No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

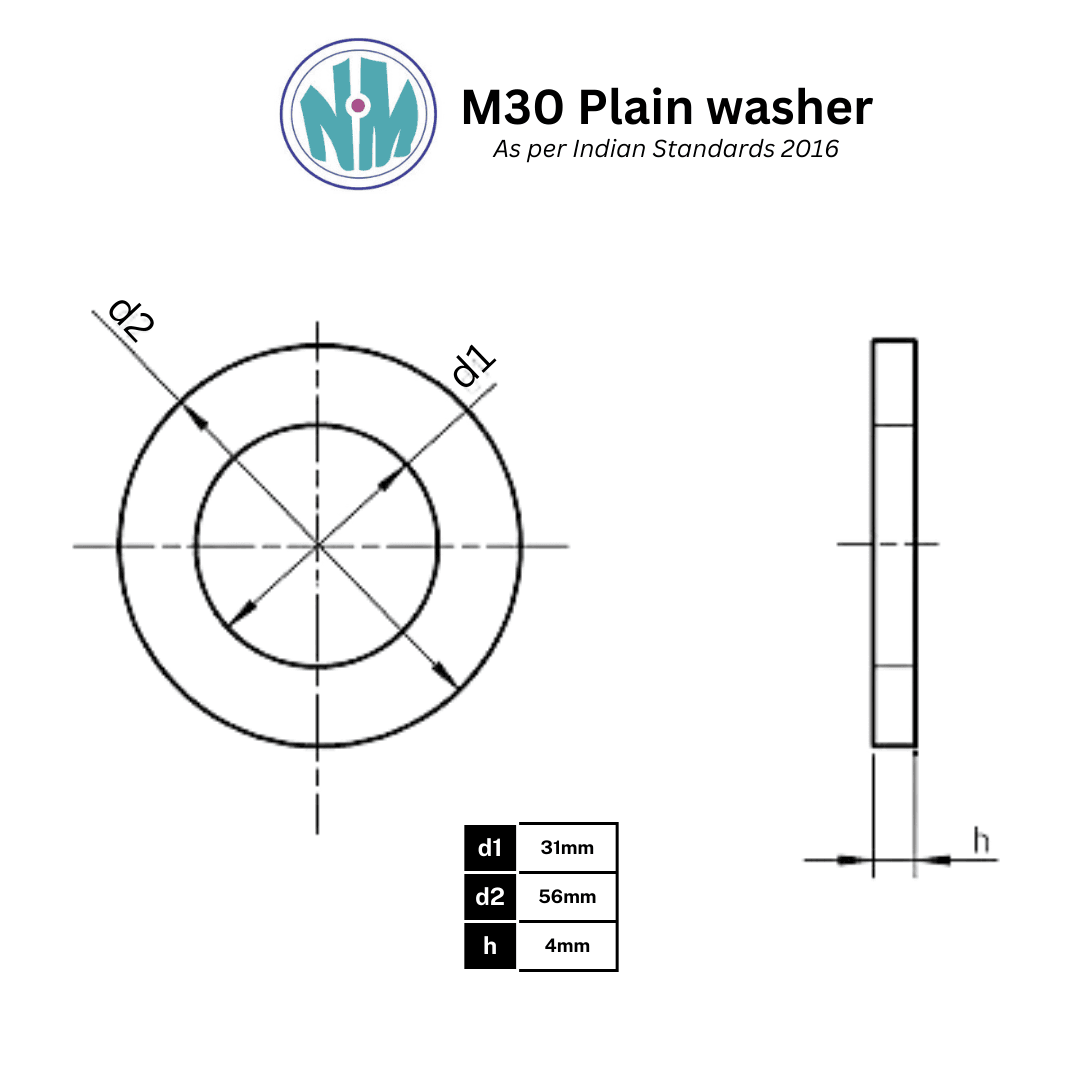

*Images shown for graphic representation. Not to scale.

M30 Copper Plain Washers – Durable, High-Performance Washers for Heavy-Duty Industrial Applications

Nafees Metal Industries is proud to introduce its high-precision M30 copper plain washers, engineered specifically for heavy-duty and industrial-grade applications that demand long-lasting durability, excellent conductivity, and superior sealing performance. Manufactured using high-purity copper, these washers are a top choice for assemblies where electrical conductivity, corrosion resistance, and thermal stability are critical.

As one of the best copper washer manufacturers in India, we are committed to delivering washers that not only meet but exceed industry expectations. Our M30 copper plain washers are meticulously crafted to deliver optimal load distribution, substrate protection, and secure fastening in a wide variety of settings—from power generation units to hydraulic systems and high-temperature machinery.

Whether you’re dealing with high-pressure hydraulic fittings, demanding electrical installations, or assemblies exposed to heat and vibration, our M30 copper plain washers provide the strength and reliability needed to maintain structural and operational integrity. With high availability in bulk, custom finishing options, and export-ready logistics, we ensure you get the right solution at the right time, every time.

What Are M30 Copper Plain Washers?

M30 copper plain washers are circular flat discs with a central hole precisely designed to fit M30 bolts or screws—meaning they’re intended for use with fasteners that have a nominal diameter of 30 millimeters. These washers are a critical component in industrial and mechanical assemblies where their primary function is to evenly distribute the load applied by a bolt or screw. This reduces surface stress, prevents material deformation, and enhances the clamping strength of the entire joint.

What makes these washers unique is their construction from high-conductivity copper, which sets them apart from washers made of steel or other materials. Their excellent thermal and electrical properties make them indispensable in applications involving current flow, heat transfer, or chemical exposure. Furthermore, copper’s malleability allows M30 copper plain washers to form tight, leak-resistant seals—especially important in fluid-based systems like hydraulic fittings and gas-tight seals.

In compliance with DIN 125 standards, our M30 copper flat washer metric series DIN 125 is ideal for industries that rely on standardized dimensions and reliability. Whether you’re assembling an electric motor, sealing a hydraulic pipe, or building HVAC systems, these washers provide unmatched functionality in terms of sealing, spacing, load-bearing, and conductivity.

Our washers are also compatible with diverse substrates such as stainless steel, aluminum, and brass, making them suitable for a wide range of fastening scenarios across multiple industries.

Why Choose Copper for M30 Washers?

Copper is one of the most preferred materials for industrial washers due to its exceptional combination of mechanical, thermal, and chemical properties. When it comes to M30 copper plain washers, copper provides performance benefits that other materials simply cannot match—especially in environments involving high pressure, elevated temperatures, electrical current, or corrosive fluids.

Here’s why copper is the ideal material choice for M30 washers:

Excellent Thermal Conductivity

Copper dissipates heat rapidly, making M30 copper plain washers ideal for applications in motors, transformers, heat exchangers, and high-temperature machinery. Their ability to manage and regulate thermal stress helps protect surrounding components from heat-related damage.Outstanding Electrical Conductivity

Copper is the industry standard for electrical components. Washers made of copper allow for minimal resistance and effective grounding in power assemblies, circuit boards, and electrical enclosures.Superior Corrosion Resistance

Copper naturally forms a protective oxide layer, making it highly resistant to corrosion, especially in marine, chemical, and hydraulic environments. This durability helps the washer maintain its sealing and load-distribution properties even after long-term use.Soft Yet Durable Structure

The ductile nature of copper enables the washer to conform to irregular surfaces, forming tight, leak-proof seals without causing damage. This is particularly beneficial in applications like copper sealing washer M30 hydraulic fittings, where a secure seal is critical.Non-Magnetic & Non-Sparking

Copper’s non-magnetic and non-sparking characteristics make M30 copper plain washers safe for use in electronic assemblies, explosive environments, and sensitive instrumentation where magnetic interference or spark risk must be avoided.Environmentally Friendly & Recyclable

Copper is fully recyclable without losing performance quality. Choosing M30 copper plain washers contributes to sustainable engineering practices.Cost-Effective for Long-Term Use

Though initially more expensive than mild steel, copper’s longer service life and reduced maintenance needs make it an economical choice over time—especially in corrosion-prone applications.

These unmatched benefits make copper the go-to material for engineers and manufacturers seeking reliability, safety, and long-term performance in critical fastening applications.

Manufacturing Excellence at Nafees Metal Industries

At Nafees Metal Industries, the production of M30 copper plain washers is a meticulous process driven by precision engineering, advanced technology, and a deep commitment to quality. As a leading manufacturer of copper washers in India, we adhere to international standards like DIN 125 and ISO 7089, ensuring our washers perform flawlessly across industrial environments.

Our manufacturing facility, located in Mumbai, is equipped with high-speed power presses, automated stamping systems, and quality control laboratories that support both high-volume and custom-made orders. Every M30 copper plain washer goes through a carefully monitored process that guarantees dimensional accuracy, material purity, and mechanical consistency.

Our Process Includes:

Raw Material Selection

We source premium-grade copper with a minimum of 99.9% purity. All materials are tested for conductivity, hardness, and composition before production begins.Precision Punching & Stamping

Washers are cold-stamped using high-tonnage presses to ensure uniform inner diameter (ID), outer diameter (OD), and thickness, conforming to the M30 copper flat washer metric series DIN 125.Deburring & Polishing

After stamping, each washer is deburred and polished to remove any sharp edges or imperfections. This guarantees a smooth finish that prevents surface damage during installation.Surface Finishing & Treatments

Based on customer requirements, washers can be delivered in natural, polished, or bright-annealed finishes. Custom coatings or oxidized finishes can also be offered for specialized industrial applications.Dimensional & Quality Checks

Every batch undergoes strict quality control, including tests for:Thickness tolerance

Flatness

Concentricity

ID/OD accuracy

Visual and surface inspection

Packaging & Logistics

We offer standard bulk packaging as well as custom-packed solutions (poly bags, labeled cartons, vacuum-sealed pouches) suitable for OEMs and exporters. Products are supplied with full documentation and test certificates when requested.

By combining skilled craftsmanship with automation and stringent QA protocols, Nafees Metal Industries ensures that each M30 copper plain washer you receive is reliable, high-performing, and ready for critical use.

Key Features of M30 Copper Plain Washers

Our M30 copper plain washers are engineered with precision and performance in mind, designed to meet the rigorous demands of industrial applications. These washers are more than just a load-distributing accessory—they’re vital components that ensure secure fastening, effective sealing, and reliable long-term operation.

Here are the standout features that make our M30 copper plain washers the preferred choice for engineers, OEMs, and maintenance professionals:

Perfect M30 Fitment

Manufactured with exact inner diameters, these washers are precision-sized to fit M30 bolts and screws, ensuring seamless assembly and alignment.DIN 125 Standard Compliance

Designed according to DIN 125 and ISO 7089 specifications, our washers meet global standards for mechanical reliability and dimensional accuracy.High Electrical & Thermal Conductivity

As copper naturally offers low resistance to both electricity and heat, these washers are ideal for electrical terminals, thermal interfaces, and grounding points.Industrial Copper Flat Washer – Corrosion-Resistant

The natural corrosion resistance of copper makes these washers suitable for aggressive environments, including those involving chemicals, saltwater, or hydraulic fluids.Soft Yet Strong for Secure Sealing

Copper’s softness allows washers to deform slightly under load, creating tight, leak-resistant seals without damaging softer or coated substrates.Compatible with Diverse Materials

Whether you’re assembling aluminum, brass, or steel components, our M30 copper plain washers deliver strong, non-reactive performance across a variety of substrates.Smooth, Polished Surface Finish

Each washer undergoes deburring and polishing, resulting in burr-free, smooth edges that are safe to handle and prevent scratching during assembly.Custom Thickness & Finish Options

We offer customization in thickness and finishing—natural, bright annealed, or polished—depending on your application requirements.Ready for Bulk Supply

With high-capacity manufacturing and inventory management, we can supply large volumes of M30 copper plain washers to OEMs, exporters, and project-based buyers without delay.Custom Branding & Packaging

Choose from bulk bags, labeled cartons, or branded packaging tailored to your distribution or export needs.Made in India with Global Standards

All washers are manufactured in our Mumbai facility using advanced machinery and skilled manpower—delivering globally competitive quality at local pricing.

These features ensure that our M30 copper plain washers not only meet your immediate assembly needs but also contribute to the longevity, safety, and efficiency of your equipment and installations.

Technical Specifications

Every M30 copper plain washer manufactured by Nafees Metal Industries is crafted to deliver consistent performance under various mechanical, thermal, and environmental conditions. Adhering to international benchmarks such as DIN 125, our washers are suitable for both standardized and customized applications in multiple industries.

Below is a detailed overview of the technical attributes of our product:

| Property | Specification |

|---|---|

| Product Name | M30 Copper Plain Washer |

| Material | Electrolytic High-Purity Copper (≥99.9% purity) |

| Inner Diameter (ID) | Approx. 30.5 mm (Precision fit for M30 bolts) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 standards |

| Thickness | Standard 2.5 mm (Available in custom thicknesses) |

| Surface Finish | Natural / Bright Annealed / Polished (optional) |

| Manufacturing Standard | DIN 125 / ISO 7089 / Metric Series |

| Washer Type | Flat, Round, Plain |

| Color | Reddish-Brown (Natural Copper Finish) |

| Available Coatings | Custom on request (e.g., Tin, Oxidized) |

| Hardness | Soft/Annealed Copper (Custom tempers available) |

| Application Fit | M30 Bolts, Screws, Studs – Metric Thread Compatible |

| Non-Magnetic | Yes |

| Conductivity | High Electrical & Thermal Conductivity |

| Packaging Options | Bulk, Poly Bags, Boxed, Custom-Labeled Cartons |

| Country of Origin | India (Manufactured in Mumbai by Nafees Metal Industries) |

These technical details make our M30 copper flat washer metric series DIN 125 a go-to solution for manufacturers, assemblers, and engineers who value precision, performance, and reliability. With customizable options and tight tolerance control, we ensure our washers match your design and operational needs perfectly.

Applications of M30 Copper Plain Washers

The versatility and material properties of M30 copper plain washers make them indispensable across a wide range of industries and systems where reliability, conductivity, sealing, and corrosion resistance are vital. Their compatibility with M30 bolts and compliance with DIN 125 standards allows for seamless integration into both new and existing mechanical and electrical assemblies.

Here are the most common and high-impact applications of M30 copper plain washers:

Hydraulic Fittings & Seals

As a trusted copper sealing washer M30 hydraulic fittings solution, these washers form secure seals under high pressure. They compress just enough to eliminate gaps between metal mating surfaces, making them ideal for fluid systems in heavy machinery, earthmovers, and industrial hydraulics.Electrical Panels & Terminal Assemblies

Their high conductivity makes them perfect for grounding, spacing, and distributing loads in switchboards, control panels, and transformer installations.HVAC Systems & Heat Exchangers

In systems that undergo temperature fluctuations, copper washers help maintain secure joints while dissipating heat to prevent stress-related damage.Oil & Gas and Petrochemical Plants

In corrosive environments where standard steel washers would degrade, these industrial copper flat washer corrosion-resistant products ensure long-lasting performance.Power Generation Units

Used in both thermal and renewable energy equipment for heat dissipation and electrical continuity.Plumbing & Water Supply Lines

Effective in creating watertight seals around large pipe flanges, valves, and plumbing unions.Automotive & Heavy Vehicles

Used for exhaust systems, battery terminals, engine assemblies, and brake line fittings.Marine Applications

Copper’s corrosion resistance makes it ideal for use in saltwater-exposed assemblies, from ship decks to offshore rigs.Machinery Base Plates & Fastener Kits

Used as spacers or stress relievers in large mechanical installations that experience vibration or bolt tension changes.Renewable Energy Systems (Solar & Wind)

Required for grounding panels and reducing resistance in current-carrying parts of solar and wind installations.

From general-purpose engineering to mission-critical sealing applications, our M30 copper plain washers deliver proven results in both static and dynamic assemblies. Their resilience, adaptability, and performance make them a smart investment for any industrial operation.

Specialty Use Case: Copper Washers in Hydraulic Systems

Hydraulic systems demand components that can withstand extreme pressure, maintain sealing integrity, and resist chemical degradation—all without compromising safety or performance. This is where M30 copper plain washers truly stand out. Their role in such systems is far more than just load distribution; they are critical to leak prevention, joint stability, and long-term system efficiency.

When used as a copper sealing washer M30 hydraulic fittings solution, these washers form a tight, compression seal between mating surfaces—often between threaded connections or bolt flanges. Thanks to copper’s natural malleability, the washer conforms to microscopic imperfections in the metal surfaces it’s paired with, effectively preventing leaks without the need for additional sealants or adhesives.

Why Copper Washers Are Ideal for Hydraulic Applications:

High Pressure Resistance

Even under thousands of PSI, copper washers maintain their seal without cracking, slipping, or corroding.Leak-Proof Sealing

The deformable nature of copper allows it to create a complete barrier, preventing leakage of hydraulic oils, coolants, or brake fluids.Chemical Compatibility

Copper resists common hydraulic fluids and solvents, ensuring chemical integrity over long operating cycles.Vibration Dampening

In machinery with moving parts, M30 copper plain washers reduce the risk of loosening caused by vibration or thermal expansion.Non-Magnetic Properties

This makes them suitable for hydraulic equipment used in sensitive environments like medical, aviation, or defense systems.

Real-World Example:

A leading manufacturer of hydraulic press machines experienced frequent leaks at threaded junctions despite using rubber and nylon washers. After switching to M30 copper plain washers, they reported:

100% leak elimination across 300+ machines

40% reduction in maintenance downtime

Zero washer-related replacements over a 12-month period

This application reinforces copper’s superiority in high-demand hydraulic environments, where failure is not an option.

Whether you’re manufacturing hydraulic presses, forklifts, CNC equipment, or construction machinery, M30 copper plain washers from Nafees Metal Industries offer unmatched sealing reliability and lifecycle cost savings, copper plain washer DIN 125 size M30.

Why Choose Nafees Metal Industries for Copper Washers?

When it comes to sourcing M30 copper plain washers, quality, reliability, and service matter just as much as the product itself. At Nafees Metal Industries, we don’t just manufacture washers—we engineer trust, value, and long-term partnerships.

As one of the leading copper washer manufacturers in India, we specialize in producing copper washers across a wide range of sizes and applications, all while adhering to strict global standards like DIN 125 and ISO 7089. Our deep industry experience, modern infrastructure, and customer-first approach make us the preferred supplier for OEMs, contractors, distributors, and international buyers alike.

Here’s Why You Should Partner with Us:

Specialized in Copper Washer Manufacturing

With decades of expertise and a dedicated production line for copper washers, we ensure high consistency, purity, and performance in every batch.Custom Sizes from M3 to M60

From small-scale electronics to large-diameter hydraulic applications, we offer an extensive size range, including M30 copper plain washers and other custom diameters upon request.Advanced In-House Testing Lab

We use precision measuring tools and conductivity, thickness, and hardness testing instruments to ensure each washer meets its technical specification.Export-Ready Operations

We support buyers across the globe with complete documentation, HS codes, packing lists, and fumigation certificates when required.Quick Turnaround Times

We maintain ready stock of fast-moving sizes and can fulfill custom bulk orders within a short lead time—often under 7 working days.Flexible Packaging & Branding

Need your washers packed with your brand label or barcodes? We offer white-labeling, retail packaging, and OEM-friendly bulk packs.Ethical & Transparent Pricing

With no hidden costs, we offer competitive rates for both domestic and international orders, helping you plan your procurement efficiently.Proudly Made in India – Trusted Worldwide

All our products are manufactured at our Mumbai-based facility using Indian raw materials, contributing to the Make in India initiative and promoting indigenous manufacturing excellence.

Whether you’re a project consultant, hardware supplier, or industrial OEM, Nafees Metal Industries is your trusted partner for sourcing high-quality M30 copper plain washers in both standard and custom specifications.

Industries We Serve

M30 Copper Plain Washers are more than just fastening aids—they are performance-critical components that find applications across a wide spectrum of industries (industrial copper flat washer corrosion resistant). At Nafees Metal Industries, we take pride in supplying these precision washers to businesses across India and around the world, catering to industries that demand durability, electrical conductivity, and high corrosion resistance.

Our copper washers are engineered to meet the diverse needs of sectors that operate in high-temperature, high-pressure, or chemically reactive environments. Below is a snapshot of the key industries we serve:

Automotive & EV Sector

Copper washers play a vital role in brake systems, fuel injection assemblies, and engine mounts. M30 washers are particularly used in larger joint areas requiring high-load distribution and fluid sealing in commercial vehicles and electric vehicles (EVs).

Heavy Machinery & Hydraulic Equipment

From hydraulic presses to earthmoving equipment, copper washers are essential for sealing fluid systems, preventing leaks, and withstanding vibration. M30 copper plain washers are ideal for joints in high-pressure hydraulic systems and oil-tight assemblies.

Electrical & Power Transmission

Thanks to copper’s excellent electrical conductivity, our washers are widely used in switchgear assemblies, circuit protection devices, and transformer systems. M30 sizes are common in industrial panels and substation installations.

Oil & Gas Industry

Whether it’s drilling rigs or refineries, M30 copper washers are used to prevent fluid leakage in flanged joints and control valves. They’re corrosion-resistant, making them ideal for offshore and onshore applications.

Railway & Aerospace

In locomotives, metro cars, and aircraft systems, copper washers are used for thermal and electrical insulation. The M30 size is perfect for vibration-prone and large assembly joints requiring secure sealing and conductivity.

Medical & Pharma Equipment

Copper’s antimicrobial properties make it a safe and hygienic material for washers used in critical care equipment, fluid dispensers, and pharmaceutical production lines.

HVAC & Refrigeration

Used in heating and cooling systems for tight sealing at compressor valves, copper washers ensure no gas or refrigerant leakage. M30 washers are commonly fitted in commercial-grade HVAC installations.

General Engineering & Maintenance

Whether in preventive maintenance kits or OEM manufacturing, M30 copper washers are regularly used in industrial tools, fixtures, and machinery across the engineering spectrum.

At Nafees Metal Industries, we understand that every industry has unique performance requirements. That’s why we offer industry-specific consultation, bulk pricing, and tailored packaging to serve each sector with precision and efficiency on M30 copper flat washer metric DIN 125 series.

FAQs – M30 Copper Plain Washers

What are M30 copper plain washers used for?

They are used for sealing, load distribution, and corrosion resistance in hydraulic, electrical, and mechanical systems.What standard do your M30 copper washers comply with?

All washers comply with DIN 125, ISO 7089, and metric standards.Do you offer custom sizes other than M30?

Yes, we manufacture from M3 to M60 copper washers with custom dimensions.Are these washers suitable for hydraulic fittings?

Absolutely, copper sealing washer M30 hydraulic fittings are one of the primary applications.Can I get zinc or tin-plated copper washers?

While copper is usually used bare, we offer special finishes based on client requirements.Are these washers non-magnetic?

Yes, copper is a non-magnetic material, making these washers ideal for sensitive environments.Can I use M30 copper plain washers in corrosive environments?

Yes, copper’s natural resistance makes it ideal for marine, chemical, and high-moisture setups.How thick are your M30 copper washers?

Standard thickness is 2.5 mm, but can be customized.Do you provide test certificates?

Yes, material test certificates are provided upon request.Is bulk purchase available?

Yes, we specialize in bulk supply with fast turnaround and export compliance.How are the washers packed?

Options include polybags, boxes, or customized packing with labels.What is the lead time for delivery?

For in-stock sizes, dispatch is within 48 hours; custom orders may take 7–10 working days.Do you export copper plain washers?

Yes, we export worldwide with full support for logistics and documentation.Are your washers RoHS compliant?

Yes, our copper washers meet RoHS compliance standards.What makes you the best manufacturer of copper washers in India?

Decades of experience, strict quality control, vast range, and trusted by industries nationwide.

How to Place a Bulk Order or Get a Quote

At Nafees Metal Industries, we believe that sourcing industrial components—like M30 Copper Plain Washers—should be a smooth, transparent, and professional experience. That’s why we’ve streamlined our order and quotation process to help buyers across India and overseas get what they need without unnecessary delays.

Whether you are a distributor, contractor, OEM, or exporter, placing a bulk order for M30 copper washers is just a few simple steps away.

Visit Our Manufacturing Facility in Mumbai

We invite you to witness the quality of our manufacturing first-hand at our state-of-the-art facility located in Mumbai-based facility. Equipped with:

Automatic power press machines

Precision measuring instruments

In-house inspection and quality testing lab

Trained technical staff with industry experience

Our facility ensures strict quality control and timely order execution. You are welcome to book a factory visit or virtual tour for a transparent understanding of our production capabilities.

Requesting a Quotation

You can request a quotation in any of the following ways:

Email us at: [info@nafeesmetalindustries.com]

Call/WhatsApp us on: [+91- 9322261781]

Visit our website: [www.nafeesmetalindustries.com] and fill out the “Get a Quote” form available on every product page.

To get a faster and more accurate quote, please mention:

Product Name: M30 Copper Plain Washer

Required Quantity (in pcs or kg)

Delivery Location (city/state or port)

Packing Preference (bulk, HDPE bags, custom branding, etc.)

Target Delivery Date (if urgent)

Any special technical requirements (if applicable)

Minimum Order Quantity & Lead Time

MOQ: As low as 50 kg or 5,000 pieces (for select sizes)

Lead Time: 5 to 10 working days depending on order volume

Dispatch: Via reputed logistics partners across India or by sea/air for exports

Bulk Export Orders

For international buyers, we provide:

Proforma Invoice

HS Code: 74152100 (for copper washers)

Packing list, commercial invoice, and certification of origin (as required)

Custom branding and palletized packing for sea export

With reliable pricing, short turnaround times, and a Mumbai-based centralized supply chain, Nafees Metal Industries is well-equipped to fulfill high-volume demands from any part of the world.

M30 Copper Plain Washers (DIN 125)

3 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M30

Inner Diameter (ID): 31 mm

Outer Diameter (OD): 56 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M30 Copper Plain Washers – Durable, High-Performance Washers for Heavy-Duty Industrial Applications

Nafees Metal Industries is proud to introduce its high-precision M30 copper plain washers, engineered specifically for heavy-duty and industrial-grade applications that demand long-lasting durability, excellent conductivity, and superior sealing performance. Manufactured using high-purity copper, these washers are a top choice for assemblies where electrical conductivity, corrosion resistance, and thermal stability are critical.

As one of the best copper washer manufacturers in India, we are committed to delivering washers that not only meet but exceed industry expectations. Our M30 copper plain washers are meticulously crafted to deliver optimal load distribution, substrate protection, and secure fastening in a wide variety of settings—from power generation units to hydraulic systems and high-temperature machinery.

Whether you’re dealing with high-pressure hydraulic fittings, demanding electrical installations, or assemblies exposed to heat and vibration, our M30 copper plain washers provide the strength and reliability needed to maintain structural and operational integrity. With high availability in bulk, custom finishing options, and export-ready logistics, we ensure you get the right solution at the right time, every time.

What Are M30 Copper Plain Washers?

M30 copper plain washers are circular flat discs with a central hole precisely designed to fit M30 bolts or screws—meaning they’re intended for use with fasteners that have a nominal diameter of 30 millimeters. These washers are a critical component in industrial and mechanical assemblies where their primary function is to evenly distribute the load applied by a bolt or screw. This reduces surface stress, prevents material deformation, and enhances the clamping strength of the entire joint.

What makes these washers unique is their construction from high-conductivity copper, which sets them apart from washers made of steel or other materials. Their excellent thermal and electrical properties make them indispensable in applications involving current flow, heat transfer, or chemical exposure. Furthermore, copper’s malleability allows M30 copper plain washers to form tight, leak-resistant seals—especially important in fluid-based systems like hydraulic fittings and gas-tight seals.

In compliance with DIN 125 standards, our M30 copper flat washer metric series DIN 125 is ideal for industries that rely on standardized dimensions and reliability. Whether you’re assembling an electric motor, sealing a hydraulic pipe, or building HVAC systems, these washers provide unmatched functionality in terms of sealing, spacing, load-bearing, and conductivity.

Our washers are also compatible with diverse substrates such as stainless steel, aluminum, and brass, making them suitable for a wide range of fastening scenarios across multiple industries.

Why Choose Copper for M30 Washers?

Copper is one of the most preferred materials for industrial washers due to its exceptional combination of mechanical, thermal, and chemical properties. When it comes to M30 copper plain washers, copper provides performance benefits that other materials simply cannot match—especially in environments involving high pressure, elevated temperatures, electrical current, or corrosive fluids.

Here’s why copper is the ideal material choice for M30 washers:

Excellent Thermal Conductivity

Copper dissipates heat rapidly, making M30 copper plain washers ideal for applications in motors, transformers, heat exchangers, and high-temperature machinery. Their ability to manage and regulate thermal stress helps protect surrounding components from heat-related damage.Outstanding Electrical Conductivity

Copper is the industry standard for electrical components. Washers made of copper allow for minimal resistance and effective grounding in power assemblies, circuit boards, and electrical enclosures.Superior Corrosion Resistance

Copper naturally forms a protective oxide layer, making it highly resistant to corrosion, especially in marine, chemical, and hydraulic environments. This durability helps the washer maintain its sealing and load-distribution properties even after long-term use.Soft Yet Durable Structure

The ductile nature of copper enables the washer to conform to irregular surfaces, forming tight, leak-proof seals without causing damage. This is particularly beneficial in applications like copper sealing washer M30 hydraulic fittings, where a secure seal is critical.Non-Magnetic & Non-Sparking

Copper’s non-magnetic and non-sparking characteristics make M30 copper plain washers safe for use in electronic assemblies, explosive environments, and sensitive instrumentation where magnetic interference or spark risk must be avoided.Environmentally Friendly & Recyclable

Copper is fully recyclable without losing performance quality. Choosing M30 copper plain washers contributes to sustainable engineering practices.Cost-Effective for Long-Term Use

Though initially more expensive than mild steel, copper’s longer service life and reduced maintenance needs make it an economical choice over time—especially in corrosion-prone applications.

These unmatched benefits make copper the go-to material for engineers and manufacturers seeking reliability, safety, and long-term performance in critical fastening applications.

Manufacturing Excellence at Nafees Metal Industries

At Nafees Metal Industries, the production of M30 copper plain washers is a meticulous process driven by precision engineering, advanced technology, and a deep commitment to quality. As a leading manufacturer of copper washers in India, we adhere to international standards like DIN 125 and ISO 7089, ensuring our washers perform flawlessly across industrial environments.

Our manufacturing facility, located in Mumbai, is equipped with high-speed power presses, automated stamping systems, and quality control laboratories that support both high-volume and custom-made orders. Every M30 copper plain washer goes through a carefully monitored process that guarantees dimensional accuracy, material purity, and mechanical consistency.

Our Process Includes:

Raw Material Selection

We source premium-grade copper with a minimum of 99.9% purity. All materials are tested for conductivity, hardness, and composition before production begins.Precision Punching & Stamping

Washers are cold-stamped using high-tonnage presses to ensure uniform inner diameter (ID), outer diameter (OD), and thickness, conforming to the M30 copper flat washer metric series DIN 125.Deburring & Polishing

After stamping, each washer is deburred and polished to remove any sharp edges or imperfections. This guarantees a smooth finish that prevents surface damage during installation.Surface Finishing & Treatments

Based on customer requirements, washers can be delivered in natural, polished, or bright-annealed finishes. Custom coatings or oxidized finishes can also be offered for specialized industrial applications.Dimensional & Quality Checks

Every batch undergoes strict quality control, including tests for:Thickness tolerance

Flatness

Concentricity

ID/OD accuracy

Visual and surface inspection

Packaging & Logistics

We offer standard bulk packaging as well as custom-packed solutions (poly bags, labeled cartons, vacuum-sealed pouches) suitable for OEMs and exporters. Products are supplied with full documentation and test certificates when requested.

By combining skilled craftsmanship with automation and stringent QA protocols, Nafees Metal Industries ensures that each M30 copper plain washer you receive is reliable, high-performing, and ready for critical use.

Key Features of M30 Copper Plain Washers

Our M30 copper plain washers are engineered with precision and performance in mind, designed to meet the rigorous demands of industrial applications. These washers are more than just a load-distributing accessory—they’re vital components that ensure secure fastening, effective sealing, and reliable long-term operation.

Here are the standout features that make our M30 copper plain washers the preferred choice for engineers, OEMs, and maintenance professionals:

Perfect M30 Fitment

Manufactured with exact inner diameters, these washers are precision-sized to fit M30 bolts and screws, ensuring seamless assembly and alignment.DIN 125 Standard Compliance

Designed according to DIN 125 and ISO 7089 specifications, our washers meet global standards for mechanical reliability and dimensional accuracy.High Electrical & Thermal Conductivity

As copper naturally offers low resistance to both electricity and heat, these washers are ideal for electrical terminals, thermal interfaces, and grounding points.Industrial Copper Flat Washer – Corrosion-Resistant

The natural corrosion resistance of copper makes these washers suitable for aggressive environments, including those involving chemicals, saltwater, or hydraulic fluids.Soft Yet Strong for Secure Sealing

Copper’s softness allows washers to deform slightly under load, creating tight, leak-resistant seals without damaging softer or coated substrates.Compatible with Diverse Materials

Whether you’re assembling aluminum, brass, or steel components, our M30 copper plain washers deliver strong, non-reactive performance across a variety of substrates.Smooth, Polished Surface Finish

Each washer undergoes deburring and polishing, resulting in burr-free, smooth edges that are safe to handle and prevent scratching during assembly.Custom Thickness & Finish Options

We offer customization in thickness and finishing—natural, bright annealed, or polished—depending on your application requirements.Ready for Bulk Supply

With high-capacity manufacturing and inventory management, we can supply large volumes of M30 copper plain washers to OEMs, exporters, and project-based buyers without delay.Custom Branding & Packaging

Choose from bulk bags, labeled cartons, or branded packaging tailored to your distribution or export needs.Made in India with Global Standards

All washers are manufactured in our Mumbai facility using advanced machinery and skilled manpower—delivering globally competitive quality at local pricing.

These features ensure that our M30 copper plain washers not only meet your immediate assembly needs but also contribute to the longevity, safety, and efficiency of your equipment and installations.

Technical Specifications

Every M30 copper plain washer manufactured by Nafees Metal Industries is crafted to deliver consistent performance under various mechanical, thermal, and environmental conditions. Adhering to international benchmarks such as DIN 125, our washers are suitable for both standardized and customized applications in multiple industries.

Below is a detailed overview of the technical attributes of our product:

| Property | Specification |

|---|---|

| Product Name | M30 Copper Plain Washer |

| Material | Electrolytic High-Purity Copper (≥99.9% purity) |

| Inner Diameter (ID) | Approx. 30.5 mm (Precision fit for M30 bolts) |

| Outer Diameter (OD) | As per DIN 125 / ISO 7089 standards |

| Thickness | Standard 2.5 mm (Available in custom thicknesses) |

| Surface Finish | Natural / Bright Annealed / Polished (optional) |

| Manufacturing Standard | DIN 125 / ISO 7089 / Metric Series |

| Washer Type | Flat, Round, Plain |

| Color | Reddish-Brown (Natural Copper Finish) |

| Available Coatings | Custom on request (e.g., Tin, Oxidized) |

| Hardness | Soft/Annealed Copper (Custom tempers available) |

| Application Fit | M30 Bolts, Screws, Studs – Metric Thread Compatible |

| Non-Magnetic | Yes |

| Conductivity | High Electrical & Thermal Conductivity |

| Packaging Options | Bulk, Poly Bags, Boxed, Custom-Labeled Cartons |

| Country of Origin | India (Manufactured in Mumbai by Nafees Metal Industries) |

These technical details make our M30 copper flat washer metric series DIN 125 a go-to solution for manufacturers, assemblers, and engineers who value precision, performance, and reliability. With customizable options and tight tolerance control, we ensure our washers match your design and operational needs perfectly.

Applications of M30 Copper Plain Washers

The versatility and material properties of M30 copper plain washers make them indispensable across a wide range of industries and systems where reliability, conductivity, sealing, and corrosion resistance are vital. Their compatibility with M30 bolts and compliance with DIN 125 standards allows for seamless integration into both new and existing mechanical and electrical assemblies.

Here are the most common and high-impact applications of M30 copper plain washers:

Hydraulic Fittings & Seals

As a trusted copper sealing washer M30 hydraulic fittings solution, these washers form secure seals under high pressure. They compress just enough to eliminate gaps between metal mating surfaces, making them ideal for fluid systems in heavy machinery, earthmovers, and industrial hydraulics.Electrical Panels & Terminal Assemblies

Their high conductivity makes them perfect for grounding, spacing, and distributing loads in switchboards, control panels, and transformer installations.HVAC Systems & Heat Exchangers

In systems that undergo temperature fluctuations, copper washers help maintain secure joints while dissipating heat to prevent stress-related damage.Oil & Gas and Petrochemical Plants

In corrosive environments where standard steel washers would degrade, these industrial copper flat washer corrosion-resistant products ensure long-lasting performance.Power Generation Units

Used in both thermal and renewable energy equipment for heat dissipation and electrical continuity.Plumbing & Water Supply Lines

Effective in creating watertight seals around large pipe flanges, valves, and plumbing unions.Automotive & Heavy Vehicles

Used for exhaust systems, battery terminals, engine assemblies, and brake line fittings.Marine Applications

Copper’s corrosion resistance makes it ideal for use in saltwater-exposed assemblies, from ship decks to offshore rigs.Machinery Base Plates & Fastener Kits

Used as spacers or stress relievers in large mechanical installations that experience vibration or bolt tension changes.Renewable Energy Systems (Solar & Wind)

Required for grounding panels and reducing resistance in current-carrying parts of solar and wind installations.

From general-purpose engineering to mission-critical sealing applications, our M30 copper plain washers deliver proven results in both static and dynamic assemblies. Their resilience, adaptability, and performance make them a smart investment for any industrial operation.

Specialty Use Case: Copper Washers in Hydraulic Systems

Hydraulic systems demand components that can withstand extreme pressure, maintain sealing integrity, and resist chemical degradation—all without compromising safety or performance. This is where M30 copper plain washers truly stand out. Their role in such systems is far more than just load distribution; they are critical to leak prevention, joint stability, and long-term system efficiency.

When used as a copper sealing washer M30 hydraulic fittings solution, these washers form a tight, compression seal between mating surfaces—often between threaded connections or bolt flanges. Thanks to copper’s natural malleability, the washer conforms to microscopic imperfections in the metal surfaces it’s paired with, effectively preventing leaks without the need for additional sealants or adhesives.

Why Copper Washers Are Ideal for Hydraulic Applications:

High Pressure Resistance

Even under thousands of PSI, copper washers maintain their seal without cracking, slipping, or corroding.Leak-Proof Sealing

The deformable nature of copper allows it to create a complete barrier, preventing leakage of hydraulic oils, coolants, or brake fluids.Chemical Compatibility

Copper resists common hydraulic fluids and solvents, ensuring chemical integrity over long operating cycles.Vibration Dampening

In machinery with moving parts, M30 copper plain washers reduce the risk of loosening caused by vibration or thermal expansion.Non-Magnetic Properties

This makes them suitable for hydraulic equipment used in sensitive environments like medical, aviation, or defense systems.

Real-World Example:

A leading manufacturer of hydraulic press machines experienced frequent leaks at threaded junctions despite using rubber and nylon washers. After switching to M30 copper plain washers, they reported:

100% leak elimination across 300+ machines

40% reduction in maintenance downtime

Zero washer-related replacements over a 12-month period

This application reinforces copper’s superiority in high-demand hydraulic environments, where failure is not an option.

Whether you’re manufacturing hydraulic presses, forklifts, CNC equipment, or construction machinery, M30 copper plain washers from Nafees Metal Industries offer unmatched sealing reliability and lifecycle cost savings, copper plain washer DIN 125 size M30.

Why Choose Nafees Metal Industries for Copper Washers?

When it comes to sourcing M30 copper plain washers, quality, reliability, and service matter just as much as the product itself. At Nafees Metal Industries, we don’t just manufacture washers—we engineer trust, value, and long-term partnerships.

As one of the leading copper washer manufacturers in India, we specialize in producing copper washers across a wide range of sizes and applications, all while adhering to strict global standards like DIN 125 and ISO 7089. Our deep industry experience, modern infrastructure, and customer-first approach make us the preferred supplier for OEMs, contractors, distributors, and international buyers alike.

Here’s Why You Should Partner with Us:

Specialized in Copper Washer Manufacturing

With decades of expertise and a dedicated production line for copper washers, we ensure high consistency, purity, and performance in every batch.Custom Sizes from M3 to M60

From small-scale electronics to large-diameter hydraulic applications, we offer an extensive size range, including M30 copper plain washers and other custom diameters upon request.Advanced In-House Testing Lab

We use precision measuring tools and conductivity, thickness, and hardness testing instruments to ensure each washer meets its technical specification.Export-Ready Operations

We support buyers across the globe with complete documentation, HS codes, packing lists, and fumigation certificates when required.Quick Turnaround Times

We maintain ready stock of fast-moving sizes and can fulfill custom bulk orders within a short lead time—often under 7 working days.Flexible Packaging & Branding

Need your washers packed with your brand label or barcodes? We offer white-labeling, retail packaging, and OEM-friendly bulk packs.Ethical & Transparent Pricing

With no hidden costs, we offer competitive rates for both domestic and international orders, helping you plan your procurement efficiently.Proudly Made in India – Trusted Worldwide

All our products are manufactured at our Mumbai-based facility using Indian raw materials, contributing to the Make in India initiative and promoting indigenous manufacturing excellence.

Whether you’re a project consultant, hardware supplier, or industrial OEM, Nafees Metal Industries is your trusted partner for sourcing high-quality M30 copper plain washers in both standard and custom specifications.

Industries We Serve

M30 Copper Plain Washers are more than just fastening aids—they are performance-critical components that find applications across a wide spectrum of industries (industrial copper flat washer corrosion resistant). At Nafees Metal Industries, we take pride in supplying these precision washers to businesses across India and around the world, catering to industries that demand durability, electrical conductivity, and high corrosion resistance.

Our copper washers are engineered to meet the diverse needs of sectors that operate in high-temperature, high-pressure, or chemically reactive environments. Below is a snapshot of the key industries we serve:

Automotive & EV Sector

Copper washers play a vital role in brake systems, fuel injection assemblies, and engine mounts. M30 washers are particularly used in larger joint areas requiring high-load distribution and fluid sealing in commercial vehicles and electric vehicles (EVs).

Heavy Machinery & Hydraulic Equipment

From hydraulic presses to earthmoving equipment, copper washers are essential for sealing fluid systems, preventing leaks, and withstanding vibration. M30 copper plain washers are ideal for joints in high-pressure hydraulic systems and oil-tight assemblies.

Electrical & Power Transmission

Thanks to copper’s excellent electrical conductivity, our washers are widely used in switchgear assemblies, circuit protection devices, and transformer systems. M30 sizes are common in industrial panels and substation installations.

Oil & Gas Industry

Whether it’s drilling rigs or refineries, M30 copper washers are used to prevent fluid leakage in flanged joints and control valves. They’re corrosion-resistant, making them ideal for offshore and onshore applications.

Railway & Aerospace

In locomotives, metro cars, and aircraft systems, copper washers are used for thermal and electrical insulation. The M30 size is perfect for vibration-prone and large assembly joints requiring secure sealing and conductivity.

Medical & Pharma Equipment

Copper’s antimicrobial properties make it a safe and hygienic material for washers used in critical care equipment, fluid dispensers, and pharmaceutical production lines.

HVAC & Refrigeration

Used in heating and cooling systems for tight sealing at compressor valves, copper washers ensure no gas or refrigerant leakage. M30 washers are commonly fitted in commercial-grade HVAC installations.

General Engineering & Maintenance

Whether in preventive maintenance kits or OEM manufacturing, M30 copper washers are regularly used in industrial tools, fixtures, and machinery across the engineering spectrum.

At Nafees Metal Industries, we understand that every industry has unique performance requirements. That’s why we offer industry-specific consultation, bulk pricing, and tailored packaging to serve each sector with precision and efficiency on M30 copper flat washer metric DIN 125 series.

FAQs – M30 Copper Plain Washers

What are M30 copper plain washers used for?

They are used for sealing, load distribution, and corrosion resistance in hydraulic, electrical, and mechanical systems.What standard do your M30 copper washers comply with?

All washers comply with DIN 125, ISO 7089, and metric standards.Do you offer custom sizes other than M30?

Yes, we manufacture from M3 to M60 copper washers with custom dimensions.Are these washers suitable for hydraulic fittings?

Absolutely, copper sealing washer M30 hydraulic fittings are one of the primary applications.Can I get zinc or tin-plated copper washers?

While copper is usually used bare, we offer special finishes based on client requirements.Are these washers non-magnetic?

Yes, copper is a non-magnetic material, making these washers ideal for sensitive environments.Can I use M30 copper plain washers in corrosive environments?

Yes, copper’s natural resistance makes it ideal for marine, chemical, and high-moisture setups.How thick are your M30 copper washers?

Standard thickness is 2.5 mm, but can be customized.Do you provide test certificates?

Yes, material test certificates are provided upon request.Is bulk purchase available?

Yes, we specialize in bulk supply with fast turnaround and export compliance.How are the washers packed?

Options include polybags, boxes, or customized packing with labels.What is the lead time for delivery?

For in-stock sizes, dispatch is within 48 hours; custom orders may take 7–10 working days.Do you export copper plain washers?

Yes, we export worldwide with full support for logistics and documentation.Are your washers RoHS compliant?

Yes, our copper washers meet RoHS compliance standards.What makes you the best manufacturer of copper washers in India?

Decades of experience, strict quality control, vast range, and trusted by industries nationwide.

How to Place a Bulk Order or Get a Quote

At Nafees Metal Industries, we believe that sourcing industrial components—like M30 Copper Plain Washers—should be a smooth, transparent, and professional experience. That’s why we’ve streamlined our order and quotation process to help buyers across India and overseas get what they need without unnecessary delays.

Whether you are a distributor, contractor, OEM, or exporter, placing a bulk order for M30 copper washers is just a few simple steps away.

Visit Our Manufacturing Facility in Mumbai

We invite you to witness the quality of our manufacturing first-hand at our state-of-the-art facility located in Mumbai-based facility. Equipped with:

Automatic power press machines

Precision measuring instruments

In-house inspection and quality testing lab

Trained technical staff with industry experience

Our facility ensures strict quality control and timely order execution. You are welcome to book a factory visit or virtual tour for a transparent understanding of our production capabilities.

Requesting a Quotation

You can request a quotation in any of the following ways:

Email us at: [info@nafeesmetalindustries.com]

Call/WhatsApp us on: [+91- 9322261781]

Visit our website: [www.nafeesmetalindustries.com] and fill out the “Get a Quote” form available on every product page.

To get a faster and more accurate quote, please mention:

Product Name: M30 Copper Plain Washer

Required Quantity (in pcs or kg)

Delivery Location (city/state or port)

Packing Preference (bulk, HDPE bags, custom branding, etc.)

Target Delivery Date (if urgent)

Any special technical requirements (if applicable)

Minimum Order Quantity & Lead Time

MOQ: As low as 50 kg or 5,000 pieces (for select sizes)

Lead Time: 5 to 10 working days depending on order volume

Dispatch: Via reputed logistics partners across India or by sea/air for exports

Bulk Export Orders

For international buyers, we provide:

Proforma Invoice

HS Code: 74152100 (for copper washers)

Packing list, commercial invoice, and certification of origin (as required)

Custom branding and palletized packing for sea export

With reliable pricing, short turnaround times, and a Mumbai-based centralized supply chain, Nafees Metal Industries is well-equipped to fulfill high-volume demands from any part of the world.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch