No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

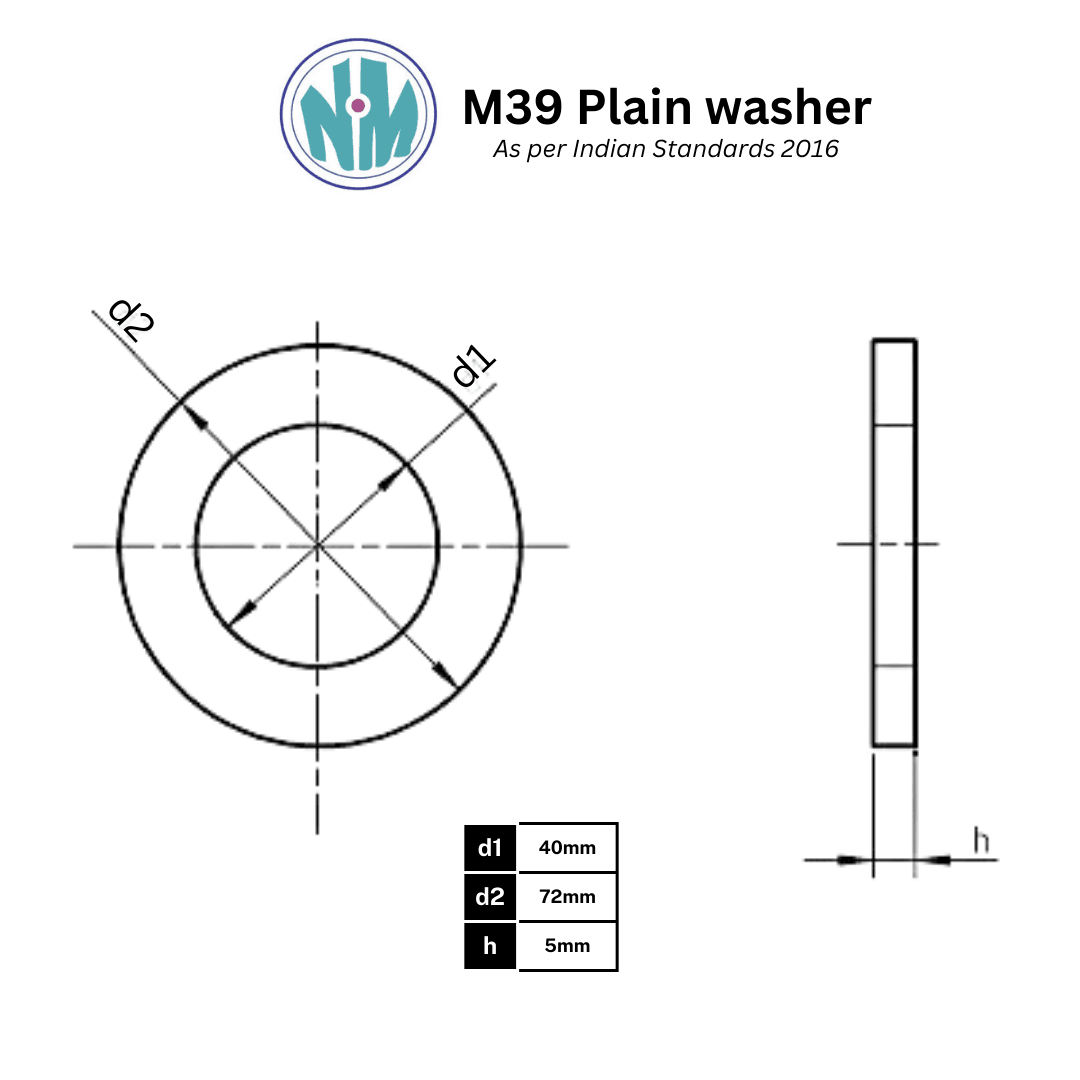

*Images shown for graphic representation. Not to scale.

M39 SS202 Plain Washers – Superior Stainless Steel Flat Washers for Industrial Excellence

Introduction

In the realm of industrial hardware, even the smallest components can determine the success or failure of a project. Among these seemingly insignificant but critically important parts are M39 SS202 Plain Washers. Engineered with precision and crafted from premium-grade SS202 stainless steel, these washers offer unparalleled reliability in load distribution, corrosion resistance, and assembly integrity. Whether you’re working on heavy-duty machinery, structural frameworks, or sensitive electronic assemblies, M39 SS202 Plain Washers deliver consistent performance and durability.

At Nafees Metal Industries, we specialize in designing and manufacturing high-precision washers tailored to meet the rigorous demands of modern industrial applications. As the Best M39 SS202 Plain Washers manufacturer, our mission is to provide products that balance performance, affordability, and quality assurance. In this comprehensive guide, we’ll explore the construction, benefits, and real-world applications of M39 SS202 Plain Washers, share expert installation tips, and explain why you should Buy M39 SS202 Plain Washers in Bulk from a trusted supplier.

What Are M39 SS202 Plain Washers?

M39 SS202 Plain Washers are circular, flat discs with a central aperture precisely sized to fit M39 bolts or screws. Their flat, unthreaded design allows them to function as load-distribution elements, protecting surfaces from bolt heads or nuts and reducing stress concentration. When tightened, these washers distribute forces more evenly across the mating surfaces, safeguarding against deformation, fatigue, and potential failures.

Constructed from SS202 stainless steel, these washers feature a chromium-manganese-nickel alloy composition. This combination yields excellent strength, toughness, and corrosion resistance—yet at a lower cost than higher-end stainless steels. As a result, M39 SS202 Plain Washers offer an optimal blend of performance and economic value.

Material Insights: Why SS202?

Choosing the right material is critical in washer performance. While premium grades like SS304 or SS316 offer superior corrosion resistance, SS202 stainless steel strikes a desirable balance between functionality and affordability.

Key Advantages of SS202:

Corrosion Resistance: Metal assemblies in damp or mildly corrosive environments benefit from SS202’s ability to resist rust and staining.

High Tensile Strength: SS202 offers dependable load-bearing capabilities without sacrificing ductility.

Cost‑Effective: Compared to SS304/316, SS202 is more economical while maintaining excellent performance for many industrial uses.

Manufacturing Efficiency: SS202 is easier to form and machine, enabling tight tolerances and consistent quality in high-volume production runs.

When it comes to M39 SS202 Plain Washers, this material choice ensures dependable industrial performance without breaking the budget.

High-Precision Stainless Steel Flat Washers

Nafees Metal Packaging

Manufacturing Process of M39 SS202 Plain Washers

Nafees Metal Industries employs a rigorous process to produce M39 SS202 Plain Washers that meet stringent industrial standards:

Premium Raw Material Sourcing

We procure certified SS202 stainless steel sheets with guaranteed chemical and mechanical properties, ensuring consistent raw material quality.Precision Cutting

CNC stamps are used to accurately punch washer profiles, adhering to exact inner and outer diameter specifications required for M39 fasteners.Thermal Enhancement

Post-cutting thermal treatment refines mechanical properties, balancing hardness, ductility, and tensile strength.Surface Smoothing

Deburring and polishing produce clean finishes with smooth edges to prevent surface damage during installation.Finishing Options

Washers are delivered in a plain stainless finish, but custom coatings (e.g. zinc plating, passivation) are available for added corrosion protection or visual consistency.Stringent Quality Inspections

Each batch undergoes dimensional checks, tensile testing, and surface quality verifications. Random samples are third-party tested to comply with IS or DIN standards.Efficient Packaging

Washers are boxed, labeled, and prepared based on volume or project needs, ensuring on-time deliveries and minimizing packaging mix-ups.

Key Features of M39 SS202 Plain Washers

Here’s what sets M39 SS202 Plain Washers apart:

Precision-Engineered Fit

Inner holes are sized to match M39 bolts/screws, ensuring tight, secure installation with minimal play.Excellence in Load Distribution

Their flat profile ensures load is spread over a larger area, protecting softer substrates from indentation or localized stress.Vibration Resistance

While not lock-washers, they reduce the risk of loosening in high-vibration systems when used correctly with nuts and bolts.Superior Corrosion Resistance

Resistant in typical industrial, construction, and mild marine atmospheres. Optional coatings are available to enhance longevity in harsher environments.Low Maintenance

Their stainless construction rarely requires upkeep. Occasional cleaning is sufficient to maintain performance.Versatility

Suitable for a wide variety of applications—from structural steelwork and automotive assemblies to conveyor systems and electronic enclosures.Economical & Reliable

SS202 offers industrial-grade performance at a fraction of the cost of premium stainless alloys, making M39 SS202 Plain Washers a cost-effective component.

Technical Specifications

Here’s a detailed breakdown of M39 SS202 Plain Washers by key parameters:

| Property | Description |

|---|---|

| Product | M39 SS202 Plain Washer |

| Material | SS202 Stainless Steel |

| Inner Diameter | Precisely matched to M39 bolt/screw (around 39 mm ID) |

| Outer Diameter | Defined by IS/DIN standards for load distribution |

| Thickness | Engineered for optimal strength and load-bearing |

| Finish | Plain stainless; custom coatings available |

| Shape | Flat, round disc with smooth edges |

Note: Dimensions can be customized in special orders, while standard tolerances comply with industrial guidelines.

Where Are M39 SS202 Plain Washers Used?

M39 SS202 Plain Washers have versatile applications across various industries:

1 Construction & Structural Steelwork

Used in building high-rise structures, bridges, and steel frameworks, these washers ensure joints remain robust. They protect connectors from compressive forces, reducing material fatigue in metal beams or concrete assemblies.

2 Automotive & Heavy Vehicle Manufacturing

Ideal for securing engine mounts, chassis bolts, suspension bolts, and other critical fastenings. Their ability to distribute load and resist loosening under vibration makes them essential in vehicle assembly lines.

3 Industrial Machinery & Equipment

On turbines, pumps, conveyors, and heavy machinery, M39 SS202 Plain Washers preserve bolt clamping forces, extending service life and enhancing equipment safety.

4 Marine & Offshore Projects

SS202’s corrosion resistance makes these washers ideal for coastal installations, boat-mounted equipment, dock hardware, and marine structural bolts. For saltwater resilience, coated variants provide extra protection.

5 Electrical & Electronics

In panels, switchgear, and circuit board assemblies, they cushion sensitive surfaces from fastener pressure and prevent physical damage during installation.

6 General Manufacturing & Maintenance

Useful in assembly and repair operations across industries. Their ease of installation and compatibility with M39 hardware make them practical for in-plant maintenance or Do-It-Yourself projects.

Benefits of Choosing M39 SS202 Plain Washers

✅ Enhanced Corrosion Resistance

Compared to carbon steel washers, SS202 offers significantly better durability in damp or mildly corrosive environments. This means longer-lasting assemblies and reduced maintenance.

✅ Optimized Load Distribution

The flat profile minimizes stress concentrations, extending the service life of materials and components.

✅ Cost-Effective Industrial Grade

SS202 delivers solid performance at lower cost, offering a reliable yet economical choice compared to premium stainless alloys.

✅ Improved Assembly Efficiency

Precision-made with smooth edges and exact fit, they are quick and easy to install, even in tight spaces.

✅ Low Maintenance Requirements

Their inherent corrosion resistance minimizes the need for upkeep; occasional cleaning is all that’s needed.

✅ Adaptable to Many Uses

From light-duty electronics to heavy industrial applications, M39 SS202 Plain Washers meet a broad range of requirements.

Buying Guide: Buy M39 SS202 Plain Washers in Bulk

When planning a project or maintenance schedule, bulk sourcing your washers can provide strong advantages:

Economy of Scale: Bulk orders reduce per-unit cost, making it easier to maintain budget control.

Quality Uniformity: Single-batch production ensures consistent material properties and dimensions.

Reliable Supply: Bulk ordering eliminates frantic reorders during critical phases, minimizing project disruptions.

Tailored Packaging: Customized labeling, portioning, and packaging simplifies inventory control on construction or manufacturing sites.

At Nafees Metal Industries, we’re the go-to choice if you’re looking to Buy M39 SS202 Plain Washers in Bulk. With local and international logistics, custom packaging, and flexible volume options, we cater to everything from 1,000 to 1,000,000+ piece orders.

Why Choose Us as Your Best M39 SS202 Plain Washers Manufacturer

Selecting the right manufacturer is critical—and here’s why Nafees Metal Industries stands out:

ISO-Certified Production: Ensures high standards in every batch.

Full In‑House Manufacturing: Allows complete control over quality, materials, and production timelines.

Advanced CNC Capabilities: Enables tight tolerances and capacity for custom orders.

Robust Quality Assurance: Rigorous checks by both in-house and third-party labs guarantee compliance with applicable standards.

Reliable Pan-India & Global Distribution: Ensures on-time delivery, no matter the destination.

Technical Support: We assist you with selection, installation guidance, and engineering recommendations tailored to your application.

Customized Solutions: From coatings and custom dimensions to branded packaging, we can tailor washers to your exact needs.

Fast Turnaround: Standard items in stock for immediate dispatch; custom orders delivered rapidly.

After‑Sales Assistance: We remain available for field support, failure analysis, and stocking advice long after purchase.

Installation & Best Practices

To maximize performance and longevity of M39 SS202 Plain Washers, follow these expert tips:

Ensure Proper Pairing

Always use washers with the correct M39 bolt or nut size.Double-Sided Application

For critical joints, use a washer under both the head and nut for balanced load distribution.Surface Preparation

Clean mating surfaces and washers to remove dust, oil, or debris before tightening.Appropriate Torque

Use a calibrated torque wrench to tighten bolts to manufacturer specifications.Orderly Assembly

Assemble in rotation for evenly distributed clamping force.Coating Uses

If operating in corrosive environments, consider zinc or passivation coatings for added protection.Periodic Inspections

Check bolts and washers periodically, especially in high-vibration or outdoor settings.Reuse Guidelines

M39 SS202 Plain Washers can be reused if free of deformation, corrosion, and maintain flatness—inspect before reusing.

Maintenance Recommendations

Proper maintenance can significantly extend washer lifespan:

Storage Management

Keep washers dry and in sealed containers until use.Regular Visual Checks

Inspect for rust, pitting, surface stains, and flatness at scheduled intervals.Gentle Cleaning

Use mild soap and water to clean; avoid harsh chemicals that can compromise SS202 protection.Tightening Checks

Re-torque bolts to prevent loosening after initial installation.Coating Refresh

For coated washers in harsh environments, reapply protective coatings if wear or exposure is observed.

Real‑World Case Study: Mumbai Coastal Infrastructure Project

Client: A leading civil engineering firm responsible for building coastal infrastructure in Mumbai.

Challenges

Severe Corrosion due to high humidity and salt-laden coastal air.

High Loads from heavy-duty structural connections and mechanical systems.

Mass Procurement over 250,000 washers needed to meet deadline demands.

Critical Schedule — delays would result in significant financial penalties.

Our Solution

Supplied M39 SS202 Plain Washers with additional zinc plating for enhanced saltwater protection

Employed CNC-produced parts with tight tolerance for secure fit

Conducted salt spray and tensile testing in-house and with third-party labs

Delivered in phase-wise batches, enabling smooth installation without site interruption

Provided virtual training for installation crews on torque settings and washer selection

Results

Zero Corrosion on washers after 18 months of coastal exposure

Zero Slippage or Structural Failures in routine inspections

Cost Savings due to reduced maintenance and superior performance

Project Completed On-Time, enabling the client to avoid penalties

Project led to repeat orders—M39 SS202 Plain Washers became the standard fastening solution

Frequently Asked Questions (FAQs)

Q1. What are M39 SS202 Plain Washers used for?

M39 SS202 Plain Washers are used in industrial applications to distribute the load of M39 bolts or screws, reduce surface damage, and ensure secure fastening in construction, machinery, automotive, and structural projects.

Q2. Are M39 SS202 Plain Washers corrosion-resistant?

Yes, they are made from SS202 stainless steel, which offers good resistance to rust and corrosion, making them suitable for both indoor and outdoor use. For marine or high-moisture environments, we also offer zinc-coated versions.

Q3. Can I use M39 SS202 Plain Washers with galvanized bolts?

Yes, but it’s recommended to use similarly coated washers (e.g., zinc-plated) to avoid galvanic corrosion between dissimilar metals, especially in outdoor or corrosive conditions.

Q4. What is the inner diameter of M39 SS202 Plain Washers?

The inner diameter is precisely manufactured to accommodate M39 bolts, typically around 39 mm, ensuring a snug and accurate fit.

Q5. Do M39 SS202 Plain Washers come in different finishes?

Absolutely. We offer a plain stainless finish by default, with optional finishes such as zinc plating, nickel coating, and passivation for enhanced protection.

Q6. Can these washers be used in high-vibration applications?

Yes. M39 SS202 Plain Washers are suitable for high-vibration environments like automotive and industrial machinery. For additional vibration resistance, they can be paired with spring or lock washers.

Q7. Are M39 SS202 Plain Washers magnetic?

SS202 stainless steel has slight magnetic properties due to its composition, but it does not affect washer performance in most applications.

Q8. Do you provide quality certificates with your washers?

Yes, every bulk order can be accompanied by Mill Test Certificates (MTC), third-party inspection reports, and dimensional analysis upon request.

Q9. How do I store unused M39 SS202 Plain Washers?

Store them in a dry, sealed container away from moisture, chemicals, or direct sunlight to prevent surface rust. For long-term storage in coastal areas, coated washers are recommended.

Q10. Can M39 SS202 Plain Washers be reused?

They can be reused if undamaged and free of corrosion or warping. Always inspect the washer before reuse to ensure it maintains structural integrity.

Q11. Do you export M39 SS202 Plain Washers?

Yes, Nafees Metal Industries exports M39 SS202 Plain Washers internationally. We provide proper documentation, export packaging, and ensure compliance with destination country standards.

Q12. Can I order a custom-sized M39 SS202 Plain Washer?

Absolutely. We offer customization for dimensions, thickness, coatings, and packaging. Let us know your specifications, and we’ll manufacture to your needs.

Q13. What’s the lead time for large-volume orders?

For standard sizes, dispatch happens within a few days. Custom sizes or coated washers may take 2–4 weeks depending on complexity and order volume.

Q14. Are these washers suitable for food-grade applications?

No. While SS202 offers good general-purpose corrosion resistance, it is not ideal for food-grade or highly sanitary environments. Use SS304 or SS316 for such applications.

Q15. Why choose Nafees Metal Industries for M39 SS202 Plain Washers?

We offer ISO-certified production, in-house manufacturing, CNC precision, flexible customizations, and fast delivery across India and globally. As the Best M39 SS202 Plain Washers manufacturer, we’re trusted by industries for reliability and service.

14. How to Order & Contact Us

Ready to experience the strength of well-made washers? Here’s how:

Define Your Requirements

Specify internal/external diameters, thickness, desired coating, and quantity.Request a Quote

Contact our sales team via phone (📞 +91 9322261781) or email with your specs and expected delivery date.Receive Sample

We can dispatch samples quickly for fitment and quality checks.Approve the Prototype

Confirm dimensions and coatings; we’ll initiate production as per schedule.Place Bulk Order

Get unmatched pricing for bulk volumes. We offer flexible packaging to suit your project logistics.Delivery

Standard orders ship from Mumbai; we support national and international delivery.After‑Sales Support

We remain available to assist with any installation, inspection, or troubleshooting needs.

15. Why Nafees Metal Industries Leads the Way

Choosing the Best M39 SS202 Plain Washers manufacturer isn’t just about pricing—it’s also about capability, support, and reliability. Here’s what makes us stand out:

Decades of Fastener Experience

State‑of‑the‑art CNC machining

ISO‑9001 certified quality systems

Robust R & D for new designs and coatings

Comprehensive testing and traceability

Clear communication and prompt updates

Global dispatch capability from Mumbai

Dedication to sustainability and responsible sourcing

Whether you need standard washers or a bespoke fastening solution, Nafees Metal industries combines engineering excellence with competitive pricing and reliable delivery.

In today’s industrial landscape, fastening integrity is essential for safety, performance, and maintenance efficiency. M39 SS202 Plain Washers—with precision craftsmanship, corrosion-resistant SS202 material, and flexible procurement options—offer a reliable solution for a wide range of applications. Whether you’re designing structural frameworks, manufacturing heavy equipment, or maintaining marine infrastructure, these washers ensure secure fastening and long-term operational excellence.

If you want to Buy M39 SS202 Plain Washers in Bulk, benefit from consistent quality, timely delivery, and customized solutions, contact us today. As your Best M39 SS202 Plain Washers manufacturer, we guarantee a seamless experience from sample to shipment.

Order now or visit us at Reay Road, Mumbai, to explore our full range of SS202 Washers and Stainless Steel Flat Washers tailored to your specific needs.

M39 SS202 Plain Washers

8 people are viewing this product right now

₹45.12 Original price was: ₹45.12.₹37.60Current price is: ₹37.60. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M9

Inner Diameter (ID): 40 mm

Outer Diameter (OD): 72 mm

Thickness (t): 5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M39 SS202 Plain Washers – Superior Stainless Steel Flat Washers for Industrial Excellence

Introduction

In the realm of industrial hardware, even the smallest components can determine the success or failure of a project. Among these seemingly insignificant but critically important parts are M39 SS202 Plain Washers. Engineered with precision and crafted from premium-grade SS202 stainless steel, these washers offer unparalleled reliability in load distribution, corrosion resistance, and assembly integrity. Whether you’re working on heavy-duty machinery, structural frameworks, or sensitive electronic assemblies, M39 SS202 Plain Washers deliver consistent performance and durability.

At Nafees Metal Industries, we specialize in designing and manufacturing high-precision washers tailored to meet the rigorous demands of modern industrial applications. As the Best M39 SS202 Plain Washers manufacturer, our mission is to provide products that balance performance, affordability, and quality assurance. In this comprehensive guide, we’ll explore the construction, benefits, and real-world applications of M39 SS202 Plain Washers, share expert installation tips, and explain why you should Buy M39 SS202 Plain Washers in Bulk from a trusted supplier.

What Are M39 SS202 Plain Washers?

M39 SS202 Plain Washers are circular, flat discs with a central aperture precisely sized to fit M39 bolts or screws. Their flat, unthreaded design allows them to function as load-distribution elements, protecting surfaces from bolt heads or nuts and reducing stress concentration. When tightened, these washers distribute forces more evenly across the mating surfaces, safeguarding against deformation, fatigue, and potential failures.

Constructed from SS202 stainless steel, these washers feature a chromium-manganese-nickel alloy composition. This combination yields excellent strength, toughness, and corrosion resistance—yet at a lower cost than higher-end stainless steels. As a result, M39 SS202 Plain Washers offer an optimal blend of performance and economic value.

Material Insights: Why SS202?

Choosing the right material is critical in washer performance. While premium grades like SS304 or SS316 offer superior corrosion resistance, SS202 stainless steel strikes a desirable balance between functionality and affordability.

Key Advantages of SS202:

Corrosion Resistance: Metal assemblies in damp or mildly corrosive environments benefit from SS202’s ability to resist rust and staining.

High Tensile Strength: SS202 offers dependable load-bearing capabilities without sacrificing ductility.

Cost‑Effective: Compared to SS304/316, SS202 is more economical while maintaining excellent performance for many industrial uses.

Manufacturing Efficiency: SS202 is easier to form and machine, enabling tight tolerances and consistent quality in high-volume production runs.

When it comes to M39 SS202 Plain Washers, this material choice ensures dependable industrial performance without breaking the budget.

High-Precision Stainless Steel Flat Washers

Nafees Metal Packaging

Manufacturing Process of M39 SS202 Plain Washers

Nafees Metal Industries employs a rigorous process to produce M39 SS202 Plain Washers that meet stringent industrial standards:

Premium Raw Material Sourcing

We procure certified SS202 stainless steel sheets with guaranteed chemical and mechanical properties, ensuring consistent raw material quality.Precision Cutting

CNC stamps are used to accurately punch washer profiles, adhering to exact inner and outer diameter specifications required for M39 fasteners.Thermal Enhancement

Post-cutting thermal treatment refines mechanical properties, balancing hardness, ductility, and tensile strength.Surface Smoothing

Deburring and polishing produce clean finishes with smooth edges to prevent surface damage during installation.Finishing Options

Washers are delivered in a plain stainless finish, but custom coatings (e.g. zinc plating, passivation) are available for added corrosion protection or visual consistency.Stringent Quality Inspections

Each batch undergoes dimensional checks, tensile testing, and surface quality verifications. Random samples are third-party tested to comply with IS or DIN standards.Efficient Packaging

Washers are boxed, labeled, and prepared based on volume or project needs, ensuring on-time deliveries and minimizing packaging mix-ups.

Key Features of M39 SS202 Plain Washers

Here’s what sets M39 SS202 Plain Washers apart:

Precision-Engineered Fit

Inner holes are sized to match M39 bolts/screws, ensuring tight, secure installation with minimal play.Excellence in Load Distribution

Their flat profile ensures load is spread over a larger area, protecting softer substrates from indentation or localized stress.Vibration Resistance

While not lock-washers, they reduce the risk of loosening in high-vibration systems when used correctly with nuts and bolts.Superior Corrosion Resistance

Resistant in typical industrial, construction, and mild marine atmospheres. Optional coatings are available to enhance longevity in harsher environments.Low Maintenance

Their stainless construction rarely requires upkeep. Occasional cleaning is sufficient to maintain performance.Versatility

Suitable for a wide variety of applications—from structural steelwork and automotive assemblies to conveyor systems and electronic enclosures.Economical & Reliable

SS202 offers industrial-grade performance at a fraction of the cost of premium stainless alloys, making M39 SS202 Plain Washers a cost-effective component.

Technical Specifications

Here’s a detailed breakdown of M39 SS202 Plain Washers by key parameters:

| Property | Description |

|---|---|

| Product | M39 SS202 Plain Washer |

| Material | SS202 Stainless Steel |

| Inner Diameter | Precisely matched to M39 bolt/screw (around 39 mm ID) |

| Outer Diameter | Defined by IS/DIN standards for load distribution |

| Thickness | Engineered for optimal strength and load-bearing |

| Finish | Plain stainless; custom coatings available |

| Shape | Flat, round disc with smooth edges |

Note: Dimensions can be customized in special orders, while standard tolerances comply with industrial guidelines.

Where Are M39 SS202 Plain Washers Used?

M39 SS202 Plain Washers have versatile applications across various industries:

1 Construction & Structural Steelwork

Used in building high-rise structures, bridges, and steel frameworks, these washers ensure joints remain robust. They protect connectors from compressive forces, reducing material fatigue in metal beams or concrete assemblies.

2 Automotive & Heavy Vehicle Manufacturing

Ideal for securing engine mounts, chassis bolts, suspension bolts, and other critical fastenings. Their ability to distribute load and resist loosening under vibration makes them essential in vehicle assembly lines.

3 Industrial Machinery & Equipment

On turbines, pumps, conveyors, and heavy machinery, M39 SS202 Plain Washers preserve bolt clamping forces, extending service life and enhancing equipment safety.

4 Marine & Offshore Projects

SS202’s corrosion resistance makes these washers ideal for coastal installations, boat-mounted equipment, dock hardware, and marine structural bolts. For saltwater resilience, coated variants provide extra protection.

5 Electrical & Electronics

In panels, switchgear, and circuit board assemblies, they cushion sensitive surfaces from fastener pressure and prevent physical damage during installation.

6 General Manufacturing & Maintenance

Useful in assembly and repair operations across industries. Their ease of installation and compatibility with M39 hardware make them practical for in-plant maintenance or Do-It-Yourself projects.

Benefits of Choosing M39 SS202 Plain Washers

✅ Enhanced Corrosion Resistance

Compared to carbon steel washers, SS202 offers significantly better durability in damp or mildly corrosive environments. This means longer-lasting assemblies and reduced maintenance.

✅ Optimized Load Distribution

The flat profile minimizes stress concentrations, extending the service life of materials and components.

✅ Cost-Effective Industrial Grade

SS202 delivers solid performance at lower cost, offering a reliable yet economical choice compared to premium stainless alloys.

✅ Improved Assembly Efficiency

Precision-made with smooth edges and exact fit, they are quick and easy to install, even in tight spaces.

✅ Low Maintenance Requirements

Their inherent corrosion resistance minimizes the need for upkeep; occasional cleaning is all that’s needed.

✅ Adaptable to Many Uses

From light-duty electronics to heavy industrial applications, M39 SS202 Plain Washers meet a broad range of requirements.

Buying Guide: Buy M39 SS202 Plain Washers in Bulk

When planning a project or maintenance schedule, bulk sourcing your washers can provide strong advantages:

Economy of Scale: Bulk orders reduce per-unit cost, making it easier to maintain budget control.

Quality Uniformity: Single-batch production ensures consistent material properties and dimensions.

Reliable Supply: Bulk ordering eliminates frantic reorders during critical phases, minimizing project disruptions.

Tailored Packaging: Customized labeling, portioning, and packaging simplifies inventory control on construction or manufacturing sites.

At Nafees Metal Industries, we’re the go-to choice if you’re looking to Buy M39 SS202 Plain Washers in Bulk. With local and international logistics, custom packaging, and flexible volume options, we cater to everything from 1,000 to 1,000,000+ piece orders.

Why Choose Us as Your Best M39 SS202 Plain Washers Manufacturer

Selecting the right manufacturer is critical—and here’s why Nafees Metal Industries stands out:

ISO-Certified Production: Ensures high standards in every batch.

Full In‑House Manufacturing: Allows complete control over quality, materials, and production timelines.

Advanced CNC Capabilities: Enables tight tolerances and capacity for custom orders.

Robust Quality Assurance: Rigorous checks by both in-house and third-party labs guarantee compliance with applicable standards.

Reliable Pan-India & Global Distribution: Ensures on-time delivery, no matter the destination.

Technical Support: We assist you with selection, installation guidance, and engineering recommendations tailored to your application.

Customized Solutions: From coatings and custom dimensions to branded packaging, we can tailor washers to your exact needs.

Fast Turnaround: Standard items in stock for immediate dispatch; custom orders delivered rapidly.

After‑Sales Assistance: We remain available for field support, failure analysis, and stocking advice long after purchase.

Installation & Best Practices

To maximize performance and longevity of M39 SS202 Plain Washers, follow these expert tips:

Ensure Proper Pairing

Always use washers with the correct M39 bolt or nut size.Double-Sided Application

For critical joints, use a washer under both the head and nut for balanced load distribution.Surface Preparation

Clean mating surfaces and washers to remove dust, oil, or debris before tightening.Appropriate Torque

Use a calibrated torque wrench to tighten bolts to manufacturer specifications.Orderly Assembly

Assemble in rotation for evenly distributed clamping force.Coating Uses

If operating in corrosive environments, consider zinc or passivation coatings for added protection.Periodic Inspections

Check bolts and washers periodically, especially in high-vibration or outdoor settings.Reuse Guidelines

M39 SS202 Plain Washers can be reused if free of deformation, corrosion, and maintain flatness—inspect before reusing.

Maintenance Recommendations

Proper maintenance can significantly extend washer lifespan:

Storage Management

Keep washers dry and in sealed containers until use.Regular Visual Checks

Inspect for rust, pitting, surface stains, and flatness at scheduled intervals.Gentle Cleaning

Use mild soap and water to clean; avoid harsh chemicals that can compromise SS202 protection.Tightening Checks

Re-torque bolts to prevent loosening after initial installation.Coating Refresh

For coated washers in harsh environments, reapply protective coatings if wear or exposure is observed.

Real‑World Case Study: Mumbai Coastal Infrastructure Project

Client: A leading civil engineering firm responsible for building coastal infrastructure in Mumbai.

Challenges

Severe Corrosion due to high humidity and salt-laden coastal air.

High Loads from heavy-duty structural connections and mechanical systems.

Mass Procurement over 250,000 washers needed to meet deadline demands.

Critical Schedule — delays would result in significant financial penalties.

Our Solution

Supplied M39 SS202 Plain Washers with additional zinc plating for enhanced saltwater protection

Employed CNC-produced parts with tight tolerance for secure fit

Conducted salt spray and tensile testing in-house and with third-party labs

Delivered in phase-wise batches, enabling smooth installation without site interruption

Provided virtual training for installation crews on torque settings and washer selection

Results

Zero Corrosion on washers after 18 months of coastal exposure

Zero Slippage or Structural Failures in routine inspections

Cost Savings due to reduced maintenance and superior performance

Project Completed On-Time, enabling the client to avoid penalties

Project led to repeat orders—M39 SS202 Plain Washers became the standard fastening solution

Frequently Asked Questions (FAQs)

Q1. What are M39 SS202 Plain Washers used for?

M39 SS202 Plain Washers are used in industrial applications to distribute the load of M39 bolts or screws, reduce surface damage, and ensure secure fastening in construction, machinery, automotive, and structural projects.

Q2. Are M39 SS202 Plain Washers corrosion-resistant?

Yes, they are made from SS202 stainless steel, which offers good resistance to rust and corrosion, making them suitable for both indoor and outdoor use. For marine or high-moisture environments, we also offer zinc-coated versions.

Q3. Can I use M39 SS202 Plain Washers with galvanized bolts?

Yes, but it’s recommended to use similarly coated washers (e.g., zinc-plated) to avoid galvanic corrosion between dissimilar metals, especially in outdoor or corrosive conditions.

Q4. What is the inner diameter of M39 SS202 Plain Washers?

The inner diameter is precisely manufactured to accommodate M39 bolts, typically around 39 mm, ensuring a snug and accurate fit.

Q5. Do M39 SS202 Plain Washers come in different finishes?

Absolutely. We offer a plain stainless finish by default, with optional finishes such as zinc plating, nickel coating, and passivation for enhanced protection.

Q6. Can these washers be used in high-vibration applications?

Yes. M39 SS202 Plain Washers are suitable for high-vibration environments like automotive and industrial machinery. For additional vibration resistance, they can be paired with spring or lock washers.

Q7. Are M39 SS202 Plain Washers magnetic?

SS202 stainless steel has slight magnetic properties due to its composition, but it does not affect washer performance in most applications.

Q8. Do you provide quality certificates with your washers?

Yes, every bulk order can be accompanied by Mill Test Certificates (MTC), third-party inspection reports, and dimensional analysis upon request.

Q9. How do I store unused M39 SS202 Plain Washers?

Store them in a dry, sealed container away from moisture, chemicals, or direct sunlight to prevent surface rust. For long-term storage in coastal areas, coated washers are recommended.

Q10. Can M39 SS202 Plain Washers be reused?

They can be reused if undamaged and free of corrosion or warping. Always inspect the washer before reuse to ensure it maintains structural integrity.

Q11. Do you export M39 SS202 Plain Washers?

Yes, Nafees Metal Industries exports M39 SS202 Plain Washers internationally. We provide proper documentation, export packaging, and ensure compliance with destination country standards.

Q12. Can I order a custom-sized M39 SS202 Plain Washer?

Absolutely. We offer customization for dimensions, thickness, coatings, and packaging. Let us know your specifications, and we’ll manufacture to your needs.

Q13. What’s the lead time for large-volume orders?

For standard sizes, dispatch happens within a few days. Custom sizes or coated washers may take 2–4 weeks depending on complexity and order volume.

Q14. Are these washers suitable for food-grade applications?

No. While SS202 offers good general-purpose corrosion resistance, it is not ideal for food-grade or highly sanitary environments. Use SS304 or SS316 for such applications.

Q15. Why choose Nafees Metal Industries for M39 SS202 Plain Washers?

We offer ISO-certified production, in-house manufacturing, CNC precision, flexible customizations, and fast delivery across India and globally. As the Best M39 SS202 Plain Washers manufacturer, we’re trusted by industries for reliability and service.

14. How to Order & Contact Us

Ready to experience the strength of well-made washers? Here’s how:

Define Your Requirements

Specify internal/external diameters, thickness, desired coating, and quantity.Request a Quote

Contact our sales team via phone (📞 +91 9322261781) or email with your specs and expected delivery date.Receive Sample

We can dispatch samples quickly for fitment and quality checks.Approve the Prototype

Confirm dimensions and coatings; we’ll initiate production as per schedule.Place Bulk Order

Get unmatched pricing for bulk volumes. We offer flexible packaging to suit your project logistics.Delivery

Standard orders ship from Mumbai; we support national and international delivery.After‑Sales Support

We remain available to assist with any installation, inspection, or troubleshooting needs.

15. Why Nafees Metal Industries Leads the Way

Choosing the Best M39 SS202 Plain Washers manufacturer isn’t just about pricing—it’s also about capability, support, and reliability. Here’s what makes us stand out:

Decades of Fastener Experience

State‑of‑the‑art CNC machining

ISO‑9001 certified quality systems

Robust R & D for new designs and coatings

Comprehensive testing and traceability

Clear communication and prompt updates

Global dispatch capability from Mumbai

Dedication to sustainability and responsible sourcing

Whether you need standard washers or a bespoke fastening solution, Nafees Metal industries combines engineering excellence with competitive pricing and reliable delivery.

In today’s industrial landscape, fastening integrity is essential for safety, performance, and maintenance efficiency. M39 SS202 Plain Washers—with precision craftsmanship, corrosion-resistant SS202 material, and flexible procurement options—offer a reliable solution for a wide range of applications. Whether you’re designing structural frameworks, manufacturing heavy equipment, or maintaining marine infrastructure, these washers ensure secure fastening and long-term operational excellence.

If you want to Buy M39 SS202 Plain Washers in Bulk, benefit from consistent quality, timely delivery, and customized solutions, contact us today. As your Best M39 SS202 Plain Washers manufacturer, we guarantee a seamless experience from sample to shipment.

Order now or visit us at Reay Road, Mumbai, to explore our full range of SS202 Washers and Stainless Steel Flat Washers tailored to your specific needs.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch