No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M22 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M4 Mild Steel Plain Washers – Best M4 MS Flat Washers for Industrial Use

Introduction

Small fasteners can have a huge impact. In industrial, electrical, or general-purpose assemblies, the humble washer is what makes a bolt truly reliable. M4 Mild Steel Plain Washers are one of the most widely used sizes for light-duty, high-precision fastening jobs — especially when you’re working with thin sheet metal, panels, or soft materials that need protection.

At Nafees Metal Industries, we understand that a washer is never just a washer. Each piece must maintain tight tolerances, deliver consistent performance, and work seamlessly in your production line. That’s why manufacturers, OEMs, and contractors choose us for the Best M4 MS Flat Washers for Industrial Use, all made from premium mild steel and engineered for repeatable results.

In this guide, you’ll discover exactly why M4 Mild Steel Plain Washers deserve a place in your next project: what they are, how they’re made, the benefits they bring, real-world case study results, and practical tips for installation and maintenance. If you plan to Buy M4 Mild Steel Washers in Bulk, this will help you make the right choice with total confidence.

Role of M4 Mild Steel Plain Washers in Industrial Applications

When you tighten a bolt, the force clamps the parts together. But if that force is too concentrated, it can deform, dent, or even tear through the material. That’s where washers come in — they act as a buffer, spreading the load, preventing surface damage, and absorbing vibrations.

For small fasteners like M4 bolts, the risk of damaging thin or soft materials is even higher. Without washers, you can easily crack a panel, strip a hole, or loosen the bolt during vibration. M4 Mild Steel Plain Washers solve this by:

Distributing force evenly to prevent stress points

Protecting surface finishes like paint or powder coating

Adding friction to resist vibration-induced loosening

Extending the life of the entire assembly

These are reasons why Mild Steel Flat Washers remain the go-to solution for thousands of everyday applications.

What Are M4 Mild Steel Plain Washers

A M4 Mild Steel Plain Washer is a small, flat, circular disc with a precisely punched center hole designed to fit M4 fasteners snugly. Its simple design hides its importance — by sitting between the bolt head (or nut) and the surface, it prevents local deformation, protects coatings, and improves the joint’s durability.

How They Work

When you tighten an M4 bolt, the washer spreads the clamping force across a larger area. This is essential when fastening thin metal sheets, plastic parts, or painted surfaces that can easily scratch or crack. In light machinery or electronics, these washers also help the bolt maintain its hold when exposed to vibration, temperature fluctuations, or repeated use.

The result: safer, cleaner, longer-lasting assemblies — all with one small but mighty part.

Material Details: Mild Steel for Reliable Performance

Why mild steel? For general-purpose plain washers, mild steel remains the smart choice because it combines strength, flexibility, and cost-effectiveness.

Mild steel, or low carbon steel, contains a low percentage of carbon, making it ductile enough to bend slightly under load without cracking. This flexibility is perfect for washers, as they need to hold shape under compression yet adapt to minor surface imperfections.

Advantages of Mild Steel Flat Washers include:

Strength: Handles moderate clamping loads without warping.

Ductility: Absorbs shock and vibration rather than transferring it all to the bolt or base material.

Formability: Can be punched and stamped to tight tolerances.

Cost-Effective: Cheaper than stainless steel for non-corrosive or indoor conditions.

Adaptability: Can be zinc or phosphate coated for mild corrosion protection.

For small bolts like M4s, mild steel is strong enough to protect your assembly without adding unnecessary cost — exactly why these washers remain a staple for both OEMs and end-users alike.

How M4 Mild Steel Plain Washers Are Manufactured

Every batch of M4 Mild Steel Plain Washers we make undergoes rigorous production and inspection to ensure dimensional consistency and strength.

Key Steps:

Raw Material Selection: Certified mild steel sheets are sourced to meet IS/ISO standards.

Precision Punching: CNC-controlled presses punch each washer to exact inner and outer diameter specs.

Deburring: Automated deburring removes sharp edges, making them safe and assembly-line ready.

Optional Coating: Washers can be supplied plain oiled, zinc-plated, or phosphate-coated.

Inspection: Each batch is checked for dimensional tolerances, coating thickness, and burr-free finish.

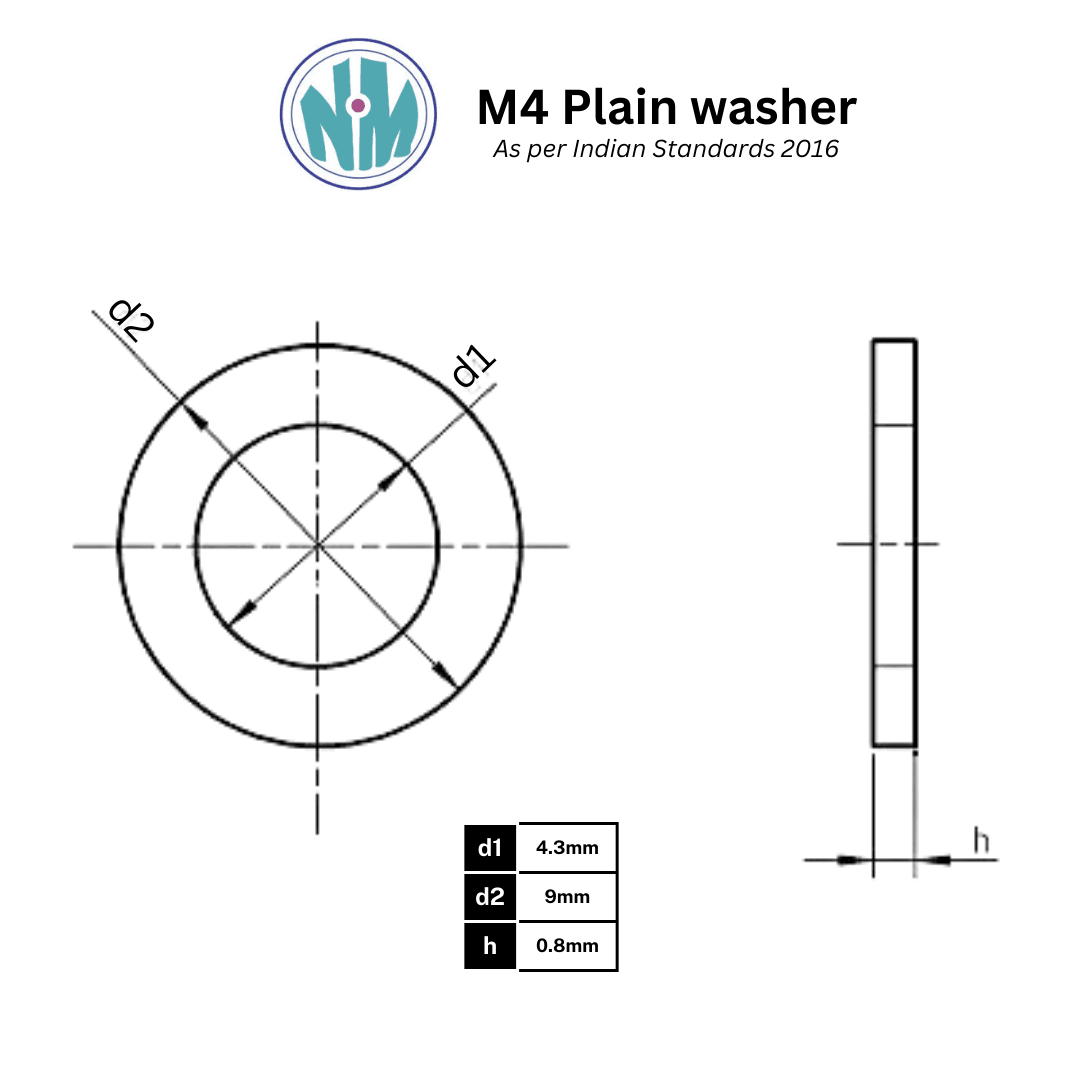

Typical Specifications for M4 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | ~4.3 mm (fits M4 bolts securely) |

| Outer Diameter | 8–10 mm |

| Thickness | Per IS/ISO/DIN standards |

| Finish | Plain, zinc-plated, or phosphate-coated |

| Material | Mild Steel |

| Shape | Flat disc |

Key Features of M4 Mild Steel Plain Washers

Accurate Load Distribution

One of the main roles of any plain washer is to spread the load of a bolt or screw evenly over the surface. For small-diameter bolts like M4, this becomes even more important because the clamping force is concentrated on a tiny area. Without a washer, torquing an M4 bolt directly onto soft materials like aluminum or thin sheet metal can punch through the material or cause local deformation. With M4 Mild Steel Plain Washers, the pressure spreads over a wider surface area, ensuring the base material withstands the bolt’s force without distortion — especially vital for layered or coated surfaces.

Surface Protection

Painted or coated surfaces are common in panels, enclosures, and furniture. Tightening a bolt without a washer can scratch, chip, or strip that coating, exposing the metal underneath to corrosion. M4 Mild Steel Plain Washers act as a buffer, absorbing friction so your surface finish stays intact. The result is a cleaner, more professional look that keeps your products looking new longer.

Resistance to Vibration

Machines vibrate. Electronics heat up and cool down. Furniture and panels face daily movement. These tiny shifts can loosen bolts over time. The flat washer adds a layer of friction that helps resist rotational loosening. This means fewer inspections, fewer maintenance hours, and more peace of mind for critical assemblies.

Durability and Reusability

Our washers hold up under repeated tightening and removal. This matters for fixtures that require periodic disassembly for cleaning, upgrades, or inspection. Each washer keeps its shape and integrity, saving you money on replacements.

Compact, Lightweight Design

The compact size of M4 Mild Steel Plain Washers makes them perfect for tight spaces in electronics, control boxes, or decorative panels where a large washer would be impractical.

Versatility Across Industries

From consumer goods and appliances to DIY and craft projects, M4 is a universal size. You can stock up and use them across multiple projects with confidence.

Applications of M4 Mild Steel Plain Washers

When it comes to versatility, M4 Mild Steel Plain Washers truly punch above their weight. Their small size, durable mild steel construction, and ability to handle light to moderate loads make them an everyday essential across multiple industries. Here’s how different sectors use these washers to solve practical fastening challenges and ensure long-lasting reliability.

Electronics & Electrical Panels

In the electronics industry, M4 Mild Steel Plain Washers are often used to secure PCBs, switchgear, and terminal boxes. Their main job is to distribute the small but precise clamping force of M4 fasteners across fragile materials — like thin aluminum panels or plastic casings. This prevents hairline cracks around screw holes, protects protective coatings, and ensures that vibration from moving parts or thermal expansion doesn’t loosen critical connections.

Example: In a control cabinet, dozens of M4 screws might hold circuit boards, cable brackets, or access covers in place. A missing washer here could mean a cracked board, a short circuit, or extra warranty costs down the road. A simple washer solves it all.

HVAC Systems

HVAC panels, ductwork, and mounting brackets frequently rely on M4-sized fasteners because these systems have many small panels that need secure yet lightweight joining. M4 Mild Steel Plain Washers help protect the sheet metal flanges from deformation during installation and maintenance.

They’re especially useful in HVAC equipment that’s opened repeatedly for servicing — a good washer prevents the screw from digging into the metal over time, ensuring a tight seal and vibration resistance, even in high-humidity or mild outdoor conditions when paired with a protective coating.

Appliance Manufacturing

Manufacturers of small household appliances — fans, light fixtures, kitchen gadgets — rely on M4 Mild Steel Plain Washers to keep parts aligned and surface finishes intact. Painted or powder-coated metal parts are easily scratched by direct screw heads. Washers act as a buffer, preventing damage and maintaining the visual appeal that customers expect.

In mass production, the repeatable quality offered by burr-free, precision mild steel washers also helps reduce assembly line jams and costly rework.

Furniture & Fixtures

Metal furniture frames, decorative brackets, shelving systems, and modular cabinets often use M4 bolts and washers for discreet, tight-fitting connections. M4 Mild Steel Plain Washers protect powder-coated surfaces from scratches, ensure even load spread, and keep connections tight over time.

They’re equally popular in DIY furniture kits, giving hobbyists and professionals a neat, professional finish while making disassembly easier if needed.

Automotive & Transportation

Although larger fasteners are more common in heavy automotive work, certain small brackets, interior fittings, and electrical harness clips still depend on M4 screws. In these cases, M4 Mild Steel Plain Washers help prevent rattling or paint damage to interior panels, dashboards, or custom fittings. This small component plays a big role in maintaining a quiet, rattle-free ride.

DIY, Repairs & Maintenance

For general-purpose repairs, home improvement, and craft projects, M4 Mild Steel Plain Washers are a must-have in every hardware box. From securing light fixtures to mounting photo frames or repairing lightweight garden tools, these washers protect surfaces and maintain tightness with minimal fuss.

Their mild steel construction makes them cost-effective for indoor use, and with the right coating, they’re good for mild outdoor exposure too.

Custom Assemblies & OEM Products

OEMs in sectors like consumer electronics, point-of-sale equipment, and lighting often specify M4 Mild Steel Plain Washers for specialized enclosures that need reliable joints but can’t afford to compromise on aesthetics. When your product demands a clean, scratch-free finish with repeatable performance, these washers deliver — batch after batch.

Why Buy M4 Mild Steel Washers in Bulk

When you Buy M4 Mild Steel Washers in Bulk, you unlock big advantages:

Volume discounts that reduce your project cost.

Inventory consistency so you don’t run out mid-project.

Quality consistency with washers from the same production batch.

Custom packing to match your assembly line requirements.

Faster turnaround with a dedicated bulk supply agreement.

It’s smart business, especially when your projects use thousands of small fasteners every month.

Why Choose the Best M4 MS Flat Washers for Industrial Use

Nafees Metal Industries stands apart as the Best M4 MS Flat Washers for Industrial Use because we combine decades of manufacturing experience with responsive service. Our washers comply with IS/ISO standards, come with mill test certificates, and can be tailored for special coatings or dimensions. You get a trusted partner that guarantees quality at competitive prices — every time.

Installation Tips for M4 Mild Steel Plain Washers

Always use washers on both bolt head and nut side if both contact sensitive surfaces.

Clean surfaces to remove debris that could scratch or damage your panels.

Tighten bolts to the correct torque to avoid over-compression that might deform the washer.

Use coated washers in humid or mildly corrosive environments.

Maintenance for M4 Mild Steel Plain Washers

Inspect regularly for cracks, warping, or corrosion.

Replace washers that show signs of significant wear.

Store extra washers in dry, sealed bins.

Keep plain washers oiled if storing for extended periods.

Case Study: How M4 MS Washers Resolved Panel Damage for an Electronics Manufacturer

Background

A mid-sized electronics OEM based in Pune manufactures high-precision electrical control panels used in industrial machinery. Each panel houses delicate components mounted on thin aluminum sheets that are powder coated for durability and aesthetics. To secure these panels, the production line used M4 bolts without washers — believing that the small bolts didn’t need load distribution hardware.

Problem

After the product launch, the quality team noticed that up to 20% of panels failed final inspection because of hairline cracks, chipped paint, and deformed mounting holes around the M4 bolts. When these panels were shipped, vibration during transport would worsen the cracks, leading to customer complaints, warranty claims, and returns.

A root cause analysis revealed that the direct contact of the bolt head with the painted aluminum surface created excessive localized stress. Even when torque specs were correct, the force concentrated on the tiny area under the bolt head was enough to damage the coating and weaken the structural integrity.

Solution

The company approached Nafees Metal Industries for a simple, cost-effective fix. After reviewing the panel specs, fastener type, and environmental conditions, our technical team recommended switching to M4 Mild Steel Plain Washers with a light zinc coating to provide mild corrosion resistance while maintaining a tight fit around the M4 bolts.

We produced a trial batch of precision M4 Mild Steel Plain Washers, tested for burr-free edges and exact tolerances so they would not interfere with the tight clearances inside the control panels.

Implementation

Within two weeks, the company integrated the washers into their assembly line. Operators placed a washer under every bolt head that secured circuit boards and metal covers. Installation was simple — no new tools or major process changes were required.

Results

The impact was immediate:

The rejection rate for cracked or chipped panels dropped from 20% to less than 2% within the first month.

Customers reported zero complaints about loose panels during transport.

The company reduced warranty claim costs by approximately 15% for that product line.

Overall assembly consistency improved since the washers provided repeatable clamping force distribution, even with minor variations in material thickness.

The small added cost of each M4 Mild Steel Plain Washer was more than offset by the savings in scrap, rework, and returns.

Customer Feedback

The production head noted:

“We never imagined that something as simple and inexpensive as a plain washer could make such a big difference. It’s a lesson in not cutting corners on the smallest parts.”

Takeaway

This case clearly shows how M4 Mild Steel Plain Washers protect painted or coated panels, prevent costly surface damage, and ensure long-term reliability — even for small fasteners in low-load applications. For any OEM where aesthetic quality and structural strength matter, the right washer is not optional — it’s essential.

Related Products

M3, M5, M6 Mild Steel Plain Washers

Spring Washers for vibration-heavy assemblies

Stainless Steel Flat Washers for high-corrosion environments

Final Words

Protect every bolt, every panel, and every investment with the trusted performance of M4 Mild Steel Plain Washers. Get consistent supply, tight tolerances, and competitive pricing from your reliable Best M4 MS Flat Washers for Industrial Use partner.

FAQs

What are M4 Mild Steel Plain Washers used for?

They distribute load, protect surfaces, and resist vibration loosening in small assemblies.

Are they reusable?

Yes, if not deformed or corroded.

Do you offer coated versions?

Yes — zinc and phosphate coatings available.

Are they suitable for outdoor use?

Yes, with appropriate coating.

What industries use them most?

Electronics, HVAC, furniture, appliances, and general hardware.

Do you provide test certificates?

Yes, MTCs available on request.

What’s your lead time?

7–14 days for bulk orders.

Do you offer samples?

Yes, free samples for evaluation.

How should I store them?

In dry, sealed containers to prevent rust.

When should I replace them?

If bent, cracked, or severely corroded.

Do you export?

Yes — domestic and international supply available.

Can you customize sizes?

Yes — custom diameters, thickness, or finishes.

Do you supply other sizes?

Yes — M3 to M16 and beyond.

Do you do bulk packaging?

Yes — custom bulk packs available.

Why choose Nafees Metal Industries?

Trusted quality, on-time supply, and the best M4 Mild Steel Plain Washers for your project.

Nafees Metal industries is recognized as a reliable manufacturer and bulk supplier of M4 Mild Steel Plain Washers. With our modern manufacturing facility at Reay Road, Mumbai, we maintain strict quality control and use the latest technology to deliver washers that meet the rigorous demands of various industries. As the Best M4 MS Flat Washers Manufacturer, we guarantee precision, competitive pricing, and on-time delivery.

If you’re planning to Buy M4 Mild Steel Plain Washers in Bulk, you can rely on us for high-quality products and excellent customer support. Partner with us to secure your fasteners with confidence and keep your operations running smoothly.

M4 Mild Steel Plain Washers

19 people are viewing this product right now

₹0.11 Original price was: ₹0.11.₹0.09Current price is: ₹0.09. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M4

Inner Diameter (ID): 4.3 mm

Outer Diameter (OD): 9 mm

Thickness (t): 0.8 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M4 Mild Steel Plain Washers – Best M4 MS Flat Washers for Industrial Use

Introduction

Small fasteners can have a huge impact. In industrial, electrical, or general-purpose assemblies, the humble washer is what makes a bolt truly reliable. M4 Mild Steel Plain Washers are one of the most widely used sizes for light-duty, high-precision fastening jobs — especially when you’re working with thin sheet metal, panels, or soft materials that need protection.

At Nafees Metal Industries, we understand that a washer is never just a washer. Each piece must maintain tight tolerances, deliver consistent performance, and work seamlessly in your production line. That’s why manufacturers, OEMs, and contractors choose us for the Best M4 MS Flat Washers for Industrial Use, all made from premium mild steel and engineered for repeatable results.

In this guide, you’ll discover exactly why M4 Mild Steel Plain Washers deserve a place in your next project: what they are, how they’re made, the benefits they bring, real-world case study results, and practical tips for installation and maintenance. If you plan to Buy M4 Mild Steel Washers in Bulk, this will help you make the right choice with total confidence.

Role of M4 Mild Steel Plain Washers in Industrial Applications

When you tighten a bolt, the force clamps the parts together. But if that force is too concentrated, it can deform, dent, or even tear through the material. That’s where washers come in — they act as a buffer, spreading the load, preventing surface damage, and absorbing vibrations.

For small fasteners like M4 bolts, the risk of damaging thin or soft materials is even higher. Without washers, you can easily crack a panel, strip a hole, or loosen the bolt during vibration. M4 Mild Steel Plain Washers solve this by:

Distributing force evenly to prevent stress points

Protecting surface finishes like paint or powder coating

Adding friction to resist vibration-induced loosening

Extending the life of the entire assembly

These are reasons why Mild Steel Flat Washers remain the go-to solution for thousands of everyday applications.

What Are M4 Mild Steel Plain Washers

A M4 Mild Steel Plain Washer is a small, flat, circular disc with a precisely punched center hole designed to fit M4 fasteners snugly. Its simple design hides its importance — by sitting between the bolt head (or nut) and the surface, it prevents local deformation, protects coatings, and improves the joint’s durability.

How They Work

When you tighten an M4 bolt, the washer spreads the clamping force across a larger area. This is essential when fastening thin metal sheets, plastic parts, or painted surfaces that can easily scratch or crack. In light machinery or electronics, these washers also help the bolt maintain its hold when exposed to vibration, temperature fluctuations, or repeated use.

The result: safer, cleaner, longer-lasting assemblies — all with one small but mighty part.

Material Details: Mild Steel for Reliable Performance

Why mild steel? For general-purpose plain washers, mild steel remains the smart choice because it combines strength, flexibility, and cost-effectiveness.

Mild steel, or low carbon steel, contains a low percentage of carbon, making it ductile enough to bend slightly under load without cracking. This flexibility is perfect for washers, as they need to hold shape under compression yet adapt to minor surface imperfections.

Advantages of Mild Steel Flat Washers include:

Strength: Handles moderate clamping loads without warping.

Ductility: Absorbs shock and vibration rather than transferring it all to the bolt or base material.

Formability: Can be punched and stamped to tight tolerances.

Cost-Effective: Cheaper than stainless steel for non-corrosive or indoor conditions.

Adaptability: Can be zinc or phosphate coated for mild corrosion protection.

For small bolts like M4s, mild steel is strong enough to protect your assembly without adding unnecessary cost — exactly why these washers remain a staple for both OEMs and end-users alike.

How M4 Mild Steel Plain Washers Are Manufactured

Every batch of M4 Mild Steel Plain Washers we make undergoes rigorous production and inspection to ensure dimensional consistency and strength.

Key Steps:

Raw Material Selection: Certified mild steel sheets are sourced to meet IS/ISO standards.

Precision Punching: CNC-controlled presses punch each washer to exact inner and outer diameter specs.

Deburring: Automated deburring removes sharp edges, making them safe and assembly-line ready.

Optional Coating: Washers can be supplied plain oiled, zinc-plated, or phosphate-coated.

Inspection: Each batch is checked for dimensional tolerances, coating thickness, and burr-free finish.

Typical Specifications for M4 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | ~4.3 mm (fits M4 bolts securely) |

| Outer Diameter | 8–10 mm |

| Thickness | Per IS/ISO/DIN standards |

| Finish | Plain, zinc-plated, or phosphate-coated |

| Material | Mild Steel |

| Shape | Flat disc |

Key Features of M4 Mild Steel Plain Washers

Accurate Load Distribution

One of the main roles of any plain washer is to spread the load of a bolt or screw evenly over the surface. For small-diameter bolts like M4, this becomes even more important because the clamping force is concentrated on a tiny area. Without a washer, torquing an M4 bolt directly onto soft materials like aluminum or thin sheet metal can punch through the material or cause local deformation. With M4 Mild Steel Plain Washers, the pressure spreads over a wider surface area, ensuring the base material withstands the bolt’s force without distortion — especially vital for layered or coated surfaces.

Surface Protection

Painted or coated surfaces are common in panels, enclosures, and furniture. Tightening a bolt without a washer can scratch, chip, or strip that coating, exposing the metal underneath to corrosion. M4 Mild Steel Plain Washers act as a buffer, absorbing friction so your surface finish stays intact. The result is a cleaner, more professional look that keeps your products looking new longer.

Resistance to Vibration

Machines vibrate. Electronics heat up and cool down. Furniture and panels face daily movement. These tiny shifts can loosen bolts over time. The flat washer adds a layer of friction that helps resist rotational loosening. This means fewer inspections, fewer maintenance hours, and more peace of mind for critical assemblies.

Durability and Reusability

Our washers hold up under repeated tightening and removal. This matters for fixtures that require periodic disassembly for cleaning, upgrades, or inspection. Each washer keeps its shape and integrity, saving you money on replacements.

Compact, Lightweight Design

The compact size of M4 Mild Steel Plain Washers makes them perfect for tight spaces in electronics, control boxes, or decorative panels where a large washer would be impractical.

Versatility Across Industries

From consumer goods and appliances to DIY and craft projects, M4 is a universal size. You can stock up and use them across multiple projects with confidence.

Applications of M4 Mild Steel Plain Washers

When it comes to versatility, M4 Mild Steel Plain Washers truly punch above their weight. Their small size, durable mild steel construction, and ability to handle light to moderate loads make them an everyday essential across multiple industries. Here’s how different sectors use these washers to solve practical fastening challenges and ensure long-lasting reliability.

Electronics & Electrical Panels

In the electronics industry, M4 Mild Steel Plain Washers are often used to secure PCBs, switchgear, and terminal boxes. Their main job is to distribute the small but precise clamping force of M4 fasteners across fragile materials — like thin aluminum panels or plastic casings. This prevents hairline cracks around screw holes, protects protective coatings, and ensures that vibration from moving parts or thermal expansion doesn’t loosen critical connections.

Example: In a control cabinet, dozens of M4 screws might hold circuit boards, cable brackets, or access covers in place. A missing washer here could mean a cracked board, a short circuit, or extra warranty costs down the road. A simple washer solves it all.

HVAC Systems

HVAC panels, ductwork, and mounting brackets frequently rely on M4-sized fasteners because these systems have many small panels that need secure yet lightweight joining. M4 Mild Steel Plain Washers help protect the sheet metal flanges from deformation during installation and maintenance.

They’re especially useful in HVAC equipment that’s opened repeatedly for servicing — a good washer prevents the screw from digging into the metal over time, ensuring a tight seal and vibration resistance, even in high-humidity or mild outdoor conditions when paired with a protective coating.

Appliance Manufacturing

Manufacturers of small household appliances — fans, light fixtures, kitchen gadgets — rely on M4 Mild Steel Plain Washers to keep parts aligned and surface finishes intact. Painted or powder-coated metal parts are easily scratched by direct screw heads. Washers act as a buffer, preventing damage and maintaining the visual appeal that customers expect.

In mass production, the repeatable quality offered by burr-free, precision mild steel washers also helps reduce assembly line jams and costly rework.

Furniture & Fixtures

Metal furniture frames, decorative brackets, shelving systems, and modular cabinets often use M4 bolts and washers for discreet, tight-fitting connections. M4 Mild Steel Plain Washers protect powder-coated surfaces from scratches, ensure even load spread, and keep connections tight over time.

They’re equally popular in DIY furniture kits, giving hobbyists and professionals a neat, professional finish while making disassembly easier if needed.

Automotive & Transportation

Although larger fasteners are more common in heavy automotive work, certain small brackets, interior fittings, and electrical harness clips still depend on M4 screws. In these cases, M4 Mild Steel Plain Washers help prevent rattling or paint damage to interior panels, dashboards, or custom fittings. This small component plays a big role in maintaining a quiet, rattle-free ride.

DIY, Repairs & Maintenance

For general-purpose repairs, home improvement, and craft projects, M4 Mild Steel Plain Washers are a must-have in every hardware box. From securing light fixtures to mounting photo frames or repairing lightweight garden tools, these washers protect surfaces and maintain tightness with minimal fuss.

Their mild steel construction makes them cost-effective for indoor use, and with the right coating, they’re good for mild outdoor exposure too.

Custom Assemblies & OEM Products

OEMs in sectors like consumer electronics, point-of-sale equipment, and lighting often specify M4 Mild Steel Plain Washers for specialized enclosures that need reliable joints but can’t afford to compromise on aesthetics. When your product demands a clean, scratch-free finish with repeatable performance, these washers deliver — batch after batch.

Why Buy M4 Mild Steel Washers in Bulk

When you Buy M4 Mild Steel Washers in Bulk, you unlock big advantages:

Volume discounts that reduce your project cost.

Inventory consistency so you don’t run out mid-project.

Quality consistency with washers from the same production batch.

Custom packing to match your assembly line requirements.

Faster turnaround with a dedicated bulk supply agreement.

It’s smart business, especially when your projects use thousands of small fasteners every month.

Why Choose the Best M4 MS Flat Washers for Industrial Use

Nafees Metal Industries stands apart as the Best M4 MS Flat Washers for Industrial Use because we combine decades of manufacturing experience with responsive service. Our washers comply with IS/ISO standards, come with mill test certificates, and can be tailored for special coatings or dimensions. You get a trusted partner that guarantees quality at competitive prices — every time.

Installation Tips for M4 Mild Steel Plain Washers

Always use washers on both bolt head and nut side if both contact sensitive surfaces.

Clean surfaces to remove debris that could scratch or damage your panels.

Tighten bolts to the correct torque to avoid over-compression that might deform the washer.

Use coated washers in humid or mildly corrosive environments.

Maintenance for M4 Mild Steel Plain Washers

Inspect regularly for cracks, warping, or corrosion.

Replace washers that show signs of significant wear.

Store extra washers in dry, sealed bins.

Keep plain washers oiled if storing for extended periods.

Case Study: How M4 MS Washers Resolved Panel Damage for an Electronics Manufacturer

Background

A mid-sized electronics OEM based in Pune manufactures high-precision electrical control panels used in industrial machinery. Each panel houses delicate components mounted on thin aluminum sheets that are powder coated for durability and aesthetics. To secure these panels, the production line used M4 bolts without washers — believing that the small bolts didn’t need load distribution hardware.

Problem

After the product launch, the quality team noticed that up to 20% of panels failed final inspection because of hairline cracks, chipped paint, and deformed mounting holes around the M4 bolts. When these panels were shipped, vibration during transport would worsen the cracks, leading to customer complaints, warranty claims, and returns.

A root cause analysis revealed that the direct contact of the bolt head with the painted aluminum surface created excessive localized stress. Even when torque specs were correct, the force concentrated on the tiny area under the bolt head was enough to damage the coating and weaken the structural integrity.

Solution

The company approached Nafees Metal Industries for a simple, cost-effective fix. After reviewing the panel specs, fastener type, and environmental conditions, our technical team recommended switching to M4 Mild Steel Plain Washers with a light zinc coating to provide mild corrosion resistance while maintaining a tight fit around the M4 bolts.

We produced a trial batch of precision M4 Mild Steel Plain Washers, tested for burr-free edges and exact tolerances so they would not interfere with the tight clearances inside the control panels.

Implementation

Within two weeks, the company integrated the washers into their assembly line. Operators placed a washer under every bolt head that secured circuit boards and metal covers. Installation was simple — no new tools or major process changes were required.

Results

The impact was immediate:

The rejection rate for cracked or chipped panels dropped from 20% to less than 2% within the first month.

Customers reported zero complaints about loose panels during transport.

The company reduced warranty claim costs by approximately 15% for that product line.

Overall assembly consistency improved since the washers provided repeatable clamping force distribution, even with minor variations in material thickness.

The small added cost of each M4 Mild Steel Plain Washer was more than offset by the savings in scrap, rework, and returns.

Customer Feedback

The production head noted:

“We never imagined that something as simple and inexpensive as a plain washer could make such a big difference. It’s a lesson in not cutting corners on the smallest parts.”

Takeaway

This case clearly shows how M4 Mild Steel Plain Washers protect painted or coated panels, prevent costly surface damage, and ensure long-term reliability — even for small fasteners in low-load applications. For any OEM where aesthetic quality and structural strength matter, the right washer is not optional — it’s essential.

Related Products

M3, M5, M6 Mild Steel Plain Washers

Spring Washers for vibration-heavy assemblies

Stainless Steel Flat Washers for high-corrosion environments

Final Words

Protect every bolt, every panel, and every investment with the trusted performance of M4 Mild Steel Plain Washers. Get consistent supply, tight tolerances, and competitive pricing from your reliable Best M4 MS Flat Washers for Industrial Use partner.

FAQs

What are M4 Mild Steel Plain Washers used for?

They distribute load, protect surfaces, and resist vibration loosening in small assemblies.

Are they reusable?

Yes, if not deformed or corroded.

Do you offer coated versions?

Yes — zinc and phosphate coatings available.

Are they suitable for outdoor use?

Yes, with appropriate coating.

What industries use them most?

Electronics, HVAC, furniture, appliances, and general hardware.

Do you provide test certificates?

Yes, MTCs available on request.

What’s your lead time?

7–14 days for bulk orders.

Do you offer samples?

Yes, free samples for evaluation.

How should I store them?

In dry, sealed containers to prevent rust.

When should I replace them?

If bent, cracked, or severely corroded.

Do you export?

Yes — domestic and international supply available.

Can you customize sizes?

Yes — custom diameters, thickness, or finishes.

Do you supply other sizes?

Yes — M3 to M16 and beyond.

Do you do bulk packaging?

Yes — custom bulk packs available.

Why choose Nafees Metal Industries?

Trusted quality, on-time supply, and the best M4 Mild Steel Plain Washers for your project.

Nafees Metal industries is recognized as a reliable manufacturer and bulk supplier of M4 Mild Steel Plain Washers. With our modern manufacturing facility at Reay Road, Mumbai, we maintain strict quality control and use the latest technology to deliver washers that meet the rigorous demands of various industries. As the Best M4 MS Flat Washers Manufacturer, we guarantee precision, competitive pricing, and on-time delivery.

If you’re planning to Buy M4 Mild Steel Plain Washers in Bulk, you can rely on us for high-quality products and excellent customer support. Partner with us to secure your fasteners with confidence and keep your operations running smoothly.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch