No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M3 SS202 Plain Washers – Premium Stainless Steel Washers for Industrial Reliability

At Nafees Metal Industries, we proudly manufacture and supply premium-quality M3 SS202 Plain Washers, engineered to meet the demanding needs of modern industrial environments. Designed for precision, strength, and durability, these washers are a crucial component for any fastening system that requires load distribution, surface protection, and vibration resistance.

Crafted from SS202 grade stainless steel, our M3 plain washers offer a winning combination of corrosion resistance, mechanical performance, and cost-efficiency. Their small M3 size (3mm internal diameter) makes them ideal for precision applications in compact assemblies—ranging from electronic devices and automotive components to electrical panels, home appliances, and construction fittings.

As one of the best manufacturers of plain washers in India, our commitment goes beyond just quality production. We ensure dimensional accuracy, smooth surface finishes, and consistent thickness in every piece—qualities that are vital when washers are used in safety-critical or high-performance assemblies.

Whether you are an OEM looking for bulk M3 stainless steel washers, a maintenance engineer replacing components in a mechanical system, or a distributor sourcing reliable fastening hardware, our M3 SS202 Plain Washers deliver unmatched value. Their lightweight yet sturdy build allows them to serve both functional and structural purposes—distributing pressure evenly across the fastening surface, preventing surface damage, and reducing loosening due to vibration or torque.

We understand the need for reliable and economical fastening solutions. That’s why our M3 SS202 Plain Washers are produced in line with global standards such as DIN 125A and IS, using state-of-the-art manufacturing technology and a rigorous quality control process.

At Nafees Metal Industries, excellence is not just a goal—it’s a guarantee. Our focus on innovation, performance, and client satisfaction has made us a preferred partner for stainless steel washers across India and globally. Choose our M3 SS202 Plain Washers for industrial-grade fastening that you can count on—every single time.

Why Choose Our M3 SS202 Plain Washers? Best SS202 plain washers for industrial use

When industries seek components that perform flawlessly under pressure, they turn to trusted names. Our M3 SS202 Plain Washers are the result of decades of expertise, precision machining, and a deep understanding of fastener performance under industrial stress.

Each washer is crafted using SS202 stainless steel—a material that delivers a perfect balance between strength, durability, and affordability. We follow globally accepted manufacturing standards (DIN 125A / IS), ensuring dimensional accuracy and consistent mechanical properties batch after batch.

Key reasons to choose our washers:

Precision-tuned to fit M3 fasteners with zero tolerance mismatch.

Mass production capacity for timely delivery in both small and large volumes.

Strict quality checks at every stage—from raw material to final dispatch.

Trusted by OEMs, exporters, and fabrication workshops across India and overseas.

Features of M3 SS202 Plain Washers

Our M3 SS202 Plain Washers are engineered with precision to deliver uncompromised performance in compact fastening systems. Below is a detailed breakdown of the core features that make our washers a preferred choice for industrial applications:

1. Made from High-Quality SS202 Stainless Steel

These washers are manufactured using SS202-grade stainless steel, known for its excellent combination of tensile strength, cost-effectiveness, and moderate corrosion resistance. SS202 offers better wear resistance than mild steel and is ideal for indoor and semi-exposed conditions. The material ensures the washer retains its structural integrity even in vibration-heavy or moderately corrosive environments.

2. Perfect Compatibility with M3 Fasteners

Designed specifically for M3 bolts and screws, the inner diameter and outer dimensions strictly conform to DIN 125A and IS standards. This ensures a tight and precise fit without slippage, reducing the chances of fastener loosening under load or vibration.

3. Even Load Distribution

One of the primary functions of a plain washer is to distribute load uniformly across the fastening surface. Our M3 plain washers eliminate the risk of surface damage, localized stress, or fastener pull-through by creating a broader and more stable contact surface between the fastener and the base material.

4. Precision Thickness for Structural Consistency

Each washer is manufactured with consistent thickness across batches, ensuring uniform clamping force. Whether you’re using automated or manual torqueing tools, the washer maintains mechanical balance, preventing overtightening or loosening over time.

5. Smooth, Burr-Free Finish

The washers undergo deburring and surface smoothing processes to eliminate sharp edges and imperfections. This results in a clean, user-safe product that won’t damage painted or polished surfaces during installation. The smooth finish also improves handling and assembly speed in production lines.

6. Enhanced Surface Finish Options

Depending on the requirement, we offer polished, plain, or oil-coated surface finishes. These options enhance the washer’s resistance to oxidation and improve its appearance—making it suitable for both functional and visible assembly applications.

7. Compact but Strong

Despite being small in size, M3 SS202 Plain Washers are built to withstand significant loads. Their material and design allow them to perform reliably in applications that demand strength in a minimal footprint—making them ideal for electronics, electrical panels, and small-scale mechanical systems.

8. Dimensional Accuracy with Tight Tolerances

Our washers are produced with tight dimensional tolerances to ensure consistent performance in high-precision assemblies. This is particularly important in industries like electronics, aerospace, and automotive, where any deviation in component size can affect performance or safety.

9. Long-Term Durability

Thanks to the properties of SS202 stainless steel, these washers maintain their mechanical performance over long-term usage. They resist deformation under stress, remain unaffected by temperature fluctuations, and provide lasting fastening support in dynamic environments.

10. Lightweight and Low Maintenance

M3 SS202 Plain Washers are lightweight, making them ideal for weight-sensitive applications like portable devices or modular assemblies. Additionally, the corrosion-resistant nature of SS202 reduces maintenance frequency and cost over the washer’s lifespan.

Applications of M3 SS202 Plain Washers

Our washers are highly versatile and used across diverse industries where M3 bolts or screws are part of the assembly. These include:

1. Automotive Assemblies

In the automotive sector, M3 SS202 Plain Washers play a crucial role in securing small bolts and screws in vehicle interior panels, dashboard assemblies, sensor brackets, and electronic modules. Their ability to distribute load evenly and reduce surface pressure ensures that delicate components like circuit housings, lighting fixtures, and trims remain securely fastened during vehicle operation and vibrations.

2. Electrical Installations

M3 washers are extensively used in switchboards, circuit breaker panels, motor enclosures, terminal boxes, and control panels. Their stainless steel construction prevents rusting in environments exposed to current flow, moisture, and minor heating. They ensure strong electrical connections by preventing over-tightening or damage to delicate substrates like plastic enclosures or copper busbars.

3. Precision Electronics & PCB Mounting

In electronic device manufacturing, these washers are ideal for mounting PCBs (Printed Circuit Boards), microcontroller units, display panels, and other sensitive hardware. Their lightweight nature and accurate sizing reduce the risk of short circuits, while the deburred surface ensures safe contact with fragile components.

4. Construction and Infrastructure Projects

Although M3 is a smaller size, it is frequently used in anchoring light fixtures, control systems, signage, and HVAC enclosures in modern construction. They are particularly beneficial in interior fittings, where components like access panels, sensor systems, and safety fixtures must be mounted securely with corrosion-resistant hardware.

5. Mechanical Fastening in Light Equipment

From handheld machinery to precision instruments, the washers act as a barrier to prevent fastener head damage to surfaces and improve torque performance. In machines like textile units, packaging equipment, or small compressors, these washers ensure the longevity of bolted joints.

6. Home Appliances and Consumer Electronics

Washers in the M3 size range are widely used in the assembly of consumer appliances such as washing machines, microwave ovens, blenders, fans, and induction cooktops. Their stainless steel body ensures longevity even in moisture-prone environments and reduces loosening during repetitive operations like motor spinning or vibration.

7. Railway and Metro Coach Components

Used in wiring systems, panel fittings, and instrumentation units within trains and metro coaches, M3 SS202 Plain Washers help maintain secure, vibration-resistant joints without adding bulk or unnecessary weight to electrical or mechanical modules.

8. Aerospace and Defense Equipment (Non-Critical Assemblies)

In non-critical fastening applications where weight and precision matter more than extreme environmental resistance, these washers find use in enclosure panels, display mounts, and sensor brackets. SS202 provides a reliable balance of strength and cost in such controlled environments.

9. Renewable Energy Systems

They are used in the assembly of internal components in solar inverters, battery casings, and mounting structures where small yet durable washers are needed to maintain mechanical integrity under light outdoor exposure.

10. Furniture and Modular Workstations

Compact and corrosion-resistant, these washers are ideal for fastening drawer slides, hinges, control knobs, and modular joints in furniture, especially those exposed to varying humidity like office workstations, hospital beds, or kitchen units.

11. Robotics and Automation Systems

Automation assemblies often involve sensors, actuators, cameras, and control units, all of which require micro-sized, stable, and vibration-resistant joints. M3 SS202 Plain Washers provide the dimensional stability and resistance needed in high-speed or repetitive-motion environments.

12. Instrumentation and Measurement Devices

These washers are often used in fastening measuring tools, digital readouts, lab instruments, and calibration devices where minimal vibration or component displacement could cause errors. Their tight tolerances help retain positional accuracy of mounted sensors or indicators.

13. Solar and Smart Energy Panels (Internal Fastening)

Within enclosures or battery housings of solar panels and inverters, these washers are used to fasten and support internal circuits and boards, ensuring long-lasting electrical connections even in changing ambient temperatures.

Advantages of SS202 Material in Washers

SS202 stainless steel is a cost-effective alternative to SS304, while still offering dependable mechanical and environmental resistance. Here are the advantages:

Economic Efficiency: A great choice for high-volume users who need stainless steel performance at lower cost.

Moderate Corrosion Resistance: Performs well in dry and mildly moist environments such as indoor factories or vehicle cabins.

High Strength and Ductility: Withstands mechanical strain during tightening without deformation.

Excellent Machinability: Easily processed into precision components without compromising surface finish or structure.

Non-Magnetic in Annealed Condition: Suitable for applications where magnetic interference is a concern.

Choosing SS202 washers is ideal when seeking a mid-range solution that doesn’t compromise on performance or appearance.

Customization & Packaging

We understand that every project has unique requirements. That’s why we offer:

Custom Sizes & Tolerances: Tailor your washers to fit exact engineering drawings or design needs.

Surface Finish Options: Choose from polished, unpolished, or oil-coated surfaces based on end use.

Packaging Flexibility: Options include:

Individual polybags for retail or export

Small boxes and cartons for industrial buyers

Bulk packaging in pallets for wholesalers or OEMs

Private Labeling: Available for resellers or distributors.

Bulk Orders & Export

As a trusted industrial washer supplier in India, we cater to both domestic and international markets with:

Streamlined Manufacturing: Our automated machinery ensures consistent output even for large batch orders.

Export-Ready Documentation: We offer invoices, test certificates, country of origin details, and custom packing lists.

On-Time Dispatch: Logistics support for delivery to any part of India and globally, with a strong network of freight partners.

Competitive Pricing: Our large-scale operations allow us to keep prices affordable without reducing product quality.

If you’re looking to buy bulk M3 stainless steel washers, we are fully equipped to fulfill your needs on schedule.

Technical Specifications

| Parameter | Specification |

|---|---|

| Size | M3 (3mm inner diameter) |

| Material | SS202 Stainless Steel |

| Outer Diameter | As per DIN 125A / IS standards |

| Thickness | Standard or as per customer requirement |

| Tolerance | ± 0.1mm (customizable upon request) |

| Surface Finish | Polished / Oil-coated / Plain |

| Edge Type | Deburred, chamfered for smooth handling |

| Application Fit | Designed for M3 bolts and screw fasteners |

Why Nafees Metal Industries?

When you choose Nafees Metal industries, you choose a legacy of quality, precision, and customer-focused service. Every batch of M3 SS202 Plain Washers is produced using advanced technology and rigorous inspections to ensure they perform exactly as promised.

We offer competitive pricing, flexible quantities, and timely delivery. Whether you want a few pieces or wish to buy bulk M3 stainless steel washers, we’ll ensure your order meets your needs. Count on us for your stainless steel washers and all other industrial washers needs — we’re here to help you build with confidence.

With decades of legacy and a strong manufacturing backbone, we stand out for:

Mumbai-Based, India-Wide Presence: Serving clients pan-India and internationally.

In-House Quality Lab: Every washer batch is tested for compliance, strength, and finish.

Custom Engineering Support: We help customers choose or design the best washer type for their specific use.

Bulk Manufacturing Capabilities: We cater to OEMs, large infrastructure projects, exporters, and industrial traders.

Trusted by Industry Leaders: Our clients span across electrical, railway, automotive, construction, and more.

We’ve earned our place as one of the best stainless steel washer manufacturers in India through consistency, trust, and technical mastery.

Case Study: Enhancing Assembly Line Efficiency Using M3 SS202 Plain Washers

Industry: Electronics and Consumer Appliances

Location: Maharashtra, India

Use Case: Precision fastening in small-scale component assemblies

Product Used: M3 SS202 Plain Washers

Volume Supplied: 120,000 units/month (bulk supply)

Duration: Ongoing since Q3, 2023

Background

A leading manufacturer of consumer electronics in India was facing recurring issues in their small-part assembly lines. The company assembled control panels and circuit housings where minute screws and bolts were used for fastening plastic and metal enclosures. Over time, they observed two primary issues:

Fasteners loosening due to repeated vibrations during operation and logistics.

Surface cracking and deformation around fastener holes, especially on delicate ABS plastic and aluminum panels.

The client needed a cost-effective washer that could handle these precision requirements without increasing the overall bill of materials.

Solution Provided

After a detailed requirement analysis, Nafees Metal Industries recommended the integration of M3 SS202 Plain Washers into their screw-fastening operations. The washers were chosen for their:

Small internal diameter (3mm) suited for miniature fasteners

High tensile strength to resist deformation under repeated torque

Moderate corrosion resistance suitable for indoor and semi-humid environments

Excellent surface smoothness for reducing abrasion and stress on enclosures

Cost-effective composition, making them ideal for large-volume usage

We manufactured and supplied washers in strict adherence to DIN 125A specifications, with a tolerance of ±0.1mm and a polished surface finish for improved aesthetics and contact consistency.

Implementation Strategy

The integration was done in a phased manner:

Initial Batch Testing – 10,000 washers were tested for performance under vibration cycles, torque endurance, and environmental simulation.

Process Optimization – After successful testing, the washers were incorporated into automated assembly heads and manual torque setups.

Bulk Integration – Upon confirmation of product compatibility, we moved to monthly bulk dispatches of 120,000 washers.

Results & Impact

The client reported the following improvements within 6 months of continuous use:

42% Reduction in fastener loosening incidents across the assembly line

Zero cracking incidents on plastic enclosures post washer integration

28% Improvement in torque retention and mechanical stability

20% Cost Savings compared to previous stainless steel washer models (SS304)

Streamlined packaging helped reduce assembly time by 15 seconds per unit

The solution not only resolved their core technical challenges but also contributed to overall product quality and operational efficiency.

Client Feedback (Paraphrased)

“The M3 SS202 Plain Washers supplied by Nafees Metal Industries met all our engineering, performance, and procurement goals. We were impressed by the dimensional consistency, quick turnaround, and affordability at scale.”

Conclusion

This case study exemplifies how M3 SS202 Plain Washers from Nafees Metal Industries can make a measurable difference in precision assembly operations. With a balance of engineering-grade performance and cost-effectiveness, these washers prove to be a reliable solution for manufacturers seeking durability, quality, and scalable supply.

Whether you operate in electronics, automotive, electrical, or home appliance industries, our washers are built to solve fastening challenges while supporting your bottom line.

FAQs about M3 SS202 Plain Washers

What is the standard size of M3 SS202 Plain Washers?

These washers have a 3mm internal diameter and conform to DIN 125A outer diameter and thickness specifications, ideal for M3 bolts.Are M3 SS202 Plain Washers corrosion resistant?

Yes, SS202 offers moderate corrosion resistance suitable for indoor environments or semi-protected outdoor uses.What is the difference between SS202 and SS304 washers?

SS202 is cost-effective and adequate for general use, while SS304 provides higher corrosion resistance for harsher environments.Can I use these in electrical applications?

Definitely. They are suitable for PCBs, switches, wiring brackets, and low-voltage panels.Do you provide material test certificates?

Yes, Mill Test Certificates (MTC) are provided on request to validate grade, hardness, and chemical composition.Can I place bulk orders for export?

Absolutely. We offer export-grade packaging and international logistics services.Are custom dimensions available?

Yes, based on your technical drawings or tolerance needs, we can manufacture washers with exact specs.How are these washers packaged?

Options include polybags, cartons, and wooden pallets depending on the volume and destination.Are samples available?

Yes, we offer samples upon request, depending on quantity and application clarity.How do M3 washers improve assembly quality?

They distribute tightening force evenly, preventing surface deformation and joint failure.Are M3 washers suitable for automotive applications?

Yes, especially in compact areas such as electronics, sensors, and lighting fixtures.What are the tolerances on these washers?

Our standard tolerance is ±0.1mm; however, tighter tolerances are possible with custom orders.Can I order directly from your website?

Yes. You can use the inquiry form or contact details listed at https://nafeesmetalindustries.com.Do you support third-party inspections?

Yes, third-party inspection is welcome and can be arranged before dispatch.Why choose Nafees Metal Industries?

For consistent quality, on-time delivery, and transparent pricing—backed by a reputation built on trust.

Order the Best M3 SS202 Plain Washers Today

Upgrade your fastening solutions with our M3 SS202 Plain Washers, trusted by professionals across industries. For more information or custom requirements, visit our manufacturing unit at Reay Road, Mumbai, or reach out to our sales team today.

M3 SS202 Plain Washers

26 people are viewing this product right now

₹14.04 Original price was: ₹14.04.₹11.70Current price is: ₹11.70. /per piece

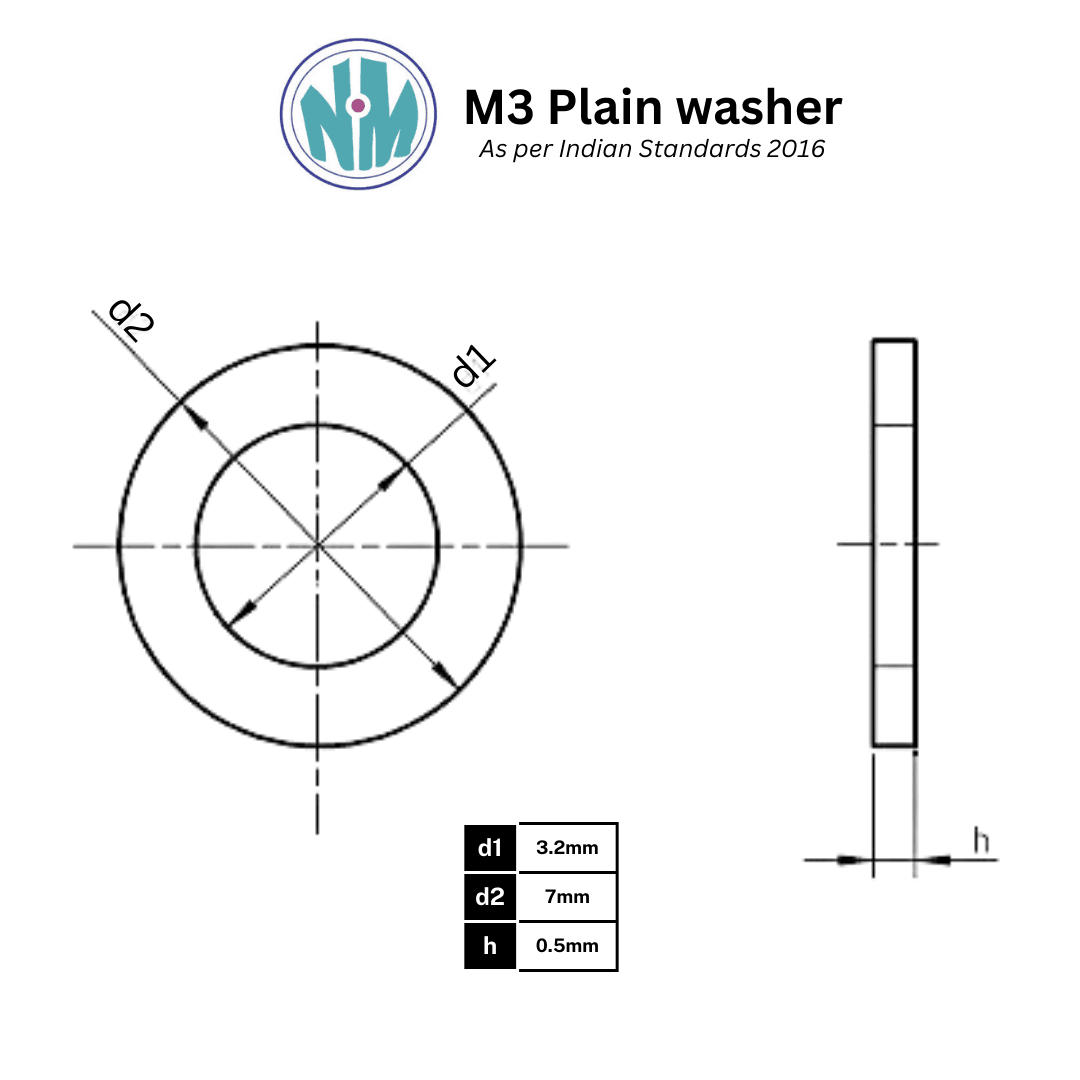

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M3

Inner Diameter (ID): 3.2 mm

Outer Diameter (OD): 7 mm

Thickness (t): 0.5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M3 SS202 Plain Washers – Premium Stainless Steel Washers for Industrial Reliability

At Nafees Metal Industries, we proudly manufacture and supply premium-quality M3 SS202 Plain Washers, engineered to meet the demanding needs of modern industrial environments. Designed for precision, strength, and durability, these washers are a crucial component for any fastening system that requires load distribution, surface protection, and vibration resistance.

Crafted from SS202 grade stainless steel, our M3 plain washers offer a winning combination of corrosion resistance, mechanical performance, and cost-efficiency. Their small M3 size (3mm internal diameter) makes them ideal for precision applications in compact assemblies—ranging from electronic devices and automotive components to electrical panels, home appliances, and construction fittings.

As one of the best manufacturers of plain washers in India, our commitment goes beyond just quality production. We ensure dimensional accuracy, smooth surface finishes, and consistent thickness in every piece—qualities that are vital when washers are used in safety-critical or high-performance assemblies.

Whether you are an OEM looking for bulk M3 stainless steel washers, a maintenance engineer replacing components in a mechanical system, or a distributor sourcing reliable fastening hardware, our M3 SS202 Plain Washers deliver unmatched value. Their lightweight yet sturdy build allows them to serve both functional and structural purposes—distributing pressure evenly across the fastening surface, preventing surface damage, and reducing loosening due to vibration or torque.

We understand the need for reliable and economical fastening solutions. That’s why our M3 SS202 Plain Washers are produced in line with global standards such as DIN 125A and IS, using state-of-the-art manufacturing technology and a rigorous quality control process.

At Nafees Metal Industries, excellence is not just a goal—it’s a guarantee. Our focus on innovation, performance, and client satisfaction has made us a preferred partner for stainless steel washers across India and globally. Choose our M3 SS202 Plain Washers for industrial-grade fastening that you can count on—every single time.

Why Choose Our M3 SS202 Plain Washers? Best SS202 plain washers for industrial use

When industries seek components that perform flawlessly under pressure, they turn to trusted names. Our M3 SS202 Plain Washers are the result of decades of expertise, precision machining, and a deep understanding of fastener performance under industrial stress.

Each washer is crafted using SS202 stainless steel—a material that delivers a perfect balance between strength, durability, and affordability. We follow globally accepted manufacturing standards (DIN 125A / IS), ensuring dimensional accuracy and consistent mechanical properties batch after batch.

Key reasons to choose our washers:

Precision-tuned to fit M3 fasteners with zero tolerance mismatch.

Mass production capacity for timely delivery in both small and large volumes.

Strict quality checks at every stage—from raw material to final dispatch.

Trusted by OEMs, exporters, and fabrication workshops across India and overseas.

Features of M3 SS202 Plain Washers

Our M3 SS202 Plain Washers are engineered with precision to deliver uncompromised performance in compact fastening systems. Below is a detailed breakdown of the core features that make our washers a preferred choice for industrial applications:

1. Made from High-Quality SS202 Stainless Steel

These washers are manufactured using SS202-grade stainless steel, known for its excellent combination of tensile strength, cost-effectiveness, and moderate corrosion resistance. SS202 offers better wear resistance than mild steel and is ideal for indoor and semi-exposed conditions. The material ensures the washer retains its structural integrity even in vibration-heavy or moderately corrosive environments.

2. Perfect Compatibility with M3 Fasteners

Designed specifically for M3 bolts and screws, the inner diameter and outer dimensions strictly conform to DIN 125A and IS standards. This ensures a tight and precise fit without slippage, reducing the chances of fastener loosening under load or vibration.

3. Even Load Distribution

One of the primary functions of a plain washer is to distribute load uniformly across the fastening surface. Our M3 plain washers eliminate the risk of surface damage, localized stress, or fastener pull-through by creating a broader and more stable contact surface between the fastener and the base material.

4. Precision Thickness for Structural Consistency

Each washer is manufactured with consistent thickness across batches, ensuring uniform clamping force. Whether you’re using automated or manual torqueing tools, the washer maintains mechanical balance, preventing overtightening or loosening over time.

5. Smooth, Burr-Free Finish

The washers undergo deburring and surface smoothing processes to eliminate sharp edges and imperfections. This results in a clean, user-safe product that won’t damage painted or polished surfaces during installation. The smooth finish also improves handling and assembly speed in production lines.

6. Enhanced Surface Finish Options

Depending on the requirement, we offer polished, plain, or oil-coated surface finishes. These options enhance the washer’s resistance to oxidation and improve its appearance—making it suitable for both functional and visible assembly applications.

7. Compact but Strong

Despite being small in size, M3 SS202 Plain Washers are built to withstand significant loads. Their material and design allow them to perform reliably in applications that demand strength in a minimal footprint—making them ideal for electronics, electrical panels, and small-scale mechanical systems.

8. Dimensional Accuracy with Tight Tolerances

Our washers are produced with tight dimensional tolerances to ensure consistent performance in high-precision assemblies. This is particularly important in industries like electronics, aerospace, and automotive, where any deviation in component size can affect performance or safety.

9. Long-Term Durability

Thanks to the properties of SS202 stainless steel, these washers maintain their mechanical performance over long-term usage. They resist deformation under stress, remain unaffected by temperature fluctuations, and provide lasting fastening support in dynamic environments.

10. Lightweight and Low Maintenance

M3 SS202 Plain Washers are lightweight, making them ideal for weight-sensitive applications like portable devices or modular assemblies. Additionally, the corrosion-resistant nature of SS202 reduces maintenance frequency and cost over the washer’s lifespan.

Applications of M3 SS202 Plain Washers

Our washers are highly versatile and used across diverse industries where M3 bolts or screws are part of the assembly. These include:

1. Automotive Assemblies

In the automotive sector, M3 SS202 Plain Washers play a crucial role in securing small bolts and screws in vehicle interior panels, dashboard assemblies, sensor brackets, and electronic modules. Their ability to distribute load evenly and reduce surface pressure ensures that delicate components like circuit housings, lighting fixtures, and trims remain securely fastened during vehicle operation and vibrations.

2. Electrical Installations

M3 washers are extensively used in switchboards, circuit breaker panels, motor enclosures, terminal boxes, and control panels. Their stainless steel construction prevents rusting in environments exposed to current flow, moisture, and minor heating. They ensure strong electrical connections by preventing over-tightening or damage to delicate substrates like plastic enclosures or copper busbars.

3. Precision Electronics & PCB Mounting

In electronic device manufacturing, these washers are ideal for mounting PCBs (Printed Circuit Boards), microcontroller units, display panels, and other sensitive hardware. Their lightweight nature and accurate sizing reduce the risk of short circuits, while the deburred surface ensures safe contact with fragile components.

4. Construction and Infrastructure Projects

Although M3 is a smaller size, it is frequently used in anchoring light fixtures, control systems, signage, and HVAC enclosures in modern construction. They are particularly beneficial in interior fittings, where components like access panels, sensor systems, and safety fixtures must be mounted securely with corrosion-resistant hardware.

5. Mechanical Fastening in Light Equipment

From handheld machinery to precision instruments, the washers act as a barrier to prevent fastener head damage to surfaces and improve torque performance. In machines like textile units, packaging equipment, or small compressors, these washers ensure the longevity of bolted joints.

6. Home Appliances and Consumer Electronics

Washers in the M3 size range are widely used in the assembly of consumer appliances such as washing machines, microwave ovens, blenders, fans, and induction cooktops. Their stainless steel body ensures longevity even in moisture-prone environments and reduces loosening during repetitive operations like motor spinning or vibration.

7. Railway and Metro Coach Components

Used in wiring systems, panel fittings, and instrumentation units within trains and metro coaches, M3 SS202 Plain Washers help maintain secure, vibration-resistant joints without adding bulk or unnecessary weight to electrical or mechanical modules.

8. Aerospace and Defense Equipment (Non-Critical Assemblies)

In non-critical fastening applications where weight and precision matter more than extreme environmental resistance, these washers find use in enclosure panels, display mounts, and sensor brackets. SS202 provides a reliable balance of strength and cost in such controlled environments.

9. Renewable Energy Systems

They are used in the assembly of internal components in solar inverters, battery casings, and mounting structures where small yet durable washers are needed to maintain mechanical integrity under light outdoor exposure.

10. Furniture and Modular Workstations

Compact and corrosion-resistant, these washers are ideal for fastening drawer slides, hinges, control knobs, and modular joints in furniture, especially those exposed to varying humidity like office workstations, hospital beds, or kitchen units.

11. Robotics and Automation Systems

Automation assemblies often involve sensors, actuators, cameras, and control units, all of which require micro-sized, stable, and vibration-resistant joints. M3 SS202 Plain Washers provide the dimensional stability and resistance needed in high-speed or repetitive-motion environments.

12. Instrumentation and Measurement Devices

These washers are often used in fastening measuring tools, digital readouts, lab instruments, and calibration devices where minimal vibration or component displacement could cause errors. Their tight tolerances help retain positional accuracy of mounted sensors or indicators.

13. Solar and Smart Energy Panels (Internal Fastening)

Within enclosures or battery housings of solar panels and inverters, these washers are used to fasten and support internal circuits and boards, ensuring long-lasting electrical connections even in changing ambient temperatures.

Advantages of SS202 Material in Washers

SS202 stainless steel is a cost-effective alternative to SS304, while still offering dependable mechanical and environmental resistance. Here are the advantages:

Economic Efficiency: A great choice for high-volume users who need stainless steel performance at lower cost.

Moderate Corrosion Resistance: Performs well in dry and mildly moist environments such as indoor factories or vehicle cabins.

High Strength and Ductility: Withstands mechanical strain during tightening without deformation.

Excellent Machinability: Easily processed into precision components without compromising surface finish or structure.

Non-Magnetic in Annealed Condition: Suitable for applications where magnetic interference is a concern.

Choosing SS202 washers is ideal when seeking a mid-range solution that doesn’t compromise on performance or appearance.

Customization & Packaging

We understand that every project has unique requirements. That’s why we offer:

Custom Sizes & Tolerances: Tailor your washers to fit exact engineering drawings or design needs.

Surface Finish Options: Choose from polished, unpolished, or oil-coated surfaces based on end use.

Packaging Flexibility: Options include:

Individual polybags for retail or export

Small boxes and cartons for industrial buyers

Bulk packaging in pallets for wholesalers or OEMs

Private Labeling: Available for resellers or distributors.

Bulk Orders & Export

As a trusted industrial washer supplier in India, we cater to both domestic and international markets with:

Streamlined Manufacturing: Our automated machinery ensures consistent output even for large batch orders.

Export-Ready Documentation: We offer invoices, test certificates, country of origin details, and custom packing lists.

On-Time Dispatch: Logistics support for delivery to any part of India and globally, with a strong network of freight partners.

Competitive Pricing: Our large-scale operations allow us to keep prices affordable without reducing product quality.

If you’re looking to buy bulk M3 stainless steel washers, we are fully equipped to fulfill your needs on schedule.

Technical Specifications

| Parameter | Specification |

|---|---|

| Size | M3 (3mm inner diameter) |

| Material | SS202 Stainless Steel |

| Outer Diameter | As per DIN 125A / IS standards |

| Thickness | Standard or as per customer requirement |

| Tolerance | ± 0.1mm (customizable upon request) |

| Surface Finish | Polished / Oil-coated / Plain |

| Edge Type | Deburred, chamfered for smooth handling |

| Application Fit | Designed for M3 bolts and screw fasteners |

Why Nafees Metal Industries?

When you choose Nafees Metal industries, you choose a legacy of quality, precision, and customer-focused service. Every batch of M3 SS202 Plain Washers is produced using advanced technology and rigorous inspections to ensure they perform exactly as promised.

We offer competitive pricing, flexible quantities, and timely delivery. Whether you want a few pieces or wish to buy bulk M3 stainless steel washers, we’ll ensure your order meets your needs. Count on us for your stainless steel washers and all other industrial washers needs — we’re here to help you build with confidence.

With decades of legacy and a strong manufacturing backbone, we stand out for:

Mumbai-Based, India-Wide Presence: Serving clients pan-India and internationally.

In-House Quality Lab: Every washer batch is tested for compliance, strength, and finish.

Custom Engineering Support: We help customers choose or design the best washer type for their specific use.

Bulk Manufacturing Capabilities: We cater to OEMs, large infrastructure projects, exporters, and industrial traders.

Trusted by Industry Leaders: Our clients span across electrical, railway, automotive, construction, and more.

We’ve earned our place as one of the best stainless steel washer manufacturers in India through consistency, trust, and technical mastery.

Case Study: Enhancing Assembly Line Efficiency Using M3 SS202 Plain Washers

Industry: Electronics and Consumer Appliances

Location: Maharashtra, India

Use Case: Precision fastening in small-scale component assemblies

Product Used: M3 SS202 Plain Washers

Volume Supplied: 120,000 units/month (bulk supply)

Duration: Ongoing since Q3, 2023

Background

A leading manufacturer of consumer electronics in India was facing recurring issues in their small-part assembly lines. The company assembled control panels and circuit housings where minute screws and bolts were used for fastening plastic and metal enclosures. Over time, they observed two primary issues:

Fasteners loosening due to repeated vibrations during operation and logistics.

Surface cracking and deformation around fastener holes, especially on delicate ABS plastic and aluminum panels.

The client needed a cost-effective washer that could handle these precision requirements without increasing the overall bill of materials.

Solution Provided

After a detailed requirement analysis, Nafees Metal Industries recommended the integration of M3 SS202 Plain Washers into their screw-fastening operations. The washers were chosen for their:

Small internal diameter (3mm) suited for miniature fasteners

High tensile strength to resist deformation under repeated torque

Moderate corrosion resistance suitable for indoor and semi-humid environments

Excellent surface smoothness for reducing abrasion and stress on enclosures

Cost-effective composition, making them ideal for large-volume usage

We manufactured and supplied washers in strict adherence to DIN 125A specifications, with a tolerance of ±0.1mm and a polished surface finish for improved aesthetics and contact consistency.

Implementation Strategy

The integration was done in a phased manner:

Initial Batch Testing – 10,000 washers were tested for performance under vibration cycles, torque endurance, and environmental simulation.

Process Optimization – After successful testing, the washers were incorporated into automated assembly heads and manual torque setups.

Bulk Integration – Upon confirmation of product compatibility, we moved to monthly bulk dispatches of 120,000 washers.

Results & Impact

The client reported the following improvements within 6 months of continuous use:

42% Reduction in fastener loosening incidents across the assembly line

Zero cracking incidents on plastic enclosures post washer integration

28% Improvement in torque retention and mechanical stability

20% Cost Savings compared to previous stainless steel washer models (SS304)

Streamlined packaging helped reduce assembly time by 15 seconds per unit

The solution not only resolved their core technical challenges but also contributed to overall product quality and operational efficiency.

Client Feedback (Paraphrased)

“The M3 SS202 Plain Washers supplied by Nafees Metal Industries met all our engineering, performance, and procurement goals. We were impressed by the dimensional consistency, quick turnaround, and affordability at scale.”

Conclusion

This case study exemplifies how M3 SS202 Plain Washers from Nafees Metal Industries can make a measurable difference in precision assembly operations. With a balance of engineering-grade performance and cost-effectiveness, these washers prove to be a reliable solution for manufacturers seeking durability, quality, and scalable supply.

Whether you operate in electronics, automotive, electrical, or home appliance industries, our washers are built to solve fastening challenges while supporting your bottom line.

FAQs about M3 SS202 Plain Washers

What is the standard size of M3 SS202 Plain Washers?

These washers have a 3mm internal diameter and conform to DIN 125A outer diameter and thickness specifications, ideal for M3 bolts.Are M3 SS202 Plain Washers corrosion resistant?

Yes, SS202 offers moderate corrosion resistance suitable for indoor environments or semi-protected outdoor uses.What is the difference between SS202 and SS304 washers?

SS202 is cost-effective and adequate for general use, while SS304 provides higher corrosion resistance for harsher environments.Can I use these in electrical applications?

Definitely. They are suitable for PCBs, switches, wiring brackets, and low-voltage panels.Do you provide material test certificates?

Yes, Mill Test Certificates (MTC) are provided on request to validate grade, hardness, and chemical composition.Can I place bulk orders for export?

Absolutely. We offer export-grade packaging and international logistics services.Are custom dimensions available?

Yes, based on your technical drawings or tolerance needs, we can manufacture washers with exact specs.How are these washers packaged?

Options include polybags, cartons, and wooden pallets depending on the volume and destination.Are samples available?

Yes, we offer samples upon request, depending on quantity and application clarity.How do M3 washers improve assembly quality?

They distribute tightening force evenly, preventing surface deformation and joint failure.Are M3 washers suitable for automotive applications?

Yes, especially in compact areas such as electronics, sensors, and lighting fixtures.What are the tolerances on these washers?

Our standard tolerance is ±0.1mm; however, tighter tolerances are possible with custom orders.Can I order directly from your website?

Yes. You can use the inquiry form or contact details listed at https://nafeesmetalindustries.com.Do you support third-party inspections?

Yes, third-party inspection is welcome and can be arranged before dispatch.Why choose Nafees Metal Industries?

For consistent quality, on-time delivery, and transparent pricing—backed by a reputation built on trust.

Order the Best M3 SS202 Plain Washers Today

Upgrade your fastening solutions with our M3 SS202 Plain Washers, trusted by professionals across industries. For more information or custom requirements, visit our manufacturing unit at Reay Road, Mumbai, or reach out to our sales team today.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch