No products in the cart.

Key Features

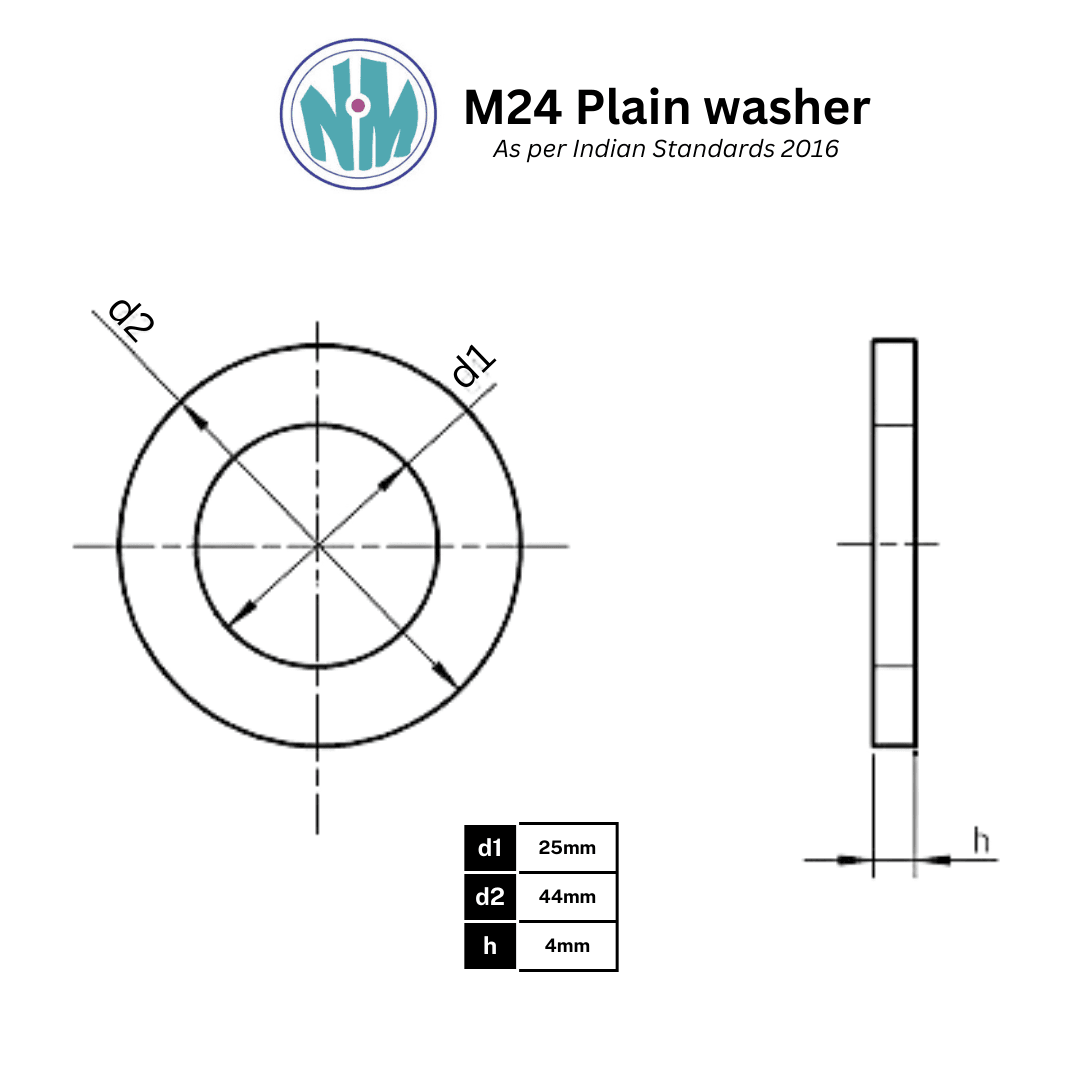

M24 SS202 Plain Washers come with a wide range of features that make them ideal for industrial use. Each feature adds value to the overall performance, making these washers dependable in challenging environments.

Uniform Load Distribution: Ensures that the force applied by a bolt or nut is spread across a larger surface area, preventing damage to the underlying material.

Precision Fit for M24 Bolts: Designed with tight tolerances to match M24 bolts perfectly, ensuring no misalignment or slippage.

Moderate Corrosion Resistance: Made from SS202 stainless steel, these washers resist oxidation and rust under most indoor and semi-outdoor conditions.

Smooth Surface Finish: Reduces friction and wear on bolted joints, contributing to ease of installation and longevity.

High Dimensional Accuracy: CNC-machined for consistency, these washers maintain strict tolerances across large production batches.

Long Service Life: Engineered to endure repeated stress, vibration, and weather fluctuations, leading to longer intervals between replacements.

Low Maintenance: Once installed, they require minimal upkeep, especially when used in environments appropriate for SS202 grade steel.

Vibration Dampening Capability: Helps in reducing loosening over time, especially in machines or structures exposed to mechanical movement or impact.

SS202 Grade Material Integrity: The chemical and physical properties of SS202 make it an ideal material for robust fastening solutions at a reasonable cost.

Custom & Bulk Packaging Available: Clients can choose from multiple packaging options—bulk crates, pouches, or box-labeled sets—for project-specific requirements.

Applications & Use Cases

The versatility of M24 SS202 Plain Washers enables their deployment across a wide range of industrial and commercial applications. Their robust design and SS202 material composition make them especially suitable for scenarios demanding strength, stability, and vibration resistance.

1. Automotive Industry

Used extensively in engine mounts, suspension joints, axle connections, and undercarriage systems where high vibration damping and load distribution are crucial. Their reliable performance helps maintain torque and prevents loosening in high-motion settings.

2. Construction & Infrastructure

In steel frameworks, bridges, and structural joints, these washers play a critical role in preventing bolt embedment, distributing tension, and ensuring long-term assembly reliability—even under fluctuating environmental conditions.

3. Industrial Machinery

Fastening large machines involves strong bolt-and-washer systems. M24 SS202 Plain Washers are commonly used in conveyors, pumps, CNC machines, and heavy presses to absorb vibrations and protect load-bearing surfaces.

4. Railways & Transport Equipment

Rail joint assemblies and rolling stock require fasteners that stay tight over long durations. These washers help maintain bolt integrity in vibrating and load-shifting conditions.

5. Wind & Solar Energy Installations

In turbines and panel frames exposed to constant motion and weather exposure, M24 SS202 Plain Washers offer reliable corrosion resistance and tension management.

6. Electrical Panels & Equipment

Though large in size, M24 washers are used in heavy switchgear and transformer bolt assemblies to ensure firm contact and ground continuity without damaging panel surfaces.

7. General Fabrication & DIY Projects

From custom machinery builds to robust furniture and modular steel structures, these washers deliver performance and reliability in non-commercial environments as well.

Each use case reinforces the washer’s ability to protect against wear, enhance bolt grip, and improve overall joint security.

Why Buy M24 SS202 Plain Washers in Bulk

Bulk procurement of M24 SS202 Plain Washers offers numerous operational and financial advantages, especially for manufacturers, infrastructure developers, contractors, and distributors:

Cost Efficiency: Bulk orders come with tiered pricing, significantly reducing the cost per unit—ideal for large projects or resellers.

Stock Readiness: Maintain continuous availability of washers at your worksite or facility, reducing delays due to last-minute shortages.

Uniformity Across Batches: Bulk production ensures consistency in quality, size, and finish across all washers supplied.

Custom Packaging: Receive your washers in custom-labeled, project-specific packaging formats that simplify handling and identification on-site.

Repeat Order Simplicity: Once you establish batch specs, reordering becomes seamless through pre-defined codes and supply protocols.

Long-Term Project Planning: Helps in accurate forecasting and inventory control for ongoing or phased construction/mechanical assembly projects.

Whether you’re an OEM or a construction firm, choosing to Buy M24 SS202 Plain Washers in Bulk ensures peace of mind and uninterrupted workflow.

Why Choose the Best M24 SS202 Plain Washers Manufacturer

Finding a reliable manufacturing partner ensures that your components meet performance expectations while aligning with your budget and delivery timelines. Here’s why our facility is considered the Best M24 SS202 Washers for Industrial Use:

In-House Production: Full control over materials, processes, and inspection ensures every washer matches spec requirements precisely.

Quality Certifications: ISO 9001:2015 certification and RoHS compliance guarantee standardized practices and materials.

Batch Testing & Traceability: Detailed records and test reports are available for every batch shipped, ensuring accountability and confidence.

Custom Manufacturing Capabilities: We provide tailor-made sizes, finishes, and packaging configurations based on client requests.

On-Time Delivery: Strong logistics networks ensure your washers arrive where and when needed—globally.

Technical Assistance: Our team of engineers supports you with design recommendations and washer selection for specific applications.

Choosing the Best M24 SS202 Plain Washers manufacturer translates into long-term savings, product reliability, and a seamless supply experience.

Installation Tips

To achieve optimal performance, durability, and structural integrity from M24 SS202 Plain Washers, it’s essential to follow proper installation practices. Below is a step-by-step guide along with best practices that apply to both large-scale industrial projects and precision mechanical assemblies:

1. Surface Preparation

Before placing the washer, ensure that the surfaces it will contact—whether under the bolt head or the nut—are clean, flat, and free of:

Dust or debris

Rust or corrosion

Oil, grease, or other contaminants

Contaminated or uneven surfaces can reduce the washer’s ability to distribute load evenly, leading to premature wear or joint failure.

2. Correct Washer Orientation and Placement

Always place the washer flat against the surface. Ensure:

The washer sits flush without any tilt

The bolt or nut passes cleanly through the central hole

No gaps exist between the washer and the mating surface

Incorrect placement can compromise the washer’s performance and lead to uneven clamping force.

3. Dual Washer Installation (Optional for Critical Joints)

In high-vibration or load-sensitive environments, it’s recommended to use two washers per bolt—one under the bolt head and one under the nut. This provides:

Balanced force distribution

Additional vibration resistance

Reduced surface indentation on both contact areas

4. Use the Correct Torque Settings

Over-tightening a bolt or nut can cause:

Washer deformation

Crushing of the mating material

Loss of elasticity in the fastening system

Under-tightening, on the other hand, can lead to a loose joint. Always refer to the torque specifications for M24 bolts based on the material and load conditions.

5. Compatibility with Coated or Treated Bolts

When using coated bolts (e.g., zinc-plated or galvanized), ensure that the washer material (SS202) is compatible to avoid:

Galvanic corrosion

Electrochemical reactions

Surface degradation

If needed, apply a thin protective layer or use isolation washers to reduce metal-to-metal interaction.

6. Alignment Checks During Installation

Especially in structural applications, it’s important to:

Confirm alignment of the bolt, washer, and nut

Use alignment tools or jigs for high-precision assemblies

Avoid forcing the washer into place if the bolt or nut is misaligned

This ensures proper seating and prevents stress build-up in the fastening system.

7. Recheck After Assembly

After the initial tightening:

Allow the joint to rest for a few minutes

Re-check bolt tension to compensate for material relaxation or settling

Apply secondary locking methods if needed (thread lockers, lock nuts, etc.)

By carefully following these installation tips, you can significantly extend the life of both the washer and the entire bolted assembly. Proper installation also improves safety, minimizes rework, and ensures consistent load-bearing performance in critical applications.

Maintenance Guidelines

Even though M24 SS202 Plain Washers are built for durability, some basic practices help maximize their lifecycle:

Store Properly: Keep washers in a dry, controlled environment to prevent moisture-related surface oxidation.

Inspect Regularly: Periodically check for flattening, distortion, or corrosion—especially in vibrating machinery or exposed conditions.

Clean When Needed: For grease or dirt buildup, clean washers with a cloth and mild degreaser. Avoid abrasive tools.

Replace on Warning Signs: Replace washers showing signs of deformation, pitting, or excessive wear.

Regular care ensures your fastening systems remain secure and maintenance costs stay minimal.