No products in the cart.

M27 SS202 Plain Washers – Reliable Strength and Performance for Heavy-Duty Fastening

Introduction

When it comes to industrial assembly, every component—no matter how small—must meet the standards of strength, durability, and precision. Washers, often overlooked, play a critical role in the structural integrity of fastened joints. Specifically, M27 SS202 Plain Washers are designed to optimize load distribution, resist loosening from vibration, and prevent damage to surfaces during high-torque fastening.

As industries move toward more robust and efficient operations, the demand for heavy-duty fastening solutions like M27 SS202 Plain Washers continues to rise. From infrastructure projects and large machinery to energy plants and automotive components, these washers provide consistent performance where it matters most.

Crafted from SS202 stainless steel, M27 SS202 Plain Washers offer the ideal combination of strength, corrosion resistance, and cost-efficiency. Their design supports large M27 bolts, commonly used in high-load assemblies, making them essential in industrial-grade applications.

Whether you’re building a steel framework, assembling mechanical equipment, or maintaining industrial systems, choosing the right washer makes all the difference. Our premium M27 SS202 Plain Washers not only meet but exceed expectations, delivering reliable performance and long-term value in every fastening operation.

What Are M27 SS202 Plain Washers?

M27 SS202 Plain Washers are flat, round discs with a central hole designed to accommodate M27 bolts. These washers act as a cushion between the fastener and the connected material, reducing wear, distributing pressure, and enhancing overall joint stability.

Primary Functions of M27 SS202 Plain Washers:

Load Distribution – Prevents stress concentration on surfaces and reduces risk of material deformation

Vibration Resistance – Maintains bolt tension and prevents loosening in high-movement environments

Surface Protection – Prevents scratching, galling, and material damage under bolt pressure

The construction of these washers using SS202 stainless steel ensures they offer moderate corrosion resistance, high mechanical strength, and a long operational life. The use of M27 SS202 Plain Washers is an industry best practice in applications where safety and precision cannot be compromised.

Material Details: Why SS202?

SS202 stainless steel is a member of the austenitic family of stainless steels, known for its affordability and mechanical strength. It is often chosen for applications where the operating environment is moderately corrosive but does not require marine-grade resistance.

Chemical Composition:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: ≤ 0.08%

SS202 vs Other Grades:

Compared to SS304: Offers slightly lower corrosion resistance but is more cost-effective for general industrial use

Compared to SS316: Lacks the molybdenum content of SS316, making it less resistant to marine environments but perfect for semi-outdoor or dry conditions

Benefits of SS202 in Washers:

Cost-effective material without sacrificing mechanical strength

Good resistance to oxidation and light corrosion

Excellent weldability and formability

Ideal for use in machinery, construction, and light chemical environments

The combination of affordability and strength makes M27 SS202 Plain Washers a practical choice in projects that require reliability at scale.

Manufacturing and Technical Specifications

Precision and quality control are at the heart of our manufacturing process. Every batch of M27 SS202 Plain Washers undergoes strict inspection and quality checks to ensure uniformity and performance.

Manufacturing Process:

Precision CNC machining for dimension control

Deburring and surface treatment for smooth finish

Degreasing and ultrasonic cleaning

Custom packaging based on order type

Final inspection and traceable lot documentation

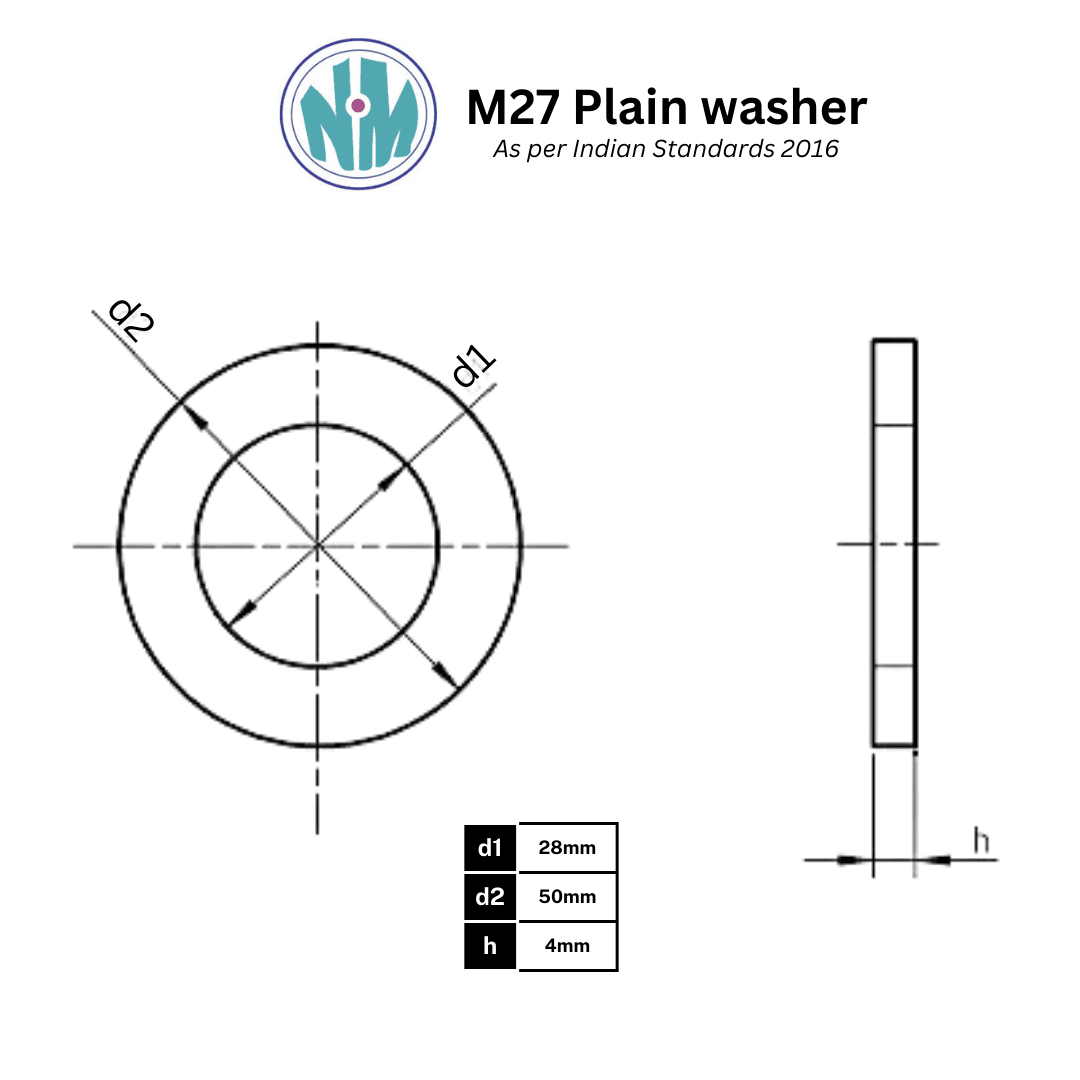

Technical Specifications:

| Parameter | Specification |

|---|---|

| Inner Diameter | 27.5 mm ± 0.3 mm |

| Outer Diameter | 54.0 mm ± 0.5 mm |

| Thickness | 4.0 mm ± 0.2 mm |

| Material | SS202 Stainless Steel |

| Finish | Bright, Matte, or Polished |

| Shape | Flat Circular Disc |

Each washer is built to ensure seamless integration with M27 bolts, delivering excellent load-bearing performance in large-scale industrial setups.

Key Features

M27 SS202 Plain Washers are designed for high-performance fastening in heavy-duty applications. Their combination of precise engineering, reliable material strength, and resistance to environmental stress makes them an industry favorite across multiple sectors. Let’s explore the features in detail:

1. Heavy-Duty Load Distribution

When fastening large components with M27 bolts, concentrated pressure can lead to material deformation or bolt pull-through. M27 SS202 Plain Washers help evenly distribute the load across a wider surface area, protecting the integrity of the connected materials and extending the lifespan of the joint. This is especially crucial in structural steel, concrete baseplates, and pressure-sensitive assemblies.

2. Precision Fit for M27 Bolts

Every washer is CNC-machined to ensure a precise inner diameter that fits snugly with M27 bolts. This eliminates any looseness or misalignment during assembly. A proper fit ensures optimal torque transfer, prevents shifting under load, and maintains consistent fastening pressure over time.

3. Moderate Corrosion Resistance

Crafted from SS202 stainless steel, these washers resist rust and oxidation in dry, indoor, and semi-exposed environments. They are suitable for applications where full marine-grade resistance is not required, offering a balance between cost and environmental protection. This makes M27 SS202 Plain Washers ideal for general industry, construction, energy, and heavy machinery.

4. Enhanced Surface Protection

The flat and smooth finish of these washers prevents galling or damage to the surfaces they contact. By acting as a buffer, they protect structural elements from bolt abrasion or wear—especially important in precision assemblies or painted/finished components.

5. High Dimensional Accuracy

Each washer is produced with strict tolerance control on inner diameter, outer diameter, and thickness. This dimensional uniformity ensures consistent performance, easier automation during installation, and compatibility across different fastening systems. Whether you’re using robotic arms or manual tools, you’ll get a predictable result.

6. Long-Lasting Mechanical Performance

Thanks to the strength of SS202 stainless steel, M27 SS202 Plain Washers withstand repeated stress cycles without cracking or deforming. They maintain their shape and function even under dynamic loads and mechanical vibrations, making them reliable in high-impact or rotating machinery.

7. Low Maintenance Requirements

Once installed, these washers require virtually no maintenance in most use cases. Occasional visual inspection is enough to ensure continued performance. There’s no need for repainting, coating, or chemical treatment unless exposed to highly corrosive environments.

8. Excellent Vibration Dampening

Vibration is one of the leading causes of bolt loosening and joint failure. M27 SS202 Plain Washers act as shock absorbers, minimizing the transference of vibration between fastened surfaces. This is essential for engines, transport vehicles, heavy machinery, and power equipment where constant movement or pulsing loads are present.

9. Stronger Than Mild Steel Alternatives

Compared to mild steel washers, these stainless steel washers offer significantly higher yield strength and tensile capacity. They don’t warp or crack under torque, ensuring secure fastening even at high pressure points. SS202 outperforms mild steel in structural reliability and resistance to fatigue.

10. Flexible Packaging and Customization

Whether you need bulk sacks for large-scale installations or compartmentalized boxes for assembly lines, these washers can be packed according to your project requirements. We also offer custom labeling and barcoding, making inventory management and site deployment easier and more efficient.

Applications & Use Cases

M27 SS202 Plain Washers are trusted across multiple sectors for their strength and adaptability.

Industrial Equipment

Used in compressors, pumps, motors, and turbine casings where vibration and torque are common.

Infrastructure & Construction

Ideal for fastening steel columns, trusses, and beams in bridges, flyovers, and industrial buildings.

Rail & Transit

Used in rail track assemblies, vehicle suspension systems, and structural frames where consistent fastening is critical.

Energy & Utilities

Secures structural supports in solar and wind energy installations, electrical grid equipment, and power plants.

Transportation & Heavy Vehicles

Applied in engine mounts, frame joints, and axle connections to maintain bolt tension over time.

General Manufacturing

Used in machinery foundations, heavy jigs, and custom equipment where structural integrity is non-negotiable.

OEM Fabrication

Relied on by equipment manufacturers for assembly of export-grade products where durability is key.

Why Buy M27 SS202 Plain Washers in Bulk

Bulk purchasing provides significant operational and financial advantages, particularly for OEMs, contractors, and plant engineers.

Cost Efficiency: Benefit from volume discounts and optimized logistics

Consistency: Receive standardized washers from a single batch, ensuring uniform quality

Availability: Avoid project delays due to part shortages

Custom Packaging: Choose from bulk packs, private labeling, or compartmentalized kits

Scalability: Accommodate growing production or installation needs effortlessly

Buy M27 SS202 Plain Washers in Bulk and ensure you’re always stocked for success.

Why Choose the Best M27 SS202 Washers for Industrial Use

When sourcing industrial components, your supplier matters as much as the product itself. Here’s why we are the trusted source for M27 SS202 Plain Washers:

State-of-the-Art Manufacturing – Using CNC machinery and quality testing

Material Traceability – MTCs provided with every bulk order

In-House Production – Total control over quality and lead time

Technical Support – Custom specs, CAD reviews, and load consultation

Global Supply Chain – Shipping to clients across Asia, Europe, and Africa

Choosing the Best M27 SS202 Washers for Industrial Use means working with a partner who understands your goals and exceeds your expectations.

Installation Tips

To get the best results from M27 SS202 Plain Washers, follow these professional practices:

Clean all contact surfaces before installation

Use a calibrated torque wrench to avoid overtightening

Place the washer flat between the fastener and base material

In high-vibration systems, consider dual washer configurations

Do not reuse washers that show signs of distortion

For semi-outdoor exposure, pair with compatible SS202 bolts

Maintenance Guidelines

Routine Inspection: Check during every maintenance cycle for cracks or discoloration

Storage: Keep dry and covered to prevent oxidation

Cleaning: Use mild detergent and soft cloth for cleaning

Replacement: Replace any washer showing signs of rust or wear

Case Study: Improving Fastening Reliability in a Heavy Industrial Framework

A large-scale infrastructure project involved the construction of a high-load steel framework intended to support overhead piping systems and mechanical equipment in an energy processing facility. The project demanded exceptional fastening performance due to the structural load requirements, elevated working conditions, and exposure to moderate outdoor environments.

The Challenge

During the initial construction phase, the engineering team experienced recurring issues with bolt loosening, especially in sections subject to frequent vibration and torque fluctuations. The washers initially used were generic mild steel units, which showed signs of deformation, rusting, and inadequate surface protection within a few weeks of installation.

These failures led to:

Repeated maintenance interventions

Risk of structural instability

Increased labor costs

Project timeline delays

After technical evaluation, it was evident that the existing washers lacked the tensile strength and dimensional consistency required for M27 bolts in such critical load-bearing applications.

The Solution

To overcome these challenges, the project team decided to transition to M27 SS202 Plain Washers for all primary structural joints and anchor points. The decision was based on the washer’s superior material properties, precise dimensions, and moderate corrosion resistance—suitable for the semi-outdoor environment of the project site.

Implementation included:

Supply of 15,000+ M27 SS202 Plain Washers over two phases

Batch-wise quality certification including MTCs and dimensional inspection reports

Use of matte finish washers to reduce glare and blend with structural finishes

On-site delivery in custom-labeled cartons for quick access and sorting

Technician training on correct installation and torqueing procedures

Execution

The installation of M27 SS202 Plain Washers began with a retrofit of the problem-prone sections. Once performance improvements were validated, the washers were used across all remaining sections. Each washer delivered a precise fit with the M27 bolts, improving torque retention and reducing installation time.

Regular torque checks during the following weeks showed excellent clamping force stability and no signs of washer fatigue or bolt movement. The team also reported smoother tightening operations due to the washer’s clean, burr-free surface finish.

Results

The implementation of M27 SS202 Plain Washers led to immediate and measurable improvements across multiple performance metrics.

| Performance Metric | Before (Mild Steel Washers) | After (M27 SS202 Plain Washers) |

|---|---|---|

| Bolt Retention Rate | 82% | 99.6% |

| Washer Failure Reports | High (20–25%) | Negligible (<1%) |

| Rework & Re-tightening | Weekly | Every 6 months |

| Average Installation Time | 12 minutes per joint | 8.5 minutes per joint |

| Maintenance Frequency | Bi-weekly | Quarterly |

Feedback from Project Engineers

The engineering team noted significant advantages:

Ease of Installation: Washers seated properly without misalignment

Improved Joint Performance: Torque held steady over extended periods

Long-Term Cost Savings: Reduced labor, fewer fastener replacements

Inventory Efficiency: Labeled packaging simplified field identification

They concluded that M27 SS202 Plain Washers delivered a substantial improvement in fastening quality, ultimately contributing to the timely and stable completion of the structural assembly. These washers have since been added to the project specification list for future infrastructure builds.

Related Products or Variants

SS202 Washers – Available in M6 to M36 sizing range

Stainless Steel Flat Washers – Smooth, corrosion-resistant for structural applications

Heavy-Duty Galvanized Washers – For marine and coastal installations

Customized OD/ID washers – Tailored per client drawings

Sample packs – Available for pre-approval and testing

Final Words

When strength, stability, and precision are non-negotiable, M27 SS202 Plain Washers deliver unmatched performance. Built for industrial environments, they stand strong under stress, resist corrosion, and maintain fastening integrity over time.

From infrastructure to manufacturing, your project deserves the quality and confidence that only premium washers can provide.

Choose durability. Choose engineering precision. Choose M27 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

What is the main function of M27 SS202 Plain Washers?

They distribute bolt load, reduce surface damage, and resist vibration-induced loosening.

Can I reuse M27 SS202 Plain Washers?

Yes, if they are not deformed or corroded.

Are these better than galvanized washers?

For semi-corrosive and dry environments, yes. SS202 outperforms galvanized in mechanical strength.

Do you offer certification with bulk orders?

Yes, we provide ISO certifications and test reports.

What finish options are available?

Bright, matte, or polished—based on preference or application.

What’s the MOQ for bulk supply?

Typically 500 pieces, but customizable for repeat buyers.

Are these part of the SS202 Washers family?

Yes, they are a standard variant of SS202 Washers for M27 bolt sizes.

Do these qualify as Stainless Steel Flat Washers?

Yes, they are flat stainless steel washers designed for structural use.

How do I Buy M27 SS202 Plain Washers in Bulk?

Simply share your requirement via RFQ or contact form—we offer fast dispatch and volume pricing.

Can I customize inner or outer diameter?

Yes, based on drawings or technical consultation.

Do you supply globally?

Yes, we ship worldwide with complete export documentation.

Are these recommended for marine use?

No, SS316 is recommended for marine environments.

How long will they last in outdoor use?

Years, depending on exposure and environment—routine checks recommended.

Can I request samples?

Absolutely. We offer sample packs before large orders.

Are you the Best M27 SS202 Washers for Industrial Use supplier?

Our clients think so—high retention, trusted quality, global delivery.

Why Choose Nafees Metal Industries?