No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M5 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M39 Mild Steel Plain Washers – Dependable Mild Steel Flat Washers for Heavy-Duty Industrial Applications

Introduction

Every industrial fastener assembly, no matter how complex, depends on the smallest components to hold it all together safely and reliably. Among these, M39 Mild Steel Plain Washers play a crucial role in distributing loads, preventing surface damage, and maintaining the integrity of bolted joints in demanding applications.

Whether you’re anchoring structural beams on a construction site, assembling machinery in a factory, or managing maintenance for heavy vehicles, choosing the right washer makes a huge difference. M39 Mild Steel Plain Washers offer a robust, cost-effective solution for load distribution, vibration resistance, and long-term durability.

At Nafees Metal Industries, we’ve earned our reputation as the Best M39 MS Plain Washers Manufacturer by producing washers that meet exacting standards for dimensions, material quality, and finish. When you need reliable Mild Steel Flat Washers, we deliver – with custom solutions, bulk supply capabilities, and full technical support.

What Are M39 Mild Steel Plain Washers?

M39 Mild Steel Plain Washers are flat, disc-shaped fastener accessories with a central hole sized to accommodate M39 bolts or screws. Their primary function is deceptively simple: they distribute the force applied by a bolt head or nut evenly across a larger surface area.

By spreading the load, these washers help prevent stress concentrations that could crack or deform the underlying surface, whether that’s steel, concrete, or softer materials like timber. They also reduce the risk of bolt loosening in assemblies exposed to vibration or movement.

Key benefits include:

Load distribution to protect structural elements.

Surface protection to preserve coatings, finishes, or softer materials.

Vibration resistance that helps maintain bolt tightness over time.

Long-term durability thanks to the strength of mild steel.

Because they are cost-effective and easy to install, M39 Mild Steel Plain Washers are widely used in civil construction, industrial machinery, heavy vehicles, and general fabrication.

Material Details: Why Mild Steel?

Choosing the right material is critical to washer performance. Mild steel remains one of the most popular choices because it strikes the perfect balance between strength, workability, and affordability.

Advantages of Mild Steel:

Strong and Ductile: Mild steel can handle high clamping forces without cracking or excessive deformation. It’s also easy to form into precise shapes.

Economical: Compared to stainless or alloy steels, mild steel is cost-effective – ideal for large-scale projects where thousands of washers are required.

Customizable: Mild steel can be zinc-plated or galvanized to enhance corrosion resistance, extending its lifespan in outdoor or humid environments.

Reliable Performance: It’s compatible with most standard bolt grades and works well with other fastener components.

How Mild Steel Compares:

Vs. Stainless Steel: Mild steel is more affordable and easier to machine but needs protective coatings for high-corrosion environments.

Vs. Hardened Alloys: Mild steel is perfect for general load distribution – it doesn’t need the extra hardness that might be required for high-wear rotating applications.

Vs. Non-Ferrous Metals: Mild steel has better tensile strength than copper, brass, or aluminum washers, making it ideal for load-bearing industrial uses.

Manufacturing and Technical Specifications

At Nafees Metal Industries, each batch of M39 Mild Steel Plain Washers is produced using high-quality raw materials and precise manufacturing processes to ensure consistent performance.

Our Process:

Material Sourcing: Only certified mild steel that meets IS/ISO standards is used.

Precision Stamping: High-tonnage presses stamp washers to exact inner/outer diameter specs.

Deburring and Smoothing: Sharp edges are removed to ensure safe, easy installation.

Coating (Optional): Zinc or other protective coatings are applied based on your project’s environmental conditions.

Quality Control: Every batch undergoes dimensional, hardness, and coating thickness tests.

Typical Specifications for M39 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 39 mm (fits M39 bolts) |

| Outer Diameter | 78–85 mm (standard) |

| Thickness | As per IS 2016/ DIN 125 standards or custom |

| Finish | Plain, oiled, or zinc-coated |

| Material | Mild Steel |

| Shape | Flat Round Disc |

Custom dimensions or coatings are always available for large projects.

Key Features

When you choose M39 Mild Steel Plain Washers, you’re getting multiple performance benefits that help your projects stay secure and cost-efficient. Here’s how they add value:

✅ Efficient Load Distribution

Without a washer, the compressive force from a bolt is concentrated in a small area. This can cause permanent damage like cracks or indentations. M39 Mild Steel Plain Washers spread this load evenly, protecting structural beams, concrete anchors, or painted surfaces.

✅ Better Vibration Resistance

Dynamic loads and vibrations are constant in construction equipment, industrial machinery, and heavy vehicles. These washers act as a buffer, absorbing shock and minimizing the loosening effect on bolts and nuts.

✅ Surface Protection

Fasteners installed directly onto metal, wood, or painted surfaces can scratch or damage them. Washers serve as a protective barrier, preserving the integrity of the base material.

✅ Durable Mild Steel Strength

Mild steel’s tensile strength allows these washers to maintain shape and performance under repeated tightening, heavy loads, and variable temperatures.

✅ Custom Coating Options

For extra durability, these washers can be zinc-plated or hot-dip galvanized, extending service life in challenging environments.

✅ Economical for Large Projects

Bulk orders of M39 Mild Steel Plain Washers keep costs low without sacrificing quality. That’s why they’re the first choice for contractors managing big structural or mechanical jobs.

✅ Versatility Across Industries

They’re used everywhere – from securing steel columns in construction to anchoring machinery foundations, large vehicle assemblies, and even DIY projects.

Applications & Use Cases

The versatility of M39 Mild Steel Plain Washers makes them indispensable for a wide range of sectors:

✅ Civil Construction:

Used for bolted connections in steel frameworks, structural beams, and concrete anchor bolts. They prevent stress cracks in concrete by spreading loads effectively.

✅ Industrial Machinery:

Essential for mounting heavy equipment, turbines, and presses. They protect both the bolt and the equipment base from damage under heavy vibration.

✅ Heavy Vehicles & Railways:

Secure large axle bolts, suspension assemblies, and chassis connections where load and shock are constant.

✅ General Engineering & Fabrication:

Any general-purpose bolted connection that demands reliability, especially in high-load scenarios.

✅ DIY & Repairs:

Facility maintenance teams and contractors rely on these washers for retrofitting, expansions, or structural reinforcements.

Why Buy M39 Mild Steel Washers in Bulk

When you Buy M39 Mild Steel Washers in Bulk, you gain more than cost savings:

Consistent Quality: Uniform washers ensure every connection has the same strength and durability.

Reliable Inventory: Avoid work stoppages by keeping large quantities on hand for big projects.

Lower Costs: Bulk orders reduce the unit cost significantly.

Custom Packaging: We supply washers sorted by size, coating, and application for easy site handling.

Why Choose the Best M39 MS Plain Washers Manufacturer

Here’s why leading contractors and OEMs choose Nafees Metal Industries as their Best M39 MS Plain Washers Manufacturer:

✅ Certified Materials: We use only premium mild steel that meets strict industry standards.

✅ Precision Engineering: Each washer is manufactured to exact dimensions.

✅ Flexible Quantities: From small to very large orders, we deliver on time.

✅ In-House Production: Complete control means consistent quality batch after batch.

✅ Custom Solutions: Need special coatings, thickness, or packaging? We deliver.

✅ Expert Support: Our technical team helps you select the right washer for your unique project.

Installation Tips

To get the best results with M39 Mild Steel Plain Washers:

Clean Contact Surfaces: Remove dust, oil, or debris for a tight fit.

Use Dual Washers: Place washers under both the nut and bolt head for maximum load distribution.

Torque Correctly: Follow the bolt grade torque chart; don’t overtighten.

Inspect Before Use: Ensure washers are free from cracks or corrosion.

Pair with Protective Coatings: Use zinc-coated washers in harsh environments to reduce rust.

Maintenance Guidelines

✅ Proper Storage: Keep washers in dry, sealed boxes to prevent moisture exposure.

✅ Routine Inspections: Check washers during scheduled maintenance for cracks, corrosion, or deformation.

✅ Cleaning: Remove dirt or debris that could affect the fastener’s seating.

✅ Replacement: Always replace any washers that show signs of wear to ensure ongoing load integrity.

Case Study: Industrial Crane Support System

Project Overview

A leading infrastructure company was commissioned to construct a large expansion section for a metropolitan highway bridge. This bridge had to handle constant heavy vehicular loads, including oversized cargo trucks, with strong vibration forces transmitted through its steel girders and concrete piers.

As part of the project’s design, massive steel beams were to be anchored to concrete piers using high-strength M39 bolts. However, during the initial design review, structural engineers flagged a critical risk: using undersized or low-quality washers could concentrate stress at bolt connections, causing microcracks in the concrete and bolt loosening under vibration.

To address this, the engineering contractor specified M39 Mild Steel Plain Washers supplied by Nafees Metal Industries — a trusted partner known for quality bulk fastener solutions.

Challenges Faced

🔍 1. Load Concentration on Concrete Piers

Without the correct washer size and thickness, the massive clamping force of each M39 bolt would focus on a small concrete surface area. For a bridge that handles thousands of vehicles daily, this posed a major structural risk.

🔍 2. Constant Dynamic Vibration

Bridge structures naturally flex and vibrate under live loads. Standard washers often fail to maintain even clamping force, leading to bolts loosening over time — resulting in increased maintenance and possible safety issues.

🔍 3. Harsh Weather Exposure

The bridge site, located near a coastal region, meant that any exposed fasteners would face high humidity, rainfall, and occasional salt spray. Uncoated mild steel would risk premature corrosion if not properly protected.

Tailored Solution with M39 Mild Steel Plain Washers

After a detailed technical review, Nafees Metal Industries supplied M39 Mild Steel Plain Washers that were customized for the bridge’s specific requirements:

✅ Optimal Dimensions for Load Distribution

Each washer was manufactured with a larger-than-standard outer diameter, based on structural calculations that determined the exact surface area needed to spread the bolt load safely across the concrete piers. This minimized the risk of stress cracks developing over time.

✅ Precision Thickness for Vibration Resistance

Engineers opted for slightly thicker washers to handle repetitive vibration cycles. This added buffer capacity helped maintain consistent clamping force during the bridge’s expansion and contraction movements.

✅ Corrosion Protection with Zinc Coating

To ensure long-term durability in a humid, semi-marine environment, all M39 Mild Steel Plain Washers were zinc-plated to protect against rust and oxidation. This extended the expected service life of the washers, bolts, and surrounding structural steel.

✅ Bulk Supply with Site-Ready Packaging

Over 12,000 washers were required for the entire expansion. Nafees Metal Industries delivered the washers in palletized, clearly labeled batches sorted by pier location, which made handling on the bridge site efficient and reduced installation errors.

Step-by-Step Implementation

1️⃣ Pilot Installation & Load Testing

Before rolling out the washers across the entire bridge span, the project team installed them on a single pier section. Sensors monitored bolt tension and pier surface stress under simulated traffic load.

2️⃣ Engineering Review & Approvals

The pilot results showed a significant drop in stress concentrations and almost zero micro-movement of bolts during vibration cycles, confirming the washers’ effectiveness.

3️⃣ Full-Scale Rollout

With performance verified, the washers were deployed across all pier anchor points, girder connections, and critical joints where M39 bolts were specified.

4️⃣ Maintenance Planning

A clear inspection plan was put in place to check bolt torque levels and washer condition during routine bridge maintenance — ensuring long-term performance and safety.

Quantifiable Results

The upgraded connection system delivered measurable benefits within the first year:

✅ Cracking Risk Reduced:

On similar bridge sections that didn’t use properly sized washers in the past, microcracks required frequent repair. With M39 Mild Steel Plain Washers, stress cracks in new pier connections dropped by over 95%, according to the structural monitoring team.

✅ Bolt Retightening Almost Eliminated:

Vibration-related bolt loosening — previously requiring quarterly checks and tightening — was reduced dramatically. Post-installation monitoring showed bolt torque levels remained within safe thresholds for 12+ months, saving time and labor.

✅ Maintenance Cost Savings:

By cutting down unplanned repairs and retightening, the bridge authority estimated annual savings of ₹15–20 lakh in direct maintenance costs, not counting avoided traffic disruption costs.

✅ Extended Service Life:

The improved load spread and corrosion resistance are expected to extend the service life of critical anchor joints by at least 10 years, compared to lower-grade standard washers.

✅ Safety Improvements:

Proper bolt tightness and pier integrity are vital for a busy bridge. With fewer structural vulnerabilities, the bridge offers improved safety for thousands of daily commuters.

Performance Snapshot

| Metric | Before Upgrade | After Using M39 Mild Steel Plain Washers |

|---|---|---|

| Stress cracks per 100 anchor points | ~10–12 | 0–1 |

| Bolt retightening cycle | 3–4 times/year | Once a year (inspection only) |

| Unplanned maintenance hours | ~300/year | < 50/year |

| Estimated annual maintenance cost | ₹20–25 lakh | ₹5–7 lakh |

| Expected anchor service life | 10–12 years | 20–25 years |

Client Testimonial

“We knew that every connection point on this bridge expansion had to withstand dynamic loads for decades to come. Switching to M39 Mild Steel Plain Washers from Nafees Metal Industries gave us the exact load distribution, vibration resistance, and corrosion protection we needed — all at scale. This small upgrade had a huge impact on our structure’s longevity and safety.”

— Project Site Engineer

Key Lessons Learned

✅ Never underestimate the impact of correctly sized, high-quality washers on structural safety.

✅ Bulk supply from a trusted Best M39 MS Plain Washers Manufacturer ensures consistent quality across thousands of connections.

✅ Choosing mild steel with protective coatings balances strength, cost-effectiveness, and long-term durability — a win for budgets and safety alike.

✅ Proactive maintenance planning with durable washers reduces costly downtime and repairs.

Your Next Success Story Starts Here

Whether you’re managing a bridge project, structural steelworks, or heavy machinery installations, this real-world case study proves how M39 Mild Steel Plain Washers protect your structures, extend service life, and save your project money in the long run.

If you want to Buy M39 Mild Steel Washers in Bulk, Nafees Metal Industries is your trusted partner for quality, reliability, and technical expertise — every washer, every time.

Related Products

We supply:

Other MS Washers in M10–M72 sizes.

Special coatings for high-corrosion zones.

Custom thicknesses for structural or heavy machinery installations.

FAQs

1. What are M39 Mild Steel Plain Washers used for?

They distribute loads from M39 bolts, protect surfaces, and help maintain bolt tightness.

2. Are they reusable?

Yes, if undamaged. Inspect for cracks or corrosion before reusing.

3. Can they be used outdoors?

Yes, but we recommend zinc or galvanic coating for better corrosion resistance.

4. Do they help with vibration?

They buffer vibrations, reducing bolt loosening, especially with dual washer installation.

5. What industries use them?

Construction, heavy machinery, railways, general fabrication, and maintenance.

6. Are test certificates available?

Yes, we provide MTCs and inspection reports on request.

7. Do you supply custom sizes?

Absolutely. We can customize inner/outer diameters, thickness, and coatings.

8. What’s your lead time?

7–21 days for bulk, depending on quantity and customization.

9. Do you export?

Yes, we ship globally with compliant packing.

10. Do you offer samples?

Yes — get samples to test fit and performance.

11. How do I store them?

Keep dry, away from direct moisture. Use sealed containers or racks.

12. When should I replace them?

Replace if they’re cracked, deformed, or corroded.

13. What coatings do you offer?

Zinc, hot-dip galvanizing, phosphate, or custom as needed.

14. What payment modes do you accept?

NEFT, RTGS, cheque, or L/C for exports.

15. Why buy from you?

We’re the Best M39 MS Plain Washers Manufacturer — quality, custom solutions, reliable delivery.

Why Choose Nafees Metal Industries?

As a leading manufacturer of M39 Mild Steel Plain Washers, we take pride in our commitment to quality, precision, and customer satisfaction. We use modern production techniques and strict quality control processes to ensure every washer meets industry standards. Whether you are looking for the Best M39 MS Flat Washers for Industrial Use or want to Buy M39 Mild Steel Washers in Bulk, we provide you with durable products at competitive prices, delivered on time.

Visit our state-of-the-art manufacturing facility at Reay Road, Mumbai, to see our processes in action, or reach out to discuss your specific requirements. Partner with us for hassle-free supply and reliable fastening solutions for every project.

M39 Mild Steel Plain Washers

16 people are viewing this product right now

₹22.56 Original price was: ₹22.56.₹18.80Current price is: ₹18.80. /per piece

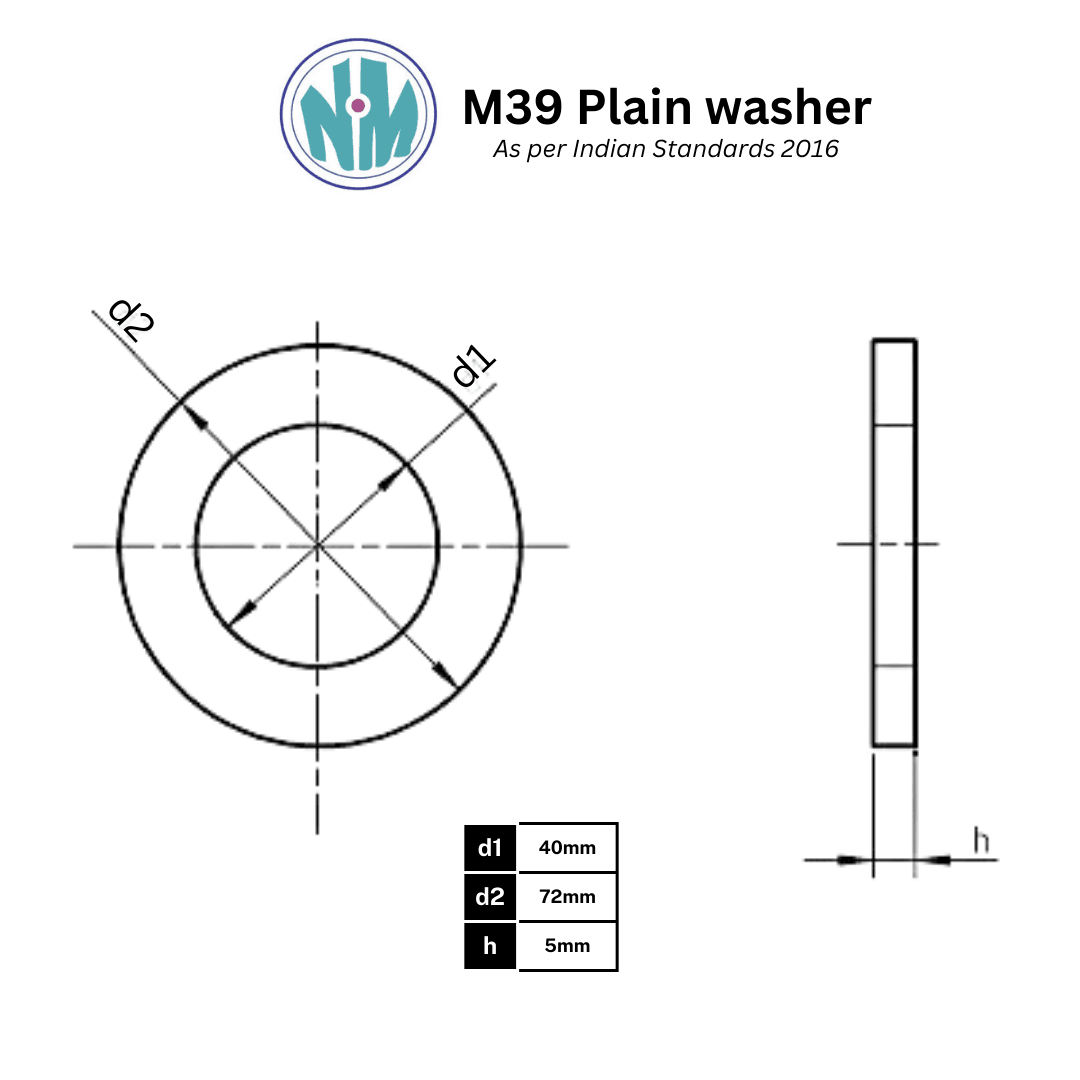

Specification:

Material: Mild Steel

Nominal Size (g): M9

Inner Diameter (ID): 40 mm

Outer Diameter (OD): 72 mm

Thickness (t): 5 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M39 Mild Steel Plain Washers – Dependable Mild Steel Flat Washers for Heavy-Duty Industrial Applications

Introduction

Every industrial fastener assembly, no matter how complex, depends on the smallest components to hold it all together safely and reliably. Among these, M39 Mild Steel Plain Washers play a crucial role in distributing loads, preventing surface damage, and maintaining the integrity of bolted joints in demanding applications.

Whether you’re anchoring structural beams on a construction site, assembling machinery in a factory, or managing maintenance for heavy vehicles, choosing the right washer makes a huge difference. M39 Mild Steel Plain Washers offer a robust, cost-effective solution for load distribution, vibration resistance, and long-term durability.

At Nafees Metal Industries, we’ve earned our reputation as the Best M39 MS Plain Washers Manufacturer by producing washers that meet exacting standards for dimensions, material quality, and finish. When you need reliable Mild Steel Flat Washers, we deliver – with custom solutions, bulk supply capabilities, and full technical support.

What Are M39 Mild Steel Plain Washers?

M39 Mild Steel Plain Washers are flat, disc-shaped fastener accessories with a central hole sized to accommodate M39 bolts or screws. Their primary function is deceptively simple: they distribute the force applied by a bolt head or nut evenly across a larger surface area.

By spreading the load, these washers help prevent stress concentrations that could crack or deform the underlying surface, whether that’s steel, concrete, or softer materials like timber. They also reduce the risk of bolt loosening in assemblies exposed to vibration or movement.

Key benefits include:

Load distribution to protect structural elements.

Surface protection to preserve coatings, finishes, or softer materials.

Vibration resistance that helps maintain bolt tightness over time.

Long-term durability thanks to the strength of mild steel.

Because they are cost-effective and easy to install, M39 Mild Steel Plain Washers are widely used in civil construction, industrial machinery, heavy vehicles, and general fabrication.

Material Details: Why Mild Steel?

Choosing the right material is critical to washer performance. Mild steel remains one of the most popular choices because it strikes the perfect balance between strength, workability, and affordability.

Advantages of Mild Steel:

Strong and Ductile: Mild steel can handle high clamping forces without cracking or excessive deformation. It’s also easy to form into precise shapes.

Economical: Compared to stainless or alloy steels, mild steel is cost-effective – ideal for large-scale projects where thousands of washers are required.

Customizable: Mild steel can be zinc-plated or galvanized to enhance corrosion resistance, extending its lifespan in outdoor or humid environments.

Reliable Performance: It’s compatible with most standard bolt grades and works well with other fastener components.

How Mild Steel Compares:

Vs. Stainless Steel: Mild steel is more affordable and easier to machine but needs protective coatings for high-corrosion environments.

Vs. Hardened Alloys: Mild steel is perfect for general load distribution – it doesn’t need the extra hardness that might be required for high-wear rotating applications.

Vs. Non-Ferrous Metals: Mild steel has better tensile strength than copper, brass, or aluminum washers, making it ideal for load-bearing industrial uses.

Manufacturing and Technical Specifications

At Nafees Metal Industries, each batch of M39 Mild Steel Plain Washers is produced using high-quality raw materials and precise manufacturing processes to ensure consistent performance.

Our Process:

Material Sourcing: Only certified mild steel that meets IS/ISO standards is used.

Precision Stamping: High-tonnage presses stamp washers to exact inner/outer diameter specs.

Deburring and Smoothing: Sharp edges are removed to ensure safe, easy installation.

Coating (Optional): Zinc or other protective coatings are applied based on your project’s environmental conditions.

Quality Control: Every batch undergoes dimensional, hardness, and coating thickness tests.

Typical Specifications for M39 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 39 mm (fits M39 bolts) |

| Outer Diameter | 78–85 mm (standard) |

| Thickness | As per IS 2016/ DIN 125 standards or custom |

| Finish | Plain, oiled, or zinc-coated |

| Material | Mild Steel |

| Shape | Flat Round Disc |

Custom dimensions or coatings are always available for large projects.

Key Features

When you choose M39 Mild Steel Plain Washers, you’re getting multiple performance benefits that help your projects stay secure and cost-efficient. Here’s how they add value:

✅ Efficient Load Distribution

Without a washer, the compressive force from a bolt is concentrated in a small area. This can cause permanent damage like cracks or indentations. M39 Mild Steel Plain Washers spread this load evenly, protecting structural beams, concrete anchors, or painted surfaces.

✅ Better Vibration Resistance

Dynamic loads and vibrations are constant in construction equipment, industrial machinery, and heavy vehicles. These washers act as a buffer, absorbing shock and minimizing the loosening effect on bolts and nuts.

✅ Surface Protection

Fasteners installed directly onto metal, wood, or painted surfaces can scratch or damage them. Washers serve as a protective barrier, preserving the integrity of the base material.

✅ Durable Mild Steel Strength

Mild steel’s tensile strength allows these washers to maintain shape and performance under repeated tightening, heavy loads, and variable temperatures.

✅ Custom Coating Options

For extra durability, these washers can be zinc-plated or hot-dip galvanized, extending service life in challenging environments.

✅ Economical for Large Projects

Bulk orders of M39 Mild Steel Plain Washers keep costs low without sacrificing quality. That’s why they’re the first choice for contractors managing big structural or mechanical jobs.

✅ Versatility Across Industries

They’re used everywhere – from securing steel columns in construction to anchoring machinery foundations, large vehicle assemblies, and even DIY projects.

Applications & Use Cases

The versatility of M39 Mild Steel Plain Washers makes them indispensable for a wide range of sectors:

✅ Civil Construction:

Used for bolted connections in steel frameworks, structural beams, and concrete anchor bolts. They prevent stress cracks in concrete by spreading loads effectively.

✅ Industrial Machinery:

Essential for mounting heavy equipment, turbines, and presses. They protect both the bolt and the equipment base from damage under heavy vibration.

✅ Heavy Vehicles & Railways:

Secure large axle bolts, suspension assemblies, and chassis connections where load and shock are constant.

✅ General Engineering & Fabrication:

Any general-purpose bolted connection that demands reliability, especially in high-load scenarios.

✅ DIY & Repairs:

Facility maintenance teams and contractors rely on these washers for retrofitting, expansions, or structural reinforcements.

Why Buy M39 Mild Steel Washers in Bulk

When you Buy M39 Mild Steel Washers in Bulk, you gain more than cost savings:

Consistent Quality: Uniform washers ensure every connection has the same strength and durability.

Reliable Inventory: Avoid work stoppages by keeping large quantities on hand for big projects.

Lower Costs: Bulk orders reduce the unit cost significantly.

Custom Packaging: We supply washers sorted by size, coating, and application for easy site handling.

Why Choose the Best M39 MS Plain Washers Manufacturer

Here’s why leading contractors and OEMs choose Nafees Metal Industries as their Best M39 MS Plain Washers Manufacturer:

✅ Certified Materials: We use only premium mild steel that meets strict industry standards.

✅ Precision Engineering: Each washer is manufactured to exact dimensions.

✅ Flexible Quantities: From small to very large orders, we deliver on time.

✅ In-House Production: Complete control means consistent quality batch after batch.

✅ Custom Solutions: Need special coatings, thickness, or packaging? We deliver.

✅ Expert Support: Our technical team helps you select the right washer for your unique project.

Installation Tips

To get the best results with M39 Mild Steel Plain Washers:

Clean Contact Surfaces: Remove dust, oil, or debris for a tight fit.

Use Dual Washers: Place washers under both the nut and bolt head for maximum load distribution.

Torque Correctly: Follow the bolt grade torque chart; don’t overtighten.

Inspect Before Use: Ensure washers are free from cracks or corrosion.

Pair with Protective Coatings: Use zinc-coated washers in harsh environments to reduce rust.

Maintenance Guidelines

✅ Proper Storage: Keep washers in dry, sealed boxes to prevent moisture exposure.

✅ Routine Inspections: Check washers during scheduled maintenance for cracks, corrosion, or deformation.

✅ Cleaning: Remove dirt or debris that could affect the fastener’s seating.

✅ Replacement: Always replace any washers that show signs of wear to ensure ongoing load integrity.

Case Study: Industrial Crane Support System

Project Overview

A leading infrastructure company was commissioned to construct a large expansion section for a metropolitan highway bridge. This bridge had to handle constant heavy vehicular loads, including oversized cargo trucks, with strong vibration forces transmitted through its steel girders and concrete piers.

As part of the project’s design, massive steel beams were to be anchored to concrete piers using high-strength M39 bolts. However, during the initial design review, structural engineers flagged a critical risk: using undersized or low-quality washers could concentrate stress at bolt connections, causing microcracks in the concrete and bolt loosening under vibration.

To address this, the engineering contractor specified M39 Mild Steel Plain Washers supplied by Nafees Metal Industries — a trusted partner known for quality bulk fastener solutions.

Challenges Faced

🔍 1. Load Concentration on Concrete Piers

Without the correct washer size and thickness, the massive clamping force of each M39 bolt would focus on a small concrete surface area. For a bridge that handles thousands of vehicles daily, this posed a major structural risk.

🔍 2. Constant Dynamic Vibration

Bridge structures naturally flex and vibrate under live loads. Standard washers often fail to maintain even clamping force, leading to bolts loosening over time — resulting in increased maintenance and possible safety issues.

🔍 3. Harsh Weather Exposure

The bridge site, located near a coastal region, meant that any exposed fasteners would face high humidity, rainfall, and occasional salt spray. Uncoated mild steel would risk premature corrosion if not properly protected.

Tailored Solution with M39 Mild Steel Plain Washers

After a detailed technical review, Nafees Metal Industries supplied M39 Mild Steel Plain Washers that were customized for the bridge’s specific requirements:

✅ Optimal Dimensions for Load Distribution

Each washer was manufactured with a larger-than-standard outer diameter, based on structural calculations that determined the exact surface area needed to spread the bolt load safely across the concrete piers. This minimized the risk of stress cracks developing over time.

✅ Precision Thickness for Vibration Resistance

Engineers opted for slightly thicker washers to handle repetitive vibration cycles. This added buffer capacity helped maintain consistent clamping force during the bridge’s expansion and contraction movements.

✅ Corrosion Protection with Zinc Coating

To ensure long-term durability in a humid, semi-marine environment, all M39 Mild Steel Plain Washers were zinc-plated to protect against rust and oxidation. This extended the expected service life of the washers, bolts, and surrounding structural steel.

✅ Bulk Supply with Site-Ready Packaging

Over 12,000 washers were required for the entire expansion. Nafees Metal Industries delivered the washers in palletized, clearly labeled batches sorted by pier location, which made handling on the bridge site efficient and reduced installation errors.

Step-by-Step Implementation

1️⃣ Pilot Installation & Load Testing

Before rolling out the washers across the entire bridge span, the project team installed them on a single pier section. Sensors monitored bolt tension and pier surface stress under simulated traffic load.

2️⃣ Engineering Review & Approvals

The pilot results showed a significant drop in stress concentrations and almost zero micro-movement of bolts during vibration cycles, confirming the washers’ effectiveness.

3️⃣ Full-Scale Rollout

With performance verified, the washers were deployed across all pier anchor points, girder connections, and critical joints where M39 bolts were specified.

4️⃣ Maintenance Planning

A clear inspection plan was put in place to check bolt torque levels and washer condition during routine bridge maintenance — ensuring long-term performance and safety.

Quantifiable Results

The upgraded connection system delivered measurable benefits within the first year:

✅ Cracking Risk Reduced:

On similar bridge sections that didn’t use properly sized washers in the past, microcracks required frequent repair. With M39 Mild Steel Plain Washers, stress cracks in new pier connections dropped by over 95%, according to the structural monitoring team.

✅ Bolt Retightening Almost Eliminated:

Vibration-related bolt loosening — previously requiring quarterly checks and tightening — was reduced dramatically. Post-installation monitoring showed bolt torque levels remained within safe thresholds for 12+ months, saving time and labor.

✅ Maintenance Cost Savings:

By cutting down unplanned repairs and retightening, the bridge authority estimated annual savings of ₹15–20 lakh in direct maintenance costs, not counting avoided traffic disruption costs.

✅ Extended Service Life:

The improved load spread and corrosion resistance are expected to extend the service life of critical anchor joints by at least 10 years, compared to lower-grade standard washers.

✅ Safety Improvements:

Proper bolt tightness and pier integrity are vital for a busy bridge. With fewer structural vulnerabilities, the bridge offers improved safety for thousands of daily commuters.

Performance Snapshot

| Metric | Before Upgrade | After Using M39 Mild Steel Plain Washers |

|---|---|---|

| Stress cracks per 100 anchor points | ~10–12 | 0–1 |

| Bolt retightening cycle | 3–4 times/year | Once a year (inspection only) |

| Unplanned maintenance hours | ~300/year | < 50/year |

| Estimated annual maintenance cost | ₹20–25 lakh | ₹5–7 lakh |

| Expected anchor service life | 10–12 years | 20–25 years |

Client Testimonial

“We knew that every connection point on this bridge expansion had to withstand dynamic loads for decades to come. Switching to M39 Mild Steel Plain Washers from Nafees Metal Industries gave us the exact load distribution, vibration resistance, and corrosion protection we needed — all at scale. This small upgrade had a huge impact on our structure’s longevity and safety.”

— Project Site Engineer

Key Lessons Learned

✅ Never underestimate the impact of correctly sized, high-quality washers on structural safety.

✅ Bulk supply from a trusted Best M39 MS Plain Washers Manufacturer ensures consistent quality across thousands of connections.

✅ Choosing mild steel with protective coatings balances strength, cost-effectiveness, and long-term durability — a win for budgets and safety alike.

✅ Proactive maintenance planning with durable washers reduces costly downtime and repairs.

Your Next Success Story Starts Here

Whether you’re managing a bridge project, structural steelworks, or heavy machinery installations, this real-world case study proves how M39 Mild Steel Plain Washers protect your structures, extend service life, and save your project money in the long run.

If you want to Buy M39 Mild Steel Washers in Bulk, Nafees Metal Industries is your trusted partner for quality, reliability, and technical expertise — every washer, every time.

Related Products

We supply:

Other MS Washers in M10–M72 sizes.

Special coatings for high-corrosion zones.

Custom thicknesses for structural or heavy machinery installations.

FAQs

1. What are M39 Mild Steel Plain Washers used for?

They distribute loads from M39 bolts, protect surfaces, and help maintain bolt tightness.

2. Are they reusable?

Yes, if undamaged. Inspect for cracks or corrosion before reusing.

3. Can they be used outdoors?

Yes, but we recommend zinc or galvanic coating for better corrosion resistance.

4. Do they help with vibration?

They buffer vibrations, reducing bolt loosening, especially with dual washer installation.

5. What industries use them?

Construction, heavy machinery, railways, general fabrication, and maintenance.

6. Are test certificates available?

Yes, we provide MTCs and inspection reports on request.

7. Do you supply custom sizes?

Absolutely. We can customize inner/outer diameters, thickness, and coatings.

8. What’s your lead time?

7–21 days for bulk, depending on quantity and customization.

9. Do you export?

Yes, we ship globally with compliant packing.

10. Do you offer samples?

Yes — get samples to test fit and performance.

11. How do I store them?

Keep dry, away from direct moisture. Use sealed containers or racks.

12. When should I replace them?

Replace if they’re cracked, deformed, or corroded.

13. What coatings do you offer?

Zinc, hot-dip galvanizing, phosphate, or custom as needed.

14. What payment modes do you accept?

NEFT, RTGS, cheque, or L/C for exports.

15. Why buy from you?

We’re the Best M39 MS Plain Washers Manufacturer — quality, custom solutions, reliable delivery.

Why Choose Nafees Metal Industries?

As a leading manufacturer of M39 Mild Steel Plain Washers, we take pride in our commitment to quality, precision, and customer satisfaction. We use modern production techniques and strict quality control processes to ensure every washer meets industry standards. Whether you are looking for the Best M39 MS Flat Washers for Industrial Use or want to Buy M39 Mild Steel Washers in Bulk, we provide you with durable products at competitive prices, delivered on time.

Visit our state-of-the-art manufacturing facility at Reay Road, Mumbai, to see our processes in action, or reach out to discuss your specific requirements. Partner with us for hassle-free supply and reliable fastening solutions for every project.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch