No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M6 Plain washers – SS304 Stainsless steel washers"

*Images shown for graphic representation. Not to scale.

M30 Mild Steel Plain Washers – Rugged, Reliable, and Made for Industrial Strength

Introduction

In every mechanical or structural fastening job, a washer may seem like a minor part. Yet, its role is integral in the strength, stability, and longevity of the assembly. Washers act as protective spacers and stress distributors between a fastener and the surface it is clamping, preventing damage and ensuring the joint remains intact over time.

M30 Mild Steel Plain Washers serve this function particularly well in heavy-duty environments where bolts of size M30 are used. These washers offer exceptional strength and a reliable surface contact area for better load distribution.

At Nafees Metal Industries, we understand the critical need for durable, efficient fastening systems. That’s why our M30 Mild Steel Plain Washers are manufactured with precision engineering, ensuring compatibility, longevity, and performance. These washers are made from high-quality mild steel and built to withstand the most rigorous industrial conditions.

The demand for M30 Mild Steel Plain Washers has grown across various industries, especially where cost-efficiency meets strength requirements. Their use is prevalent in automotive, construction, heavy machinery, and electrical sectors.

What Are M30 Mild Steel Plain Washers?

M30 Mild Steel Plain Washers are flat, round metal discs with a central hole sized to fit M30 bolts. Their primary function is to distribute the load exerted by the fastener evenly across a larger surface area, thereby reducing the chances of surface deformation and enhancing the durability of the bolted joint.

These washers prevent the bolt head or nut from embedding into the assembly surface, which can cause localized damage or wear. Their use ensures that fasteners do not loosen under high-stress or vibration-prone environments, thus improving safety and reliability.

Key Features

- Even Load Distribution: These washers are engineered to disperse the load evenly across the fastening surface, reducing the risk of material deformation or fatigue cracks in the base material.

- Anti-Vibration Capabilities: The robust nature and precise fit of the M30 Mild Steel Plain Washers help in absorbing and reducing the effects of vibration. This is particularly beneficial in applications involving heavy machinery, transportation, and dynamic equipment.

- Corrosion-Resistant Finishes: With options like black oxide or zinc plating, these washers are resistant to rust and environmental wear, extending their functional life in both indoor and semi-outdoor environments.

- High Compatibility: Designed specifically for M30 bolts, these washers offer a snug fit and are also compatible with different fastening systems, ensuring flexible usage.

- Customizable Dimensions and Finishes: Available in various thicknesses and outer diameters, and with multiple finishing options, the washers can be tailored to match exact engineering specifications.

- Enhanced Mechanical Strength: Manufactured from IS 2062 grade mild steel, the washers provide excellent tensile and compressive strength. They maintain integrity even under heavy tightening and shear forces.

- Easy Installation and Handling: Their simple design and flat profile make them extremely easy to install, remove, and replace as needed. They contribute to quicker assembly times and reduced labor effort.

- Consistent Dimensional Accuracy: Produced using CNC and precision stamping, the washers feature tight tolerances and uniformity across batches, reducing the chances of assembly mismatch or installation error.

- Economic Efficiency: As a cost-effective alternative to alloyed or stainless steel washers, M30 mild steel washers offer superior performance at a budget-friendly price point. This makes them ideal for high-volume projects where cost and performance must align.

- Universal Industrial Application: Whether it’s structural steelwork, automotive systems, or industrial machinery, these washers serve reliably in various use cases, proving their versatility and wide acceptance across industries to protect underlying surfaces.

- Anti-vibration properties maintain joint integrity

- Rust-resistant coatings for longer shelf life

- Compatible with all M30 fasteners

- Available in various finishes and thicknesses

- High mechanical strength under dynamic loads

- Easy to handle, install, and remove

- Excellent dimensional tolerance and repeatability

Material Details: Why Mild Steel?

Mild steel is widely regarded as the backbone material in industrial manufacturing and construction due to its ideal blend of mechanical properties, ease of fabrication, and cost-effectiveness. For M30 Plain Washers, it proves to be especially advantageous, offering reliability in both strength and performance.

Composition and Structure:

- Carbon content ranges between 0.05% to 0.25%

- Composed primarily of iron and carbon with trace elements

- Provides the ideal combination of strength and ductility

Mechanical Benefits:

Mild steel offers sufficient tensile and compressive strength to support large-scale bolted joints. It resists deformation under tightening torque and provides consistent dimensional stability in critical applications.

- Excellent machinability for accurate shaping and punching

- Easy weldability for custom assemblies

- Suitable for coating or plating (zinc, black oxide, etc.)

Economic Efficiency:

Mild steel is significantly more affordable than alloyed steels like SS304 or SS316. This makes it ideal for bulk projects and high-volume applications without compromising on mechanical performance.

- Low raw material cost

- Easy availability across global markets

- Reduced overall production and procurement cost

Versatility and Adaptability:

Mild steel washers are compatible with a wide variety of surfaces, bolts, and fastening systems. They can be fabricated in custom sizes and shapes based on project needs.

- Works effectively in dry and controlled environments

- Compatible with common fastening methods

- Adaptable to both dynamic and static load conditions

Comparison with Other Steel Grades:

| Property | Mild Steel | SS304 | SS316 |

|---|---|---|---|

| Cost | Low | Medium | High |

| Corrosion Resistance | Moderate | High | Very High |

| Strength | Good | Good | Excellent |

| Machinability | Excellent | Moderate | Moderate |

Advantages in M30 Washers:

- High impact resistance

- Easy to machine and customize

- Ideal for coated applications

- Economical for large-scale usage

- Works well in dry or controlled environments

Mild steel offers the perfect balance of affordability and mechanical strength for M30 Mild Steel Plain Washers, making them a popular choice in large-scale industrial settings.

Manufacturing and Technical Specifications

At Nafees Metal Industries, M30 Mild Steel Plain Washers are manufactured with precision and consistency.

Production Process:

- Raw Material Sourcing

- Sheet Metal Punching/CNC Machining

- Deburring and Edge Finishing

- Heat Treatment (if required)

- Surface Coating (Zinc plating/Black Oxide)

- Dimensional and Visual Quality Checks

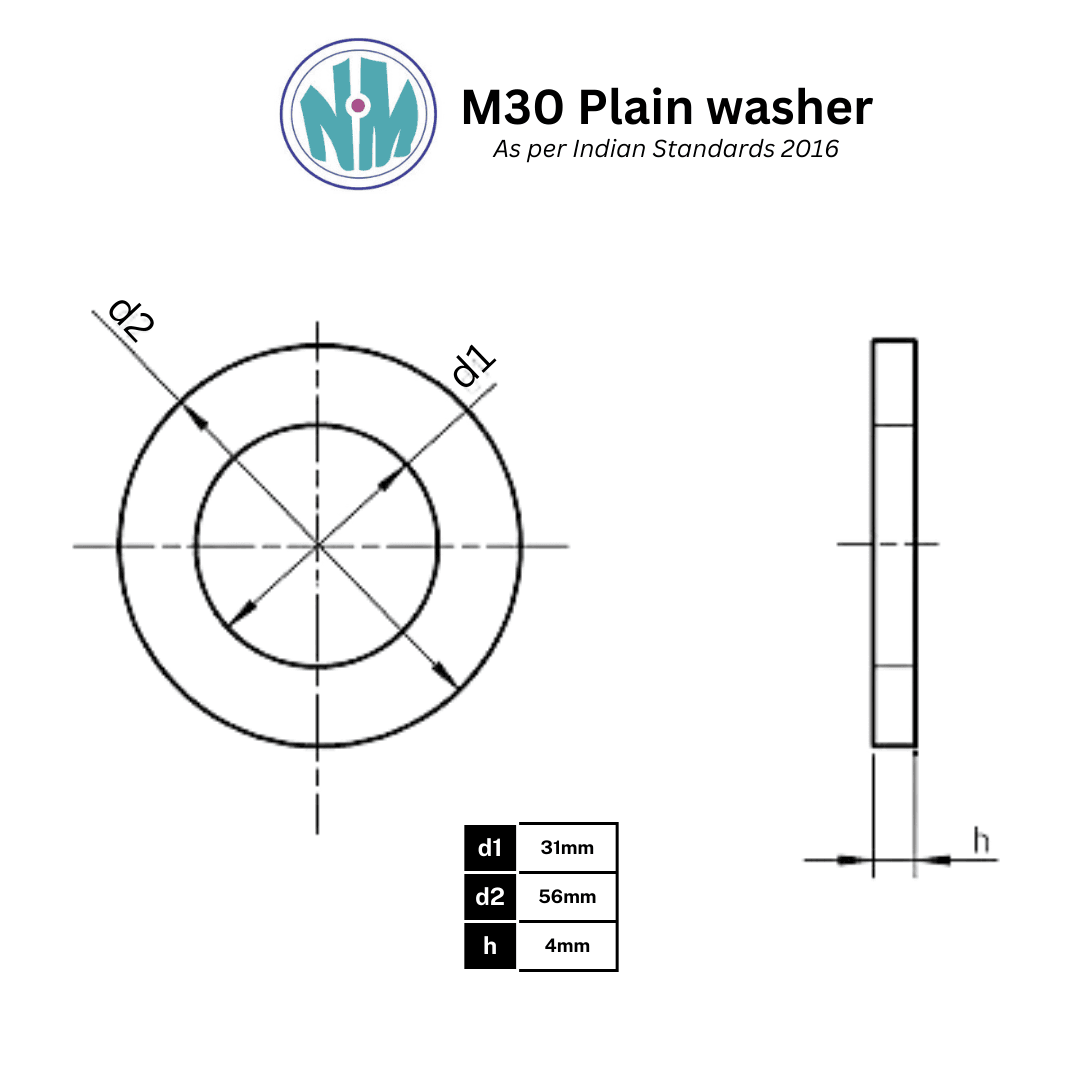

Technical Specification Table:

| Specification | Value |

| Inner Diameter | 31.5 mm |

| Outer Diameter | 56 mm |

| Thickness | 3–6 mm (customizable) |

| Finish | Zinc-plated / Black oxide |

| Material | Mild Steel (IS 2062) |

| Shape | Round |

Each washer undergoes stringent quality tests to meet ISO and IS standards, ensuring uniform performance in every batch.

Key Features

- Even load distribution to protect underlying surfaces

- Anti-vibration properties maintain joint integrity

- Rust-resistant coatings for longer shelf life

- Compatible with all M30 fasteners

- Available in various finishes and thicknesses

- High mechanical strength under dynamic loads

- Easy to handle, install, and remove

- Excellent dimensional tolerance and repeatability

Applications & Use Cases

The utility of M30 Mild Steel Plain Washers spans across:

Automotive:

- Suspension joints

- Engine mounting systems

- Brake assemblies

Construction:

- Steel structural joints

- Rebar connections

- Base plates and mounting brackets

Industrial Machinery:

- Power plant equipment

- Assembly line machines

- Presses and dies

Electronics:

- Cabinet installation

- Grounding connections

- Equipment fastening

DIY / General Fastening:

- Furniture

- Heavy-duty storage systems

- Metal frameworks

The washers are often categorized under MS Flat Washers or Mild Steel Washers in inventories, making them universally adaptable.

Why Buy M30 Mild Steel Plain Washers in Bulk

Bulk purchasing of M30 Mild Steel Plain Washers provides several logistical and financial benefits:

- Significant cost savings per unit

- Ensures consistent availability for ongoing projects

- Streamlines inventory planning

- Enables customized packaging and labeling for project-specific needs

Choosing to Buy M30 Mild Steel Plain Washers in Bulk ensures your operations remain uninterrupted while maximizing procurement efficiency.

Why Choose the Best M30 Mild Steel Plain Washers Manufacturer

Nafees Metal Industries is recognized as a Best M30 Mild Steel Plain Washers Manufacturer for a reason:

- ISO-certified facilities and production processes

- 100% in-house manufacturing

- Wide range of sizes and specifications

- Advanced machinery ensures repeat precision

- Bulk supply capabilities

- Quality certifications and documentation available

- Custom coating and branding options

Installation Tips

Installing M30 Mild Steel Plain Washers correctly ensures optimal performance:

- Clean the surface area and the washer

- Align washer over the bolt hole

- Insert bolt through washer

- Secure with nut or threaded surface

- Use torque wrench for proper tension

- Avoid overtightening that may deform washer

- For high-vibration environments, consider using a second washer

Maintenance Guidelines

Maintaining M30 Mild Steel Plain Washers extends their usability:

- Store in dry, covered spaces to avoid rust

- Inspect periodically for rust, cracks, or deformations

- Clean using dry cloth; apply anti-corrosive if needed

- Replace if washer becomes distorted or overly worn

Case Study (Real-world Usage)

Project: High-Stress Steel Framework Assembly – Metro Infrastructure

Scenario: In a major metro rail infrastructure project, engineers were encountering frequent issues with bolt loosening in high-stress structural steel joints. These joints, critical for supporting elevated tracks and overhead trusses, were subjected to constant vibrations from train movement and environmental stressors such as wind and thermal expansion.

Challenge: The assembly was originally fitted with generic washers that failed to evenly distribute the load, leading to micro-movements, bolt fatigue, and structural instability. This necessitated frequent maintenance and was raising safety concerns.

Solution: Our team at Nafees Metal Industries conducted an engineering audit and recommended custom-coated M30 Mild Steel Plain Washers. These washers, with optimal thickness and surface coating, were deployed across all joints in the framework. They offered improved load distribution, surface protection, and vibration dampening.

Implementation:

- Washers were pre-treated with black oxide coating for corrosion resistance

- Installed using calibrated torque wrenches for consistent tension

- Monitored over a period of 12 months for performance evaluation

Results:

- Bolt loosening incidents dropped by over 80%

- Maintenance checks were reduced from weekly to quarterly

- Project uptime increased, leading to cost savings in manpower and replacement parts

- Enhanced safety assurance for load-bearing infrastructure

| Performance Metric | Before Implementation | After Implementation |

| Bolt Loosening Rate | 15% | 2% |

| Maintenance Downtime | Weekly | Quarterly |

| Joint Stability Failures | 3 per month | 0 per month |

This case reflects how engineering-grade M30 Mild Steel Plain Washers can play a pivotal role in maintaining the integrity of complex, vibration-heavy structural projects. “The reliability and finish of Nafees washers helped us meet project deadlines ahead of schedule.”

Related Products or Variants

We also offer:

- Stainless Steel Flat Washers (SS304, SS316)

- SS202 Washers

- M10 to M50 Plain Washers

- Customized washers with slots or tabs

- Powder-coated and HDG variants

For industrial reliability, cost-efficiency, and mechanical integrity, M30 Mild Steel Plain Washers are a trusted solution. Choose a manufacturer who understands the importance of precision, consistency, and durability.

Order now or request a free sample to see the quality for yourself. M30 Mild Steel Plain Washers – Engineered for strength, built for performance.

FAQs (15 Questions with Answers)

- What size bolt fits with M30 Mild Steel Plain Washers?

These washers are specifically designed to fit M30 bolts, which have a nominal diameter of 30 mm. - Can these washers be reused?

Yes, as long as the washer is not deformed, corroded, or worn out, it can be reused in multiple fastening applications. - Are coatings like zinc or black oxide available?

Yes. We offer multiple surface finishes including zinc plating and black oxide to enhance corrosion resistance. - What is the thickness tolerance?

Thickness tolerance generally ranges between ±0.2 mm, depending on the specific requirement and manufacturing process. - Do you offer test certificates?

Yes, test certificates including material test reports (MTRs) and dimensional inspection reports can be provided upon request. - Can these be used in marine environments?

While mild steel washers are not ideal for marine environments, zinc-plated or specially coated variants may offer some protection. For long-term marine use, stainless steel is preferred. - What are the packaging options?

We offer standard corrugated box packaging, HDPE bags, and customized bulk packaging with labeling as per client requirements. - How many washers are packed per box?

Typically, 50 to 100 washers are packed per box, but this can vary based on size, thickness, and client preferences. - Do you export internationally?

Yes. We have a robust logistics network and documentation process in place for global shipments. - What is the shelf life of coated washers?

With proper storage, zinc-plated washers have a shelf life of up to 2 years. Uncoated washers should be used sooner or stored in low-humidity environments. - Can I order a mix of sizes?

Yes, we accommodate mixed size orders for clients requiring a variety of washer dimensions in one shipment. - Are you an OEM supplier?

Yes. We supply to several original equipment manufacturers (OEMs) across sectors such as construction, automotive, and industrial machinery. - Can I visit the factory before placing bulk orders?

Absolutely. We encourage factory visits and audits by clients to assess our capabilities and processes. - What’s the minimum order quantity?

The standard minimum order quantity is 500 units, though it can be adjusted based on specific project needs. - How soon can you deliver bulk orders of M30 Mild Steel Plain Washers?

Standard lead time is 5–7 business days, depending on the order volume and any custom requirements.

These washers are specifically designed to fit M30 bolts, which have a nominal diameter of 30 mm. - Can these washers be reused?

Yes, as long as the washer is not deformed, corroded, or worn out, it can be reused in multiple fastening applications. - Are coatings like zinc or black oxide available?

Yes. We offer multiple surface finishes including zinc plating and black oxide to enhance corrosion resistance. - What is the thickness tolerance?

Thickness tolerance generally ranges between ±0.2 mm, depending on the specific requirement and manufacturing process. - Do you offer test certificates?

Yes, test certificates including material test reports (MTRs) and dimensional inspection reports can be provided upon request. - Can these be used in marine environments?

While mild steel washers are not ideal for marine environments, zinc-plated or specially coated variants may offer some protection. For long-term marine use, stainless steel is preferred. - What are the packaging options?

We offer standard corrugated box packaging, HDPE bags, and customized bulk packaging with labeling as per client requirements. - How many washers are packed per box?

Typically, 50 to 100 washers are packed per box, but this can vary based on size, thickness, and client preferences. - Do you export internationally?

Yes. We have a robust logistics network and documentation process in place for global shipments. - What is the shelf life of coated washers?

With proper storage, zinc-plated washers have a shelf life of up to 2 years. Uncoated washers should be used sooner or stored in low-humidity environments. - Can I order a mix of sizes?

Yes, we accommodate mixed size orders for clients requiring a variety of washer dimensions in one shipment. - Are you an OEM supplier?

Yes. We supply to several original equipment manufacturers (OEMs) across sectors such as construction, automotive, and industrial machinery. - Can I visit the factory before placing bulk orders?

Absolutely. We encourage factory visits and audits by clients to assess our capabilities and processes. - What’s the minimum order quantity?

The standard minimum order quantity is 500 units, though it can be adjusted based on specific project needs. - How soon can you deliver bulk orders of M30 Mild Steel Plain Washers?

Standard lead time is 5–7 business days, depending on the order volume and any custom requirements.

Why Choose Nafees Metal Industries?

At Nafees Metal industries, we believe your projects deserve the best fastening solutions. As a leading M30 Mild Steel Plain Washers manufacturer, we combine modern production techniques, high-grade raw materials, and strict inspections to deliver washers you can trust.

✔️ Advanced machinery and quality checks ensure precise dimensions.

✔️ Competitive prices and timely supply for single or bulk orders.

✔️ Options for custom sizes and protective coatings.

✔️ Friendly support and transparent communication.

Whether you need a small batch or want to buy M30 Mild Steel Plain Washers in bulk, we’re ready to support your industrial needs.

Visit or Contact Us

Discover how our high-performance washers can add strength and longevity to your assemblies. Visit our manufacturing unit at Reay Road, Mumbai, or reach out for a free quote, technical advice, or to place a bulk order.

Nafees Metal Industries — your trusted partner for durable, precision-engineered mild steel plain washers.

M30 Mild Steel Plain washers

21 people are viewing this product right now

₹7.20 Original price was: ₹7.20.₹6.00Current price is: ₹6.00. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M30

Inner Diameter (ID): 31 mm

Outer Diameter (OD): 56 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M30 Mild Steel Plain Washers – Rugged, Reliable, and Made for Industrial Strength

Introduction

In every mechanical or structural fastening job, a washer may seem like a minor part. Yet, its role is integral in the strength, stability, and longevity of the assembly. Washers act as protective spacers and stress distributors between a fastener and the surface it is clamping, preventing damage and ensuring the joint remains intact over time.

M30 Mild Steel Plain Washers serve this function particularly well in heavy-duty environments where bolts of size M30 are used. These washers offer exceptional strength and a reliable surface contact area for better load distribution.

At Nafees Metal Industries, we understand the critical need for durable, efficient fastening systems. That’s why our M30 Mild Steel Plain Washers are manufactured with precision engineering, ensuring compatibility, longevity, and performance. These washers are made from high-quality mild steel and built to withstand the most rigorous industrial conditions.

The demand for M30 Mild Steel Plain Washers has grown across various industries, especially where cost-efficiency meets strength requirements. Their use is prevalent in automotive, construction, heavy machinery, and electrical sectors.

What Are M30 Mild Steel Plain Washers?

M30 Mild Steel Plain Washers are flat, round metal discs with a central hole sized to fit M30 bolts. Their primary function is to distribute the load exerted by the fastener evenly across a larger surface area, thereby reducing the chances of surface deformation and enhancing the durability of the bolted joint.

These washers prevent the bolt head or nut from embedding into the assembly surface, which can cause localized damage or wear. Their use ensures that fasteners do not loosen under high-stress or vibration-prone environments, thus improving safety and reliability.

Key Features

- Even Load Distribution: These washers are engineered to disperse the load evenly across the fastening surface, reducing the risk of material deformation or fatigue cracks in the base material.

- Anti-Vibration Capabilities: The robust nature and precise fit of the M30 Mild Steel Plain Washers help in absorbing and reducing the effects of vibration. This is particularly beneficial in applications involving heavy machinery, transportation, and dynamic equipment.

- Corrosion-Resistant Finishes: With options like black oxide or zinc plating, these washers are resistant to rust and environmental wear, extending their functional life in both indoor and semi-outdoor environments.

- High Compatibility: Designed specifically for M30 bolts, these washers offer a snug fit and are also compatible with different fastening systems, ensuring flexible usage.

- Customizable Dimensions and Finishes: Available in various thicknesses and outer diameters, and with multiple finishing options, the washers can be tailored to match exact engineering specifications.

- Enhanced Mechanical Strength: Manufactured from IS 2062 grade mild steel, the washers provide excellent tensile and compressive strength. They maintain integrity even under heavy tightening and shear forces.

- Easy Installation and Handling: Their simple design and flat profile make them extremely easy to install, remove, and replace as needed. They contribute to quicker assembly times and reduced labor effort.

- Consistent Dimensional Accuracy: Produced using CNC and precision stamping, the washers feature tight tolerances and uniformity across batches, reducing the chances of assembly mismatch or installation error.

- Economic Efficiency: As a cost-effective alternative to alloyed or stainless steel washers, M30 mild steel washers offer superior performance at a budget-friendly price point. This makes them ideal for high-volume projects where cost and performance must align.

- Universal Industrial Application: Whether it’s structural steelwork, automotive systems, or industrial machinery, these washers serve reliably in various use cases, proving their versatility and wide acceptance across industries to protect underlying surfaces.

- Anti-vibration properties maintain joint integrity

- Rust-resistant coatings for longer shelf life

- Compatible with all M30 fasteners

- Available in various finishes and thicknesses

- High mechanical strength under dynamic loads

- Easy to handle, install, and remove

- Excellent dimensional tolerance and repeatability

Material Details: Why Mild Steel?

Mild steel is widely regarded as the backbone material in industrial manufacturing and construction due to its ideal blend of mechanical properties, ease of fabrication, and cost-effectiveness. For M30 Plain Washers, it proves to be especially advantageous, offering reliability in both strength and performance.

Composition and Structure:

- Carbon content ranges between 0.05% to 0.25%

- Composed primarily of iron and carbon with trace elements

- Provides the ideal combination of strength and ductility

Mechanical Benefits:

Mild steel offers sufficient tensile and compressive strength to support large-scale bolted joints. It resists deformation under tightening torque and provides consistent dimensional stability in critical applications.

- Excellent machinability for accurate shaping and punching

- Easy weldability for custom assemblies

- Suitable for coating or plating (zinc, black oxide, etc.)

Economic Efficiency:

Mild steel is significantly more affordable than alloyed steels like SS304 or SS316. This makes it ideal for bulk projects and high-volume applications without compromising on mechanical performance.

- Low raw material cost

- Easy availability across global markets

- Reduced overall production and procurement cost

Versatility and Adaptability:

Mild steel washers are compatible with a wide variety of surfaces, bolts, and fastening systems. They can be fabricated in custom sizes and shapes based on project needs.

- Works effectively in dry and controlled environments

- Compatible with common fastening methods

- Adaptable to both dynamic and static load conditions

Comparison with Other Steel Grades:

| Property | Mild Steel | SS304 | SS316 |

|---|---|---|---|

| Cost | Low | Medium | High |

| Corrosion Resistance | Moderate | High | Very High |

| Strength | Good | Good | Excellent |

| Machinability | Excellent | Moderate | Moderate |

Advantages in M30 Washers:

- High impact resistance

- Easy to machine and customize

- Ideal for coated applications

- Economical for large-scale usage

- Works well in dry or controlled environments

Mild steel offers the perfect balance of affordability and mechanical strength for M30 Mild Steel Plain Washers, making them a popular choice in large-scale industrial settings.

Manufacturing and Technical Specifications

At Nafees Metal Industries, M30 Mild Steel Plain Washers are manufactured with precision and consistency.

Production Process:

- Raw Material Sourcing

- Sheet Metal Punching/CNC Machining

- Deburring and Edge Finishing

- Heat Treatment (if required)

- Surface Coating (Zinc plating/Black Oxide)

- Dimensional and Visual Quality Checks

Technical Specification Table:

| Specification | Value |

| Inner Diameter | 31.5 mm |

| Outer Diameter | 56 mm |

| Thickness | 3–6 mm (customizable) |

| Finish | Zinc-plated / Black oxide |

| Material | Mild Steel (IS 2062) |

| Shape | Round |

Each washer undergoes stringent quality tests to meet ISO and IS standards, ensuring uniform performance in every batch.

Key Features

- Even load distribution to protect underlying surfaces

- Anti-vibration properties maintain joint integrity

- Rust-resistant coatings for longer shelf life

- Compatible with all M30 fasteners

- Available in various finishes and thicknesses

- High mechanical strength under dynamic loads

- Easy to handle, install, and remove

- Excellent dimensional tolerance and repeatability

Applications & Use Cases

The utility of M30 Mild Steel Plain Washers spans across:

Automotive:

- Suspension joints

- Engine mounting systems

- Brake assemblies

Construction:

- Steel structural joints

- Rebar connections

- Base plates and mounting brackets

Industrial Machinery:

- Power plant equipment

- Assembly line machines

- Presses and dies

Electronics:

- Cabinet installation

- Grounding connections

- Equipment fastening

DIY / General Fastening:

- Furniture

- Heavy-duty storage systems

- Metal frameworks

The washers are often categorized under MS Flat Washers or Mild Steel Washers in inventories, making them universally adaptable.

Why Buy M30 Mild Steel Plain Washers in Bulk

Bulk purchasing of M30 Mild Steel Plain Washers provides several logistical and financial benefits:

- Significant cost savings per unit

- Ensures consistent availability for ongoing projects

- Streamlines inventory planning

- Enables customized packaging and labeling for project-specific needs

Choosing to Buy M30 Mild Steel Plain Washers in Bulk ensures your operations remain uninterrupted while maximizing procurement efficiency.

Why Choose the Best M30 Mild Steel Plain Washers Manufacturer

Nafees Metal Industries is recognized as a Best M30 Mild Steel Plain Washers Manufacturer for a reason:

- ISO-certified facilities and production processes

- 100% in-house manufacturing

- Wide range of sizes and specifications

- Advanced machinery ensures repeat precision

- Bulk supply capabilities

- Quality certifications and documentation available

- Custom coating and branding options

Installation Tips

Installing M30 Mild Steel Plain Washers correctly ensures optimal performance:

- Clean the surface area and the washer

- Align washer over the bolt hole

- Insert bolt through washer

- Secure with nut or threaded surface

- Use torque wrench for proper tension

- Avoid overtightening that may deform washer

- For high-vibration environments, consider using a second washer

Maintenance Guidelines

Maintaining M30 Mild Steel Plain Washers extends their usability:

- Store in dry, covered spaces to avoid rust

- Inspect periodically for rust, cracks, or deformations

- Clean using dry cloth; apply anti-corrosive if needed

- Replace if washer becomes distorted or overly worn

Case Study (Real-world Usage)

Project: High-Stress Steel Framework Assembly – Metro Infrastructure

Scenario: In a major metro rail infrastructure project, engineers were encountering frequent issues with bolt loosening in high-stress structural steel joints. These joints, critical for supporting elevated tracks and overhead trusses, were subjected to constant vibrations from train movement and environmental stressors such as wind and thermal expansion.

Challenge: The assembly was originally fitted with generic washers that failed to evenly distribute the load, leading to micro-movements, bolt fatigue, and structural instability. This necessitated frequent maintenance and was raising safety concerns.

Solution: Our team at Nafees Metal Industries conducted an engineering audit and recommended custom-coated M30 Mild Steel Plain Washers. These washers, with optimal thickness and surface coating, were deployed across all joints in the framework. They offered improved load distribution, surface protection, and vibration dampening.

Implementation:

- Washers were pre-treated with black oxide coating for corrosion resistance

- Installed using calibrated torque wrenches for consistent tension

- Monitored over a period of 12 months for performance evaluation

Results:

- Bolt loosening incidents dropped by over 80%

- Maintenance checks were reduced from weekly to quarterly

- Project uptime increased, leading to cost savings in manpower and replacement parts

- Enhanced safety assurance for load-bearing infrastructure

| Performance Metric | Before Implementation | After Implementation |

| Bolt Loosening Rate | 15% | 2% |

| Maintenance Downtime | Weekly | Quarterly |

| Joint Stability Failures | 3 per month | 0 per month |

This case reflects how engineering-grade M30 Mild Steel Plain Washers can play a pivotal role in maintaining the integrity of complex, vibration-heavy structural projects. “The reliability and finish of Nafees washers helped us meet project deadlines ahead of schedule.”

Related Products or Variants

We also offer:

- Stainless Steel Flat Washers (SS304, SS316)

- SS202 Washers

- M10 to M50 Plain Washers

- Customized washers with slots or tabs

- Powder-coated and HDG variants

For industrial reliability, cost-efficiency, and mechanical integrity, M30 Mild Steel Plain Washers are a trusted solution. Choose a manufacturer who understands the importance of precision, consistency, and durability.

Order now or request a free sample to see the quality for yourself. M30 Mild Steel Plain Washers – Engineered for strength, built for performance.

FAQs (15 Questions with Answers)

- What size bolt fits with M30 Mild Steel Plain Washers?

These washers are specifically designed to fit M30 bolts, which have a nominal diameter of 30 mm. - Can these washers be reused?

Yes, as long as the washer is not deformed, corroded, or worn out, it can be reused in multiple fastening applications. - Are coatings like zinc or black oxide available?

Yes. We offer multiple surface finishes including zinc plating and black oxide to enhance corrosion resistance. - What is the thickness tolerance?

Thickness tolerance generally ranges between ±0.2 mm, depending on the specific requirement and manufacturing process. - Do you offer test certificates?

Yes, test certificates including material test reports (MTRs) and dimensional inspection reports can be provided upon request. - Can these be used in marine environments?

While mild steel washers are not ideal for marine environments, zinc-plated or specially coated variants may offer some protection. For long-term marine use, stainless steel is preferred. - What are the packaging options?

We offer standard corrugated box packaging, HDPE bags, and customized bulk packaging with labeling as per client requirements. - How many washers are packed per box?

Typically, 50 to 100 washers are packed per box, but this can vary based on size, thickness, and client preferences. - Do you export internationally?

Yes. We have a robust logistics network and documentation process in place for global shipments. - What is the shelf life of coated washers?

With proper storage, zinc-plated washers have a shelf life of up to 2 years. Uncoated washers should be used sooner or stored in low-humidity environments. - Can I order a mix of sizes?

Yes, we accommodate mixed size orders for clients requiring a variety of washer dimensions in one shipment. - Are you an OEM supplier?

Yes. We supply to several original equipment manufacturers (OEMs) across sectors such as construction, automotive, and industrial machinery. - Can I visit the factory before placing bulk orders?

Absolutely. We encourage factory visits and audits by clients to assess our capabilities and processes. - What’s the minimum order quantity?

The standard minimum order quantity is 500 units, though it can be adjusted based on specific project needs. - How soon can you deliver bulk orders of M30 Mild Steel Plain Washers?

Standard lead time is 5–7 business days, depending on the order volume and any custom requirements.

These washers are specifically designed to fit M30 bolts, which have a nominal diameter of 30 mm. - Can these washers be reused?

Yes, as long as the washer is not deformed, corroded, or worn out, it can be reused in multiple fastening applications. - Are coatings like zinc or black oxide available?

Yes. We offer multiple surface finishes including zinc plating and black oxide to enhance corrosion resistance. - What is the thickness tolerance?

Thickness tolerance generally ranges between ±0.2 mm, depending on the specific requirement and manufacturing process. - Do you offer test certificates?

Yes, test certificates including material test reports (MTRs) and dimensional inspection reports can be provided upon request. - Can these be used in marine environments?

While mild steel washers are not ideal for marine environments, zinc-plated or specially coated variants may offer some protection. For long-term marine use, stainless steel is preferred. - What are the packaging options?

We offer standard corrugated box packaging, HDPE bags, and customized bulk packaging with labeling as per client requirements. - How many washers are packed per box?

Typically, 50 to 100 washers are packed per box, but this can vary based on size, thickness, and client preferences. - Do you export internationally?

Yes. We have a robust logistics network and documentation process in place for global shipments. - What is the shelf life of coated washers?

With proper storage, zinc-plated washers have a shelf life of up to 2 years. Uncoated washers should be used sooner or stored in low-humidity environments. - Can I order a mix of sizes?

Yes, we accommodate mixed size orders for clients requiring a variety of washer dimensions in one shipment. - Are you an OEM supplier?

Yes. We supply to several original equipment manufacturers (OEMs) across sectors such as construction, automotive, and industrial machinery. - Can I visit the factory before placing bulk orders?

Absolutely. We encourage factory visits and audits by clients to assess our capabilities and processes. - What’s the minimum order quantity?

The standard minimum order quantity is 500 units, though it can be adjusted based on specific project needs. - How soon can you deliver bulk orders of M30 Mild Steel Plain Washers?

Standard lead time is 5–7 business days, depending on the order volume and any custom requirements.

Why Choose Nafees Metal Industries?

At Nafees Metal industries, we believe your projects deserve the best fastening solutions. As a leading M30 Mild Steel Plain Washers manufacturer, we combine modern production techniques, high-grade raw materials, and strict inspections to deliver washers you can trust.

✔️ Advanced machinery and quality checks ensure precise dimensions.

✔️ Competitive prices and timely supply for single or bulk orders.

✔️ Options for custom sizes and protective coatings.

✔️ Friendly support and transparent communication.

Whether you need a small batch or want to buy M30 Mild Steel Plain Washers in bulk, we’re ready to support your industrial needs.

Visit or Contact Us

Discover how our high-performance washers can add strength and longevity to your assemblies. Visit our manufacturing unit at Reay Road, Mumbai, or reach out for a free quote, technical advice, or to place a bulk order.

Nafees Metal Industries — your trusted partner for durable, precision-engineered mild steel plain washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch