No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

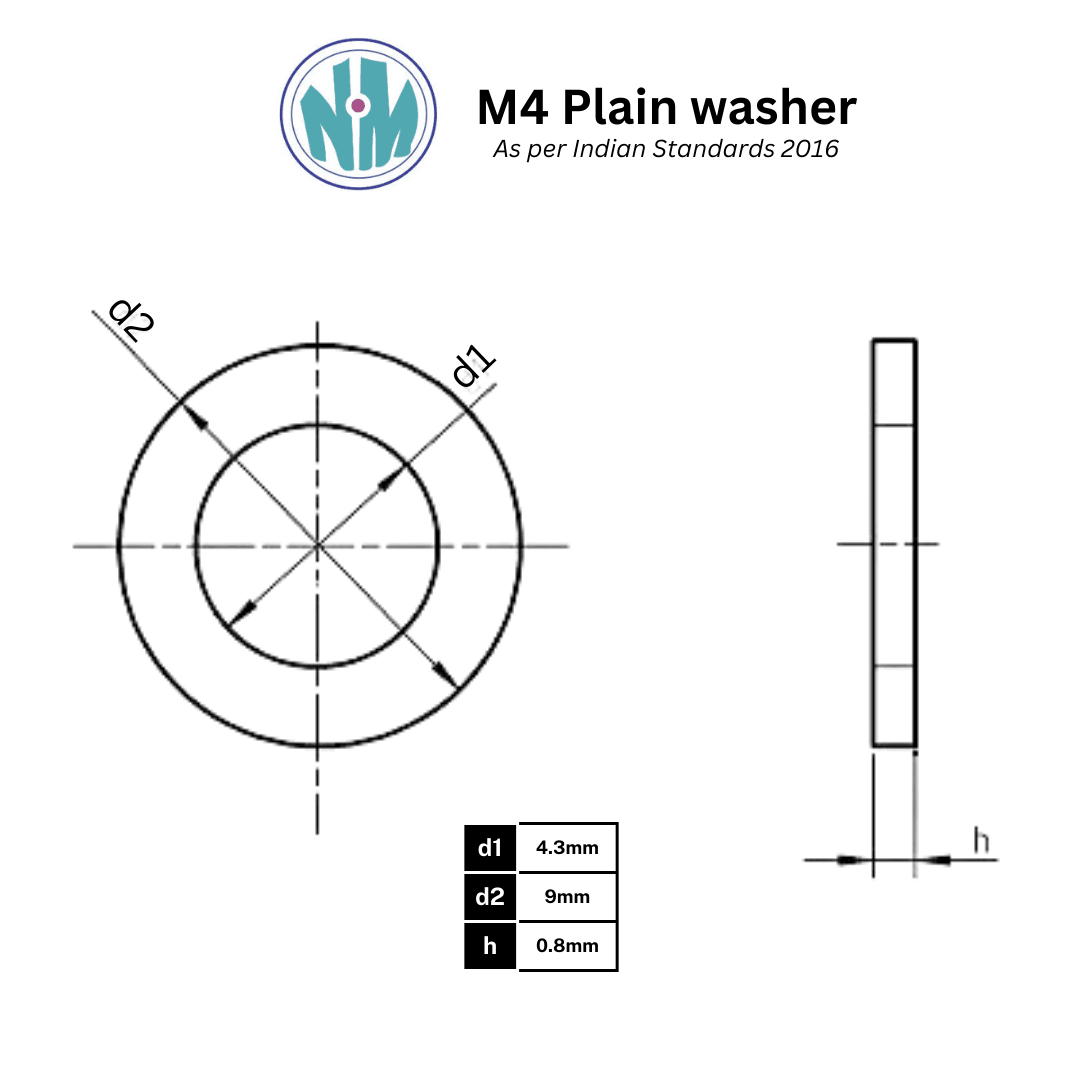

*Images shown for graphic representation. Not to scale.

M4 Brass Plain Washer – Durable Flat Washers for Precision Applications

At Nafees Metal Industries, we specialize in manufacturing premium quality M4 Brass Plain Washers for precision fastening applications across multiple industries. As one of the most trusted Brass Plain Washers Manufacturer in India, we ensure each washer is engineered with tight tolerances, durable finishes, and high-performance materials for long-lasting functionality.

Our M4 Brass Plain Washer is meticulously designed to accommodate M4-sized bolts or screws (4 mm diameter), making it a perfect fit for delicate electronics, instruments, and mechanical assemblies. Manufactured in our state-of-the-art facility in Mumbai, these washers offer outstanding resistance to corrosion, excellent electrical conductivity, and a polished appearance that enhances both performance and aesthetics.

Whether you are an OEM, distributor, or contractor, our M4 Brass Plain Washer provides you with consistent quality, reliability, and value for high-volume use cases. Trusted by professionals across sectors like electricals, automotive, aerospace, and manufacturing, these washers are tailored to support precise fastening while preventing wear and substrate damage.

Our commitment to the Make in India initiative ensures every M4 Brass Plain Washer is proudly crafted with precision, performance, and purpose.

What is an M4 Brass Plain Washer?

An M4 Brass Plain Washer is a flat, circular disc with a centrally located hole designed to fit M4 bolts or screws (4 mm diameter). Its primary role is to evenly distribute the load of the fastener during tightening, which protects the underlying surface, increases the longevity of the joint, and provides a smooth bearing surface.

Crafted from premium-grade brass, the M4 Brass Plain Washer combines strength, electrical conductivity, and corrosion resistance—making it ideal for electrical, mechanical, and precision-based applications. Brass, as a non-ferrous alloy, also minimizes the risk of sparking and offers superior resistance to moisture and chemical exposure.

Each M4 Brass Plain Washer from Nafees Metal Industries is manufactured with high dimensional accuracy and uniform thickness to ensure optimal performance even under dynamic load conditions. Whether you are working with PCB assemblies, light machinery, or household appliances, these washers prevent fastener pull-through and maintain joint integrity over time.

In addition to their mechanical benefits, M4 Brass Plain Washers also enhance aesthetics—especially in applications where visible hardware must maintain a clean and refined appearance.

Typical attributes include:

Inner Diameter (ID): ~4.3 mm to fit M4 bolts

Outer Diameter (OD): As per DIN 125 / ISO 7089 or custom

Thickness: Generally ranges between 0.5 mm to 1.0 mm (customizable)

Material: Pure or high-grade alloyed brass

Finish: Natural brass, polished, or coated (as per request)

These washers are an integral part of Brass Flat Washers categories used worldwide across industries where performance and material integrity are paramount.

Why Brass for M4 Washers?

Brass is a highly preferred material for manufacturing M4 washers due to its unique combination of mechanical strength, corrosion resistance, and aesthetic appeal. Choosing an M4 Brass Plain Washer means opting for performance, reliability, and longevity in demanding environments.

Here’s why brass is an ideal material for M4 washers:

1. Excellent Corrosion Resistance

Brass naturally resists corrosion from moisture, air, and mild chemicals. This makes the M4 Brass Plain Washer suitable for both indoor and semi-exposed environments where durability is essential.

2. Non-Magnetic and Spark-Resistant

Unlike ferrous metals, brass is non-magnetic and spark-proof, making it a safe choice for sensitive electronic and electrical assemblies. This ensures the M4 Brass Plain Washer doesn’t interfere with circuits or pose a fire hazard.

3. Superior Electrical Conductivity

One of the major reasons industries prefer M4 Brass Plain Washers in electrical applications is brass’s high electrical conductivity. It helps maintain efficient current flow in connections, especially in PCB and switchgear assemblies.

4. Smooth Finish & Aesthetic Appeal

Brass has a distinct golden finish, offering a visually appealing component for exposed mechanical joints. The polished look of an M4 Brass Plain Washer complements high-end applications where appearance matters.

5. Long-Term Dimensional Stability

Brass maintains its shape and structural integrity even under thermal fluctuations or prolonged stress. This gives M4 Brass Plain Washers an edge in applications requiring tight, reliable fastening over time.

6. Environmentally Friendly & Recyclable

Brass is a recyclable material, supporting sustainable manufacturing practices. At Nafees Metal Industries, we prioritize eco-conscious production while maintaining top-tier quality for every M4 Brass Plain Washer.

7. Customizable Coatings

Although brass is naturally corrosion-resistant, additional coatings such as nickel or chrome can be applied for enhanced protection and appearance based on client requirements.

By choosing M4 Brass Plain Washers, you benefit from a material that meets industrial-grade standards while ensuring reliability, conductivity, and corrosion resistance.

How Are M4 Brass Plain Washers Manufactured?

At Nafees Metal Industries, each brass washer we produce is a result of precision engineering and strict quality control. The manufacturing process of our M4-sized brass plain washers is designed to meet both national and international standards such as IS 2016, DIN 125, and ISO 7089.

Here’s a detailed overview of the production steps:

1. Material Selection and Testing

We begin by sourcing high-grade brass sheets that meet the required mechanical and chemical properties. These sheets are inspected for consistency, hardness, and surface quality before moving into production.

2. Precision Punching

Using high-precision power press machines, brass sheets are cold-stamped to create the washer shape. The inner diameter is specifically punched to accommodate M4 bolts, while the outer diameter follows standard or client-specified dimensions.

3. Deburring and Surface Finishing

Each washer undergoes deburring to remove sharp edges, ensuring safe handling and smooth assembly. The surface is then polished or finished depending on the application—options include natural brass, bright polish, or nickel-plated surfaces.

4. Thickness Control

We maintain uniform thickness across all washers, generally between 0.5 mm to 1.0 mm, based on application need. This ensures even load distribution during fastening.

5. Quality Checks

Every batch is subjected to dimensional inspections, hardness tests, and visual checks. We verify the inner and outer diameters, concentricity, and overall finish to deliver consistent and reliable washers.

6. Packaging & Dispatch

Once passed through quality checks, the washers are packed in polybags, cartons, or customized packaging as per client requirements. We also provide bulk packing solutions for OEMs and large-scale buyers.

Our advanced manufacturing unit in Mumbai allows us to fulfill small and large orders with short lead times. As a Brass Plain Washers Manufacturer, we are equipped to deliver both standard and custom washers for any industrial requirement.

Key Features of M4 Brass Plain Washers

Our M4 brass washers are engineered for performance, precision, and longevity. Whether used in electronic devices, electrical panels, or mechanical subassemblies, these washers offer a wide range of functional and material benefits that make them indispensable across industries.

Below are the standout features that set our products apart:

1. Precision Fit

Each washer is dimensionally accurate to fit standard M4 bolts and screws. The inner diameter is finely punched for a snug, stable hold that maintains alignment during tightening.

2. Uniform Thickness

Maintaining uniform thickness is critical to ensure even pressure distribution. Our M4 washers are available in standard thicknesses from 0.5 mm to 1.0 mm and can be customized based on application-specific needs.

3. Corrosion Resistance

Being made from brass, these washers offer natural resistance to rust and oxidation, especially in indoor or semi-exposed environments. This extends the lifespan of the fastener system.

4. Electrical Conductivity

These washers are ideal for electrical applications due to brass’s high conductivity. They maintain reliable current flow while securing joints firmly in place.

5. Smooth Edges and Polished Finish

To ensure safe handling and avoid abrasion to surrounding materials, each washer is finished with burr-free, polished edges. This makes them easier to install and handle during assembly.

6. Mechanical Strength

Despite their small size, M4 washers offer excellent mechanical strength and rigidity, making them suitable for both static and light dynamic loads.

7. Aesthetic Appeal

Brass has a natural gold-like sheen, giving the washer a premium look—especially suitable for applications where the fastener remains visible.

8. Custom Coating Options

We provide zinc, nickel, and chrome plating options to further enhance durability, appearance, and corrosion resistance. Coatings can be customized based on end-use or environmental factors.

9. Non-Magnetic Material

Brass is non-magnetic, which makes these washers ideal for sensitive instrumentation and electronic applications where magnetic interference is unacceptable.

10. Bulk Availability

These washers are available in large volumes, ready to dispatch for OEMs, resellers, and assembly units. We support urgent deliveries with export-ready documentation.

Each brass flat washer we produce carries our commitment to quality, precision, and customer satisfaction. That’s what makes Nafees Metal Industries a preferred choice for industries across India and beyond.

Technical Specifications

Our M4-sized brass washers are crafted in line with global manufacturing and quality standards. The technical profile outlined below ensures that customers can match their fastening needs with precision and clarity.

| Property | Specification |

|---|---|

| Product Name | M4 Brass Plain Washer |

| Material | High-Grade Brass (CuZn Alloy) |

| Inner Diameter (ID) | Approx. 4.3 mm (to fit M4 bolts or screws) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 or customized |

| Thickness | 0.5 mm to 1.0 mm (custom thickness available) |

| Hardness | 80–120 HV (depending on brass grade used) |

| Surface Finish | Natural Brass / Polished / Nickel-Plated / Custom Coating |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Corrosion Resistance | Excellent for indoor and mild outdoor use |

| Electrical Conductivity | High (Ideal for electrical applications) |

| Tensile Strength | 300–550 MPa (varies with brass alloy and treatment) |

| Magnetic Properties | Non-Magnetic |

| Packaging | Bulk in polybags, corrugated boxes, or custom packed |

| Application Category | Electrical, Mechanical, Electronic, Instrumentation, Fastening |

We ensure every technical attribute aligns with real-world application requirements. Whether you’re in electronics assembly, HVAC, instrumentation, or consumer goods manufacturing, these washers offer reliable performance and compatibility with global fastening standards.

Applications of M4 Brass Plain Washers

M4 Brass Plain Washers are designed for precision, durability, and reliability—making them highly versatile across a wide range of industries and use cases. Their corrosion resistance, conductivity, and dimensional accuracy make them the washer of choice in compact fastening systems where strength and conductivity are equally important.

Below are the major industries and applications where M4 brass washers are widely used:

1. Electrical Panels & Components

Used extensively in switchgear, MCBs, terminals, and electrical housings where high conductivity and corrosion resistance are required. The washers help maintain strong electrical joints and avoid surface degradation.

2. Printed Circuit Boards (PCBs)

Protect delicate circuit boards from fastener stress by distributing load evenly. These washers are ideal for mounting PCBs in electronic devices, ensuring no trace damage or cracking occurs.

3. Consumer Electronics

Found in compact gadgets like mobile chargers, adapters, speakers, and electronic displays where secure yet lightweight and conductive fastening is necessary.

4. Automotive Electronics

Applied in ECUs, sensor assemblies, and vehicle infotainment systems for vibration-free, secure mounting with minimal risk of oxidation.

5. Aerospace and Avionics

Valued for non-magnetic and corrosion-resistant properties in avionics hardware and cabin electronic assemblies, where component reliability is non-negotiable.

6. Telecommunication Equipment

Essential in grounding and fastening applications in routers, towers, and data transmission devices due to brass’s stable conductivity.

7. Instrumentation and Meters

Used in assembling precision measuring instruments like voltmeters, pressure gauges, and timers that require stable joints and material compatibility.

8. Home Appliances

Ideal for light assemblies in kitchen appliances, fans, and electronic switches, where space and reliability are critical.

9. Renewable Energy Systems

Employed in solar inverter panels and control boxes where conductivity, rust resistance, and durability support long-term performance.

10. Fastener Kits for Maintenance and Repairs

Frequently included in MRO toolkits, as their M4 size fits most standard small hardware used across industries.

Because of their small size and high utility, M4 Brass Plain Washers play a critical role in securing sensitive assemblies, reducing wear, and improving long-term operational efficiency.

Advantages of Using M4 Brass Washers

M4 Brass Plain Washers offer a range of functional, mechanical, and environmental benefits that make them superior to many other fastening alternatives in small-scale or precision-based applications. At Nafees Metal Industries, we ensure these advantages are enhanced through our expert manufacturing, quality assurance, and customer-first approach.

Here’s why M4 brass washers are the preferred choice across industries:

1. Superior Load Distribution

These washers effectively spread the load of the fastener, preventing damage to delicate substrates such as PCB boards, plastic casings, and soft metal components.

2. Corrosion Resistance

Brass provides excellent resistance to rust and tarnish, ensuring longevity even in slightly humid or corrosive environments—especially important for indoor electrical and electronic applications.

3. Electrical Conductivity

One of the top reasons to use M4 brass washers is their excellent conductivity, which ensures uninterrupted current flow and strong, secure electrical contacts in assemblies.

4. Non-Sparking Material

Brass does not produce sparks when struck, making these washers safe to use in environments where flammable gases or sensitive circuits are present.

5. Aesthetic Finish

Their naturally polished gold-like finish provides a clean, premium look—ideal for visible fastener applications in consumer electronics or decorative hardware.

6. Non-Magnetic

M4 brass washers are completely non-magnetic, ensuring they do not interfere with sensitive electronic devices or instruments that require zero magnetic interference.

7. High Dimensional Stability

Even under dynamic load conditions, the material retains its shape and strength, making it reliable for light mechanical and electronic assemblies.

8. Easy to Install and Handle

With burr-free edges and a smooth finish, these washers offer safe and quick installation without causing damage to nearby components or assemblies.

9. Custom Finish and Size Options

Available in various surface coatings such as nickel, chrome, or plain brass, along with thickness and diameter customization based on specific requirements.

10. Cost-Effective for Volume Use

Despite their premium properties, M4 brass washers offer great value in bulk procurement—especially for OEMs and industrial buyers looking to optimize long-term costs without compromising quality.

When sourced from a trusted Brass Plain Washers Manufacturer like Nafees Metal Industries, these advantages translate into smoother assembly operations, enhanced product life, and higher end-user satisfaction.

Buy M4 Brass Plain Washers in Bulk – Trusted Manufacturer in India

If you’re looking for high-quality M4 brass washers with bulk availability, reliable delivery, and customization options, Nafees Metal Industries is your ideal sourcing partner. Recognized as a top-tier Brass Plain Washers Manufacturer in India, we specialize in supplying industrial-grade washers that meet both functional and aesthetic standards.

Our Mumbai-based manufacturing unit is fully equipped with advanced machinery, strict quality controls, and skilled manpower, enabling us to produce and dispatch large quantities of M4 Brass Plain Washers across India and to global markets. Whether you need standard dimensions or require customized thickness, coatings, or packaging, we offer full flexibility and support.

Why Buy from Nafees Metal Industries?

Bulk Availability

We maintain large stocks of M4 washers, ready for immediate shipment to OEMs, distributors, and end users.Custom Coating & Packaging

Get your washers zinc-coated, nickel-plated, or chrome-finished with packaging tailored to your workflow—whether poly bags, carton boxes, or export pallets.Competitive Pricing

Our in-house manufacturing allows us to offer highly competitive rates without compromising on precision or finish.Quick Turnaround Times

We specialize in fast production and dispatch, ensuring that even urgent orders are fulfilled on time with export-ready documentation.Expert Technical Support

Our team of engineers and product specialists can help you choose the right size, finish, and specifications for your application.PAN India and Global Supply

We serve customers across India and export to the Middle East, Southeast Asia, and Europe with complete documentation and packaging compliance.

When you choose Nafees Metal Industries, you’re not just buying a product—you’re investing in consistency, support, and a long-term relationship with one of the most reliable names in Industrial Brass Washers.

Looking to Buy Brass Washers Online? We invite you to browse our full product range on

https://nafeesmetalindustries.com/

or contact our sales team for a quick quote.

Case Study: Boosting Reliability in PCB Assembly with M4 Brass Washers

Client: A leading electronics OEM specializing in smart home devices

Location: Bengaluru, India

Challenge: Circuit boards were facing microcracks and premature failure due to uneven fastening pressure during assembly. The client was previously using generic steel washers that caused surface indentation and poor conductivity.

Problem Overview:

Microcracks on PCB surfaces after repeated fastening.

Inconsistent grounding caused by oxidation of steel washers.

Assembly time increased due to improper washer alignment and handling.

Post-sale complaints and product returns due to unstable electronic modules.

Solution Implemented:

The client partnered with Nafees Metal Industries to switch to high-precision M4 Brass Plain Washers with a polished finish and custom thickness (0.8 mm). Our team also recommended using nickel-plated brass washers to further enhance corrosion resistance and conductivity.

Results:

Reduced Assembly Time by 22%: Easy-to-handle brass washers with burr-free edges reduced manual effort during fastening.

100% Elimination of PCB Surface Damage: The washers provided even load distribution without causing stress points or cracks.

Improved Electrical Performance: Stable grounding and reduced resistance due to brass’s high conductivity.

Decreased Product Returns: Complaint rate dropped by 47% within the first two months of implementation.

Repeat Order Value Increased by 60%: The OEM doubled their monthly procurement volume and integrated our washers across multiple product lines.

Key Takeaway:

Switching to M4 Brass Plain Washers manufactured by Nafees Metal Industries not only solved the client’s technical challenges but also improved their overall product reliability and customer satisfaction.

This case study demonstrates how a seemingly small component like a washer can play a pivotal role in product performance when manufactured with precision and expertise.

Why Choose Nafees Metal Industries for Brass Washers?

At Nafees Metal Industries, we are more than just a supplier — we are your manufacturing partner for precision-engineered brass washers tailored to meet the highest industrial standards. With decades of industry expertise, state-of-the-art infrastructure, and a customer-first approach, we have established ourselves as a leading Brass Plain Washers Manufacturer in India.

Here’s what makes us the preferred source for buyers across the country and overseas:

1. Specialized Expertise in Brass Washer Manufacturing

Our core focus lies in producing washers — from plain to spring and disc types — with specialization in various sizes like M4 brass washers. Every washer is produced with attention to detail, ensuring consistent quality and performance.

2. In-House Production with Advanced Machinery

From raw material selection to final packaging, every process is handled in-house. Our facility in Mumbai is equipped with modern power presses, deburring machines, and quality inspection tools to ensure every washer meets the required tolerances.

3. Customized Solutions

Whether you need specific thicknesses, finishes, coatings, or packaging formats — we offer full customization based on your application or brand guidelines. Be it a single prototype or bulk volume, we adapt to your needs.

4. Certified Quality Assurance

All washers undergo multi-level quality checks for parameters like:

Dimensional tolerance (ID/OD)

Surface smoothness

Coating adhesion

Hardness and mechanical stability

We comply with IS 2016, DIN 125, and ISO 7089 standards.

5. Bulk Supply with Timely Delivery

We maintain ready stock of standard sizes such as M2, M3, M4, M5, M6, and more. Our streamlined supply chain allows us to fulfill high-volume orders on time, anywhere in India or for export.

6. Transparent and Competitive Pricing

We offer industry-best pricing without compromising on product integrity. Our goal is to provide lasting value to OEMs, wholesalers, and industrial buyers.

7. Trusted by Leading Brands

Our washers are used by leading names in electronics, automotive, power systems, consumer appliances, and more. Our growing repeat customer base is a testament to the quality we deliver.

8. Support for the ‘Make in India’ Vision

Every M4 Brass Plain Washer is manufactured with pride in India using locally sourced materials, contributing to self-reliant industrial growth and economic development.

When you partner with us, you’re choosing unmatched consistency, customizability, and quality—delivered by one of the most reliable names in the Industrial Brass Washers segment.

Frequently Asked Questions (FAQs)

1. What is an M4 Brass Plain Washer?

An M4 Brass Plain Washer is a flat circular disc with a central hole designed to fit M4 bolts or screws (4 mm diameter). It distributes load evenly, reduces surface damage, and improves fastening performance in electrical and mechanical assemblies.

2. Where are M4 brass washers commonly used?

They are used in electronics, PCB mounting, electrical panels, instrumentation, home appliances, automotive electronics, and precision devices requiring compact and conductive fastening solutions.

3. Why should I choose brass instead of steel for M4 washers?

Brass offers superior corrosion resistance, excellent electrical conductivity, is non-magnetic, and is aesthetically appealing. It’s ideal for electronic and decorative uses, unlike steel which may corrode or interfere magnetically.

4. Are M4 Brass Plain Washers suitable for outdoor use?

They are suitable for mildly exposed environments, especially when nickel or chrome-plated. For harsh or marine environments, additional coating may be required for extended performance.

5. Can I customize the dimensions or coating of M4 brass washers?

Yes. At Nafees Metal Industries, we offer customized sizes, thicknesses, inner/outer diameters, and surface coatings (zinc, nickel, chrome) as per your project requirements.

6. What is the standard thickness of an M4 brass washer?

Standard thickness ranges between 0.5 mm and 1.0 mm. However, we can manufacture washers with custom thicknesses depending on the application.

7. Are these washers electrically conductive?

Yes, brass is a highly conductive metal, making M4 brass washers ideal for electrical applications such as grounding, PCB assembly, and switchgear fastening.

8. Do you offer M4 brass washers in bulk quantities?

Absolutely. We specialize in bulk manufacturing and supply for OEMs, wholesalers, and industrial buyers across India and for export.

9. What packaging options are available for bulk orders?

We offer poly bags, corrugated cartons, labeled boxes, or custom packaging as per client specifications. Export packaging with labeling and documentation is also available.

10. Are your brass washers manufactured in India?

Yes, all our brass washers are proudly manufactured in our Mumbai-based facility under the ‘Make in India’ initiative, using Indian-sourced high-grade brass.

11. How are M4 brass washers different from standard washers?

M4 brass washers are made from non-ferrous material (brass), which gives them better corrosion resistance, conductivity, and a premium finish—ideal for applications requiring precision and durability.

12. How do I ensure compatibility with my bolts?

Ensure your bolts or screws are labeled as M4 (4 mm). Our M4 washers have an inner diameter of approx. 4.3 mm, suitable for secure and accurate fitting with M4 fasteners.

13. Can I order a small batch before bulk purchase?

Yes, we welcome sample or small trial orders before scaling to larger quantities. This allows you to test product fit and performance in your specific application.

14. Do you export brass washers internationally?

Yes, we export to several countries with complete compliance in documentation, packaging, and international standards. We cater to Middle East, Southeast Asia, Europe, and more.

15. How can I place an order or get a quote?

You can visit our website https://nafeesmetalindustries.com/, fill out the inquiry form, or contact our sales team directly for a personalized quote.

M4 Brass Plain washers (DIN 125)

19 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Brass

Nominal Size (g): M4

Inner Diameter (ID): 4.3 mm

Outer Diameter (OD): 9 mm

Thickness (t): 0.8 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M4 Brass Plain Washer – Durable Flat Washers for Precision Applications

At Nafees Metal Industries, we specialize in manufacturing premium quality M4 Brass Plain Washers for precision fastening applications across multiple industries. As one of the most trusted Brass Plain Washers Manufacturer in India, we ensure each washer is engineered with tight tolerances, durable finishes, and high-performance materials for long-lasting functionality.

Our M4 Brass Plain Washer is meticulously designed to accommodate M4-sized bolts or screws (4 mm diameter), making it a perfect fit for delicate electronics, instruments, and mechanical assemblies. Manufactured in our state-of-the-art facility in Mumbai, these washers offer outstanding resistance to corrosion, excellent electrical conductivity, and a polished appearance that enhances both performance and aesthetics.

Whether you are an OEM, distributor, or contractor, our M4 Brass Plain Washer provides you with consistent quality, reliability, and value for high-volume use cases. Trusted by professionals across sectors like electricals, automotive, aerospace, and manufacturing, these washers are tailored to support precise fastening while preventing wear and substrate damage.

Our commitment to the Make in India initiative ensures every M4 Brass Plain Washer is proudly crafted with precision, performance, and purpose.

What is an M4 Brass Plain Washer?

An M4 Brass Plain Washer is a flat, circular disc with a centrally located hole designed to fit M4 bolts or screws (4 mm diameter). Its primary role is to evenly distribute the load of the fastener during tightening, which protects the underlying surface, increases the longevity of the joint, and provides a smooth bearing surface.

Crafted from premium-grade brass, the M4 Brass Plain Washer combines strength, electrical conductivity, and corrosion resistance—making it ideal for electrical, mechanical, and precision-based applications. Brass, as a non-ferrous alloy, also minimizes the risk of sparking and offers superior resistance to moisture and chemical exposure.

Each M4 Brass Plain Washer from Nafees Metal Industries is manufactured with high dimensional accuracy and uniform thickness to ensure optimal performance even under dynamic load conditions. Whether you are working with PCB assemblies, light machinery, or household appliances, these washers prevent fastener pull-through and maintain joint integrity over time.

In addition to their mechanical benefits, M4 Brass Plain Washers also enhance aesthetics—especially in applications where visible hardware must maintain a clean and refined appearance.

Typical attributes include:

Inner Diameter (ID): ~4.3 mm to fit M4 bolts

Outer Diameter (OD): As per DIN 125 / ISO 7089 or custom

Thickness: Generally ranges between 0.5 mm to 1.0 mm (customizable)

Material: Pure or high-grade alloyed brass

Finish: Natural brass, polished, or coated (as per request)

These washers are an integral part of Brass Flat Washers categories used worldwide across industries where performance and material integrity are paramount.

Why Brass for M4 Washers?

Brass is a highly preferred material for manufacturing M4 washers due to its unique combination of mechanical strength, corrosion resistance, and aesthetic appeal. Choosing an M4 Brass Plain Washer means opting for performance, reliability, and longevity in demanding environments.

Here’s why brass is an ideal material for M4 washers:

1. Excellent Corrosion Resistance

Brass naturally resists corrosion from moisture, air, and mild chemicals. This makes the M4 Brass Plain Washer suitable for both indoor and semi-exposed environments where durability is essential.

2. Non-Magnetic and Spark-Resistant

Unlike ferrous metals, brass is non-magnetic and spark-proof, making it a safe choice for sensitive electronic and electrical assemblies. This ensures the M4 Brass Plain Washer doesn’t interfere with circuits or pose a fire hazard.

3. Superior Electrical Conductivity

One of the major reasons industries prefer M4 Brass Plain Washers in electrical applications is brass’s high electrical conductivity. It helps maintain efficient current flow in connections, especially in PCB and switchgear assemblies.

4. Smooth Finish & Aesthetic Appeal

Brass has a distinct golden finish, offering a visually appealing component for exposed mechanical joints. The polished look of an M4 Brass Plain Washer complements high-end applications where appearance matters.

5. Long-Term Dimensional Stability

Brass maintains its shape and structural integrity even under thermal fluctuations or prolonged stress. This gives M4 Brass Plain Washers an edge in applications requiring tight, reliable fastening over time.

6. Environmentally Friendly & Recyclable

Brass is a recyclable material, supporting sustainable manufacturing practices. At Nafees Metal Industries, we prioritize eco-conscious production while maintaining top-tier quality for every M4 Brass Plain Washer.

7. Customizable Coatings

Although brass is naturally corrosion-resistant, additional coatings such as nickel or chrome can be applied for enhanced protection and appearance based on client requirements.

By choosing M4 Brass Plain Washers, you benefit from a material that meets industrial-grade standards while ensuring reliability, conductivity, and corrosion resistance.

How Are M4 Brass Plain Washers Manufactured?

At Nafees Metal Industries, each brass washer we produce is a result of precision engineering and strict quality control. The manufacturing process of our M4-sized brass plain washers is designed to meet both national and international standards such as IS 2016, DIN 125, and ISO 7089.

Here’s a detailed overview of the production steps:

1. Material Selection and Testing

We begin by sourcing high-grade brass sheets that meet the required mechanical and chemical properties. These sheets are inspected for consistency, hardness, and surface quality before moving into production.

2. Precision Punching

Using high-precision power press machines, brass sheets are cold-stamped to create the washer shape. The inner diameter is specifically punched to accommodate M4 bolts, while the outer diameter follows standard or client-specified dimensions.

3. Deburring and Surface Finishing

Each washer undergoes deburring to remove sharp edges, ensuring safe handling and smooth assembly. The surface is then polished or finished depending on the application—options include natural brass, bright polish, or nickel-plated surfaces.

4. Thickness Control

We maintain uniform thickness across all washers, generally between 0.5 mm to 1.0 mm, based on application need. This ensures even load distribution during fastening.

5. Quality Checks

Every batch is subjected to dimensional inspections, hardness tests, and visual checks. We verify the inner and outer diameters, concentricity, and overall finish to deliver consistent and reliable washers.

6. Packaging & Dispatch

Once passed through quality checks, the washers are packed in polybags, cartons, or customized packaging as per client requirements. We also provide bulk packing solutions for OEMs and large-scale buyers.

Our advanced manufacturing unit in Mumbai allows us to fulfill small and large orders with short lead times. As a Brass Plain Washers Manufacturer, we are equipped to deliver both standard and custom washers for any industrial requirement.

Key Features of M4 Brass Plain Washers

Our M4 brass washers are engineered for performance, precision, and longevity. Whether used in electronic devices, electrical panels, or mechanical subassemblies, these washers offer a wide range of functional and material benefits that make them indispensable across industries.

Below are the standout features that set our products apart:

1. Precision Fit

Each washer is dimensionally accurate to fit standard M4 bolts and screws. The inner diameter is finely punched for a snug, stable hold that maintains alignment during tightening.

2. Uniform Thickness

Maintaining uniform thickness is critical to ensure even pressure distribution. Our M4 washers are available in standard thicknesses from 0.5 mm to 1.0 mm and can be customized based on application-specific needs.

3. Corrosion Resistance

Being made from brass, these washers offer natural resistance to rust and oxidation, especially in indoor or semi-exposed environments. This extends the lifespan of the fastener system.

4. Electrical Conductivity

These washers are ideal for electrical applications due to brass’s high conductivity. They maintain reliable current flow while securing joints firmly in place.

5. Smooth Edges and Polished Finish

To ensure safe handling and avoid abrasion to surrounding materials, each washer is finished with burr-free, polished edges. This makes them easier to install and handle during assembly.

6. Mechanical Strength

Despite their small size, M4 washers offer excellent mechanical strength and rigidity, making them suitable for both static and light dynamic loads.

7. Aesthetic Appeal

Brass has a natural gold-like sheen, giving the washer a premium look—especially suitable for applications where the fastener remains visible.

8. Custom Coating Options

We provide zinc, nickel, and chrome plating options to further enhance durability, appearance, and corrosion resistance. Coatings can be customized based on end-use or environmental factors.

9. Non-Magnetic Material

Brass is non-magnetic, which makes these washers ideal for sensitive instrumentation and electronic applications where magnetic interference is unacceptable.

10. Bulk Availability

These washers are available in large volumes, ready to dispatch for OEMs, resellers, and assembly units. We support urgent deliveries with export-ready documentation.

Each brass flat washer we produce carries our commitment to quality, precision, and customer satisfaction. That’s what makes Nafees Metal Industries a preferred choice for industries across India and beyond.

Technical Specifications

Our M4-sized brass washers are crafted in line with global manufacturing and quality standards. The technical profile outlined below ensures that customers can match their fastening needs with precision and clarity.

| Property | Specification |

|---|---|

| Product Name | M4 Brass Plain Washer |

| Material | High-Grade Brass (CuZn Alloy) |

| Inner Diameter (ID) | Approx. 4.3 mm (to fit M4 bolts or screws) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 or customized |

| Thickness | 0.5 mm to 1.0 mm (custom thickness available) |

| Hardness | 80–120 HV (depending on brass grade used) |

| Surface Finish | Natural Brass / Polished / Nickel-Plated / Custom Coating |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Corrosion Resistance | Excellent for indoor and mild outdoor use |

| Electrical Conductivity | High (Ideal for electrical applications) |

| Tensile Strength | 300–550 MPa (varies with brass alloy and treatment) |

| Magnetic Properties | Non-Magnetic |

| Packaging | Bulk in polybags, corrugated boxes, or custom packed |

| Application Category | Electrical, Mechanical, Electronic, Instrumentation, Fastening |

We ensure every technical attribute aligns with real-world application requirements. Whether you’re in electronics assembly, HVAC, instrumentation, or consumer goods manufacturing, these washers offer reliable performance and compatibility with global fastening standards.

Applications of M4 Brass Plain Washers

M4 Brass Plain Washers are designed for precision, durability, and reliability—making them highly versatile across a wide range of industries and use cases. Their corrosion resistance, conductivity, and dimensional accuracy make them the washer of choice in compact fastening systems where strength and conductivity are equally important.

Below are the major industries and applications where M4 brass washers are widely used:

1. Electrical Panels & Components

Used extensively in switchgear, MCBs, terminals, and electrical housings where high conductivity and corrosion resistance are required. The washers help maintain strong electrical joints and avoid surface degradation.

2. Printed Circuit Boards (PCBs)

Protect delicate circuit boards from fastener stress by distributing load evenly. These washers are ideal for mounting PCBs in electronic devices, ensuring no trace damage or cracking occurs.

3. Consumer Electronics

Found in compact gadgets like mobile chargers, adapters, speakers, and electronic displays where secure yet lightweight and conductive fastening is necessary.

4. Automotive Electronics

Applied in ECUs, sensor assemblies, and vehicle infotainment systems for vibration-free, secure mounting with minimal risk of oxidation.

5. Aerospace and Avionics

Valued for non-magnetic and corrosion-resistant properties in avionics hardware and cabin electronic assemblies, where component reliability is non-negotiable.

6. Telecommunication Equipment

Essential in grounding and fastening applications in routers, towers, and data transmission devices due to brass’s stable conductivity.

7. Instrumentation and Meters

Used in assembling precision measuring instruments like voltmeters, pressure gauges, and timers that require stable joints and material compatibility.

8. Home Appliances

Ideal for light assemblies in kitchen appliances, fans, and electronic switches, where space and reliability are critical.

9. Renewable Energy Systems

Employed in solar inverter panels and control boxes where conductivity, rust resistance, and durability support long-term performance.

10. Fastener Kits for Maintenance and Repairs

Frequently included in MRO toolkits, as their M4 size fits most standard small hardware used across industries.

Because of their small size and high utility, M4 Brass Plain Washers play a critical role in securing sensitive assemblies, reducing wear, and improving long-term operational efficiency.

Advantages of Using M4 Brass Washers

M4 Brass Plain Washers offer a range of functional, mechanical, and environmental benefits that make them superior to many other fastening alternatives in small-scale or precision-based applications. At Nafees Metal Industries, we ensure these advantages are enhanced through our expert manufacturing, quality assurance, and customer-first approach.

Here’s why M4 brass washers are the preferred choice across industries:

1. Superior Load Distribution

These washers effectively spread the load of the fastener, preventing damage to delicate substrates such as PCB boards, plastic casings, and soft metal components.

2. Corrosion Resistance

Brass provides excellent resistance to rust and tarnish, ensuring longevity even in slightly humid or corrosive environments—especially important for indoor electrical and electronic applications.

3. Electrical Conductivity

One of the top reasons to use M4 brass washers is their excellent conductivity, which ensures uninterrupted current flow and strong, secure electrical contacts in assemblies.

4. Non-Sparking Material

Brass does not produce sparks when struck, making these washers safe to use in environments where flammable gases or sensitive circuits are present.

5. Aesthetic Finish

Their naturally polished gold-like finish provides a clean, premium look—ideal for visible fastener applications in consumer electronics or decorative hardware.

6. Non-Magnetic

M4 brass washers are completely non-magnetic, ensuring they do not interfere with sensitive electronic devices or instruments that require zero magnetic interference.

7. High Dimensional Stability

Even under dynamic load conditions, the material retains its shape and strength, making it reliable for light mechanical and electronic assemblies.

8. Easy to Install and Handle

With burr-free edges and a smooth finish, these washers offer safe and quick installation without causing damage to nearby components or assemblies.

9. Custom Finish and Size Options

Available in various surface coatings such as nickel, chrome, or plain brass, along with thickness and diameter customization based on specific requirements.

10. Cost-Effective for Volume Use

Despite their premium properties, M4 brass washers offer great value in bulk procurement—especially for OEMs and industrial buyers looking to optimize long-term costs without compromising quality.

When sourced from a trusted Brass Plain Washers Manufacturer like Nafees Metal Industries, these advantages translate into smoother assembly operations, enhanced product life, and higher end-user satisfaction.

Buy M4 Brass Plain Washers in Bulk – Trusted Manufacturer in India

If you’re looking for high-quality M4 brass washers with bulk availability, reliable delivery, and customization options, Nafees Metal Industries is your ideal sourcing partner. Recognized as a top-tier Brass Plain Washers Manufacturer in India, we specialize in supplying industrial-grade washers that meet both functional and aesthetic standards.

Our Mumbai-based manufacturing unit is fully equipped with advanced machinery, strict quality controls, and skilled manpower, enabling us to produce and dispatch large quantities of M4 Brass Plain Washers across India and to global markets. Whether you need standard dimensions or require customized thickness, coatings, or packaging, we offer full flexibility and support.

Why Buy from Nafees Metal Industries?

Bulk Availability

We maintain large stocks of M4 washers, ready for immediate shipment to OEMs, distributors, and end users.Custom Coating & Packaging

Get your washers zinc-coated, nickel-plated, or chrome-finished with packaging tailored to your workflow—whether poly bags, carton boxes, or export pallets.Competitive Pricing

Our in-house manufacturing allows us to offer highly competitive rates without compromising on precision or finish.Quick Turnaround Times

We specialize in fast production and dispatch, ensuring that even urgent orders are fulfilled on time with export-ready documentation.Expert Technical Support

Our team of engineers and product specialists can help you choose the right size, finish, and specifications for your application.PAN India and Global Supply

We serve customers across India and export to the Middle East, Southeast Asia, and Europe with complete documentation and packaging compliance.

When you choose Nafees Metal Industries, you’re not just buying a product—you’re investing in consistency, support, and a long-term relationship with one of the most reliable names in Industrial Brass Washers.

Looking to Buy Brass Washers Online? We invite you to browse our full product range on

https://nafeesmetalindustries.com/

or contact our sales team for a quick quote.

Case Study: Boosting Reliability in PCB Assembly with M4 Brass Washers

Client: A leading electronics OEM specializing in smart home devices

Location: Bengaluru, India

Challenge: Circuit boards were facing microcracks and premature failure due to uneven fastening pressure during assembly. The client was previously using generic steel washers that caused surface indentation and poor conductivity.

Problem Overview:

Microcracks on PCB surfaces after repeated fastening.

Inconsistent grounding caused by oxidation of steel washers.

Assembly time increased due to improper washer alignment and handling.

Post-sale complaints and product returns due to unstable electronic modules.

Solution Implemented:

The client partnered with Nafees Metal Industries to switch to high-precision M4 Brass Plain Washers with a polished finish and custom thickness (0.8 mm). Our team also recommended using nickel-plated brass washers to further enhance corrosion resistance and conductivity.

Results:

Reduced Assembly Time by 22%: Easy-to-handle brass washers with burr-free edges reduced manual effort during fastening.

100% Elimination of PCB Surface Damage: The washers provided even load distribution without causing stress points or cracks.

Improved Electrical Performance: Stable grounding and reduced resistance due to brass’s high conductivity.

Decreased Product Returns: Complaint rate dropped by 47% within the first two months of implementation.

Repeat Order Value Increased by 60%: The OEM doubled their monthly procurement volume and integrated our washers across multiple product lines.

Key Takeaway:

Switching to M4 Brass Plain Washers manufactured by Nafees Metal Industries not only solved the client’s technical challenges but also improved their overall product reliability and customer satisfaction.

This case study demonstrates how a seemingly small component like a washer can play a pivotal role in product performance when manufactured with precision and expertise.

Why Choose Nafees Metal Industries for Brass Washers?

At Nafees Metal Industries, we are more than just a supplier — we are your manufacturing partner for precision-engineered brass washers tailored to meet the highest industrial standards. With decades of industry expertise, state-of-the-art infrastructure, and a customer-first approach, we have established ourselves as a leading Brass Plain Washers Manufacturer in India.

Here’s what makes us the preferred source for buyers across the country and overseas:

1. Specialized Expertise in Brass Washer Manufacturing

Our core focus lies in producing washers — from plain to spring and disc types — with specialization in various sizes like M4 brass washers. Every washer is produced with attention to detail, ensuring consistent quality and performance.

2. In-House Production with Advanced Machinery

From raw material selection to final packaging, every process is handled in-house. Our facility in Mumbai is equipped with modern power presses, deburring machines, and quality inspection tools to ensure every washer meets the required tolerances.

3. Customized Solutions

Whether you need specific thicknesses, finishes, coatings, or packaging formats — we offer full customization based on your application or brand guidelines. Be it a single prototype or bulk volume, we adapt to your needs.

4. Certified Quality Assurance

All washers undergo multi-level quality checks for parameters like:

Dimensional tolerance (ID/OD)

Surface smoothness

Coating adhesion

Hardness and mechanical stability

We comply with IS 2016, DIN 125, and ISO 7089 standards.

5. Bulk Supply with Timely Delivery

We maintain ready stock of standard sizes such as M2, M3, M4, M5, M6, and more. Our streamlined supply chain allows us to fulfill high-volume orders on time, anywhere in India or for export.

6. Transparent and Competitive Pricing

We offer industry-best pricing without compromising on product integrity. Our goal is to provide lasting value to OEMs, wholesalers, and industrial buyers.

7. Trusted by Leading Brands

Our washers are used by leading names in electronics, automotive, power systems, consumer appliances, and more. Our growing repeat customer base is a testament to the quality we deliver.

8. Support for the ‘Make in India’ Vision

Every M4 Brass Plain Washer is manufactured with pride in India using locally sourced materials, contributing to self-reliant industrial growth and economic development.

When you partner with us, you’re choosing unmatched consistency, customizability, and quality—delivered by one of the most reliable names in the Industrial Brass Washers segment.

Frequently Asked Questions (FAQs)

1. What is an M4 Brass Plain Washer?

An M4 Brass Plain Washer is a flat circular disc with a central hole designed to fit M4 bolts or screws (4 mm diameter). It distributes load evenly, reduces surface damage, and improves fastening performance in electrical and mechanical assemblies.

2. Where are M4 brass washers commonly used?

They are used in electronics, PCB mounting, electrical panels, instrumentation, home appliances, automotive electronics, and precision devices requiring compact and conductive fastening solutions.

3. Why should I choose brass instead of steel for M4 washers?

Brass offers superior corrosion resistance, excellent electrical conductivity, is non-magnetic, and is aesthetically appealing. It’s ideal for electronic and decorative uses, unlike steel which may corrode or interfere magnetically.

4. Are M4 Brass Plain Washers suitable for outdoor use?

They are suitable for mildly exposed environments, especially when nickel or chrome-plated. For harsh or marine environments, additional coating may be required for extended performance.

5. Can I customize the dimensions or coating of M4 brass washers?

Yes. At Nafees Metal Industries, we offer customized sizes, thicknesses, inner/outer diameters, and surface coatings (zinc, nickel, chrome) as per your project requirements.

6. What is the standard thickness of an M4 brass washer?

Standard thickness ranges between 0.5 mm and 1.0 mm. However, we can manufacture washers with custom thicknesses depending on the application.

7. Are these washers electrically conductive?

Yes, brass is a highly conductive metal, making M4 brass washers ideal for electrical applications such as grounding, PCB assembly, and switchgear fastening.

8. Do you offer M4 brass washers in bulk quantities?

Absolutely. We specialize in bulk manufacturing and supply for OEMs, wholesalers, and industrial buyers across India and for export.

9. What packaging options are available for bulk orders?

We offer poly bags, corrugated cartons, labeled boxes, or custom packaging as per client specifications. Export packaging with labeling and documentation is also available.

10. Are your brass washers manufactured in India?

Yes, all our brass washers are proudly manufactured in our Mumbai-based facility under the ‘Make in India’ initiative, using Indian-sourced high-grade brass.

11. How are M4 brass washers different from standard washers?

M4 brass washers are made from non-ferrous material (brass), which gives them better corrosion resistance, conductivity, and a premium finish—ideal for applications requiring precision and durability.

12. How do I ensure compatibility with my bolts?

Ensure your bolts or screws are labeled as M4 (4 mm). Our M4 washers have an inner diameter of approx. 4.3 mm, suitable for secure and accurate fitting with M4 fasteners.

13. Can I order a small batch before bulk purchase?

Yes, we welcome sample or small trial orders before scaling to larger quantities. This allows you to test product fit and performance in your specific application.

14. Do you export brass washers internationally?

Yes, we export to several countries with complete compliance in documentation, packaging, and international standards. We cater to Middle East, Southeast Asia, Europe, and more.

15. How can I place an order or get a quote?

You can visit our website https://nafeesmetalindustries.com/, fill out the inquiry form, or contact our sales team directly for a personalized quote.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Brass Plain Washers, Plain Washers, Washers

Tag: Brass

Got Questions?

Feel free to

Get in touch