No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

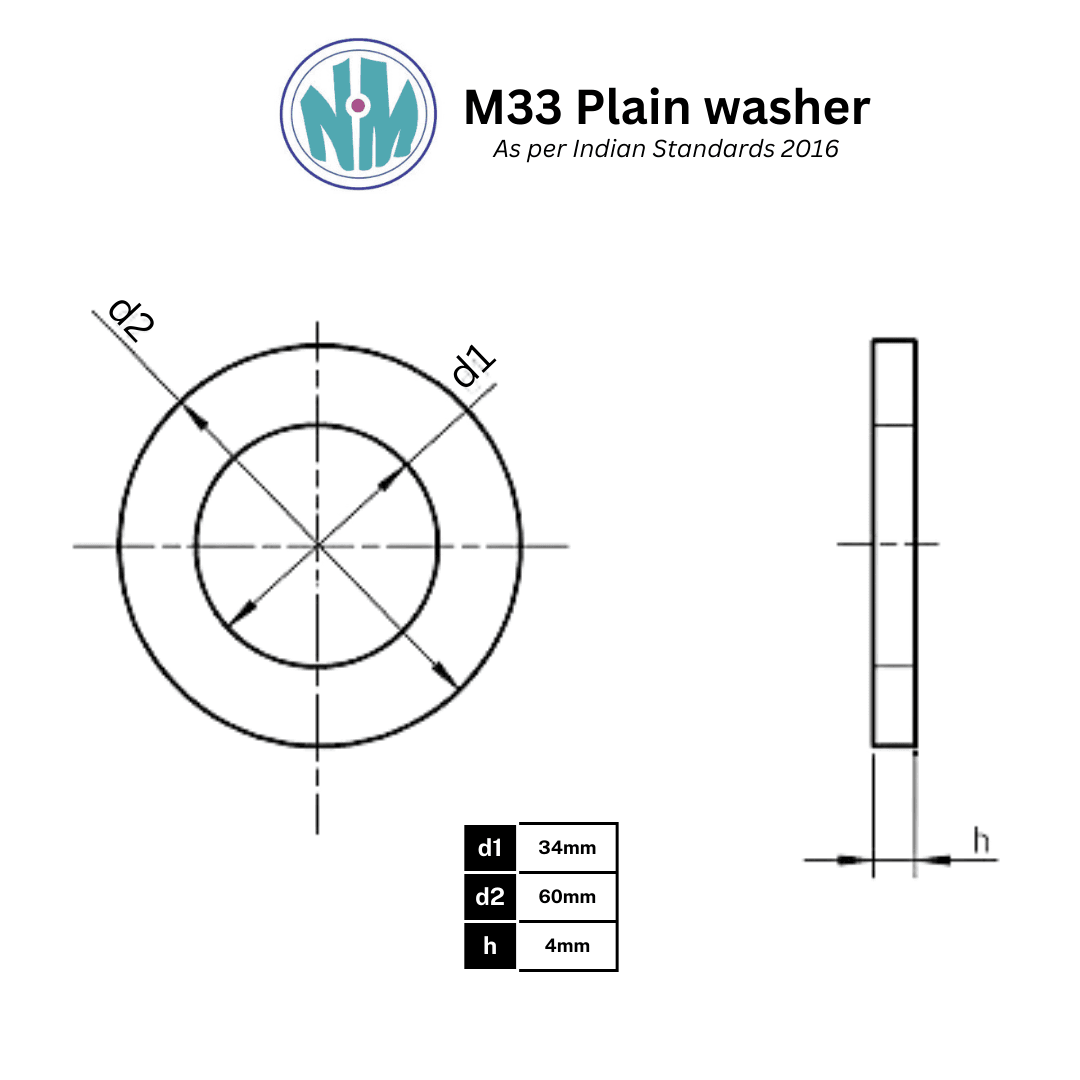

*Images shown for graphic representation. Not to scale.

M33 Copper Plain Washers – High-Performance Flat Washers for Electrical and Hydraulic Precision

At Nafees Metal Industries, we specialize in engineering high-precision washers for demanding industrial needs. Our M33 copper plain washers are a premium solution designed for high-load, high-conductivity, and corrosion-sensitive environments. Made from commercial-grade pure copper, these washers are widely used in electrical installations, hydraulic fittings, and heavy-duty mechanical assemblies where both sealing and conductivity are critical.

As leading copper washer manufacturers in India, we understand the importance of dimensional precision, material consistency, and long-term reliability. That’s why each M33 copper plain washer is crafted to meet global standards such as DIN 125, ensuring a perfect fit for M33 metric bolts and other fastening systems. These flat washers not only provide excellent load distribution but also deliver superior electrical and thermal conductivity, making them indispensable in mission-critical applications like power grids, control panels, HVAC units, and fluid handling systems.

Whether you require washers for sealing hydraulic fluids, grounding electrical components, or assembling corrosion-resistant equipment, our M33 copper plain washers deliver unmatched performance and longevity. With in-house manufacturing capabilities, strict quality control, and export-ready logistics, Nafees Metal Industries is your reliable partner for bulk and customized copper washer requirements.

Choose our M33 copper plain washers for precision, protection, and performance—crafted in India, trusted worldwide.

What Are M33 Copper Plain Washers?

M33 copper plain washers are precision-engineered, flat, circular components made from high-purity copper, featuring a central hole with a nominal inner diameter of 33 mm to fit M33 bolts and screws. These washers serve a vital role in mechanical, electrical, and fluid-sealing systems by distributing loads evenly, reducing surface stress, and enhancing the overall stability of fastener assemblies. They are part of the metric series DIN 125 standard, which ensures consistent sizing and interchangeability across international industrial applications.

Unlike standard washers made of mild steel or stainless steel, M33 copper plain washers offer additional benefits such as exceptional thermal and electrical conductivity, excellent malleability, and natural corrosion resistance, especially in harsh, humid, or chemically active environments. Their soft metal composition allows for slight deformation under compression, making them ideal for sealing surfaces and preventing leaks—particularly in hydraulic fittings, electrical grounding systems, and HVAC components.

Copper’s non-magnetic and non-sparking properties also make these washers suitable for use in sensitive or hazardous environments like power plants, chemical processing units, and explosive-prone zones. This is why industries involved in energy transmission, marine equipment, electronics, and precision engineering prefer M33 copper plain washers over conventional alternatives.

When used in conjunction with M33 bolts, these washers provide a protective barrier between the bolt head or nut and the material surface, helping to avoid localized stress points, stripping, or permanent damage to the substrate. They also absorb minor vibrations and offer a snug fit, thus improving assembly reliability.

To sum up, M33 copper plain washers are more than just spacer components—they’re critical functional elements that ensure the mechanical and electrical integrity of industrial assemblies. Designed in compliance with DIN 125 and made from high-grade copper, these washers represent an optimal blend of performance, protection, and precision, particularly in high-demand environments.

Why Choose Copper for M33 Washers?

Copper is one of the most versatile and performance-rich materials used in the manufacturing of washers, particularly for specialized applications that demand high conductivity, corrosion resistance, and seal integrity. When it comes to M33 copper plain washers, the use of copper as the base material offers a distinct set of advantages that go far beyond what standard mild steel or stainless steel washers can deliver.

Here’s why copper is the ideal material for producing M33 copper plain washers:

Exceptional Electrical Conductivity

Copper is the second-best electrical conductor among metals, just after silver. This makes M33 copper plain washers a preferred choice in electrical installations, terminals, grounding assemblies, and battery connections. They allow for smooth current flow and help prevent resistance build-up, overheating, or power loss at contact points.Superior Thermal Conductivity

In heat-intensive applications such as transformers, HVAC systems, and heat exchangers, copper washers dissipate heat efficiently, reducing the risk of thermal damage. This is especially beneficial in M33 copper flat washer metric series DIN 125 formats used in industrial and engineering environments.Corrosion Resistance

Copper forms a natural oxide layer when exposed to air, acting as a barrier against corrosion. This property is particularly useful in marine, chemical, or outdoor applications where washers are exposed to moisture, salt, or aggressive environments. Our industrial copper flat washer corrosion-resistant design helps maintain mechanical performance and longevity.High Malleability and Ductility

Copper is easy to shape and deform without cracking, making it ideal for washers that need to form tight seals under compression. In hydraulic systems, for example, copper sealing washer M33 hydraulic fittings provide leak-proof joints even at high pressures.Non-Magnetic & Non-Sparking Nature

Copper is inherently non-ferrous and does not produce sparks upon impact, making it safe for use in explosive or flammable environments such as oil refineries, fuel systems, and chemical plants. This makes M33 copper plain washers a must-have for high-safety installations.Environmental Friendliness & Recyclability

Copper is a fully recyclable material without loss of properties. Choosing M33 copper plain washers is not only a smart technical decision but also an environmentally responsible one, contributing to sustainable manufacturing practices.Compatibility with Various Finishes

Copper washers can be easily tin-plated or nickel-coated to further enhance their performance. At Nafees Metal Industries, we offer custom surface treatments on demand to suit your application—be it conductivity enhancement, aesthetic preference, or corrosion control.Dimensional Stability Under Load

Unlike rubber or plastic alternatives, copper washers maintain their form under high mechanical stress and temperatures, providing consistent performance throughout their lifecycle.

In summary, copper offers a perfect synergy of conductivity, durability, malleability, and corrosion resistance, making it the ideal material for M33 copper plain washers used in heavy-duty industrial environments. Whether it’s for electrical safety, hydraulic sealing, or mechanical stability, copper ensures long-lasting and dependable performance.

That’s why at Nafees Metal Industries, we choose high-purity copper to craft our M33 copper plain washers, delivering unmatched value to industries across India and the globe.

Manufacturing Process of M33 Copper Plain Washers

At Nafees Metal Industries, we follow a highly controlled and precision-oriented process to manufacture M33 copper plain washers that comply with international standards such as DIN 125, ISO 7089, and IS 2016. Every washer is crafted with utmost attention to detail, ensuring exceptional performance, durability, and dimensional accuracy.

Being one of the best copper washer manufacturers in India, our production methodology combines skilled craftsmanship with modern technology, resulting in washers that meet the critical requirements of industrial applications such as hydraulic fittings, electrical terminals, and heavy-duty mechanical assemblies.

Here is a step-by-step overview of how M33 copper plain washers are manufactured at our facility:

1. Raw Material Selection and Sourcing

The process begins with the procurement of high-purity copper sheets or coils (≥99.9% Cu). The raw material is tested for composition, grain structure, and mechanical properties to ensure it meets the required industrial grade for producing M33 copper plain washers. Only certified, defect-free copper is passed to the next stage.

2. Sheet Cutting and Preparation

Copper sheets are cut into manageable sizes based on production batch volumes. These sheets are then leveled and cleaned to remove any surface oxides, oil, or residues. A smooth and clean surface is essential for precise stamping and finishing.

3. Precision Punching (Stamping Process)

Using automated high-tonnage power press machines, washers are punched out from the copper sheets. The dies are custom-designed to match the M33 inner diameter (33 mm) and the outer diameter as per DIN 125 standards. The M33 copper flat washer metric series DIN 125 design ensures compatibility with M33 bolts in metric applications.

During this process:

The inner hole and outer circumference are simultaneously stamped to ensure perfect concentricity.

Tolerances are strictly maintained to meet industrial-grade dimensional requirements.

4. Deburring and Edge Smoothing

After stamping, the washers undergo a deburring process to remove sharp edges or metal burrs left behind during punching. This is essential to:

Prevent surface damage during application.

Improve handling safety.

Ensure a clean, uniform finish.

We use rotary tumblers, brushing wheels, or vibratory finishing machines depending on the batch size and desired finish.

5. Heat Treatment (Optional – Annealing Process)

For applications that demand enhanced sealing ability or softer washers—such as copper sealing washer M33 hydraulic fittings—the washers undergo annealing. This heat treatment process:

Relieves internal stresses.

Improves ductility and malleability.

Enhances the washer’s ability to conform to uneven surfaces, ensuring tight seals.

6. Surface Treatment or Coating (Optional)

While copper is naturally corrosion-resistant, certain applications may require an added protective or functional coating. Based on customer requirements, we offer:

Tin plating – for improved solderability and corrosion resistance.

Nickel plating – for durability and resistance to tarnish.

Plain finish – for standard non-coated usage.

Each coating is applied using electroplating or immersion methods, followed by post-treatment rinsing and drying.

7. Dimensional Inspection and Quality Control

Every batch of M33 copper plain washers undergoes rigorous quality checks at multiple stages:

Inner diameter and outer diameter precision (verified using GO/NO-GO gauges and digital calipers).

Thickness uniformity.

Flatness and surface smoothness.

Surface finish adherence (plating thickness if applicable).

These checks ensure conformity with DIN 125 and ISO 7089 specifications.

8. Sorting and Packaging

The washers are sorted based on finish type, thickness, and application grade. Packaging is done in:

Poly bags

Corrugated boxes

Custom-labeled cartons based on client preferences.

Our packaging ensures safe transit and long-term shelf life, especially for export orders.

9. Dispatch and Delivery

Finished washers are stored in a controlled environment before being dispatched. We support both domestic and international shipping, with export documentation, batch traceability, and certificates of compliance provided upon request.

Why Our Manufacturing Process Stands Out

Made in India – All washers are produced at our state-of-the-art Mumbai facility.

In-House Tooling and Die Maintenance – For consistent quality and rapid prototyping.

Bulk Readiness – Fast turnaround times for large-scale OEM requirements.

Custom Washer Production – From M3 to M40, with optional design flexibility.

ISO-Compliant Processes – Ensures long-term performance and product traceability.

In essence, our M33 copper plain washers are not just components — they are a result of meticulous engineering, robust quality control, and a commitment to excellence. Whether you need washers for sealing, conductivity, or structural stability, Nafees Metal Industries delivers products you can depend on.

Key Features of M33 Copper Plain Washers

At Nafees Metal Industries, we engineer M33 copper plain washers to meet the highest standards of performance, durability, and dimensional precision. Designed specifically for M33 metric bolts, these flat washers deliver unmatched efficiency in load distribution, electrical conductivity, sealing, and corrosion resistance.

Here are the standout features that make our M33 copper plain washers the preferred choice across industries:

1. Precision Fit for M33 Fasteners

Each washer is meticulously manufactured to ensure a perfect inner diameter of 33 mm, aligning seamlessly with M33 bolts and screws. This snug fit eliminates lateral movement during assembly, enhances fastening strength, and minimizes structural stress.

2. DIN 125 Compliance – Global Compatibility

Our M33 copper plain washers strictly adhere to DIN 125 / ISO 7089 standards, ensuring dimensional accuracy and universal compatibility across international industrial systems. This makes them ideal for exporters, OEMs, and globally aligned supply chains.

3. Excellent Load Distribution

The flat and wide surface of the washer allows even distribution of clamping force, reducing pressure on the substrate. This feature helps prevent surface indentation, deformation, or material damage—particularly when fastening onto soft metals, plastic, or electronic housings.

4. Outstanding Thermal and Electrical Conductivity

Copper is a premium conductor of both electricity and heat. These washers ensure consistent electrical grounding, reduce heat build-up, and improve current flow in power electronics, battery packs, and circuit boards. This is critical for high-load and high-frequency operations.

5. Corrosion-Resistant Material Composition

Crafted from high-purity copper, these washers naturally resist corrosion and tarnishing, even in marine or humid conditions. This feature ensures long-term reliability, particularly for exposed assemblies or outdoor installations.

6. Smooth Surface Finish and Deburred Edges

All M33 copper plain washers are deburred and polished to remove sharp edges or irregularities. The result is:

Safer handling during assembly.

Better contact surfaces for electrical flow.

No risk of damaging adjacent components or substrates.

7. Enhanced Sealability

Due to copper’s malleability, our washers offer excellent surface conformity under bolt compression. This makes them suitable for applications involving fluid or air sealing, such as copper sealing washer M33 hydraulic fittings or pipe connections.

8. Custom Coatings and Finishes Available

While the standard finish is plain copper, we offer optional surface treatments like:

Tin plating for solder-friendly electrical use.

Nickel coating for added corrosion resistance and aesthetic appeal.

These finishes can be customized to match your industry’s specific requirements.

9. Broad Application Compatibility

Our washers are versatile and suitable for multiple use-cases including:

Electrical panels

HVAC units

Hydraulic systems

Power tools

Aerospace fasteners

Marine hardware

Renewable energy equipment

This makes our industrial copper flat washer corrosion-resistant ideal for both light-duty and mission-critical applications.

10. High Dimensional Stability Under Load

Unlike rubber or plastic alternatives, M33 copper plain washers retain their shape under prolonged mechanical stress. Their ability to withstand pressure and vibration makes them highly durable and dependable in static as well as dynamic assemblies.

11. Non-Magnetic and Safe for Sensitive Environments

Copper’s non-magnetic and non-sparking characteristics make these washers safe for use in:

Electronic enclosures

MRI equipment

Explosive-prone environments such as fuel storage or chemical plants

12. Scalable for Bulk Procurement

Whether you’re an OEM, contractor, or distributor, our production capacity allows for bulk manufacturing of M33 copper plain washers without compromising quality or delivery timelines. We offer bulk pricing, consistent supply, and custom labeling options.

13. Customizable Dimensions on Request

Need a specific outer diameter or thickness for your application? We offer customization based on your drawings or tolerance preferences while still maintaining core compliance with DIN 125 standards.

14. Lightweight and Stackable for Assembly Lines

Despite being robust, copper washers are lightweight and easy to handle, store, and integrate into automated or manual assembly lines. This contributes to faster production workflows and minimal downtime.

15. Proudly Made in India – Global Quality Standards

All our M33 copper plain washers are manufactured at our in-house facility in Mumbai using high-end machinery and skilled workmanship. As a part of the Make in India initiative, we ensure top-grade products that are export-ready and globally competitive.

Applications of M33 Copper Plain Washers

Electrical Terminals: Provides efficient grounding and conductivity.

Hydraulic Assemblies: Used as copper sealing washer M33 hydraulic fittings.

Heat Exchangers: Enhances thermal conductivity and seal integrity.

HVAC Equipment: Prevents leakage and vibration in heavy-duty components.

Marine and Aerospace Fastening: Withstands corrosion in aggressive environments.

Power Equipment Manufacturing: Protects components under high current flow.

Precision Engineering: Fits accurately in sensitive high-load assemblies.

The M33 copper flat washer metric series DIN 125 design ensures global compatibility with metric system fasteners.

Technical Specifications

At Nafees Metal Industries, we provide M33 copper plain washers that are engineered to meet strict quality and performance parameters. Each washer is designed according to DIN 125 / ISO 7089 specifications, ensuring compatibility, strength, and operational safety across a wide range of industrial applications.

Below is the complete breakdown of the technical specifications of our M33 copper plain washers, offering detailed insight into their construction, dimensions, tolerances, finishes, and application compatibility.

| Property | Specification |

|---|---|

| Product Name | M33 Copper Plain Washer |

| Focus Keyword | M33 copper plain washers (repeated across listing for SEO optimization) |

| Material | Commercial-Grade Pure Copper (≥ 99.9% Copper Content) |

| Inner Diameter (ID) | 33 mm (Fits Standard M33 Bolts and Screws) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 (Customizable on Request) |

| Thickness | Standard: 2.0 mm (Customizable between 1.5 mm – 3.0 mm based on application) |

| Tolerances | ±0.1 mm on ID/OD and Thickness (Tighter tolerances available on demand) |

| Standard Compliance | DIN 125 / ISO 7089 / IS 2016 |

| Surface Finish Options | Plain (as manufactured), Tin-Plated, Nickel-Plated |

| Hardness | Soft Annealed or Hard Temper (Based on application needs) |

| Conductivity | Excellent – Ideal for electrical grounding and thermal transfer |

| Magnetic Properties | Non-Magnetic – Safe for electronic and explosive environments |

| Corrosion Resistance | High – Especially in indoor, humid, and marine-like conditions |

| Flammability | Non-Sparking – Suitable for hazardous/explosive zones |

| Packaging Options | Poly Bags, Cartons, Palletized Shipments, Custom-Labeled Packaging |

| MOQ (Minimum Order Quantity) | Flexible – From sample packs to large-scale OEM procurement |

| Country of Origin | India – Manufactured at our ISO-compliant Mumbai-based facility |

| Application Categories | Electrical, Hydraulic, HVAC, Power Equipment, Automotive, Marine, Aerospace |

| Export-Ready | Yes – Includes batch certificates, HS code, COA, and other required documentation |

| Customization Availability | Yes – ID/OD, thickness, finish, and packaging can be customized per request |

Key Industrial Codes Covered:

DIN 125 A – Plain washers, metric series

ISO 7089 – Metric flat washers with standard hardness

IS 2016 – Indian Standard for plain washers in mechanical fasteners

Why These Specifications Matter

Every technical specification of our M33 copper plain washers is designed to fulfill specific industrial needs:

Precise ID and OD ensure seamless integration into fastener assemblies.

Copper purity guarantees superior performance in electrical and sealing functions.

DIN and ISO compliance makes our washers export-ready and suitable for global markets.

Surface finish options give customers flexibility depending on operating environments and assembly needs.

Customizability ensures we can serve specialized sectors like aerospace, renewables, and defense.

These technical details make our washers more than just spacers—they are high-precision, mission-critical components that improve equipment safety, efficiency, and lifespan.

Advantages of M33 Copper Plain Washers

Superior heat and current conductivity.

Prevents surface marring or galling.

Corrosion-resistant and durable.

Compatible with a wide range of bolts and systems.

Easily stackable for adjustable tolerance fitting.

Available in bulk for industrial procurement.

Our industrial copper flat washer corrosion-resistant design makes it highly sought-after for mission-critical installations.

Buy M33 Copper Plain Washers in Bulk – Best Manufacturer in India

Nafees Metal Industries is one of the best copper washer manufacturers in India, offering tailored solutions, custom sizes, and high-volume deliveries for OEMs and industries across the country.

We support:

Large-scale orders at competitive prices

Custom packaging and export documentation

Fast nationwide shipping and on-time delivery

Dedicated technical support and assistance

Assured quality with traceable batch certification

Whether you need copper washers for electrical, mechanical, or hydraulic use — we’re your trusted partner.

Frequently Asked Questions (FAQs) About M33 Copper Plain Washers

What are M33 copper plain washers used for?

They are used to evenly distribute fastener loads and enhance conductivity in electrical, hydraulic, and industrial applications.Are these washers compliant with any standards?

Yes, our M33 copper plain washers comply with DIN 125, ISO 7089, and IS 2016 standards.Can I get M33 copper washers with a specific coating?

Yes, finishes such as tin-plating and nickel-coating are available upon request.Are copper plain washers corrosion-resistant?

Yes, copper naturally resists corrosion, making it suitable for harsh environments.Do you offer custom packaging for bulk orders?

Absolutely, we offer packaging in cartons, poly bags, or as per client needs.What’s the thickness of your M33 copper washer?

Standard thickness is 2 mm but customizable on request.Are these washers made in India?

Yes, proudly manufactured in our ISO-compliant Mumbai facility.How do copper washers compare to stainless steel?

Copper offers better electrical/thermal conductivity but lower mechanical strength than stainless steel.Can I use these washers for hydraulic fittings?

Yes, they are suitable as copper sealing washer M33 hydraulic fittings.Do you ship internationally?

Yes, we are export-ready and provide necessary compliance documents.Are copper washers reusable?

They are reusable depending on the compression load and application, but for sealing, one-time use is preferred.What industries commonly use M33 copper plain washers?

Electronics, electrical, HVAC, marine, automotive, and aerospace sectors.Can I buy a small quantity for testing?

Yes, we offer samples and low-MOQ options for new clients.Do you manufacture other sizes of copper washers?

Yes, we offer a complete range from M3 to M40 and custom sizes.How do I place an order?

Visit https://nafeesmetalindustries.com/ or contact us directly for custom quotations.

Why Choose Nafees Metal Industries for M33 Copper Plain Washers?

At Nafees Metal Industries, we don’t just manufacture washers — we engineer precision, reliability, and trust into every single piece. As one of the leading washer manufacturers in India, our commitment to quality, consistency, and customer satisfaction sets us apart in a competitive industrial landscape.

With high conductivity, robust sealing, and corrosion resistance, M33 copper plain washers from Nafees Metal Industries offer unmatched reliability for precision applications. Engineered as per DIN 125, manufactured with excellence, and supported by our technical team, these washers are a smart investment for industries prioritizing performance and durability.

Here’s why global buyers and top-tier industries consistently choose Nafees Metal Industries for their M33 copper plain washer requirements:

1. In-House State-of-the-Art Manufacturing Unit

Our washers are manufactured at our fully-equipped facility in Mumbai-based facility using high-precision power press machines and automated stamping tools to ensure tight dimensional control, batch consistency, and surface integrity.

ISO-compliant production process

Bulk production capability for high-volume OEM needs

On-site tool room for die maintenance and custom tooling

Strict in-line and post-production quality checks

Batch traceability and packaging customization

We welcome clients and sourcing managers to visit our manufacturing unit and witness firsthand the care, skill, and scale with which we produce every washer.

2. Superior Raw Materials

We use 99.9% pure commercial-grade copper sourced from trusted Indian suppliers, ensuring top performance in electrical conductivity, corrosion resistance, and thermal stability — all vital for industries like power, HVAC, marine, and electronics.

3. Precision Engineering & DIN Compliance

All our M33 copper plain washers are produced in accordance with DIN 125 / ISO 7089 standards, ensuring compatibility with metric fasteners worldwide. Every washer is made with precision-cut inner diameters, consistent thickness, and smooth surfaces for optimal assembly.

4. Flexible Customization Options

Whether you need a different outer diameter, thickness, surface finish, or even private labeling for retail-ready packaging — we offer complete customization to meet your technical, aesthetic, and branding needs.

5. Fast Dispatch & Global Shipping

With ready stock, efficient packaging, and tie-ups with leading logistics partners, we ensure on-time dispatch for both domestic and export orders. From cartons to pallets, we ship in your preferred mode with HS codes, invoices, test reports, and more.

6. Experienced, Customer-Focused Team

We believe in long-term partnerships. Our dedicated team ensures:

Fast response times

Transparent communication

Technical support for selection and customization

After-sales service and reordering ease

Trusted by Industries Across India and Abroad

From automobile OEMs and electrical contractors to marine engineers and heavy industries, Nafees Metal Industries is a trusted name for high-performance washer solutions. Our long-term clients value our manufacturing integrity, product consistency, and competitive pricing.

Experience manufacturing excellence — choose Nafees Metal Industries for M33 copper plain washers that deliver unmatched performance, lasting value, and quality you can rely on.

M33 Copper Plain Washers (DIN 125)

19 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M33

Inner Diameter (ID): 34 mm

Outer Diameter (OD): 60 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M33 Copper Plain Washers – High-Performance Flat Washers for Electrical and Hydraulic Precision

At Nafees Metal Industries, we specialize in engineering high-precision washers for demanding industrial needs. Our M33 copper plain washers are a premium solution designed for high-load, high-conductivity, and corrosion-sensitive environments. Made from commercial-grade pure copper, these washers are widely used in electrical installations, hydraulic fittings, and heavy-duty mechanical assemblies where both sealing and conductivity are critical.

As leading copper washer manufacturers in India, we understand the importance of dimensional precision, material consistency, and long-term reliability. That’s why each M33 copper plain washer is crafted to meet global standards such as DIN 125, ensuring a perfect fit for M33 metric bolts and other fastening systems. These flat washers not only provide excellent load distribution but also deliver superior electrical and thermal conductivity, making them indispensable in mission-critical applications like power grids, control panels, HVAC units, and fluid handling systems.

Whether you require washers for sealing hydraulic fluids, grounding electrical components, or assembling corrosion-resistant equipment, our M33 copper plain washers deliver unmatched performance and longevity. With in-house manufacturing capabilities, strict quality control, and export-ready logistics, Nafees Metal Industries is your reliable partner for bulk and customized copper washer requirements.

Choose our M33 copper plain washers for precision, protection, and performance—crafted in India, trusted worldwide.

What Are M33 Copper Plain Washers?

M33 copper plain washers are precision-engineered, flat, circular components made from high-purity copper, featuring a central hole with a nominal inner diameter of 33 mm to fit M33 bolts and screws. These washers serve a vital role in mechanical, electrical, and fluid-sealing systems by distributing loads evenly, reducing surface stress, and enhancing the overall stability of fastener assemblies. They are part of the metric series DIN 125 standard, which ensures consistent sizing and interchangeability across international industrial applications.

Unlike standard washers made of mild steel or stainless steel, M33 copper plain washers offer additional benefits such as exceptional thermal and electrical conductivity, excellent malleability, and natural corrosion resistance, especially in harsh, humid, or chemically active environments. Their soft metal composition allows for slight deformation under compression, making them ideal for sealing surfaces and preventing leaks—particularly in hydraulic fittings, electrical grounding systems, and HVAC components.

Copper’s non-magnetic and non-sparking properties also make these washers suitable for use in sensitive or hazardous environments like power plants, chemical processing units, and explosive-prone zones. This is why industries involved in energy transmission, marine equipment, electronics, and precision engineering prefer M33 copper plain washers over conventional alternatives.

When used in conjunction with M33 bolts, these washers provide a protective barrier between the bolt head or nut and the material surface, helping to avoid localized stress points, stripping, or permanent damage to the substrate. They also absorb minor vibrations and offer a snug fit, thus improving assembly reliability.

To sum up, M33 copper plain washers are more than just spacer components—they’re critical functional elements that ensure the mechanical and electrical integrity of industrial assemblies. Designed in compliance with DIN 125 and made from high-grade copper, these washers represent an optimal blend of performance, protection, and precision, particularly in high-demand environments.

Why Choose Copper for M33 Washers?

Copper is one of the most versatile and performance-rich materials used in the manufacturing of washers, particularly for specialized applications that demand high conductivity, corrosion resistance, and seal integrity. When it comes to M33 copper plain washers, the use of copper as the base material offers a distinct set of advantages that go far beyond what standard mild steel or stainless steel washers can deliver.

Here’s why copper is the ideal material for producing M33 copper plain washers:

Exceptional Electrical Conductivity

Copper is the second-best electrical conductor among metals, just after silver. This makes M33 copper plain washers a preferred choice in electrical installations, terminals, grounding assemblies, and battery connections. They allow for smooth current flow and help prevent resistance build-up, overheating, or power loss at contact points.Superior Thermal Conductivity

In heat-intensive applications such as transformers, HVAC systems, and heat exchangers, copper washers dissipate heat efficiently, reducing the risk of thermal damage. This is especially beneficial in M33 copper flat washer metric series DIN 125 formats used in industrial and engineering environments.Corrosion Resistance

Copper forms a natural oxide layer when exposed to air, acting as a barrier against corrosion. This property is particularly useful in marine, chemical, or outdoor applications where washers are exposed to moisture, salt, or aggressive environments. Our industrial copper flat washer corrosion-resistant design helps maintain mechanical performance and longevity.High Malleability and Ductility

Copper is easy to shape and deform without cracking, making it ideal for washers that need to form tight seals under compression. In hydraulic systems, for example, copper sealing washer M33 hydraulic fittings provide leak-proof joints even at high pressures.Non-Magnetic & Non-Sparking Nature

Copper is inherently non-ferrous and does not produce sparks upon impact, making it safe for use in explosive or flammable environments such as oil refineries, fuel systems, and chemical plants. This makes M33 copper plain washers a must-have for high-safety installations.Environmental Friendliness & Recyclability

Copper is a fully recyclable material without loss of properties. Choosing M33 copper plain washers is not only a smart technical decision but also an environmentally responsible one, contributing to sustainable manufacturing practices.Compatibility with Various Finishes

Copper washers can be easily tin-plated or nickel-coated to further enhance their performance. At Nafees Metal Industries, we offer custom surface treatments on demand to suit your application—be it conductivity enhancement, aesthetic preference, or corrosion control.Dimensional Stability Under Load

Unlike rubber or plastic alternatives, copper washers maintain their form under high mechanical stress and temperatures, providing consistent performance throughout their lifecycle.

In summary, copper offers a perfect synergy of conductivity, durability, malleability, and corrosion resistance, making it the ideal material for M33 copper plain washers used in heavy-duty industrial environments. Whether it’s for electrical safety, hydraulic sealing, or mechanical stability, copper ensures long-lasting and dependable performance.

That’s why at Nafees Metal Industries, we choose high-purity copper to craft our M33 copper plain washers, delivering unmatched value to industries across India and the globe.

Manufacturing Process of M33 Copper Plain Washers

At Nafees Metal Industries, we follow a highly controlled and precision-oriented process to manufacture M33 copper plain washers that comply with international standards such as DIN 125, ISO 7089, and IS 2016. Every washer is crafted with utmost attention to detail, ensuring exceptional performance, durability, and dimensional accuracy.

Being one of the best copper washer manufacturers in India, our production methodology combines skilled craftsmanship with modern technology, resulting in washers that meet the critical requirements of industrial applications such as hydraulic fittings, electrical terminals, and heavy-duty mechanical assemblies.

Here is a step-by-step overview of how M33 copper plain washers are manufactured at our facility:

1. Raw Material Selection and Sourcing

The process begins with the procurement of high-purity copper sheets or coils (≥99.9% Cu). The raw material is tested for composition, grain structure, and mechanical properties to ensure it meets the required industrial grade for producing M33 copper plain washers. Only certified, defect-free copper is passed to the next stage.

2. Sheet Cutting and Preparation

Copper sheets are cut into manageable sizes based on production batch volumes. These sheets are then leveled and cleaned to remove any surface oxides, oil, or residues. A smooth and clean surface is essential for precise stamping and finishing.

3. Precision Punching (Stamping Process)

Using automated high-tonnage power press machines, washers are punched out from the copper sheets. The dies are custom-designed to match the M33 inner diameter (33 mm) and the outer diameter as per DIN 125 standards. The M33 copper flat washer metric series DIN 125 design ensures compatibility with M33 bolts in metric applications.

During this process:

The inner hole and outer circumference are simultaneously stamped to ensure perfect concentricity.

Tolerances are strictly maintained to meet industrial-grade dimensional requirements.

4. Deburring and Edge Smoothing

After stamping, the washers undergo a deburring process to remove sharp edges or metal burrs left behind during punching. This is essential to:

Prevent surface damage during application.

Improve handling safety.

Ensure a clean, uniform finish.

We use rotary tumblers, brushing wheels, or vibratory finishing machines depending on the batch size and desired finish.

5. Heat Treatment (Optional – Annealing Process)

For applications that demand enhanced sealing ability or softer washers—such as copper sealing washer M33 hydraulic fittings—the washers undergo annealing. This heat treatment process:

Relieves internal stresses.

Improves ductility and malleability.

Enhances the washer’s ability to conform to uneven surfaces, ensuring tight seals.

6. Surface Treatment or Coating (Optional)

While copper is naturally corrosion-resistant, certain applications may require an added protective or functional coating. Based on customer requirements, we offer:

Tin plating – for improved solderability and corrosion resistance.

Nickel plating – for durability and resistance to tarnish.

Plain finish – for standard non-coated usage.

Each coating is applied using electroplating or immersion methods, followed by post-treatment rinsing and drying.

7. Dimensional Inspection and Quality Control

Every batch of M33 copper plain washers undergoes rigorous quality checks at multiple stages:

Inner diameter and outer diameter precision (verified using GO/NO-GO gauges and digital calipers).

Thickness uniformity.

Flatness and surface smoothness.

Surface finish adherence (plating thickness if applicable).

These checks ensure conformity with DIN 125 and ISO 7089 specifications.

8. Sorting and Packaging

The washers are sorted based on finish type, thickness, and application grade. Packaging is done in:

Poly bags

Corrugated boxes

Custom-labeled cartons based on client preferences.

Our packaging ensures safe transit and long-term shelf life, especially for export orders.

9. Dispatch and Delivery

Finished washers are stored in a controlled environment before being dispatched. We support both domestic and international shipping, with export documentation, batch traceability, and certificates of compliance provided upon request.

Why Our Manufacturing Process Stands Out

Made in India – All washers are produced at our state-of-the-art Mumbai facility.

In-House Tooling and Die Maintenance – For consistent quality and rapid prototyping.

Bulk Readiness – Fast turnaround times for large-scale OEM requirements.

Custom Washer Production – From M3 to M40, with optional design flexibility.

ISO-Compliant Processes – Ensures long-term performance and product traceability.

In essence, our M33 copper plain washers are not just components — they are a result of meticulous engineering, robust quality control, and a commitment to excellence. Whether you need washers for sealing, conductivity, or structural stability, Nafees Metal Industries delivers products you can depend on.

Key Features of M33 Copper Plain Washers

At Nafees Metal Industries, we engineer M33 copper plain washers to meet the highest standards of performance, durability, and dimensional precision. Designed specifically for M33 metric bolts, these flat washers deliver unmatched efficiency in load distribution, electrical conductivity, sealing, and corrosion resistance.

Here are the standout features that make our M33 copper plain washers the preferred choice across industries:

1. Precision Fit for M33 Fasteners

Each washer is meticulously manufactured to ensure a perfect inner diameter of 33 mm, aligning seamlessly with M33 bolts and screws. This snug fit eliminates lateral movement during assembly, enhances fastening strength, and minimizes structural stress.

2. DIN 125 Compliance – Global Compatibility

Our M33 copper plain washers strictly adhere to DIN 125 / ISO 7089 standards, ensuring dimensional accuracy and universal compatibility across international industrial systems. This makes them ideal for exporters, OEMs, and globally aligned supply chains.

3. Excellent Load Distribution

The flat and wide surface of the washer allows even distribution of clamping force, reducing pressure on the substrate. This feature helps prevent surface indentation, deformation, or material damage—particularly when fastening onto soft metals, plastic, or electronic housings.

4. Outstanding Thermal and Electrical Conductivity

Copper is a premium conductor of both electricity and heat. These washers ensure consistent electrical grounding, reduce heat build-up, and improve current flow in power electronics, battery packs, and circuit boards. This is critical for high-load and high-frequency operations.

5. Corrosion-Resistant Material Composition

Crafted from high-purity copper, these washers naturally resist corrosion and tarnishing, even in marine or humid conditions. This feature ensures long-term reliability, particularly for exposed assemblies or outdoor installations.

6. Smooth Surface Finish and Deburred Edges

All M33 copper plain washers are deburred and polished to remove sharp edges or irregularities. The result is:

Safer handling during assembly.

Better contact surfaces for electrical flow.

No risk of damaging adjacent components or substrates.

7. Enhanced Sealability

Due to copper’s malleability, our washers offer excellent surface conformity under bolt compression. This makes them suitable for applications involving fluid or air sealing, such as copper sealing washer M33 hydraulic fittings or pipe connections.

8. Custom Coatings and Finishes Available

While the standard finish is plain copper, we offer optional surface treatments like:

Tin plating for solder-friendly electrical use.

Nickel coating for added corrosion resistance and aesthetic appeal.

These finishes can be customized to match your industry’s specific requirements.

9. Broad Application Compatibility

Our washers are versatile and suitable for multiple use-cases including:

Electrical panels

HVAC units

Hydraulic systems

Power tools

Aerospace fasteners

Marine hardware

Renewable energy equipment

This makes our industrial copper flat washer corrosion-resistant ideal for both light-duty and mission-critical applications.

10. High Dimensional Stability Under Load

Unlike rubber or plastic alternatives, M33 copper plain washers retain their shape under prolonged mechanical stress. Their ability to withstand pressure and vibration makes them highly durable and dependable in static as well as dynamic assemblies.

11. Non-Magnetic and Safe for Sensitive Environments

Copper’s non-magnetic and non-sparking characteristics make these washers safe for use in:

Electronic enclosures

MRI equipment

Explosive-prone environments such as fuel storage or chemical plants

12. Scalable for Bulk Procurement

Whether you’re an OEM, contractor, or distributor, our production capacity allows for bulk manufacturing of M33 copper plain washers without compromising quality or delivery timelines. We offer bulk pricing, consistent supply, and custom labeling options.

13. Customizable Dimensions on Request

Need a specific outer diameter or thickness for your application? We offer customization based on your drawings or tolerance preferences while still maintaining core compliance with DIN 125 standards.

14. Lightweight and Stackable for Assembly Lines

Despite being robust, copper washers are lightweight and easy to handle, store, and integrate into automated or manual assembly lines. This contributes to faster production workflows and minimal downtime.

15. Proudly Made in India – Global Quality Standards

All our M33 copper plain washers are manufactured at our in-house facility in Mumbai using high-end machinery and skilled workmanship. As a part of the Make in India initiative, we ensure top-grade products that are export-ready and globally competitive.

Applications of M33 Copper Plain Washers

Electrical Terminals: Provides efficient grounding and conductivity.

Hydraulic Assemblies: Used as copper sealing washer M33 hydraulic fittings.

Heat Exchangers: Enhances thermal conductivity and seal integrity.

HVAC Equipment: Prevents leakage and vibration in heavy-duty components.

Marine and Aerospace Fastening: Withstands corrosion in aggressive environments.

Power Equipment Manufacturing: Protects components under high current flow.

Precision Engineering: Fits accurately in sensitive high-load assemblies.

The M33 copper flat washer metric series DIN 125 design ensures global compatibility with metric system fasteners.

Technical Specifications

At Nafees Metal Industries, we provide M33 copper plain washers that are engineered to meet strict quality and performance parameters. Each washer is designed according to DIN 125 / ISO 7089 specifications, ensuring compatibility, strength, and operational safety across a wide range of industrial applications.

Below is the complete breakdown of the technical specifications of our M33 copper plain washers, offering detailed insight into their construction, dimensions, tolerances, finishes, and application compatibility.

| Property | Specification |

|---|---|

| Product Name | M33 Copper Plain Washer |

| Focus Keyword | M33 copper plain washers (repeated across listing for SEO optimization) |

| Material | Commercial-Grade Pure Copper (≥ 99.9% Copper Content) |

| Inner Diameter (ID) | 33 mm (Fits Standard M33 Bolts and Screws) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 (Customizable on Request) |

| Thickness | Standard: 2.0 mm (Customizable between 1.5 mm – 3.0 mm based on application) |

| Tolerances | ±0.1 mm on ID/OD and Thickness (Tighter tolerances available on demand) |

| Standard Compliance | DIN 125 / ISO 7089 / IS 2016 |

| Surface Finish Options | Plain (as manufactured), Tin-Plated, Nickel-Plated |

| Hardness | Soft Annealed or Hard Temper (Based on application needs) |

| Conductivity | Excellent – Ideal for electrical grounding and thermal transfer |

| Magnetic Properties | Non-Magnetic – Safe for electronic and explosive environments |

| Corrosion Resistance | High – Especially in indoor, humid, and marine-like conditions |

| Flammability | Non-Sparking – Suitable for hazardous/explosive zones |

| Packaging Options | Poly Bags, Cartons, Palletized Shipments, Custom-Labeled Packaging |

| MOQ (Minimum Order Quantity) | Flexible – From sample packs to large-scale OEM procurement |

| Country of Origin | India – Manufactured at our ISO-compliant Mumbai-based facility |

| Application Categories | Electrical, Hydraulic, HVAC, Power Equipment, Automotive, Marine, Aerospace |

| Export-Ready | Yes – Includes batch certificates, HS code, COA, and other required documentation |

| Customization Availability | Yes – ID/OD, thickness, finish, and packaging can be customized per request |

Key Industrial Codes Covered:

DIN 125 A – Plain washers, metric series

ISO 7089 – Metric flat washers with standard hardness

IS 2016 – Indian Standard for plain washers in mechanical fasteners

Why These Specifications Matter

Every technical specification of our M33 copper plain washers is designed to fulfill specific industrial needs:

Precise ID and OD ensure seamless integration into fastener assemblies.

Copper purity guarantees superior performance in electrical and sealing functions.

DIN and ISO compliance makes our washers export-ready and suitable for global markets.

Surface finish options give customers flexibility depending on operating environments and assembly needs.

Customizability ensures we can serve specialized sectors like aerospace, renewables, and defense.

These technical details make our washers more than just spacers—they are high-precision, mission-critical components that improve equipment safety, efficiency, and lifespan.

Advantages of M33 Copper Plain Washers

Superior heat and current conductivity.

Prevents surface marring or galling.

Corrosion-resistant and durable.

Compatible with a wide range of bolts and systems.

Easily stackable for adjustable tolerance fitting.

Available in bulk for industrial procurement.

Our industrial copper flat washer corrosion-resistant design makes it highly sought-after for mission-critical installations.

Buy M33 Copper Plain Washers in Bulk – Best Manufacturer in India

Nafees Metal Industries is one of the best copper washer manufacturers in India, offering tailored solutions, custom sizes, and high-volume deliveries for OEMs and industries across the country.

We support:

Large-scale orders at competitive prices

Custom packaging and export documentation

Fast nationwide shipping and on-time delivery

Dedicated technical support and assistance

Assured quality with traceable batch certification

Whether you need copper washers for electrical, mechanical, or hydraulic use — we’re your trusted partner.

Frequently Asked Questions (FAQs) About M33 Copper Plain Washers

What are M33 copper plain washers used for?

They are used to evenly distribute fastener loads and enhance conductivity in electrical, hydraulic, and industrial applications.Are these washers compliant with any standards?

Yes, our M33 copper plain washers comply with DIN 125, ISO 7089, and IS 2016 standards.Can I get M33 copper washers with a specific coating?

Yes, finishes such as tin-plating and nickel-coating are available upon request.Are copper plain washers corrosion-resistant?

Yes, copper naturally resists corrosion, making it suitable for harsh environments.Do you offer custom packaging for bulk orders?

Absolutely, we offer packaging in cartons, poly bags, or as per client needs.What’s the thickness of your M33 copper washer?

Standard thickness is 2 mm but customizable on request.Are these washers made in India?

Yes, proudly manufactured in our ISO-compliant Mumbai facility.How do copper washers compare to stainless steel?

Copper offers better electrical/thermal conductivity but lower mechanical strength than stainless steel.Can I use these washers for hydraulic fittings?

Yes, they are suitable as copper sealing washer M33 hydraulic fittings.Do you ship internationally?

Yes, we are export-ready and provide necessary compliance documents.Are copper washers reusable?

They are reusable depending on the compression load and application, but for sealing, one-time use is preferred.What industries commonly use M33 copper plain washers?

Electronics, electrical, HVAC, marine, automotive, and aerospace sectors.Can I buy a small quantity for testing?

Yes, we offer samples and low-MOQ options for new clients.Do you manufacture other sizes of copper washers?

Yes, we offer a complete range from M3 to M40 and custom sizes.How do I place an order?

Visit https://nafeesmetalindustries.com/ or contact us directly for custom quotations.

Why Choose Nafees Metal Industries for M33 Copper Plain Washers?

At Nafees Metal Industries, we don’t just manufacture washers — we engineer precision, reliability, and trust into every single piece. As one of the leading washer manufacturers in India, our commitment to quality, consistency, and customer satisfaction sets us apart in a competitive industrial landscape.

With high conductivity, robust sealing, and corrosion resistance, M33 copper plain washers from Nafees Metal Industries offer unmatched reliability for precision applications. Engineered as per DIN 125, manufactured with excellence, and supported by our technical team, these washers are a smart investment for industries prioritizing performance and durability.

Here’s why global buyers and top-tier industries consistently choose Nafees Metal Industries for their M33 copper plain washer requirements:

1. In-House State-of-the-Art Manufacturing Unit

Our washers are manufactured at our fully-equipped facility in Mumbai-based facility using high-precision power press machines and automated stamping tools to ensure tight dimensional control, batch consistency, and surface integrity.

ISO-compliant production process

Bulk production capability for high-volume OEM needs

On-site tool room for die maintenance and custom tooling

Strict in-line and post-production quality checks

Batch traceability and packaging customization

We welcome clients and sourcing managers to visit our manufacturing unit and witness firsthand the care, skill, and scale with which we produce every washer.

2. Superior Raw Materials

We use 99.9% pure commercial-grade copper sourced from trusted Indian suppliers, ensuring top performance in electrical conductivity, corrosion resistance, and thermal stability — all vital for industries like power, HVAC, marine, and electronics.

3. Precision Engineering & DIN Compliance

All our M33 copper plain washers are produced in accordance with DIN 125 / ISO 7089 standards, ensuring compatibility with metric fasteners worldwide. Every washer is made with precision-cut inner diameters, consistent thickness, and smooth surfaces for optimal assembly.

4. Flexible Customization Options

Whether you need a different outer diameter, thickness, surface finish, or even private labeling for retail-ready packaging — we offer complete customization to meet your technical, aesthetic, and branding needs.

5. Fast Dispatch & Global Shipping

With ready stock, efficient packaging, and tie-ups with leading logistics partners, we ensure on-time dispatch for both domestic and export orders. From cartons to pallets, we ship in your preferred mode with HS codes, invoices, test reports, and more.

6. Experienced, Customer-Focused Team

We believe in long-term partnerships. Our dedicated team ensures:

Fast response times

Transparent communication

Technical support for selection and customization

After-sales service and reordering ease

Trusted by Industries Across India and Abroad

From automobile OEMs and electrical contractors to marine engineers and heavy industries, Nafees Metal Industries is a trusted name for high-performance washer solutions. Our long-term clients value our manufacturing integrity, product consistency, and competitive pricing.

Experience manufacturing excellence — choose Nafees Metal Industries for M33 copper plain washers that deliver unmatched performance, lasting value, and quality you can rely on.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch