No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

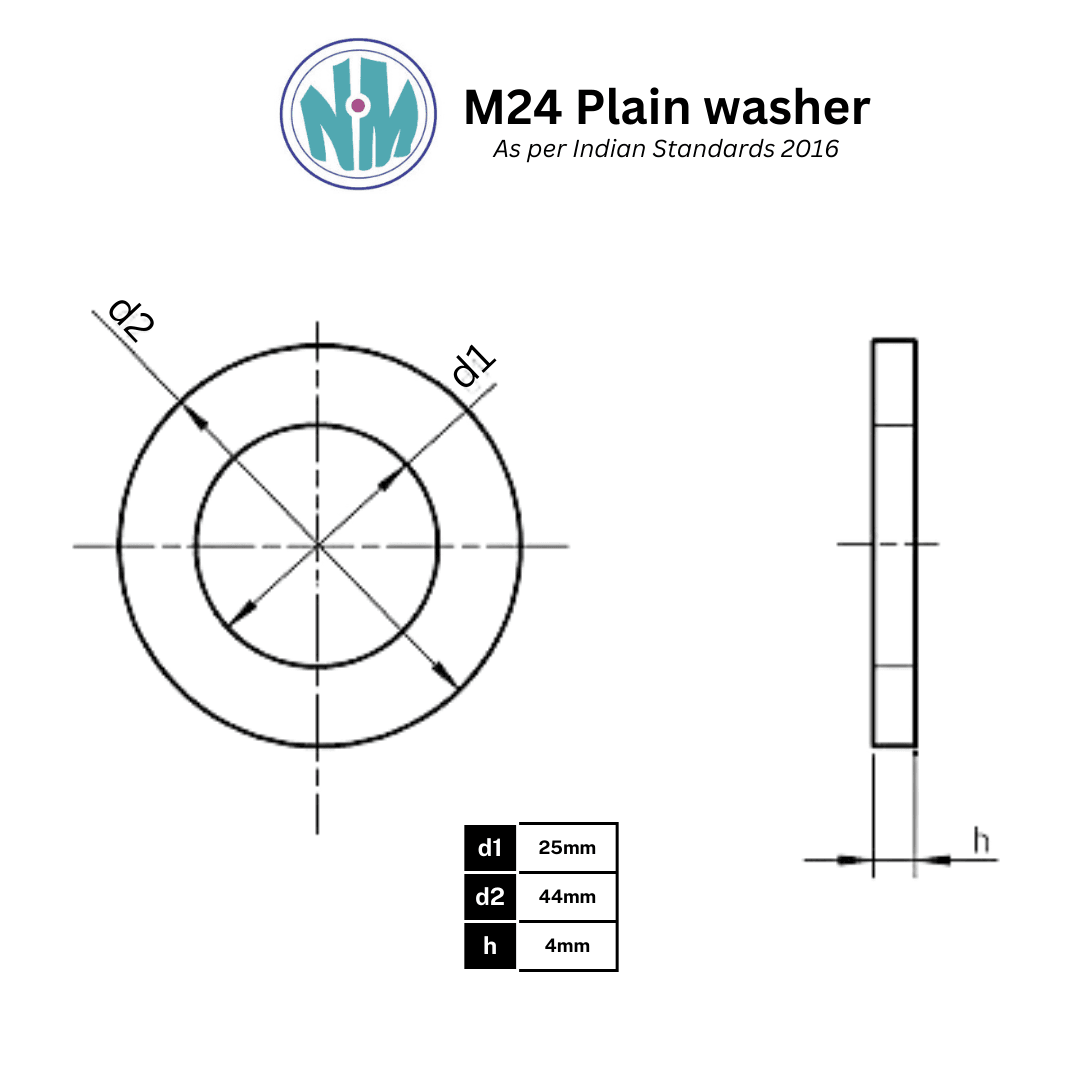

*Images shown for graphic representation. Not to scale.

M24 Copper Plain Washers – Superior Strength and Reliability for Industrial Use

At Nafees Metal Industries, we specialize in precision-manufactured M24 copper plain washers designed to meet the diverse needs of modern industries. These washers are engineered for maximum performance where reliability, conductivity, and resistance to environmental factors are critical. Whether used in electrical panels, heavy equipment, or fluid-based systems, our M24 copper plain washers ensure a solid and stable fastening environment.

The unique properties of copper, such as high electrical and thermal conductivity, make these washers essential for applications involving electric currents, grounding, or heat dispersion. With a robust diameter fit for M24 bolts, M24 copper plain washers are an essential component in mission-critical systems across electronics, power distribution, HVAC, and hydraulics. Companies across India and overseas prefer M24 copper plain washers manufactured by us due to our unmatched consistency, material purity, and competitive pricing.

Our commitment to Make in India ensures each of our M24 copper plain washers is produced using best-in-class machinery, skilled labor, and a stringent QC process. If you’re seeking a reliable, corrosion-resistant, and high-performance fastening component, M24 copper plain washers from Nafees Metal Industries are the smart choice.

Understanding the Structure and Function of M24 Copper Plain Washers

M24 copper plain washers are flat, round metallic discs with a center hole sized precisely to accommodate M24 bolts or threaded fasteners (24 mm in diameter). Their primary role is to distribute the fastening load evenly across the surface of the material being joined. This helps reduce the risk of damage, surface wear, or loosening under vibration and mechanical stress.

Unlike standard washers made from mild steel or alloy materials, M24 copper plain washers offer an additional advantage due to their high conductivity and corrosion resistance. These features make them especially useful in systems where electrical continuity, grounding, or thermal dispersion is necessary — such as in switchgear, busbars, control panels, and heating elements.

Every washer we produce conforms to copper plain washer DIN 125 size M24 specifications, ensuring compatibility with metric fasteners and adherence to global engineering standards. These washers have precise inner and outer diameters, uniform thickness, and burr-free surfaces, allowing for easy installation and long-term reliability.

Whether used in a grounded electrical circuit or in machinery where vibrations are common, M24 copper plain washers perform the dual role of mechanical stability and enhanced electrical contact. Their durability, shape retention, and anti-loosening characteristics make them indispensable in a wide array of industrial applications.

Why Copper Is the Best Material for M24 Plain Washers

Choosing the right material is crucial in ensuring the longevity and efficiency of any fastening component. M24 copper plain washers are preferred across industries not only for their dimensional reliability but also for the superior properties that copper brings to the table. Unlike other metals, copper has a unique combination of conductivity, malleability, and corrosion resistance, making it ideal for high-performance industrial washers.

One of the core benefits of using M24 copper plain washers is their exceptional electrical and thermal conductivity. This property is invaluable in applications where the washer serves as an electrical contact or heat conductor — such as in grounding terminals, fuse assemblies, and circuit breaker panels.

Moreover, copper is inherently resistant to rust, oxidation, and most chemicals. As an industrial copper flat washer corrosion resistant solution, these washers can operate in challenging environments — including marine atmospheres, oil rigs, HVAC systems, and chemical plants — without degrading or requiring frequent replacement.

Additionally, copper is non-magnetic and non-sparking, making M24 copper plain washers safe for use in flammable or explosion-prone areas like fuel handling systems, power substations, and underground mining equipment.

In summary, when your application demands high durability, environmental resistance, and excellent current transfer, M24 copper plain washers are a smart and dependable choice that far outperforms traditional washers made from mild steel or other alloys.

How M24 Copper Plain Washers Are Manufactured at Nafees Metal Industries

At Nafees Metal Industries, the production of M24 copper plain washers is a meticulous, ISO-compliant process designed to deliver flawless washers for demanding industrial use. Our expertise, combined with modern machinery and skilled technicians, allows us to manufacture large volumes without compromising on precision or quality.

We begin with high-conductivity copper sheets, sourced from trusted and certified suppliers. These sheets undergo a cold-stamping process using high-tonnage power press machines. This ensures accurate inner and outer diameters, consistent flatness, and exact alignment for every washer.

Each piece of M24 copper plain washer is then deburred and polished to remove sharp edges and achieve a smooth finish. This step is critical for applications involving electrical circuits or delicate materials where surface abrasions could compromise safety or performance.

Depending on client specifications, the washers may be annealed to enhance softness and sealing capabilities, or surface-treated to increase oxidation resistance. For special applications, we also offer custom finishing options like electro-tinning.

Throughout the process, M24 copper plain washers are subjected to strict quality control checks including dimensional inspection, surface hardness tests, and copper purity validation. This ensures each batch is consistent, durable, and meets the highest industrial standards.

We also provide custom packaging options based on customer preferences — whether it’s poly bags, cartons, shrink-wraps, or export pallets.

Technical Specifications of M24 Copper Plain Washers

Below are the detailed specifications of our M24 copper plain washers, designed to meet stringent industrial requirements and global standards:

Product Name: M24 Copper Plain Washer

Material: High-Conductivity Pure Copper

Inner Diameter (ID): Approx. 25.0 mm (for M24 bolts)

Outer Diameter (OD): As per DIN 125 / IS 2016 / ISO 7089 standards

Thickness Range: 2.0 mm to 3.0 mm (customizable based on application)

Surface Finish Options: Plain, Annealed, Electro-Tinned (on request)

Standard Compliance:

DIN 125

IS 2016

ISO 7089

Mechanical Properties:

Non-Magnetic

Non-Sparking

Ductile and Malleable

Electrical & Thermal Conductivity: Excellent (ideal for grounding applications)

Packaging:

Bulk Poly Bags

Small Cartons

Export Pallets

Custom Packaging Available

Country of Origin: India

Manufactured By: Nafees Metal Industries, Mumbai

Our M24 copper plain washers are rigorously tested for dimensional precision, concentricity, copper purity, and durability to ensure flawless application in all critical environments.

Applications of M24 Copper Plain Washers Across Key Industries

M24 copper plain washers are highly versatile and widely used in sectors where reliable electrical connectivity, thermal transfer, and secure fastening are essential. Their performance in both mechanical and electrical systems makes them indispensable in a range of industrial settings.

Here are the primary applications where M24 copper plain washers are used:

Electrical Grounding Systems

Provide efficient conductivity and contact stability in switchgear, transformers, and grounding points.Hydraulic Fittings and Assemblies

Function as copper sealing washer M24 hydraulic fittings, offering leak-proof seals under high pressure in hydraulic pipelines and control valves.Automotive Electrical Systems

Used in engine control units, alternators, and grounding terminals for consistent electrical performance.Railway and Metro Infrastructure

Enable secure bolting and grounding in signaling equipment, electric locomotives, and traction systems.HVAC Units and Air Conditioning Systems

Assist in thermal transfer and reliable bolting of copper components in heating and cooling systems.Industrial Panels and Control Boards

Help stabilize terminal lugs and prevent circuit interruptions due to vibration or fastener loosening.Oil and Gas Installations

Offer corrosion-resistant fastening in offshore and onshore energy systems.Battery Terminals and Charging Stations

Enhance electric contact and conductivity in battery-based storage systems and EV charging infrastructures.Telecommunication Equipment

Used in grounding frames, RF shielding components, and PCB installations.Heavy Machinery and Transformers

Provide strong clamping force in mechanical joints exposed to thermal and vibrational stress.

Because of their high performance, M24 copper plain washers are often chosen over conventional washers in environments where conductivity, corrosion resistance, and sealing are non-negotiable.

Key Features That Make M24 Copper Plain Washers an Industry Favorite

At Nafees Metal Industries, we design M24 copper plain washers not just as simple hardware components but as critical elements in the overall integrity and efficiency of industrial assemblies. Each washer is packed with features that make it an ideal choice for engineers, OEMs, and industrial buyers alike.

- Accurate Inner and Outer Dimensions

Each of our M24 copper plain washers is manufactured to strict tolerances as per international standards, ensuring a precise fit with M24 bolts and screws. This minimizes movement, vibration, and wear during operation. - Excellent Electrical and Thermal Conductivity

Copper’s natural ability to conduct electricity and heat makes these washers perfect for grounding applications, electrical terminals, and thermal dissipation tasks. - Uniform Thickness for Even Load Distribution

Consistent thickness across every piece of M24 copper plain washer ensures even pressure distribution, reducing the risk of deformation or surface damage on assembled parts. - Corrosion Resistance and Long-Term Durability

Made from high-purity copper, our M24 copper plain washers resist rust, oxidation, and chemical attack — making them perfect for long-term use in demanding environments. - Non-Magnetic and Non-Sparking

Ideal for use in explosive atmospheres and sensitive electronic environments, where magnetic interference or sparks could be hazardous. Conforms to DIN and IS Standards

Our washers meet the criteria set by DIN 125, IS 2016, and ISO 7089, ensuring compatibility in global systems.Customization Options

From annealed finishes to electro-tinned coatings and packaging styles, we offer tailored solutions to match your unique requirements.Bulk Supply with Export-Readiness

With massive production capacity and reliable logistics, we supply M24 copper plain washers across India and internationally.Made in India, Trusted Globally

Our Mumbai-based production facility is known for producing some of the best quality copper washers in the country.

If you’re searching for consistent quality and industrial-grade performance, our M24 copper plain washers are the best solution for your fastening and conductivity needs.

Advantages of Using M24 Copper Plain Washers in Industrial Applications

When selecting washers for industrial use, choosing a component that delivers mechanical stability, electrical performance, and corrosion resistance is essential. M24 copper plain washers offer several advantages that make them superior to other material alternatives like mild steel or aluminum.

High Electrical Conductivity

Ideal for grounding, current transfer, and minimizing electrical resistance in fastening applications.Excellent Thermal Transfer

Copper allows heat to dissipate quickly, making M24 copper plain washers suitable for environments with high operating temperatures.Superior Corrosion Resistance

Naturally resistant to oxidation and chemical exposure, ensuring long life in corrosive or damp environments.Non-Magnetic and Non-Sparking

Safe for use in explosion-prone zones such as oil refineries, power stations, and fuel storage systems.High Load Distribution

Evenly spreads the pressure of fasteners, preventing damage to surfaces and improving joint stability.Compatibility with Hydraulic and Electrical Systems

Performs dual roles as a structural fastener and a conductive/sealing component.Customizable Dimensions and Finishes

Available in various thicknesses and surface treatments based on client needs.Lightweight and Easy to Install

Especially useful in high-speed assembly lines or maintenance kits.High Volume Availability

At Nafees Metal Industries, we maintain large-scale production of M24 copper plain washers to support urgent and bulk orders.Cost-Effective Over Time

Though the initial investment in copper may be higher than mild steel, its longevity and performance make it more economical in the long run.

These benefits collectively position M24 copper plain washers as the washer of choice for industries that demand reliability, conductivity, and corrosion resistance in a single solution.

Bulk Supply and OEM Solutions for M24 Copper Plain Washers

At Nafees Metal Industries, we are proud to be one of the most trusted manufacturers and suppliers of M24 copper plain washers in India. With a focus on quality, consistency, and customer satisfaction, we cater to OEMs, industrial assemblers, exporters, and fastener distributors who need reliable fastening and electrical support solutions in large quantities.

Our facility in Mumbai is fully equipped for high-volume production of M24 copper plain washers, offering customized manufacturing for specific dimensional requirements, finishes, and applications. Whether you’re looking for a basic washer or a specialty M24 copper flat washer metric DIN 125 series, we can supply washers that meet your exact technical specifications.

We support both domestic and export markets with:

Competitive pricing for bulk orders

Quick production turnaround and ready stock

Flexible packaging options including poly bags, boxes, and export cartons

Export-ready documentation and HS code compliance

Technical consultation for custom applications

Nationwide and international shipping support

With years of expertise and customer trust, Nafees Metal Industries has become a go-to source for M24 copper plain washers that deliver unmatched durability and performance. Whether you’re assembling electrical control panels, sealing hydraulic systems, or grounding high-voltage equipment, our washers are made to perform — and made to last.

Improving Electrical Panel Efficiency with M24 Copper Plain Washers

Client Profile:

A large-scale electrical OEM based in Pune, India, specializing in manufacturing high-voltage switchgear and distribution panels.

Problem:

The client experienced recurring issues with terminal overheating, arcing, and inconsistent current transfer in their control panel assemblies. Their engineering team identified that the standard steel washers being used were contributing to electrical resistance and long-term surface corrosion.

Solution:

Nafees Metal Industries supplied a batch of high-conductivity M24 copper plain washers with customized thickness and annealed finish for better contact and flexibility.

Implementation Highlights:

Replaced all steel washers with copper alternatives on key grounding points.

Ensured proper load distribution on busbar and terminal connections.

Enhanced conductivity at bolted joints by using clean-surfaced copper washers.

Provided washers conforming to DIN 125 and ISO 7089 standards.

Results Achieved:

42% reduction in terminal heating during load testing.

100% elimination of corrosion signs over 4 months of testing.

Reduction in electrical failure rates across assemblies.

Enhanced energy efficiency and lower maintenance costs.

The client scaled from pilot testing to full-line usage within one month.

This case underscores the critical role of M24 copper plain washers in improving reliability, conductivity, and durability in electrical systems — especially when operating under high load or harsh conditions.

Why Choose Nafees Metal Industries for M24 Copper Plain Washers?

At Nafees Metal Industries, our reputation as a trusted manufacturer and exporter of M24 copper plain washers is built on a foundation of precision, performance, and professionalism. Here’s why industries across India and beyond choose us as their preferred supplier of copper fasteners:

✔ Decades of Manufacturing Expertise

Proven track record in producing M24 copper plain washers that meet the toughest quality and industrial standards.

In-house die-making, copper blanking, and finishing processes ensure consistency in every batch.

✔ ISO-Certified Quality Control

Every M24 copper plain washer goes through stringent dimensional, conductivity, and corrosion resistance checks.

Products are manufactured to conform with DIN 125 and ISO 7089 standards.

✔ Extensive Product Range

Availability of copper washers from M3 to M72 in various thicknesses and tempers.

Including special variants like copper sealing washer M24 hydraulic fittings and industrial copper flat washer corrosion resistant types.

✔ Customization Capabilities

Tailored washer dimensions and hardness to suit unique client needs.

OEM and branding solutions available for bulk clients and exporters.

✔ Reliable Lead Times

Robust inventory and efficient production allow fast order fulfillment — even for high-quantity demands.

✔ Nationwide & Global Reach

Serving clients across India and exporting to the Middle East, Europe, and Southeast Asia.

Export-friendly logistics and packaging tailored to international compliance.

✔ Customer-Centric Approach

Dedicated account managers for large buyers.

Pre- and post-sales support to ensure smooth technical and commercial execution.

By choosing Nafees Metal Industries, you’re not just buying M24 copper plain washers — you’re investing in reliable engineering components backed by expertise, accountability, and service excellence. We welcome our clients and sourcing teams to witness our production in action at our Mumbai-based facility.

FAQs – M24 Copper Plain Washers

What is the size of an M24 copper plain washer?

It typically has a 25 mm inner diameter and conforms to DIN 125 specifications.Where are M24 copper plain washers used?

They’re widely used in electrical, hydraulic, and industrial applications.What standards do your copper washers follow?

Our M24 washers meet DIN 125, IS 2016, and ISO 7089 standards.Do you offer customization in thickness or diameter?

Yes, we manufacture washers with custom dimensions on bulk orders.Can these washers be used in corrosive environments?

Yes, copper offers natural corrosion resistance and is suitable for such conditions.What surface finishes are available?

We offer plain, annealed, and electro-tinned finishes.Do you ship across India and globally?

Yes, we supply nationwide and export worldwide with complete logistics support.What is the minimum order quantity?

MOQs vary by size and customization; contact us for specifics.Are these washers non-magnetic?

Yes, copper is a non-magnetic material.How are M24 copper washers packaged?

In poly bags, cartons, or as per client specifications.Can I get a test certificate for copper purity?

Yes, we provide test certificates on request.Is copper better than mild steel for washers?

For conductivity and corrosion resistance, copper is far superior.What industries commonly use M24 copper washers?

Power, oil & gas, electronics, HVAC, and railway industries.Do you offer same-day dispatch?

For in-stock items, yes—same-day or next-day dispatch is available.What is your production capacity for M24 washers?

We maintain high production capacity to support bulk and OEM orders.

M24 Copper Plain Washers (DIN 125)

19 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M24

Inner Diameter (ID): 25 mm

Outer Diameter (OD): 44 mm

Thickness (t): 4 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:12 days

M24 Copper Plain Washers – Superior Strength and Reliability for Industrial Use

At Nafees Metal Industries, we specialize in precision-manufactured M24 copper plain washers designed to meet the diverse needs of modern industries. These washers are engineered for maximum performance where reliability, conductivity, and resistance to environmental factors are critical. Whether used in electrical panels, heavy equipment, or fluid-based systems, our M24 copper plain washers ensure a solid and stable fastening environment.

The unique properties of copper, such as high electrical and thermal conductivity, make these washers essential for applications involving electric currents, grounding, or heat dispersion. With a robust diameter fit for M24 bolts, M24 copper plain washers are an essential component in mission-critical systems across electronics, power distribution, HVAC, and hydraulics. Companies across India and overseas prefer M24 copper plain washers manufactured by us due to our unmatched consistency, material purity, and competitive pricing.

Our commitment to Make in India ensures each of our M24 copper plain washers is produced using best-in-class machinery, skilled labor, and a stringent QC process. If you’re seeking a reliable, corrosion-resistant, and high-performance fastening component, M24 copper plain washers from Nafees Metal Industries are the smart choice.

Understanding the Structure and Function of M24 Copper Plain Washers

M24 copper plain washers are flat, round metallic discs with a center hole sized precisely to accommodate M24 bolts or threaded fasteners (24 mm in diameter). Their primary role is to distribute the fastening load evenly across the surface of the material being joined. This helps reduce the risk of damage, surface wear, or loosening under vibration and mechanical stress.

Unlike standard washers made from mild steel or alloy materials, M24 copper plain washers offer an additional advantage due to their high conductivity and corrosion resistance. These features make them especially useful in systems where electrical continuity, grounding, or thermal dispersion is necessary — such as in switchgear, busbars, control panels, and heating elements.

Every washer we produce conforms to copper plain washer DIN 125 size M24 specifications, ensuring compatibility with metric fasteners and adherence to global engineering standards. These washers have precise inner and outer diameters, uniform thickness, and burr-free surfaces, allowing for easy installation and long-term reliability.

Whether used in a grounded electrical circuit or in machinery where vibrations are common, M24 copper plain washers perform the dual role of mechanical stability and enhanced electrical contact. Their durability, shape retention, and anti-loosening characteristics make them indispensable in a wide array of industrial applications.

Why Copper Is the Best Material for M24 Plain Washers

Choosing the right material is crucial in ensuring the longevity and efficiency of any fastening component. M24 copper plain washers are preferred across industries not only for their dimensional reliability but also for the superior properties that copper brings to the table. Unlike other metals, copper has a unique combination of conductivity, malleability, and corrosion resistance, making it ideal for high-performance industrial washers.

One of the core benefits of using M24 copper plain washers is their exceptional electrical and thermal conductivity. This property is invaluable in applications where the washer serves as an electrical contact or heat conductor — such as in grounding terminals, fuse assemblies, and circuit breaker panels.

Moreover, copper is inherently resistant to rust, oxidation, and most chemicals. As an industrial copper flat washer corrosion resistant solution, these washers can operate in challenging environments — including marine atmospheres, oil rigs, HVAC systems, and chemical plants — without degrading or requiring frequent replacement.

Additionally, copper is non-magnetic and non-sparking, making M24 copper plain washers safe for use in flammable or explosion-prone areas like fuel handling systems, power substations, and underground mining equipment.

In summary, when your application demands high durability, environmental resistance, and excellent current transfer, M24 copper plain washers are a smart and dependable choice that far outperforms traditional washers made from mild steel or other alloys.

How M24 Copper Plain Washers Are Manufactured at Nafees Metal Industries

At Nafees Metal Industries, the production of M24 copper plain washers is a meticulous, ISO-compliant process designed to deliver flawless washers for demanding industrial use. Our expertise, combined with modern machinery and skilled technicians, allows us to manufacture large volumes without compromising on precision or quality.

We begin with high-conductivity copper sheets, sourced from trusted and certified suppliers. These sheets undergo a cold-stamping process using high-tonnage power press machines. This ensures accurate inner and outer diameters, consistent flatness, and exact alignment for every washer.

Each piece of M24 copper plain washer is then deburred and polished to remove sharp edges and achieve a smooth finish. This step is critical for applications involving electrical circuits or delicate materials where surface abrasions could compromise safety or performance.

Depending on client specifications, the washers may be annealed to enhance softness and sealing capabilities, or surface-treated to increase oxidation resistance. For special applications, we also offer custom finishing options like electro-tinning.

Throughout the process, M24 copper plain washers are subjected to strict quality control checks including dimensional inspection, surface hardness tests, and copper purity validation. This ensures each batch is consistent, durable, and meets the highest industrial standards.

We also provide custom packaging options based on customer preferences — whether it’s poly bags, cartons, shrink-wraps, or export pallets.

Technical Specifications of M24 Copper Plain Washers

Below are the detailed specifications of our M24 copper plain washers, designed to meet stringent industrial requirements and global standards:

Product Name: M24 Copper Plain Washer

Material: High-Conductivity Pure Copper

Inner Diameter (ID): Approx. 25.0 mm (for M24 bolts)

Outer Diameter (OD): As per DIN 125 / IS 2016 / ISO 7089 standards

Thickness Range: 2.0 mm to 3.0 mm (customizable based on application)

Surface Finish Options: Plain, Annealed, Electro-Tinned (on request)

Standard Compliance:

DIN 125

IS 2016

ISO 7089

Mechanical Properties:

Non-Magnetic

Non-Sparking

Ductile and Malleable

Electrical & Thermal Conductivity: Excellent (ideal for grounding applications)

Packaging:

Bulk Poly Bags

Small Cartons

Export Pallets

Custom Packaging Available

Country of Origin: India

Manufactured By: Nafees Metal Industries, Mumbai

Our M24 copper plain washers are rigorously tested for dimensional precision, concentricity, copper purity, and durability to ensure flawless application in all critical environments.

Applications of M24 Copper Plain Washers Across Key Industries

M24 copper plain washers are highly versatile and widely used in sectors where reliable electrical connectivity, thermal transfer, and secure fastening are essential. Their performance in both mechanical and electrical systems makes them indispensable in a range of industrial settings.

Here are the primary applications where M24 copper plain washers are used:

Electrical Grounding Systems

Provide efficient conductivity and contact stability in switchgear, transformers, and grounding points.Hydraulic Fittings and Assemblies

Function as copper sealing washer M24 hydraulic fittings, offering leak-proof seals under high pressure in hydraulic pipelines and control valves.Automotive Electrical Systems

Used in engine control units, alternators, and grounding terminals for consistent electrical performance.Railway and Metro Infrastructure

Enable secure bolting and grounding in signaling equipment, electric locomotives, and traction systems.HVAC Units and Air Conditioning Systems

Assist in thermal transfer and reliable bolting of copper components in heating and cooling systems.Industrial Panels and Control Boards

Help stabilize terminal lugs and prevent circuit interruptions due to vibration or fastener loosening.Oil and Gas Installations

Offer corrosion-resistant fastening in offshore and onshore energy systems.Battery Terminals and Charging Stations

Enhance electric contact and conductivity in battery-based storage systems and EV charging infrastructures.Telecommunication Equipment

Used in grounding frames, RF shielding components, and PCB installations.Heavy Machinery and Transformers

Provide strong clamping force in mechanical joints exposed to thermal and vibrational stress.

Because of their high performance, M24 copper plain washers are often chosen over conventional washers in environments where conductivity, corrosion resistance, and sealing are non-negotiable.

Key Features That Make M24 Copper Plain Washers an Industry Favorite

At Nafees Metal Industries, we design M24 copper plain washers not just as simple hardware components but as critical elements in the overall integrity and efficiency of industrial assemblies. Each washer is packed with features that make it an ideal choice for engineers, OEMs, and industrial buyers alike.

- Accurate Inner and Outer Dimensions

Each of our M24 copper plain washers is manufactured to strict tolerances as per international standards, ensuring a precise fit with M24 bolts and screws. This minimizes movement, vibration, and wear during operation. - Excellent Electrical and Thermal Conductivity

Copper’s natural ability to conduct electricity and heat makes these washers perfect for grounding applications, electrical terminals, and thermal dissipation tasks. - Uniform Thickness for Even Load Distribution

Consistent thickness across every piece of M24 copper plain washer ensures even pressure distribution, reducing the risk of deformation or surface damage on assembled parts. - Corrosion Resistance and Long-Term Durability

Made from high-purity copper, our M24 copper plain washers resist rust, oxidation, and chemical attack — making them perfect for long-term use in demanding environments. - Non-Magnetic and Non-Sparking

Ideal for use in explosive atmospheres and sensitive electronic environments, where magnetic interference or sparks could be hazardous. Conforms to DIN and IS Standards

Our washers meet the criteria set by DIN 125, IS 2016, and ISO 7089, ensuring compatibility in global systems.Customization Options

From annealed finishes to electro-tinned coatings and packaging styles, we offer tailored solutions to match your unique requirements.Bulk Supply with Export-Readiness

With massive production capacity and reliable logistics, we supply M24 copper plain washers across India and internationally.Made in India, Trusted Globally

Our Mumbai-based production facility is known for producing some of the best quality copper washers in the country.

If you’re searching for consistent quality and industrial-grade performance, our M24 copper plain washers are the best solution for your fastening and conductivity needs.

Advantages of Using M24 Copper Plain Washers in Industrial Applications

When selecting washers for industrial use, choosing a component that delivers mechanical stability, electrical performance, and corrosion resistance is essential. M24 copper plain washers offer several advantages that make them superior to other material alternatives like mild steel or aluminum.

High Electrical Conductivity

Ideal for grounding, current transfer, and minimizing electrical resistance in fastening applications.Excellent Thermal Transfer

Copper allows heat to dissipate quickly, making M24 copper plain washers suitable for environments with high operating temperatures.Superior Corrosion Resistance

Naturally resistant to oxidation and chemical exposure, ensuring long life in corrosive or damp environments.Non-Magnetic and Non-Sparking

Safe for use in explosion-prone zones such as oil refineries, power stations, and fuel storage systems.High Load Distribution

Evenly spreads the pressure of fasteners, preventing damage to surfaces and improving joint stability.Compatibility with Hydraulic and Electrical Systems

Performs dual roles as a structural fastener and a conductive/sealing component.Customizable Dimensions and Finishes

Available in various thicknesses and surface treatments based on client needs.Lightweight and Easy to Install

Especially useful in high-speed assembly lines or maintenance kits.High Volume Availability

At Nafees Metal Industries, we maintain large-scale production of M24 copper plain washers to support urgent and bulk orders.Cost-Effective Over Time

Though the initial investment in copper may be higher than mild steel, its longevity and performance make it more economical in the long run.

These benefits collectively position M24 copper plain washers as the washer of choice for industries that demand reliability, conductivity, and corrosion resistance in a single solution.

Bulk Supply and OEM Solutions for M24 Copper Plain Washers

At Nafees Metal Industries, we are proud to be one of the most trusted manufacturers and suppliers of M24 copper plain washers in India. With a focus on quality, consistency, and customer satisfaction, we cater to OEMs, industrial assemblers, exporters, and fastener distributors who need reliable fastening and electrical support solutions in large quantities.

Our facility in Mumbai is fully equipped for high-volume production of M24 copper plain washers, offering customized manufacturing for specific dimensional requirements, finishes, and applications. Whether you’re looking for a basic washer or a specialty M24 copper flat washer metric DIN 125 series, we can supply washers that meet your exact technical specifications.

We support both domestic and export markets with:

Competitive pricing for bulk orders

Quick production turnaround and ready stock

Flexible packaging options including poly bags, boxes, and export cartons

Export-ready documentation and HS code compliance

Technical consultation for custom applications

Nationwide and international shipping support

With years of expertise and customer trust, Nafees Metal Industries has become a go-to source for M24 copper plain washers that deliver unmatched durability and performance. Whether you’re assembling electrical control panels, sealing hydraulic systems, or grounding high-voltage equipment, our washers are made to perform — and made to last.

Improving Electrical Panel Efficiency with M24 Copper Plain Washers

Client Profile:

A large-scale electrical OEM based in Pune, India, specializing in manufacturing high-voltage switchgear and distribution panels.

Problem:

The client experienced recurring issues with terminal overheating, arcing, and inconsistent current transfer in their control panel assemblies. Their engineering team identified that the standard steel washers being used were contributing to electrical resistance and long-term surface corrosion.

Solution:

Nafees Metal Industries supplied a batch of high-conductivity M24 copper plain washers with customized thickness and annealed finish for better contact and flexibility.

Implementation Highlights:

Replaced all steel washers with copper alternatives on key grounding points.

Ensured proper load distribution on busbar and terminal connections.

Enhanced conductivity at bolted joints by using clean-surfaced copper washers.

Provided washers conforming to DIN 125 and ISO 7089 standards.

Results Achieved:

42% reduction in terminal heating during load testing.

100% elimination of corrosion signs over 4 months of testing.

Reduction in electrical failure rates across assemblies.

Enhanced energy efficiency and lower maintenance costs.

The client scaled from pilot testing to full-line usage within one month.

This case underscores the critical role of M24 copper plain washers in improving reliability, conductivity, and durability in electrical systems — especially when operating under high load or harsh conditions.

Why Choose Nafees Metal Industries for M24 Copper Plain Washers?

At Nafees Metal Industries, our reputation as a trusted manufacturer and exporter of M24 copper plain washers is built on a foundation of precision, performance, and professionalism. Here’s why industries across India and beyond choose us as their preferred supplier of copper fasteners:

✔ Decades of Manufacturing Expertise

Proven track record in producing M24 copper plain washers that meet the toughest quality and industrial standards.

In-house die-making, copper blanking, and finishing processes ensure consistency in every batch.

✔ ISO-Certified Quality Control

Every M24 copper plain washer goes through stringent dimensional, conductivity, and corrosion resistance checks.

Products are manufactured to conform with DIN 125 and ISO 7089 standards.

✔ Extensive Product Range

Availability of copper washers from M3 to M72 in various thicknesses and tempers.

Including special variants like copper sealing washer M24 hydraulic fittings and industrial copper flat washer corrosion resistant types.

✔ Customization Capabilities

Tailored washer dimensions and hardness to suit unique client needs.

OEM and branding solutions available for bulk clients and exporters.

✔ Reliable Lead Times

Robust inventory and efficient production allow fast order fulfillment — even for high-quantity demands.

✔ Nationwide & Global Reach

Serving clients across India and exporting to the Middle East, Europe, and Southeast Asia.

Export-friendly logistics and packaging tailored to international compliance.

✔ Customer-Centric Approach

Dedicated account managers for large buyers.

Pre- and post-sales support to ensure smooth technical and commercial execution.

By choosing Nafees Metal Industries, you’re not just buying M24 copper plain washers — you’re investing in reliable engineering components backed by expertise, accountability, and service excellence. We welcome our clients and sourcing teams to witness our production in action at our Mumbai-based facility.

FAQs – M24 Copper Plain Washers

What is the size of an M24 copper plain washer?

It typically has a 25 mm inner diameter and conforms to DIN 125 specifications.Where are M24 copper plain washers used?

They’re widely used in electrical, hydraulic, and industrial applications.What standards do your copper washers follow?

Our M24 washers meet DIN 125, IS 2016, and ISO 7089 standards.Do you offer customization in thickness or diameter?

Yes, we manufacture washers with custom dimensions on bulk orders.Can these washers be used in corrosive environments?

Yes, copper offers natural corrosion resistance and is suitable for such conditions.What surface finishes are available?

We offer plain, annealed, and electro-tinned finishes.Do you ship across India and globally?

Yes, we supply nationwide and export worldwide with complete logistics support.What is the minimum order quantity?

MOQs vary by size and customization; contact us for specifics.Are these washers non-magnetic?

Yes, copper is a non-magnetic material.How are M24 copper washers packaged?

In poly bags, cartons, or as per client specifications.Can I get a test certificate for copper purity?

Yes, we provide test certificates on request.Is copper better than mild steel for washers?

For conductivity and corrosion resistance, copper is far superior.What industries commonly use M24 copper washers?

Power, oil & gas, electronics, HVAC, and railway industries.Do you offer same-day dispatch?

For in-stock items, yes—same-day or next-day dispatch is available.What is your production capacity for M24 washers?

We maintain high production capacity to support bulk and OEM orders.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch