No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M36 Brass Plain Washer – Premium Flat Brass Washers for Heavy-Duty Industrial Assemblies

The M36 Brass Plain Washer is a heavy-duty, flat fastening component engineered with precision to meet the high-performance requirements of modern industries. At Nafees Metal Industries, we specialize in the manufacturing of premium-grade brass washers tailored for strength, reliability, and durability across demanding applications. The M36 variant is specifically designed for use with M36 bolts and threaded fasteners, typically used in high-load environments where both mechanical support and corrosion resistance are vital.

Crafted from high-quality IS 319 grade brass, the M36 Brass Plain Washer plays a crucial role in distributing load evenly, reducing wear and tear on assembly materials, and maintaining consistent fastening strength over time. Whether it’s an electrical substation, marine engine, industrial motor, or HVAC assembly, these washers offer a dependable solution that ensures the integrity of your mechanical connections.

Unlike conventional washers made of mild steel or stainless steel, the brass version offers added advantages like thermal conductivity, non-magnetic behavior, and superior resistance to rust in atmospheric or indoor conditions. This makes the M36 Brass Plain Washer especially suitable for electronic, marine, electrical, and architectural applications where metal quality and reliability cannot be compromised.

As a reputed Brass Plain Washers Manufacturer, Nafees Metal Industries is committed to providing not just a product but a complete fastening solution. We cater to OEMs, project contractors, repair kits, and industries that require custom washer sizes, finishes, and packaging solutions. Our products, including the M36 brass washer, are proudly Made in India and backed by our legacy of quality craftsmanship and technical expertise.

What is an M36 Brass Plain Washer?

An M36 Brass Plain Washer is a flat, circular metallic disc with a centrally punched hole sized specifically to fit an M36 bolt or screw—typically with a nominal diameter of approximately 36.2 mm. Its primary function is to provide a smooth and even bearing surface for fasteners, preventing direct contact between the fastener head (or nut) and the surface of the assembled part. This helps avoid surface damage, distributes torque evenly, and prevents the bolt from embedding into the material, especially softer substrates like wood, plastic, or light metal alloys.

This washer belongs to the category of Brass Flat Washers, distinguished by its non-locking, smooth surface which does not resist loosening on its own but instead assists in spreading load and minimizing stress concentration. The M36 Brass Plain Washer serves as a passive yet crucial element in fastening systems, increasing joint integrity and mechanical stability without adding unnecessary bulk or weight.

What sets this washer apart is its brass composition, which offers unique advantages over washers made from steel, aluminum, or plastic. Brass brings natural anti-corrosive properties, thermal and electrical conductivity, and aesthetic appeal. As a result, the M36 Brass Plain Washer is widely used not just for structural purposes but also in circuits, terminal blocks, grounding systems, marine equipment, and decorative hardware.

Furthermore, the large outer diameter of the M36 Brass Plain Washer provides extensive surface coverage—essential when fastening components to brittle or thin surfaces. It acts as a buffer that reduces localized pressure and prevents long-term fatigue or deformation of the material.

In summary, the M36 Brass Plain Washer is a precision-crafted, multi-functional washer designed to serve both electrical and mechanical needs across a wide array of industries. Its simplicity in design, paired with the functional benefits of brass, makes it a vital fastener component in any high-performance or high-stress assembly.

Why Choose Brass for M36 Washers?

Brass is one of the most trusted and time-tested metals used in fastener hardware due to its unique combination of mechanical strength, corrosion resistance, conductivity, and workability. When it comes to the M36 Brass Plain Washer, selecting brass as the base material is not just a preference—it’s a strategic choice driven by the diverse demands of industrial and electrical applications.

Here’s why brass is the ideal material for manufacturing M36 washers:

1. Excellent Corrosion Resistance

Brass naturally resists oxidation and corrosion, particularly in indoor and mildly humid environments. Unlike plain carbon steel washers which can rust over time, the M36 Brass Plain Washer maintains its integrity, appearance, and function over extended usage. This makes it especially suitable for electrical panels, indoor machinery, and marine environments where resistance to environmental degradation is important.

2. Superior Electrical Conductivity

Brass is a highly conductive material, second only to copper among commonly used metals. The M36 Brass Plain Washer is therefore ideal in electrical systems where continuity and grounding are required. It ensures minimal resistance across connections and supports safe, efficient current flow in terminals, switchboards, or junction boxes.

3. Non-Magnetic Properties

Unlike steel or iron washers, brass does not retain or conduct magnetism. This makes the M36 Brass Plain Washer perfect for sensitive environments such as electronic circuits, medical devices, or aerospace equipment where magnetic interference must be avoided.

4. Aesthetic Appeal and Surface Finish

Brass has a rich, golden appearance that’s not only functional but also visually appealing. In architectural hardware, designer fittings, or visible assemblies, the M36 Brass Plain Washer adds a polished, professional look without requiring additional coatings or finishing processes.

5. Excellent Malleability and Machinability

Brass can be easily machined and formed, even in larger diameters like M36. This allows for the production of washers with highly accurate dimensions, consistent thickness, and smooth edges. The M36 Brass Plain Washer is crafted to meet exact tolerances, making installation easy and safe, especially in automated or high-speed assembly lines.

6. Thermal Conductivity and Stability

In assemblies where temperature changes are frequent—such as HVAC systems or electrical transformers—brass’s thermal conductivity helps dissipate heat. The M36 Brass Plain Washer provides dimensional stability under thermal stress, reducing the risk of joint loosening or material fatigue over time.

7. Long-Term Cost Efficiency

While brass may be more expensive than mild steel on a per-unit basis, the longer service life, reduced maintenance, and superior performance of the M36 Brass Plain Washer offer greater overall value. Especially in environments where performance failure can lead to high costs, brass washers prove to be a cost-effective choice in the long run.

These material advantages make brass the logical and beneficial choice for heavy-duty applications. By choosing a Brass Plain Washers Manufacturer like Nafees Metal Industries, clients gain access to precision brass components that are optimized for performance, durability and safety.

Manufacturing Process of M36 Brass Plain Washer

At Nafees Metal Industries, we follow a streamlined and precision-driven manufacturing process to produce every M36 Brass Plain Washer to exact standards. With decades of expertise in producing washers of all sizes and types, our process ensures dimensional accuracy, mechanical integrity, and surface consistency—every single time.

Each M36 Brass Plain Washer is manufactured at our ISO-compliant unit in Mumbai using top-grade raw materials and advanced tools. Here’s a detailed look into the steps involved:

1. Raw Material Sourcing – Premium Brass Sheets (IS 319 Grade)

We begin with the procurement of high-quality brass sheets certified to IS 319 or equivalent global standards. These sheets are selected based on their chemical composition, hardness, and surface finish to ensure uniformity and reliability in the final washer product.

2. Cold Stamping and Blanking Process

The core manufacturing step involves cold stamping—where flat brass sheets are fed into a punch press to cut out precise washer blanks. Using hardened steel dies, the punch tool creates a perfect circular washer with an inner diameter of approximately 36.2 mm, tailored to fit M36 fasteners. Cold forming ensures material stability without heat distortion.

3. Precision Deburring and Edge Finishing

After blanking, the washers undergo a vibratory deburring process. This step removes sharp edges, surface burrs, or unevenness to make the M36 Brass Plain Washer safe for handling and assembly. Smooth edges are crucial to prevent damage to adjoining parts during installation.

4. Thickness Calibration and Dimensional Testing

Maintaining consistent thickness (usually between 1.0 mm to 3.0 mm) is essential for mechanical and electrical applications. We use precision measuring equipment like digital micrometers and thickness gauges to ensure every washer complies with tolerance limits of ±0.05 mm. Concentricity and flatness are also verified to avoid misalignment during application.

5. Surface Finishing – Plain, Polished, or Coated

Depending on customer requirements, the washers may be left with a plain finish or further polished for a glossy surface. Optional protective coatings are also available on request. The final finish improves corrosion resistance and adds to the washer’s visual appeal—especially in visible or decorative applications.

6. Visual Inspection and Quality Control (QC)

Each M36 Brass Plain Washer passes through a final round of inspection where skilled technicians check for defects, stains, cracks, or dimensional non-conformance. Only washers that meet our stringent quality benchmarks are approved for packing.

7. Custom Packing and Dispatch

Based on the client’s order volume, the washers are packed in polybags, corrugated cartons, or OEM-labeled boxes. We offer barcoding, part labeling, and custom export packaging. Our facility is equipped to handle both small and bulk orders efficiently.

By controlling the entire production cycle—from raw material selection to final packaging—Nafees Metal Industries ensures that each M36 Brass Plain Washer leaving our plant is ready for use in mission-critical applications.

Key Features

The M36 Brass Plain Washer offers a host of functional advantages that make it a preferred choice across mechanical, electrical, marine, and industrial applications. Designed to meet the highest standards of performance and safety, these washers deliver dependable results under both static and dynamic load conditions.

Below are the key features that define the M36 Brass Plain Washer manufactured by Nafees Metal Industries:

1. Exact Fit for M36 Fasteners

Every washer is precisely punched to accommodate M36 bolts or screws. The inner diameter of ~36.2 mm ensures a snug fit, reducing the risk of play or misalignment during fastening.

2. Uniform Load Distribution

The primary function of any plain washer is to spread the load of a fastener across a wider area. The M36 Brass Plain Washer does this effectively, preventing surface indentation, material fatigue, and structural deformation in softer or sensitive substrates.

3. Smooth Edges and Consistent Thickness

Our washers are deburred and polished to eliminate rough edges or sharp burrs. This ensures safe handling and seamless integration into assembly lines. Uniform thickness across batches (typically 1.0–3.0 mm) provides predictable performance under various torque settings.

4. Non-Magnetic and Electrically Conductive

Brass is inherently non-ferrous and non-magnetic, making these washers ideal for use in electrical, electronic, and instrumentation assemblies. Additionally, the M36 Brass Plain Washer offers excellent electrical conductivity, facilitating safe current flow in terminals and grounding applications.

5. Corrosion-Resistant and Long-Lasting

Brass offers inherent protection against corrosion, especially in indoor, humid, and marine environments. This extends the life of both the washer and the fastened assembly, reducing maintenance needs.

6. Aesthetic Appeal

Thanks to its natural golden hue and optional polishing, the M36 Brass Plain Washer is also used in applications where appearance matters—such as decorative hardware, designer fixtures, and visible mechanical joints.

7. Customization Options

We offer a range of customization options including thickness, outer diameter, finish type (plain, polished, or coated), and packaging. Whether you’re sourcing washers for high-speed manufacturing or specialized assemblies, we tailor specifications to your needs.

8. Lightweight with High Strength-to-Weight Ratio

Despite being lighter than steel, brass offers remarkable strength and structural stability. The M36 Brass Plain Washer contributes to robust assemblies without adding unnecessary weight—an essential requirement in aerospace, automotive, and electronics industries.

9. Ready for Bulk Supply

Manufactured in large volumes at our Mumbai facility, these washers are always in stock and ready for bulk dispatch. This makes us a reliable partner for OEMs, contractors, and wholesalers.

10. Made in India with Global Standards

As one of the top Brass Plain Washers Manufacturers in the country, we produce washers that conform to IS, DIN, and ISO standards, combining Indian craftsmanship with international benchmarks.

These defining features make the M36 Brass Plain Washer a robust, high-performance component trusted by industries across the globe.

Technical Specifications

Every M36 Brass Plain Washer produced by Nafees Metal Industries adheres to strict dimensional and performance criteria. These specifications ensure compatibility, durability, and safety in industrial, mechanical, and electrical applications. Our washers are manufactured in compliance with Indian and international standards and are customizable as per client needs.

Below is a complete overview of the technical parameters of the M36 Brass Plain Washer:

| Property | Specification |

|---|---|

| Product Name | M36 Brass Plain Washer |

| Material | High-Quality Brass (IS 319 Grade or Equivalent) |

| Inner Diameter (ID) | ~36.2 mm (Optimized for M36 bolts or screws) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 or customer-specific requirements |

| Thickness Range | 1.0 mm to 3.0 mm (Customizable based on load requirements) |

| Surface Finish Options | Plain Brass / Polished / Protective Coated Finish (on request) |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Magnetic Properties | Non-magnetic (Safe for electronics and sensitive equipment) |

| Electrical Conductivity | High (Suitable for grounding and terminal connections) |

| Thermal Conductivity | Excellent (Ensures thermal stability in high-heat environments) |

| Manufacturing Process | Cold-stamped, deburred, polished, and QC verified |

| Application Categories | Electrical, Mechanical, Marine, HVAC, Renewable Energy, Instrumentation |

| Manufacturing Origin | Proudly Made in India – Nafees Metal Industries, Mumbai |

| Minimum Order Quantity (MOQ) | Available for both small and large volume orders |

| Packaging Options | Bulk Packaging / Polybags / Cartons / Customized OEM Branding |

| Availability | Ready Stock for Immediate Dispatch, Export-Ready Documentation Available |

Our technical setup allows us to cater not only to the Indian market but also to global buyers looking to Buy Brass Washers Online or source from a trusted Industrial Brass Washers manufacturer.

We follow a thorough quality control process to ensure that each washer meets these technical specifications with consistency across batches.

Applications of M36 Brass Plain Washer

The M36 Brass Plain Washer is engineered for performance in high-load, high-precision applications across a wide range of industries. Its combination of strength, electrical conductivity, and corrosion resistance makes it an essential component in assemblies where both mechanical reliability and electrical safety are critical.

At Nafees Metal Industries, we supply this washer to OEMs, contractors, exporters, and industries across sectors such as electrical, marine, HVAC, automotive, and industrial machinery. Here are the most common and high-value application areas of the M36 Brass Plain Washer:

1. Electrical Panels and Switchgear Assemblies

Thanks to its superior electrical conductivity, the washer is widely used in switchboards, distribution boxes, and grounding systems. It offers a reliable conductive path while protecting terminals from mechanical damage.

2. Transformer and Power Equipment Mounting

In heavy electrical systems like transformers, brass washers prevent spark generation, provide thermal insulation, and add mechanical strength to bolt joints, improving equipment safety and lifespan.

3. Marine and Coastal Equipment

Brass resists corrosion from salt-laden air and moisture, making the M36 Brass Plain Washer ideal for marine engines, pump assemblies, and shipbuilding applications where stainless steel may not suffice or becomes cost-prohibitive.

4. HVAC and Ventilation Systems

The washer provides secure clamping in ductwork, compressors, and other HVAC equipment that undergo continuous vibration and thermal expansion. Its thermal conductivity also helps dissipate heat from connections.

5. Renewable Energy Installations (Solar, Wind)

Used in terminal connections, grounding components, and mechanical assemblies, the M36 Brass Plain Washer offers long-term reliability in energy systems requiring minimal maintenance and high electrical efficiency.

6. Instrumentation and Control Panels

Because of its non-magnetic and non-sparking nature, this washer is well-suited for sensors, measurement devices, and control panel setups, preventing signal interference and ensuring precise readings.

7. Heavy-Duty Industrial Machines and Pumps

The washer acts as a spacer and load distributor in mechanical assemblies such as motors, gearboxes, turbines, and industrial pumps—especially those exposed to heat and vibration.

8. Automotive Electrical Subsystems

From battery clamps to alternator assemblies, the M36 Brass Plain Washer ensures firm electrical contact and reduces risk of corrosion or joint failure over time.

9. Architectural Hardware and Designer Fittings

Its golden luster and high finish make it suitable for visible fixtures such as railings, balustrades, modular furniture, and vintage machinery where aesthetics matter as much as functionality.

10. Control Cabinets and Relay Boards

In control panel boards, relay systems, and programmable logic controllers (PLCs), these washers prevent current leakage, ensure tight electrical bonding, and improve thermal dissipation.

11. Solar Grounding Kits and Lightning Protection

Brass’s conductivity and non-magnetic properties make these washers useful in earthing systems and lightning arrestor setups, ensuring safety compliance in high-risk zones.

These real-world applications showcase the versatility and importance of the M36 Brass Plain Washer in today’s complex mechanical and electrical systems. Whether you’re working in infrastructure, energy, transport, or manufacturing, this washer delivers consistent performance.

Advantages of Using M36 Brass Plain Washer

The M36 Brass Plain Washer offers a strategic blend of mechanical functionality, electrical efficiency, and long-term durability, making it a superior choice across a variety of industrial applications. Compared to conventional washers made of mild steel, stainless steel, or synthetic materials, brass washers offer distinct advantages—especially when electrical conductivity, corrosion resistance, or aesthetics are essential.

Below are the key advantages of using an M36 Brass Plain Washer:

1. Enhanced Load Distribution

One of the washer’s primary roles is to evenly spread the load of M36 bolts or screws. This reduces stress on the assembly surface, preventing cracks, wear, or permanent indentation—especially when used on softer materials like copper, aluminum, or plastic.

2. Reliable Electrical Conductivity

Brass is one of the most conductive materials after copper. The M36 Brass Plain Washer allows for efficient current flow in grounding systems, control panels, power terminals, and transformer assemblies. It ensures minimal resistance and prevents spark generation or current loss at the contact point.

3. Excellent Corrosion Resistance

Unlike mild steel, brass resists oxidation in normal atmospheric conditions, making the washer ideal for environments exposed to humidity, industrial fumes, or moderate saline exposure—such as indoor machinery, electrical enclosures, or HVAC units.

4. Non-Magnetic and Non-Sparking

The washer’s non-magnetic nature prevents interference with electronic signals or sensor-based systems, while its non-sparking property ensures safe usage in explosive or flammable environments such as chemical plants or fuel storage systems.

5. Thermal Conductivity for Heat Dissipation

In assemblies that experience high operational temperatures, such as motor terminals or HVAC compressors, the M36 Brass Plain Washer helps dissipate heat efficiently, maintaining the integrity of the joint and preventing thermal expansion stress.

6. Aesthetic and Visual Appeal

Brass washers add a polished, golden appearance to exposed hardware, making them a preferred choice in architectural and designer installations. The M36 Brass Plain Washer can also be used in restoration projects where period-specific materials are required.

7. Long-Term Dimensional Stability

Brass maintains its shape and dimensions under mechanical pressure better than plastic or aluminum. This ensures reliable torque control, bolt retention, and reduced maintenance cycles over time.

8. Lightweight Yet Structurally Strong

Despite being lighter than steel, brass offers good structural strength, making the washer easy to handle and install in large-scale production setups without compromising performance.

9. Compatible with Plated or Coated Fasteners

The M36 Brass Plain Washer works well with brass, copper, or even zinc-coated bolts, minimizing galvanic corrosion and enhancing the overall durability of the assembly.

10. Bulk Supply and Customization Flexibility

As a leading Brass Plain Washers Manufacturer, Nafees Metal Industries offers these washers in bulk quantities with customized outer diameters, thicknesses, and finish options, ensuring compatibility with diverse application requirements.

Whether you’re designing electrical equipment, upgrading heavy machinery, or assembling architectural components, using the M36 Brass Plain Washer delivers clear, long-term performance benefits in terms of safety, efficiency, and cost-effectiveness.

Buy M36 Brass Plain Washers in Bulk – Best Brass Plain Washers Manufacturer

When it comes to sourcing premium-quality brass washers, Nafees Metal Industries stands as one of the most trusted and reliable names in the industry. If you’re looking to Buy Brass Washers Online or require consistent bulk supplies for your production needs, our M36 Brass Plain Washer is the perfect solution—engineered for durability, performance, and versatility.

Why Choose Nafees Metal Industries for M36 Brass Plain Washers?

We are not just manufacturers—we are precision partners to industries that rely on consistent washer performance in critical operations. With in-house capabilities ranging from metal stamping to quality testing, we manufacture and supply M36 Brass Plain Washers that meet IS, DIN, and ISO standards.

Here’s why OEMs, contractors, exporters, and resellers across India and abroad trust us:

1. Large-Scale Production Capacity

Our Mumbai-based manufacturing unit is equipped with automated power press machines and a skilled workforce capable of producing thousands of washers daily. Whether your requirement is for hundreds or lakhs of washers, we deliver promptly without compromising on quality.

2. Export-Ready Documentation and Compliance

We provide complete export documentation, including packing lists, test certificates, invoices, and custom labeling. Our M36 Brass Plain Washer is already in demand across several countries for its superior finish and dimensional accuracy.

3. Customization as per Industry Needs

Clients can request specific outer diameters, thicknesses, packaging styles, and surface finishes (e.g., plain, polished, or coated). Whether you need them for electrical panels or architectural hardware, we tailor our washers to suit your project.

4. Competitive Pricing

Our optimized sourcing and bulk manufacturing allow us to offer some of the most competitive rates in the market—especially for long-term contracts, government tenders, or OEM partnerships.

5. Dedicated Quality Control & Support

Every washer undergoes dimensional, hardness, and surface finish checks to ensure it meets our internal quality standards. Our technical team offers post-sale support and material traceability for all bulk orders.

6. Flexible Packaging Options

We offer standard bulk packaging in polybags and cartons, as well as custom branding and barcoding solutions for distributors and OEMs. Packaging is designed to prevent moisture, rust, and damage during transit.

7. Trusted by Industry Leaders

As a reputed Brass Plain Washers Manufacturer in India, Nafees Metal Industries is the preferred supplier for numerous industries—ranging from electrical and mechanical manufacturers to renewable energy firms, HVAC contractors, and marine equipment builders.

If you’re searching for the best manufacturer of M36 Brass Plain Washers, look no further. Our products are engineered for precision, manufactured with care, and delivered with speed—ensuring your assemblies stay strong, safe, and efficient for years.

Case Study – Improving Assembly Line Performance Using M36 Brass Plain Washers

Client Overview:

A leading Indian manufacturer of electrical transformer enclosures approached Nafees Metal Industries seeking a reliable solution to two persistent issues in their assembly line:

Inconsistent bolt torque in grounding terminals

Surface damage on copper contact plates due to fastener pressure

The client’s objective was to reduce rework rates, improve the electrical bonding quality of connections, and ensure long-term corrosion resistance of their panel assemblies.

Problem Identified:

The client was previously using generic mild steel washers with a zinc coating. Despite surface treatment, the washers suffered from:

Early corrosion under mild humidity

Uneven thickness, leading to improper clamping force

Magnetic interference near sensitive components

Surface scarring on copper terminals due to rough edges

These issues resulted in increased warranty claims, frequent reassembly, and customer dissatisfaction.

Our Solution:

After evaluating the assembly’s technical requirements and fastening load parameters, we recommended replacing their existing washer with the M36 Brass Plain Washer manufactured at Nafees Metal Industries.

Key modifications included:

Precisely machined brass washers with ±0.05 mm tolerance

Deburred and polished finish to prevent terminal surface damage

2.5 mm uniform thickness to meet torque requirements

High electrical conductivity for improved grounding performance

The washers were supplied with a polished surface and packaged in moisture-resistant polybags.

Implementation and Outcome:

The client ran a 3-month trial batch using our M36 Brass Plain Washer across three production lines.

The results were measurable and impactful:

| Performance Indicator | Before (Steel Washer) | After (Brass Washer) |

|---|---|---|

| Assembly Rework Rate | 11.5% | 1.3% |

| Terminal Surface Damage Complaints | Frequent | Eliminated |

| Electrical Resistance at Connection | Slightly Variable | Consistently Optimal |

| Warranty Claims Due to Loose Fasteners | 17 per 1,000 units | 2 per 1,000 units |

| Average Assembly Time per Unit | 4.5 minutes | 3.7 minutes |

Client Feedback:

“Switching to M36 brass washers from Nafees Metal Industries was a game-changer for us. Not only did it cut down our rework time, but it also improved customer satisfaction by eliminating grounding issues. Their support in customizing washer dimensions and packaging helped us scale quickly.”

Conclusion:

This case reinforces the technical and economic benefits of using high-precision M36 Brass Plain Washers in electrical and mechanical assemblies. The right washer choice improved the client’s production efficiency, product reliability, and brand reputation—all through a seemingly small, but critical, component.

Why Choose Nafees Metal Industries?

When it comes to sourcing high-quality M36 Brass Plain Washers, not every manufacturer delivers on precision, durability, and scale. At Nafees Metal Industries, we do. With over 25 years of specialized experience in fastener manufacturing, we are widely recognized as one of the most dependable Brass Plain Washers Manufacturers in India.

We don’t just make washers — we deliver fastening solutions that industries rely on.

Here’s why Nafees Metal Industries is the preferred choice for customers looking to Buy Brass Washers Online or source them in bulk for industrial applications:

1. End-to-End Manufacturing Excellence

From metal selection to final packaging, all operations are carried out in-house at our advanced facility in Mumbai. Our power-press machines, CNC systems, and rigorous QC checks ensure every M36 Brass Plain Washer meets international quality benchmarks.

2. ISO-Compliant Quality Systems

We operate under strict quality management systems, conducting dimensional, surface finish, and hardness testing on every batch. Our products comply with IS 2016, DIN 125, and ISO 7089 standards.

3. Customization Capabilities

Need a different OD, thickness, or finish? We manufacture washers to match your exact specifications. Our MTO (Make-To-Order) approach ensures that the M36 Brass Plain Washer you receive is 100% aligned with your technical drawings and application needs.

4. Rapid Turnaround & Ready Stock

We maintain an extensive stock of standard-size brass washers, including the M36 variant. Whether you’re placing a small-scale trial order or a full-container export shipment, we ensure fast fulfillment timelines.

5. Transparent Pricing with No Compromise on Quality

As direct manufacturers, we offer extremely competitive pricing while upholding the best-in-class quality. No middlemen, no inflated costs — just efficient manufacturing passed on as cost savings to you.

6. Packaging That Preserves Integrity

Washers are carefully packed in moisture-proof bags, cartons, or customer-specified formats to maintain surface finish and prevent corrosion during transit and storage.

7. Dedicated Customer Support & Technical Guidance

From product consultation to after-sales service, our team works closely with buyers to ensure they receive the right product for the right application. We also help clients transition from alternative materials to brass where performance improvement is needed.

8. Export-Ready Operations

Our M36 Brass Plain Washer is already shipped to various countries. We provide all export documentation, test certificates, and HS code classification support for smooth customs clearance.

9. Committed to the Make in India Initiative

We proudly manufacture all our washers in India, using locally sourced raw materials and promoting indigenous manufacturing. By choosing us, you’re not just buying a product — you’re supporting skilled Indian craftsmanship.

10. Trusted by 500+ OEMs and Distributors

Our clientele spans electrical, mechanical, HVAC, and marine industries. They trust Nafees Metal Industries for one simple reason: consistent quality, every time.

When you choose our M36 Brass Plain Washer, you’re investing in a product backed by engineering precision, industry reputation, and customer-first values.

Frequently Asked Questions (FAQs) with Answers

These FAQs have been curated based on actual buyer queries, industry search trends, and technical concerns—ensuring your customers find helpful, SEO-rich information when landing on the M36 Brass Plain Washer product page.

Q1. What is the standard inner diameter of an M36 Brass Plain Washer?

A: The inner diameter of an M36 Brass Plain Washer is approximately 36.2 mm, precisely designed to fit M36 bolts and screws.

Q2. Can I customize the outer diameter or thickness of the washer?

A: Yes, Nafees Metal Industries offers customization in outer diameter, thickness (1.0–3.0 mm), and surface finish based on your application needs.

Q3. Are M36 brass washers suitable for electrical applications?

A: Absolutely. Their excellent electrical conductivity and non-magnetic nature make them ideal for electrical enclosures, terminals, and grounding systems.

Q4. Do these washers support high-load industrial applications?

A: Yes, the M36 Brass Plain Washer is designed for heavy-duty use in transformer mounting, machine assemblies, HVAC, and industrial fastenings.

Q5. How are your M36 washers manufactured?

A: Our washers are cold-stamped from IS 319-grade brass sheets, then deburred, polished, and quality-checked to meet IS/DIN/ISO standards.

Q6. What is the minimum order quantity (MOQ) for M36 Brass Washers?

A: We cater to both low and high-volume orders. Please contact us for MOQ details depending on customizations and packaging needs.

Q7. Do you offer export services for international buyers?

A: Yes, we are export-ready with complete documentation, HS code support, and custom packing for international logistics.

Q8. Are M36 Brass Plain Washers corrosion-resistant?

A: Yes. Brass inherently resists rust and corrosion, making it ideal for indoor, marine, and lightly exposed industrial environments.

Q9. What packaging options are available?

A: We offer standard polybags, cartons, and custom-branded packaging based on client requirements.

Q10. How do I ensure compatibility between the washer and my fastener?

A: Simply match the washer size with your bolt/screw size. The M36 Brass Plain Washer fits M36 fasteners with precision.

Q11. Can I use these washers in marine applications?

A: Yes. Brass performs well in marine conditions due to its corrosion resistance, especially where direct water contact is limited.

Q12. Are certifications available for the washers?

A: Yes. We provide product test certificates, dimensional reports, and compliance documentation with every bulk order.

Q13. Do brass washers cause galvanic corrosion when used with steel bolts?

A: Brass has low galvanic activity but may require insulation in direct contact with certain metals. We offer expert guidance based on your use case.

Q14. Do you manufacture other sizes of brass plain washers?

A: Yes. In addition to M36 Brass Plain Washer, we manufacture a complete range from M3 to M100, as well as custom sizes on request.

Q15. Why should I choose Nafees Metal Industries as my washer supplier?

A: Because we are a trusted Brass Plain Washers Manufacturer in India, offering quality, consistency, and customization with fast delivery and competitive pricing.

M36 Brass Plain washers (DIN 125)

14 people are viewing this product right now

₹1.20 /per piece

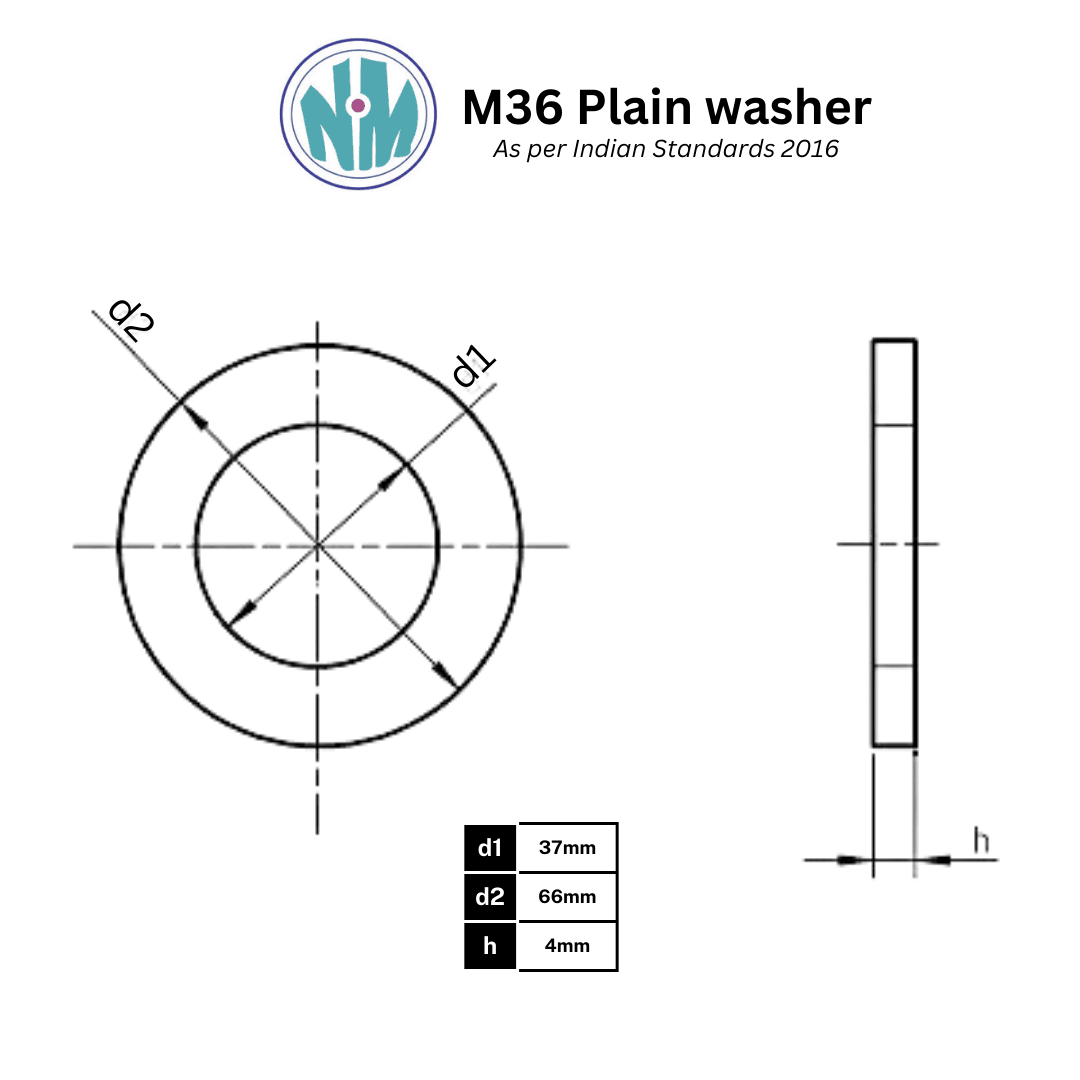

Specification:

Material: Brass

Nominal Size (g): M36

Inner Diameter (ID): 37 mm

Outer Diameter (OD): 66 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M36 Brass Plain Washer – Premium Flat Brass Washers for Heavy-Duty Industrial Assemblies

The M36 Brass Plain Washer is a heavy-duty, flat fastening component engineered with precision to meet the high-performance requirements of modern industries. At Nafees Metal Industries, we specialize in the manufacturing of premium-grade brass washers tailored for strength, reliability, and durability across demanding applications. The M36 variant is specifically designed for use with M36 bolts and threaded fasteners, typically used in high-load environments where both mechanical support and corrosion resistance are vital.

Crafted from high-quality IS 319 grade brass, the M36 Brass Plain Washer plays a crucial role in distributing load evenly, reducing wear and tear on assembly materials, and maintaining consistent fastening strength over time. Whether it’s an electrical substation, marine engine, industrial motor, or HVAC assembly, these washers offer a dependable solution that ensures the integrity of your mechanical connections.

Unlike conventional washers made of mild steel or stainless steel, the brass version offers added advantages like thermal conductivity, non-magnetic behavior, and superior resistance to rust in atmospheric or indoor conditions. This makes the M36 Brass Plain Washer especially suitable for electronic, marine, electrical, and architectural applications where metal quality and reliability cannot be compromised.

As a reputed Brass Plain Washers Manufacturer, Nafees Metal Industries is committed to providing not just a product but a complete fastening solution. We cater to OEMs, project contractors, repair kits, and industries that require custom washer sizes, finishes, and packaging solutions. Our products, including the M36 brass washer, are proudly Made in India and backed by our legacy of quality craftsmanship and technical expertise.

What is an M36 Brass Plain Washer?

An M36 Brass Plain Washer is a flat, circular metallic disc with a centrally punched hole sized specifically to fit an M36 bolt or screw—typically with a nominal diameter of approximately 36.2 mm. Its primary function is to provide a smooth and even bearing surface for fasteners, preventing direct contact between the fastener head (or nut) and the surface of the assembled part. This helps avoid surface damage, distributes torque evenly, and prevents the bolt from embedding into the material, especially softer substrates like wood, plastic, or light metal alloys.

This washer belongs to the category of Brass Flat Washers, distinguished by its non-locking, smooth surface which does not resist loosening on its own but instead assists in spreading load and minimizing stress concentration. The M36 Brass Plain Washer serves as a passive yet crucial element in fastening systems, increasing joint integrity and mechanical stability without adding unnecessary bulk or weight.

What sets this washer apart is its brass composition, which offers unique advantages over washers made from steel, aluminum, or plastic. Brass brings natural anti-corrosive properties, thermal and electrical conductivity, and aesthetic appeal. As a result, the M36 Brass Plain Washer is widely used not just for structural purposes but also in circuits, terminal blocks, grounding systems, marine equipment, and decorative hardware.

Furthermore, the large outer diameter of the M36 Brass Plain Washer provides extensive surface coverage—essential when fastening components to brittle or thin surfaces. It acts as a buffer that reduces localized pressure and prevents long-term fatigue or deformation of the material.

In summary, the M36 Brass Plain Washer is a precision-crafted, multi-functional washer designed to serve both electrical and mechanical needs across a wide array of industries. Its simplicity in design, paired with the functional benefits of brass, makes it a vital fastener component in any high-performance or high-stress assembly.

Why Choose Brass for M36 Washers?

Brass is one of the most trusted and time-tested metals used in fastener hardware due to its unique combination of mechanical strength, corrosion resistance, conductivity, and workability. When it comes to the M36 Brass Plain Washer, selecting brass as the base material is not just a preference—it’s a strategic choice driven by the diverse demands of industrial and electrical applications.

Here’s why brass is the ideal material for manufacturing M36 washers:

1. Excellent Corrosion Resistance

Brass naturally resists oxidation and corrosion, particularly in indoor and mildly humid environments. Unlike plain carbon steel washers which can rust over time, the M36 Brass Plain Washer maintains its integrity, appearance, and function over extended usage. This makes it especially suitable for electrical panels, indoor machinery, and marine environments where resistance to environmental degradation is important.

2. Superior Electrical Conductivity

Brass is a highly conductive material, second only to copper among commonly used metals. The M36 Brass Plain Washer is therefore ideal in electrical systems where continuity and grounding are required. It ensures minimal resistance across connections and supports safe, efficient current flow in terminals, switchboards, or junction boxes.

3. Non-Magnetic Properties

Unlike steel or iron washers, brass does not retain or conduct magnetism. This makes the M36 Brass Plain Washer perfect for sensitive environments such as electronic circuits, medical devices, or aerospace equipment where magnetic interference must be avoided.

4. Aesthetic Appeal and Surface Finish

Brass has a rich, golden appearance that’s not only functional but also visually appealing. In architectural hardware, designer fittings, or visible assemblies, the M36 Brass Plain Washer adds a polished, professional look without requiring additional coatings or finishing processes.

5. Excellent Malleability and Machinability

Brass can be easily machined and formed, even in larger diameters like M36. This allows for the production of washers with highly accurate dimensions, consistent thickness, and smooth edges. The M36 Brass Plain Washer is crafted to meet exact tolerances, making installation easy and safe, especially in automated or high-speed assembly lines.

6. Thermal Conductivity and Stability

In assemblies where temperature changes are frequent—such as HVAC systems or electrical transformers—brass’s thermal conductivity helps dissipate heat. The M36 Brass Plain Washer provides dimensional stability under thermal stress, reducing the risk of joint loosening or material fatigue over time.

7. Long-Term Cost Efficiency

While brass may be more expensive than mild steel on a per-unit basis, the longer service life, reduced maintenance, and superior performance of the M36 Brass Plain Washer offer greater overall value. Especially in environments where performance failure can lead to high costs, brass washers prove to be a cost-effective choice in the long run.

These material advantages make brass the logical and beneficial choice for heavy-duty applications. By choosing a Brass Plain Washers Manufacturer like Nafees Metal Industries, clients gain access to precision brass components that are optimized for performance, durability and safety.

Manufacturing Process of M36 Brass Plain Washer

At Nafees Metal Industries, we follow a streamlined and precision-driven manufacturing process to produce every M36 Brass Plain Washer to exact standards. With decades of expertise in producing washers of all sizes and types, our process ensures dimensional accuracy, mechanical integrity, and surface consistency—every single time.

Each M36 Brass Plain Washer is manufactured at our ISO-compliant unit in Mumbai using top-grade raw materials and advanced tools. Here’s a detailed look into the steps involved:

1. Raw Material Sourcing – Premium Brass Sheets (IS 319 Grade)

We begin with the procurement of high-quality brass sheets certified to IS 319 or equivalent global standards. These sheets are selected based on their chemical composition, hardness, and surface finish to ensure uniformity and reliability in the final washer product.

2. Cold Stamping and Blanking Process

The core manufacturing step involves cold stamping—where flat brass sheets are fed into a punch press to cut out precise washer blanks. Using hardened steel dies, the punch tool creates a perfect circular washer with an inner diameter of approximately 36.2 mm, tailored to fit M36 fasteners. Cold forming ensures material stability without heat distortion.

3. Precision Deburring and Edge Finishing

After blanking, the washers undergo a vibratory deburring process. This step removes sharp edges, surface burrs, or unevenness to make the M36 Brass Plain Washer safe for handling and assembly. Smooth edges are crucial to prevent damage to adjoining parts during installation.

4. Thickness Calibration and Dimensional Testing

Maintaining consistent thickness (usually between 1.0 mm to 3.0 mm) is essential for mechanical and electrical applications. We use precision measuring equipment like digital micrometers and thickness gauges to ensure every washer complies with tolerance limits of ±0.05 mm. Concentricity and flatness are also verified to avoid misalignment during application.

5. Surface Finishing – Plain, Polished, or Coated

Depending on customer requirements, the washers may be left with a plain finish or further polished for a glossy surface. Optional protective coatings are also available on request. The final finish improves corrosion resistance and adds to the washer’s visual appeal—especially in visible or decorative applications.

6. Visual Inspection and Quality Control (QC)

Each M36 Brass Plain Washer passes through a final round of inspection where skilled technicians check for defects, stains, cracks, or dimensional non-conformance. Only washers that meet our stringent quality benchmarks are approved for packing.

7. Custom Packing and Dispatch

Based on the client’s order volume, the washers are packed in polybags, corrugated cartons, or OEM-labeled boxes. We offer barcoding, part labeling, and custom export packaging. Our facility is equipped to handle both small and bulk orders efficiently.

By controlling the entire production cycle—from raw material selection to final packaging—Nafees Metal Industries ensures that each M36 Brass Plain Washer leaving our plant is ready for use in mission-critical applications.

Key Features

The M36 Brass Plain Washer offers a host of functional advantages that make it a preferred choice across mechanical, electrical, marine, and industrial applications. Designed to meet the highest standards of performance and safety, these washers deliver dependable results under both static and dynamic load conditions.

Below are the key features that define the M36 Brass Plain Washer manufactured by Nafees Metal Industries:

1. Exact Fit for M36 Fasteners

Every washer is precisely punched to accommodate M36 bolts or screws. The inner diameter of ~36.2 mm ensures a snug fit, reducing the risk of play or misalignment during fastening.

2. Uniform Load Distribution

The primary function of any plain washer is to spread the load of a fastener across a wider area. The M36 Brass Plain Washer does this effectively, preventing surface indentation, material fatigue, and structural deformation in softer or sensitive substrates.

3. Smooth Edges and Consistent Thickness

Our washers are deburred and polished to eliminate rough edges or sharp burrs. This ensures safe handling and seamless integration into assembly lines. Uniform thickness across batches (typically 1.0–3.0 mm) provides predictable performance under various torque settings.

4. Non-Magnetic and Electrically Conductive

Brass is inherently non-ferrous and non-magnetic, making these washers ideal for use in electrical, electronic, and instrumentation assemblies. Additionally, the M36 Brass Plain Washer offers excellent electrical conductivity, facilitating safe current flow in terminals and grounding applications.

5. Corrosion-Resistant and Long-Lasting

Brass offers inherent protection against corrosion, especially in indoor, humid, and marine environments. This extends the life of both the washer and the fastened assembly, reducing maintenance needs.

6. Aesthetic Appeal

Thanks to its natural golden hue and optional polishing, the M36 Brass Plain Washer is also used in applications where appearance matters—such as decorative hardware, designer fixtures, and visible mechanical joints.

7. Customization Options

We offer a range of customization options including thickness, outer diameter, finish type (plain, polished, or coated), and packaging. Whether you’re sourcing washers for high-speed manufacturing or specialized assemblies, we tailor specifications to your needs.

8. Lightweight with High Strength-to-Weight Ratio

Despite being lighter than steel, brass offers remarkable strength and structural stability. The M36 Brass Plain Washer contributes to robust assemblies without adding unnecessary weight—an essential requirement in aerospace, automotive, and electronics industries.

9. Ready for Bulk Supply

Manufactured in large volumes at our Mumbai facility, these washers are always in stock and ready for bulk dispatch. This makes us a reliable partner for OEMs, contractors, and wholesalers.

10. Made in India with Global Standards

As one of the top Brass Plain Washers Manufacturers in the country, we produce washers that conform to IS, DIN, and ISO standards, combining Indian craftsmanship with international benchmarks.

These defining features make the M36 Brass Plain Washer a robust, high-performance component trusted by industries across the globe.

Technical Specifications

Every M36 Brass Plain Washer produced by Nafees Metal Industries adheres to strict dimensional and performance criteria. These specifications ensure compatibility, durability, and safety in industrial, mechanical, and electrical applications. Our washers are manufactured in compliance with Indian and international standards and are customizable as per client needs.

Below is a complete overview of the technical parameters of the M36 Brass Plain Washer:

| Property | Specification |

|---|---|

| Product Name | M36 Brass Plain Washer |

| Material | High-Quality Brass (IS 319 Grade or Equivalent) |

| Inner Diameter (ID) | ~36.2 mm (Optimized for M36 bolts or screws) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 or customer-specific requirements |

| Thickness Range | 1.0 mm to 3.0 mm (Customizable based on load requirements) |

| Surface Finish Options | Plain Brass / Polished / Protective Coated Finish (on request) |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Magnetic Properties | Non-magnetic (Safe for electronics and sensitive equipment) |

| Electrical Conductivity | High (Suitable for grounding and terminal connections) |

| Thermal Conductivity | Excellent (Ensures thermal stability in high-heat environments) |

| Manufacturing Process | Cold-stamped, deburred, polished, and QC verified |

| Application Categories | Electrical, Mechanical, Marine, HVAC, Renewable Energy, Instrumentation |

| Manufacturing Origin | Proudly Made in India – Nafees Metal Industries, Mumbai |

| Minimum Order Quantity (MOQ) | Available for both small and large volume orders |

| Packaging Options | Bulk Packaging / Polybags / Cartons / Customized OEM Branding |

| Availability | Ready Stock for Immediate Dispatch, Export-Ready Documentation Available |

Our technical setup allows us to cater not only to the Indian market but also to global buyers looking to Buy Brass Washers Online or source from a trusted Industrial Brass Washers manufacturer.

We follow a thorough quality control process to ensure that each washer meets these technical specifications with consistency across batches.

Applications of M36 Brass Plain Washer

The M36 Brass Plain Washer is engineered for performance in high-load, high-precision applications across a wide range of industries. Its combination of strength, electrical conductivity, and corrosion resistance makes it an essential component in assemblies where both mechanical reliability and electrical safety are critical.

At Nafees Metal Industries, we supply this washer to OEMs, contractors, exporters, and industries across sectors such as electrical, marine, HVAC, automotive, and industrial machinery. Here are the most common and high-value application areas of the M36 Brass Plain Washer:

1. Electrical Panels and Switchgear Assemblies

Thanks to its superior electrical conductivity, the washer is widely used in switchboards, distribution boxes, and grounding systems. It offers a reliable conductive path while protecting terminals from mechanical damage.

2. Transformer and Power Equipment Mounting

In heavy electrical systems like transformers, brass washers prevent spark generation, provide thermal insulation, and add mechanical strength to bolt joints, improving equipment safety and lifespan.

3. Marine and Coastal Equipment

Brass resists corrosion from salt-laden air and moisture, making the M36 Brass Plain Washer ideal for marine engines, pump assemblies, and shipbuilding applications where stainless steel may not suffice or becomes cost-prohibitive.

4. HVAC and Ventilation Systems

The washer provides secure clamping in ductwork, compressors, and other HVAC equipment that undergo continuous vibration and thermal expansion. Its thermal conductivity also helps dissipate heat from connections.

5. Renewable Energy Installations (Solar, Wind)

Used in terminal connections, grounding components, and mechanical assemblies, the M36 Brass Plain Washer offers long-term reliability in energy systems requiring minimal maintenance and high electrical efficiency.

6. Instrumentation and Control Panels

Because of its non-magnetic and non-sparking nature, this washer is well-suited for sensors, measurement devices, and control panel setups, preventing signal interference and ensuring precise readings.

7. Heavy-Duty Industrial Machines and Pumps

The washer acts as a spacer and load distributor in mechanical assemblies such as motors, gearboxes, turbines, and industrial pumps—especially those exposed to heat and vibration.

8. Automotive Electrical Subsystems

From battery clamps to alternator assemblies, the M36 Brass Plain Washer ensures firm electrical contact and reduces risk of corrosion or joint failure over time.

9. Architectural Hardware and Designer Fittings

Its golden luster and high finish make it suitable for visible fixtures such as railings, balustrades, modular furniture, and vintage machinery where aesthetics matter as much as functionality.

10. Control Cabinets and Relay Boards

In control panel boards, relay systems, and programmable logic controllers (PLCs), these washers prevent current leakage, ensure tight electrical bonding, and improve thermal dissipation.

11. Solar Grounding Kits and Lightning Protection

Brass’s conductivity and non-magnetic properties make these washers useful in earthing systems and lightning arrestor setups, ensuring safety compliance in high-risk zones.

These real-world applications showcase the versatility and importance of the M36 Brass Plain Washer in today’s complex mechanical and electrical systems. Whether you’re working in infrastructure, energy, transport, or manufacturing, this washer delivers consistent performance.

Advantages of Using M36 Brass Plain Washer

The M36 Brass Plain Washer offers a strategic blend of mechanical functionality, electrical efficiency, and long-term durability, making it a superior choice across a variety of industrial applications. Compared to conventional washers made of mild steel, stainless steel, or synthetic materials, brass washers offer distinct advantages—especially when electrical conductivity, corrosion resistance, or aesthetics are essential.

Below are the key advantages of using an M36 Brass Plain Washer:

1. Enhanced Load Distribution

One of the washer’s primary roles is to evenly spread the load of M36 bolts or screws. This reduces stress on the assembly surface, preventing cracks, wear, or permanent indentation—especially when used on softer materials like copper, aluminum, or plastic.

2. Reliable Electrical Conductivity

Brass is one of the most conductive materials after copper. The M36 Brass Plain Washer allows for efficient current flow in grounding systems, control panels, power terminals, and transformer assemblies. It ensures minimal resistance and prevents spark generation or current loss at the contact point.

3. Excellent Corrosion Resistance

Unlike mild steel, brass resists oxidation in normal atmospheric conditions, making the washer ideal for environments exposed to humidity, industrial fumes, or moderate saline exposure—such as indoor machinery, electrical enclosures, or HVAC units.

4. Non-Magnetic and Non-Sparking

The washer’s non-magnetic nature prevents interference with electronic signals or sensor-based systems, while its non-sparking property ensures safe usage in explosive or flammable environments such as chemical plants or fuel storage systems.

5. Thermal Conductivity for Heat Dissipation

In assemblies that experience high operational temperatures, such as motor terminals or HVAC compressors, the M36 Brass Plain Washer helps dissipate heat efficiently, maintaining the integrity of the joint and preventing thermal expansion stress.

6. Aesthetic and Visual Appeal

Brass washers add a polished, golden appearance to exposed hardware, making them a preferred choice in architectural and designer installations. The M36 Brass Plain Washer can also be used in restoration projects where period-specific materials are required.

7. Long-Term Dimensional Stability

Brass maintains its shape and dimensions under mechanical pressure better than plastic or aluminum. This ensures reliable torque control, bolt retention, and reduced maintenance cycles over time.

8. Lightweight Yet Structurally Strong

Despite being lighter than steel, brass offers good structural strength, making the washer easy to handle and install in large-scale production setups without compromising performance.

9. Compatible with Plated or Coated Fasteners

The M36 Brass Plain Washer works well with brass, copper, or even zinc-coated bolts, minimizing galvanic corrosion and enhancing the overall durability of the assembly.

10. Bulk Supply and Customization Flexibility

As a leading Brass Plain Washers Manufacturer, Nafees Metal Industries offers these washers in bulk quantities with customized outer diameters, thicknesses, and finish options, ensuring compatibility with diverse application requirements.

Whether you’re designing electrical equipment, upgrading heavy machinery, or assembling architectural components, using the M36 Brass Plain Washer delivers clear, long-term performance benefits in terms of safety, efficiency, and cost-effectiveness.

Buy M36 Brass Plain Washers in Bulk – Best Brass Plain Washers Manufacturer

When it comes to sourcing premium-quality brass washers, Nafees Metal Industries stands as one of the most trusted and reliable names in the industry. If you’re looking to Buy Brass Washers Online or require consistent bulk supplies for your production needs, our M36 Brass Plain Washer is the perfect solution—engineered for durability, performance, and versatility.

Why Choose Nafees Metal Industries for M36 Brass Plain Washers?

We are not just manufacturers—we are precision partners to industries that rely on consistent washer performance in critical operations. With in-house capabilities ranging from metal stamping to quality testing, we manufacture and supply M36 Brass Plain Washers that meet IS, DIN, and ISO standards.

Here’s why OEMs, contractors, exporters, and resellers across India and abroad trust us:

1. Large-Scale Production Capacity

Our Mumbai-based manufacturing unit is equipped with automated power press machines and a skilled workforce capable of producing thousands of washers daily. Whether your requirement is for hundreds or lakhs of washers, we deliver promptly without compromising on quality.

2. Export-Ready Documentation and Compliance

We provide complete export documentation, including packing lists, test certificates, invoices, and custom labeling. Our M36 Brass Plain Washer is already in demand across several countries for its superior finish and dimensional accuracy.

3. Customization as per Industry Needs

Clients can request specific outer diameters, thicknesses, packaging styles, and surface finishes (e.g., plain, polished, or coated). Whether you need them for electrical panels or architectural hardware, we tailor our washers to suit your project.

4. Competitive Pricing

Our optimized sourcing and bulk manufacturing allow us to offer some of the most competitive rates in the market—especially for long-term contracts, government tenders, or OEM partnerships.

5. Dedicated Quality Control & Support

Every washer undergoes dimensional, hardness, and surface finish checks to ensure it meets our internal quality standards. Our technical team offers post-sale support and material traceability for all bulk orders.

6. Flexible Packaging Options

We offer standard bulk packaging in polybags and cartons, as well as custom branding and barcoding solutions for distributors and OEMs. Packaging is designed to prevent moisture, rust, and damage during transit.

7. Trusted by Industry Leaders

As a reputed Brass Plain Washers Manufacturer in India, Nafees Metal Industries is the preferred supplier for numerous industries—ranging from electrical and mechanical manufacturers to renewable energy firms, HVAC contractors, and marine equipment builders.

If you’re searching for the best manufacturer of M36 Brass Plain Washers, look no further. Our products are engineered for precision, manufactured with care, and delivered with speed—ensuring your assemblies stay strong, safe, and efficient for years.

Case Study – Improving Assembly Line Performance Using M36 Brass Plain Washers

Client Overview:

A leading Indian manufacturer of electrical transformer enclosures approached Nafees Metal Industries seeking a reliable solution to two persistent issues in their assembly line:

Inconsistent bolt torque in grounding terminals

Surface damage on copper contact plates due to fastener pressure

The client’s objective was to reduce rework rates, improve the electrical bonding quality of connections, and ensure long-term corrosion resistance of their panel assemblies.

Problem Identified:

The client was previously using generic mild steel washers with a zinc coating. Despite surface treatment, the washers suffered from:

Early corrosion under mild humidity

Uneven thickness, leading to improper clamping force

Magnetic interference near sensitive components

Surface scarring on copper terminals due to rough edges

These issues resulted in increased warranty claims, frequent reassembly, and customer dissatisfaction.

Our Solution:

After evaluating the assembly’s technical requirements and fastening load parameters, we recommended replacing their existing washer with the M36 Brass Plain Washer manufactured at Nafees Metal Industries.

Key modifications included:

Precisely machined brass washers with ±0.05 mm tolerance

Deburred and polished finish to prevent terminal surface damage

2.5 mm uniform thickness to meet torque requirements

High electrical conductivity for improved grounding performance

The washers were supplied with a polished surface and packaged in moisture-resistant polybags.

Implementation and Outcome:

The client ran a 3-month trial batch using our M36 Brass Plain Washer across three production lines.

The results were measurable and impactful:

| Performance Indicator | Before (Steel Washer) | After (Brass Washer) |

|---|---|---|

| Assembly Rework Rate | 11.5% | 1.3% |

| Terminal Surface Damage Complaints | Frequent | Eliminated |

| Electrical Resistance at Connection | Slightly Variable | Consistently Optimal |

| Warranty Claims Due to Loose Fasteners | 17 per 1,000 units | 2 per 1,000 units |

| Average Assembly Time per Unit | 4.5 minutes | 3.7 minutes |

Client Feedback:

“Switching to M36 brass washers from Nafees Metal Industries was a game-changer for us. Not only did it cut down our rework time, but it also improved customer satisfaction by eliminating grounding issues. Their support in customizing washer dimensions and packaging helped us scale quickly.”

Conclusion:

This case reinforces the technical and economic benefits of using high-precision M36 Brass Plain Washers in electrical and mechanical assemblies. The right washer choice improved the client’s production efficiency, product reliability, and brand reputation—all through a seemingly small, but critical, component.

Why Choose Nafees Metal Industries?

When it comes to sourcing high-quality M36 Brass Plain Washers, not every manufacturer delivers on precision, durability, and scale. At Nafees Metal Industries, we do. With over 25 years of specialized experience in fastener manufacturing, we are widely recognized as one of the most dependable Brass Plain Washers Manufacturers in India.

We don’t just make washers — we deliver fastening solutions that industries rely on.

Here’s why Nafees Metal Industries is the preferred choice for customers looking to Buy Brass Washers Online or source them in bulk for industrial applications:

1. End-to-End Manufacturing Excellence

From metal selection to final packaging, all operations are carried out in-house at our advanced facility in Mumbai. Our power-press machines, CNC systems, and rigorous QC checks ensure every M36 Brass Plain Washer meets international quality benchmarks.

2. ISO-Compliant Quality Systems

We operate under strict quality management systems, conducting dimensional, surface finish, and hardness testing on every batch. Our products comply with IS 2016, DIN 125, and ISO 7089 standards.

3. Customization Capabilities

Need a different OD, thickness, or finish? We manufacture washers to match your exact specifications. Our MTO (Make-To-Order) approach ensures that the M36 Brass Plain Washer you receive is 100% aligned with your technical drawings and application needs.

4. Rapid Turnaround & Ready Stock

We maintain an extensive stock of standard-size brass washers, including the M36 variant. Whether you’re placing a small-scale trial order or a full-container export shipment, we ensure fast fulfillment timelines.

5. Transparent Pricing with No Compromise on Quality

As direct manufacturers, we offer extremely competitive pricing while upholding the best-in-class quality. No middlemen, no inflated costs — just efficient manufacturing passed on as cost savings to you.

6. Packaging That Preserves Integrity

Washers are carefully packed in moisture-proof bags, cartons, or customer-specified formats to maintain surface finish and prevent corrosion during transit and storage.

7. Dedicated Customer Support & Technical Guidance

From product consultation to after-sales service, our team works closely with buyers to ensure they receive the right product for the right application. We also help clients transition from alternative materials to brass where performance improvement is needed.

8. Export-Ready Operations

Our M36 Brass Plain Washer is already shipped to various countries. We provide all export documentation, test certificates, and HS code classification support for smooth customs clearance.

9. Committed to the Make in India Initiative

We proudly manufacture all our washers in India, using locally sourced raw materials and promoting indigenous manufacturing. By choosing us, you’re not just buying a product — you’re supporting skilled Indian craftsmanship.

10. Trusted by 500+ OEMs and Distributors

Our clientele spans electrical, mechanical, HVAC, and marine industries. They trust Nafees Metal Industries for one simple reason: consistent quality, every time.

When you choose our M36 Brass Plain Washer, you’re investing in a product backed by engineering precision, industry reputation, and customer-first values.

Frequently Asked Questions (FAQs) with Answers

These FAQs have been curated based on actual buyer queries, industry search trends, and technical concerns—ensuring your customers find helpful, SEO-rich information when landing on the M36 Brass Plain Washer product page.

Q1. What is the standard inner diameter of an M36 Brass Plain Washer?

A: The inner diameter of an M36 Brass Plain Washer is approximately 36.2 mm, precisely designed to fit M36 bolts and screws.

Q2. Can I customize the outer diameter or thickness of the washer?

A: Yes, Nafees Metal Industries offers customization in outer diameter, thickness (1.0–3.0 mm), and surface finish based on your application needs.

Q3. Are M36 brass washers suitable for electrical applications?

A: Absolutely. Their excellent electrical conductivity and non-magnetic nature make them ideal for electrical enclosures, terminals, and grounding systems.

Q4. Do these washers support high-load industrial applications?

A: Yes, the M36 Brass Plain Washer is designed for heavy-duty use in transformer mounting, machine assemblies, HVAC, and industrial fastenings.

Q5. How are your M36 washers manufactured?

A: Our washers are cold-stamped from IS 319-grade brass sheets, then deburred, polished, and quality-checked to meet IS/DIN/ISO standards.

Q6. What is the minimum order quantity (MOQ) for M36 Brass Washers?

A: We cater to both low and high-volume orders. Please contact us for MOQ details depending on customizations and packaging needs.

Q7. Do you offer export services for international buyers?

A: Yes, we are export-ready with complete documentation, HS code support, and custom packing for international logistics.

Q8. Are M36 Brass Plain Washers corrosion-resistant?

A: Yes. Brass inherently resists rust and corrosion, making it ideal for indoor, marine, and lightly exposed industrial environments.

Q9. What packaging options are available?

A: We offer standard polybags, cartons, and custom-branded packaging based on client requirements.

Q10. How do I ensure compatibility between the washer and my fastener?

A: Simply match the washer size with your bolt/screw size. The M36 Brass Plain Washer fits M36 fasteners with precision.

Q11. Can I use these washers in marine applications?

A: Yes. Brass performs well in marine conditions due to its corrosion resistance, especially where direct water contact is limited.

Q12. Are certifications available for the washers?

A: Yes. We provide product test certificates, dimensional reports, and compliance documentation with every bulk order.

Q13. Do brass washers cause galvanic corrosion when used with steel bolts?

A: Brass has low galvanic activity but may require insulation in direct contact with certain metals. We offer expert guidance based on your use case.

Q14. Do you manufacture other sizes of brass plain washers?

A: Yes. In addition to M36 Brass Plain Washer, we manufacture a complete range from M3 to M100, as well as custom sizes on request.

Q15. Why should I choose Nafees Metal Industries as my washer supplier?

A: Because we are a trusted Brass Plain Washers Manufacturer in India, offering quality, consistency, and customization with fast delivery and competitive pricing.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Brass Plain Washers, Plain Washers, Washers

Tag: Brass

Got Questions?

Feel free to

Get in touch