No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

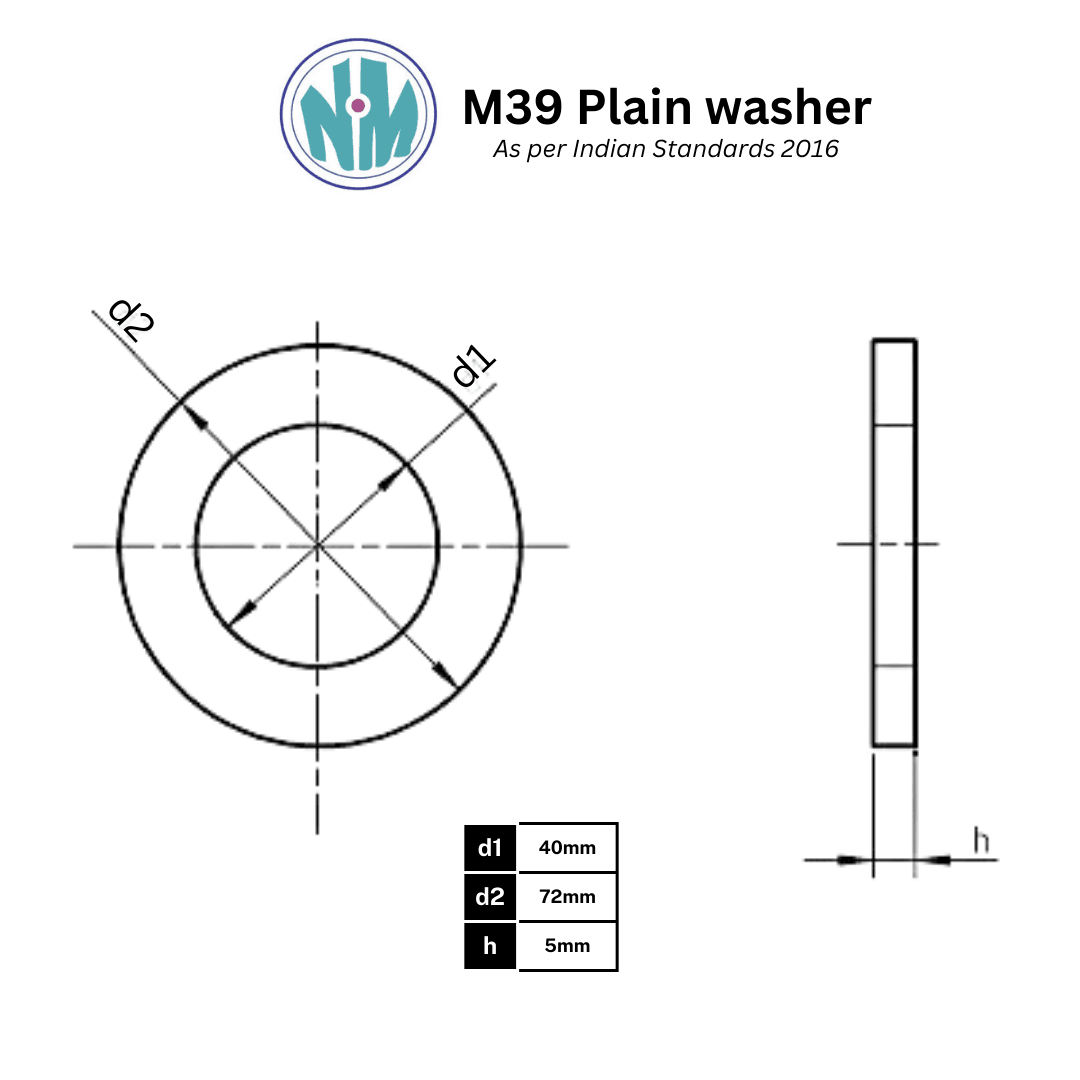

*Images shown for graphic representation. Not to scale.

M39 Copper Plain Washers – Premium Industrial Copper Flat Washers for Corrosion-Resistant Fastening

At Nafees Metal Industries, we take pride in being among the best manufacturers and suppliers of premium-grade copper washers in India. Our M39 Copper Plain Washers are engineered with precision to deliver unmatched performance in high-demand industrial and mechanical fastening applications. As a reputed name in the washer manufacturing industry, our focus on quality, durability, and dimensional accuracy ensures that each M39 washer meets the most stringent international standards.

M39 Copper Plain Washers are circular flat washers with an internal diameter suited for M39 bolts and screws. These washers are manufactured using high-purity copper, providing exceptional conductivity, corrosion resistance, and thermal stability. Ideal for heavy-duty electrical applications, mechanical joints, fluid sealing systems, and marine-grade assemblies, these washers serve as reliable load distributors and vibration dampeners while preventing damage to connected surfaces.

Designed for industries where both mechanical performance and electrical integrity are critical, our M39 Copper Plain Washers are widely trusted across power distribution systems, switchgear assemblies, heavy machinery, and high-vibration environments. We strictly adhere to DIN 125 standards for all our copper washers, ensuring compatibility with global metric specifications and M-series bolt dimensions.

What truly sets us apart as one of the best manufacturers of copper plain washers in India is our ability to provide precision-made components with custom surface treatments, exact tolerances, and fast delivery across domestic and international markets. With a fully equipped manufacturing facility in Mumbai, our team ensures each washer undergoes thorough inspection to guarantee optimal performance under operational stress.

Whether you are looking to buy M39 Copper Plain Washers in bulk, need custom specifications, or want expert guidance for your assembly requirements, Nafees Metal Industries is your trusted partner for quality, reliability, and supply consistency in the copper washer segment.

What Are M39 Copper Plain Washers?

M39 Copper Plain Washers are large-diameter flat washers specifically designed to fit M39 metric bolts and screws. These washers serve as essential components in fastening systems by providing an even load distribution across the surface area of bolted joints. Manufactured from high-purity, soft-drawn copper, these washers are particularly valued in industries where electrical conductivity, thermal performance, and corrosion resistance are non-negotiable.

As per DIN 125 copper flat washers metric series, these washers conform to standardized dimensions that ensure compatibility with metric fasteners in the M-series. Their smooth surface and consistent thickness make them ideal for protecting equipment surfaces, reducing friction, preventing bolt loosening due to vibration, and maintaining torque consistency.

In industries such as power transmission, electronics, oil and gas, marine engineering, automotive, and HVAC systems, M39 Copper Plain Washers are trusted components in critical applications. They are also used in gaskets, electrical contacts, busbars, and heat-sensitive assemblies. Thanks to their metallic softness and ductility, copper washers can form a tight seal even under uneven or imperfect surfaces—making them suitable for industrial copper flat washer corrosion resistant installations.

At Nafees Metal Industries, each washer is crafted with precision, meeting both mechanical and electrical performance benchmarks. Whether you’re working with high-amperage electrical connections or corrosive environments like marine or chemical plants, our copper plain washers are engineered to endure the demands of industrial applications.

Why Choose Copper for M39 Washers?

Choosing copper as the base material for M39 plain washers is driven by both performance and reliability. Copper is a non-ferrous, corrosion-resistant, and highly conductive metal—making it ideal for applications that demand electrical connectivity, thermal dissipation, sealing capabilities, and long-term stability in harsh environments.

Here’s why copper is preferred for M39 Copper Plain Washers:

Excellent Electrical Conductivity

Copper is the second-best conductor of electricity after silver. In electrical installations, copper flat washers DIN 125 are commonly used to maintain uninterrupted current flow, minimize resistance, and prevent heat buildup around fasteners in electrical terminals and power busbars.Superior Corrosion Resistance

Copper naturally resists oxidation and corrosion in both dry and moist environments. This makes M39 Copper Plain Washers ideal for marine, chemical, and outdoor applications where ferrous washers would degrade over time. These washers are especially effective in industrial copper flat washer corrosion resistant assemblies.Thermal Conductivity

When bolts are exposed to high temperatures, copper acts as a heat sink, dissipating heat efficiently. That’s why copper plain washer M‑series metric size is commonly used in engines, generators, HVAC systems, and heavy electrical equipment.Soft and Ductile for Better Sealing

Copper’s malleability enables it to deform slightly when compressed, ensuring tight sealing even on uneven surfaces. This makes it perfect for applications in hydraulics, pneumatics, and flanged joints.Chemical Compatibility

Copper shows excellent resistance to many industrial fluids, making DIN 125 copper flat washers metric series suitable for oil & gas refineries, plumbing systems, and petrochemical installations.Non-Magnetic and Non-Sparking

In sensitive areas like mining, aerospace, and defense where spark prevention is crucial, copper is preferred due to its non-sparking and non-magnetic properties.Long Service Life

Copper does not become brittle or degrade over time like plastic or rubber washers. It retains its structural integrity, providing dependable performance over years of use.Aesthetic and Premium Appearance

In high-end equipment or visible fittings, the reddish sheen of copper adds a professional finish to assemblies—ideal for architectural or showcase installations.

How Are M39 Copper Plain Washers Manufactured?

At Nafees Metal Industries, we manufacture M39 Copper Plain Washers through a precision-driven process that ensures dimensional accuracy, corrosion resistance, and long-term durability. As one of the leading copper washer manufacturers in India, we follow ISO-certified protocols and deploy advanced tooling technology to produce washers that meet the highest industrial standards.

Here’s a detailed look at our manufacturing process:

Raw Material Selection – High-Grade Electrolytic Copper

We source high-purity electrolytic copper (minimum 99.9% purity), ensuring excellent conductivity, malleability, and anti-corrosive properties. The copper sheets are tested for thickness, grain uniformity, and chemical composition before processing.Cold Rolling and Sheet Preparation

The copper sheets are cold-rolled to achieve uniform thickness suitable for M39-sized washers. Cold rolling increases the metal’s strength while maintaining its ductility—ideal for large-diameter applications like M39 Copper Plain Washers.Precision Punching Using CNC Tools

The washer blanks are punched using CNC-controlled high-tonnage power presses. This ensures consistent inner diameter (ID), outer diameter (OD), and flatness for each piece. The M39 size corresponds to a 39 mm bolt/screw diameter, and our process ensures exact fitment with minimal tolerance deviation.Deburring and Edge Smoothing

To eliminate sharp edges and burrs, each washer undergoes mechanical or vibratory deburring. Smooth edges are critical in preventing damage to surfaces and maintaining sealing effectiveness during fastening.Annealing (If Required)

For certain applications requiring extra softness or increased ductility, washers are annealed in a controlled atmosphere furnace. This heat treatment ensures stress relief and enhances the sealing performance, especially under thermal expansion.Surface Cleaning and Polishing

Washers are cleaned using ultrasonic or solvent-based systems to remove any residual oil, dirt, or oxidation. A final polishing step gives the washers a smooth, bright finish suitable for both functional and aesthetic use.Coating or Protective Film (Optional)

While copper itself is corrosion-resistant, some clients require additional protection or patina control. We offer options like clear coatings, anti-tarnish lacquers, or oxidation-resistant packaging for long-term storage and shipment.Dimensional and Quality Inspection

Every batch is subjected to stringent quality checks including:ID/OD tolerance measurement

Thickness accuracy (as per DIN 125 standard)

Surface integrity and roundness

Hardness and tensile testing (as required)

This ensures each M39 Copper Plain Washer complies with industry standards such as DIN 125, IS 2016, and ISO 7089.

Custom Packaging and Labeling

Based on the buyer’s needs, we offer washers in polybags, corrugated boxes, or export-quality cartons. Labeling includes product size, batch number, coating details, and compliance tags for easy traceability.

Key Features of M39 Copper Plain Washers

Nafees Metal Industries’ M39 Copper Plain Washers are engineered with a high level of precision, designed to deliver reliable performance in industrial environments where strength, conductivity, and corrosion resistance are essential. As one of the best copper washer manufacturers in India, we ensure every washer meets the exacting demands of our clients across electrical, mechanical, and heavy-duty fastening applications.

Here are the standout features of our M39 Copper Plain Washers:

1. Accurate Fitment for M39 Fasteners

Each washer is crafted to fit M39 bolts or screws with absolute precision. The inner diameter is designed to snugly accommodate the fastener shank, ensuring stable and vibration-free assemblies.

2. Manufactured from Pure Electrolytic Copper

We use high-purity copper with excellent conductivity and corrosion resistance. The material complies with industrial-grade copper standards, ensuring longevity and optimal performance under mechanical and electrical loads.

3. Compliant with DIN 125 Standards

Our M39 Copper Plain Washers conform to DIN 125 specifications, ensuring global compatibility in metric systems. This makes them ideal replacements for OEM parts or use in export-grade assemblies.

4. Excellent Load Distribution

The wide outer diameter of the washer helps distribute load uniformly over the surface, preventing surface damage and increasing joint stability—especially in high-torque or oversized applications.

5. Superior Corrosion Resistance

Copper’s natural resistance to moisture, chemicals, and oxidation makes it the best choice for washers used in outdoor, marine, electrical, and chemical processing environments.

6. Smooth, Burr-Free Surface

Post-punching, every washer undergoes deburring and surface finishing processes. This eliminates sharp edges and ensures safe handling, better sealing, and easier integration into assemblies.

7. Available with Custom Coating Options

Though copper is naturally corrosion-resistant, optional coatings (such as anti-tarnish lacquer or oxidation protectants) are available to enhance shelf-life or aesthetic requirements.

8. High Conductivity for Electrical Applications

Being made from pure copper, these washers ensure uninterrupted conductivity, making them ideal for use in grounding systems, battery terminals, switchgear, and control panels.

9. Heat and Pressure Resilient

Copper has high thermal conductivity and can withstand extreme pressure and temperature fluctuations, making it suitable for high-load industrial applications.

10. Multiple Thickness Options Available

We offer customizable thickness ranges based on customer needs—whether for sealing, spacing, or high-load bearing purposes. Standard and custom dimensions are both supported.

11. Eco-Friendly and 100% Recyclable

Copper washers are a sustainable choice due to their reusability and minimal environmental impact. All our washers are RoHS-compliant and environmentally responsible.

12. Bulk Ready with Fast Turnaround

Our Mumbai-based facility maintains a large inventory of standard sizes like M39, enabling fast dispatch for bulk orders. We also accept made-to-order requests with short lead times.

13. Packaging Options for OEMs and Exporters

From small polybag packaging to bulk cartons with barcode labeling, we offer packaging solutions tailored to OEMs, resellers, and export partners.

14. Proudly Made in India

Every washer is manufactured in-house at our Mumbai factory, combining local skill with advanced production processes under the “Make in India” initiative.

15. Trusted by Industry Leaders

Nafees Metal Industries has earned the trust of manufacturers, EPC contractors, automotive assemblers, and electronic component makers across India and the Middle East for our consistent washer quality and professional support.

Applications of M39 Copper Plain Washers

Electrical Panels & Circuit Breakers – Ensures effective grounding and heat dissipation.

Transformers & Switchgears – High-conductivity fastener support.

Marine & Offshore Installations – Corrosion-resistant joint sealing.

HVAC Systems & Plumbing – Leak-proof sealing under thermal expansion.

Automotive & Railways – Used in terminals, battery connectors, and assemblies.

Solar Panels & Wind Turbines – Grounding and weather-resistant fasteners.

Medical & Defense Equipment – Non-magnetic and oxidation-resistant washers.

M39 Copper Washers Size & Technical Specifications

| Property | Specification |

|---|---|

| Product Name | M39 Copper Plain Washer |

| Material | High-Grade Copper |

| Inner Diameter (ID) | Approx. 39.5 mm (for M39 bolts) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 |

| Thickness | 2.0 mm (customizable from 1.0–5.0 mm) |

| Surface Finish | Polished / Plain / Tinned |

| Metric Size | M-Series (M39) |

| Corrosion Resistance | Excellent (suitable for marine exposure) |

| Standard Compliance | DIN 125 / IS 2016 |

| Packaging | Bulk, Poly Bag, or Custom Export Packs |

| Made in India | Yes – Manufactured in Mumbai |

At Nafees Metal Industries, our M39 Copper Plain Washers are manufactured to meet the highest engineering standards and dimensional accuracy. These washers are carefully designed for demanding applications where both mechanical stability and electrical conductivity are essential. Below are the complete specifications:

1. Product Name:

M39 Copper Plain Washers

2. Material Composition:

High-grade electrolytic copper (≥99.9% purity)

Compliant with IS, ASTM B152, and RoHS environmental standards

3. Size Details:

Inner Diameter (ID): 39 mm (precisely matching M39 bolt shank)

Outer Diameter (OD): 65 mm (customizable upon request)

Thickness: Standard: 3 mm (Available from 1 mm to 5 mm)

Tolerance: ±0.1 mm (ID/OD/Thickness)

4. Standard Compliance:

Conforms to DIN 125 / IS 2016 standards

Compatible with ISO metric bolt systems

Meets industrial requirements for copper flat washers

5. Surface Finish Options:

Natural copper finish (standard)

Optional anti-tarnish lacquer coating

Electropolished or bright finish for premium applications

6. Hardness:

Typically HV 40-60 (annealed copper)

Work-hardened versions available upon request

7. Electrical Conductivity:

Excellent electrical performance

IACS conductivity ≥ 97%

Ideal for electrical grounding and busbar systems

8. Thermal Resistance:

Service temperature range: -50°C to 300°C

Does not degrade under thermal cycling or vibration

9. Corrosion Resistance:

Naturally corrosion-resistant in atmospheric and mildly acidic environments

Optional protective coatings for harsh environments available

10. Manufacturing Process:

CNC-punched from cold-rolled copper sheets

Deburred and quality-checked manually and via precision instruments

Custom sizes can be laser-cut or press-formed for large orders

11. Customization Options:

Custom ID, OD, and thickness ranges

Logo stamping or part number engraving

Packaging customization (bulk, box, bag with barcode)

12. Packaging & Supply:

Packed in polybags or boxes of 100 / 500 / 1000 units

Export-ready packaging with labeling

MOQ: 500 units

Ready stock available for standard M39 size

13. Application Standards:

Suitable for use in electrical panels, grounding assemblies, oil & gas pipelines, marine structures, HVAC systems, and pressure vessels.

14. Country of Origin:

India – Manufactured at our Mumbai-based ISO-certified facility

15. Brand:

Nafees Metal Industries – Trusted Copper Washer Manufacturer in India

Why Choose Nafees Metal Industries for M39 Copper Washers?

Top Manufacturer of Copper Washers in India with over two decades of experience.

Custom Sizing and Thickness Available – Full support for OEM and export specifications.

Fast Dispatch and Nationwide Delivery – In-stock washers available for immediate shipping.

Expert Support Team – Technical consultation for usage, compatibility, and volume requirements.

Strict Quality Checks – From raw material sourcing to dispatch.

We are a proud part of the Make in India initiative, supplying to industries across India, UAE, Africa, and Southeast Asia and across the world

Buy Bulk M20 SS304 Plain Washers – Top-Grade Alternatives Also Available

Though this page focuses on M39 Copper Plain Washers, we also specialize in M20 SS304 Plain Washers—ideal for high-strength and corrosion-resistant fastening. These washers are in high demand for heavy-duty industrial and structural applications. If you’re seeking a cost-effective and reliable alternative to copper, consider our stainless steel variants.

FAQs About M39 Copper Plain Washers

1. What are M39 Copper Plain Washers used for?

M39 Copper Plain Washers are used to evenly distribute the load of M39 bolts or screws, reduce surface damage, and enhance conductivity in mechanical and electrical assemblies. They are ideal for high-load, high-conductivity applications like transformers, switchgears, and earthing systems.

2. Why should I choose copper washers over steel washers?

Copper washers offer excellent thermal and electrical conductivity, corrosion resistance, and a non-sparking property. They are superior for use in electrical and chemical environments compared to steel washers.

3. Are your M39 Copper Plain Washers manufactured in India?

Yes, all our copper washers, including M39 size, are proudly manufactured in our ISO-certified facility in Mumbai, India. Nafees Metal Industries is one of the leading copper washer manufacturers in India.

4. What is the inner diameter of an M39 copper washer?

The inner diameter is precisely 39 mm to accommodate M39 bolts or threaded fasteners, as per DIN 125 copper flat washers metric series.

5. Do your washers comply with DIN standards?

Yes, our M39 Copper Plain Washers comply with DIN 125 and IS 2016 standards for flat washers. Custom dimensions can be made upon request.

6. Are these washers suitable for electrical grounding?

Absolutely. Copper has excellent conductivity, and our washers are widely used in grounding applications, control panels, busbars, and electrical switchboards.

7. Can I use M39 copper plain washers in marine environments?

Yes. Copper is naturally corrosion-resistant. For prolonged marine exposure, we recommend a protective coating to enhance performance.

8. What finishes are available for M39 copper flat washers?

We offer natural copper finish (standard), anti-tarnish lacquer coating, electropolished finish, and custom coatings depending on your application’s environment.

9. Are bulk and custom packaging options available?

Yes. We offer flexible packaging—from bulk cartons to custom barcoded bags. Packaging can be tailored for retail, OEM supply, or export needs.

10. What is the minimum order quantity (MOQ)?

Our standard MOQ is 500 pieces for M39 Copper Plain Washers. For trial orders or custom sizes, MOQ terms can be flexible.

11. Can I get M39 copper washers with my company logo or part number engraved?

Yes. We offer custom stamping, logo engraving, or part number marking for OEMs and industrial buyers.

12. What is the delivery time for M39 copper washers?

Ready-stock orders are dispatched within 1–3 business days. Custom orders may take 7–10 working days depending on volume and finish.

13. What makes Nafees Metal Industries the best manufacturer of copper washers in India?

We combine advanced manufacturing, strict quality control, rapid order fulfillment, competitive pricing, and customizable solutions. Our products meet both Indian and global standards.

14. Are M39 copper plain washers reusable?

Yes, if not deformed during tightening, these washers can be reused, especially in non-critical or low-stress applications.

15. How do I place a bulk order?

You can reach out via our website https://nafeesmetalindustries.com, email us, or call directly. Our team will assist you with specifications, pricing, and logistics.

Why Choose Nafees Metal Industries for M39 Copper Plain Washers?

At Nafees Metal Industries, we are more than just manufacturers — we are solution providers trusted by industrial clients across India and abroad. Here’s why leading OEMs, electrical engineers, and heavy machinery manufacturers rely on us for M39 Copper Plain Washers and other fastening solutions:

Specialized Expertise in Copper Washers

With years of hands-on experience, we have mastered the art of manufacturing copper plain washers across all standard and custom sizes — including M3 to M100 and beyond.Precision Engineering

Our copper washers conform to strict tolerance limits with flawless concentricity, smooth finishes, and uniform thickness — ideal for both electrical conductivity and structural reliability.Material Traceability & Purity

We use high-conductivity industrial-grade copper sheets, fully tested for mechanical properties and purity. Every washer is made from certified material that meets or exceeds DIN and IS standards.ISO-Certified Manufacturing

Our facility in Mumbai operates under ISO-certified processes, using CNC presses, automated deburring systems, and skilled manual inspections to ensure unmatched quality.Bulk Supply & Custom Orders

Whether you need 1,000 or 1 million M39 Copper Plain Washers, we offer consistent supply, flexible packaging, and customization options based on your design or coating requirements.Competitive Pricing with Zero Compromise on Quality

As a direct manufacturer, we control the entire production process in-house — resulting in better prices and higher reliability compared to resellers or importers.Fast Dispatch Across India & Export-Ready Logistics

Our logistics team ensures prompt deliveries pan-India and internationally, complete with all export documents, test certificates, and HS codes.

Visit Our Manufacturing Unit

We welcome our clients and sourcing teams to witness our production in action at our Mumbai-based facility. Whether you’re auditing suppliers or exploring partnerships, a guided visit gives you firsthand insight into:

Our modern machine shop and press lines

Raw material storage and quality control labs

Packaging, dispatch, and inventory zones

Customization and prototyping units

To schedule your visit, please contact us via contact form or call us directly. We’ll be happy to organize a walkthrough tailored to your interest.

M39 Copper Plain washers (DIN 125)

27 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M9

Inner Diameter (ID): 40 mm

Outer Diameter (OD): 72 mm

Thickness (t): 5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M39 Copper Plain Washers – Premium Industrial Copper Flat Washers for Corrosion-Resistant Fastening

At Nafees Metal Industries, we take pride in being among the best manufacturers and suppliers of premium-grade copper washers in India. Our M39 Copper Plain Washers are engineered with precision to deliver unmatched performance in high-demand industrial and mechanical fastening applications. As a reputed name in the washer manufacturing industry, our focus on quality, durability, and dimensional accuracy ensures that each M39 washer meets the most stringent international standards.

M39 Copper Plain Washers are circular flat washers with an internal diameter suited for M39 bolts and screws. These washers are manufactured using high-purity copper, providing exceptional conductivity, corrosion resistance, and thermal stability. Ideal for heavy-duty electrical applications, mechanical joints, fluid sealing systems, and marine-grade assemblies, these washers serve as reliable load distributors and vibration dampeners while preventing damage to connected surfaces.

Designed for industries where both mechanical performance and electrical integrity are critical, our M39 Copper Plain Washers are widely trusted across power distribution systems, switchgear assemblies, heavy machinery, and high-vibration environments. We strictly adhere to DIN 125 standards for all our copper washers, ensuring compatibility with global metric specifications and M-series bolt dimensions.

What truly sets us apart as one of the best manufacturers of copper plain washers in India is our ability to provide precision-made components with custom surface treatments, exact tolerances, and fast delivery across domestic and international markets. With a fully equipped manufacturing facility in Mumbai, our team ensures each washer undergoes thorough inspection to guarantee optimal performance under operational stress.

Whether you are looking to buy M39 Copper Plain Washers in bulk, need custom specifications, or want expert guidance for your assembly requirements, Nafees Metal Industries is your trusted partner for quality, reliability, and supply consistency in the copper washer segment.

What Are M39 Copper Plain Washers?

M39 Copper Plain Washers are large-diameter flat washers specifically designed to fit M39 metric bolts and screws. These washers serve as essential components in fastening systems by providing an even load distribution across the surface area of bolted joints. Manufactured from high-purity, soft-drawn copper, these washers are particularly valued in industries where electrical conductivity, thermal performance, and corrosion resistance are non-negotiable.

As per DIN 125 copper flat washers metric series, these washers conform to standardized dimensions that ensure compatibility with metric fasteners in the M-series. Their smooth surface and consistent thickness make them ideal for protecting equipment surfaces, reducing friction, preventing bolt loosening due to vibration, and maintaining torque consistency.

In industries such as power transmission, electronics, oil and gas, marine engineering, automotive, and HVAC systems, M39 Copper Plain Washers are trusted components in critical applications. They are also used in gaskets, electrical contacts, busbars, and heat-sensitive assemblies. Thanks to their metallic softness and ductility, copper washers can form a tight seal even under uneven or imperfect surfaces—making them suitable for industrial copper flat washer corrosion resistant installations.

At Nafees Metal Industries, each washer is crafted with precision, meeting both mechanical and electrical performance benchmarks. Whether you’re working with high-amperage electrical connections or corrosive environments like marine or chemical plants, our copper plain washers are engineered to endure the demands of industrial applications.

Why Choose Copper for M39 Washers?

Choosing copper as the base material for M39 plain washers is driven by both performance and reliability. Copper is a non-ferrous, corrosion-resistant, and highly conductive metal—making it ideal for applications that demand electrical connectivity, thermal dissipation, sealing capabilities, and long-term stability in harsh environments.

Here’s why copper is preferred for M39 Copper Plain Washers:

Excellent Electrical Conductivity

Copper is the second-best conductor of electricity after silver. In electrical installations, copper flat washers DIN 125 are commonly used to maintain uninterrupted current flow, minimize resistance, and prevent heat buildup around fasteners in electrical terminals and power busbars.Superior Corrosion Resistance

Copper naturally resists oxidation and corrosion in both dry and moist environments. This makes M39 Copper Plain Washers ideal for marine, chemical, and outdoor applications where ferrous washers would degrade over time. These washers are especially effective in industrial copper flat washer corrosion resistant assemblies.Thermal Conductivity

When bolts are exposed to high temperatures, copper acts as a heat sink, dissipating heat efficiently. That’s why copper plain washer M‑series metric size is commonly used in engines, generators, HVAC systems, and heavy electrical equipment.Soft and Ductile for Better Sealing

Copper’s malleability enables it to deform slightly when compressed, ensuring tight sealing even on uneven surfaces. This makes it perfect for applications in hydraulics, pneumatics, and flanged joints.Chemical Compatibility

Copper shows excellent resistance to many industrial fluids, making DIN 125 copper flat washers metric series suitable for oil & gas refineries, plumbing systems, and petrochemical installations.Non-Magnetic and Non-Sparking

In sensitive areas like mining, aerospace, and defense where spark prevention is crucial, copper is preferred due to its non-sparking and non-magnetic properties.Long Service Life

Copper does not become brittle or degrade over time like plastic or rubber washers. It retains its structural integrity, providing dependable performance over years of use.Aesthetic and Premium Appearance

In high-end equipment or visible fittings, the reddish sheen of copper adds a professional finish to assemblies—ideal for architectural or showcase installations.

How Are M39 Copper Plain Washers Manufactured?

At Nafees Metal Industries, we manufacture M39 Copper Plain Washers through a precision-driven process that ensures dimensional accuracy, corrosion resistance, and long-term durability. As one of the leading copper washer manufacturers in India, we follow ISO-certified protocols and deploy advanced tooling technology to produce washers that meet the highest industrial standards.

Here’s a detailed look at our manufacturing process:

Raw Material Selection – High-Grade Electrolytic Copper

We source high-purity electrolytic copper (minimum 99.9% purity), ensuring excellent conductivity, malleability, and anti-corrosive properties. The copper sheets are tested for thickness, grain uniformity, and chemical composition before processing.Cold Rolling and Sheet Preparation

The copper sheets are cold-rolled to achieve uniform thickness suitable for M39-sized washers. Cold rolling increases the metal’s strength while maintaining its ductility—ideal for large-diameter applications like M39 Copper Plain Washers.Precision Punching Using CNC Tools

The washer blanks are punched using CNC-controlled high-tonnage power presses. This ensures consistent inner diameter (ID), outer diameter (OD), and flatness for each piece. The M39 size corresponds to a 39 mm bolt/screw diameter, and our process ensures exact fitment with minimal tolerance deviation.Deburring and Edge Smoothing

To eliminate sharp edges and burrs, each washer undergoes mechanical or vibratory deburring. Smooth edges are critical in preventing damage to surfaces and maintaining sealing effectiveness during fastening.Annealing (If Required)

For certain applications requiring extra softness or increased ductility, washers are annealed in a controlled atmosphere furnace. This heat treatment ensures stress relief and enhances the sealing performance, especially under thermal expansion.Surface Cleaning and Polishing

Washers are cleaned using ultrasonic or solvent-based systems to remove any residual oil, dirt, or oxidation. A final polishing step gives the washers a smooth, bright finish suitable for both functional and aesthetic use.Coating or Protective Film (Optional)

While copper itself is corrosion-resistant, some clients require additional protection or patina control. We offer options like clear coatings, anti-tarnish lacquers, or oxidation-resistant packaging for long-term storage and shipment.Dimensional and Quality Inspection

Every batch is subjected to stringent quality checks including:ID/OD tolerance measurement

Thickness accuracy (as per DIN 125 standard)

Surface integrity and roundness

Hardness and tensile testing (as required)

This ensures each M39 Copper Plain Washer complies with industry standards such as DIN 125, IS 2016, and ISO 7089.

Custom Packaging and Labeling

Based on the buyer’s needs, we offer washers in polybags, corrugated boxes, or export-quality cartons. Labeling includes product size, batch number, coating details, and compliance tags for easy traceability.

Key Features of M39 Copper Plain Washers

Nafees Metal Industries’ M39 Copper Plain Washers are engineered with a high level of precision, designed to deliver reliable performance in industrial environments where strength, conductivity, and corrosion resistance are essential. As one of the best copper washer manufacturers in India, we ensure every washer meets the exacting demands of our clients across electrical, mechanical, and heavy-duty fastening applications.

Here are the standout features of our M39 Copper Plain Washers:

1. Accurate Fitment for M39 Fasteners

Each washer is crafted to fit M39 bolts or screws with absolute precision. The inner diameter is designed to snugly accommodate the fastener shank, ensuring stable and vibration-free assemblies.

2. Manufactured from Pure Electrolytic Copper

We use high-purity copper with excellent conductivity and corrosion resistance. The material complies with industrial-grade copper standards, ensuring longevity and optimal performance under mechanical and electrical loads.

3. Compliant with DIN 125 Standards

Our M39 Copper Plain Washers conform to DIN 125 specifications, ensuring global compatibility in metric systems. This makes them ideal replacements for OEM parts or use in export-grade assemblies.

4. Excellent Load Distribution

The wide outer diameter of the washer helps distribute load uniformly over the surface, preventing surface damage and increasing joint stability—especially in high-torque or oversized applications.

5. Superior Corrosion Resistance

Copper’s natural resistance to moisture, chemicals, and oxidation makes it the best choice for washers used in outdoor, marine, electrical, and chemical processing environments.

6. Smooth, Burr-Free Surface

Post-punching, every washer undergoes deburring and surface finishing processes. This eliminates sharp edges and ensures safe handling, better sealing, and easier integration into assemblies.

7. Available with Custom Coating Options

Though copper is naturally corrosion-resistant, optional coatings (such as anti-tarnish lacquer or oxidation protectants) are available to enhance shelf-life or aesthetic requirements.

8. High Conductivity for Electrical Applications

Being made from pure copper, these washers ensure uninterrupted conductivity, making them ideal for use in grounding systems, battery terminals, switchgear, and control panels.

9. Heat and Pressure Resilient

Copper has high thermal conductivity and can withstand extreme pressure and temperature fluctuations, making it suitable for high-load industrial applications.

10. Multiple Thickness Options Available

We offer customizable thickness ranges based on customer needs—whether for sealing, spacing, or high-load bearing purposes. Standard and custom dimensions are both supported.

11. Eco-Friendly and 100% Recyclable

Copper washers are a sustainable choice due to their reusability and minimal environmental impact. All our washers are RoHS-compliant and environmentally responsible.

12. Bulk Ready with Fast Turnaround

Our Mumbai-based facility maintains a large inventory of standard sizes like M39, enabling fast dispatch for bulk orders. We also accept made-to-order requests with short lead times.

13. Packaging Options for OEMs and Exporters

From small polybag packaging to bulk cartons with barcode labeling, we offer packaging solutions tailored to OEMs, resellers, and export partners.

14. Proudly Made in India

Every washer is manufactured in-house at our Mumbai factory, combining local skill with advanced production processes under the “Make in India” initiative.

15. Trusted by Industry Leaders

Nafees Metal Industries has earned the trust of manufacturers, EPC contractors, automotive assemblers, and electronic component makers across India and the Middle East for our consistent washer quality and professional support.

Applications of M39 Copper Plain Washers

Electrical Panels & Circuit Breakers – Ensures effective grounding and heat dissipation.

Transformers & Switchgears – High-conductivity fastener support.

Marine & Offshore Installations – Corrosion-resistant joint sealing.

HVAC Systems & Plumbing – Leak-proof sealing under thermal expansion.

Automotive & Railways – Used in terminals, battery connectors, and assemblies.

Solar Panels & Wind Turbines – Grounding and weather-resistant fasteners.

Medical & Defense Equipment – Non-magnetic and oxidation-resistant washers.

M39 Copper Washers Size & Technical Specifications

| Property | Specification |

|---|---|

| Product Name | M39 Copper Plain Washer |

| Material | High-Grade Copper |

| Inner Diameter (ID) | Approx. 39.5 mm (for M39 bolts) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 |

| Thickness | 2.0 mm (customizable from 1.0–5.0 mm) |

| Surface Finish | Polished / Plain / Tinned |

| Metric Size | M-Series (M39) |

| Corrosion Resistance | Excellent (suitable for marine exposure) |

| Standard Compliance | DIN 125 / IS 2016 |

| Packaging | Bulk, Poly Bag, or Custom Export Packs |

| Made in India | Yes – Manufactured in Mumbai |

At Nafees Metal Industries, our M39 Copper Plain Washers are manufactured to meet the highest engineering standards and dimensional accuracy. These washers are carefully designed for demanding applications where both mechanical stability and electrical conductivity are essential. Below are the complete specifications:

1. Product Name:

M39 Copper Plain Washers

2. Material Composition:

High-grade electrolytic copper (≥99.9% purity)

Compliant with IS, ASTM B152, and RoHS environmental standards

3. Size Details:

Inner Diameter (ID): 39 mm (precisely matching M39 bolt shank)

Outer Diameter (OD): 65 mm (customizable upon request)

Thickness: Standard: 3 mm (Available from 1 mm to 5 mm)

Tolerance: ±0.1 mm (ID/OD/Thickness)

4. Standard Compliance:

Conforms to DIN 125 / IS 2016 standards

Compatible with ISO metric bolt systems

Meets industrial requirements for copper flat washers

5. Surface Finish Options:

Natural copper finish (standard)

Optional anti-tarnish lacquer coating

Electropolished or bright finish for premium applications

6. Hardness:

Typically HV 40-60 (annealed copper)

Work-hardened versions available upon request

7. Electrical Conductivity:

Excellent electrical performance

IACS conductivity ≥ 97%

Ideal for electrical grounding and busbar systems

8. Thermal Resistance:

Service temperature range: -50°C to 300°C

Does not degrade under thermal cycling or vibration

9. Corrosion Resistance:

Naturally corrosion-resistant in atmospheric and mildly acidic environments

Optional protective coatings for harsh environments available

10. Manufacturing Process:

CNC-punched from cold-rolled copper sheets

Deburred and quality-checked manually and via precision instruments

Custom sizes can be laser-cut or press-formed for large orders

11. Customization Options:

Custom ID, OD, and thickness ranges

Logo stamping or part number engraving

Packaging customization (bulk, box, bag with barcode)

12. Packaging & Supply:

Packed in polybags or boxes of 100 / 500 / 1000 units

Export-ready packaging with labeling

MOQ: 500 units

Ready stock available for standard M39 size

13. Application Standards:

Suitable for use in electrical panels, grounding assemblies, oil & gas pipelines, marine structures, HVAC systems, and pressure vessels.

14. Country of Origin:

India – Manufactured at our Mumbai-based ISO-certified facility

15. Brand:

Nafees Metal Industries – Trusted Copper Washer Manufacturer in India

Why Choose Nafees Metal Industries for M39 Copper Washers?

Top Manufacturer of Copper Washers in India with over two decades of experience.

Custom Sizing and Thickness Available – Full support for OEM and export specifications.

Fast Dispatch and Nationwide Delivery – In-stock washers available for immediate shipping.

Expert Support Team – Technical consultation for usage, compatibility, and volume requirements.

Strict Quality Checks – From raw material sourcing to dispatch.

We are a proud part of the Make in India initiative, supplying to industries across India, UAE, Africa, and Southeast Asia and across the world

Buy Bulk M20 SS304 Plain Washers – Top-Grade Alternatives Also Available

Though this page focuses on M39 Copper Plain Washers, we also specialize in M20 SS304 Plain Washers—ideal for high-strength and corrosion-resistant fastening. These washers are in high demand for heavy-duty industrial and structural applications. If you’re seeking a cost-effective and reliable alternative to copper, consider our stainless steel variants.

FAQs About M39 Copper Plain Washers

1. What are M39 Copper Plain Washers used for?

M39 Copper Plain Washers are used to evenly distribute the load of M39 bolts or screws, reduce surface damage, and enhance conductivity in mechanical and electrical assemblies. They are ideal for high-load, high-conductivity applications like transformers, switchgears, and earthing systems.

2. Why should I choose copper washers over steel washers?

Copper washers offer excellent thermal and electrical conductivity, corrosion resistance, and a non-sparking property. They are superior for use in electrical and chemical environments compared to steel washers.

3. Are your M39 Copper Plain Washers manufactured in India?

Yes, all our copper washers, including M39 size, are proudly manufactured in our ISO-certified facility in Mumbai, India. Nafees Metal Industries is one of the leading copper washer manufacturers in India.

4. What is the inner diameter of an M39 copper washer?

The inner diameter is precisely 39 mm to accommodate M39 bolts or threaded fasteners, as per DIN 125 copper flat washers metric series.

5. Do your washers comply with DIN standards?

Yes, our M39 Copper Plain Washers comply with DIN 125 and IS 2016 standards for flat washers. Custom dimensions can be made upon request.

6. Are these washers suitable for electrical grounding?

Absolutely. Copper has excellent conductivity, and our washers are widely used in grounding applications, control panels, busbars, and electrical switchboards.

7. Can I use M39 copper plain washers in marine environments?

Yes. Copper is naturally corrosion-resistant. For prolonged marine exposure, we recommend a protective coating to enhance performance.

8. What finishes are available for M39 copper flat washers?

We offer natural copper finish (standard), anti-tarnish lacquer coating, electropolished finish, and custom coatings depending on your application’s environment.

9. Are bulk and custom packaging options available?

Yes. We offer flexible packaging—from bulk cartons to custom barcoded bags. Packaging can be tailored for retail, OEM supply, or export needs.

10. What is the minimum order quantity (MOQ)?

Our standard MOQ is 500 pieces for M39 Copper Plain Washers. For trial orders or custom sizes, MOQ terms can be flexible.

11. Can I get M39 copper washers with my company logo or part number engraved?

Yes. We offer custom stamping, logo engraving, or part number marking for OEMs and industrial buyers.

12. What is the delivery time for M39 copper washers?

Ready-stock orders are dispatched within 1–3 business days. Custom orders may take 7–10 working days depending on volume and finish.

13. What makes Nafees Metal Industries the best manufacturer of copper washers in India?

We combine advanced manufacturing, strict quality control, rapid order fulfillment, competitive pricing, and customizable solutions. Our products meet both Indian and global standards.

14. Are M39 copper plain washers reusable?

Yes, if not deformed during tightening, these washers can be reused, especially in non-critical or low-stress applications.

15. How do I place a bulk order?

You can reach out via our website https://nafeesmetalindustries.com, email us, or call directly. Our team will assist you with specifications, pricing, and logistics.

Why Choose Nafees Metal Industries for M39 Copper Plain Washers?

At Nafees Metal Industries, we are more than just manufacturers — we are solution providers trusted by industrial clients across India and abroad. Here’s why leading OEMs, electrical engineers, and heavy machinery manufacturers rely on us for M39 Copper Plain Washers and other fastening solutions:

Specialized Expertise in Copper Washers

With years of hands-on experience, we have mastered the art of manufacturing copper plain washers across all standard and custom sizes — including M3 to M100 and beyond.Precision Engineering

Our copper washers conform to strict tolerance limits with flawless concentricity, smooth finishes, and uniform thickness — ideal for both electrical conductivity and structural reliability.Material Traceability & Purity

We use high-conductivity industrial-grade copper sheets, fully tested for mechanical properties and purity. Every washer is made from certified material that meets or exceeds DIN and IS standards.ISO-Certified Manufacturing

Our facility in Mumbai operates under ISO-certified processes, using CNC presses, automated deburring systems, and skilled manual inspections to ensure unmatched quality.Bulk Supply & Custom Orders

Whether you need 1,000 or 1 million M39 Copper Plain Washers, we offer consistent supply, flexible packaging, and customization options based on your design or coating requirements.Competitive Pricing with Zero Compromise on Quality

As a direct manufacturer, we control the entire production process in-house — resulting in better prices and higher reliability compared to resellers or importers.Fast Dispatch Across India & Export-Ready Logistics

Our logistics team ensures prompt deliveries pan-India and internationally, complete with all export documents, test certificates, and HS codes.

Visit Our Manufacturing Unit

We welcome our clients and sourcing teams to witness our production in action at our Mumbai-based facility. Whether you’re auditing suppliers or exploring partnerships, a guided visit gives you firsthand insight into:

Our modern machine shop and press lines

Raw material storage and quality control labs

Packaging, dispatch, and inventory zones

Customization and prototyping units

To schedule your visit, please contact us via contact form or call us directly. We’ll be happy to organize a walkthrough tailored to your interest.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch