No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

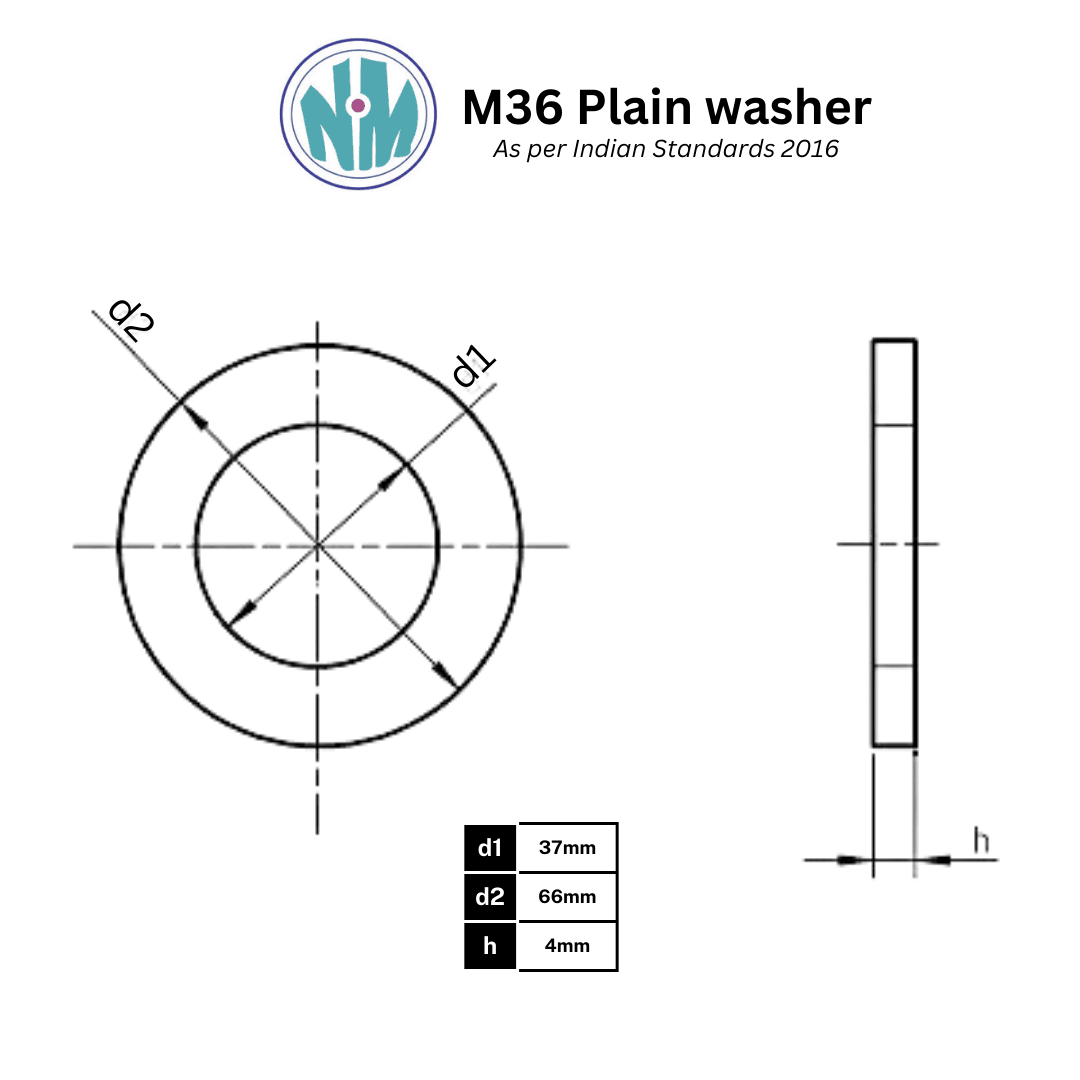

*Images shown for graphic representation. Not to scale.

M36 Copper Plain Washers – Premium Copper Flat Washers for Heavy-Duty Industrial Use

At Nafees Metal Industries, we specialize in manufacturing and supplying high-precision M36 copper plain washers designed for demanding industrial environments. These washers are engineered to offer outstanding load distribution, electrical conductivity, and sealing performance in large-scale fastening systems.

M36 copper plain washers are flat, circular discs with a central hole perfectly dimensioned to accommodate M36 bolts or screws (with a 36 mm nominal diameter). Their primary function is to spread the load of a fastener, minimize surface damage, and enhance the longevity and reliability of the joint. When used in conjunction with M36 bolts, they help stabilize the assembly, reduce vibration, and prevent fastener pull-through—especially in high-vibration or high-heat environments.

Crafted from high-purity copper, these washers are non-ferrous, thermally conductive, and corrosion-resistant—making them ideal for use in electrical installations, heavy-duty mechanical assemblies, HVAC units, marine structures, and hydraulic equipment. In addition to their mechanical benefits, copper’s natural resistance to rust and its high ductility make it an excellent choice for precision sealing and durable fastening.

Our facility in Mumbai, India, is equipped with modern manufacturing technology and ISO-certified quality processes to ensure dimensional precision, uniform thickness, and a smooth surface finish on every piece. As a trusted copper washer manufacturer in India, Nafees Metal Industries is committed to delivering superior products that exceed performance expectations and meet international quality standards.

Whether you need M36 copper plain washers in small batches for prototypes or in large volumes for assembly lines, we have the capacity, infrastructure, and technical expertise to fulfill your requirements with competitive pricing and quick delivery timelines.

What Are M36 Copper Plain Washers?

M36 copper plain washers are precision-engineered flat components designed to be used with M36-sized fasteners, which have a nominal diameter of 36 millimeters. These washers are disc-shaped, with a smooth surface and a centered hole that fits snugly around the shank of the bolt or screw. They belong to the DIN 125 flat washer standard, which ensures universal dimensional consistency for industrial use.

The primary role of a copper plain washer is to distribute the load of a threaded fastener (like a bolt or nut) across a larger surface area. This prevents localized stress on the material being fastened, which can otherwise lead to cracking, warping, or premature wear. In heavy-duty mechanical assemblies, where M36 bolts are common, this load-spreading capability is critical to ensuring long-term durability and structural integrity.

But the value of these washers goes beyond just load distribution:

Copper’s ductility makes the washer conform slightly to uneven surfaces, providing a better seal between components.

Its electrical conductivity makes it the material of choice in electrical systems and grounding applications.

Copper’s corrosion resistance ensures long-term performance in marine, humid, or chemical-rich environments.

Thermal resistance makes them suitable for high-heat environments such as engines or HVAC systems.

These washers also act as spacers, vibration dampeners, and sealing elements in various assemblies. For example, they are widely used in hydraulic systems, electrical panels, and equipment housings where both mechanical and conductive properties are crucial.

Each M36 copper plain washer manufactured by Nafees Metal Industries is crafted from premium-grade copper sheets that comply with global metallurgical standards. Whether your application demands dimensional precision, heat resistance, or conductivity, our washers meet the mark.

They are also commonly referred to by related terms such as:

Copper plain washer DIN 125 size M36

M36 copper flat washer metric series DIN 125

Copper sealing washer M36 hydraulic fittings

By offering washers that meet both IS 2016 and DIN 125 standards, we ensure you get not only dimensional accuracy but also a product that’s globally accepted and application-ready.

Why Use Copper for M36 Washers?

Copper has long been recognized for its unique combination of mechanical, thermal, and chemical properties, making it a superior choice for washers—especially in demanding industrial environments. When it comes to large-diameter washers like M36 copper plain washers, the material selection becomes even more critical due to the larger surface area under stress and the typical applications in which these washers are used.

Here’s why copper is the ideal material for M36 washers:

1. Exceptional Thermal Conductivity

Copper has one of the highest thermal conductivities among metals. This means M36 copper plain washers are capable of withstanding and distributing heat efficiently without deforming or losing strength. In industries like HVAC, engine assemblies, and electrical enclosures, this property is vital to maintain performance and prevent heat buildup around fastened components.

2. Superior Electrical Conductivity

Copper’s outstanding electrical conductivity (second only to silver) makes these washers indispensable in electrical and grounding systems. When used in busbars, circuit boxes, or other conductive installations, M36 copper plain washers ensure optimal electrical contact between surfaces, reducing resistance and heat generation. For industries such as renewable energy, telecom, and industrial automation, this feature is non-negotiable.

3. Natural Corrosion Resistance

Copper forms a natural oxide layer when exposed to air, which protects it from further oxidation. This corrosion resistance makes M36 copper plain washers highly durable in marine environments, chemical plants, and humid zones. Unlike mild steel, copper doesn’t rust, making it a better long-term investment for assemblies exposed to moisture or harsh conditions.

4. Excellent Malleability and Sealing Ability

Copper is a soft, ductile metal. This makes it excellent for applications requiring a tight seal. In hydraulic fittings, pneumatic systems, and plumbing, M36 copper sealing washers compress evenly under bolt pressure, filling in micro-gaps and ensuring a leak-proof joint. This property is especially useful in the copper sealing washer M36 hydraulic fittings category.

5. Non-Magnetic and Non-Sparking Properties

In sensitive environments like explosive zones, MRI rooms, and high-precision electronics, the use of non-magnetic and non-sparking components is essential. M36 copper plain washers meet these requirements perfectly, providing both safety and performance.

6. Chemical Stability

Copper remains stable and non-reactive in most acidic and alkaline environments. This chemical inertness makes these washers suitable for chemical processing plants, oil & gas industries, and any assembly exposed to corrosive media.

7. Environmental and Lifecycle Benefits

Copper is 100% recyclable without losing its properties. Using M36 copper plain washers contributes to sustainable manufacturing practices while offering a long service life with minimal maintenance.

In short, copper combines strength with softness, conductivity with corrosion resistance, and durability with flexibility. These attributes make it the ideal choice for large-format flat washers used in critical industrial settings. At Nafees Metal Industries, we harness these properties to produce M36 copper plain washers that outperform conventional alternatives in every measurable way.

Manufacturing Process of M36 Copper Plain Washers

At Nafees Metal Industries, our commitment to precision and quality begins at the very first step of production. The manufacturing process of our M36 copper plain washers is designed to meet strict industry standards like DIN 125 and ISO 7089, while also allowing flexibility for custom orders and bulk industrial supply. Every washer that leaves our Mumbai-based unit is a result of highly controlled procedures, modern machinery, and skilled workforce.

Here’s a detailed look at how we manufacture M36 copper plain washers:

1. Raw Material Selection

We begin with the careful selection of 99.9% pure copper sheets, sourced from certified vendors across India. Only high-grade copper is used to ensure the washer offers excellent conductivity, corrosion resistance, and sealing performance. These sheets are inspected for uniformity, thickness, grain structure, and impurity content before entering production.

2. Sheet Cutting and Blank Preparation

The copper sheets are cut into blanks—flat pieces of metal—sized appropriately for M36 washer dimensions. CNC-controlled cutting ensures precise outer diameters in line with DIN 125 specifications. For M36 washers, the outer diameter typically ranges between 66 to 72 mm, depending on the variant or application.

3. Precision Punching and Hole Formation

Each blank is then fed into a hydraulic or mechanical power press, where a precision punch creates the central hole to match the M36 bolt’s nominal diameter. Our presses are calibrated to punch the inner diameter at approximately 37.0 mm, ensuring a snug fit over the bolt and reliable alignment in assemblies.

4. Deburring and Surface Smoothing

Post-punching, the washers may have sharp edges or micro-burrs. To eliminate these and enhance safety during installation, every M36 copper plain washer undergoes a deburring and polishing process. This step not only removes imperfections but also ensures smooth edges and a uniform surface finish, crucial for proper sealing and load distribution.

5. Heat Treatment (If Required)

In some custom applications, annealing or controlled heat treatment is applied to increase the ductility of the washer or relieve internal stresses in the copper. This is especially important for washers intended for sealing in high-pressure hydraulic or pneumatic systems.

6. Surface Finishing Options

While copper naturally resists corrosion, we also offer custom surface finishes based on client requirements:

Polished finish for improved aesthetics and oxidation delay

Tin-plated or nickel-plated options for enhanced corrosion protection in extreme environments

Anti-tarnish coatings for electrical applications requiring clean contact surfaces

7. Quality Control and Testing

We perform multiple quality inspections throughout the process:

Dimensional accuracy tests (using Vernier calipers, micrometers, and gauges)

Surface flatness and thickness verification

Visual inspection for uniformity and cleanliness

Hardness testing when required for sealing applications

Every batch of M36 copper plain washers is also logged with traceability documentation, ensuring batch-level accountability.

8. Packaging and Dispatch

Once approved, the washers are packed according to the buyer’s requirement. We offer:

Bulk packaging in polybags or woven sacks

Retail-ready packaging in boxes or kits

Custom labeling and branding for OEMs

All products are barcoded, batch-coded, and securely packed to avoid damage during transit. Our in-house logistics and documentation team ensures quick domestic dispatch and hassle-free exports.

By controlling every aspect of production, from raw copper sheet to finished washer, Nafees Metal Industries guarantees that every M36 copper plain washer delivers reliability, consistency, and high performance across industrial and commercial applications.

Key Features of M36 Copper Plain Washers

At Nafees Metal Industries, we engineer our M36 copper plain washers to meet the high expectations of modern industrial applications. Each washer is crafted not only for structural strength but also for long-term reliability in environments that demand corrosion resistance, electrical conductivity, and thermal performance.

Below are the standout features that make our M36 copper plain washers a preferred choice for manufacturers, OEMs, and industrial users across India and globally:

1. Accurate Fitment for M36 Bolts and Screws

Each washer is precision-punched with an inner diameter of approximately 37.0 mm, ensuring a perfect fit for M36-sized fasteners. This snug fit guarantees effective load transfer, reduces bolt movement under stress, and promotes consistent torque control in mechanical assemblies.

2. Optimal Load Distribution

By providing a broader surface area under the bolt head or nut, our M36 copper plain washers spread the load evenly, minimizing the risk of damage to flanges, enclosures, or panels. This also enhances the clamping force and reduces the chance of material deformation or fatigue over time.

3. Copper’s Corrosion Resistance

Our washers are made from high-purity copper, which naturally forms a protective oxide layer. This makes them highly resistant to corrosion in marine, electrical, humid, and mildly acidic environments, ensuring longevity even under challenging conditions.

4. Uniform Thickness and Flatness

Each washer is manufactured with tight tolerances on thickness (standard 3.0 mm, customizable) and flatness. This ensures reliable stacking, torque control, and sealing in precision assemblies like copper sealing washer M36 hydraulic fittings.

5. Smooth Edges and Burr-Free Surface

Our advanced deburring and polishing process results in smooth edges and a clean surface finish. This reduces the risk of cuts during handling and prevents damage to adjacent parts, cables, or sealing surfaces during assembly.

6. High Conductivity

As copper is one of the best conductors of electricity, these washers are highly suitable for grounding and current-carrying applications, where electrical contact integrity is critical. Their low-resistance interface makes them ideal for high-voltage and EMI-sensitive environments.

7. Custom Coating Options Available

Although copper is corrosion-resistant by nature, we offer optional surface coatings such as tin, nickel, or anti-tarnish finishes for specialized applications. These treatments can extend service life, enhance electrical contact, or improve visual aesthetics in exposed environments.

8. Ideal for High-Pressure Sealing Applications

Thanks to copper’s malleability, these washers perform exceptionally well in sealing applications. In hydraulic or pneumatic systems, they conform to uneven surfaces, helping create leak-proof joints, particularly useful for fluid transfer and pressure-retaining components.

9. Compatible with DIN 125 / ISO 7089 Standards

All our M36 copper plain washers conform to DIN 125 or ISO 7089 dimensional standards, ensuring compatibility with global industrial fastening systems and making them suitable for domestic and export applications.

10. Made in India with Global Quality Standards

Proudly manufactured in our Mumbai-based facility, these washers benefit from stringent quality control, state-of-the-art machinery, and a skilled workforce. We serve both Indian and global industries with a reputation for precision, reliability, and prompt delivery.

11. Bulk Availability with Fast Dispatch

Our inventory is fully stocked for bulk requirements, and we offer fast dispatch and custom packaging solutions to meet the logistical needs of OEMs, industrial suppliers, and export clients.

12. Environmentally Friendly Material

Copper is 100% recyclable without degradation. Our washers are an eco-conscious choice that aligns with global sustainability goals and green manufacturing practices.

Each of these features has been designed to deliver maximum performance in every application. When you choose M36 copper plain washers from Nafees Metal Industries, you’re choosing engineering excellence, material purity, and manufacturing precision that stands the test of time.

Technical Specifications of M36 Copper Plain Washers

Our M36 copper plain washers are manufactured with a strong emphasis on dimensional precision, material purity, and international standard compliance. Whether used in electrical panels, mechanical joints, or hydraulic fittings, each washer is engineered to perform with consistency and reliability.

Below is a detailed technical breakdown of our M36 copper plain washers, highlighting key attributes that make them ideal for demanding industrial environments:

| Property | Specification |

|---|---|

| Product Name | M36 Copper Plain Washer |

| Material | High-purity Copper (≥ 99.9%) – ETP Grade or equivalent |

| Inner Diameter (ID) | Approx. 37.0 mm – designed for M36 bolts and fasteners |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 (commonly 66 mm to 72 mm depending on application) |

| Thickness | Standard 3.0 mm (customizable between 2.5 mm – 4.0 mm based on requirement) |

| Washer Type | Flat Washer – Plain, non-locking |

| Series | M36 copper flat washer metric series DIN 125 |

| Surface Finish | Plain (Standard) / Polished / Tin-Plated / Nickel-Plated / Anti-Tarnish Coating (on request) |

| Hardness | Soft (annealed) or Semi-hard (as required for sealing or clamping strength) |

| Tensile Strength | 200–250 MPa (annealed copper) |

| Conductivity | Excellent – IACS 100% Electrical Conductivity |

| Melting Point | 1085°C – ideal for high-temperature operations |

| Compliance Standards | DIN 125, ISO 7089, and IS 2016 |

| Manufacturing Process | Cold-punched, deburred, polished, and optionally coated |

| Customization | Available in dimensions, thickness, and surface finish as per customer specification |

| Application Category | Electrical, Marine, Hydraulic, HVAC, Mechanical Fastening, Automotive |

| Corrosion Resistance | High – suitable for humid, marine, and chemical environments |

| Packaging Options | Bulk Polybags, Corrugated Cartons, Custom-Labeled OEM Boxes |

| Country of Origin | Proudly Made in India – Manufactured at Nafees Metal Industries, Mumbai |

These technical specifications reflect our deep commitment to delivering superior-quality M36 copper plain washers that meet industrial demands for safety, durability, and long-term performance.

Our washers are compatible with a wide range of industrial standards and can be tailored in terms of inner/outer diameter, thickness, and finish based on your project’s unique requirements.

Whether you’re sourcing for local assembly or global export, Nafees Metal Industries ensures that every washer is built to exceed expectations.

Applications of M36 Copper Plain Washers

M36 copper plain washers are highly versatile components used in a wide range of industrial and commercial applications. Their unique properties—such as high conductivity, thermal resistance, and excellent corrosion protection as industrial copper flat washer corrosion resistant—make them ideal for both mechanical and electrical systems where reliability and longevity are critical.

Here’s a detailed look at where and how M36 copper plain washers are commonly used:

1. Electrical Installations & Grounding

Copper’s outstanding electrical conductivity (100% IACS) makes these washers highly effective in:

Busbar connections in control panels

Grounding terminals for earthing circuits

Battery terminals and junction boxes

Power transformers and substations

M36 size is often used in heavy-duty power systems or large electrical enclosures requiring secure grounding.

2. Mechanical Fastening in Industrial Assemblies

As a load-spreading element, M36 copper washers are widely used with bolts and nuts in:

HVAC systems

Boiler joints

Compressor housing clamps

Pipeline flange couplings

These washers help distribute load evenly and prevent damage to the assembled surface, especially in vibration-prone environments.

3. Hydraulic and Pneumatic Fittings

Copper washers serve as sealing washers in:

Hydraulic lines and pumps

Pneumatic brake systems

Oil and fuel line connections

Due to copper’s malleability, it forms an effective seal between flanged or threaded joints, preventing leaks under high pressure.

4. Automotive & Heavy Machinery

M36 copper flat washer metric DIN 125 series are used in:

Axle assemblies

Engine mountings

Chassis components

Electrical terminals of large vehicles

They perform reliably even under thermal stress and high-vibration conditions commonly found in transport and industrial machinery.

5. Marine and Corrosive Environments

Copper’s corrosion resistance makes these washers ideal for:

Shipbuilding

Underwater machinery

Oil rigs and offshore platforms

They act as long-term rust-proof barriers between metals in contact with saltwater or moisture-laden air.

6. Renewable Energy Systems

These washers are also integrated into:

Solar panel mountings

Wind turbine connectors

Battery packs in energy storage units

Copper washers in these systems ensure both electrical conductivity and mechanical durability under extreme outdoor conditions.

7. Instrumentation and Sensitive Equipment

In precision electronics and lab instrumentation, copper washers are preferred for:

EMI shielding (electromagnetic interference)

Sensor protection

Shielded enclosures

The non-magnetic nature of copper helps in reducing interference while maintaining conductive continuity.

At Nafees Metal Industries, our M36 copper plain washers are crafted to suit all these application areas with maximum performance and longevity. Whether you’re an OEM, contractor, or maintenance professional, our washers can be trusted to support both structural integrity and electrical efficiency.

Why Choose Nafees Metal Industries for M36 Copper Plain Washers?

When it comes to sourcing M36 copper plain washers, quality, precision, and reliability are non-negotiable. At Nafees Metal Industries, we pride ourselves on being one of India’s most trusted manufacturers and suppliers of copper washers—especially for heavy-duty applications. Here’s why industrial buyers, OEMs, and engineers across the country choose us over others:

1. In-House Manufacturing Facility in Mumbai

Our state-of-the-art facility, located in the heart of Mumbai’s industrial zone, is equipped with:

High-tonnage power press machines

Precision CNC die-cutting tools

Dedicated quality inspection units

This enables us to manufacture M36 copper plain washers with dimensional accuracy, excellent surface finish, and tight tolerances that meet both IS 2016 and DIN 125 standards.

2. Premium-Grade Raw Materials

We use only 100% pure copper sheets sourced from verified mills that meet international metallurgical standards. Our material quality ensures:

Maximum conductivity

Superior corrosion resistance

Excellent sealing and load distribution

Each batch undergoes chemical and physical testing before production to maintain consistency.

3. Customized Production Capability

Apart from standard M36 washers, we also offer:

Thickness customization (e.g., 1.5mm, 2mm, 3mm)

Hardness adjustment as per application

Burr-free and deburred finishes

We understand that every industry has specific needs—and we’re fully equipped to meet them with agility.

4. Bulk & On-Time Supply

With large-scale production and efficient logistics, we fulfill bulk orders for:

OEMs and component suppliers

Electrical panel manufacturers

Infrastructure & fabrication companies

We maintain steady inventory and just-in-time supply chains to reduce your procurement delays.

5. Competitive Pricing with No Compromise on Quality

We offer factory-direct pricing for all our copper washers—making sure our clients get excellent value for money without compromising on durability or finish.

6. Stringent Quality Control

Every washer goes through a multi-step QC process including:

Dimensional inspection

Surface finish check

Random batch hardness testing

Visual defect screening

We adhere to ISO-compliant internal QA protocols.

7. Trusted by Pan-India Clients

We’ve successfully supplied copper washers to:

Electrical component manufacturers

Automotive part suppliers

Marine and oil & gas contractors

HVAC and plumbing companies

Our reputation is built on decades of consistent quality and reliable service.

By choosing Nafees Metal Industries, you’re not just buying a washer—you’re investing in peace of mind, technical excellence, and dependable performance.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we’re not just another washer manufacturer—we’re your long-term industrial fastening partner. With over a decade of experience in precision engineering, we’ve built a solid reputation for delivering high-quality metal washers that meet the toughest industrial standards. Here’s why businesses across India and the globe choose us for their copper plain washer DIN 125 size M36 requirements:

Strategically Located Manufacturing Facility – Mumbai, India

Our ISO-compliant production facility is located in Mumbai-based facility—India’s leading industrial and commercial hub. This location offers us excellent connectivity to:

Major ports like Nhava Sheva (JNPT) for efficient global exports.

A vast network of logistics partners for rapid pan-India delivery.

Access to high-quality raw materials and skilled labor.

Being based in Mumbai also enables us to serve clients from automotive, electrical, marine, and construction industries faster and more reliably.

Modern Infrastructure & In-House Capabilities

We operate with:

Power press machines ranging from 10 to 200 tons for precise, bulk manufacturing.

Tooling and die fabrication in-house to create customized washer profiles.

Copper sheet and strip processing for accurate dimensioning and thickness control.

Regular quality checks with micrometers, calipers, and gauges to ensure tolerances are maintained.

Every batch undergoes stringent quality assurance checks before dispatch.

Extensive Washer Portfolio

Apart from M36 Copper Plain Washers, we manufacture a wide range of industrial washers including:

Spring washers

Belleville disc washers

SS plain washers (SS202, SS304, SS316)

MS (Mild Steel) and brass washers

Custom sizes (M3 to M64 and beyond)

This makes us a one-stop solution for all your washer requirements.

Trusted by Diverse Industries

Our washers are used by OEMs, EPC contractors, MEP companies, and manufacturers across:

Heavy engineering

Automotive and railways

Electrical and electronics

Oil & gas and petrochemical

Renewable energy

Marine and offshore sectors

We cater to both small-scale buyers and bulk industrial procurement needs with equal attention.

Reliable Exports & Bulk Supply

With a growing network of international buyers, we regularly export copper and stainless steel washers to:

UAE

Saudi Arabia

Qatar

Kenya

Sri Lanka

Singapore

Malaysia, and more.

We offer:

Bulk order fulfillment

Private labelling & custom branding

Packaging based on international standards

Dedicated export coordination support

Transparent, Professional, and Customer-First Approach

We take pride in:

Prompt responses and personalized quotes.

Fair pricing with no hidden costs.

Timely delivery and consistent availability of stock.

Welcoming factory visits, audits, and virtual inspections.

Our goal is to ensure your supply chain never experiences delays due to fastener shortages.

Whether you’re a distributor, project buyer, or end-user, Nafees Metal Industries is committed to becoming your go-to washer supplier—backed by quality, consistency, and trust.

Frequently Asked Questions (FAQs)

What is the size of an M36 copper plain washer?

It is designed for M36 bolts, with an approximate inner diameter of 37 mm, as per DIN 125.Are these washers corrosion-resistant?

Yes, copper offers natural corrosion resistance, especially suitable for humid and marine environments.Do M36 copper washers offer electrical conductivity?

Absolutely. Copper is one of the best conductors of electricity, ideal for grounding applications.Can I get a polished finish for decorative use?

Yes, we offer polished finishes on request for aesthetic or functional requirements.Are M36 copper flat washers reusable?

In most applications, yes—especially if they are not deformed during installation.Are these washers compatible with stainless steel bolts?

Yes, but ensure galvanic compatibility in high-moisture environments.What is the minimum order quantity?

We supply from 500 pcs up to bulk industrial quantities. Contact us for MOQ flexibility.Can you ship to the UAE or other international locations?

Yes, we are export-ready with all required documentation and certifications.What standards do your M36 copper washers comply with?

They follow DIN 125 and ISO 7089 dimensional and performance standards.What industries use M36 copper washers?

Electrical, marine, chemical, HVAC, and machinery industries are common users.Are these washers available in metric series?

Yes, we offer M36 copper flat washer metric series DIN 125.Do copper washers help with sealing?

Yes, especially in hydraulic and pneumatic fittings, acting as effective sealing washers.How do I order copper washers in custom packaging?

Just mention your packaging requirement while placing the order.Are there better alternatives to copper for this washer type?

For electrical and corrosion-prone environments, copper is unmatched. Alternatives may lack conductivity or sealing performance.Why choose Nafees Metal Industries?

We offer consistent quality, competitive pricing, custom solutions, and bulk readiness as one of India’s leading copper washer manufacturers.

M36 Copper Plain Washers (DIN 125)

12 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M36

Inner Diameter (ID): 37 mm

Outer Diameter (OD): 66 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M36 Copper Plain Washers – Premium Copper Flat Washers for Heavy-Duty Industrial Use

At Nafees Metal Industries, we specialize in manufacturing and supplying high-precision M36 copper plain washers designed for demanding industrial environments. These washers are engineered to offer outstanding load distribution, electrical conductivity, and sealing performance in large-scale fastening systems.

M36 copper plain washers are flat, circular discs with a central hole perfectly dimensioned to accommodate M36 bolts or screws (with a 36 mm nominal diameter). Their primary function is to spread the load of a fastener, minimize surface damage, and enhance the longevity and reliability of the joint. When used in conjunction with M36 bolts, they help stabilize the assembly, reduce vibration, and prevent fastener pull-through—especially in high-vibration or high-heat environments.

Crafted from high-purity copper, these washers are non-ferrous, thermally conductive, and corrosion-resistant—making them ideal for use in electrical installations, heavy-duty mechanical assemblies, HVAC units, marine structures, and hydraulic equipment. In addition to their mechanical benefits, copper’s natural resistance to rust and its high ductility make it an excellent choice for precision sealing and durable fastening.

Our facility in Mumbai, India, is equipped with modern manufacturing technology and ISO-certified quality processes to ensure dimensional precision, uniform thickness, and a smooth surface finish on every piece. As a trusted copper washer manufacturer in India, Nafees Metal Industries is committed to delivering superior products that exceed performance expectations and meet international quality standards.

Whether you need M36 copper plain washers in small batches for prototypes or in large volumes for assembly lines, we have the capacity, infrastructure, and technical expertise to fulfill your requirements with competitive pricing and quick delivery timelines.

What Are M36 Copper Plain Washers?

M36 copper plain washers are precision-engineered flat components designed to be used with M36-sized fasteners, which have a nominal diameter of 36 millimeters. These washers are disc-shaped, with a smooth surface and a centered hole that fits snugly around the shank of the bolt or screw. They belong to the DIN 125 flat washer standard, which ensures universal dimensional consistency for industrial use.

The primary role of a copper plain washer is to distribute the load of a threaded fastener (like a bolt or nut) across a larger surface area. This prevents localized stress on the material being fastened, which can otherwise lead to cracking, warping, or premature wear. In heavy-duty mechanical assemblies, where M36 bolts are common, this load-spreading capability is critical to ensuring long-term durability and structural integrity.

But the value of these washers goes beyond just load distribution:

Copper’s ductility makes the washer conform slightly to uneven surfaces, providing a better seal between components.

Its electrical conductivity makes it the material of choice in electrical systems and grounding applications.

Copper’s corrosion resistance ensures long-term performance in marine, humid, or chemical-rich environments.

Thermal resistance makes them suitable for high-heat environments such as engines or HVAC systems.

These washers also act as spacers, vibration dampeners, and sealing elements in various assemblies. For example, they are widely used in hydraulic systems, electrical panels, and equipment housings where both mechanical and conductive properties are crucial.

Each M36 copper plain washer manufactured by Nafees Metal Industries is crafted from premium-grade copper sheets that comply with global metallurgical standards. Whether your application demands dimensional precision, heat resistance, or conductivity, our washers meet the mark.

They are also commonly referred to by related terms such as:

Copper plain washer DIN 125 size M36

M36 copper flat washer metric series DIN 125

Copper sealing washer M36 hydraulic fittings

By offering washers that meet both IS 2016 and DIN 125 standards, we ensure you get not only dimensional accuracy but also a product that’s globally accepted and application-ready.

Why Use Copper for M36 Washers?

Copper has long been recognized for its unique combination of mechanical, thermal, and chemical properties, making it a superior choice for washers—especially in demanding industrial environments. When it comes to large-diameter washers like M36 copper plain washers, the material selection becomes even more critical due to the larger surface area under stress and the typical applications in which these washers are used.

Here’s why copper is the ideal material for M36 washers:

1. Exceptional Thermal Conductivity

Copper has one of the highest thermal conductivities among metals. This means M36 copper plain washers are capable of withstanding and distributing heat efficiently without deforming or losing strength. In industries like HVAC, engine assemblies, and electrical enclosures, this property is vital to maintain performance and prevent heat buildup around fastened components.

2. Superior Electrical Conductivity

Copper’s outstanding electrical conductivity (second only to silver) makes these washers indispensable in electrical and grounding systems. When used in busbars, circuit boxes, or other conductive installations, M36 copper plain washers ensure optimal electrical contact between surfaces, reducing resistance and heat generation. For industries such as renewable energy, telecom, and industrial automation, this feature is non-negotiable.

3. Natural Corrosion Resistance

Copper forms a natural oxide layer when exposed to air, which protects it from further oxidation. This corrosion resistance makes M36 copper plain washers highly durable in marine environments, chemical plants, and humid zones. Unlike mild steel, copper doesn’t rust, making it a better long-term investment for assemblies exposed to moisture or harsh conditions.

4. Excellent Malleability and Sealing Ability

Copper is a soft, ductile metal. This makes it excellent for applications requiring a tight seal. In hydraulic fittings, pneumatic systems, and plumbing, M36 copper sealing washers compress evenly under bolt pressure, filling in micro-gaps and ensuring a leak-proof joint. This property is especially useful in the copper sealing washer M36 hydraulic fittings category.

5. Non-Magnetic and Non-Sparking Properties

In sensitive environments like explosive zones, MRI rooms, and high-precision electronics, the use of non-magnetic and non-sparking components is essential. M36 copper plain washers meet these requirements perfectly, providing both safety and performance.

6. Chemical Stability

Copper remains stable and non-reactive in most acidic and alkaline environments. This chemical inertness makes these washers suitable for chemical processing plants, oil & gas industries, and any assembly exposed to corrosive media.

7. Environmental and Lifecycle Benefits

Copper is 100% recyclable without losing its properties. Using M36 copper plain washers contributes to sustainable manufacturing practices while offering a long service life with minimal maintenance.

In short, copper combines strength with softness, conductivity with corrosion resistance, and durability with flexibility. These attributes make it the ideal choice for large-format flat washers used in critical industrial settings. At Nafees Metal Industries, we harness these properties to produce M36 copper plain washers that outperform conventional alternatives in every measurable way.

Manufacturing Process of M36 Copper Plain Washers

At Nafees Metal Industries, our commitment to precision and quality begins at the very first step of production. The manufacturing process of our M36 copper plain washers is designed to meet strict industry standards like DIN 125 and ISO 7089, while also allowing flexibility for custom orders and bulk industrial supply. Every washer that leaves our Mumbai-based unit is a result of highly controlled procedures, modern machinery, and skilled workforce.

Here’s a detailed look at how we manufacture M36 copper plain washers:

1. Raw Material Selection

We begin with the careful selection of 99.9% pure copper sheets, sourced from certified vendors across India. Only high-grade copper is used to ensure the washer offers excellent conductivity, corrosion resistance, and sealing performance. These sheets are inspected for uniformity, thickness, grain structure, and impurity content before entering production.

2. Sheet Cutting and Blank Preparation

The copper sheets are cut into blanks—flat pieces of metal—sized appropriately for M36 washer dimensions. CNC-controlled cutting ensures precise outer diameters in line with DIN 125 specifications. For M36 washers, the outer diameter typically ranges between 66 to 72 mm, depending on the variant or application.

3. Precision Punching and Hole Formation

Each blank is then fed into a hydraulic or mechanical power press, where a precision punch creates the central hole to match the M36 bolt’s nominal diameter. Our presses are calibrated to punch the inner diameter at approximately 37.0 mm, ensuring a snug fit over the bolt and reliable alignment in assemblies.

4. Deburring and Surface Smoothing

Post-punching, the washers may have sharp edges or micro-burrs. To eliminate these and enhance safety during installation, every M36 copper plain washer undergoes a deburring and polishing process. This step not only removes imperfections but also ensures smooth edges and a uniform surface finish, crucial for proper sealing and load distribution.

5. Heat Treatment (If Required)

In some custom applications, annealing or controlled heat treatment is applied to increase the ductility of the washer or relieve internal stresses in the copper. This is especially important for washers intended for sealing in high-pressure hydraulic or pneumatic systems.

6. Surface Finishing Options

While copper naturally resists corrosion, we also offer custom surface finishes based on client requirements:

Polished finish for improved aesthetics and oxidation delay

Tin-plated or nickel-plated options for enhanced corrosion protection in extreme environments

Anti-tarnish coatings for electrical applications requiring clean contact surfaces

7. Quality Control and Testing

We perform multiple quality inspections throughout the process:

Dimensional accuracy tests (using Vernier calipers, micrometers, and gauges)

Surface flatness and thickness verification

Visual inspection for uniformity and cleanliness

Hardness testing when required for sealing applications

Every batch of M36 copper plain washers is also logged with traceability documentation, ensuring batch-level accountability.

8. Packaging and Dispatch

Once approved, the washers are packed according to the buyer’s requirement. We offer:

Bulk packaging in polybags or woven sacks

Retail-ready packaging in boxes or kits

Custom labeling and branding for OEMs

All products are barcoded, batch-coded, and securely packed to avoid damage during transit. Our in-house logistics and documentation team ensures quick domestic dispatch and hassle-free exports.

By controlling every aspect of production, from raw copper sheet to finished washer, Nafees Metal Industries guarantees that every M36 copper plain washer delivers reliability, consistency, and high performance across industrial and commercial applications.

Key Features of M36 Copper Plain Washers

At Nafees Metal Industries, we engineer our M36 copper plain washers to meet the high expectations of modern industrial applications. Each washer is crafted not only for structural strength but also for long-term reliability in environments that demand corrosion resistance, electrical conductivity, and thermal performance.

Below are the standout features that make our M36 copper plain washers a preferred choice for manufacturers, OEMs, and industrial users across India and globally:

1. Accurate Fitment for M36 Bolts and Screws

Each washer is precision-punched with an inner diameter of approximately 37.0 mm, ensuring a perfect fit for M36-sized fasteners. This snug fit guarantees effective load transfer, reduces bolt movement under stress, and promotes consistent torque control in mechanical assemblies.

2. Optimal Load Distribution

By providing a broader surface area under the bolt head or nut, our M36 copper plain washers spread the load evenly, minimizing the risk of damage to flanges, enclosures, or panels. This also enhances the clamping force and reduces the chance of material deformation or fatigue over time.

3. Copper’s Corrosion Resistance

Our washers are made from high-purity copper, which naturally forms a protective oxide layer. This makes them highly resistant to corrosion in marine, electrical, humid, and mildly acidic environments, ensuring longevity even under challenging conditions.

4. Uniform Thickness and Flatness

Each washer is manufactured with tight tolerances on thickness (standard 3.0 mm, customizable) and flatness. This ensures reliable stacking, torque control, and sealing in precision assemblies like copper sealing washer M36 hydraulic fittings.

5. Smooth Edges and Burr-Free Surface

Our advanced deburring and polishing process results in smooth edges and a clean surface finish. This reduces the risk of cuts during handling and prevents damage to adjacent parts, cables, or sealing surfaces during assembly.

6. High Conductivity

As copper is one of the best conductors of electricity, these washers are highly suitable for grounding and current-carrying applications, where electrical contact integrity is critical. Their low-resistance interface makes them ideal for high-voltage and EMI-sensitive environments.

7. Custom Coating Options Available

Although copper is corrosion-resistant by nature, we offer optional surface coatings such as tin, nickel, or anti-tarnish finishes for specialized applications. These treatments can extend service life, enhance electrical contact, or improve visual aesthetics in exposed environments.

8. Ideal for High-Pressure Sealing Applications

Thanks to copper’s malleability, these washers perform exceptionally well in sealing applications. In hydraulic or pneumatic systems, they conform to uneven surfaces, helping create leak-proof joints, particularly useful for fluid transfer and pressure-retaining components.

9. Compatible with DIN 125 / ISO 7089 Standards

All our M36 copper plain washers conform to DIN 125 or ISO 7089 dimensional standards, ensuring compatibility with global industrial fastening systems and making them suitable for domestic and export applications.

10. Made in India with Global Quality Standards

Proudly manufactured in our Mumbai-based facility, these washers benefit from stringent quality control, state-of-the-art machinery, and a skilled workforce. We serve both Indian and global industries with a reputation for precision, reliability, and prompt delivery.

11. Bulk Availability with Fast Dispatch

Our inventory is fully stocked for bulk requirements, and we offer fast dispatch and custom packaging solutions to meet the logistical needs of OEMs, industrial suppliers, and export clients.

12. Environmentally Friendly Material

Copper is 100% recyclable without degradation. Our washers are an eco-conscious choice that aligns with global sustainability goals and green manufacturing practices.

Each of these features has been designed to deliver maximum performance in every application. When you choose M36 copper plain washers from Nafees Metal Industries, you’re choosing engineering excellence, material purity, and manufacturing precision that stands the test of time.

Technical Specifications of M36 Copper Plain Washers

Our M36 copper plain washers are manufactured with a strong emphasis on dimensional precision, material purity, and international standard compliance. Whether used in electrical panels, mechanical joints, or hydraulic fittings, each washer is engineered to perform with consistency and reliability.

Below is a detailed technical breakdown of our M36 copper plain washers, highlighting key attributes that make them ideal for demanding industrial environments:

| Property | Specification |

|---|---|

| Product Name | M36 Copper Plain Washer |

| Material | High-purity Copper (≥ 99.9%) – ETP Grade or equivalent |

| Inner Diameter (ID) | Approx. 37.0 mm – designed for M36 bolts and fasteners |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 (commonly 66 mm to 72 mm depending on application) |

| Thickness | Standard 3.0 mm (customizable between 2.5 mm – 4.0 mm based on requirement) |

| Washer Type | Flat Washer – Plain, non-locking |

| Series | M36 copper flat washer metric series DIN 125 |

| Surface Finish | Plain (Standard) / Polished / Tin-Plated / Nickel-Plated / Anti-Tarnish Coating (on request) |

| Hardness | Soft (annealed) or Semi-hard (as required for sealing or clamping strength) |

| Tensile Strength | 200–250 MPa (annealed copper) |

| Conductivity | Excellent – IACS 100% Electrical Conductivity |

| Melting Point | 1085°C – ideal for high-temperature operations |

| Compliance Standards | DIN 125, ISO 7089, and IS 2016 |

| Manufacturing Process | Cold-punched, deburred, polished, and optionally coated |

| Customization | Available in dimensions, thickness, and surface finish as per customer specification |

| Application Category | Electrical, Marine, Hydraulic, HVAC, Mechanical Fastening, Automotive |

| Corrosion Resistance | High – suitable for humid, marine, and chemical environments |

| Packaging Options | Bulk Polybags, Corrugated Cartons, Custom-Labeled OEM Boxes |

| Country of Origin | Proudly Made in India – Manufactured at Nafees Metal Industries, Mumbai |

These technical specifications reflect our deep commitment to delivering superior-quality M36 copper plain washers that meet industrial demands for safety, durability, and long-term performance.

Our washers are compatible with a wide range of industrial standards and can be tailored in terms of inner/outer diameter, thickness, and finish based on your project’s unique requirements.

Whether you’re sourcing for local assembly or global export, Nafees Metal Industries ensures that every washer is built to exceed expectations.

Applications of M36 Copper Plain Washers

M36 copper plain washers are highly versatile components used in a wide range of industrial and commercial applications. Their unique properties—such as high conductivity, thermal resistance, and excellent corrosion protection as industrial copper flat washer corrosion resistant—make them ideal for both mechanical and electrical systems where reliability and longevity are critical.

Here’s a detailed look at where and how M36 copper plain washers are commonly used:

1. Electrical Installations & Grounding

Copper’s outstanding electrical conductivity (100% IACS) makes these washers highly effective in:

Busbar connections in control panels

Grounding terminals for earthing circuits

Battery terminals and junction boxes

Power transformers and substations

M36 size is often used in heavy-duty power systems or large electrical enclosures requiring secure grounding.

2. Mechanical Fastening in Industrial Assemblies

As a load-spreading element, M36 copper washers are widely used with bolts and nuts in:

HVAC systems

Boiler joints

Compressor housing clamps

Pipeline flange couplings

These washers help distribute load evenly and prevent damage to the assembled surface, especially in vibration-prone environments.

3. Hydraulic and Pneumatic Fittings

Copper washers serve as sealing washers in:

Hydraulic lines and pumps

Pneumatic brake systems

Oil and fuel line connections

Due to copper’s malleability, it forms an effective seal between flanged or threaded joints, preventing leaks under high pressure.

4. Automotive & Heavy Machinery

M36 copper flat washer metric DIN 125 series are used in:

Axle assemblies

Engine mountings

Chassis components

Electrical terminals of large vehicles

They perform reliably even under thermal stress and high-vibration conditions commonly found in transport and industrial machinery.

5. Marine and Corrosive Environments

Copper’s corrosion resistance makes these washers ideal for:

Shipbuilding

Underwater machinery

Oil rigs and offshore platforms

They act as long-term rust-proof barriers between metals in contact with saltwater or moisture-laden air.

6. Renewable Energy Systems

These washers are also integrated into:

Solar panel mountings

Wind turbine connectors

Battery packs in energy storage units

Copper washers in these systems ensure both electrical conductivity and mechanical durability under extreme outdoor conditions.

7. Instrumentation and Sensitive Equipment

In precision electronics and lab instrumentation, copper washers are preferred for:

EMI shielding (electromagnetic interference)

Sensor protection

Shielded enclosures

The non-magnetic nature of copper helps in reducing interference while maintaining conductive continuity.

At Nafees Metal Industries, our M36 copper plain washers are crafted to suit all these application areas with maximum performance and longevity. Whether you’re an OEM, contractor, or maintenance professional, our washers can be trusted to support both structural integrity and electrical efficiency.

Why Choose Nafees Metal Industries for M36 Copper Plain Washers?

When it comes to sourcing M36 copper plain washers, quality, precision, and reliability are non-negotiable. At Nafees Metal Industries, we pride ourselves on being one of India’s most trusted manufacturers and suppliers of copper washers—especially for heavy-duty applications. Here’s why industrial buyers, OEMs, and engineers across the country choose us over others:

1. In-House Manufacturing Facility in Mumbai

Our state-of-the-art facility, located in the heart of Mumbai’s industrial zone, is equipped with:

High-tonnage power press machines

Precision CNC die-cutting tools

Dedicated quality inspection units

This enables us to manufacture M36 copper plain washers with dimensional accuracy, excellent surface finish, and tight tolerances that meet both IS 2016 and DIN 125 standards.

2. Premium-Grade Raw Materials

We use only 100% pure copper sheets sourced from verified mills that meet international metallurgical standards. Our material quality ensures:

Maximum conductivity

Superior corrosion resistance

Excellent sealing and load distribution

Each batch undergoes chemical and physical testing before production to maintain consistency.

3. Customized Production Capability

Apart from standard M36 washers, we also offer:

Thickness customization (e.g., 1.5mm, 2mm, 3mm)

Hardness adjustment as per application

Burr-free and deburred finishes

We understand that every industry has specific needs—and we’re fully equipped to meet them with agility.

4. Bulk & On-Time Supply

With large-scale production and efficient logistics, we fulfill bulk orders for:

OEMs and component suppliers

Electrical panel manufacturers

Infrastructure & fabrication companies

We maintain steady inventory and just-in-time supply chains to reduce your procurement delays.

5. Competitive Pricing with No Compromise on Quality

We offer factory-direct pricing for all our copper washers—making sure our clients get excellent value for money without compromising on durability or finish.

6. Stringent Quality Control

Every washer goes through a multi-step QC process including:

Dimensional inspection

Surface finish check

Random batch hardness testing

Visual defect screening

We adhere to ISO-compliant internal QA protocols.

7. Trusted by Pan-India Clients

We’ve successfully supplied copper washers to:

Electrical component manufacturers

Automotive part suppliers

Marine and oil & gas contractors

HVAC and plumbing companies

Our reputation is built on decades of consistent quality and reliable service.

By choosing Nafees Metal Industries, you’re not just buying a washer—you’re investing in peace of mind, technical excellence, and dependable performance.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we’re not just another washer manufacturer—we’re your long-term industrial fastening partner. With over a decade of experience in precision engineering, we’ve built a solid reputation for delivering high-quality metal washers that meet the toughest industrial standards. Here’s why businesses across India and the globe choose us for their copper plain washer DIN 125 size M36 requirements:

Strategically Located Manufacturing Facility – Mumbai, India

Our ISO-compliant production facility is located in Mumbai-based facility—India’s leading industrial and commercial hub. This location offers us excellent connectivity to:

Major ports like Nhava Sheva (JNPT) for efficient global exports.

A vast network of logistics partners for rapid pan-India delivery.

Access to high-quality raw materials and skilled labor.

Being based in Mumbai also enables us to serve clients from automotive, electrical, marine, and construction industries faster and more reliably.

Modern Infrastructure & In-House Capabilities

We operate with:

Power press machines ranging from 10 to 200 tons for precise, bulk manufacturing.

Tooling and die fabrication in-house to create customized washer profiles.

Copper sheet and strip processing for accurate dimensioning and thickness control.

Regular quality checks with micrometers, calipers, and gauges to ensure tolerances are maintained.

Every batch undergoes stringent quality assurance checks before dispatch.

Extensive Washer Portfolio

Apart from M36 Copper Plain Washers, we manufacture a wide range of industrial washers including:

Spring washers

Belleville disc washers

SS plain washers (SS202, SS304, SS316)

MS (Mild Steel) and brass washers

Custom sizes (M3 to M64 and beyond)

This makes us a one-stop solution for all your washer requirements.

Trusted by Diverse Industries

Our washers are used by OEMs, EPC contractors, MEP companies, and manufacturers across:

Heavy engineering

Automotive and railways

Electrical and electronics

Oil & gas and petrochemical

Renewable energy

Marine and offshore sectors

We cater to both small-scale buyers and bulk industrial procurement needs with equal attention.

Reliable Exports & Bulk Supply

With a growing network of international buyers, we regularly export copper and stainless steel washers to:

UAE

Saudi Arabia

Qatar

Kenya

Sri Lanka

Singapore

Malaysia, and more.

We offer:

Bulk order fulfillment

Private labelling & custom branding

Packaging based on international standards

Dedicated export coordination support

Transparent, Professional, and Customer-First Approach

We take pride in:

Prompt responses and personalized quotes.

Fair pricing with no hidden costs.

Timely delivery and consistent availability of stock.

Welcoming factory visits, audits, and virtual inspections.

Our goal is to ensure your supply chain never experiences delays due to fastener shortages.

Whether you’re a distributor, project buyer, or end-user, Nafees Metal Industries is committed to becoming your go-to washer supplier—backed by quality, consistency, and trust.

Frequently Asked Questions (FAQs)

What is the size of an M36 copper plain washer?

It is designed for M36 bolts, with an approximate inner diameter of 37 mm, as per DIN 125.Are these washers corrosion-resistant?

Yes, copper offers natural corrosion resistance, especially suitable for humid and marine environments.Do M36 copper washers offer electrical conductivity?

Absolutely. Copper is one of the best conductors of electricity, ideal for grounding applications.Can I get a polished finish for decorative use?

Yes, we offer polished finishes on request for aesthetic or functional requirements.Are M36 copper flat washers reusable?

In most applications, yes—especially if they are not deformed during installation.Are these washers compatible with stainless steel bolts?

Yes, but ensure galvanic compatibility in high-moisture environments.What is the minimum order quantity?

We supply from 500 pcs up to bulk industrial quantities. Contact us for MOQ flexibility.Can you ship to the UAE or other international locations?

Yes, we are export-ready with all required documentation and certifications.What standards do your M36 copper washers comply with?

They follow DIN 125 and ISO 7089 dimensional and performance standards.What industries use M36 copper washers?

Electrical, marine, chemical, HVAC, and machinery industries are common users.Are these washers available in metric series?

Yes, we offer M36 copper flat washer metric series DIN 125.Do copper washers help with sealing?

Yes, especially in hydraulic and pneumatic fittings, acting as effective sealing washers.How do I order copper washers in custom packaging?

Just mention your packaging requirement while placing the order.Are there better alternatives to copper for this washer type?

For electrical and corrosion-prone environments, copper is unmatched. Alternatives may lack conductivity or sealing performance.Why choose Nafees Metal Industries?

We offer consistent quality, competitive pricing, custom solutions, and bulk readiness as one of India’s leading copper washer manufacturers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch