No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M3 Copper Plain Washers – Best Corrosion-Resistant Flat Washers for Precision Applications

Nafees Metal Industries proudly presents M3 copper plain washers, precision-engineered for demanding industrial environments where conductivity, corrosion resistance, and mechanical integrity are essential. These flat washers are specifically designed to complement M3-sized fasteners, making them ideal for small-scale electrical, electronic, and mechanical applications. Whether you’re assembling circuit boards, hydraulic systems, or control panels, our M3 copper plain washers provide exceptional load distribution, surface protection, and sealing capability.

Recognized as one of the best manufacturers of copper washers in India, we ensure each batch of M3 copper plain washers is produced using high-quality copper that meets global standards. Our washers are manufactured in accordance with copper plain washer DIN 125 size M3 specifications, ensuring uniformity, reliability, and compatibility for your critical fastening needs.

What Are M3 Copper Plain Washers?

M3 copper plain washers are precision-cut circular copper components with a central hole perfectly sized to fit M3 bolts or screws (3 mm diameter). Their primary role is to distribute load evenly under a bolt or nut, preventing damage to the surface beneath and enhancing the clamping strength of the fastener. These washers are indispensable in applications that require superior electrical conductivity, corrosion resistance, and precision fastening.

Engineered as part of the M3 copper flat washer metric series DIN 125, these washers conform to international standards, making them suitable for global industrial applications. When used in electrical and electronic assemblies, M3 copper plain washers help maintain uninterrupted conductivity, reducing the risk of heat buildup and voltage drops.

Beyond electronics, they are widely used in mechanical subassemblies and sensitive hydraulic setups. Thanks to their excellent thermal and electrical conductivity, M3 copper plain washers also serve as grounding elements in electrical enclosures and components.

At Nafees Metal Industries, every piece of M3 copper plain washer is manufactured to tight tolerances, ensuring they meet the exact dimensions defined by copper plain washer DIN 125 size M3. These washers are crucial for industries that demand reliable performance from every fastening point—no matter how small.

Why Choose Copper for M3 Washers?

Copper is one of the most versatile and valuable materials used in industrial fastening, and when it comes to small-diameter components like M3 copper plain washers, the advantages of copper become even more significant. These washers are not just about spacing or load distribution—they are about enhancing performance in critical electrical, mechanical, and hydraulic assemblies.

M3 copper plain washers are widely preferred due to copper’s exceptional electrical conductivity, which allows uninterrupted current flow in sensitive electronics. This makes them ideal for PCB mounting, circuit connections, and terminal clamps. Furthermore, copper provides excellent thermal conductivity, which helps in heat dissipation across contact surfaces, reducing the risk of overheating in electronic or power systems.

Corrosion resistance is another major advantage. In environments where rust or oxidation can compromise the fastening system, M3 copper plain washers remain reliable, making them a perfect example of an industrial copper flat washer corrosion-resistant solution. Their non-magnetic nature makes them compatible with magnet-sensitive components, further expanding their application scope.

For hydraulic and pneumatic systems, M3 copper plain washers serve as effective sealing components, particularly in fittings, where they are referred to as copper sealing washer M3 hydraulic fittings. This dual functionality—as a spacer and a seal—adds to their value in compact assemblies.

The flexibility of copper also allows these washers to deform slightly under pressure, filling surface irregularities and forming a tighter seal. Whether you’re looking at durability, conductivity, corrosion protection, or sealing capability, M3 copper plain washers deliver superior results, all while being compliant with the M3 copper flat washer metric series DIN 125.

How Are M3 Copper Plain Washers Manufactured?

At Nafees Metal Industries, M3 copper plain washers are manufactured in our ISO-certified facility in Mumbai using precision-controlled processes that ensure dimensional accuracy, surface finish, and performance reliability. Our in-house production is designed to meet the requirements of industries that demand consistency, safety, and global standard compliance.

The process begins with high-purity electrolytic copper sheets, known for their conductivity and corrosion resistance. These sheets are cut and prepared for stamping using advanced CNC punching machines that ensure every M3 copper plain washer meets exact dimensional tolerances defined by copper plain washer DIN 125 size M3.

After punching, the washers undergo deburring and polishing, which gives them smooth edges and eliminates any sharp projections that could interfere with assembly or damage nearby components. This step ensures that each M3 copper plain washer is safe to handle and ideal for use in sensitive electronics or hydraulic fittings.

Surface treatment is an optional but often requested part of the process. Some clients prefer plain finishes for conductivity, while others opt for anti-oxidation coatings, especially for washers used in high-humidity environments. Our production line can accommodate both.

Each batch of M3 copper plain washers goes through rigorous quality checks that test for:

Dimensional accuracy (inner and outer diameter, thickness)

Flatness and surface smoothness

Material integrity (copper purity, hardness)

Visual inspection for uniformity

Our commitment to precision and quality ensures that every washer we produce adheres to the M3 copper flat washer metric series DIN 125 standards. Whether you need small quantities or large industrial volumes, our manufacturing process guarantees that your M3 copper plain washers will perform reliably in every application.

Key Features of M3 Copper Plain Washers

M3 copper plain washers from Nafees Metal Industries are engineered with features that make them indispensable in high-precision fastening applications. These washers are not only tailored to meet technical standards like copper plain washer DIN 125 size M3, but also offer practical benefits that enhance performance in real-world use cases.

Here are the standout features of our M3 copper plain washers:

Precision Inner Diameter: Designed to fit M3 bolts and screws with exact alignment. This ensures that each M3 copper plain washer sits flush without play or misalignment.

Superior Load Distribution: The flat structure spreads clamping force evenly, preventing material damage under the bolt or nut. This is especially important in delicate assemblies like PCBs or aluminum panels.

High Electrical Conductivity: Made from pure copper, these washers are ideal for grounding and current transmission, making M3 copper plain washers essential in electronic and electrical systems.

Corrosion Resistance: Each washer resists rust and oxidation, ensuring long service life even in humid or chemically exposed environments—qualifying them as a trusted industrial copper flat washer corrosion-resistant solution.

Smooth, Burr-Free Finish: Post-processing ensures that the surface and edges are polished and free of imperfections, preventing any potential injury during handling or damage to neighboring parts.

Versatile Finish Options: Available in plain copper or coated for anti-oxidation. Clients can request coatings based on usage in marine, industrial, or automotive environments.

Conformance to Global Standards: As part of the M3 copper flat washer metric series DIN 125, these washers are suitable for both domestic and international applications.

Bulk Availability & OEM Customization: We offer these washers in large volumes with the option of custom packaging, labeling, and finish—ideal for OEMs and industrial suppliers.

With these features, M3 copper plain washers serve as more than just spacers—they become integral components that improve performance, safety, and longevity in your assemblies.

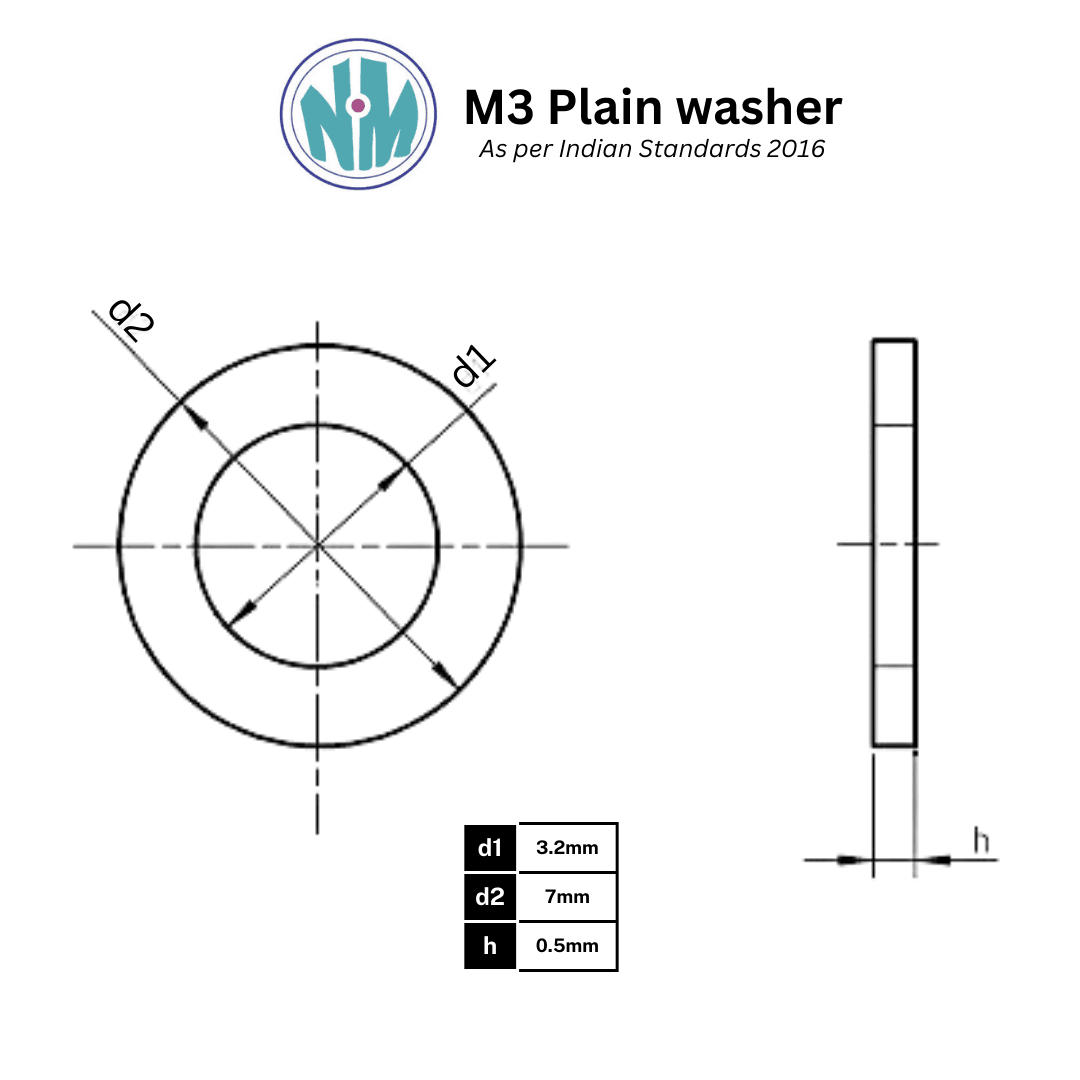

Technical Specifications

To meet the varied requirements of industrial, electrical, and mechanical applications, M3 copper plain washers from Nafees Metal Industries are manufactured to strict dimensional and material standards. Every washer is crafted to ensure compatibility, performance, and reliability in demanding environments.

Below are the detailed technical specifications for our M3 copper plain washers:

| Property | Specification |

|---|---|

| Product Name | M3 Copper Plain Washer |

| Material | High-purity Electrolytic Copper |

| Inner Diameter (ID) | Approx. 3.2 mm (fits M3 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 |

| Thickness | 0.5–1.0 mm (customizable on request) |

| Surface Finish | Plain / Anti-oxidation Coated |

| Compliance | copper plain washer DIN 125 size M3 |

| Washer Series | M3 copper flat washer metric series DIN 125 |

| Packaging | Bulk Cartons / Poly Bags / Custom-Labeled Kits |

| Application Use | Electrical Panels, Hydraulic Fittings, PCBs |

Each of our M3 copper plain washers undergoes material testing and size verification, ensuring every piece aligns with the M3 copper flat washer metric series DIN 125 requirements. This technical accuracy makes them suitable for industries such as electronics, hydraulics, automotive, and energy, where washer performance is critical.

As trusted Indian manufacturers of M3 copper plain washers, we ensure that our technical specifications are not only accurate but adaptable to client-specific requirements such as custom thickness, finish, and packaging.

Applications of M3 Copper Plain Washers

M3 copper plain washers are valued across diverse industries for their compact size, high conductivity, and corrosion-resistant properties. Their design makes them exceptionally effective in critical fastening, sealing, and grounding applications—especially where space is limited but performance cannot be compromised.

Here are the key application areas for M3 copper plain washers:

Electrical and Electronic Devices: In PCB assemblies, terminal blocks, and control panels, M3 copper plain washers ensure uniform clamping pressure without damaging the circuit board, while also maintaining electrical continuity. Their conductivity makes them ideal for grounding and current flow.

Hydraulic and Pneumatic Systems: Used as copper sealing washer M3 hydraulic fittings, these washers prevent fluid leakage at connection points. Their deformability allows them to conform to mating surfaces, enhancing sealing under pressure.

Telecommunications Equipment: Their compact form and conductive nature make M3 copper plain washers essential in high-frequency communication modules where non-magnetic, corrosion-resistant washers are needed.

Automotive and Aerospace Components: In assemblies where space optimization is crucial, M3 copper plain washers provide vibration resistance, grounding, and long-term durability even under high stress.

HVAC and Marine Applications: As industrial copper flat washer corrosion-resistant components, these washers are suitable for damp, saline, or chemically aggressive environments where traditional materials fail.

Consumer Electronics and Gadgets: From assembling speakers and chargers to internal fastenings in compact appliances, M3 copper plain washers provide insulation, support, and longevity.

Solar Energy Systems: Used in solar inverter connections and junction boxes where conductivity and long-term corrosion resistance are vital.

Thanks to their versatility, standard compliance, and performance characteristics, M3 copper plain washers are indispensable in modern manufacturing and assembly lines. Whether for fastening, grounding, spacing, or sealing, they deliver consistent results across applications.

Advantages of Using M3 Copper Washers

M3 copper plain washers offer more than just dimensional compatibility—they provide critical performance advantages that make them the preferred choice for precision assemblies across industries. Whether you’re in electronics, automotive, hydraulics, or heavy machinery, these washers deliver benefits that directly impact efficiency, safety, and durability.

Here are the major advantages of using M3 copper plain washers:

Excellent Electrical Conductivity: Copper is one of the most conductive metals, making M3 copper plain washers ideal for electrical grounding and current-carrying components in PCBs, circuit breakers, and terminal connections.

Corrosion Resistance in Harsh Environments: Classified as an industrial copper flat washer corrosion-resistant solution, these washers perform reliably in humid, saline, or chemically exposed environments without degrading or rusting.

Improved Fastening Integrity: By spreading the load evenly under fasteners, M3 copper plain washers prevent surface damage, cracking, or deformation—especially when used on softer materials like plastics or composites.

Thermal Stability: Copper’s high thermal conductivity allows it to dissipate heat generated at the fastening point, which helps prevent overheating in power systems and electronic devices.

Ideal for Sealing Applications: As effective copper sealing washer M3 hydraulic fittings, they conform to surface irregularities and offer tight, leak-proof seals in pressurized systems.

Compliance with Global Standards: Designed in line with the M3 copper flat washer metric series DIN 125, they guarantee universal compatibility and consistent performance across international markets.

Lightweight and Easy to Handle: Small but strong, these washers are easy to manage in automated assembly lines, maintenance kits, and manual installations.

Eco-Friendly Material Choice: Copper is fully recyclable, helping your organization meet green manufacturing and sustainability goals.

Customization Options: Nafees Metal Industries offers tailored dimensions, coatings, and packaging for bulk OEM buyers, reinforcing our reputation as one of the best copper washer manufacturers in India.

Made in India, Trusted Worldwide: Manufactured at our Mumbai facility with strict quality controls, M3 copper plain washers reflect the craftsmanship and reliability associated with Indian engineering excellence.

These benefits make M3 copper plain washers the go-to solution for engineers, assemblers, and procurement managers seeking a high-performance, long-lasting washer that meets both technical and commercial expectations.

Buy Bulk M3 Copper Plain Washers – Best Indian Manufacturer

When it comes to sourcing reliable and high-quality M3 copper plain washers, Nafees Metal Industries stands out as a trusted name among manufacturers and bulk suppliers in India. We specialize in the production of copper washers in standard and custom sizes, with a focus on delivering precision, durability, and corrosion resistance for demanding industrial applications.

Whether you’re a procurement officer for an OEM, a distributor catering to local markets, or an export house looking for top-grade copper components, our M3 copper plain washers are the perfect solution. Manufactured to the copper plain washer DIN 125 size M3 standard, these washers offer dimensional accuracy, electrical conductivity, and long-lasting performance.

Here’s why we are considered the best manufacturer and bulk supplier of M3 copper plain washers in India:

Large-Scale Production Capacity: We maintain a ready stock of standard sizes including M3, M5, M6, M8, M10, M12, M16, M20 and beyond—ensuring you get fast fulfillment for bulk orders.

Custom Finishes & Thicknesses: Need a specific thickness or coating? We deliver M3 copper plain washers in plain copper or coated variants based on your application needs, including anti-oxidation layers.

OEM-Focused Support: We provide custom labeling, branding, and packaging options to suit OEM, trader, or retailer requirements.

Export-Ready Services: From HS codes to packing lists, we offer complete export documentation and international dispatch capabilities. Our M3 copper flat washer metric series DIN 125 products meet global standards and are RoHS compliant.

Mumbai-Based Manufacturing Facility: Our central location helps us serve domestic clients with reduced lead times while supporting international logistics efficiently.

Transparent Pricing & Quick Dispatch: Competitive bulk pricing without compromising on quality. We process and ship large orders promptly across India and globally.

Partner with Nafees Metal Industries and benefit from a reliable supply of M3 copper plain washers that meet industry demands and exceed expectations. With a proven track record and a commitment to quality, we are proud to support the fastener and electrical hardware industries as one of India’s top copper washer manufacturers.

Case Study – Copper Washers in Control Panel Assemblies

A well-known electrical control panel manufacturer based in Vadodara, Gujarat, was facing recurring issues with terminal loosening, circuit corrosion, and increased assembly time. Their engineers identified the root cause: poor conductivity and inconsistent clamping from standard steel washers used with M3 fasteners. After thorough evaluation, they switched to M3 copper plain washers from Nafees Metal Industries.

Solution Implemented:

They replaced all steel washers in their PCB and terminal clamp sections with high-conductivity, corrosion-resistant M3 copper plain washers, conforming to copper plain washer DIN 125 size M3 specifications.

Measured Outcomes Over 6 Months:

27% Reduction in circuit board assembly time due to easy handling and precise fitment

100% Elimination of terminal corrosion issues, even in high-humidity test conditions

Enhanced Electrical Flow, improving grounding and voltage consistency across the panel

Zero Failures reported during post-assembly vibration and heat testing

50% Increase in repeat order volume within three months of implementation

The client also benefited from Nafees Metal Industries’ quick turnaround time, bulk-ready stock, and custom-labeled packaging. The success of this integration reaffirmed their trust in us as the leading supplier of M3 copper plain washers and cemented our role in their long-term vendor list.

This case study highlights how M3 copper plain washers, especially those adhering to the M3 copper flat washer metric DIN 125 series, can dramatically improve assembly line performance, durability, and electrical safety.

Why Choose Nafees Metal Industries for M3 Copper Plain Washers?

When it comes to quality, consistency, and service, Nafees Metal Industries stands out as one of India’s most trusted manufacturers of M3 copper plain washers. Backed by advanced machinery, skilled professionals, and a commitment to international standards, we deliver washer solutions that outperform and outlast.

1. In-House Manufacturing Facility in Mumbai

Our fully equipped manufacturing unit is located in Mumbai, India’s leading industrial hub. This unit houses power press machines, high-precision dies, automated deburring tools, and quality control systems that allow us to produce large volumes of M3 copper plain washers with exceptional accuracy and surface finish. Our facility also supports rapid prototyping and custom production runs, allowing us to fulfill both standard and specialized orders efficiently.

2. Precision Engineering at Scale

Each M3 copper plain washer is engineered with care, ensuring a perfect internal diameter for M3 bolts, smooth edges for safe handling, and uniform thickness for load stability. We strictly follow copper plain washer DIN 125 size M3 specifications and support the M3 copper flat washer metric series DIN 125, ensuring interchangeability and global applicability.

3. Superior Copper Material

We use premium-grade electrolytic copper to manufacture washers with high thermal and electrical conductivity. These M3 copper plain washers are naturally corrosion-resistant and perfect for applications like grounding, terminal fastening, and even copper sealing washer M3 hydraulic fittings, where leak prevention is essential.

4. Competitive Bulk Supply

Thanks to our high-capacity unit and stock management systems, we maintain ready-to-dispatch inventories for standard sizes and process custom bulk orders with short lead times. Our pricing model is tailored to help wholesalers, exporters, and OEMs gain long-term cost benefits without sacrificing quality.

5. Export-Ready & Industry Compliant

Nafees Metal Industries is already exporting industrial copper flat washer corrosion resistant products to countries like UAE, Qatar, Oman, and Southeast Asia. All products come with proper documentation, RoHS compliance (on request), and customizable packaging to ensure safe and smooth international deliveries.

6. End-to-End Customization

From product labeling to washer thickness, ID-OD variations, and packing options, we offer end-to-end customization for your unique application requirements. Whether you’re building electrical control panels or hydraulic units, our M3 copper plain washers can be tailored for optimal fit and function.

Choosing Nafees Metal Industries means partnering with a manufacturer that combines modern infrastructure with old-school integrity. Our Mumbai facility reflects our dedication to quality, scalability, and precision — making us your go-to source for reliable washer solutions.

Frequently Asked Questions (FAQs)

What is the purpose of M3 copper plain washers?

They distribute load evenly, improve electrical conductivity, and prevent corrosion at fastener joints.Are M3 copper washers suitable for high-voltage electrical systems?

Yes, they offer excellent conductivity and are widely used in electrical and electronic circuits.What does ‘DIN 125’ mean in copper washers?

It’s a European standard that defines dimensional properties of flat washers, ensuring global compatibility.Do copper washers rust?

No, copper does not rust. It resists corrosion naturally and forms a protective oxide layer over time.Can I get anti-oxidation coated M3 copper washers?

Yes, Nafees Metal Industries provides optional coatings based on your application needs.Where are these washers manufactured?

All washers are manufactured at our advanced facility in Mumbai, India.Are M3 copper plain washers reusable?

In non-critical applications, yes. However, for sealing or electrical grounding, new washers are recommended.Do you export copper washers?

Yes, we supply across India and export globally with complete documentation.Can I order customized washer sizes or thicknesses?

Absolutely. We specialize in custom sizes, hole diameters, and finishes for bulk orders.What packaging options are available?

Bulk cartons, small kits, poly bags, and client-branded labeling are available.Are your washers compliant with international quality standards?

Yes, our products comply with DIN, IS, and ISO norms.Do you provide M3 copper washers for hydraulic fittings?

Yes, we supply copper sealing washer M3 hydraulic fittings widely used in hydraulic and pneumatic systems.What is the standard thickness of M3 copper plain washers?

Typically 0.5–1.0 mm, but we offer customization as per client needs.How fast is delivery across India?

We ensure quick dispatch within 2–5 days for most bulk orders.Why choose Nafees Metal Industries?

We are trusted manufacturers of industrial copper flat washer corrosion-resistant products known for quality, consistency, and customer support.

M3 Copper Plain Washers (DIN 125)

2 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M3

Inner Diameter (ID): 3.2 mm

Outer Diameter (OD): 7 mm

Thickness (t): 0.5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M3 Copper Plain Washers – Best Corrosion-Resistant Flat Washers for Precision Applications

Nafees Metal Industries proudly presents M3 copper plain washers, precision-engineered for demanding industrial environments where conductivity, corrosion resistance, and mechanical integrity are essential. These flat washers are specifically designed to complement M3-sized fasteners, making them ideal for small-scale electrical, electronic, and mechanical applications. Whether you’re assembling circuit boards, hydraulic systems, or control panels, our M3 copper plain washers provide exceptional load distribution, surface protection, and sealing capability.

Recognized as one of the best manufacturers of copper washers in India, we ensure each batch of M3 copper plain washers is produced using high-quality copper that meets global standards. Our washers are manufactured in accordance with copper plain washer DIN 125 size M3 specifications, ensuring uniformity, reliability, and compatibility for your critical fastening needs.

What Are M3 Copper Plain Washers?

M3 copper plain washers are precision-cut circular copper components with a central hole perfectly sized to fit M3 bolts or screws (3 mm diameter). Their primary role is to distribute load evenly under a bolt or nut, preventing damage to the surface beneath and enhancing the clamping strength of the fastener. These washers are indispensable in applications that require superior electrical conductivity, corrosion resistance, and precision fastening.

Engineered as part of the M3 copper flat washer metric series DIN 125, these washers conform to international standards, making them suitable for global industrial applications. When used in electrical and electronic assemblies, M3 copper plain washers help maintain uninterrupted conductivity, reducing the risk of heat buildup and voltage drops.

Beyond electronics, they are widely used in mechanical subassemblies and sensitive hydraulic setups. Thanks to their excellent thermal and electrical conductivity, M3 copper plain washers also serve as grounding elements in electrical enclosures and components.

At Nafees Metal Industries, every piece of M3 copper plain washer is manufactured to tight tolerances, ensuring they meet the exact dimensions defined by copper plain washer DIN 125 size M3. These washers are crucial for industries that demand reliable performance from every fastening point—no matter how small.

Why Choose Copper for M3 Washers?

Copper is one of the most versatile and valuable materials used in industrial fastening, and when it comes to small-diameter components like M3 copper plain washers, the advantages of copper become even more significant. These washers are not just about spacing or load distribution—they are about enhancing performance in critical electrical, mechanical, and hydraulic assemblies.

M3 copper plain washers are widely preferred due to copper’s exceptional electrical conductivity, which allows uninterrupted current flow in sensitive electronics. This makes them ideal for PCB mounting, circuit connections, and terminal clamps. Furthermore, copper provides excellent thermal conductivity, which helps in heat dissipation across contact surfaces, reducing the risk of overheating in electronic or power systems.

Corrosion resistance is another major advantage. In environments where rust or oxidation can compromise the fastening system, M3 copper plain washers remain reliable, making them a perfect example of an industrial copper flat washer corrosion-resistant solution. Their non-magnetic nature makes them compatible with magnet-sensitive components, further expanding their application scope.

For hydraulic and pneumatic systems, M3 copper plain washers serve as effective sealing components, particularly in fittings, where they are referred to as copper sealing washer M3 hydraulic fittings. This dual functionality—as a spacer and a seal—adds to their value in compact assemblies.

The flexibility of copper also allows these washers to deform slightly under pressure, filling surface irregularities and forming a tighter seal. Whether you’re looking at durability, conductivity, corrosion protection, or sealing capability, M3 copper plain washers deliver superior results, all while being compliant with the M3 copper flat washer metric series DIN 125.

How Are M3 Copper Plain Washers Manufactured?

At Nafees Metal Industries, M3 copper plain washers are manufactured in our ISO-certified facility in Mumbai using precision-controlled processes that ensure dimensional accuracy, surface finish, and performance reliability. Our in-house production is designed to meet the requirements of industries that demand consistency, safety, and global standard compliance.

The process begins with high-purity electrolytic copper sheets, known for their conductivity and corrosion resistance. These sheets are cut and prepared for stamping using advanced CNC punching machines that ensure every M3 copper plain washer meets exact dimensional tolerances defined by copper plain washer DIN 125 size M3.

After punching, the washers undergo deburring and polishing, which gives them smooth edges and eliminates any sharp projections that could interfere with assembly or damage nearby components. This step ensures that each M3 copper plain washer is safe to handle and ideal for use in sensitive electronics or hydraulic fittings.

Surface treatment is an optional but often requested part of the process. Some clients prefer plain finishes for conductivity, while others opt for anti-oxidation coatings, especially for washers used in high-humidity environments. Our production line can accommodate both.

Each batch of M3 copper plain washers goes through rigorous quality checks that test for:

Dimensional accuracy (inner and outer diameter, thickness)

Flatness and surface smoothness

Material integrity (copper purity, hardness)

Visual inspection for uniformity

Our commitment to precision and quality ensures that every washer we produce adheres to the M3 copper flat washer metric series DIN 125 standards. Whether you need small quantities or large industrial volumes, our manufacturing process guarantees that your M3 copper plain washers will perform reliably in every application.

Key Features of M3 Copper Plain Washers

M3 copper plain washers from Nafees Metal Industries are engineered with features that make them indispensable in high-precision fastening applications. These washers are not only tailored to meet technical standards like copper plain washer DIN 125 size M3, but also offer practical benefits that enhance performance in real-world use cases.

Here are the standout features of our M3 copper plain washers:

Precision Inner Diameter: Designed to fit M3 bolts and screws with exact alignment. This ensures that each M3 copper plain washer sits flush without play or misalignment.

Superior Load Distribution: The flat structure spreads clamping force evenly, preventing material damage under the bolt or nut. This is especially important in delicate assemblies like PCBs or aluminum panels.

High Electrical Conductivity: Made from pure copper, these washers are ideal for grounding and current transmission, making M3 copper plain washers essential in electronic and electrical systems.

Corrosion Resistance: Each washer resists rust and oxidation, ensuring long service life even in humid or chemically exposed environments—qualifying them as a trusted industrial copper flat washer corrosion-resistant solution.

Smooth, Burr-Free Finish: Post-processing ensures that the surface and edges are polished and free of imperfections, preventing any potential injury during handling or damage to neighboring parts.

Versatile Finish Options: Available in plain copper or coated for anti-oxidation. Clients can request coatings based on usage in marine, industrial, or automotive environments.

Conformance to Global Standards: As part of the M3 copper flat washer metric series DIN 125, these washers are suitable for both domestic and international applications.

Bulk Availability & OEM Customization: We offer these washers in large volumes with the option of custom packaging, labeling, and finish—ideal for OEMs and industrial suppliers.

With these features, M3 copper plain washers serve as more than just spacers—they become integral components that improve performance, safety, and longevity in your assemblies.

Technical Specifications

To meet the varied requirements of industrial, electrical, and mechanical applications, M3 copper plain washers from Nafees Metal Industries are manufactured to strict dimensional and material standards. Every washer is crafted to ensure compatibility, performance, and reliability in demanding environments.

Below are the detailed technical specifications for our M3 copper plain washers:

| Property | Specification |

|---|---|

| Product Name | M3 Copper Plain Washer |

| Material | High-purity Electrolytic Copper |

| Inner Diameter (ID) | Approx. 3.2 mm (fits M3 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 |

| Thickness | 0.5–1.0 mm (customizable on request) |

| Surface Finish | Plain / Anti-oxidation Coated |

| Compliance | copper plain washer DIN 125 size M3 |

| Washer Series | M3 copper flat washer metric series DIN 125 |

| Packaging | Bulk Cartons / Poly Bags / Custom-Labeled Kits |

| Application Use | Electrical Panels, Hydraulic Fittings, PCBs |

Each of our M3 copper plain washers undergoes material testing and size verification, ensuring every piece aligns with the M3 copper flat washer metric series DIN 125 requirements. This technical accuracy makes them suitable for industries such as electronics, hydraulics, automotive, and energy, where washer performance is critical.

As trusted Indian manufacturers of M3 copper plain washers, we ensure that our technical specifications are not only accurate but adaptable to client-specific requirements such as custom thickness, finish, and packaging.

Applications of M3 Copper Plain Washers

M3 copper plain washers are valued across diverse industries for their compact size, high conductivity, and corrosion-resistant properties. Their design makes them exceptionally effective in critical fastening, sealing, and grounding applications—especially where space is limited but performance cannot be compromised.

Here are the key application areas for M3 copper plain washers:

Electrical and Electronic Devices: In PCB assemblies, terminal blocks, and control panels, M3 copper plain washers ensure uniform clamping pressure without damaging the circuit board, while also maintaining electrical continuity. Their conductivity makes them ideal for grounding and current flow.

Hydraulic and Pneumatic Systems: Used as copper sealing washer M3 hydraulic fittings, these washers prevent fluid leakage at connection points. Their deformability allows them to conform to mating surfaces, enhancing sealing under pressure.

Telecommunications Equipment: Their compact form and conductive nature make M3 copper plain washers essential in high-frequency communication modules where non-magnetic, corrosion-resistant washers are needed.

Automotive and Aerospace Components: In assemblies where space optimization is crucial, M3 copper plain washers provide vibration resistance, grounding, and long-term durability even under high stress.

HVAC and Marine Applications: As industrial copper flat washer corrosion-resistant components, these washers are suitable for damp, saline, or chemically aggressive environments where traditional materials fail.

Consumer Electronics and Gadgets: From assembling speakers and chargers to internal fastenings in compact appliances, M3 copper plain washers provide insulation, support, and longevity.

Solar Energy Systems: Used in solar inverter connections and junction boxes where conductivity and long-term corrosion resistance are vital.

Thanks to their versatility, standard compliance, and performance characteristics, M3 copper plain washers are indispensable in modern manufacturing and assembly lines. Whether for fastening, grounding, spacing, or sealing, they deliver consistent results across applications.

Advantages of Using M3 Copper Washers

M3 copper plain washers offer more than just dimensional compatibility—they provide critical performance advantages that make them the preferred choice for precision assemblies across industries. Whether you’re in electronics, automotive, hydraulics, or heavy machinery, these washers deliver benefits that directly impact efficiency, safety, and durability.

Here are the major advantages of using M3 copper plain washers:

Excellent Electrical Conductivity: Copper is one of the most conductive metals, making M3 copper plain washers ideal for electrical grounding and current-carrying components in PCBs, circuit breakers, and terminal connections.

Corrosion Resistance in Harsh Environments: Classified as an industrial copper flat washer corrosion-resistant solution, these washers perform reliably in humid, saline, or chemically exposed environments without degrading or rusting.

Improved Fastening Integrity: By spreading the load evenly under fasteners, M3 copper plain washers prevent surface damage, cracking, or deformation—especially when used on softer materials like plastics or composites.

Thermal Stability: Copper’s high thermal conductivity allows it to dissipate heat generated at the fastening point, which helps prevent overheating in power systems and electronic devices.

Ideal for Sealing Applications: As effective copper sealing washer M3 hydraulic fittings, they conform to surface irregularities and offer tight, leak-proof seals in pressurized systems.

Compliance with Global Standards: Designed in line with the M3 copper flat washer metric series DIN 125, they guarantee universal compatibility and consistent performance across international markets.

Lightweight and Easy to Handle: Small but strong, these washers are easy to manage in automated assembly lines, maintenance kits, and manual installations.

Eco-Friendly Material Choice: Copper is fully recyclable, helping your organization meet green manufacturing and sustainability goals.

Customization Options: Nafees Metal Industries offers tailored dimensions, coatings, and packaging for bulk OEM buyers, reinforcing our reputation as one of the best copper washer manufacturers in India.

Made in India, Trusted Worldwide: Manufactured at our Mumbai facility with strict quality controls, M3 copper plain washers reflect the craftsmanship and reliability associated with Indian engineering excellence.

These benefits make M3 copper plain washers the go-to solution for engineers, assemblers, and procurement managers seeking a high-performance, long-lasting washer that meets both technical and commercial expectations.

Buy Bulk M3 Copper Plain Washers – Best Indian Manufacturer

When it comes to sourcing reliable and high-quality M3 copper plain washers, Nafees Metal Industries stands out as a trusted name among manufacturers and bulk suppliers in India. We specialize in the production of copper washers in standard and custom sizes, with a focus on delivering precision, durability, and corrosion resistance for demanding industrial applications.

Whether you’re a procurement officer for an OEM, a distributor catering to local markets, or an export house looking for top-grade copper components, our M3 copper plain washers are the perfect solution. Manufactured to the copper plain washer DIN 125 size M3 standard, these washers offer dimensional accuracy, electrical conductivity, and long-lasting performance.

Here’s why we are considered the best manufacturer and bulk supplier of M3 copper plain washers in India:

Large-Scale Production Capacity: We maintain a ready stock of standard sizes including M3, M5, M6, M8, M10, M12, M16, M20 and beyond—ensuring you get fast fulfillment for bulk orders.

Custom Finishes & Thicknesses: Need a specific thickness or coating? We deliver M3 copper plain washers in plain copper or coated variants based on your application needs, including anti-oxidation layers.

OEM-Focused Support: We provide custom labeling, branding, and packaging options to suit OEM, trader, or retailer requirements.

Export-Ready Services: From HS codes to packing lists, we offer complete export documentation and international dispatch capabilities. Our M3 copper flat washer metric series DIN 125 products meet global standards and are RoHS compliant.

Mumbai-Based Manufacturing Facility: Our central location helps us serve domestic clients with reduced lead times while supporting international logistics efficiently.

Transparent Pricing & Quick Dispatch: Competitive bulk pricing without compromising on quality. We process and ship large orders promptly across India and globally.

Partner with Nafees Metal Industries and benefit from a reliable supply of M3 copper plain washers that meet industry demands and exceed expectations. With a proven track record and a commitment to quality, we are proud to support the fastener and electrical hardware industries as one of India’s top copper washer manufacturers.

Case Study – Copper Washers in Control Panel Assemblies

A well-known electrical control panel manufacturer based in Vadodara, Gujarat, was facing recurring issues with terminal loosening, circuit corrosion, and increased assembly time. Their engineers identified the root cause: poor conductivity and inconsistent clamping from standard steel washers used with M3 fasteners. After thorough evaluation, they switched to M3 copper plain washers from Nafees Metal Industries.

Solution Implemented:

They replaced all steel washers in their PCB and terminal clamp sections with high-conductivity, corrosion-resistant M3 copper plain washers, conforming to copper plain washer DIN 125 size M3 specifications.

Measured Outcomes Over 6 Months:

27% Reduction in circuit board assembly time due to easy handling and precise fitment

100% Elimination of terminal corrosion issues, even in high-humidity test conditions

Enhanced Electrical Flow, improving grounding and voltage consistency across the panel

Zero Failures reported during post-assembly vibration and heat testing

50% Increase in repeat order volume within three months of implementation

The client also benefited from Nafees Metal Industries’ quick turnaround time, bulk-ready stock, and custom-labeled packaging. The success of this integration reaffirmed their trust in us as the leading supplier of M3 copper plain washers and cemented our role in their long-term vendor list.

This case study highlights how M3 copper plain washers, especially those adhering to the M3 copper flat washer metric DIN 125 series, can dramatically improve assembly line performance, durability, and electrical safety.

Why Choose Nafees Metal Industries for M3 Copper Plain Washers?

When it comes to quality, consistency, and service, Nafees Metal Industries stands out as one of India’s most trusted manufacturers of M3 copper plain washers. Backed by advanced machinery, skilled professionals, and a commitment to international standards, we deliver washer solutions that outperform and outlast.

1. In-House Manufacturing Facility in Mumbai

Our fully equipped manufacturing unit is located in Mumbai, India’s leading industrial hub. This unit houses power press machines, high-precision dies, automated deburring tools, and quality control systems that allow us to produce large volumes of M3 copper plain washers with exceptional accuracy and surface finish. Our facility also supports rapid prototyping and custom production runs, allowing us to fulfill both standard and specialized orders efficiently.

2. Precision Engineering at Scale

Each M3 copper plain washer is engineered with care, ensuring a perfect internal diameter for M3 bolts, smooth edges for safe handling, and uniform thickness for load stability. We strictly follow copper plain washer DIN 125 size M3 specifications and support the M3 copper flat washer metric series DIN 125, ensuring interchangeability and global applicability.

3. Superior Copper Material

We use premium-grade electrolytic copper to manufacture washers with high thermal and electrical conductivity. These M3 copper plain washers are naturally corrosion-resistant and perfect for applications like grounding, terminal fastening, and even copper sealing washer M3 hydraulic fittings, where leak prevention is essential.

4. Competitive Bulk Supply

Thanks to our high-capacity unit and stock management systems, we maintain ready-to-dispatch inventories for standard sizes and process custom bulk orders with short lead times. Our pricing model is tailored to help wholesalers, exporters, and OEMs gain long-term cost benefits without sacrificing quality.

5. Export-Ready & Industry Compliant

Nafees Metal Industries is already exporting industrial copper flat washer corrosion resistant products to countries like UAE, Qatar, Oman, and Southeast Asia. All products come with proper documentation, RoHS compliance (on request), and customizable packaging to ensure safe and smooth international deliveries.

6. End-to-End Customization

From product labeling to washer thickness, ID-OD variations, and packing options, we offer end-to-end customization for your unique application requirements. Whether you’re building electrical control panels or hydraulic units, our M3 copper plain washers can be tailored for optimal fit and function.

Choosing Nafees Metal Industries means partnering with a manufacturer that combines modern infrastructure with old-school integrity. Our Mumbai facility reflects our dedication to quality, scalability, and precision — making us your go-to source for reliable washer solutions.

Frequently Asked Questions (FAQs)

What is the purpose of M3 copper plain washers?

They distribute load evenly, improve electrical conductivity, and prevent corrosion at fastener joints.Are M3 copper washers suitable for high-voltage electrical systems?

Yes, they offer excellent conductivity and are widely used in electrical and electronic circuits.What does ‘DIN 125’ mean in copper washers?

It’s a European standard that defines dimensional properties of flat washers, ensuring global compatibility.Do copper washers rust?

No, copper does not rust. It resists corrosion naturally and forms a protective oxide layer over time.Can I get anti-oxidation coated M3 copper washers?

Yes, Nafees Metal Industries provides optional coatings based on your application needs.Where are these washers manufactured?

All washers are manufactured at our advanced facility in Mumbai, India.Are M3 copper plain washers reusable?

In non-critical applications, yes. However, for sealing or electrical grounding, new washers are recommended.Do you export copper washers?

Yes, we supply across India and export globally with complete documentation.Can I order customized washer sizes or thicknesses?

Absolutely. We specialize in custom sizes, hole diameters, and finishes for bulk orders.What packaging options are available?

Bulk cartons, small kits, poly bags, and client-branded labeling are available.Are your washers compliant with international quality standards?

Yes, our products comply with DIN, IS, and ISO norms.Do you provide M3 copper washers for hydraulic fittings?

Yes, we supply copper sealing washer M3 hydraulic fittings widely used in hydraulic and pneumatic systems.What is the standard thickness of M3 copper plain washers?

Typically 0.5–1.0 mm, but we offer customization as per client needs.How fast is delivery across India?

We ensure quick dispatch within 2–5 days for most bulk orders.Why choose Nafees Metal Industries?

We are trusted manufacturers of industrial copper flat washer corrosion-resistant products known for quality, consistency, and customer support.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch