No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

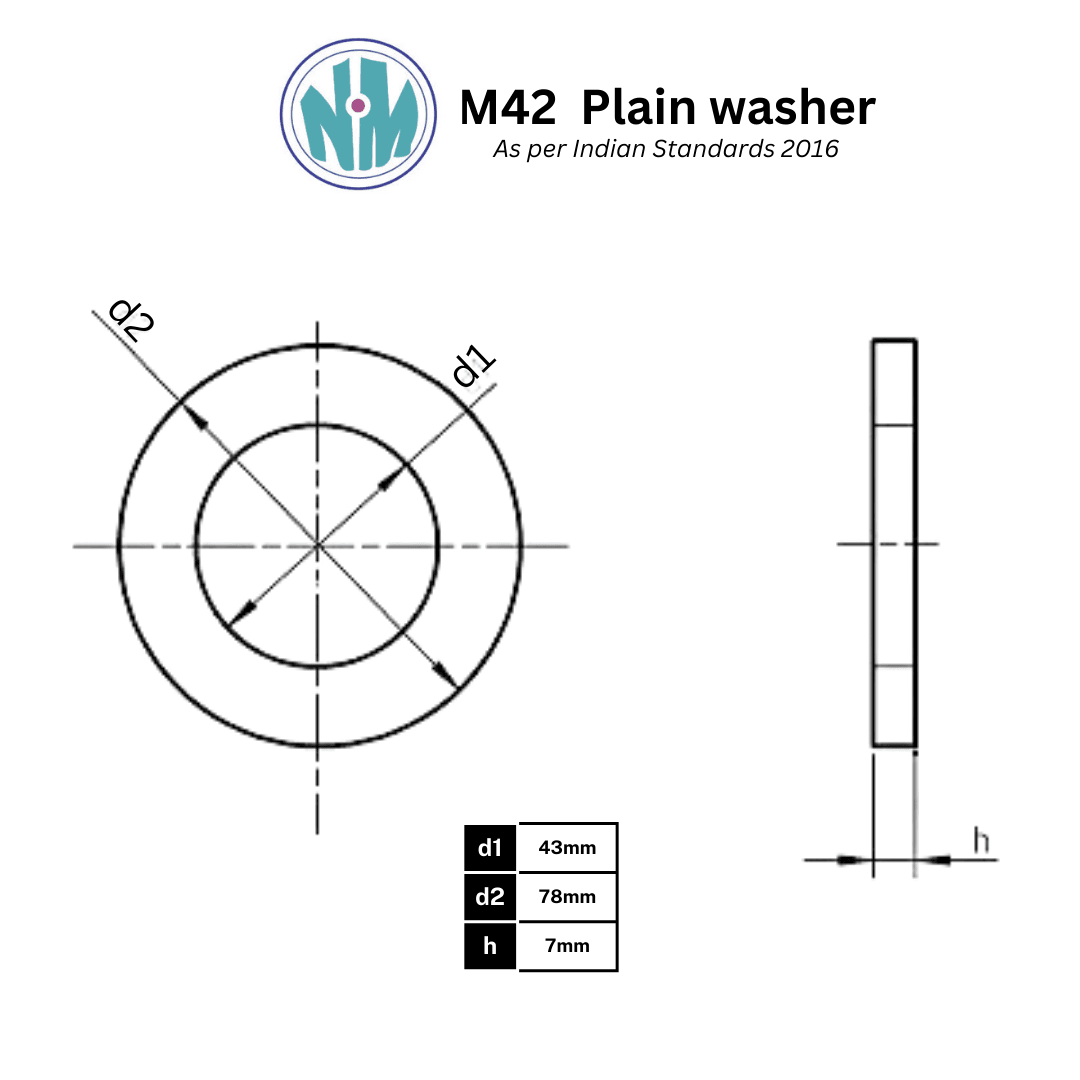

*Images shown for graphic representation. Not to scale.

M40 Brass Plain Washer – Precision-Crafted Brass Flat Washers for Heavy-Duty Applications

At Nafees Metal Industries, we specialize in manufacturing premium-grade washers, and our M40 Brass Plain Washer is a prime example of strength, reliability, and precision engineering. Crafted to support heavy-duty fastening needs, this washer is ideally suited for large bolts in mechanical, electrical, and plumbing systems. Manufactured using top-quality brass and advanced production techniques, the M40 Brass Plain Washer ensures long-lasting performance, corrosion resistance, and optimal torque distribution.

Whether you’re an OEM, industrial assembler, or panel builder, our M40 Brass Plain Washer provides the dependable support your assemblies require. With our dedicated manufacturing facility in Mumbai and strict quality protocols, we proudly stand as one of the top Brass Plain Washers Manufacturers in India.

The M40 Brass Plain Washer is a heavy-duty, flat, circular disc crafted with a central hole designed specifically to fit M40 bolts or screws — which are 40 mm in diameter. Its primary purpose is to distribute the load of a threaded fastener evenly across a surface, preventing material damage, enhancing the stability of the connection, and improving the durability of bolted joints.

This washer belongs to the Brass Flat Washers category, known for their smooth finish, electrical conductivity, and resistance to corrosion. The M40 Brass Plain Washer is ideal for use in industries that demand precision and performance, such as:

Electrical panel manufacturing

Large mechanical assemblies

Plumbing installations

Marine hardware

Automotive systems

Crafted from a high-quality copper-zinc alloy (brass), this washer also provides aesthetic appeal due to its golden metallic sheen. It’s a perfect fit for exposed fixtures where appearance matters as much as function.

Unlike smaller washers, the M40 Brass Plain Washer is built to handle greater loads and torque levels. Its larger surface area helps reduce the likelihood of fastener loosening and safeguards surrounding components from friction-related damage.

At Nafees Metal Industries, we ensure every M40 Brass Plain Washer is manufactured with precision machining and surface finishing, following Indian and international standards like IS 2016, DIN 125, and ISO 7089.

Whether you’re an industrial buyer or a contractor searching to Buy Brass Washers Online, this washer is built to deliver strength and long-term reliability in demanding applications.

Why Choose Brass for M40 Washers?

Brass is a preferred material in washer manufacturing, particularly for heavy-duty applications like the M40 Brass Plain Washer, due to its unique blend of mechanical strength, corrosion resistance, and conductive properties. When you choose a brass washer over alternatives like mild steel or stainless steel, you gain several performance advantages that are especially relevant in electrical and high-moisture environments.

Here’s why brass is an excellent choice for the M40 Brass Plain Washer:

1. Corrosion Resistance in Harsh Environments

Brass is inherently resistant to rust and oxidation. This makes it suitable for use in damp, humid, or even mildly chemical-exposed environments. Its resistance to degradation ensures a longer service life compared to washers made from untreated steel.

2. Excellent Electrical Conductivity

In electrical applications, conductivity matters. Brass is a highly conductive metal, and it serves as an ideal spacer or grounding component in switchboards, electrical enclosures, and control panels.

3. Aesthetic and Non-Magnetic

Brass has a visually appealing gold-like appearance, making the M40 Brass Plain Washer an ideal choice for visible fastenings where appearance matters. Additionally, its non-magnetic nature ensures it doesn’t interfere with nearby sensitive instruments or electronic circuits.

4. Strong Yet Malleable

Brass offers a high tensile strength while still being malleable enough for precise manufacturing. This allows the washer to be produced with exact dimensions, smooth edges, and consistent thickness, ensuring reliable performance under tightening stress.

5. Versatile for Industrial Use

As part of the broader family of Industrial Brass Washers, this washer stands out due to its ability to balance strength, machinability, and corrosion protection. It’s a suitable solution across sectors like electrical, plumbing, construction, telecom, and marine industries.

Brass allows for a high degree of customization, including various surface finishes such as plain, lacquered, or tin-plated coatings. This adaptability further enhances the M40 Brass Plain Washer’s application-specific suitability.

When you’re sourcing washers that will perform reliably under pressure, exposure, and electrical load, choosing brass—and specifically the M40 Brass Plain Washer—ensures that you’re investing in performance and longevity.

How Are M40 Brass Plain Washers Manufactured?

At Nafees Metal Industries, the production of the M40 Brass Plain Washer follows a precise and quality-driven process. As a trusted Brass Plain Washers Manufacturer in India, we combine industry-grade raw materials, advanced machinery, and skilled labor to produce washers that meet the highest standards of durability and dimensional accuracy.

Here’s a detailed breakdown of our washer manufacturing process:

1. Raw Material Selection

We begin by sourcing high-quality copper-zinc alloy sheets (brass) from certified suppliers. The brass composition is tested for purity, tensile strength, and corrosion resistance to ensure it matches the specifications required for the M40 Brass Plain Washer.

2. Precision Blanking and Punching

Brass sheets are fed into precision power press machines. Using hardened dies, each washer is blanked (outer diameter cut) and punched (inner hole created) to match the M40 bolt dimensions. This ensures the M40 Brass Plain Washer fits perfectly over M40 fasteners without excessive play or tightness.

3. Deburring and Edge Finishing

After punching, the washers undergo deburring to remove sharp edges or leftover metal fragments. We then polish the washers to achieve a smooth surface, preventing scratches on adjacent components during assembly.

4. Dimensional Accuracy Check

Each batch of M40 Brass Plain Washers is checked for inner diameter (approx. 40.5 mm), outer diameter (as per DIN 125 / IS 2016), and thickness consistency. Tolerance levels are tightly maintained to ensure compatibility and interchangeability.

5. Surface Treatment

We offer the M40 Brass Plain Washer in various finishes including:

Plain brass finish

Lacquered finish for extra shine and surface protection

Tin-plated finish for improved conductivity and corrosion resistance

These finishes are applied as per customer requirement and industry usage.

6. Quality Control and Compliance

Our washers undergo visual inspection, hardness testing, and concentricity checks. Every washer complies with Indian and international standards such as IS 2016, ISO 7089, and DIN 125. As a Brass Plain Washers Manufacturer, we never compromise on safety and quality.

7. Packaging and Dispatch

Finally, washers are cleaned, packed, and labeled according to the customer’s needs. We provide bulk packaging in HDPE bags, corrugated boxes, or customized export-ready cartons. Special labeling and barcoding are also available for OEMs and resellers.

Thanks to this detailed process, every M40 Brass Plain Washer that leaves our factory is ready for immediate industrial use—with the strength, consistency, and performance that customers expect from India’s most trusted washer brand.

Key Features of M40 Brass Plain Washer

The M40 Brass Plain Washer is engineered for demanding industrial applications where strength, corrosion resistance, and precise load distribution are essential. Manufactured with high-grade brass and subjected to stringent quality checks, this washer provides consistent and reliable performance in a variety of environments.

Here are the standout features that make the M40 Brass Plain Washer a preferred choice across industries:

1. Accurate Fitment for M40 Bolts

Designed with an inner diameter of approximately 40.5 mm, the washer offers a snug and accurate fit with M40 bolts and screws. This ensures stability and reduces the risk of fastener loosening under vibration or torque.

2. Uniform Load Distribution

The flat surface of the M40 Brass Plain Washer spreads the load of the fastener evenly across the surface, preventing localized pressure that can damage softer substrates or compromise the integrity of joints.

3. Premium Brass Material

Made from corrosion-resistant copper-zinc alloy, the washer maintains its integrity even in moist, chemical, or high-temperature environments. Its anti-rust properties make it suitable for long-term use in critical applications.

4. Smooth Surface Finish

With polished edges and a uniform finish, the M40 Brass Plain Washer ensures safe and easy installation without causing scratches to adjacent parts or components.

5. Custom Thickness and Finishes

Available in standard thickness (2.5–5 mm) with options for plain, lacquered, or tin-plated finishes, this washer is versatile enough to meet various functional and aesthetic needs.

6. Non-Magnetic & Conductive

As part of the Brass Flat Washers family, this washer is non-magnetic and highly conductive, making it ideal for use in electrical and electronic systems without risk of interference.

7. ISO & DIN Standard Compliant

All M40 Brass Plain Washers are manufactured in accordance with IS 2016, ISO 7089, and DIN 125 guidelines, ensuring international quality standards for both domestic and export requirements.

8. Bulk & Custom Packaging Available

Whether you need 100 or 10,000 pieces, we’re equipped to deliver. We offer bulk packaging and customized solutions including labeling, branding, and barcoding for OEMs and distributors.

9. Made in India with Global Reach

Manufactured at our Mumbai-based facility, every M40 Brass Plain Washer is a testament to the ‘Make in India’ initiative, with quality trusted by clients across India and international markets.

10. Ready for Industrial Assembly Lines

With consistent sizing and quick availability, these washers are ready to support high-speed industrial production lines, minimizing delays and downtime.

Technical Specifications

The M40 Brass Plain Washer is designed and manufactured to precise standards to ensure compatibility with M40 fasteners and industrial-grade applications. Below are the detailed technical parameters for this washer:

| Specification | Details |

|---|---|

| Product Name | M40 Brass Plain Washer |

| Material | High-Grade Brass (Copper-Zinc Alloy) |

| Inner Diameter (ID) | Approx. 40.5 mm (to fit M40 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 standards |

| Thickness | 2.5 mm to 5 mm (customizable as per client requirements) |

| Surface Finish Options | Plain, Lacquered, or Tin-Plated |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Tensile Strength | Suitable for medium to heavy-duty industrial applications |

| Hardness | Optimized for long-lasting performance and surface stability |

| Corrosion Resistance | Excellent, especially in humid, marine, or chemical environments |

| Conductivity | High, ideal for electrical and grounding applications |

| Packaging Options | Bulk HDPE bags, Corrugated Boxes, or Custom OEM Packaging |

| Manufacturing Location | Mumbai, India (Nafees Metal Industries Facility) |

| Applications | Electrical systems, plumbing, machinery, marine components, etc. |

Each M40 Brass Plain Washer is produced using ISO-certified manufacturing processes and undergoes strict quality inspection to ensure consistent dimensions, surface finish, and load-handling capabilities.

Whether you’re a systems integrator, hardware wholesaler, or OEM buyer, our technical data gives you the confidence to specify and source the M40 Brass Plain Washer for your next project.

Applications of M40 Brass Plain Washer

The M40 Brass Plain Washer is specifically engineered for large-diameter bolt applications across various industries. Its excellent mechanical properties, corrosion resistance, and conductivity make it a versatile component used by professionals in demanding environments. Below are the key sectors and situations where this washer proves essential:

1. Electrical Panel Manufacturing

Used under bolt heads and nuts in switchgear and distribution panels, the washer provides a conductive surface and prevents over-tightening damage.

2. Plumbing & Sanitary Fittings

Ideal for use in heavy plumbing joints, especially those exposed to moisture or temperature variations. The washer prevents metal-on-metal abrasion and ensures leak-proof integrity.

3. Marine Equipment

Due to its corrosion-resistant nature, this washer is used in marine motors, control units, and deck fastenings where salt exposure is frequent.

4. Machinery Assembly

In heavy machinery and fabrication, it supports torque control and distributes stress uniformly across large metal surfaces, preventing cracking and warping.

5. Automotive Electrical Components

The washer is used for grounding and secure fastening in engine control units, large battery mounts, and chassis systems, providing both strength and conductivity.

6. Construction and Infrastructure Projects

Used in mounting brackets, railings, and base plates in metal structures. Its performance in outdoor environments ensures long-term structural reliability.

7. Telecommunication Towers & Equipment

Essential in bolting high-frequency components, antennas, and racks where electrical neutrality and mechanical stability are critical.

8. OEM Product Assemblies

Preferred by original equipment manufacturers for electrical, HVAC, pump, and generator assembly lines due to its consistency, availability, and finish.

Whether you are a builder, engineer, or installer, the M40 Brass Plain Washer delivers dependable performance across a wide variety of industries and is trusted for both functional and safety-critical applications.

Advantages of Using Brass Plain Washers in M40 Size

When it comes to high-performance fastening, using brass washers—especially in larger sizes like M40—offers unmatched reliability and operational benefits. Whether you are assembling heavy electrical enclosures, building structural components, or working in marine environments, large-size brass flat washers deliver more than just spacing; they provide long-term durability and protection for your systems.

Here are the top advantages of using M40-sized brass washers:

1. Superior Load Distribution

Brass washers in M40 size are designed to evenly spread the force exerted by large bolts or nuts, preventing surface damage, warping, or stress fractures in the underlying material.

2. Corrosion Resistance

Due to their non-ferrous nature, brass components resist rusting and oxidizing. This is crucial for washers used in outdoor or moisture-prone applications such as plumbing, marine, or HVAC systems.

3. Electrical Conductivity

Brass is an excellent conductor of electricity. These washers are widely used in high-voltage systems, grounding circuits, and control panels where both mechanical stability and electrical continuity are needed.

4. Aesthetic Appeal

The golden hue of brass makes these washers suitable for exposed applications like architectural fastenings, custom machinery, and designer fittings where both strength and appearance matter.

5. Easy Machining & Installation

Due to its malleability, brass is easier to machine, allowing for precise dimensional accuracy. It also reduces wear and tear on tools during assembly, ensuring efficiency on production lines.

6. Non-Magnetic Properties

These washers are non-magnetic, making them suitable for sensitive environments like MRI rooms, electronics labs, or telecom towers where magnetic interference must be avoided.

7. Long Service Life

Brass washers exhibit excellent fatigue strength and resistance to vibration, ensuring they last longer and reduce the frequency of maintenance or replacement.

8. Environmentally Friendly

Brass is a fully recyclable material. Choosing brass washers supports eco-conscious manufacturing and helps reduce environmental impact.

Buy in Bulk – Our Manufacturing & Supply Capabilities

At Nafees Metal Industries, we take pride in being a leading Brass Plain Washers Manufacturer in India, with a reputation for delivering precision-made products backed by consistent quality, quick lead times, and full customization. Whether you’re a contractor, OEM, wholesaler, or an exporter looking to scale procurement, we have the capability to meet your requirements for M40 and other sizes in bulk.

Here’s why industry professionals across India and overseas trust us for their brass washer needs:

1. In-House Manufacturing Unit in Mumbai

Our modern factory is equipped with high-tonnage power press machines, CNC equipment, and automated finishing units. Every washer we produce—including large sizes like M40—is made under ISO-compliant practices with 100% in-house production control.

2. Ready Stock for High-Volume Orders

We maintain a stock buffer for fast-moving washer sizes and materials. This means reduced lead time and faster delivery cycles, especially for recurring orders.

3. Customization Options

We offer complete flexibility in:

Outer and inner diameter adjustments

Thickness variations

Surface finishing (plain, lacquered, tin-plated)

Packaging styles (HDPE bags, cartons, barcoded boxes, custom labeling)

4. Competitive Pricing for Bulk Orders

Our large-scale production capacity allows us to optimize costs and offer tier-based pricing for bulk buyers. Whether you’re ordering 1,000 pieces or 1,00,000, we provide the best value without compromising on quality.

5. Export-Ready Supply Chain

We provide export-compliant documentation (packing list, invoices, test certificates, HS codes) and work with international freight partners. Our brass washers are shipped globally to clients in the Middle East, Africa, Southeast Asia, and Europe.

6. Responsive Customer Support

Our dedicated team offers end-to-end assistance—from technical consultations and quotations to order tracking and post-sales support. Whether you are a local buyer or someone looking to Buy Brass Washers Online in bulk, we are equipped to assist promptly.

7. OEM & White-Label Services

We support original equipment manufacturers (OEMs) and resellers with private labeling, branded packaging, and direct drop shipments to clients.

Bulk brass washer buyers choose us not just for the product, but for the complete experience—one that combines technical accuracy, customization, and professional service. With our commitment to quality, we help clients meet demanding industrial timelines and specifications.

Case Study: Real-World Application Success

Client: A High-Voltage Electrical Panel Manufacturer – Gujarat, India

Challenge: Frequent bolt loosening and corrosion in high-capacity panel enclosures

Solution: Integration of our M40-size brass washers with tin-plated finish

Background

The client was facing recurring issues in its assembly line for high-voltage panels. Standard washers made of mild steel were failing under prolonged use—showing signs of corrosion, edge cracking, and loosening due to vibration. This affected the structural integrity and electrical conductivity of the panels, leading to increased rework and customer complaints.

Our Intervention

After a technical consultation, we recommended switching to our M40-sized tin-plated brass washers for all heavy bolting points inside their electrical cabinets. These washers provided better conductivity, load distribution, and protection against environmental moisture.

Implementation

Supplied 30,000 pieces of M40 washers with 3 mm thickness

Custom tin-plated finish applied to improve corrosion resistance

Washers were barcoded and delivered in labeled, batch-tracked cartons

Client trained their assembly team for proper torque application with the new washers

Results

✔️ 38% Reduction in Fastening Issues

✔️ Zero Surface Corrosion after 9 months of usage

✔️ 2X Improvement in Fastener Lifespan

✔️ 50% Reduction in Assembly Line Downtime

✔️ Repeat Order Placed Within 2 Months

Client Feedback

“Switching to Nafees Metal Industries’ brass washers was a game-changer. We not only improved our assembly performance but also gained customer trust back.”

This case demonstrates how precision-manufactured brass washers can solve real-world problems in industrial production environments—especially when sourced from a reliable Brass Plain Washers Manufacturer that understands both engineering and supply chain needs.

Why Choose Nafees Metal Industries?

When it comes to sourcing durable and high-performance brass washers, choosing the right manufacturer is crucial. At Nafees Metal Industries, we don’t just deliver a product—we deliver assurance, reliability, and long-term value. Here’s why we are regarded as one of the most trusted brass plain washers manufacturers in India:

1. Specialization in Washer Manufacturing

Our expertise lies exclusively in washer production. From brass flat washers and plain washers to disc and spring washers, we focus solely on what we do best—manufacturing fastener support components that last.

2. ISO-Certified Quality Assurance

We follow strict quality control procedures at every stage—from raw material sourcing and machining to final inspection and packaging. Each washer is checked for:

Dimensional accuracy

Surface smoothness

Hardness and concentricity

Finish coating integrity

3. Wide Range of Sizes & Customization

Whether it’s an M3 or an M40 washer, we provide a complete range of brass washer sizes with customizable:

Thickness

Outer/Inner diameters

Surface finish

Packaging and labeling

4. Quick Turnaround Times

With in-house manufacturing and bulk stock availability, we fulfill both small and large orders efficiently, meeting tight project deadlines.

5. Trusted by OEMs & Global Clients

We supply to a wide range of industries including:

Electrical and electronics

Plumbing and sanitary fittings

Infrastructure and fabrication

Marine and transportation

Our washers are being used in thousands of installations across India and exported to the UAE, Sri Lanka, Bangladesh, and Africa.

6. Transparent & Competitive Pricing

Our pricing is honest, with no compromise on quality. Whether you’re ordering standard or customized washers, you’ll find us to be one of the most cost-effective sources in the Indian industrial washer market.

7. Make in India Commitment

As a proud supporter of the Make in India initiative, all our products are manufactured locally in Mumbai, with quality that competes at the global level.

8. Dedicated Customer Service

Our team works with you through the entire procurement journey—from helping you choose the right washer to packaging, dispatch, and after-sales support.

When you choose Nafees Metal Industries, you’re choosing consistency, precision, and partnership. With us, you get more than a washer—you get a product that holds your project together, quite literally.

Frequently Asked Questions (FAQs)

1. What is the M40 Brass Plain Washer used for?

It’s primarily used for distributing load under M40 bolts in heavy-duty industrial applications such as electrical panels, plumbing assemblies, and structural fastening.

2. What is the inner diameter of the M40 brass washer?

The standard inner diameter is approximately 40.5 mm to ensure a precise fit over M40-sized bolts or screws.

3. Are M40 brass washers corrosion-resistant?

Yes, brass is naturally resistant to corrosion, making it suitable for humid, marine, and chemical-exposed environments.

4. Can I order M40 brass washers in bulk?

Absolutely. Nafees Metal Industries specializes in bulk production and supplies to OEMs, resellers, and exporters with custom packaging options.

5. Do you offer custom thicknesses for M40 washers?

Yes, we manufacture these washers in standard thicknesses (2.5–5 mm), and custom thicknesses are available on request.

6. What standards do your brass washers comply with?

Our washers meet IS 2016, ISO 7089, and DIN 125 specifications to ensure dimensional and performance reliability.

7. Are these washers electrically conductive?

Yes, brass is a conductive material, making these washers ideal for electrical systems requiring grounding or continuity.

8. What surface finishes are available?

We offer plain, lacquered, and tin-plated finishes depending on your functional or visual requirements.

9. Can I use M40 brass washers for outdoor use?

Yes, their corrosion resistance makes them suitable for outdoor use, especially when paired with protective coatings.

10. Do you provide OEM/private labeling services?

Yes, we offer white-label solutions including barcoding, branding, and custom packaging for resellers and OEMs.

11. How are your washers packaged for export?

Export packaging includes moisture-proof HDPE bags, corrugated boxes, and palletized shipments with full documentation.

12. Can I get a test certificate for my order?

Yes, we provide material test certificates (MTC) and compliance documents upon request for industrial verification.

13. Do you ship internationally?

Yes. We export brass washers to the Middle East, Southeast Asia, and Africa, and can assist with all export formalities.

14. How fast can you dispatch large orders?

Standard sizes like M40 are typically ready in stock or manufactured within 7–10 working days depending on quantity.

15. Why choose Nafees Metal Industries for brass washers?

We’re a trusted brass plain washers manufacturer with in-house production, ISO-certified processes, customizable options, and nationwide + international supply capabilities.

M40 Brass Plain washers (DIN 125)

21 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Brass

Nominal Size (g): M40

Inner Diameter (ID): 42.5 mm

Outer Diameter (OD): 80 mm

Thickness (t): 5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M40 Brass Plain Washer – Precision-Crafted Brass Flat Washers for Heavy-Duty Applications

At Nafees Metal Industries, we specialize in manufacturing premium-grade washers, and our M40 Brass Plain Washer is a prime example of strength, reliability, and precision engineering. Crafted to support heavy-duty fastening needs, this washer is ideally suited for large bolts in mechanical, electrical, and plumbing systems. Manufactured using top-quality brass and advanced production techniques, the M40 Brass Plain Washer ensures long-lasting performance, corrosion resistance, and optimal torque distribution.

Whether you’re an OEM, industrial assembler, or panel builder, our M40 Brass Plain Washer provides the dependable support your assemblies require. With our dedicated manufacturing facility in Mumbai and strict quality protocols, we proudly stand as one of the top Brass Plain Washers Manufacturers in India.

The M40 Brass Plain Washer is a heavy-duty, flat, circular disc crafted with a central hole designed specifically to fit M40 bolts or screws — which are 40 mm in diameter. Its primary purpose is to distribute the load of a threaded fastener evenly across a surface, preventing material damage, enhancing the stability of the connection, and improving the durability of bolted joints.

This washer belongs to the Brass Flat Washers category, known for their smooth finish, electrical conductivity, and resistance to corrosion. The M40 Brass Plain Washer is ideal for use in industries that demand precision and performance, such as:

Electrical panel manufacturing

Large mechanical assemblies

Plumbing installations

Marine hardware

Automotive systems

Crafted from a high-quality copper-zinc alloy (brass), this washer also provides aesthetic appeal due to its golden metallic sheen. It’s a perfect fit for exposed fixtures where appearance matters as much as function.

Unlike smaller washers, the M40 Brass Plain Washer is built to handle greater loads and torque levels. Its larger surface area helps reduce the likelihood of fastener loosening and safeguards surrounding components from friction-related damage.

At Nafees Metal Industries, we ensure every M40 Brass Plain Washer is manufactured with precision machining and surface finishing, following Indian and international standards like IS 2016, DIN 125, and ISO 7089.

Whether you’re an industrial buyer or a contractor searching to Buy Brass Washers Online, this washer is built to deliver strength and long-term reliability in demanding applications.

Why Choose Brass for M40 Washers?

Brass is a preferred material in washer manufacturing, particularly for heavy-duty applications like the M40 Brass Plain Washer, due to its unique blend of mechanical strength, corrosion resistance, and conductive properties. When you choose a brass washer over alternatives like mild steel or stainless steel, you gain several performance advantages that are especially relevant in electrical and high-moisture environments.

Here’s why brass is an excellent choice for the M40 Brass Plain Washer:

1. Corrosion Resistance in Harsh Environments

Brass is inherently resistant to rust and oxidation. This makes it suitable for use in damp, humid, or even mildly chemical-exposed environments. Its resistance to degradation ensures a longer service life compared to washers made from untreated steel.

2. Excellent Electrical Conductivity

In electrical applications, conductivity matters. Brass is a highly conductive metal, and it serves as an ideal spacer or grounding component in switchboards, electrical enclosures, and control panels.

3. Aesthetic and Non-Magnetic

Brass has a visually appealing gold-like appearance, making the M40 Brass Plain Washer an ideal choice for visible fastenings where appearance matters. Additionally, its non-magnetic nature ensures it doesn’t interfere with nearby sensitive instruments or electronic circuits.

4. Strong Yet Malleable

Brass offers a high tensile strength while still being malleable enough for precise manufacturing. This allows the washer to be produced with exact dimensions, smooth edges, and consistent thickness, ensuring reliable performance under tightening stress.

5. Versatile for Industrial Use

As part of the broader family of Industrial Brass Washers, this washer stands out due to its ability to balance strength, machinability, and corrosion protection. It’s a suitable solution across sectors like electrical, plumbing, construction, telecom, and marine industries.

Brass allows for a high degree of customization, including various surface finishes such as plain, lacquered, or tin-plated coatings. This adaptability further enhances the M40 Brass Plain Washer’s application-specific suitability.

When you’re sourcing washers that will perform reliably under pressure, exposure, and electrical load, choosing brass—and specifically the M40 Brass Plain Washer—ensures that you’re investing in performance and longevity.

How Are M40 Brass Plain Washers Manufactured?

At Nafees Metal Industries, the production of the M40 Brass Plain Washer follows a precise and quality-driven process. As a trusted Brass Plain Washers Manufacturer in India, we combine industry-grade raw materials, advanced machinery, and skilled labor to produce washers that meet the highest standards of durability and dimensional accuracy.

Here’s a detailed breakdown of our washer manufacturing process:

1. Raw Material Selection

We begin by sourcing high-quality copper-zinc alloy sheets (brass) from certified suppliers. The brass composition is tested for purity, tensile strength, and corrosion resistance to ensure it matches the specifications required for the M40 Brass Plain Washer.

2. Precision Blanking and Punching

Brass sheets are fed into precision power press machines. Using hardened dies, each washer is blanked (outer diameter cut) and punched (inner hole created) to match the M40 bolt dimensions. This ensures the M40 Brass Plain Washer fits perfectly over M40 fasteners without excessive play or tightness.

3. Deburring and Edge Finishing

After punching, the washers undergo deburring to remove sharp edges or leftover metal fragments. We then polish the washers to achieve a smooth surface, preventing scratches on adjacent components during assembly.

4. Dimensional Accuracy Check

Each batch of M40 Brass Plain Washers is checked for inner diameter (approx. 40.5 mm), outer diameter (as per DIN 125 / IS 2016), and thickness consistency. Tolerance levels are tightly maintained to ensure compatibility and interchangeability.

5. Surface Treatment

We offer the M40 Brass Plain Washer in various finishes including:

Plain brass finish

Lacquered finish for extra shine and surface protection

Tin-plated finish for improved conductivity and corrosion resistance

These finishes are applied as per customer requirement and industry usage.

6. Quality Control and Compliance

Our washers undergo visual inspection, hardness testing, and concentricity checks. Every washer complies with Indian and international standards such as IS 2016, ISO 7089, and DIN 125. As a Brass Plain Washers Manufacturer, we never compromise on safety and quality.

7. Packaging and Dispatch

Finally, washers are cleaned, packed, and labeled according to the customer’s needs. We provide bulk packaging in HDPE bags, corrugated boxes, or customized export-ready cartons. Special labeling and barcoding are also available for OEMs and resellers.

Thanks to this detailed process, every M40 Brass Plain Washer that leaves our factory is ready for immediate industrial use—with the strength, consistency, and performance that customers expect from India’s most trusted washer brand.

Key Features of M40 Brass Plain Washer

The M40 Brass Plain Washer is engineered for demanding industrial applications where strength, corrosion resistance, and precise load distribution are essential. Manufactured with high-grade brass and subjected to stringent quality checks, this washer provides consistent and reliable performance in a variety of environments.

Here are the standout features that make the M40 Brass Plain Washer a preferred choice across industries:

1. Accurate Fitment for M40 Bolts

Designed with an inner diameter of approximately 40.5 mm, the washer offers a snug and accurate fit with M40 bolts and screws. This ensures stability and reduces the risk of fastener loosening under vibration or torque.

2. Uniform Load Distribution

The flat surface of the M40 Brass Plain Washer spreads the load of the fastener evenly across the surface, preventing localized pressure that can damage softer substrates or compromise the integrity of joints.

3. Premium Brass Material

Made from corrosion-resistant copper-zinc alloy, the washer maintains its integrity even in moist, chemical, or high-temperature environments. Its anti-rust properties make it suitable for long-term use in critical applications.

4. Smooth Surface Finish

With polished edges and a uniform finish, the M40 Brass Plain Washer ensures safe and easy installation without causing scratches to adjacent parts or components.

5. Custom Thickness and Finishes

Available in standard thickness (2.5–5 mm) with options for plain, lacquered, or tin-plated finishes, this washer is versatile enough to meet various functional and aesthetic needs.

6. Non-Magnetic & Conductive

As part of the Brass Flat Washers family, this washer is non-magnetic and highly conductive, making it ideal for use in electrical and electronic systems without risk of interference.

7. ISO & DIN Standard Compliant

All M40 Brass Plain Washers are manufactured in accordance with IS 2016, ISO 7089, and DIN 125 guidelines, ensuring international quality standards for both domestic and export requirements.

8. Bulk & Custom Packaging Available

Whether you need 100 or 10,000 pieces, we’re equipped to deliver. We offer bulk packaging and customized solutions including labeling, branding, and barcoding for OEMs and distributors.

9. Made in India with Global Reach

Manufactured at our Mumbai-based facility, every M40 Brass Plain Washer is a testament to the ‘Make in India’ initiative, with quality trusted by clients across India and international markets.

10. Ready for Industrial Assembly Lines

With consistent sizing and quick availability, these washers are ready to support high-speed industrial production lines, minimizing delays and downtime.

Technical Specifications

The M40 Brass Plain Washer is designed and manufactured to precise standards to ensure compatibility with M40 fasteners and industrial-grade applications. Below are the detailed technical parameters for this washer:

| Specification | Details |

|---|---|

| Product Name | M40 Brass Plain Washer |

| Material | High-Grade Brass (Copper-Zinc Alloy) |

| Inner Diameter (ID) | Approx. 40.5 mm (to fit M40 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 standards |

| Thickness | 2.5 mm to 5 mm (customizable as per client requirements) |

| Surface Finish Options | Plain, Lacquered, or Tin-Plated |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Tensile Strength | Suitable for medium to heavy-duty industrial applications |

| Hardness | Optimized for long-lasting performance and surface stability |

| Corrosion Resistance | Excellent, especially in humid, marine, or chemical environments |

| Conductivity | High, ideal for electrical and grounding applications |

| Packaging Options | Bulk HDPE bags, Corrugated Boxes, or Custom OEM Packaging |

| Manufacturing Location | Mumbai, India (Nafees Metal Industries Facility) |

| Applications | Electrical systems, plumbing, machinery, marine components, etc. |

Each M40 Brass Plain Washer is produced using ISO-certified manufacturing processes and undergoes strict quality inspection to ensure consistent dimensions, surface finish, and load-handling capabilities.

Whether you’re a systems integrator, hardware wholesaler, or OEM buyer, our technical data gives you the confidence to specify and source the M40 Brass Plain Washer for your next project.

Applications of M40 Brass Plain Washer

The M40 Brass Plain Washer is specifically engineered for large-diameter bolt applications across various industries. Its excellent mechanical properties, corrosion resistance, and conductivity make it a versatile component used by professionals in demanding environments. Below are the key sectors and situations where this washer proves essential:

1. Electrical Panel Manufacturing

Used under bolt heads and nuts in switchgear and distribution panels, the washer provides a conductive surface and prevents over-tightening damage.

2. Plumbing & Sanitary Fittings

Ideal for use in heavy plumbing joints, especially those exposed to moisture or temperature variations. The washer prevents metal-on-metal abrasion and ensures leak-proof integrity.

3. Marine Equipment

Due to its corrosion-resistant nature, this washer is used in marine motors, control units, and deck fastenings where salt exposure is frequent.

4. Machinery Assembly

In heavy machinery and fabrication, it supports torque control and distributes stress uniformly across large metal surfaces, preventing cracking and warping.

5. Automotive Electrical Components

The washer is used for grounding and secure fastening in engine control units, large battery mounts, and chassis systems, providing both strength and conductivity.

6. Construction and Infrastructure Projects

Used in mounting brackets, railings, and base plates in metal structures. Its performance in outdoor environments ensures long-term structural reliability.

7. Telecommunication Towers & Equipment

Essential in bolting high-frequency components, antennas, and racks where electrical neutrality and mechanical stability are critical.

8. OEM Product Assemblies

Preferred by original equipment manufacturers for electrical, HVAC, pump, and generator assembly lines due to its consistency, availability, and finish.

Whether you are a builder, engineer, or installer, the M40 Brass Plain Washer delivers dependable performance across a wide variety of industries and is trusted for both functional and safety-critical applications.

Advantages of Using Brass Plain Washers in M40 Size

When it comes to high-performance fastening, using brass washers—especially in larger sizes like M40—offers unmatched reliability and operational benefits. Whether you are assembling heavy electrical enclosures, building structural components, or working in marine environments, large-size brass flat washers deliver more than just spacing; they provide long-term durability and protection for your systems.

Here are the top advantages of using M40-sized brass washers:

1. Superior Load Distribution

Brass washers in M40 size are designed to evenly spread the force exerted by large bolts or nuts, preventing surface damage, warping, or stress fractures in the underlying material.

2. Corrosion Resistance

Due to their non-ferrous nature, brass components resist rusting and oxidizing. This is crucial for washers used in outdoor or moisture-prone applications such as plumbing, marine, or HVAC systems.

3. Electrical Conductivity

Brass is an excellent conductor of electricity. These washers are widely used in high-voltage systems, grounding circuits, and control panels where both mechanical stability and electrical continuity are needed.

4. Aesthetic Appeal

The golden hue of brass makes these washers suitable for exposed applications like architectural fastenings, custom machinery, and designer fittings where both strength and appearance matter.

5. Easy Machining & Installation

Due to its malleability, brass is easier to machine, allowing for precise dimensional accuracy. It also reduces wear and tear on tools during assembly, ensuring efficiency on production lines.

6. Non-Magnetic Properties

These washers are non-magnetic, making them suitable for sensitive environments like MRI rooms, electronics labs, or telecom towers where magnetic interference must be avoided.

7. Long Service Life

Brass washers exhibit excellent fatigue strength and resistance to vibration, ensuring they last longer and reduce the frequency of maintenance or replacement.

8. Environmentally Friendly

Brass is a fully recyclable material. Choosing brass washers supports eco-conscious manufacturing and helps reduce environmental impact.

Buy in Bulk – Our Manufacturing & Supply Capabilities

At Nafees Metal Industries, we take pride in being a leading Brass Plain Washers Manufacturer in India, with a reputation for delivering precision-made products backed by consistent quality, quick lead times, and full customization. Whether you’re a contractor, OEM, wholesaler, or an exporter looking to scale procurement, we have the capability to meet your requirements for M40 and other sizes in bulk.

Here’s why industry professionals across India and overseas trust us for their brass washer needs:

1. In-House Manufacturing Unit in Mumbai

Our modern factory is equipped with high-tonnage power press machines, CNC equipment, and automated finishing units. Every washer we produce—including large sizes like M40—is made under ISO-compliant practices with 100% in-house production control.

2. Ready Stock for High-Volume Orders

We maintain a stock buffer for fast-moving washer sizes and materials. This means reduced lead time and faster delivery cycles, especially for recurring orders.

3. Customization Options

We offer complete flexibility in:

Outer and inner diameter adjustments

Thickness variations

Surface finishing (plain, lacquered, tin-plated)

Packaging styles (HDPE bags, cartons, barcoded boxes, custom labeling)

4. Competitive Pricing for Bulk Orders

Our large-scale production capacity allows us to optimize costs and offer tier-based pricing for bulk buyers. Whether you’re ordering 1,000 pieces or 1,00,000, we provide the best value without compromising on quality.

5. Export-Ready Supply Chain

We provide export-compliant documentation (packing list, invoices, test certificates, HS codes) and work with international freight partners. Our brass washers are shipped globally to clients in the Middle East, Africa, Southeast Asia, and Europe.

6. Responsive Customer Support

Our dedicated team offers end-to-end assistance—from technical consultations and quotations to order tracking and post-sales support. Whether you are a local buyer or someone looking to Buy Brass Washers Online in bulk, we are equipped to assist promptly.

7. OEM & White-Label Services

We support original equipment manufacturers (OEMs) and resellers with private labeling, branded packaging, and direct drop shipments to clients.

Bulk brass washer buyers choose us not just for the product, but for the complete experience—one that combines technical accuracy, customization, and professional service. With our commitment to quality, we help clients meet demanding industrial timelines and specifications.

Case Study: Real-World Application Success

Client: A High-Voltage Electrical Panel Manufacturer – Gujarat, India

Challenge: Frequent bolt loosening and corrosion in high-capacity panel enclosures

Solution: Integration of our M40-size brass washers with tin-plated finish

Background

The client was facing recurring issues in its assembly line for high-voltage panels. Standard washers made of mild steel were failing under prolonged use—showing signs of corrosion, edge cracking, and loosening due to vibration. This affected the structural integrity and electrical conductivity of the panels, leading to increased rework and customer complaints.

Our Intervention

After a technical consultation, we recommended switching to our M40-sized tin-plated brass washers for all heavy bolting points inside their electrical cabinets. These washers provided better conductivity, load distribution, and protection against environmental moisture.

Implementation

Supplied 30,000 pieces of M40 washers with 3 mm thickness

Custom tin-plated finish applied to improve corrosion resistance

Washers were barcoded and delivered in labeled, batch-tracked cartons

Client trained their assembly team for proper torque application with the new washers

Results

✔️ 38% Reduction in Fastening Issues

✔️ Zero Surface Corrosion after 9 months of usage

✔️ 2X Improvement in Fastener Lifespan

✔️ 50% Reduction in Assembly Line Downtime

✔️ Repeat Order Placed Within 2 Months

Client Feedback

“Switching to Nafees Metal Industries’ brass washers was a game-changer. We not only improved our assembly performance but also gained customer trust back.”

This case demonstrates how precision-manufactured brass washers can solve real-world problems in industrial production environments—especially when sourced from a reliable Brass Plain Washers Manufacturer that understands both engineering and supply chain needs.

Why Choose Nafees Metal Industries?

When it comes to sourcing durable and high-performance brass washers, choosing the right manufacturer is crucial. At Nafees Metal Industries, we don’t just deliver a product—we deliver assurance, reliability, and long-term value. Here’s why we are regarded as one of the most trusted brass plain washers manufacturers in India:

1. Specialization in Washer Manufacturing

Our expertise lies exclusively in washer production. From brass flat washers and plain washers to disc and spring washers, we focus solely on what we do best—manufacturing fastener support components that last.

2. ISO-Certified Quality Assurance

We follow strict quality control procedures at every stage—from raw material sourcing and machining to final inspection and packaging. Each washer is checked for:

Dimensional accuracy

Surface smoothness

Hardness and concentricity

Finish coating integrity

3. Wide Range of Sizes & Customization

Whether it’s an M3 or an M40 washer, we provide a complete range of brass washer sizes with customizable:

Thickness

Outer/Inner diameters

Surface finish

Packaging and labeling

4. Quick Turnaround Times

With in-house manufacturing and bulk stock availability, we fulfill both small and large orders efficiently, meeting tight project deadlines.

5. Trusted by OEMs & Global Clients

We supply to a wide range of industries including:

Electrical and electronics

Plumbing and sanitary fittings

Infrastructure and fabrication

Marine and transportation

Our washers are being used in thousands of installations across India and exported to the UAE, Sri Lanka, Bangladesh, and Africa.

6. Transparent & Competitive Pricing

Our pricing is honest, with no compromise on quality. Whether you’re ordering standard or customized washers, you’ll find us to be one of the most cost-effective sources in the Indian industrial washer market.

7. Make in India Commitment

As a proud supporter of the Make in India initiative, all our products are manufactured locally in Mumbai, with quality that competes at the global level.

8. Dedicated Customer Service

Our team works with you through the entire procurement journey—from helping you choose the right washer to packaging, dispatch, and after-sales support.

When you choose Nafees Metal Industries, you’re choosing consistency, precision, and partnership. With us, you get more than a washer—you get a product that holds your project together, quite literally.

Frequently Asked Questions (FAQs)

1. What is the M40 Brass Plain Washer used for?

It’s primarily used for distributing load under M40 bolts in heavy-duty industrial applications such as electrical panels, plumbing assemblies, and structural fastening.

2. What is the inner diameter of the M40 brass washer?

The standard inner diameter is approximately 40.5 mm to ensure a precise fit over M40-sized bolts or screws.

3. Are M40 brass washers corrosion-resistant?

Yes, brass is naturally resistant to corrosion, making it suitable for humid, marine, and chemical-exposed environments.

4. Can I order M40 brass washers in bulk?

Absolutely. Nafees Metal Industries specializes in bulk production and supplies to OEMs, resellers, and exporters with custom packaging options.

5. Do you offer custom thicknesses for M40 washers?

Yes, we manufacture these washers in standard thicknesses (2.5–5 mm), and custom thicknesses are available on request.

6. What standards do your brass washers comply with?

Our washers meet IS 2016, ISO 7089, and DIN 125 specifications to ensure dimensional and performance reliability.

7. Are these washers electrically conductive?

Yes, brass is a conductive material, making these washers ideal for electrical systems requiring grounding or continuity.

8. What surface finishes are available?

We offer plain, lacquered, and tin-plated finishes depending on your functional or visual requirements.

9. Can I use M40 brass washers for outdoor use?

Yes, their corrosion resistance makes them suitable for outdoor use, especially when paired with protective coatings.

10. Do you provide OEM/private labeling services?

Yes, we offer white-label solutions including barcoding, branding, and custom packaging for resellers and OEMs.

11. How are your washers packaged for export?

Export packaging includes moisture-proof HDPE bags, corrugated boxes, and palletized shipments with full documentation.

12. Can I get a test certificate for my order?

Yes, we provide material test certificates (MTC) and compliance documents upon request for industrial verification.

13. Do you ship internationally?

Yes. We export brass washers to the Middle East, Southeast Asia, and Africa, and can assist with all export formalities.

14. How fast can you dispatch large orders?

Standard sizes like M40 are typically ready in stock or manufactured within 7–10 working days depending on quantity.

15. Why choose Nafees Metal Industries for brass washers?

We’re a trusted brass plain washers manufacturer with in-house production, ISO-certified processes, customizable options, and nationwide + international supply capabilities.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Brass Plain Washers, Plain Washers, Washers

Tag: Brass

Got Questions?

Feel free to

Get in touch