No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M6 Plain washers – SS304 Stainsless steel washers"

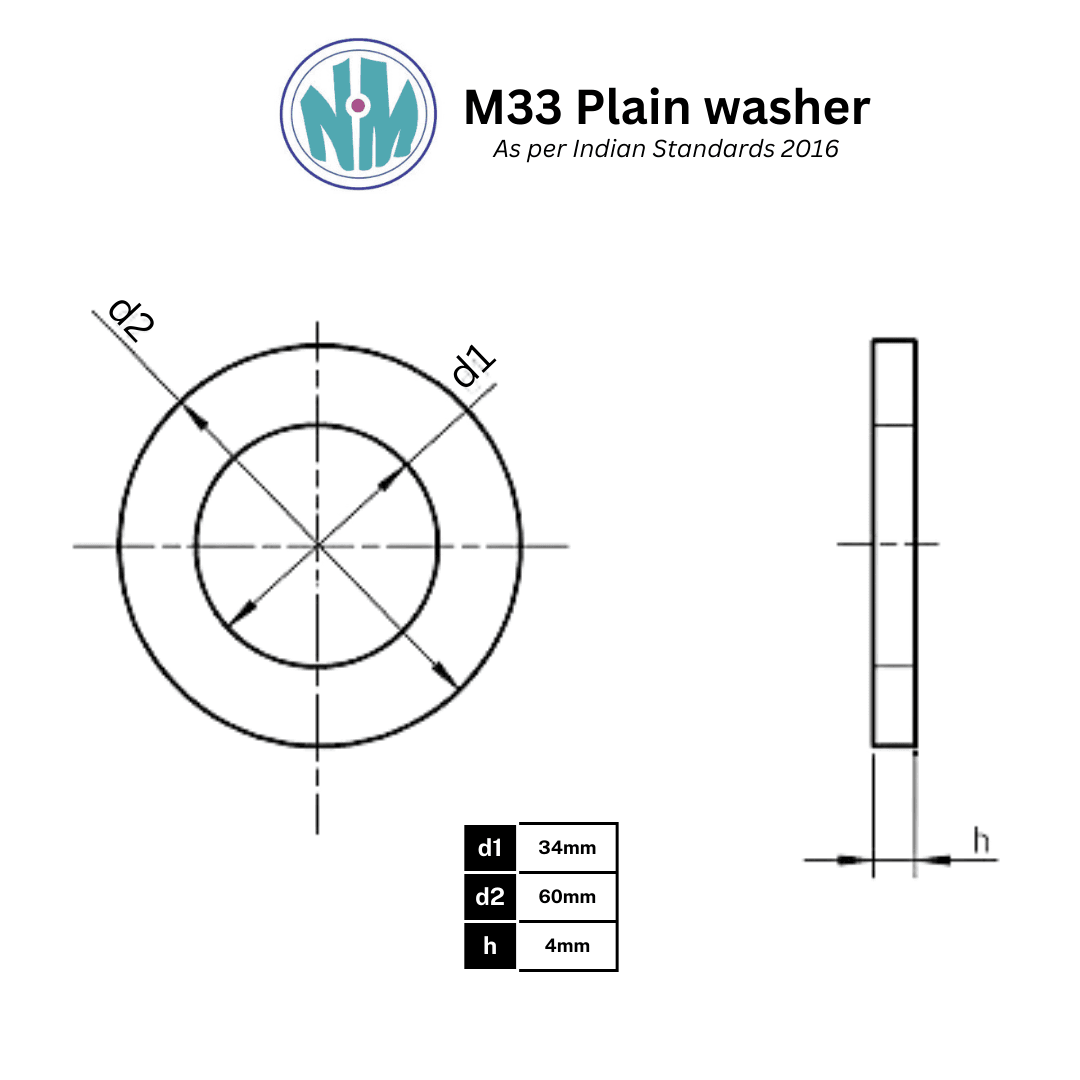

*Images shown for graphic representation. Not to scale.

M33 Mild Steel Plain Washers – Heavy-Duty Mild Steel Flat Washers for Reliable Industrial Fastening

Introduction

In every industrial fastening application, washers play an essential yet underestimated role in maintaining structural integrity, preventing fastener loosening, and protecting the surfaces they secure. Among the many types available, M33 Mild Steel Plain Washers stand out for their durability, versatility, and affordability — making them an ideal choice for high-load, heavy-duty applications.

Whether you’re operating in the automotive sector, construction, heavy machinery, or general manufacturing, the right washer makes all the difference. Choosing a material that’s tough enough to withstand vibration, stress, and repetitive tightening is vital — and mild steel remains a trusted, proven option for countless engineers and project managers.

At Nafees Metal Industries, we have decades of expertise in manufacturing and supplying M33 Mild Steel Plain Washers. Our washers are engineered for consistent load distribution, exceptional dimensional accuracy, and long-lasting performance. When you’re looking for durable Mild Steel Flat Washers to reinforce your assemblies, our products deliver every time.

What Are M33 Mild Steel Plain Washers?

M33 Mild Steel Plain Washers are robust, flat disc-shaped components with a precisely machined central hole designed to fit M33 bolts or screws. The plain washer’s primary function is to spread the load exerted by a fastener head or nut across a larger area, thereby protecting the material beneath from damage, indentation, or cracking.

Unlike specialized lock washers or spring washers, plain washers are designed for general-purpose applications where load distribution and surface protection are paramount. Their simple yet effective design makes them indispensable in everything from structural frameworks to automotive chassis, heavy equipment, and DIY maintenance work.

M33 Mild Steel Plain Washers play four vital roles:

Load Distribution: They spread the force of the fastener evenly, minimizing localized stress and potential material failure.

Vibration Resistance: They reduce the impact of constant vibration, helping to maintain fastener tightness.

Surface Protection: They shield softer or coated surfaces from scratches and deformation.

Long-Term Durability: Their sturdy mild steel construction ensures they can handle repeated tightening without losing shape or strength.

Material Details: Why Mild Steel?

When selecting washers, the material you choose can make or break the reliability of your fastening system. Mild steel remains one of the most trusted materials for plain washers due to its balance of affordability, machinability, and tensile strength.

Properties of Mild Steel:

Good ductility for shaping into precise dimensions.

Adequate tensile strength for heavy-duty load-bearing.

Excellent machinability, allowing consistent quality production.

Cost-effectiveness for bulk supply.

Comparison with Other Materials:

Compared to stainless steel, mild steel is more affordable and sufficient for indoor applications where corrosion exposure is minimal.

Compared to hardened alloy steels, mild steel provides an economical solution for projects that don’t require high heat resistance.

Compared to brass or copper washers, mild steel offers much higher strength and load-bearing capacity.

For applications where cost, strength, and ease of production matter, M33 Mild Steel Plain Washers provide unbeatable value, making them a staple in workshops, factories, and construction sites worldwide.

Manufacturing and Technical Specifications

At Nafees Metal Industries, every M33 Mild Steel Plain Washer is manufactured using a stringent process that combines precision stamping, CNC finishing, deburring, and quality checks to ensure dimensional accuracy and performance.

Our Process Includes:

Raw Material Sourcing: Only certified mild steel sheets are sourced to ensure consistency.

Precision Stamping: High-tonnage presses stamp out the washers to exact inner and outer diameters.

Deburring & Finishing: Each washer is cleaned and smoothed to eliminate sharp edges.

Final Inspection: Every batch undergoes rigorous dimension and hardness testing.

Below are typical specifications for M33 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 33 mm (fits M33 bolts) |

| Outer Diameter | Typically 65–70 mm |

| Thickness | Standard or custom as required |

| Finish | Plain or protective coated finish |

| Material | Mild Steel |

| Shape | Flat Round Disc |

We also offer protective coatings like zinc plating for additional rust resistance when needed.

Key Features

✅ Efficient Load Distribution

A fastener that applies too much pressure in one spot can crush or deform the base material. M33 Mild Steel Plain Washers distribute that load across a broader area, preventing this damage. This is critical when working with softer materials or when fasteners need to handle dynamic loads.

✅ Vibration Resistance

Machinery and structural components exposed to constant movement and vibrations are prone to fastener loosening. M33 Mild Steel Plain Washers help dampen this vibration by providing a firm, consistent seating surface that absorbs some of the dynamic energy.

✅ Corrosion Resistance Options

Though mild steel isn’t inherently rust-proof, M33 Mild Steel Plain Washers can be zinc-plated or treated with anti-corrosion finishes, extending their lifespan significantly in humid or mildly corrosive conditions.

✅ Surface Protection

They prevent direct metal-to-metal contact, reducing wear on the base material and extending its life. This protects painted, powder-coated, or treated surfaces from scratches or scuffs during installation.

✅ Consistent Fit

Every washer is produced to tight dimensional tolerances, ensuring a snug, accurate fit with M33 bolts. This consistency means every assembly is secure and reliable.

✅ Cost-Effective Versatility

From large construction beams to simple home repairs, M33 Mild Steel Plain Washers are adaptable, affordable, and easy to source in bulk — making them an economical choice for contractors and maintenance teams alike.

✅ Easy Installation

With their simple flat design, they are easy to install and remove during maintenance or repairs, minimizing labor time on-site.

Applications & Use Cases

M33 Mild Steel Plain Washers are found in a wide variety of industries and project types, including:

✅ Automotive

These washers are used to secure large suspension components, chassis connections, and other critical bolted joints that endure vibration and dynamic loads.

✅ Construction

Ideal for structural steel frameworks, bridge building, and heavy-duty supports. They ensure that bolts do not damage beams or plates while providing added stability.

✅ Industrial Machinery

Machinery that operates under heavy loads and continuous vibration benefits from the added security of M33 Mild Steel Plain Washers, which keep fasteners tight and protect mating surfaces.

✅ Electronics & Appliances

They prevent damage to delicate panels or enclosures when large bolts are needed to secure components.

✅ General Fastening / DIY

Whether building garden structures or repairing large equipment, these washers are a trusted solution for anyone who needs reliable, heavy-duty load distribution.

By using mild steel, these washers remain budget-friendly while providing reliable performance in all these sectors.

Why Buy M33 Mild Steel Plain Washers in Bulk

For contractors, OEMs, and industrial procurement teams, buying washers in large quantities offers clear benefits:

✔ Cost Savings: Bulk pricing lowers per-unit costs, boosting your overall project margins.

✔ Consistency: Uniform washers across all assemblies mean reliable quality and fit.

✔ Availability: Large inventory prevents project delays caused by running short on fasteners.

✔ Custom Packaging: Bulk orders can be packed and labeled to your site’s specific needs, saving time and reducing waste.

It’s smart, efficient, and cost-effective to Buy M33 Mild Steel Washers in Bulk from a trusted source like Nafees Metal Industries.

Why Choose the Best M33 MS Plain Washers Manufacturer

Selecting the right supplier is vital for your projects to stay on track, on budget, and within quality standards. Here’s why Nafees Metal Industries is trusted as the Best M33 MS Plain Washers Manufacturer:

✅ In-House Manufacturing: Every washer is produced under one roof, allowing us to control quality, maintain consistency, and deliver on time.

✅ Quality Certifications: We meet stringent material sourcing and production standards.

✅ Customization: Need specific dimensions, coatings, or packaging? We can tailor your order to your exact needs.

✅ Reliable Lead Times: With robust manufacturing capacity, we fulfill bulk orders without delays.

✅ Expert Support: Our team assists with technical questions, installation tips, and project-specific guidance.

Installation Tips

To get the best performance from M33 Mild Steel Plain Washers, follow these simple guidelines:

Match Bolt Size: Always pair M33 bolts with the correct M33 washer to ensure a precise fit.

Surface Cleanliness: Wipe surfaces before installing to prevent debris from affecting torque.

Position Properly: Place washers between the nut/bolt head and the surface to evenly distribute load.

Use Dual Washers: For critical joints, use washers on both the nut and bolt head sides.

Apply Correct Torque: Avoid overtightening which can deform washers and reduce effectiveness.

Maintenance Guidelines

While mild steel washers are durable, good maintenance practices can extend their life:

✅ Store Properly: Keep in dry, covered storage to prevent moisture exposure.

✅ Regular Inspections: Check for deformation or corrosion during routine maintenance.

✅ Clean When Reused: Remove dirt and oil to maintain performance.

✅ Replace If Damaged: Washers showing cracks or excessive wear should be replaced promptly.

Case Study

Project Overview

Sector: Large-scale Industrial Manufacturing

Application: Equipment foundation bolting for heavy machinery

Key Challenge: High vibration, structural shifting, and surface wear causing bolt loosening and maintenance delays.

Background

A major industrial manufacturer, responsible for producing precision-engineered parts, needed to install multiple heavy-duty industrial presses on reinforced concrete foundations. These presses operated under continuous, high-impact loads — generating significant vibration during each production cycle.

The installation team initially used standard M33 bolts with basic washers that lacked proper load distribution. Within weeks, they began noticing problems:

Frequent loosening of bolts, requiring retightening after every few days of operation.

Microcracks appearing around anchor bolt holes due to concentrated stress.

Deformation and indentations on the concrete mounting surface.

Unexpected downtime during production, leading to financial losses and project delays.

With equipment weighing several tonnes, any instability posed major safety risks and threatened production quality. The project manager needed a fast, reliable, and cost-effective solution to prevent recurring loosening and foundation damage.

The Solution: Switching to M33 Mild Steel Plain Washers

After an inspection and consultation, it was decided to replace the generic washers with precision-engineered M33 Mild Steel Plain Washers manufactured by Nafees Metal Industries.

Key reasons for selecting these washers:

Improved Load Distribution: The wider outer diameter spread the bolt’s clamping force evenly over the concrete mounting surface, minimizing stress points that caused microcracks.

Vibration Resistance: The robust mild steel washers acted as a buffer, absorbing some of the vibration forces and maintaining bolt tightness.

Surface Protection: They provided a protective barrier between the bolt head and the concrete, preventing surface chipping or crumbling.

Bulk Supply Advantage: Nafees Metal Industries supplied over 5,000 washers in a single shipment, ensuring consistent quality and minimizing delays.

Implementation

1. Prototype Testing:

The team first installed a batch of M33 Mild Steel Plain Washers on two presses as a pilot test. Load testing was conducted under full operating conditions, with vibration sensors monitoring the bolts’ integrity over several weeks.

2. Installation Support:

The supplier’s technical team provided clear installation guidelines:

Use dual washers on both bolt head and nut sides for maximum stability.

Torque bolts to the recommended tension to avoid under- or over-tightening.

Inspect washers after initial production cycles to ensure proper seating.

3. Full Rollout:

After successful testing, the washers were installed across all presses. Nafees Metal Industries delivered the entire batch pre-packed in labeled cartons by press location, making distribution on-site easier.

Results: Measurable Benefits

Within three months of using M33 Mild Steel Plain Washers, the manufacturer saw significant improvements:

✅ Bolt Loosening Reduced by 85%:

The need for weekly retightening was almost eliminated. Fasteners maintained secure clamping, even under continuous vibration.

✅ Foundation Surface Protected:

Microcracking around bolt holes decreased dramatically. The washers acted as a buffer, spreading the load evenly and preventing stress concentration.

✅ Downtime Minimized:

The presses operated longer hours without interruption, helping the company meet production deadlines. Estimated cost savings from reduced downtime were over ₹5,00,000 in the first six months alone.

✅ Maintenance Costs Dropped:

The washers’ durability reduced the need for frequent replacements or emergency bolt fixes, freeing up the maintenance team for other critical tasks.

✅ Long-Term Cost Efficiency:

The switch to M33 Mild Steel Plain Washers proved far more economical than alternative solutions like expensive high-grade lock washers or complete foundation redesigns.

Performance Data Snapshot

| Metric | Before Washers Upgrade | After Washers Upgrade |

|---|---|---|

| Bolt Loosening Incidents | ~60 per month | ~8 per month |

| Monthly Maintenance Downtime | 35–40 hours | Under 5 hours |

| Annual Maintenance Spend | ₹6–8 lakh | Under ₹2 lakh |

| Production Delays | Frequent, unscheduled | Near zero |

Customer Feedback

The engineering supervisor noted that this minor change delivered major benefits. The straightforward solution of using robust M33 Mild Steel Plain Washers helped extend the service life of bolts and the concrete foundation, improved machine stability, and protected workers’ safety on the shop floor.

“Who knew a small component like a washer could make such a big difference? We now include M33 Mild Steel Plain Washers as standard on all heavy equipment foundation bolts,” the supervisor added.

Key Takeaway

This real-world example demonstrates how the right washer choice is far more than an afterthought. Investing in high-quality M33 Mild Steel Plain Washers:

Reduces structural damage,

Controls vibration-related loosening,

Cuts maintenance costs,

And improves overall project efficiency.

For any contractor, engineer, or procurement manager dealing with heavy-duty bolted joints, M33 Mild Steel Plain Washers are a proven, practical solution that delivers real, measurable results.

Why It Matters for Your Projects

This case study shows that even in cost-driven industries, choosing the right basic hardware can prevent bigger problems down the line. When you buy from the Best M33 MS Plain Washers Manufacturer, you’re investing in quality, consistency, and the peace of mind that your assemblies will stay secure for years to come.

Related Products

Along with M33 Mild Steel Plain Washers, we supply:

Other MS Washers in sizes M6 to M56.

Zinc-plated, phosphate-coated, or painted variants for different applications.

Mild Steel Flat Washers for general hardware and construction needs.

Frequently Asked Questions (FAQs)

1. What is the primary use of M33 Mild Steel Plain Washers?

Answer: M33 Mild Steel Plain Washers are used to distribute the load of a bolt or screw evenly across a wider surface area. This prevents damage to the base material, reduces the risk of fastener loosening under stress or vibration, and protects surfaces from scratches or indentations. They’re ideal for heavy-duty structural connections, machinery, automotive assemblies, and general industrial fastening.

2. Are M33 Mild Steel Plain Washers reusable?

Answer: Yes — when installed and removed correctly, these washers can be reused multiple times. However, it’s important to inspect each washer during maintenance. If you notice cracks, bending, corrosion, or significant surface wear, it’s best to replace them to maintain fastening integrity.

3. Can they handle high-vibration applications?

Answer: Absolutely. While plain washers don’t lock fasteners in place like spring or lock washers, M33 Mild Steel Plain Washers help maintain bolt tension by providing a stable seating surface and absorbing some vibration. For extra vibration resistance, they can be paired with locking nuts or lock washers in critical joints.

4. Do you offer protective coatings on mild steel washers?

Answer: Yes. We offer various finishing options like zinc plating, black oxide coating, or phosphate treatment to enhance corrosion resistance. This makes M33 Mild Steel Plain Washers suitable for mildly corrosive or humid environments where extra protection is needed.

5. What industries use M33 Mild Steel Plain Washers most?

Answer: These washers are widely used in the automotive sector, construction, industrial machinery, electrical equipment assembly, structural steelwork, heavy equipment manufacturing, and general maintenance projects. Their versatility makes them a go-to choice wherever heavy-duty load distribution is required.

6. What’s the standard lead time for bulk orders?

Answer: Lead times typically range from 7 to 21 working days, depending on the quantity, size, and any custom coating requirements. We always strive to deliver ahead of schedule and maintain steady inventory levels for repeat clients.

7. Can I customize the washer’s dimensions?

Answer: Yes, we offer customization for dimensions like outer diameter, thickness, and surface finish to meet your specific project needs. Just share your technical drawing or specifications, and our team will confirm feasibility and lead time.

8. Are test certificates provided with each batch?

Answer: Definitely. We can provide material test certificates, dimensional inspection reports, and surface finish reports on request. This ensures you have full traceability and peace of mind about the quality of your M33 Mild Steel Plain Washers.

9. How should I store mild steel washers to prevent rust?

Answer: Store them in a dry, covered area away from moisture, chemicals, or humidity. If possible, keep them sealed in original packaging until use. For outdoor or coastal sites, using washers with a protective coating is recommended.

10. How often should I replace M33 Mild Steel Plain Washers?

Answer: Replacement frequency depends on your application’s stress, vibration levels, and maintenance cycle. Inspect washers during routine bolt checks — replace them immediately if you notice significant wear, cracks, or deformation.

11. Do you ship across India?

Answer: Yes, we supply M33 Mild Steel Plain Washers to clients all over India, serving major industries in construction, manufacturing, automotive, and more. We partner with reliable logistics providers to ensure timely delivery.

12. Is international shipping available?

Answer: Absolutely. We export to multiple countries, following all international standards for packaging and compliance. Get in touch for a custom export quote, including documentation and shipping options.

13. What payment modes do you accept?

Answer: We accept NEFT, RTGS, cheque payments, and approved online transfers. For bulk export orders, we work with secure L/C terms or trusted remittance channels.

14. Can I get a sample first?

Answer: Yes — we encourage new customers to request samples before placing large orders. This allows you to check fit, finish, and performance. Contact our sales team to arrange your sample pack.

15. How can I get a quote for bulk supply?

Answer: It’s simple. Reach out to us by email, phone, or WhatsApp with your washer size, required quantity, delivery location, and any custom specifications. We’ll share a clear, detailed quotation with lead time, pricing, and payment terms within 24 hours.

Why Choose Nafees Metal Industries?

Investing in the right washer means investing in the longevity and safety of your structures. M33 Mild Steel Plain Washers combine the strength, affordability, and versatility that today’s industries demand. Backed by our proven quality and service, you can trust Nafees Metal Industries to deliver washers that keep your projects secure and cost-effective.

Contact us today to place your bulk order with the Best M33 MS Plain Washers Manufacturer.

As an established manufacturer of M33 Mild Steel Plain Washers, Nafees Metal industries is dedicated to delivering top-notch quality with each order. We invest in advanced production processes, quality raw materials, and stringent testing to ensure our washers meet your exact requirements.

We understand the importance of reliable supply and offer flexible bulk ordering options, fast delivery times, and exceptional customer service. Whether you’re a contractor, OEM, or reseller, we make it easy to source the Best M33 MS Plain Washers Manufacturer for your projects.

Visit our modern manufacturing unit at Reay Road, Mumbai to see our commitment to quality firsthand, or reach out to us today to buy M33 Mild Steel Washers in bulk for your next project.

M33 Mild Steel Plain Washers

12 people are viewing this product right now

₹12.84 Original price was: ₹12.84.₹10.70Current price is: ₹10.70. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M33

Inner Diameter (ID): 34 mm

Outer Diameter (OD): 60 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M33 Mild Steel Plain Washers – Heavy-Duty Mild Steel Flat Washers for Reliable Industrial Fastening

Introduction

In every industrial fastening application, washers play an essential yet underestimated role in maintaining structural integrity, preventing fastener loosening, and protecting the surfaces they secure. Among the many types available, M33 Mild Steel Plain Washers stand out for their durability, versatility, and affordability — making them an ideal choice for high-load, heavy-duty applications.

Whether you’re operating in the automotive sector, construction, heavy machinery, or general manufacturing, the right washer makes all the difference. Choosing a material that’s tough enough to withstand vibration, stress, and repetitive tightening is vital — and mild steel remains a trusted, proven option for countless engineers and project managers.

At Nafees Metal Industries, we have decades of expertise in manufacturing and supplying M33 Mild Steel Plain Washers. Our washers are engineered for consistent load distribution, exceptional dimensional accuracy, and long-lasting performance. When you’re looking for durable Mild Steel Flat Washers to reinforce your assemblies, our products deliver every time.

What Are M33 Mild Steel Plain Washers?

M33 Mild Steel Plain Washers are robust, flat disc-shaped components with a precisely machined central hole designed to fit M33 bolts or screws. The plain washer’s primary function is to spread the load exerted by a fastener head or nut across a larger area, thereby protecting the material beneath from damage, indentation, or cracking.

Unlike specialized lock washers or spring washers, plain washers are designed for general-purpose applications where load distribution and surface protection are paramount. Their simple yet effective design makes them indispensable in everything from structural frameworks to automotive chassis, heavy equipment, and DIY maintenance work.

M33 Mild Steel Plain Washers play four vital roles:

Load Distribution: They spread the force of the fastener evenly, minimizing localized stress and potential material failure.

Vibration Resistance: They reduce the impact of constant vibration, helping to maintain fastener tightness.

Surface Protection: They shield softer or coated surfaces from scratches and deformation.

Long-Term Durability: Their sturdy mild steel construction ensures they can handle repeated tightening without losing shape or strength.

Material Details: Why Mild Steel?

When selecting washers, the material you choose can make or break the reliability of your fastening system. Mild steel remains one of the most trusted materials for plain washers due to its balance of affordability, machinability, and tensile strength.

Properties of Mild Steel:

Good ductility for shaping into precise dimensions.

Adequate tensile strength for heavy-duty load-bearing.

Excellent machinability, allowing consistent quality production.

Cost-effectiveness for bulk supply.

Comparison with Other Materials:

Compared to stainless steel, mild steel is more affordable and sufficient for indoor applications where corrosion exposure is minimal.

Compared to hardened alloy steels, mild steel provides an economical solution for projects that don’t require high heat resistance.

Compared to brass or copper washers, mild steel offers much higher strength and load-bearing capacity.

For applications where cost, strength, and ease of production matter, M33 Mild Steel Plain Washers provide unbeatable value, making them a staple in workshops, factories, and construction sites worldwide.

Manufacturing and Technical Specifications

At Nafees Metal Industries, every M33 Mild Steel Plain Washer is manufactured using a stringent process that combines precision stamping, CNC finishing, deburring, and quality checks to ensure dimensional accuracy and performance.

Our Process Includes:

Raw Material Sourcing: Only certified mild steel sheets are sourced to ensure consistency.

Precision Stamping: High-tonnage presses stamp out the washers to exact inner and outer diameters.

Deburring & Finishing: Each washer is cleaned and smoothed to eliminate sharp edges.

Final Inspection: Every batch undergoes rigorous dimension and hardness testing.

Below are typical specifications for M33 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | 33 mm (fits M33 bolts) |

| Outer Diameter | Typically 65–70 mm |

| Thickness | Standard or custom as required |

| Finish | Plain or protective coated finish |

| Material | Mild Steel |

| Shape | Flat Round Disc |

We also offer protective coatings like zinc plating for additional rust resistance when needed.

Key Features

✅ Efficient Load Distribution

A fastener that applies too much pressure in one spot can crush or deform the base material. M33 Mild Steel Plain Washers distribute that load across a broader area, preventing this damage. This is critical when working with softer materials or when fasteners need to handle dynamic loads.

✅ Vibration Resistance

Machinery and structural components exposed to constant movement and vibrations are prone to fastener loosening. M33 Mild Steel Plain Washers help dampen this vibration by providing a firm, consistent seating surface that absorbs some of the dynamic energy.

✅ Corrosion Resistance Options

Though mild steel isn’t inherently rust-proof, M33 Mild Steel Plain Washers can be zinc-plated or treated with anti-corrosion finishes, extending their lifespan significantly in humid or mildly corrosive conditions.

✅ Surface Protection

They prevent direct metal-to-metal contact, reducing wear on the base material and extending its life. This protects painted, powder-coated, or treated surfaces from scratches or scuffs during installation.

✅ Consistent Fit

Every washer is produced to tight dimensional tolerances, ensuring a snug, accurate fit with M33 bolts. This consistency means every assembly is secure and reliable.

✅ Cost-Effective Versatility

From large construction beams to simple home repairs, M33 Mild Steel Plain Washers are adaptable, affordable, and easy to source in bulk — making them an economical choice for contractors and maintenance teams alike.

✅ Easy Installation

With their simple flat design, they are easy to install and remove during maintenance or repairs, minimizing labor time on-site.

Applications & Use Cases

M33 Mild Steel Plain Washers are found in a wide variety of industries and project types, including:

✅ Automotive

These washers are used to secure large suspension components, chassis connections, and other critical bolted joints that endure vibration and dynamic loads.

✅ Construction

Ideal for structural steel frameworks, bridge building, and heavy-duty supports. They ensure that bolts do not damage beams or plates while providing added stability.

✅ Industrial Machinery

Machinery that operates under heavy loads and continuous vibration benefits from the added security of M33 Mild Steel Plain Washers, which keep fasteners tight and protect mating surfaces.

✅ Electronics & Appliances

They prevent damage to delicate panels or enclosures when large bolts are needed to secure components.

✅ General Fastening / DIY

Whether building garden structures or repairing large equipment, these washers are a trusted solution for anyone who needs reliable, heavy-duty load distribution.

By using mild steel, these washers remain budget-friendly while providing reliable performance in all these sectors.

Why Buy M33 Mild Steel Plain Washers in Bulk

For contractors, OEMs, and industrial procurement teams, buying washers in large quantities offers clear benefits:

✔ Cost Savings: Bulk pricing lowers per-unit costs, boosting your overall project margins.

✔ Consistency: Uniform washers across all assemblies mean reliable quality and fit.

✔ Availability: Large inventory prevents project delays caused by running short on fasteners.

✔ Custom Packaging: Bulk orders can be packed and labeled to your site’s specific needs, saving time and reducing waste.

It’s smart, efficient, and cost-effective to Buy M33 Mild Steel Washers in Bulk from a trusted source like Nafees Metal Industries.

Why Choose the Best M33 MS Plain Washers Manufacturer

Selecting the right supplier is vital for your projects to stay on track, on budget, and within quality standards. Here’s why Nafees Metal Industries is trusted as the Best M33 MS Plain Washers Manufacturer:

✅ In-House Manufacturing: Every washer is produced under one roof, allowing us to control quality, maintain consistency, and deliver on time.

✅ Quality Certifications: We meet stringent material sourcing and production standards.

✅ Customization: Need specific dimensions, coatings, or packaging? We can tailor your order to your exact needs.

✅ Reliable Lead Times: With robust manufacturing capacity, we fulfill bulk orders without delays.

✅ Expert Support: Our team assists with technical questions, installation tips, and project-specific guidance.

Installation Tips

To get the best performance from M33 Mild Steel Plain Washers, follow these simple guidelines:

Match Bolt Size: Always pair M33 bolts with the correct M33 washer to ensure a precise fit.

Surface Cleanliness: Wipe surfaces before installing to prevent debris from affecting torque.

Position Properly: Place washers between the nut/bolt head and the surface to evenly distribute load.

Use Dual Washers: For critical joints, use washers on both the nut and bolt head sides.

Apply Correct Torque: Avoid overtightening which can deform washers and reduce effectiveness.

Maintenance Guidelines

While mild steel washers are durable, good maintenance practices can extend their life:

✅ Store Properly: Keep in dry, covered storage to prevent moisture exposure.

✅ Regular Inspections: Check for deformation or corrosion during routine maintenance.

✅ Clean When Reused: Remove dirt and oil to maintain performance.

✅ Replace If Damaged: Washers showing cracks or excessive wear should be replaced promptly.

Case Study

Project Overview

Sector: Large-scale Industrial Manufacturing

Application: Equipment foundation bolting for heavy machinery

Key Challenge: High vibration, structural shifting, and surface wear causing bolt loosening and maintenance delays.

Background

A major industrial manufacturer, responsible for producing precision-engineered parts, needed to install multiple heavy-duty industrial presses on reinforced concrete foundations. These presses operated under continuous, high-impact loads — generating significant vibration during each production cycle.

The installation team initially used standard M33 bolts with basic washers that lacked proper load distribution. Within weeks, they began noticing problems:

Frequent loosening of bolts, requiring retightening after every few days of operation.

Microcracks appearing around anchor bolt holes due to concentrated stress.

Deformation and indentations on the concrete mounting surface.

Unexpected downtime during production, leading to financial losses and project delays.

With equipment weighing several tonnes, any instability posed major safety risks and threatened production quality. The project manager needed a fast, reliable, and cost-effective solution to prevent recurring loosening and foundation damage.

The Solution: Switching to M33 Mild Steel Plain Washers

After an inspection and consultation, it was decided to replace the generic washers with precision-engineered M33 Mild Steel Plain Washers manufactured by Nafees Metal Industries.

Key reasons for selecting these washers:

Improved Load Distribution: The wider outer diameter spread the bolt’s clamping force evenly over the concrete mounting surface, minimizing stress points that caused microcracks.

Vibration Resistance: The robust mild steel washers acted as a buffer, absorbing some of the vibration forces and maintaining bolt tightness.

Surface Protection: They provided a protective barrier between the bolt head and the concrete, preventing surface chipping or crumbling.

Bulk Supply Advantage: Nafees Metal Industries supplied over 5,000 washers in a single shipment, ensuring consistent quality and minimizing delays.

Implementation

1. Prototype Testing:

The team first installed a batch of M33 Mild Steel Plain Washers on two presses as a pilot test. Load testing was conducted under full operating conditions, with vibration sensors monitoring the bolts’ integrity over several weeks.

2. Installation Support:

The supplier’s technical team provided clear installation guidelines:

Use dual washers on both bolt head and nut sides for maximum stability.

Torque bolts to the recommended tension to avoid under- or over-tightening.

Inspect washers after initial production cycles to ensure proper seating.

3. Full Rollout:

After successful testing, the washers were installed across all presses. Nafees Metal Industries delivered the entire batch pre-packed in labeled cartons by press location, making distribution on-site easier.

Results: Measurable Benefits

Within three months of using M33 Mild Steel Plain Washers, the manufacturer saw significant improvements:

✅ Bolt Loosening Reduced by 85%:

The need for weekly retightening was almost eliminated. Fasteners maintained secure clamping, even under continuous vibration.

✅ Foundation Surface Protected:

Microcracking around bolt holes decreased dramatically. The washers acted as a buffer, spreading the load evenly and preventing stress concentration.

✅ Downtime Minimized:

The presses operated longer hours without interruption, helping the company meet production deadlines. Estimated cost savings from reduced downtime were over ₹5,00,000 in the first six months alone.

✅ Maintenance Costs Dropped:

The washers’ durability reduced the need for frequent replacements or emergency bolt fixes, freeing up the maintenance team for other critical tasks.

✅ Long-Term Cost Efficiency:

The switch to M33 Mild Steel Plain Washers proved far more economical than alternative solutions like expensive high-grade lock washers or complete foundation redesigns.

Performance Data Snapshot

| Metric | Before Washers Upgrade | After Washers Upgrade |

|---|---|---|

| Bolt Loosening Incidents | ~60 per month | ~8 per month |

| Monthly Maintenance Downtime | 35–40 hours | Under 5 hours |

| Annual Maintenance Spend | ₹6–8 lakh | Under ₹2 lakh |

| Production Delays | Frequent, unscheduled | Near zero |

Customer Feedback

The engineering supervisor noted that this minor change delivered major benefits. The straightforward solution of using robust M33 Mild Steel Plain Washers helped extend the service life of bolts and the concrete foundation, improved machine stability, and protected workers’ safety on the shop floor.

“Who knew a small component like a washer could make such a big difference? We now include M33 Mild Steel Plain Washers as standard on all heavy equipment foundation bolts,” the supervisor added.

Key Takeaway

This real-world example demonstrates how the right washer choice is far more than an afterthought. Investing in high-quality M33 Mild Steel Plain Washers:

Reduces structural damage,

Controls vibration-related loosening,

Cuts maintenance costs,

And improves overall project efficiency.

For any contractor, engineer, or procurement manager dealing with heavy-duty bolted joints, M33 Mild Steel Plain Washers are a proven, practical solution that delivers real, measurable results.

Why It Matters for Your Projects

This case study shows that even in cost-driven industries, choosing the right basic hardware can prevent bigger problems down the line. When you buy from the Best M33 MS Plain Washers Manufacturer, you’re investing in quality, consistency, and the peace of mind that your assemblies will stay secure for years to come.

Related Products

Along with M33 Mild Steel Plain Washers, we supply:

Other MS Washers in sizes M6 to M56.

Zinc-plated, phosphate-coated, or painted variants for different applications.

Mild Steel Flat Washers for general hardware and construction needs.

Frequently Asked Questions (FAQs)

1. What is the primary use of M33 Mild Steel Plain Washers?

Answer: M33 Mild Steel Plain Washers are used to distribute the load of a bolt or screw evenly across a wider surface area. This prevents damage to the base material, reduces the risk of fastener loosening under stress or vibration, and protects surfaces from scratches or indentations. They’re ideal for heavy-duty structural connections, machinery, automotive assemblies, and general industrial fastening.

2. Are M33 Mild Steel Plain Washers reusable?

Answer: Yes — when installed and removed correctly, these washers can be reused multiple times. However, it’s important to inspect each washer during maintenance. If you notice cracks, bending, corrosion, or significant surface wear, it’s best to replace them to maintain fastening integrity.

3. Can they handle high-vibration applications?

Answer: Absolutely. While plain washers don’t lock fasteners in place like spring or lock washers, M33 Mild Steel Plain Washers help maintain bolt tension by providing a stable seating surface and absorbing some vibration. For extra vibration resistance, they can be paired with locking nuts or lock washers in critical joints.

4. Do you offer protective coatings on mild steel washers?

Answer: Yes. We offer various finishing options like zinc plating, black oxide coating, or phosphate treatment to enhance corrosion resistance. This makes M33 Mild Steel Plain Washers suitable for mildly corrosive or humid environments where extra protection is needed.

5. What industries use M33 Mild Steel Plain Washers most?

Answer: These washers are widely used in the automotive sector, construction, industrial machinery, electrical equipment assembly, structural steelwork, heavy equipment manufacturing, and general maintenance projects. Their versatility makes them a go-to choice wherever heavy-duty load distribution is required.

6. What’s the standard lead time for bulk orders?

Answer: Lead times typically range from 7 to 21 working days, depending on the quantity, size, and any custom coating requirements. We always strive to deliver ahead of schedule and maintain steady inventory levels for repeat clients.

7. Can I customize the washer’s dimensions?

Answer: Yes, we offer customization for dimensions like outer diameter, thickness, and surface finish to meet your specific project needs. Just share your technical drawing or specifications, and our team will confirm feasibility and lead time.

8. Are test certificates provided with each batch?

Answer: Definitely. We can provide material test certificates, dimensional inspection reports, and surface finish reports on request. This ensures you have full traceability and peace of mind about the quality of your M33 Mild Steel Plain Washers.

9. How should I store mild steel washers to prevent rust?

Answer: Store them in a dry, covered area away from moisture, chemicals, or humidity. If possible, keep them sealed in original packaging until use. For outdoor or coastal sites, using washers with a protective coating is recommended.

10. How often should I replace M33 Mild Steel Plain Washers?

Answer: Replacement frequency depends on your application’s stress, vibration levels, and maintenance cycle. Inspect washers during routine bolt checks — replace them immediately if you notice significant wear, cracks, or deformation.

11. Do you ship across India?

Answer: Yes, we supply M33 Mild Steel Plain Washers to clients all over India, serving major industries in construction, manufacturing, automotive, and more. We partner with reliable logistics providers to ensure timely delivery.

12. Is international shipping available?

Answer: Absolutely. We export to multiple countries, following all international standards for packaging and compliance. Get in touch for a custom export quote, including documentation and shipping options.

13. What payment modes do you accept?

Answer: We accept NEFT, RTGS, cheque payments, and approved online transfers. For bulk export orders, we work with secure L/C terms or trusted remittance channels.

14. Can I get a sample first?

Answer: Yes — we encourage new customers to request samples before placing large orders. This allows you to check fit, finish, and performance. Contact our sales team to arrange your sample pack.

15. How can I get a quote for bulk supply?

Answer: It’s simple. Reach out to us by email, phone, or WhatsApp with your washer size, required quantity, delivery location, and any custom specifications. We’ll share a clear, detailed quotation with lead time, pricing, and payment terms within 24 hours.

Why Choose Nafees Metal Industries?

Investing in the right washer means investing in the longevity and safety of your structures. M33 Mild Steel Plain Washers combine the strength, affordability, and versatility that today’s industries demand. Backed by our proven quality and service, you can trust Nafees Metal Industries to deliver washers that keep your projects secure and cost-effective.

Contact us today to place your bulk order with the Best M33 MS Plain Washers Manufacturer.

As an established manufacturer of M33 Mild Steel Plain Washers, Nafees Metal industries is dedicated to delivering top-notch quality with each order. We invest in advanced production processes, quality raw materials, and stringent testing to ensure our washers meet your exact requirements.

We understand the importance of reliable supply and offer flexible bulk ordering options, fast delivery times, and exceptional customer service. Whether you’re a contractor, OEM, or reseller, we make it easy to source the Best M33 MS Plain Washers Manufacturer for your projects.

Visit our modern manufacturing unit at Reay Road, Mumbai to see our commitment to quality firsthand, or reach out to us today to buy M33 Mild Steel Washers in bulk for your next project.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch