences. We’ll offer a fast quote and sampling if needed. Our team also assists with technical specs, drawings, and international delivery compliance.

Final Words

When you’re working on a project that requires precision fastening, you cannot afford weak links. M40 SS202 Plain Washers provide that reliable foundation—resisting corrosion, distributing loads, and staying in place under pressure.

Backed by Nafees Metal Industries’ commitment to quality, they are your go-to solution for performance and peace of mind. So whether you’re building infrastructure, machines, or vehicles—don’t settle. Choose M40 SS202 Plain Washers made with purpose.

FAQs – M40 SS202 Plain Washers

Q1: Are M40 SS202 Plain Washers suitable for outdoor use?

Yes, especially when combined with a protective coating like zinc. SS202 offers good corrosion resistance in moderate conditions.

Q2: Can I get M40 SS202 Plain Washers in custom sizes?

Absolutely. We manufacture custom diameters and thicknesses based on your project needs.

Q3: What’s the default surface finish on these washers?

They come with a plain stainless finish. We also offer zinc, nickel, or passivation coatings upon request.

Q4: Are these washers reusable?

Yes—if undamaged and rust-free. Always inspect before reinstallation.

Q5: What certifications do you provide?

Mill Test Certificates (MTC), third-party inspection reports, and compliance with IS/DIN standards are available.

Q6: Do you ship internationally?

Yes, we export worldwide and comply with all packaging and documentation standards.

Q7: Are these magnetic?

SS202 is partially magnetic, but this doesn’t affect performance in general industrial use.

Q8: Can they be used with spring washers?

Yes. Combine with spring or lock washers for added anti-vibration protection.

Q9: What is the lead time for bulk orders?

Standard stock ships within 3–5 days. Custom orders may take 2–3 weeks depending on specs.

Q10: Are these suitable for food-grade applications?

No. Use SS304 or SS316 for food or sanitary environments.

Q11: How thick are M40 SS202 Plain Washers?

Thickness varies based on IS standards or client request—typically 4 to 6 mm.

Q12: Can I get branded or labeled packaging?

Yes. We offer private labeling, QR-coded cartons, and moisture-sealed bulk boxes.

Q13: Are you the original manufacturer or reseller?

We are an in-house manufacturer with CNC precision control—no middlemen involved.

Q14: Do you offer trial samples?

Yes. Samples are available on request for evaluation before bulk purchase.

Q15: Why choose Nafees Metal Industries over others?

We combine ISO-certified production, fast delivery, custom engineering, and proven reliability. That’s why we’re the Best M40 SS202 Plain Washers manufacturer.

Why Choose Nafees Metal Industries?

At Nafees Metal industries, we pride ourselves on producing high-quality M40 SS202 Plain Washers made from premium SS202 Stainless Steel. Our washers are engineered to meet the rigorous demands of various industries, offering top-notch durability, corrosion resistance, and reliable performance. We ensure competitive pricing, quick delivery, and outstanding customer support to meet all your fastening needs.

Best M40 SS202 Plain Washers manufacturer for dependable and high-performance fastening solutions. For more information or to visit our manufacturing unit, come to Reay Road, Mumbai, where we offer a full range of fastening products and custom solutions for all your industrial needs.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch