No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

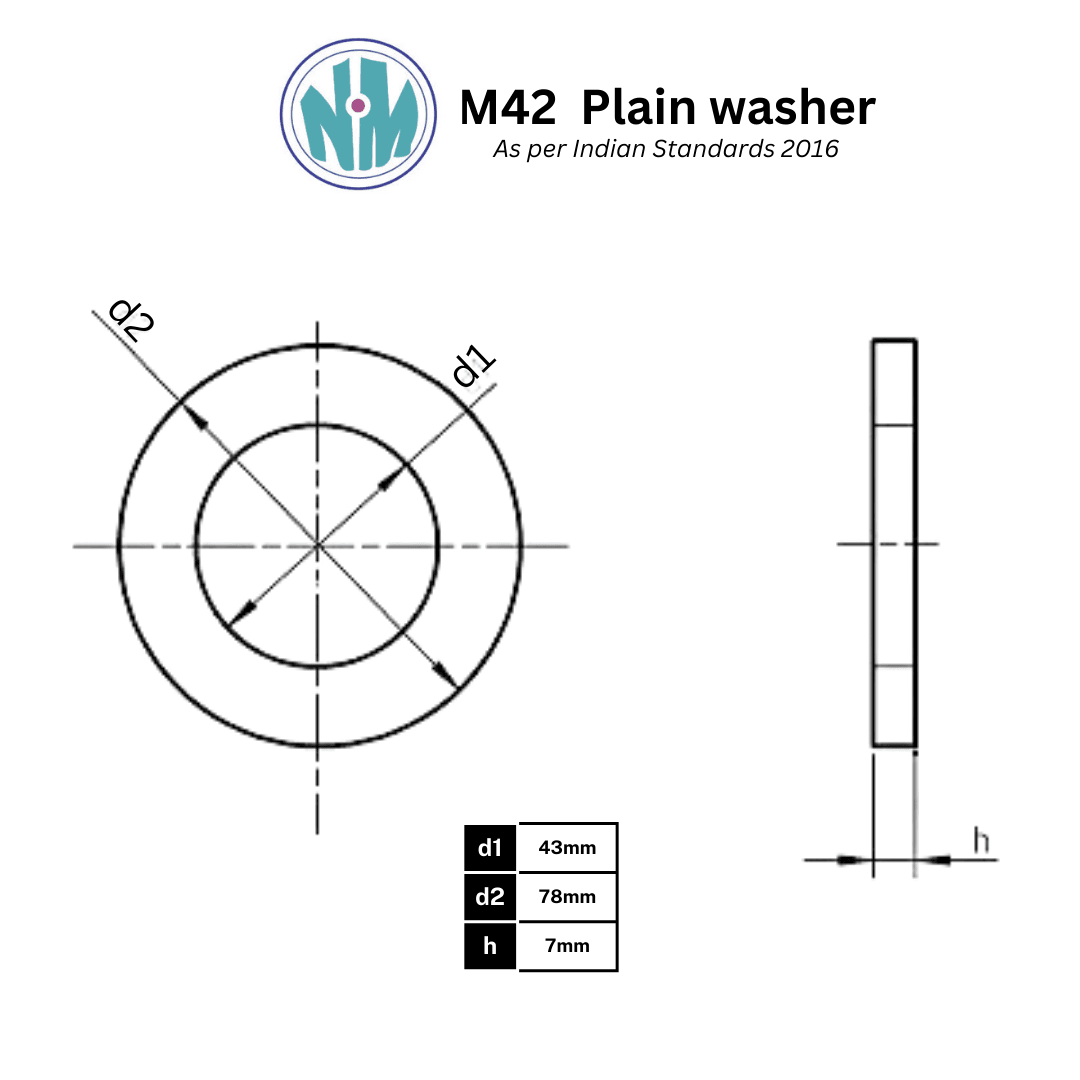

*Images shown for graphic representation. Not to scale.

M40 Copper Plain Washers – High-Precision Flat Washers for Industrial Strength & Corrosion Resistance

At Nafees Metal Industries, we specialize in manufacturing premium-grade M40 copper plain washers, designed to meet the most demanding industrial fastening applications. These washers offer a seamless combination of high strength, exceptional conductivity, and excellent corrosion resistance. Built in accordance with DIN 125 standards, our M40 copper plain washers are engineered for perfection in both function and durability.

Whether you’re operating in a hydraulic setup, high-load mechanical system, or electrical assembly, our M40 copper plain washers ensure precise load distribution, secure sealing, and long-lasting performance. From power stations to offshore rigs, these washers deliver unmatched reliability under pressure, heat, and vibration.

Our washers are precisely tailored to the M40 bolt size, ensuring easy integration into your mechanical or electrical projects. These high-performance M40 copper plain washers are perfect for professionals seeking durability and efficiency in environments where both conductivity and resistance to corrosion are essential.

As one of the most trusted names in the industry, Nafees Metal Industries proudly offers M40 copper plain washers that are not only manufactured in India at our modern facility in Mumbai, but are also available for international export, complete with all required documentation and custom packaging options.

What sets us apart is our attention to detail. Each washer undergoes rigorous quality checks and precision engineering to meet global standards. For industries that need reliable components for performance-critical environments, M40 copper plain washers from our facility offer long-term reliability and value.

In high-pressure and moisture-rich environments, especially in the hydraulics industry, our washers also perform a crucial role as copper sealing washer M40 hydraulic fittings, delivering both mechanical support and fluid sealing in one solution.

To sum up, whether you’re sourcing for your production line or handling replacement parts in a repair setup, M40 copper plain washers are a go-to solution for a wide range of demanding industrial needs.

What Are M40 Copper Plain Washers?

M40 copper plain washers are flat, round components crafted from high-purity copper, specifically designed to fit M40 bolts or screws (40 mm diameter). Their primary function is to distribute the load of the fastening system evenly across the surface, preventing surface damage and ensuring a firm, reliable connection. Because of their size and material composition, M40 copper plain washers are commonly used in heavy-duty industrial applications where both conductivity and structural support are required.

These washers feature a large outer diameter and a smooth, flat surface that enables uniform pressure distribution. This helps protect the fastened components from damage due to over-tightening or vibration. The use of copper adds the benefit of electrical and thermal conductivity, making M40 copper plain washers especially useful in environments like power generation plants, switchgear installations, marine setups, and other high-load assemblies.

Unlike regular steel or plastic washers, M40 copper plain washers provide enhanced corrosion resistance and natural sealing properties. Their malleability allows them to conform to uneven surfaces, providing a tighter fit and minimizing the risk of leaks or mechanical failure. This makes them a preferred choice for both mechanical engineers and maintenance professionals.

When sourced from a reliable manufacturer like Nafees Metal Industries, M40 copper plain washers are produced to exact international specifications. One of the most popular standards followed is DIN 125, and our washers perfectly adhere to this requirement, offering interchangeability and consistency. For this reason, many refer to these parts as copper plain washer DIN 125 size M40, indicating the combination of material, size, and compliance.

Additionally, M40 copper plain washers play a vital role in thermal dissipation when placed under components that generate heat. Their robust construction makes them suitable for static as well as dynamic load-bearing tasks, ensuring safety and durability in long-term operations.

In summary, M40 copper plain washers are not just flat discs with a hole—they are precision-engineered components critical to the safety and efficiency of many industrial systems.

Why Use Copper for M40 Washers?

Copper has long been favored in industrial fastening components due to its unmatched combination of physical, chemical, and mechanical properties. This makes it a highly desirable material for manufacturing M40 copper plain washers, especially for applications that demand superior corrosion resistance, thermal and electrical conductivity, and structural reliability.

M40 copper plain washers made from high-purity copper are exceptionally malleable. This allows them to conform to uneven surfaces during installation, creating a snug and secure seal between mating components. This is crucial in applications like hydraulic systems, electrical terminals, and high-vibration equipment. Due to their excellent ductility, M40 copper plain washers can maintain sealing integrity even under intense load and thermal fluctuation.

Another major reason for choosing copper in the construction of M40 copper plain washers is its inherent corrosion resistance. Copper forms a protective oxide layer over time that helps shield it from degradation when exposed to moisture, chemicals, or salt-laden environments. This is why M40 copper plain washers are widely used in marine and offshore structures, chemical processing equipment, and outdoor assemblies.

Furthermore, copper offers high electrical and thermal conductivity—properties that are critical in energy systems. M40 copper plain washers are therefore widely deployed in electrical enclosures, switchgears, transformers, and other power-related installations where efficient conductivity and grounding are required.

In systems where sealing is as important as load distribution, copper provides a unique advantage. It acts both as a support component and as a functional sealing medium. This dual-purpose benefit is one reason why engineers often specify M40 copper plain washers instead of conventional alternatives.

Additionally, copper is non-sparking and non-magnetic. This makes M40 copper plain washers safe for use in volatile environments such as oil refineries, chemical plants, and gas distribution networks, where other materials could pose a hazard.

From a manufacturing standpoint, copper is also easy to machine, punch, and finish, enabling us at Nafees Metal Industries to produce M40 copper plain washers with highly consistent inner and outer diameters. Our washers follow precise tolerances and are fully compliant with M40 copper flat washer metric series DIN 125, ensuring standardization and compatibility with global specifications.

In short, the material advantages of copper directly contribute to the high performance, durability, and safety of our M40 copper plain washers across diverse industrial sectors.

Manufacturing Process of M40 Copper Plain Washers

At Nafees Metal Industries, the production of M40 copper plain washers follows a meticulous, quality-controlled process designed to meet international standards and exceed customer expectations. Each washer undergoes precision forming, finishing, and inspection to ensure performance in high-pressure and high-temperature environments.

The manufacturing process for M40 copper plain washers begins with the sourcing of high-conductivity, industrial-grade copper sheets. These raw materials are carefully selected for their purity and mechanical consistency, as they form the foundation of durability and performance in every washer we produce.

Once the copper sheets are verified for compliance, the next step involves precision blanking and punching. Specialized tooling is used to cut circular blanks and punch the inner hole to match M40 bolt specifications. This ensures every washer maintains an accurate fitment with minimal deviation in dimensions. Our advanced machinery allows us to produce M40 copper plain washers in large volumes while maintaining high consistency and repeatability.

Following punching, the washers undergo deburring and edge finishing. This crucial step ensures smooth, burr-free edges that reduce the risk of surface scratching during installation and improve safety for technicians handling the washers. For applications where surface aesthetics or additional sealing is important, M40 copper plain washers can also undergo annealing. This heat treatment process enhances the softness and pliability of the washer, improving its sealing capabilities in hydraulic and pneumatic systems.

After forming and heat treatment, washers are sent through polishing or surface cleaning processes to remove oxidation or residues, giving them a clean, refined appearance and improved performance. Some customers require additional treatments such as tin plating or anti-tarnish coating, which we offer upon request for specialized applications.

Each batch of M40 copper plain washers is subjected to rigorous quality control checks, including dimensional verification (ID, OD, and thickness), surface flatness, and hardness testing. Only after passing all quality parameters are the washers approved for packing.

We offer flexible packaging solutions to suit both domestic and international clients. Whether it’s polybags, corrugated boxes, or custom-labeled cartons, M40 copper plain washers are packed securely to avoid any damage during transportation.

Our washers also conform to industry benchmarks like industrial copper flat washer corrosion-resistant grades, making them suitable for harsh operational environments and ensuring long-term performance without deterioration.

Through our advanced processes and unwavering commitment to quality, Nafees Metal Industries ensures that every unit of M40 copper plain washers is a perfect example of precision, strength, and dependability.

Key Features of M40 Copper Plain Washers

M40 copper plain washers are designed with precision, keeping in mind the rigorous demands of modern industrial environments. At Nafees Metal Industries, every washer we manufacture reflects durability, accuracy, and performance integrity. These features make M40 copper plain washers the ideal choice for high-load fastening systems, especially in sectors like electrical engineering, automotive, petrochemical, and marine industries.

Below are the core features that set our M40 copper plain washers apart:

1. Precise Dimensional Accuracy

Our M40 copper plain washers are manufactured to meet strict inner and outer diameter tolerances. They fit seamlessly with M40 bolts and screws, ensuring a tight, vibration-resistant fastening assembly every time.

2. Enhanced Load Distribution

The broad surface area of M40 copper plain washers allows for even distribution of pressure across the bolted surface. This reduces the risk of surface damage, warping, or cracking in softer materials.

3. Superior Conductivity

Made from high-purity copper, M40 copper plain washers offer outstanding electrical and thermal conductivity. They are ideal for applications where grounding, current flow, or heat dissipation is critical—such as switchgear, transformers, and energy systems.

4. Corrosion Resistance

Thanks to copper’s natural resistance to oxidation and atmospheric degradation, our M40 copper plain washers perform exceptionally well in outdoor or humid environments. They are suitable for long-term installations in corrosive conditions without needing frequent replacements.

5. Smooth Finish with Burr-Free Edges

All M40 copper plain washers are deburred and polished during the manufacturing process. This ensures smooth edges, reducing the risk of component damage or worker injury during assembly.

6. DIN Standard Compliance

Our M40 copper plain washers conform to DIN 125 and ISO 7089 standards, which makes them compatible with global applications and engineering drawings. The standardization also ensures easy sourcing and interchangeability.

7. Customization Options Available

We offer tailor-made solutions for businesses looking to alter thickness, surface finish, or packaging. Whether you need annealed washers, tin-plated variants, or extra-thick designs, Nafees Metal Industries delivers as per your project requirements.

8. Made in India – Export Ready

Manufactured in our advanced Mumbai facility, all M40 copper plain washers are proudly made in India and ready for international distribution with necessary export documentation and certifications.

9. Cost-Effective for High-Performance Results

With superior quality control, local manufacturing, and bulk production capabilities, we ensure that M40 copper plain washers offer maximum value for your investment.

Each of these features contributes to the performance and reliability that industrial engineers and OEMs expect from a high-grade washer. For mission-critical applications, M40 copper plain washers are the trusted component that never compromises on quality.

Technical Specifications

When selecting a washer for mission-critical industrial tasks, technical clarity is crucial. At Nafees Metal Industries, every batch of M40 copper plain washers is manufactured according to international standards and customized to suit diverse mechanical and electrical requirements. Below is a detailed breakdown of the standard specifications for our M40 copper plain washers, ensuring compatibility, durability, and precision in your fastening operations.

| Property | Specification |

|---|---|

| Product Name | M40 Copper Plain Washer |

| Material | High-Purity Copper (Industrial Grade) |

| Inner Diameter (ID) | Approximately 42.0 mm (to accommodate M40 bolts securely) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 (customization available) |

| Washer Thickness | 2.5 mm standard (can be customized based on application) |

| Washer Type | Flat / Plain Washer |

| Finish Options | Plain, Annealed, Polished, or Tin-Plated |

| Hardness | Soft annealed for sealing or custom tempering on request |

| Standard Compliance | DIN 125, ISO 7089 – suitable for metric engineering systems |

| Applications | Electrical, Hydraulic, Marine, Petrochemical, Power Generation |

| Temperature Tolerance | Up to 500°C for sustained thermal exposure |

| Conductivity | Excellent thermal and electrical conductivity |

| Corrosion Resistance | High resistance to rust, oxidation, and industrial chemicals |

| Manufacturing Origin | Made in India (Mumbai Manufacturing Unit) |

| Packaging Options | Polybags, Corrugated Boxes, Custom Labeling (bulk and export packaging available) |

| Bulk Availability | Ready stock maintained for large-volume industrial procurement |

Our M40 copper plain washers undergo dimensional inspection at every stage of the manufacturing process. This includes checking ID/OD tolerances, verifying concentricity, and testing hardness where applicable. For OEMs, EPC contractors, and heavy machinery manufacturers, the ability to rely on exact-fit specifications is non-negotiable—and that’s exactly what we deliver.

Additionally, we can provide technical drawings, MSDS, and test certificates along with your order for complete transparency and compliance documentation.

Whether you’re installing transformers, designing hydraulic systems, or retrofitting power infrastructure, our M40 copper plain washers deliver consistent, dependable performance across all operating conditions.

Applications of M40 Copper Plain Washers

The industrial versatility of M40 copper plain washers makes them indispensable across a wide range of sectors that rely on high-performance fasteners. Known for their superior conductivity and corrosion resistance, these washers perform exceptionally well in environments exposed to moisture, heat, vibration, and mechanical stress. Let’s explore the industries and systems where M40 copper plain washers are most effectively utilized:

1. Hydraulic Fittings & Sealing Applications

In hydraulic systems, especially in pressure lines and valve assemblies, M40 copper plain washers act as sealing components that prevent fluid leakage under high pressure. These washers are often paired with fittings where copper’s softness allows it to conform to irregularities, ensuring a tight seal. For such use, our copper sealing washer M40 hydraulic fittings solution is among the most trusted by OEMs and maintenance engineers.

2. Electrical & Electronics Installations

Due to their excellent electrical conductivity, M40 copper plain washers are widely used in power generation units, control panels, transformer assemblies, and circuit grounding systems. These washers help maintain secure electrical connections without introducing resistance or galvanic corrosion, ensuring uninterrupted current flow.

3. Petrochemical and Marine Industries

Environments rich in moisture, chemicals, and salt demand corrosion-resistant fasteners. Our M40 copper plain washers excel in these industries due to their natural resistance to oxidation. Whether it’s offshore oil rigs or chemical handling systems, they offer long-lasting performance without the need for frequent replacement.

4. Heavy Machinery and Structural Assemblies

When assembling turbines, diesel engines, heavy presses, or load-bearing joints, high-strength components are critical. Our M40 copper plain washers provide the necessary surface protection under large bolt heads and distribute compressive load to prevent damage or loosening under vibration.

5. Thermal Systems and HVAC

Heat exchangers, boilers, and HVAC systems benefit from the thermal conductivity and durability of M40 copper plain washers. They maintain fastening integrity even when subjected to frequent thermal cycling, preventing expansion-related loosening.

6. Automotive & Locomotive Manufacturing

Copper washers are increasingly used in performance-driven automotive applications, particularly in fuel lines, engine blocks, and brake assemblies. The size-specific nature of M40 copper plain washers allows them to be integrated seamlessly into metric systems where DIN 125 compatibility is required.

7. Renewable Energy Infrastructure

Wind turbines, solar inverters, and grid connectors require stable electrical connections and corrosion-free support components. M40 copper plain washers fit perfectly in these applications, improving overall system life and efficiency.

Whether you’re building critical electrical panels, tightening hydraulic couplings, or managing offshore equipment, M40 copper plain washers from Nafees Metal Industries offer long-term reliability, excellent sealing, and unmatched conductivity. If your industry requires high-precision, non-ferrous washers that meet international standards, our washers are engineered to deliver uncompromising performance.

Why Choose Nafees Metal Industries for M40 Copper Plain Washers?

When it comes to sourcing M40 copper plain washers, manufacturers and industrial buyers across India and beyond place their trust in Nafees Metal Industries. Our commitment to quality, precision, and customer satisfaction has earned us a leading position in the copper washer manufacturing industry. Here’s why our M40 copper plain washers stand out in the market:

1. State-of-the-Art Manufacturing Facility in Mumbai

Our advanced manufacturing unit in Mumbai is equipped with precision machinery, automated stamping systems, and stringent quality control mechanisms. Every M40 copper plain washer produced here adheres to exacting tolerances and meets the specifications outlined by DIN 125 standards, including compatibility with M40 copper flat washer metric series DIN 125 requirements.

2. Certified Raw Materials & Quality Assurance

We use high-grade pure copper to manufacture our washers, ensuring optimal conductivity, strength, and corrosion resistance. Each batch of M40 copper plain washers undergoes rigorous testing for dimensional accuracy, surface finish, tensile strength, and stress handling to ensure top performance in critical applications.

3. Customization & Bulk Supply Capabilities

Whether your requirement is for standard dimensions or customized solutions, we offer flexibility in order size, packaging, and delivery timelines. Our production scale allows us to fulfill both small-scale and large-volume industrial orders efficiently. If you’re looking to buy bulk industrial copper flat washer corrosion-resistant solutions, we are your one-stop source.

4. Trusted by Industries Across India

Our M40 copper plain washers are used across multiple sectors—hydraulics, automotive, marine, electrical, petrochemical, and construction—making us one of the most reliable suppliers in the Indian washer industry. Our washers are preferred for their dimensional consistency, sealing efficiency, and longevity.

5. Dedicated Customer Support

We believe in creating long-term relationships with our clients. Our team offers technical assistance, material selection guidance, and after-sales service to help you get the most from your M40 copper plain washers.

M40 Copper Plain Washers (DIN 125)

12 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M40

Inner Diameter (ID): 42.5 mm

Outer Diameter (OD): 80 mm

Thickness (t): 5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M40 Copper Plain Washers – High-Precision Flat Washers for Industrial Strength & Corrosion Resistance

At Nafees Metal Industries, we specialize in manufacturing premium-grade M40 copper plain washers, designed to meet the most demanding industrial fastening applications. These washers offer a seamless combination of high strength, exceptional conductivity, and excellent corrosion resistance. Built in accordance with DIN 125 standards, our M40 copper plain washers are engineered for perfection in both function and durability.

Whether you’re operating in a hydraulic setup, high-load mechanical system, or electrical assembly, our M40 copper plain washers ensure precise load distribution, secure sealing, and long-lasting performance. From power stations to offshore rigs, these washers deliver unmatched reliability under pressure, heat, and vibration.

Our washers are precisely tailored to the M40 bolt size, ensuring easy integration into your mechanical or electrical projects. These high-performance M40 copper plain washers are perfect for professionals seeking durability and efficiency in environments where both conductivity and resistance to corrosion are essential.

As one of the most trusted names in the industry, Nafees Metal Industries proudly offers M40 copper plain washers that are not only manufactured in India at our modern facility in Mumbai, but are also available for international export, complete with all required documentation and custom packaging options.

What sets us apart is our attention to detail. Each washer undergoes rigorous quality checks and precision engineering to meet global standards. For industries that need reliable components for performance-critical environments, M40 copper plain washers from our facility offer long-term reliability and value.

In high-pressure and moisture-rich environments, especially in the hydraulics industry, our washers also perform a crucial role as copper sealing washer M40 hydraulic fittings, delivering both mechanical support and fluid sealing in one solution.

To sum up, whether you’re sourcing for your production line or handling replacement parts in a repair setup, M40 copper plain washers are a go-to solution for a wide range of demanding industrial needs.

What Are M40 Copper Plain Washers?

M40 copper plain washers are flat, round components crafted from high-purity copper, specifically designed to fit M40 bolts or screws (40 mm diameter). Their primary function is to distribute the load of the fastening system evenly across the surface, preventing surface damage and ensuring a firm, reliable connection. Because of their size and material composition, M40 copper plain washers are commonly used in heavy-duty industrial applications where both conductivity and structural support are required.

These washers feature a large outer diameter and a smooth, flat surface that enables uniform pressure distribution. This helps protect the fastened components from damage due to over-tightening or vibration. The use of copper adds the benefit of electrical and thermal conductivity, making M40 copper plain washers especially useful in environments like power generation plants, switchgear installations, marine setups, and other high-load assemblies.

Unlike regular steel or plastic washers, M40 copper plain washers provide enhanced corrosion resistance and natural sealing properties. Their malleability allows them to conform to uneven surfaces, providing a tighter fit and minimizing the risk of leaks or mechanical failure. This makes them a preferred choice for both mechanical engineers and maintenance professionals.

When sourced from a reliable manufacturer like Nafees Metal Industries, M40 copper plain washers are produced to exact international specifications. One of the most popular standards followed is DIN 125, and our washers perfectly adhere to this requirement, offering interchangeability and consistency. For this reason, many refer to these parts as copper plain washer DIN 125 size M40, indicating the combination of material, size, and compliance.

Additionally, M40 copper plain washers play a vital role in thermal dissipation when placed under components that generate heat. Their robust construction makes them suitable for static as well as dynamic load-bearing tasks, ensuring safety and durability in long-term operations.

In summary, M40 copper plain washers are not just flat discs with a hole—they are precision-engineered components critical to the safety and efficiency of many industrial systems.

Why Use Copper for M40 Washers?

Copper has long been favored in industrial fastening components due to its unmatched combination of physical, chemical, and mechanical properties. This makes it a highly desirable material for manufacturing M40 copper plain washers, especially for applications that demand superior corrosion resistance, thermal and electrical conductivity, and structural reliability.

M40 copper plain washers made from high-purity copper are exceptionally malleable. This allows them to conform to uneven surfaces during installation, creating a snug and secure seal between mating components. This is crucial in applications like hydraulic systems, electrical terminals, and high-vibration equipment. Due to their excellent ductility, M40 copper plain washers can maintain sealing integrity even under intense load and thermal fluctuation.

Another major reason for choosing copper in the construction of M40 copper plain washers is its inherent corrosion resistance. Copper forms a protective oxide layer over time that helps shield it from degradation when exposed to moisture, chemicals, or salt-laden environments. This is why M40 copper plain washers are widely used in marine and offshore structures, chemical processing equipment, and outdoor assemblies.

Furthermore, copper offers high electrical and thermal conductivity—properties that are critical in energy systems. M40 copper plain washers are therefore widely deployed in electrical enclosures, switchgears, transformers, and other power-related installations where efficient conductivity and grounding are required.

In systems where sealing is as important as load distribution, copper provides a unique advantage. It acts both as a support component and as a functional sealing medium. This dual-purpose benefit is one reason why engineers often specify M40 copper plain washers instead of conventional alternatives.

Additionally, copper is non-sparking and non-magnetic. This makes M40 copper plain washers safe for use in volatile environments such as oil refineries, chemical plants, and gas distribution networks, where other materials could pose a hazard.

From a manufacturing standpoint, copper is also easy to machine, punch, and finish, enabling us at Nafees Metal Industries to produce M40 copper plain washers with highly consistent inner and outer diameters. Our washers follow precise tolerances and are fully compliant with M40 copper flat washer metric series DIN 125, ensuring standardization and compatibility with global specifications.

In short, the material advantages of copper directly contribute to the high performance, durability, and safety of our M40 copper plain washers across diverse industrial sectors.

Manufacturing Process of M40 Copper Plain Washers

At Nafees Metal Industries, the production of M40 copper plain washers follows a meticulous, quality-controlled process designed to meet international standards and exceed customer expectations. Each washer undergoes precision forming, finishing, and inspection to ensure performance in high-pressure and high-temperature environments.

The manufacturing process for M40 copper plain washers begins with the sourcing of high-conductivity, industrial-grade copper sheets. These raw materials are carefully selected for their purity and mechanical consistency, as they form the foundation of durability and performance in every washer we produce.

Once the copper sheets are verified for compliance, the next step involves precision blanking and punching. Specialized tooling is used to cut circular blanks and punch the inner hole to match M40 bolt specifications. This ensures every washer maintains an accurate fitment with minimal deviation in dimensions. Our advanced machinery allows us to produce M40 copper plain washers in large volumes while maintaining high consistency and repeatability.

Following punching, the washers undergo deburring and edge finishing. This crucial step ensures smooth, burr-free edges that reduce the risk of surface scratching during installation and improve safety for technicians handling the washers. For applications where surface aesthetics or additional sealing is important, M40 copper plain washers can also undergo annealing. This heat treatment process enhances the softness and pliability of the washer, improving its sealing capabilities in hydraulic and pneumatic systems.

After forming and heat treatment, washers are sent through polishing or surface cleaning processes to remove oxidation or residues, giving them a clean, refined appearance and improved performance. Some customers require additional treatments such as tin plating or anti-tarnish coating, which we offer upon request for specialized applications.

Each batch of M40 copper plain washers is subjected to rigorous quality control checks, including dimensional verification (ID, OD, and thickness), surface flatness, and hardness testing. Only after passing all quality parameters are the washers approved for packing.

We offer flexible packaging solutions to suit both domestic and international clients. Whether it’s polybags, corrugated boxes, or custom-labeled cartons, M40 copper plain washers are packed securely to avoid any damage during transportation.

Our washers also conform to industry benchmarks like industrial copper flat washer corrosion-resistant grades, making them suitable for harsh operational environments and ensuring long-term performance without deterioration.

Through our advanced processes and unwavering commitment to quality, Nafees Metal Industries ensures that every unit of M40 copper plain washers is a perfect example of precision, strength, and dependability.

Key Features of M40 Copper Plain Washers

M40 copper plain washers are designed with precision, keeping in mind the rigorous demands of modern industrial environments. At Nafees Metal Industries, every washer we manufacture reflects durability, accuracy, and performance integrity. These features make M40 copper plain washers the ideal choice for high-load fastening systems, especially in sectors like electrical engineering, automotive, petrochemical, and marine industries.

Below are the core features that set our M40 copper plain washers apart:

1. Precise Dimensional Accuracy

Our M40 copper plain washers are manufactured to meet strict inner and outer diameter tolerances. They fit seamlessly with M40 bolts and screws, ensuring a tight, vibration-resistant fastening assembly every time.

2. Enhanced Load Distribution

The broad surface area of M40 copper plain washers allows for even distribution of pressure across the bolted surface. This reduces the risk of surface damage, warping, or cracking in softer materials.

3. Superior Conductivity

Made from high-purity copper, M40 copper plain washers offer outstanding electrical and thermal conductivity. They are ideal for applications where grounding, current flow, or heat dissipation is critical—such as switchgear, transformers, and energy systems.

4. Corrosion Resistance

Thanks to copper’s natural resistance to oxidation and atmospheric degradation, our M40 copper plain washers perform exceptionally well in outdoor or humid environments. They are suitable for long-term installations in corrosive conditions without needing frequent replacements.

5. Smooth Finish with Burr-Free Edges

All M40 copper plain washers are deburred and polished during the manufacturing process. This ensures smooth edges, reducing the risk of component damage or worker injury during assembly.

6. DIN Standard Compliance

Our M40 copper plain washers conform to DIN 125 and ISO 7089 standards, which makes them compatible with global applications and engineering drawings. The standardization also ensures easy sourcing and interchangeability.

7. Customization Options Available

We offer tailor-made solutions for businesses looking to alter thickness, surface finish, or packaging. Whether you need annealed washers, tin-plated variants, or extra-thick designs, Nafees Metal Industries delivers as per your project requirements.

8. Made in India – Export Ready

Manufactured in our advanced Mumbai facility, all M40 copper plain washers are proudly made in India and ready for international distribution with necessary export documentation and certifications.

9. Cost-Effective for High-Performance Results

With superior quality control, local manufacturing, and bulk production capabilities, we ensure that M40 copper plain washers offer maximum value for your investment.

Each of these features contributes to the performance and reliability that industrial engineers and OEMs expect from a high-grade washer. For mission-critical applications, M40 copper plain washers are the trusted component that never compromises on quality.

Technical Specifications

When selecting a washer for mission-critical industrial tasks, technical clarity is crucial. At Nafees Metal Industries, every batch of M40 copper plain washers is manufactured according to international standards and customized to suit diverse mechanical and electrical requirements. Below is a detailed breakdown of the standard specifications for our M40 copper plain washers, ensuring compatibility, durability, and precision in your fastening operations.

| Property | Specification |

|---|---|

| Product Name | M40 Copper Plain Washer |

| Material | High-Purity Copper (Industrial Grade) |

| Inner Diameter (ID) | Approximately 42.0 mm (to accommodate M40 bolts securely) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 (customization available) |

| Washer Thickness | 2.5 mm standard (can be customized based on application) |

| Washer Type | Flat / Plain Washer |

| Finish Options | Plain, Annealed, Polished, or Tin-Plated |

| Hardness | Soft annealed for sealing or custom tempering on request |

| Standard Compliance | DIN 125, ISO 7089 – suitable for metric engineering systems |

| Applications | Electrical, Hydraulic, Marine, Petrochemical, Power Generation |

| Temperature Tolerance | Up to 500°C for sustained thermal exposure |

| Conductivity | Excellent thermal and electrical conductivity |

| Corrosion Resistance | High resistance to rust, oxidation, and industrial chemicals |

| Manufacturing Origin | Made in India (Mumbai Manufacturing Unit) |

| Packaging Options | Polybags, Corrugated Boxes, Custom Labeling (bulk and export packaging available) |

| Bulk Availability | Ready stock maintained for large-volume industrial procurement |

Our M40 copper plain washers undergo dimensional inspection at every stage of the manufacturing process. This includes checking ID/OD tolerances, verifying concentricity, and testing hardness where applicable. For OEMs, EPC contractors, and heavy machinery manufacturers, the ability to rely on exact-fit specifications is non-negotiable—and that’s exactly what we deliver.

Additionally, we can provide technical drawings, MSDS, and test certificates along with your order for complete transparency and compliance documentation.

Whether you’re installing transformers, designing hydraulic systems, or retrofitting power infrastructure, our M40 copper plain washers deliver consistent, dependable performance across all operating conditions.

Applications of M40 Copper Plain Washers

The industrial versatility of M40 copper plain washers makes them indispensable across a wide range of sectors that rely on high-performance fasteners. Known for their superior conductivity and corrosion resistance, these washers perform exceptionally well in environments exposed to moisture, heat, vibration, and mechanical stress. Let’s explore the industries and systems where M40 copper plain washers are most effectively utilized:

1. Hydraulic Fittings & Sealing Applications

In hydraulic systems, especially in pressure lines and valve assemblies, M40 copper plain washers act as sealing components that prevent fluid leakage under high pressure. These washers are often paired with fittings where copper’s softness allows it to conform to irregularities, ensuring a tight seal. For such use, our copper sealing washer M40 hydraulic fittings solution is among the most trusted by OEMs and maintenance engineers.

2. Electrical & Electronics Installations

Due to their excellent electrical conductivity, M40 copper plain washers are widely used in power generation units, control panels, transformer assemblies, and circuit grounding systems. These washers help maintain secure electrical connections without introducing resistance or galvanic corrosion, ensuring uninterrupted current flow.

3. Petrochemical and Marine Industries

Environments rich in moisture, chemicals, and salt demand corrosion-resistant fasteners. Our M40 copper plain washers excel in these industries due to their natural resistance to oxidation. Whether it’s offshore oil rigs or chemical handling systems, they offer long-lasting performance without the need for frequent replacement.

4. Heavy Machinery and Structural Assemblies

When assembling turbines, diesel engines, heavy presses, or load-bearing joints, high-strength components are critical. Our M40 copper plain washers provide the necessary surface protection under large bolt heads and distribute compressive load to prevent damage or loosening under vibration.

5. Thermal Systems and HVAC

Heat exchangers, boilers, and HVAC systems benefit from the thermal conductivity and durability of M40 copper plain washers. They maintain fastening integrity even when subjected to frequent thermal cycling, preventing expansion-related loosening.

6. Automotive & Locomotive Manufacturing

Copper washers are increasingly used in performance-driven automotive applications, particularly in fuel lines, engine blocks, and brake assemblies. The size-specific nature of M40 copper plain washers allows them to be integrated seamlessly into metric systems where DIN 125 compatibility is required.

7. Renewable Energy Infrastructure

Wind turbines, solar inverters, and grid connectors require stable electrical connections and corrosion-free support components. M40 copper plain washers fit perfectly in these applications, improving overall system life and efficiency.

Whether you’re building critical electrical panels, tightening hydraulic couplings, or managing offshore equipment, M40 copper plain washers from Nafees Metal Industries offer long-term reliability, excellent sealing, and unmatched conductivity. If your industry requires high-precision, non-ferrous washers that meet international standards, our washers are engineered to deliver uncompromising performance.

Why Choose Nafees Metal Industries for M40 Copper Plain Washers?

When it comes to sourcing M40 copper plain washers, manufacturers and industrial buyers across India and beyond place their trust in Nafees Metal Industries. Our commitment to quality, precision, and customer satisfaction has earned us a leading position in the copper washer manufacturing industry. Here’s why our M40 copper plain washers stand out in the market:

1. State-of-the-Art Manufacturing Facility in Mumbai

Our advanced manufacturing unit in Mumbai is equipped with precision machinery, automated stamping systems, and stringent quality control mechanisms. Every M40 copper plain washer produced here adheres to exacting tolerances and meets the specifications outlined by DIN 125 standards, including compatibility with M40 copper flat washer metric series DIN 125 requirements.

2. Certified Raw Materials & Quality Assurance

We use high-grade pure copper to manufacture our washers, ensuring optimal conductivity, strength, and corrosion resistance. Each batch of M40 copper plain washers undergoes rigorous testing for dimensional accuracy, surface finish, tensile strength, and stress handling to ensure top performance in critical applications.

3. Customization & Bulk Supply Capabilities

Whether your requirement is for standard dimensions or customized solutions, we offer flexibility in order size, packaging, and delivery timelines. Our production scale allows us to fulfill both small-scale and large-volume industrial orders efficiently. If you’re looking to buy bulk industrial copper flat washer corrosion-resistant solutions, we are your one-stop source.

4. Trusted by Industries Across India

Our M40 copper plain washers are used across multiple sectors—hydraulics, automotive, marine, electrical, petrochemical, and construction—making us one of the most reliable suppliers in the Indian washer industry. Our washers are preferred for their dimensional consistency, sealing efficiency, and longevity.

5. Dedicated Customer Support

We believe in creating long-term relationships with our clients. Our team offers technical assistance, material selection guidance, and after-sales service to help you get the most from your M40 copper plain washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch