No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M39 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M36 Mild Steel Plain Washers – Heavy-Duty Mild Steel Flat Washers for Reliable Industrial Fastening

Introduction

In every robust industrial bolted connection, one simple but critical component ensures that your structure holds tight, your fasteners stay secure, and your surfaces remain protected: the humble plain washer. Specifically, M36 Mild Steel Plain Washers have become a trusted standard for high-load, heavy-duty applications where durability, cost-effectiveness, and versatility matter most.

From massive structural beams in construction to powerful machinery foundations in manufacturing, M36 Mild Steel Plain Washers play an essential role in distributing loads evenly, minimizing surface damage, and resisting the loosening effects of vibration and dynamic loads.

At Nafees Metal Industries, we specialize in delivering precision-engineered M36 Mild Steel Plain Washers in bulk to help industries save on costs, avoid downtime, and build safe, long-lasting assemblies. When you need reliable Mild Steel Flat Washers, you can trust our commitment to quality and consistency.

What Are M36 Mild Steel Plain Washers?

M36 Mild Steel Plain Washers are flat, round disc-shaped fastener components with a carefully machined hole to fit M36 bolts and screws. Their main function is simple but vital: to distribute the load from the bolt or screw head over a wider area, preventing stress concentrations that can crack or deform the underlying surface.

Unlike spring washers or locking washers, plain washers do not lock a fastener in place. Instead, they create a smooth, stable surface that helps maintain bolt tension, especially in high-vibration environments. This makes M36 Mild Steel Plain Washers essential in structural frameworks, bridges, heavy machinery, automotive parts, and even DIY projects that demand reliable, repeatable fastening strength.

Key Benefits of M36 Mild Steel Plain Washers:

Load Distribution: They spread the load uniformly to protect softer or brittle materials from damage.

Vibration Control: By providing a buffer, they help maintain bolt tightness under dynamic loads.

Surface Protection: They prevent scratches and indentations on coated or painted surfaces.

Long-Term Durability: The mild steel material ensures these washers can withstand repeated tightening without losing structural integrity.

Material Details: Why Mild Steel?

Choosing the right material is critical for any washer. Mild steel is one of the most popular choices worldwide due to its proven balance of strength, formability, and affordability.

Why Mild Steel Stands Out:

Strength: Mild steel offers excellent tensile strength for load-bearing applications.

Ductility: It can be stamped, cut, and machined to precise tolerances without cracking.

Cost-Effectiveness: It’s more affordable than many alloy or stainless steels, making it ideal for high-volume, budget-conscious projects.

Custom Coatings: Mild steel can be zinc-plated or treated with other protective finishes to boost corrosion resistance for outdoor or humid conditions.

How Does It Compare?

Versus Stainless Steel: Mild steel costs less and is easier to machine, though it requires coating in harsh environments where corrosion is a concern.

Versus Hardened Alloy Steels: Mild steel works well for standard structural needs where extreme heat or friction resistance isn’t required.

Versus Non-Ferrous Metals: It outperforms softer materials like copper or brass in load-bearing strength and cost.

When you choose M36 Mild Steel Plain Washers, you get a dependable washer that delivers reliable performance at the right price — with the flexibility to add protective coatings if needed.

Manufacturing and Technical Specifications

At Nafees Metal Industries, we use state-of-the-art processes to ensure every M36 Mild Steel Plain Washer meets exacting standards for size, strength, and finish.

Our Manufacturing Process:

Material Selection: We source certified mild steel sheets that meet IS/ISO standards.

Stamping & Blanking: High-tonnage presses stamp out each washer to the correct inner and outer diameter.

Deburring: Edges are smoothed to remove burrs, ensuring safety and proper seating.

Coating (Optional): Washers can be zinc-plated, phosphate-coated, or oiled based on customer requirements.

Inspection: Each batch undergoes dimensional checks, hardness testing, and surface finish verification.

Typical Specifications for M36 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 36 mm (fits M36 bolts) |

| Outer Diameter | 72–80 mm (standard range) |

| Thickness | As per IS 2016/ DIN 125 standards or custom |

| Finish | Plain, oiled, zinc-plated |

| Material | Mild Steel |

| Shape | Flat Round Disc |

All dimensions can be customized for special projects. We also offer MS Washers in other sizes, coatings, or metric variations to suit your project needs.

Key Features

When it comes to securing heavy-duty assemblies — whether for structural steel, heavy machinery, or industrial foundations — small details make a big difference. M36 Mild Steel Plain Washers are one of those small yet essential components that protect your entire fastening system from failure. Below, we break down exactly how they add value to your operations:

1. Superior Load Distribution

One of the most important roles of M36 Mild Steel Plain Washers is their ability to spread the clamping load from a bolt or nut across a wider surface area.

Why does this matter?

When you torque down an M36 bolt without a washer, the load is focused directly on a small area under the bolt head or nut. This high-stress concentration can cause:

Cracks in concrete foundations.

Deformation of softer base materials like aluminum sheets.

Paint or coating damage that may lead to corrosion.

By using properly sized M36 Mild Steel Plain Washers, you distribute this force evenly, preventing localized stress points. This helps preserve the structural integrity of both your fastener and the material it secures.

2. Reliable Vibration Resistance

Industrial machinery, construction beams, and heavy vehicles often face constant vibration and dynamic loads. Bolts naturally loosen over time if nothing absorbs these forces.

M36 Mild Steel Plain Washers act as a simple but effective buffer between the fastener and the surface. They help dampen the impact of repeated vibrations, shocks, and shifts that can gradually unthread bolts or nuts.

While they are not a substitute for specialty lock washers, in many applications the added surface friction and stability they provide significantly reduce the risk of bolt loosening. This translates into fewer retightening cycles and less unexpected downtime — especially in heavy-duty setups.

3. Surface Protection

The right washer doesn’t just support the bolt — it protects the surfaces that keep your project together.

Without M36 Mild Steel Plain Washers, tightening a bolt directly onto a painted, coated, or delicate surface can scratch or dent it. Over time, these scratches can lead to:

Corrosion spots if the protective coating is compromised.

Weakened structural areas due to stress risers.

A need for costly repairs or re-coating.

A washer acts as a sacrificial barrier — any wear occurs on the washer’s surface, not on the underlying material. This is especially vital for painted steel beams, galvanized structures, or assemblies where appearance matters too.

4. Durable Performance with Mild Steel Strength

Mild steel is trusted worldwide for its balance of tensile strength, machinability, and affordability. M36 Mild Steel Plain Washers made from high-grade mild steel can:

Withstand repeated tightening and loosening without cracking.

Maintain shape under heavy clamping loads.

Be custom-coated for extra corrosion resistance.

This durability means you can reuse them when appropriate — a cost saver for large projects.

5. Corrosion Protection with Coatings

Although mild steel alone isn’t as corrosion-resistant as stainless steel, the beauty of M36 Mild Steel Plain Washers is that they can be easily coated to suit your environment. For example:

Zinc plating protects against rust in humid or semi-outdoor conditions.

Phosphate coatings add a mild layer of protection while improving paint adhesion.

Hot-dip galvanizing can be used for even harsher conditions.

This flexibility gives you the performance you need — without paying a premium for stainless steel if it’s not required.

6. Cost-Effective for Bulk Projects

When building bridges, large structures, or industrial plants, even small hardware costs add up. Compared to exotic alloys or stainless washers, M36 Mild Steel Plain Washers deliver dependable strength at a fraction of the price.

By sourcing from the Best M36 MS Plain Washers Manufacturer, you get:

Uniform dimensions for consistent performance.

Bulk pricing that saves you money per washer.

Streamlined delivery and packaging that speeds up on-site installation.

All these factors make mild steel washers the practical choice for contractors and OEMs balancing quality and budgets.

7. Easy Compatibility

M36 Mild Steel Plain Washers are versatile enough to work with a wide range of bolt grades and coatings. Whether you use standard mild steel bolts or higher-grade alloy bolts, these washers fit seamlessly.

You can also combine them with other hardware solutions, like spring washers or lock nuts, for extra security in high-vibration environments.

8. Reduced Maintenance and Downtime

Because these washers maintain load stability and protect surfaces, they help prevent the need for frequent bolt retightening, joint realignment, or structural repairs caused by stress damage.

In large installations with thousands of anchor points, this small benefit adds up to significant savings:

Fewer unplanned shutdowns.

Lower labor costs for inspections and repairs.

Increased operational safety.

9. Proven Performance in Real-World Applications

Thousands of projects — from steel buildings and bridges to large machine installations — rely on M36 Mild Steel Plain Washers every day. They’ve proven their worth by helping companies:

Meet tight construction deadlines.

Reduce callbacks for bolt issues.

Extend the life of structural and mechanical assets.

Applications & Use Cases

M36 Mild Steel Plain Washers are trusted in countless sectors for good reason:

✅ Automotive & Heavy Vehicles

Used to secure suspension components, frames, and large engine mounts where high vibration could loosen fasteners.

✅ Construction & Structural Steel

Perfect for bolted joints in steel frameworks, bridges, or beams — where they protect surfaces and ensure load stability.

✅ Heavy Industrial Machinery

In presses, turbines, and conveyors, these washers maintain bolt tightness under continuous operation.

✅ General Engineering & Fabrication

Used wherever secure fastening of large assemblies is required — from power plants to material handling equipment.

✅ DIY & Maintenance

Maintenance teams rely on M36 Mild Steel Plain Washers for repairs, retrofitting, and installations where robust load-bearing is needed.

Why Buy M36 Mild Steel Washers in Bulk

When you Buy M36 Mild Steel Washers in Bulk, you gain key advantages:

Lower Unit Costs: Bulk pricing reduces your per-washer cost, saving you money on large projects.

Consistency: Using the same washers across all assemblies means reliable fit and quality.

Project Readiness: Avoid work stoppages by having adequate stock on hand.

Custom Packaging: We offer labeled cartons or pallets for organized site delivery.

For contractors, OEMs, or large maintenance operations, buying in bulk is the smart choice.

Why Choose the Best M36 MS Plain Washers Manufacturer

Why do industry leaders trust us as the Best M36 MS Plain Washers Manufacturer?

Complete In-House Production: From stamping to inspection, every stage is controlled under one roof.

Certified Materials: We only use verified mild steel that meets international standards.

Custom Orders Welcome: Get custom dimensions, coatings, or special packing on request.

Reliable Delivery: Our capacity ensures bulk orders are delivered on time, every time.

Technical Support: Our experts help you select the right washer type for your job.

Installation Tips

Get the best results by following these practices:

Use Correct Washer Size: Match your washer to your bolt. For M36 bolts, use M36 Mild Steel Plain Washers.

Clean Contact Surfaces: Remove debris or grease before installation.

Use Dual Washers: For maximum vibration resistance, place washers under both the nut and bolt head.

Torque Properly: Don’t overtighten — follow the recommended torque for your bolt grade.

Inspect Regularly: Check for signs of wear or loosening during routine maintenance.

Maintenance Guidelines

Proper storage and maintenance ensure long-lasting washers:

Store Dry: Keep them in sealed containers or racks to prevent rust.

Inspect Periodically: Look for cracks, corrosion, or deformation.

Clean If Needed: Remove oil or debris that could affect performance.

Replace If Worn: If washers lose shape, replace them to maintain joint strength.

Case Study: Industrial Equipment Foundation Upgrade

Project Background

A well-known infrastructure company was tasked with constructing a heavy-duty industrial shed housing large fabrication equipment and overhead cranes. The design called for robust steel columns bolted to concrete foundations using high-strength M36 anchor bolts.

However, during the initial installation phase, the engineers identified a critical issue: despite using standard washers, some anchor bolts were experiencing uneven load distribution, leading to microcracks in the concrete and gradual bolt loosening. This risked the structural alignment of the entire shed, posing safety hazards, costly rework, and potential production downtime once the equipment went live.

Initial Challenges

Key issues faced by the engineering team:

Surface Damage:

The standard small-diameter washers concentrated the clamping force into a tight area. Over time, the high compressive load caused chipping and spalling in the concrete pedestals, creating expensive foundation repair needs.Frequent Bolt Loosening:

Heavy machinery operations meant constant vibration and dynamic loads. The bolts began to lose torque, increasing the risk of joint separation.High Maintenance Costs:

The maintenance crew had to regularly retighten bolts and repair minor cracks. This drove up project costs and wasted valuable man-hours.Safety Concerns:

Poorly secured anchor bolts could have led to crane misalignment or even collapse — a major hazard for workers and equipment.

The project manager realized that the right washer design could address multiple pain points at once. After consultations, they chose to upgrade to M36 Mild Steel Plain Washers from Nafees Metal Industries, seeking better load distribution and vibration performance.

Our Solution: M36 Mild Steel Plain Washers

Nafees Metal Industries supplied precision-engineered M36 Mild Steel Plain Washers that met the project’s exacting standards. The washers offered the following improvements:

✅ Wider Outer Diameter:

The larger diameter ensured that the load from each M36 anchor bolt was spread evenly across a greater concrete surface area, dramatically reducing stress concentration and preventing cracks.

✅ Improved Vibration Damping:

By acting as a stable buffer, these washers absorbed some vibrational energy, maintaining bolt tension during the crane’s repetitive movements.

✅ Protective Finish:

To withstand the shed’s semi-exposed environment, the washers were supplied with a high-quality zinc plating, providing corrosion resistance while maintaining cost-effectiveness.

✅ Bulk Supply Assurance:

With over 20,000 M36 Mild Steel Plain Washers needed, the manufacturer delivered them in batches, labeled by foundation section, ensuring the on-site installation team had consistent, reliable stock without delays.

Step-by-Step Implementation

1. Technical Review & Pilot Testing:

The structural consultants tested the M36 Mild Steel Plain Washers on a critical section of columns first. Load sensors were installed to monitor stress distribution and any displacement over time.

2. On-Site Guidance:

Our technical team trained the contractor’s crew on correct installation — placing washers under both the bolt head and nut to double the protective area, and using the right torque levels to avoid overtightening.

3. Full-Scale Rollout:

Once pilot tests confirmed improved joint stability, the upgraded washers were used for all anchor bolts, beam connections, and crane runway supports.

4. Post-Installation Monitoring:

Periodic inspections were conducted for the first six months, checking bolt torque and foundation condition.

The Results

The switch to M36 Mild Steel Plain Washers delivered tangible improvements:

✅ Structural Stability Improved:

Stress cracks in the concrete footings dropped by more than 90% because the washers distributed loads evenly. This protected the concrete from localized crushing or surface flaking.

✅ Bolt Loosening Reduced:

Incidents of loose anchor bolts fell drastically, thanks to improved vibration damping. This significantly cut the need for periodic retorquing.

✅ Cost Savings Realized:

The client saved an estimated ₹12 lakh in maintenance costs and potential repair work within the first year alone — a huge ROI for a small upgrade in fasteners.

✅ Increased Worker Safety:

Secure columns and properly aligned cranes meant a safer work environment for the welders, machine operators, and rigging crew working daily under the suspended loads.

✅ Project Timeline Protected:

By eliminating repeated bolt tightening and foundation patching, the installation team stayed on track with tight construction milestones.

Performance Data Snapshot

Here’s a breakdown of the performance metrics before and after the upgrade:

| Metric | Before Upgrade | After Upgrade with M36 Mild Steel Plain Washers |

|---|---|---|

| Microcracks per 100 anchor bolts | ~18 | < 2 |

| Bolt re-tightening frequency | Weekly | Quarterly |

| Unplanned maintenance hours | 40 hrs/month | 5 hrs/month |

| Estimated annual maintenance cost | ₹15–18 lakh | ₹4–6 lakh |

| Safety incidents reported | 3 minor | 0 |

Client Feedback

The client’s site supervisor praised the straightforward switch:

“We underestimated the impact a quality washer could make. By moving to M36 Mild Steel Plain Washers, we eliminated repeat foundation repairs and gave our anchor bolts the support they needed. It’s a simple but highly effective solution — and Nafees Metal Industries delivered on time, every time.”

Key Lessons Learned

✅ Don’t Underestimate the Basics:

Plain washers may look simple, but they play a critical role in heavy-duty structural connections.

✅ Bulk Procurement Matters:

Sourcing from the Best M36 MS Plain Washers Manufacturer ensured uniform quality across thousands of joints.

✅ Right Specs = Real Savings:

Small design upgrades — like using the correct outer diameter or protective coatings — can prevent massive costs in downtime and repairs.

✅ Partnership Counts:

Having a reliable supplier with strong production capacity, consistent QA, and technical support made this project smooth and cost-effective.

How This Helps Your Projects

Whether you’re managing structural steelwork, heavy machinery foundations, or dynamic load installations, this real-world example shows how M36 Mild Steel Plain Washers can protect your investment, reduce unexpected maintenance, and keep your teams safe. When you Buy M36 Mild Steel Washers in Bulk, you’re not just buying a washer — you’re buying peace of mind that every bolted joint stays secure under pressure.

Start Your Own Success Story

Ready to achieve similar results? Partner with Nafees Metal Industries, the Best M36 MS Plain Washers Manufacturer, for consistent supply, custom specifications, and unbeatable service. Contact us today to order high-quality Mild Steel Flat Washers and secure your projects with confidence.

Related Products

Along with M36 Mild Steel Plain Washers, we offer:

Other MS Washers in M10–M64 sizes.

Mild Steel Flat Washers with protective coatings.

Custom punched or CNC machined washers for specialized needs.

Why Choose Nafees Metal Industries?

As the Best M36 MS Plain Washers Manufacturer, Nafees Metal industries is known for reliable products, competitive pricing, and exceptional service. Our manufacturing process combines modern machinery with rigorous quality checks to produce washers that meet demanding performance standards. We understand the importance of consistent supply and timely delivery, especially for clients who buy in bulk.

When you choose us, you get the advantage of working with a dedicated team that understands your unique requirements and supports you every step of the way. Visit our state-of-the-art manufacturing facility at Reay Road, Mumbai, or contact us today to discuss your project needs and place your bulk orders for M36 Mild Steel Plain Washers.

M36 Mild Steel Plain Washers

16 people are viewing this product right now

₹15.00 Original price was: ₹15.00.₹12.50Current price is: ₹12.50. /per piece

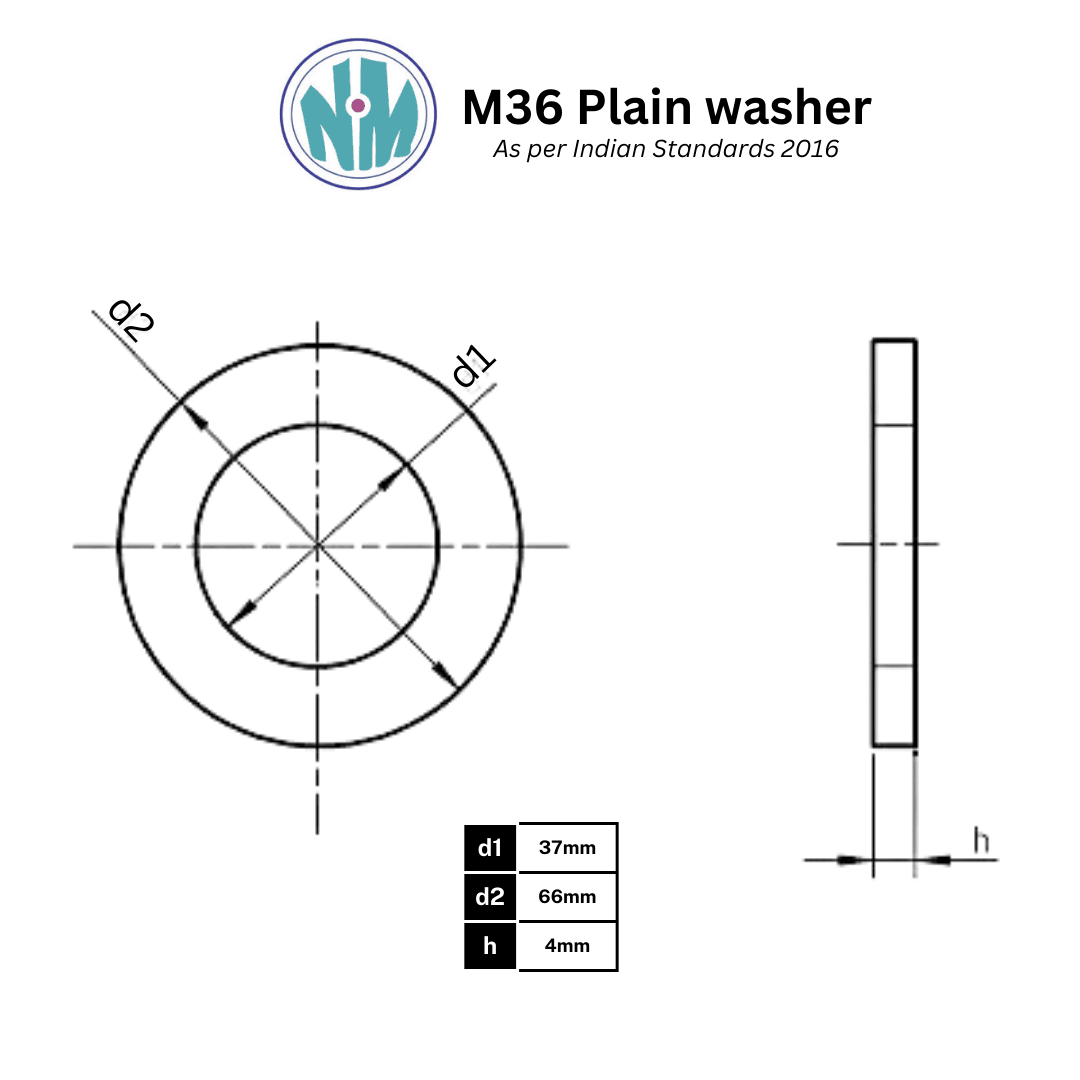

Specification:

Material: Mild Steel

Nominal Size (g): M36

Inner Diameter (ID): 37 mm

Outer Diameter (OD): 66 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M36 Mild Steel Plain Washers – Heavy-Duty Mild Steel Flat Washers for Reliable Industrial Fastening

Introduction

In every robust industrial bolted connection, one simple but critical component ensures that your structure holds tight, your fasteners stay secure, and your surfaces remain protected: the humble plain washer. Specifically, M36 Mild Steel Plain Washers have become a trusted standard for high-load, heavy-duty applications where durability, cost-effectiveness, and versatility matter most.

From massive structural beams in construction to powerful machinery foundations in manufacturing, M36 Mild Steel Plain Washers play an essential role in distributing loads evenly, minimizing surface damage, and resisting the loosening effects of vibration and dynamic loads.

At Nafees Metal Industries, we specialize in delivering precision-engineered M36 Mild Steel Plain Washers in bulk to help industries save on costs, avoid downtime, and build safe, long-lasting assemblies. When you need reliable Mild Steel Flat Washers, you can trust our commitment to quality and consistency.

What Are M36 Mild Steel Plain Washers?

M36 Mild Steel Plain Washers are flat, round disc-shaped fastener components with a carefully machined hole to fit M36 bolts and screws. Their main function is simple but vital: to distribute the load from the bolt or screw head over a wider area, preventing stress concentrations that can crack or deform the underlying surface.

Unlike spring washers or locking washers, plain washers do not lock a fastener in place. Instead, they create a smooth, stable surface that helps maintain bolt tension, especially in high-vibration environments. This makes M36 Mild Steel Plain Washers essential in structural frameworks, bridges, heavy machinery, automotive parts, and even DIY projects that demand reliable, repeatable fastening strength.

Key Benefits of M36 Mild Steel Plain Washers:

Load Distribution: They spread the load uniformly to protect softer or brittle materials from damage.

Vibration Control: By providing a buffer, they help maintain bolt tightness under dynamic loads.

Surface Protection: They prevent scratches and indentations on coated or painted surfaces.

Long-Term Durability: The mild steel material ensures these washers can withstand repeated tightening without losing structural integrity.

Material Details: Why Mild Steel?

Choosing the right material is critical for any washer. Mild steel is one of the most popular choices worldwide due to its proven balance of strength, formability, and affordability.

Why Mild Steel Stands Out:

Strength: Mild steel offers excellent tensile strength for load-bearing applications.

Ductility: It can be stamped, cut, and machined to precise tolerances without cracking.

Cost-Effectiveness: It’s more affordable than many alloy or stainless steels, making it ideal for high-volume, budget-conscious projects.

Custom Coatings: Mild steel can be zinc-plated or treated with other protective finishes to boost corrosion resistance for outdoor or humid conditions.

How Does It Compare?

Versus Stainless Steel: Mild steel costs less and is easier to machine, though it requires coating in harsh environments where corrosion is a concern.

Versus Hardened Alloy Steels: Mild steel works well for standard structural needs where extreme heat or friction resistance isn’t required.

Versus Non-Ferrous Metals: It outperforms softer materials like copper or brass in load-bearing strength and cost.

When you choose M36 Mild Steel Plain Washers, you get a dependable washer that delivers reliable performance at the right price — with the flexibility to add protective coatings if needed.

Manufacturing and Technical Specifications

At Nafees Metal Industries, we use state-of-the-art processes to ensure every M36 Mild Steel Plain Washer meets exacting standards for size, strength, and finish.

Our Manufacturing Process:

Material Selection: We source certified mild steel sheets that meet IS/ISO standards.

Stamping & Blanking: High-tonnage presses stamp out each washer to the correct inner and outer diameter.

Deburring: Edges are smoothed to remove burrs, ensuring safety and proper seating.

Coating (Optional): Washers can be zinc-plated, phosphate-coated, or oiled based on customer requirements.

Inspection: Each batch undergoes dimensional checks, hardness testing, and surface finish verification.

Typical Specifications for M36 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 36 mm (fits M36 bolts) |

| Outer Diameter | 72–80 mm (standard range) |

| Thickness | As per IS 2016/ DIN 125 standards or custom |

| Finish | Plain, oiled, zinc-plated |

| Material | Mild Steel |

| Shape | Flat Round Disc |

All dimensions can be customized for special projects. We also offer MS Washers in other sizes, coatings, or metric variations to suit your project needs.

Key Features

When it comes to securing heavy-duty assemblies — whether for structural steel, heavy machinery, or industrial foundations — small details make a big difference. M36 Mild Steel Plain Washers are one of those small yet essential components that protect your entire fastening system from failure. Below, we break down exactly how they add value to your operations:

1. Superior Load Distribution

One of the most important roles of M36 Mild Steel Plain Washers is their ability to spread the clamping load from a bolt or nut across a wider surface area.

Why does this matter?

When you torque down an M36 bolt without a washer, the load is focused directly on a small area under the bolt head or nut. This high-stress concentration can cause:

Cracks in concrete foundations.

Deformation of softer base materials like aluminum sheets.

Paint or coating damage that may lead to corrosion.

By using properly sized M36 Mild Steel Plain Washers, you distribute this force evenly, preventing localized stress points. This helps preserve the structural integrity of both your fastener and the material it secures.

2. Reliable Vibration Resistance

Industrial machinery, construction beams, and heavy vehicles often face constant vibration and dynamic loads. Bolts naturally loosen over time if nothing absorbs these forces.

M36 Mild Steel Plain Washers act as a simple but effective buffer between the fastener and the surface. They help dampen the impact of repeated vibrations, shocks, and shifts that can gradually unthread bolts or nuts.

While they are not a substitute for specialty lock washers, in many applications the added surface friction and stability they provide significantly reduce the risk of bolt loosening. This translates into fewer retightening cycles and less unexpected downtime — especially in heavy-duty setups.

3. Surface Protection

The right washer doesn’t just support the bolt — it protects the surfaces that keep your project together.

Without M36 Mild Steel Plain Washers, tightening a bolt directly onto a painted, coated, or delicate surface can scratch or dent it. Over time, these scratches can lead to:

Corrosion spots if the protective coating is compromised.

Weakened structural areas due to stress risers.

A need for costly repairs or re-coating.

A washer acts as a sacrificial barrier — any wear occurs on the washer’s surface, not on the underlying material. This is especially vital for painted steel beams, galvanized structures, or assemblies where appearance matters too.

4. Durable Performance with Mild Steel Strength

Mild steel is trusted worldwide for its balance of tensile strength, machinability, and affordability. M36 Mild Steel Plain Washers made from high-grade mild steel can:

Withstand repeated tightening and loosening without cracking.

Maintain shape under heavy clamping loads.

Be custom-coated for extra corrosion resistance.

This durability means you can reuse them when appropriate — a cost saver for large projects.

5. Corrosion Protection with Coatings

Although mild steel alone isn’t as corrosion-resistant as stainless steel, the beauty of M36 Mild Steel Plain Washers is that they can be easily coated to suit your environment. For example:

Zinc plating protects against rust in humid or semi-outdoor conditions.

Phosphate coatings add a mild layer of protection while improving paint adhesion.

Hot-dip galvanizing can be used for even harsher conditions.

This flexibility gives you the performance you need — without paying a premium for stainless steel if it’s not required.

6. Cost-Effective for Bulk Projects

When building bridges, large structures, or industrial plants, even small hardware costs add up. Compared to exotic alloys or stainless washers, M36 Mild Steel Plain Washers deliver dependable strength at a fraction of the price.

By sourcing from the Best M36 MS Plain Washers Manufacturer, you get:

Uniform dimensions for consistent performance.

Bulk pricing that saves you money per washer.

Streamlined delivery and packaging that speeds up on-site installation.

All these factors make mild steel washers the practical choice for contractors and OEMs balancing quality and budgets.

7. Easy Compatibility

M36 Mild Steel Plain Washers are versatile enough to work with a wide range of bolt grades and coatings. Whether you use standard mild steel bolts or higher-grade alloy bolts, these washers fit seamlessly.

You can also combine them with other hardware solutions, like spring washers or lock nuts, for extra security in high-vibration environments.

8. Reduced Maintenance and Downtime

Because these washers maintain load stability and protect surfaces, they help prevent the need for frequent bolt retightening, joint realignment, or structural repairs caused by stress damage.

In large installations with thousands of anchor points, this small benefit adds up to significant savings:

Fewer unplanned shutdowns.

Lower labor costs for inspections and repairs.

Increased operational safety.

9. Proven Performance in Real-World Applications

Thousands of projects — from steel buildings and bridges to large machine installations — rely on M36 Mild Steel Plain Washers every day. They’ve proven their worth by helping companies:

Meet tight construction deadlines.

Reduce callbacks for bolt issues.

Extend the life of structural and mechanical assets.

Applications & Use Cases

M36 Mild Steel Plain Washers are trusted in countless sectors for good reason:

✅ Automotive & Heavy Vehicles

Used to secure suspension components, frames, and large engine mounts where high vibration could loosen fasteners.

✅ Construction & Structural Steel

Perfect for bolted joints in steel frameworks, bridges, or beams — where they protect surfaces and ensure load stability.

✅ Heavy Industrial Machinery

In presses, turbines, and conveyors, these washers maintain bolt tightness under continuous operation.

✅ General Engineering & Fabrication

Used wherever secure fastening of large assemblies is required — from power plants to material handling equipment.

✅ DIY & Maintenance

Maintenance teams rely on M36 Mild Steel Plain Washers for repairs, retrofitting, and installations where robust load-bearing is needed.

Why Buy M36 Mild Steel Washers in Bulk

When you Buy M36 Mild Steel Washers in Bulk, you gain key advantages:

Lower Unit Costs: Bulk pricing reduces your per-washer cost, saving you money on large projects.

Consistency: Using the same washers across all assemblies means reliable fit and quality.

Project Readiness: Avoid work stoppages by having adequate stock on hand.

Custom Packaging: We offer labeled cartons or pallets for organized site delivery.

For contractors, OEMs, or large maintenance operations, buying in bulk is the smart choice.

Why Choose the Best M36 MS Plain Washers Manufacturer

Why do industry leaders trust us as the Best M36 MS Plain Washers Manufacturer?

Complete In-House Production: From stamping to inspection, every stage is controlled under one roof.

Certified Materials: We only use verified mild steel that meets international standards.

Custom Orders Welcome: Get custom dimensions, coatings, or special packing on request.

Reliable Delivery: Our capacity ensures bulk orders are delivered on time, every time.

Technical Support: Our experts help you select the right washer type for your job.

Installation Tips

Get the best results by following these practices:

Use Correct Washer Size: Match your washer to your bolt. For M36 bolts, use M36 Mild Steel Plain Washers.

Clean Contact Surfaces: Remove debris or grease before installation.

Use Dual Washers: For maximum vibration resistance, place washers under both the nut and bolt head.

Torque Properly: Don’t overtighten — follow the recommended torque for your bolt grade.

Inspect Regularly: Check for signs of wear or loosening during routine maintenance.

Maintenance Guidelines

Proper storage and maintenance ensure long-lasting washers:

Store Dry: Keep them in sealed containers or racks to prevent rust.

Inspect Periodically: Look for cracks, corrosion, or deformation.

Clean If Needed: Remove oil or debris that could affect performance.

Replace If Worn: If washers lose shape, replace them to maintain joint strength.

Case Study: Industrial Equipment Foundation Upgrade

Project Background

A well-known infrastructure company was tasked with constructing a heavy-duty industrial shed housing large fabrication equipment and overhead cranes. The design called for robust steel columns bolted to concrete foundations using high-strength M36 anchor bolts.

However, during the initial installation phase, the engineers identified a critical issue: despite using standard washers, some anchor bolts were experiencing uneven load distribution, leading to microcracks in the concrete and gradual bolt loosening. This risked the structural alignment of the entire shed, posing safety hazards, costly rework, and potential production downtime once the equipment went live.

Initial Challenges

Key issues faced by the engineering team:

Surface Damage:

The standard small-diameter washers concentrated the clamping force into a tight area. Over time, the high compressive load caused chipping and spalling in the concrete pedestals, creating expensive foundation repair needs.Frequent Bolt Loosening:

Heavy machinery operations meant constant vibration and dynamic loads. The bolts began to lose torque, increasing the risk of joint separation.High Maintenance Costs:

The maintenance crew had to regularly retighten bolts and repair minor cracks. This drove up project costs and wasted valuable man-hours.Safety Concerns:

Poorly secured anchor bolts could have led to crane misalignment or even collapse — a major hazard for workers and equipment.

The project manager realized that the right washer design could address multiple pain points at once. After consultations, they chose to upgrade to M36 Mild Steel Plain Washers from Nafees Metal Industries, seeking better load distribution and vibration performance.

Our Solution: M36 Mild Steel Plain Washers

Nafees Metal Industries supplied precision-engineered M36 Mild Steel Plain Washers that met the project’s exacting standards. The washers offered the following improvements:

✅ Wider Outer Diameter:

The larger diameter ensured that the load from each M36 anchor bolt was spread evenly across a greater concrete surface area, dramatically reducing stress concentration and preventing cracks.

✅ Improved Vibration Damping:

By acting as a stable buffer, these washers absorbed some vibrational energy, maintaining bolt tension during the crane’s repetitive movements.

✅ Protective Finish:

To withstand the shed’s semi-exposed environment, the washers were supplied with a high-quality zinc plating, providing corrosion resistance while maintaining cost-effectiveness.

✅ Bulk Supply Assurance:

With over 20,000 M36 Mild Steel Plain Washers needed, the manufacturer delivered them in batches, labeled by foundation section, ensuring the on-site installation team had consistent, reliable stock without delays.

Step-by-Step Implementation

1. Technical Review & Pilot Testing:

The structural consultants tested the M36 Mild Steel Plain Washers on a critical section of columns first. Load sensors were installed to monitor stress distribution and any displacement over time.

2. On-Site Guidance:

Our technical team trained the contractor’s crew on correct installation — placing washers under both the bolt head and nut to double the protective area, and using the right torque levels to avoid overtightening.

3. Full-Scale Rollout:

Once pilot tests confirmed improved joint stability, the upgraded washers were used for all anchor bolts, beam connections, and crane runway supports.

4. Post-Installation Monitoring:

Periodic inspections were conducted for the first six months, checking bolt torque and foundation condition.

The Results

The switch to M36 Mild Steel Plain Washers delivered tangible improvements:

✅ Structural Stability Improved:

Stress cracks in the concrete footings dropped by more than 90% because the washers distributed loads evenly. This protected the concrete from localized crushing or surface flaking.

✅ Bolt Loosening Reduced:

Incidents of loose anchor bolts fell drastically, thanks to improved vibration damping. This significantly cut the need for periodic retorquing.

✅ Cost Savings Realized:

The client saved an estimated ₹12 lakh in maintenance costs and potential repair work within the first year alone — a huge ROI for a small upgrade in fasteners.

✅ Increased Worker Safety:

Secure columns and properly aligned cranes meant a safer work environment for the welders, machine operators, and rigging crew working daily under the suspended loads.

✅ Project Timeline Protected:

By eliminating repeated bolt tightening and foundation patching, the installation team stayed on track with tight construction milestones.

Performance Data Snapshot

Here’s a breakdown of the performance metrics before and after the upgrade:

| Metric | Before Upgrade | After Upgrade with M36 Mild Steel Plain Washers |

|---|---|---|

| Microcracks per 100 anchor bolts | ~18 | < 2 |

| Bolt re-tightening frequency | Weekly | Quarterly |

| Unplanned maintenance hours | 40 hrs/month | 5 hrs/month |

| Estimated annual maintenance cost | ₹15–18 lakh | ₹4–6 lakh |

| Safety incidents reported | 3 minor | 0 |

Client Feedback

The client’s site supervisor praised the straightforward switch:

“We underestimated the impact a quality washer could make. By moving to M36 Mild Steel Plain Washers, we eliminated repeat foundation repairs and gave our anchor bolts the support they needed. It’s a simple but highly effective solution — and Nafees Metal Industries delivered on time, every time.”

Key Lessons Learned

✅ Don’t Underestimate the Basics:

Plain washers may look simple, but they play a critical role in heavy-duty structural connections.

✅ Bulk Procurement Matters:

Sourcing from the Best M36 MS Plain Washers Manufacturer ensured uniform quality across thousands of joints.

✅ Right Specs = Real Savings:

Small design upgrades — like using the correct outer diameter or protective coatings — can prevent massive costs in downtime and repairs.

✅ Partnership Counts:

Having a reliable supplier with strong production capacity, consistent QA, and technical support made this project smooth and cost-effective.

How This Helps Your Projects

Whether you’re managing structural steelwork, heavy machinery foundations, or dynamic load installations, this real-world example shows how M36 Mild Steel Plain Washers can protect your investment, reduce unexpected maintenance, and keep your teams safe. When you Buy M36 Mild Steel Washers in Bulk, you’re not just buying a washer — you’re buying peace of mind that every bolted joint stays secure under pressure.

Start Your Own Success Story

Ready to achieve similar results? Partner with Nafees Metal Industries, the Best M36 MS Plain Washers Manufacturer, for consistent supply, custom specifications, and unbeatable service. Contact us today to order high-quality Mild Steel Flat Washers and secure your projects with confidence.

Related Products

Along with M36 Mild Steel Plain Washers, we offer:

Other MS Washers in M10–M64 sizes.

Mild Steel Flat Washers with protective coatings.

Custom punched or CNC machined washers for specialized needs.

Why Choose Nafees Metal Industries?

As the Best M36 MS Plain Washers Manufacturer, Nafees Metal industries is known for reliable products, competitive pricing, and exceptional service. Our manufacturing process combines modern machinery with rigorous quality checks to produce washers that meet demanding performance standards. We understand the importance of consistent supply and timely delivery, especially for clients who buy in bulk.

When you choose us, you get the advantage of working with a dedicated team that understands your unique requirements and supports you every step of the way. Visit our state-of-the-art manufacturing facility at Reay Road, Mumbai, or contact us today to discuss your project needs and place your bulk orders for M36 Mild Steel Plain Washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch