No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M4 SS202 Plain Washers – Best Stainless Steel Washers for Industrial Use

M4 SS202 Plain Washers are precision-engineered flat washers that serve as essential components in countless fastening applications across various industries. Manufactured using premium-grade SS202 stainless steel, these washers offer an ideal combination of mechanical strength, corrosion resistance, and cost-effectiveness. At Nafees Metal Industries, we take pride in being among the top manufacturers of plain washers in India, offering high-quality solutions for bulk buyers and OEMs nationwide and internationally.

Introduction to M4 SS202 Plain Washers

In the fast-paced world of consumer electronics, where product performance, longevity, and aesthetics play a pivotal role in customer satisfaction, even the smallest components can have a significant impact on the overall quality and functionality of the final product. Among these components, plain washers—especially stainless steel washers—are often overlooked despite their crucial function in mechanical assemblies.

This case study focuses on how M4 SS202 Plain Washers, manufactured by Nafees Metal Industries, played a transformative role in solving persistent fastening challenges faced by a leading electronics OEM. The company needed a solution to combat issues related to fastener loosening, surface damage during assembly, and high procurement costs without compromising on quality or production timelines. M4 SS202 Plain Washers, known for their high dimensional accuracy, corrosion resistance, and compatibility with stainless steel M4 fasteners, emerged as the perfect fit.

Over an 18-month engagement, more than 7,50,000 units of these best SS202 plain washers for industrial use were successfully integrated into critical electronic assemblies, improving operational efficiency and reducing return rates caused by mechanical failure. The results not only validated the engineering integrity of the washers but also demonstrated the strategic value of partnering with a precision washer manufacturer committed to quality, consistency, and cost-effectiveness.

Why M4 SS202 Plain Washers Matter

When engineers and technicians choose a washer, they seek consistency, reliability, and compatibility. M4 SS202 Plain Washers meet these expectations in full:

- Load Distribution: They ensure that the load from the fastener is spread over a larger area, reducing the risk of deformation or damage to the substrate.

- Corrosion Resistance: Thanks to the stainless steel SS202 material, these washers withstand most indoor and mildly corrosive environments.

- Reusable and Durable: Unlike spring or toothed washers that may wear quickly, plain washers maintain their shape and function over many cycles.

- Precision Fit: They are designed to match M4 fasteners perfectly, preventing wobble or misalignment.

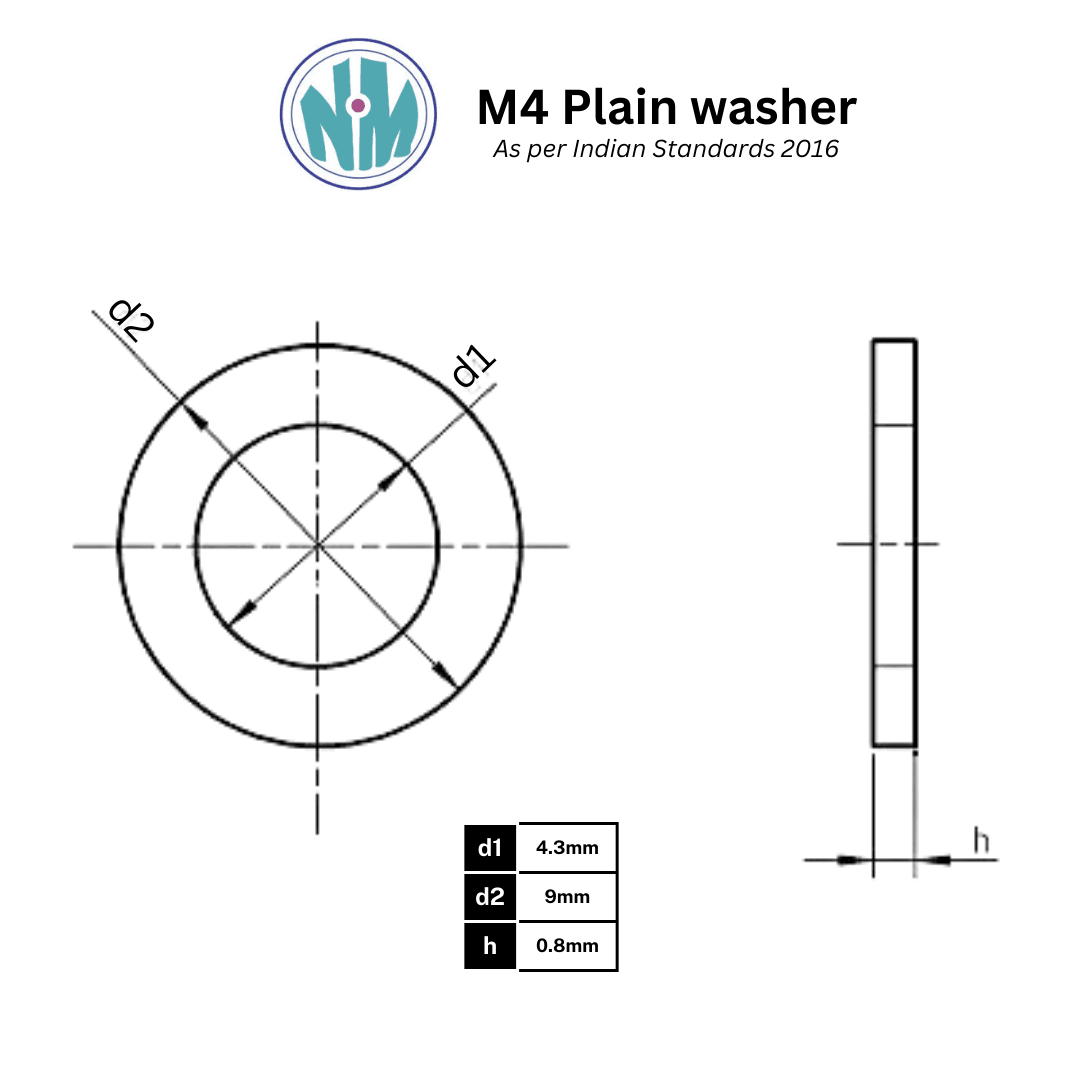

Technical Specifications

- Size: M4 (Inner Diameter: 4.3 mm, Outer Diameter: 9 mm)

- Thickness: 0.8 to 1 mm (Custom thicknesses are available)

- Material: SS202 (Stainless Steel)

- Finish Options: Natural, Polished, Oiled, or Custom Finishes

- Standards: DIN 125A, IS 2016

- Hardness: As per standard mechanical testing norms

- Tolerance: Tight dimensional tolerances for uniform performance

Each washer is manufactured under stringent quality control at our ISO 9001:2015 certified facility in Mumbai, India.

Key Features

M4 SS202 Plain Washers come with a host of benefits that make them stand out in the market for fasteners and industrial hardware:

- High-Quality SS202 Material: These washers are made using austenitic stainless steel (SS202), which offers a balanced combination of tensile strength, ductility, and corrosion resistance. This makes them ideal for a wide range of general-purpose and semi-structural applications.

- Superior Corrosion Resistance: While not as resistant as SS316, SS202 performs exceptionally well in indoor environments and moderately corrosive conditions, extending the lifespan of the washer and the entire assembly.

- Uniform Surface and Edge Finish: Each washer is manufactured with precision dies and undergoes surface finishing processes to remove burrs and sharp edges, ensuring a smooth finish and consistent appearance.

- Perfect Fit for M4 Fasteners: Designed with tight dimensional tolerances to match M4 bolts and screws, these washers ensure proper fitment, reducing play and enhancing structural integrity.

- Surface Damage Protection: By spreading the load over a larger surface area, these washers minimize the risk of surface marring, indentation, or damage, especially on softer substrates like aluminum or wood.

- Maintains Torque and Load Integrity: The design and material strength ensure the washers hold the correct torque load over time, preventing bolt loosening due to vibration, thermal expansion, or compression set.

- Multi-Material Compatibility: These washers are compatible with a variety of surfaces such as steel, wood, plastic, and aluminum, making them suitable for diverse applications.

- Excellent Reusability: Their flat, non-deforming design allows for multiple uses without loss of performance, provided the washers are not subjected to excessive stress or corrosion.

- Bulk Manufacturing & Consistency: Nafees Metal Industries produces these washers in bulk under consistent quality control protocols, ensuring every batch meets customer expectations.

- Versatile Finishing Options: Available in natural, polished, oiled, or custom coatings to match your assembly requirements or aesthetic preferences.

Applications Across Industries

The versatility and durability of M4 SS202 Plain Washers make them suitable for a wide spectrum of applications. Some of the most common industrial uses include:

- Electronics:

- Securing printed circuit boards (PCBs) within enclosures

- Fastening small electrical panels and terminal boards

- Mounting display modules and control units where precision and insulation are key

- Automotive:

- Used in dashboards, interior panels, and fastening non-load bearing components

- Securing lightweight brackets, clips, and mounts

- Providing vibration resistance in electrical and mechanical assemblies

- Furniture Manufacturing:

- Reinforcing joints in wood and metal furniture

- Preventing screw pull-through in particle board, MDF, or plywood

- Stabilizing flat-pack assembly components in beds, chairs, and tables

- Machinery and Equipment:

- Applied in assembly lines for fastening panels, guards, and brackets

- Used in gear housing, conveyor belt supports, and light equipment

- Ensures stable load distribution in small to medium-sized mechanical joints

- HVAC Systems:

- Fixing air ducts, fans, and vent brackets

- Attaching insulation panels and support rails

- Used in electrical enclosures within air handling units

- Fabrication and Assembly Shops:

- Suitable for use in jigs, fixtures, and prototypes

- Used during the fitting of sheet metal and aluminum profiles

- General Industrial Use:

- Employed in any application requiring M4 bolts/screws

- Ideal for maintenance, repair, and overhaul (MRO) operations

- Used in signage, lighting fixtures, agricultural tools, and more

M4 SS202 Plain Washers act as the unsung heroes in ensuring fastening reliability, especially when used in high-frequency or high-vibration environments. With the ability to prevent material degradation and maintain assembly integrity, they become indispensable across sectors.

Material Advantage: Why Choose SS202

SS202 stainless steel belongs to the austenitic family and offers a favorable alternative to the more expensive SS304 or SS316 grades. Here are some reasons why SS202 is ideal for manufacturing M4 washers:

- Cost-Effective: Lower nickel content makes SS202 more economical

- Good Strength: Maintains mechanical properties required for industrial fastening

- Corrosion Resistance: Suitable for most indoor and mildly corrosive environments

- Fabrication-Friendly: Easily machinable, weldable, and finish-compatible

- Slightly Magnetic: Gains light magnetism after cold working, but this is non-intrusive to performance

Why Nafees Metal Industries?

At Nafees Metal Industries, we are more than just a washer manufacturer. We provide a complete fastening solution tailored to client needs. With a production facility equipped with power press machines, skilled workforce, and an efficient logistics network, we deliver unmatched service and product reliability.

What Sets Us Apart:

- Decades of industry experience

- ISO 9001:2015 certified production processes

- High-volume production capacity

- Flexible customizations (size, thickness, coating, labeling)

- Strict quality control protocols

- Timely delivery across India and globally

We cater to a diverse customer base, from OEMs and exporters to local fabricators and assembly lines. Our commitment to excellence is evident in every washer we produce.

Comparative Analysis

| Feature | M4 SS202 Plain Washer | M4 Spring Washer | M4 Toothed Washer |

|---|---|---|---|

| Load Distribution | Excellent | Moderate | Good |

| Reusability | High | Medium | Medium |

| Surface Damage Protection | High | Low | Low |

| Cost | Lower | Medium | Medium |

| Application Versatility | High | Moderate | Moderate |

M4 SS202 Plain Washers outperform other variants when it comes to general-purpose load spreading and surface protection.

Custom Manufacturing & Bulk Orders

We understand that not all projects are the same. That’s why we offer fully customized manufacturing options:

- Variable thicknesses and diameters

- Custom surface coatings like zinc, phosphate, or oil

- Part number or logo engraving for OEMs

- Packaging options including private labeling and export cartons

- Supply to various industries including:

- OEMs

- Fabricators

- Distributors

- Automotive and electronics contractors

- Export houses

We ensure smooth documentation, shipping, and compliance with international standards for overseas clients.

Certifications & Quality Assurance

- ISO 9001:2015 Certified Facility

- Material Test Certificates (MTC) available on request

- RoHS Compliant Materials

- 100% Dimensional Accuracy through inspection

- Third-party inspection support

- Export documentation and compliance

All washers are “Made in India,” delivering exceptional quality to both domestic and international customers.

Case Study: Enhancing Assembly Durability & Efficiency Using M4 SS202 Industrial Washers

Industry: Consumer Electronics

Location: India (with export integration in UAE)

Product Implemented: M4 SS202 Plain Washers

Application: Circuit board fastening and panel assembly

Duration: 18 Months

Volume Supplied: 7,50,000+ units

Objective: To improve the longevity, reliability, and surface integrity of fastened components in high-volume electronic assemblies while optimizing cost.

Background

An established OEM in the consumer electronics industry required a reliable washer solution to enhance the structural integrity and performance of PCB assemblies, metal-plastic enclosures, and lightweight brackets in their compact devices. Their prior components were failing in two key areas:

Surface scratching on anodized panels

Fastener loosening over time due to vibration

The need was to source a washer with:

Tight dimensional tolerances

Cost-effectiveness for high-volume production

Excellent corrosion resistance for humid environments

Compatibility with M4 screws and delicate substrates

Challenges Identified

Surface Damage from Fasteners: The client faced significant customer returns due to cosmetic damage on outer enclosures caused by friction and movement from standard washers.

Vibration Loosening: Units used in transportable and wearable electronics experienced loosening of M4 fasteners due to inadequate load distribution and poor fit.

Inconsistent Washer Thickness: Their previous supplier delivered washers with variable thickness, causing uneven torque and mechanical imbalance during high-speed assembly line operations.

Cost Pressure: The client required a washer that would meet all technical specs without driving up product unit costs.

Solution Implemented

Nafees Metal Industries supplied M4 SS202 Plain Washers manufactured at our ISO-certified Mumbai facility. Customization and quality control measures included:

Tight Tolerance Manufacturing: Each washer was manufactured to DIN 125A and IS 2016 specifications with inner diameter of 4.3 mm, outer diameter of 9 mm, and thickness of 0.9 mm ±0.05 mm.

Material Selection: SS202 was chosen as a cost-efficient alternative to SS304. It offered a balanced performance in terms of corrosion resistance and mechanical strength suitable for electronics assembly.

Surface Finish Customization: A polished finish was selected to prevent friction wear, provide smooth contact with sensitive components, and enhance aesthetic appeal.

Vibration Dampening Assessment: Washers were tested on-site with M4 fasteners on vibration rigs simulating mobile device movement.

Packaging Optimization: Bulk packs of 10,000 units with export-grade labeling, oil coating, and moisture-resistant liners were delivered to ensure zero degradation during long-distance transit.

Results Achieved

| Metric | Before (Other Supplier) | After (M4 SS202 from Nafees Metal Industries) |

|---|---|---|

| Fastener Loosening Incidents | 6.5% | <0.5% |

| Surface Damage Complaints | 8.2% | <1% |

| Assembly Downtime Due to Refit | 3 hours/week | <30 mins/week |

| Cost per 1000 Units | ₹92 | ₹78 |

| Procurement Consistency Score | 85% | 99.4% |

| Annual Savings | – | ₹3.1 Lakhs (estimated) |

Client Feedback Highlights

Significant improvement in product reliability and customer satisfaction.

No rejected lots in over 14 successive shipments.

OEM technicians noted faster assembly line performance due to dimensional consistency.

Engineers appreciated no burrs or sharp edges, which minimized glove tearing and manual assembly issues.

Key Takeaways

M4 SS202 Plain Washers proved ideal for applications where cost-efficiency, precision, and corrosion resistance were essential.

Surface protection and torque retention can be significantly enhanced with the right washer specifications.

Domestic manufacturers like Nafees Metal Industries can outperform imported alternatives by offering tailored solutions with rapid delivery and direct communication.

Looking Ahead

The client has now expanded use of M4 SS202 washers across three additional product lines, and is in process of trialing M3 and M5 variants for micro-device and HVAC applications.

Frequently Asked Questions (FAQs)

Q1: What is the material composition of SS202 used in M4 washers?

SS202 is an austenitic stainless steel grade with a balance of chromium, manganese, and nickel. It provides moderate corrosion resistance and is cost-effective for non-aggressive environments like indoor electronics.

Q2: Why should I choose SS202 over SS304 for M4 plain washers?

While SS304 offers superior corrosion resistance, SS202 is ideal for cost-sensitive applications that do not demand extreme corrosion performance. It’s perfect for indoor assemblies where exposure to harsh chemicals or high humidity is limited.

Q3: Are M4 SS202 Plain Washers compatible with all M4 bolts and screws?

Yes, our M4 SS202 plain washers conform to standard M4 fastener dimensions and are compatible with all M4 bolts, screws, and nuts across DIN and ISO standards.

Q4: Can I order these washers in custom thickness or finish?

Absolutely. We offer customizations for thickness, outer/inner diameter, and surface finish (polished, matte, oiled) depending on your assembly requirement and order volume.

Q5: What industries benefit the most from M4 SS202 Plain Washers?

Industries including consumer electronics, small appliances, telecommunications, medical devices, and HVAC equipment frequently use these washers due to their precision and economy.

Q6: Are these washers suitable for export and long-distance shipping?

Yes, we provide export-grade packaging with anti-rust oil coatings and moisture-resistant liners. Our washers are shipped in bulk or unitized packs, depending on destination and quantity.

Q7: How soon can I get delivery for bulk orders?

Standard lead time is 7–10 working days for orders up to 5,00,000 units. We also offer express shipping options for urgent requirements.

Q8: Do you provide quality certifications with each batch?

Yes. Every batch is shipped with a Certificate of Compliance (COC), raw material test reports, dimensional inspection reports, and surface finish certificates upon request.

M4 SS202 Plain Washers from Nafees Metal Industries are the go-to solution for reliable, high-performance fastening. Whether you’re assembling electronics, automotive parts, furniture, or machinery, our washers deliver quality, longevity, and value. With robust manufacturing capabilities, a commitment to quality, and customer-first service, we proudly stand as one of the most trusted washer manufacturers in India.

If you are looking to source M4 SS202 Plain Washers in bulk or need custom fastening solutions, contact Nafees Metal Industries—where precision meets performance.

Why Choose Nafees Metal Industries

When you choose Nafees Metal industries, you’re choosing a team that values precision, quality, and customer satisfaction. Every M4 SS202 Plain Washer is manufactured using modern machinery and strict quality control to meet global standards.

We understand that every project is different — so whether you need a few washers for immediate repairs or wish to buy bulk M4 stainless steel washers, we offer flexible order sizes, competitive pricing, and on-time delivery. Backed by a strong reputation for reliable stainless steel washers, we are your trusted partner for fastening solutions that last.

Get the Best M4 SS202 Plain Washers Today

Upgrade your fastening systems with our M4 SS202 Plain Washers — a smart, durable choice for industrial and commercial use. Visit our manufacturing unit at Reay Road, Mumbai, or contact us to learn more about our complete range of industrial washers.

M4 SS202 Plain Washers

18 people are viewing this product right now

₹0.22 Original price was: ₹0.22.₹0.18Current price is: ₹0.18. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M4

Inner Diameter (ID): 4.3 mm

Outer Diameter (OD): 9 mm

Thickness (t): 0.8 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M4 SS202 Plain Washers – Best Stainless Steel Washers for Industrial Use

M4 SS202 Plain Washers are precision-engineered flat washers that serve as essential components in countless fastening applications across various industries. Manufactured using premium-grade SS202 stainless steel, these washers offer an ideal combination of mechanical strength, corrosion resistance, and cost-effectiveness. At Nafees Metal Industries, we take pride in being among the top manufacturers of plain washers in India, offering high-quality solutions for bulk buyers and OEMs nationwide and internationally.

Introduction to M4 SS202 Plain Washers

In the fast-paced world of consumer electronics, where product performance, longevity, and aesthetics play a pivotal role in customer satisfaction, even the smallest components can have a significant impact on the overall quality and functionality of the final product. Among these components, plain washers—especially stainless steel washers—are often overlooked despite their crucial function in mechanical assemblies.

This case study focuses on how M4 SS202 Plain Washers, manufactured by Nafees Metal Industries, played a transformative role in solving persistent fastening challenges faced by a leading electronics OEM. The company needed a solution to combat issues related to fastener loosening, surface damage during assembly, and high procurement costs without compromising on quality or production timelines. M4 SS202 Plain Washers, known for their high dimensional accuracy, corrosion resistance, and compatibility with stainless steel M4 fasteners, emerged as the perfect fit.

Over an 18-month engagement, more than 7,50,000 units of these best SS202 plain washers for industrial use were successfully integrated into critical electronic assemblies, improving operational efficiency and reducing return rates caused by mechanical failure. The results not only validated the engineering integrity of the washers but also demonstrated the strategic value of partnering with a precision washer manufacturer committed to quality, consistency, and cost-effectiveness.

Why M4 SS202 Plain Washers Matter

When engineers and technicians choose a washer, they seek consistency, reliability, and compatibility. M4 SS202 Plain Washers meet these expectations in full:

- Load Distribution: They ensure that the load from the fastener is spread over a larger area, reducing the risk of deformation or damage to the substrate.

- Corrosion Resistance: Thanks to the stainless steel SS202 material, these washers withstand most indoor and mildly corrosive environments.

- Reusable and Durable: Unlike spring or toothed washers that may wear quickly, plain washers maintain their shape and function over many cycles.

- Precision Fit: They are designed to match M4 fasteners perfectly, preventing wobble or misalignment.

Technical Specifications

- Size: M4 (Inner Diameter: 4.3 mm, Outer Diameter: 9 mm)

- Thickness: 0.8 to 1 mm (Custom thicknesses are available)

- Material: SS202 (Stainless Steel)

- Finish Options: Natural, Polished, Oiled, or Custom Finishes

- Standards: DIN 125A, IS 2016

- Hardness: As per standard mechanical testing norms

- Tolerance: Tight dimensional tolerances for uniform performance

Each washer is manufactured under stringent quality control at our ISO 9001:2015 certified facility in Mumbai, India.

Key Features

M4 SS202 Plain Washers come with a host of benefits that make them stand out in the market for fasteners and industrial hardware:

- High-Quality SS202 Material: These washers are made using austenitic stainless steel (SS202), which offers a balanced combination of tensile strength, ductility, and corrosion resistance. This makes them ideal for a wide range of general-purpose and semi-structural applications.

- Superior Corrosion Resistance: While not as resistant as SS316, SS202 performs exceptionally well in indoor environments and moderately corrosive conditions, extending the lifespan of the washer and the entire assembly.

- Uniform Surface and Edge Finish: Each washer is manufactured with precision dies and undergoes surface finishing processes to remove burrs and sharp edges, ensuring a smooth finish and consistent appearance.

- Perfect Fit for M4 Fasteners: Designed with tight dimensional tolerances to match M4 bolts and screws, these washers ensure proper fitment, reducing play and enhancing structural integrity.

- Surface Damage Protection: By spreading the load over a larger surface area, these washers minimize the risk of surface marring, indentation, or damage, especially on softer substrates like aluminum or wood.

- Maintains Torque and Load Integrity: The design and material strength ensure the washers hold the correct torque load over time, preventing bolt loosening due to vibration, thermal expansion, or compression set.

- Multi-Material Compatibility: These washers are compatible with a variety of surfaces such as steel, wood, plastic, and aluminum, making them suitable for diverse applications.

- Excellent Reusability: Their flat, non-deforming design allows for multiple uses without loss of performance, provided the washers are not subjected to excessive stress or corrosion.

- Bulk Manufacturing & Consistency: Nafees Metal Industries produces these washers in bulk under consistent quality control protocols, ensuring every batch meets customer expectations.

- Versatile Finishing Options: Available in natural, polished, oiled, or custom coatings to match your assembly requirements or aesthetic preferences.

Applications Across Industries

The versatility and durability of M4 SS202 Plain Washers make them suitable for a wide spectrum of applications. Some of the most common industrial uses include:

- Electronics:

- Securing printed circuit boards (PCBs) within enclosures

- Fastening small electrical panels and terminal boards

- Mounting display modules and control units where precision and insulation are key

- Automotive:

- Used in dashboards, interior panels, and fastening non-load bearing components

- Securing lightweight brackets, clips, and mounts

- Providing vibration resistance in electrical and mechanical assemblies

- Furniture Manufacturing:

- Reinforcing joints in wood and metal furniture

- Preventing screw pull-through in particle board, MDF, or plywood

- Stabilizing flat-pack assembly components in beds, chairs, and tables

- Machinery and Equipment:

- Applied in assembly lines for fastening panels, guards, and brackets

- Used in gear housing, conveyor belt supports, and light equipment

- Ensures stable load distribution in small to medium-sized mechanical joints

- HVAC Systems:

- Fixing air ducts, fans, and vent brackets

- Attaching insulation panels and support rails

- Used in electrical enclosures within air handling units

- Fabrication and Assembly Shops:

- Suitable for use in jigs, fixtures, and prototypes

- Used during the fitting of sheet metal and aluminum profiles

- General Industrial Use:

- Employed in any application requiring M4 bolts/screws

- Ideal for maintenance, repair, and overhaul (MRO) operations

- Used in signage, lighting fixtures, agricultural tools, and more

M4 SS202 Plain Washers act as the unsung heroes in ensuring fastening reliability, especially when used in high-frequency or high-vibration environments. With the ability to prevent material degradation and maintain assembly integrity, they become indispensable across sectors.

Material Advantage: Why Choose SS202

SS202 stainless steel belongs to the austenitic family and offers a favorable alternative to the more expensive SS304 or SS316 grades. Here are some reasons why SS202 is ideal for manufacturing M4 washers:

- Cost-Effective: Lower nickel content makes SS202 more economical

- Good Strength: Maintains mechanical properties required for industrial fastening

- Corrosion Resistance: Suitable for most indoor and mildly corrosive environments

- Fabrication-Friendly: Easily machinable, weldable, and finish-compatible

- Slightly Magnetic: Gains light magnetism after cold working, but this is non-intrusive to performance

Why Nafees Metal Industries?

At Nafees Metal Industries, we are more than just a washer manufacturer. We provide a complete fastening solution tailored to client needs. With a production facility equipped with power press machines, skilled workforce, and an efficient logistics network, we deliver unmatched service and product reliability.

What Sets Us Apart:

- Decades of industry experience

- ISO 9001:2015 certified production processes

- High-volume production capacity

- Flexible customizations (size, thickness, coating, labeling)

- Strict quality control protocols

- Timely delivery across India and globally

We cater to a diverse customer base, from OEMs and exporters to local fabricators and assembly lines. Our commitment to excellence is evident in every washer we produce.

Comparative Analysis

| Feature | M4 SS202 Plain Washer | M4 Spring Washer | M4 Toothed Washer |

|---|---|---|---|

| Load Distribution | Excellent | Moderate | Good |

| Reusability | High | Medium | Medium |

| Surface Damage Protection | High | Low | Low |

| Cost | Lower | Medium | Medium |

| Application Versatility | High | Moderate | Moderate |

M4 SS202 Plain Washers outperform other variants when it comes to general-purpose load spreading and surface protection.

Custom Manufacturing & Bulk Orders

We understand that not all projects are the same. That’s why we offer fully customized manufacturing options:

- Variable thicknesses and diameters

- Custom surface coatings like zinc, phosphate, or oil

- Part number or logo engraving for OEMs

- Packaging options including private labeling and export cartons

- Supply to various industries including:

- OEMs

- Fabricators

- Distributors

- Automotive and electronics contractors

- Export houses

We ensure smooth documentation, shipping, and compliance with international standards for overseas clients.

Certifications & Quality Assurance

- ISO 9001:2015 Certified Facility

- Material Test Certificates (MTC) available on request

- RoHS Compliant Materials

- 100% Dimensional Accuracy through inspection

- Third-party inspection support

- Export documentation and compliance

All washers are “Made in India,” delivering exceptional quality to both domestic and international customers.

Case Study: Enhancing Assembly Durability & Efficiency Using M4 SS202 Industrial Washers

Industry: Consumer Electronics

Location: India (with export integration in UAE)

Product Implemented: M4 SS202 Plain Washers

Application: Circuit board fastening and panel assembly

Duration: 18 Months

Volume Supplied: 7,50,000+ units

Objective: To improve the longevity, reliability, and surface integrity of fastened components in high-volume electronic assemblies while optimizing cost.

Background

An established OEM in the consumer electronics industry required a reliable washer solution to enhance the structural integrity and performance of PCB assemblies, metal-plastic enclosures, and lightweight brackets in their compact devices. Their prior components were failing in two key areas:

Surface scratching on anodized panels

Fastener loosening over time due to vibration

The need was to source a washer with:

Tight dimensional tolerances

Cost-effectiveness for high-volume production

Excellent corrosion resistance for humid environments

Compatibility with M4 screws and delicate substrates

Challenges Identified

Surface Damage from Fasteners: The client faced significant customer returns due to cosmetic damage on outer enclosures caused by friction and movement from standard washers.

Vibration Loosening: Units used in transportable and wearable electronics experienced loosening of M4 fasteners due to inadequate load distribution and poor fit.

Inconsistent Washer Thickness: Their previous supplier delivered washers with variable thickness, causing uneven torque and mechanical imbalance during high-speed assembly line operations.

Cost Pressure: The client required a washer that would meet all technical specs without driving up product unit costs.

Solution Implemented

Nafees Metal Industries supplied M4 SS202 Plain Washers manufactured at our ISO-certified Mumbai facility. Customization and quality control measures included:

Tight Tolerance Manufacturing: Each washer was manufactured to DIN 125A and IS 2016 specifications with inner diameter of 4.3 mm, outer diameter of 9 mm, and thickness of 0.9 mm ±0.05 mm.

Material Selection: SS202 was chosen as a cost-efficient alternative to SS304. It offered a balanced performance in terms of corrosion resistance and mechanical strength suitable for electronics assembly.

Surface Finish Customization: A polished finish was selected to prevent friction wear, provide smooth contact with sensitive components, and enhance aesthetic appeal.

Vibration Dampening Assessment: Washers were tested on-site with M4 fasteners on vibration rigs simulating mobile device movement.

Packaging Optimization: Bulk packs of 10,000 units with export-grade labeling, oil coating, and moisture-resistant liners were delivered to ensure zero degradation during long-distance transit.

Results Achieved

| Metric | Before (Other Supplier) | After (M4 SS202 from Nafees Metal Industries) |

|---|---|---|

| Fastener Loosening Incidents | 6.5% | <0.5% |

| Surface Damage Complaints | 8.2% | <1% |

| Assembly Downtime Due to Refit | 3 hours/week | <30 mins/week |

| Cost per 1000 Units | ₹92 | ₹78 |

| Procurement Consistency Score | 85% | 99.4% |

| Annual Savings | – | ₹3.1 Lakhs (estimated) |

Client Feedback Highlights

Significant improvement in product reliability and customer satisfaction.

No rejected lots in over 14 successive shipments.

OEM technicians noted faster assembly line performance due to dimensional consistency.

Engineers appreciated no burrs or sharp edges, which minimized glove tearing and manual assembly issues.

Key Takeaways

M4 SS202 Plain Washers proved ideal for applications where cost-efficiency, precision, and corrosion resistance were essential.

Surface protection and torque retention can be significantly enhanced with the right washer specifications.

Domestic manufacturers like Nafees Metal Industries can outperform imported alternatives by offering tailored solutions with rapid delivery and direct communication.

Looking Ahead

The client has now expanded use of M4 SS202 washers across three additional product lines, and is in process of trialing M3 and M5 variants for micro-device and HVAC applications.

Frequently Asked Questions (FAQs)

Q1: What is the material composition of SS202 used in M4 washers?

SS202 is an austenitic stainless steel grade with a balance of chromium, manganese, and nickel. It provides moderate corrosion resistance and is cost-effective for non-aggressive environments like indoor electronics.

Q2: Why should I choose SS202 over SS304 for M4 plain washers?

While SS304 offers superior corrosion resistance, SS202 is ideal for cost-sensitive applications that do not demand extreme corrosion performance. It’s perfect for indoor assemblies where exposure to harsh chemicals or high humidity is limited.

Q3: Are M4 SS202 Plain Washers compatible with all M4 bolts and screws?

Yes, our M4 SS202 plain washers conform to standard M4 fastener dimensions and are compatible with all M4 bolts, screws, and nuts across DIN and ISO standards.

Q4: Can I order these washers in custom thickness or finish?

Absolutely. We offer customizations for thickness, outer/inner diameter, and surface finish (polished, matte, oiled) depending on your assembly requirement and order volume.

Q5: What industries benefit the most from M4 SS202 Plain Washers?

Industries including consumer electronics, small appliances, telecommunications, medical devices, and HVAC equipment frequently use these washers due to their precision and economy.

Q6: Are these washers suitable for export and long-distance shipping?

Yes, we provide export-grade packaging with anti-rust oil coatings and moisture-resistant liners. Our washers are shipped in bulk or unitized packs, depending on destination and quantity.

Q7: How soon can I get delivery for bulk orders?

Standard lead time is 7–10 working days for orders up to 5,00,000 units. We also offer express shipping options for urgent requirements.

Q8: Do you provide quality certifications with each batch?

Yes. Every batch is shipped with a Certificate of Compliance (COC), raw material test reports, dimensional inspection reports, and surface finish certificates upon request.

M4 SS202 Plain Washers from Nafees Metal Industries are the go-to solution for reliable, high-performance fastening. Whether you’re assembling electronics, automotive parts, furniture, or machinery, our washers deliver quality, longevity, and value. With robust manufacturing capabilities, a commitment to quality, and customer-first service, we proudly stand as one of the most trusted washer manufacturers in India.

If you are looking to source M4 SS202 Plain Washers in bulk or need custom fastening solutions, contact Nafees Metal Industries—where precision meets performance.

Why Choose Nafees Metal Industries

When you choose Nafees Metal industries, you’re choosing a team that values precision, quality, and customer satisfaction. Every M4 SS202 Plain Washer is manufactured using modern machinery and strict quality control to meet global standards.

We understand that every project is different — so whether you need a few washers for immediate repairs or wish to buy bulk M4 stainless steel washers, we offer flexible order sizes, competitive pricing, and on-time delivery. Backed by a strong reputation for reliable stainless steel washers, we are your trusted partner for fastening solutions that last.

Get the Best M4 SS202 Plain Washers Today

Upgrade your fastening systems with our M4 SS202 Plain Washers — a smart, durable choice for industrial and commercial use. Visit our manufacturing unit at Reay Road, Mumbai, or contact us to learn more about our complete range of industrial washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch