No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M33 Mild Steel Plain Washers"

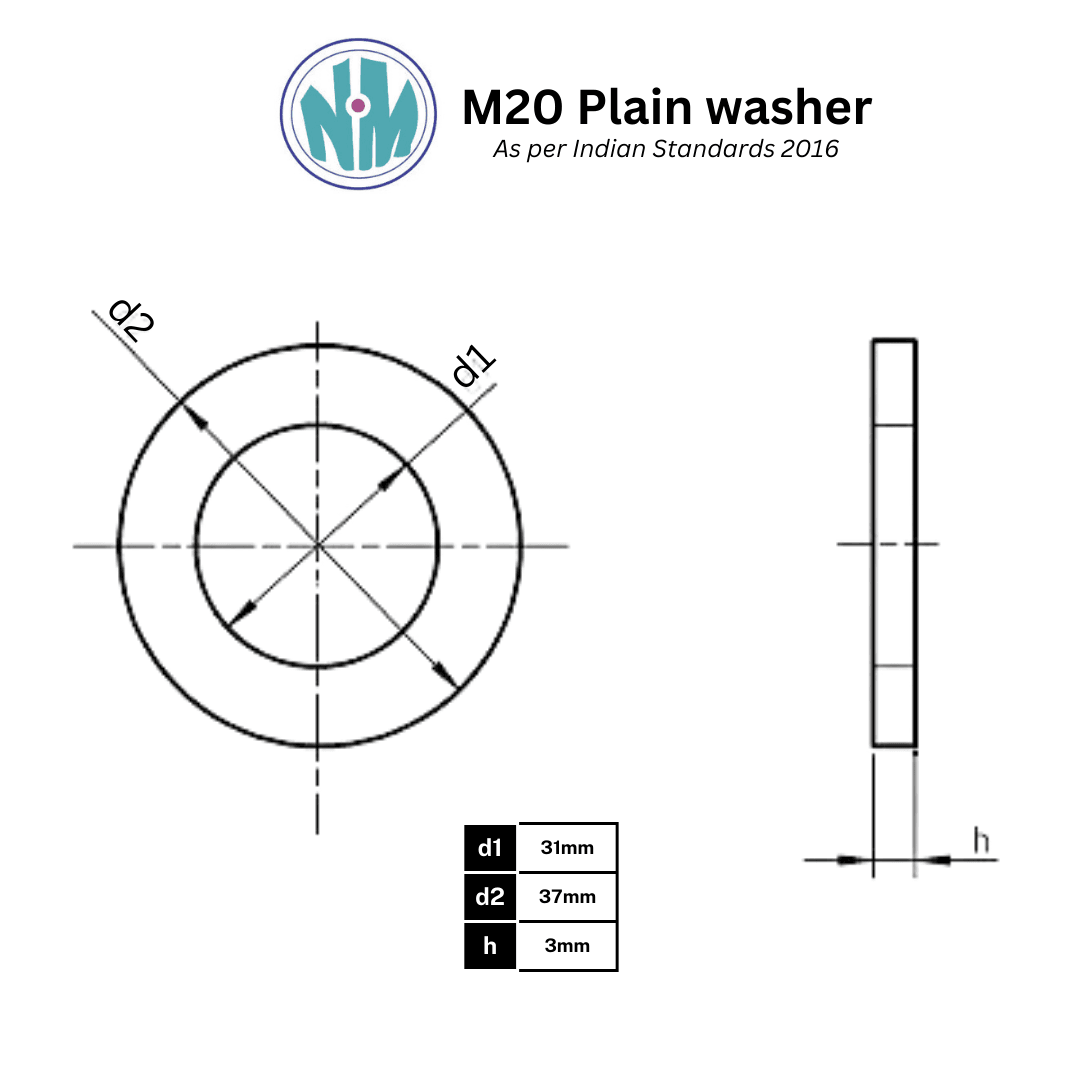

*Images shown for graphic representation. Not to scale.

M20 SS304 Plain Washers – Precision Stainless Steel Flat Washers for Heavy-Duty Applications

At Nafees Metal Industries, we proudly manufacture and supply premium M20 SS304 Plain Washers, meticulously engineered for demanding industrial environments where strength, corrosion resistance, and long-term reliability are non-negotiable. Designed for compatibility with M20 bolts and fasteners, these plain washers serve as critical components in load-bearing assemblies across sectors such as construction, machinery, heavy equipment manufacturing, marine engineering, and infrastructure development.

Each M20 SS304 Plain Washer is fabricated from high-grade AISI 304 stainless steel, renowned for its excellent resistance to rust, oxidation, and chemical exposure. Whether it’s a heavy structural connection or a high-vibration mechanical setup, these washers act as a protective barrier—distributing load, minimizing bolt loosening, and protecting surfaces from damage. Their non-magnetic, heat-resistant nature makes them suitable for applications in harsh and high-temperature conditions.

As one of the best plain washer manufacturers in India, Nafees Metal Industries ensures every washer adheres to international standards such as IS 2016, DIN 125, and ISO 7089. We maintain strict dimensional accuracy, uniform thickness, and a clean finish to enable hassle-free assembly and extended service life. With a modern manufacturing setup in Mumbai and bulk inventory support, we deliver customized solutions and packaging tailored to OEMs, distributors, and exporters across India and abroad.

Whether you’re sourcing for critical infrastructure projects, marine equipment, or industrial installations, our M20 SS304 Plain Washers are the ideal choice when performance matters.

What Are M20 SS304 Plain Washers?

M20 SS304 Plain Washers are flat, disc-shaped components designed to be used with M20-size bolts and fasteners. These washers are manufactured from stainless steel grade 304 (SS304)—an austenitic, corrosion-resistant steel known for its excellent strength, ductility, and durability. The primary role of these washers is to distribute the load of a threaded fastener evenly across the surface, prevent bolt loosening due to vibration, and protect the mating surfaces from damage.

The designation “M20” refers to the inner diameter of the washer, which is precisely crafted to accommodate M20 bolts or threaded rods. Typically used in mechanical assemblies, structural frameworks, heavy-duty equipment, and marine or corrosive environments, these washers are favored for their non-rusting, heat-resistant, and long-lasting properties.

Here are the key characteristics that define M20 SS304 Plain Washers:

Material: AISI 304 Stainless Steel, which includes chromium and nickel for enhanced corrosion resistance

Compatibility: Fits perfectly with M20 bolts (20mm nominal diameter)

Form: Flat, smooth washer with a round shape and a central hole

Functionality: Distributes pressure, protects surfaces, ensures tight fastening, and prevents damage due to high torque

Compliance: Manufactured in line with international standards like DIN 125 / ISO 7089 / IS 2016

Because of their excellent strength-to-weight ratio, resistance to rust and oxidation, and ability to perform under high stress, M20 SS304 Plain Washers are essential in industrial, commercial, and architectural applications where reliability and longevity are key. These washers also provide electrical insulation in assemblies and are highly preferred in hygienic or outdoor environments, including food processing, marine, and chemical processing sectors.

When sourced from reputed manufacturers like Nafees Metal Industries, buyers are assured of precision-engineered, defect-free washers that can be supplied in custom finishes, bulk quantities, and varied sizes depending on project needs.

Why SS304 Stainless Steel for M20 Washers?

When it comes to selecting the ideal material for flat washers like M20 Plain Washers, SS304 stainless steel stands out as the industry standard for a wide range of demanding applications. The choice of SS304 is not incidental—it’s backed by decades of proven performance in mechanical, structural, marine, and industrial use cases.

Here’s why SS304 stainless steel is the preferred material for manufacturing M20 plain washers:

1. Superior Corrosion Resistance

SS304 contains approximately 18% chromium and 8% nickel, forming a protective oxide layer on its surface that prevents rust and oxidation—even in moist, humid, or chemically aggressive environments. This makes SS304 ideal for washers used outdoors, in marine applications, or in industrial zones exposed to oils, acids, or salts.

2. High Strength and Durability

M20 SS304 Plain Washers must withstand high clamping forces and torque pressures when used in heavy machinery or structural assemblies. SS304 offers excellent tensile strength and wear resistance, ensuring that the washers do not crack, deform, or fatigue under pressure.

3. Excellent Fabrication and Machinability

SS304 allows for easy punching, cutting, and forming, which is critical for achieving precise tolerances in washer dimensions. Whether standard or custom washers are needed, SS304 offers manufacturing flexibility without compromising quality.

4. Temperature Resistance

SS304 performs well in high-temperature environments, withstanding temperatures up to 870°C (or more under specific conditions). This makes M20 SS304 Plain Washers reliable in engines, exhaust systems, and other heat-intensive applications.

5. Hygienic and Non-Magnetic Properties

In addition to mechanical performance, SS304 is known for its non-reactive surface, making it safe for use in food processing, pharmaceutical, and cleanroom applications. Moreover, it is non-magnetic in its annealed state, which is essential for applications where magnetic interference must be avoided.

6. Long-Term Value

Though SS304 washers might have a higher initial cost than carbon steel or mild steel alternatives, they offer significantly lower lifecycle costs due to their durability, minimal maintenance, and long service life. This ensures long-term savings and reduces the need for frequent replacements.

7. Global Availability and Standardization

SS304 is one of the most widely used and internationally standardized grades of stainless steel. Its availability across global markets ensures that M20 SS304 Plain Washers conform to leading norms like DIN, ASTM, IS, and ISO standards, offering consistency in quality and fitment.

How Are M20 SS304 Plain Washers Manufactured?

At Nafees Metal Industries, we follow a precise, quality-driven, and ISO-certified manufacturing process to produce premium-grade M20 SS304 Plain Washers. Every washer that leaves our facility is a result of meticulous engineering, advanced machinery, and strict quality control.

Here’s a detailed look at how our M20 SS304 Plain Washers are manufactured:

1. Selection of Raw Material – SS304 Cold Rolled Stainless Steel Sheets

The process begins with sourcing high-quality cold-rolled SS304 stainless steel sheets, known for their uniformity, mechanical strength, and corrosion resistance. Only certified and traceable SS304 grade sheets are used to ensure compliance with international standards such as ASTM A240 / A276 and DIN 125.

These sheets are selected based on the required thickness, grain orientation, and flatness, ensuring consistency across every washer batch.

2. CNC-Based Precision Punching

Once the raw material is ready, it is fed into automated CNC punching machines. Using customized dies and tools, we accurately punch the washers to meet the M20 internal diameter specifications (typically around 21 mm ID) and precise outer diameters and thicknesses according to client requirements.

CNC punching offers:

Tight tolerances for flawless fit

High repeatability across large volumes

Minimal material wastage

Speed and accuracy, even in bulk production

3. Deburring, Polishing & Cleaning

After punching, washers often have micro-burrs or sharp edges. These are removed through a controlled deburring process using tumbling or vibratory finishing.

This is followed by:

Polishing to smoothen the surface

Degreasing and cleaning to remove oil, metal particles, or dust

Ultrasonic cleaning (if required) for specialty applications such as food-grade or pharma usage

The result is a smooth, burr-free washer with excellent surface integrity.

4. Optional Surface Treatment or Passivation

Although SS304 is naturally corrosion-resistant, we offer additional surface treatments based on application needs:

Electropolishing for enhanced brightness and corrosion resistance

Passivation to remove free iron and improve oxide layer formation

Pickling for applications requiring ultra-clean surfaces

Coating or PTFE finish (on request) for added protection or low-friction needs

These treatments further enhance aesthetic appeal, chemical resistance, and durability, especially in marine, chemical, or high-humidity environments.

5. Quality Inspection and Dimensional Verification

Every batch of M20 SS304 Plain Washers undergoes rigorous quality checks as part of our ISO-certified QC protocol. This includes:

Inner Diameter (ID) Measurement: To ensure M20 bolt compatibility

Outer Diameter (OD) Check: Based on DIN or custom specs

Thickness Verification: Using calibrated micrometers

Visual Inspection: For scratches, burrs, or surface defects

Hardness Testing: As per application (optional)

Salt Spray or Corrosion Test Reports: Available on request

We provide inspection certificates, batch traceability, and even third-party testing (if required) to ensure customer confidence.

6. Packaging and Dispatch

Once approved, the washers are packed in moisture-resistant, labeled cartons with clear batch markings. For bulk orders or export, we provide:

Wooden palletized packing

Custom labeling and barcoding

Tamper-proof sealing

This guarantees that M20 SS304 Plain Washers reach customers in perfect, corrosion-free condition, ready for immediate use. At Nafees Metal Industries, we don’t just manufacture washers—we deliver precision-engineered solutions trusted by industries worldwide. Our commitment to quality, customization, and timely delivery makes us one of the leading manufacturers of plain washers in India, especially for clients seeking durable, corrosion-resistant, and ISO-compliant stainless steel flat washers.

Key Features of M20 SS304 Plain Washers

- Designed for M20 Bolts: Precise inner diameter fits securely around M20 fasteners.

- Flat Load Distribution: Prevents bolt head damage and surface indentation.

- Superior Corrosion Resistance: Withstands moisture, chemicals, and industrial conditions.

- Non-Magnetic & Hygienic: Suitable for cleanroom, medical, and food equipment installations.

- Available in Bulk: Ready stock for industrial procurement and OEM supply.

- Surface Options: Available in plain, mirror polished, or brushed finishes.

- Made in India: Manufactured with advanced tools and skilled labor in our Mumbai facility.

Technical Specifications

| Property | Specification |

|---|---|

| Product Name | M20 SS304 Plain Washer |

| Material | SS304 Stainless Steel |

| Inner Diameter (ID) | Approx. 21.0 mm (fits M20 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 |

| Thickness | 2.0 mm – 4.0 mm (Customizable) |

| Surface Finish | Plain / Polished / Brushed |

| Standard Compliance | DIN 125 / ISO 7089 / IS 2016 |

| Application Category | Heavy-Duty Industrial, Marine, Automotive |

| Packaging | Bulk / Polybag / Carton / Custom Labeling |

Applications of M20 SS304 Plain Washers

M20 SS304 Plain Washers are highly valued across industries due to their corrosion resistance, durability, dimensional accuracy, and ability to distribute load uniformly. As trusted components in high-performance fastening systems, they serve a crucial role in enhancing the integrity, longevity, and safety of bolted joints.

Here’s a detailed overview of where M20 SS304 Plain Washers are commonly used:

1. Structural Engineering

In the construction of bridges, buildings, towers, and metal frameworks, M20 SS304 Plain Washers are used to:

Provide a stable surface for nuts and bolts on steel beams and plates

Prevent damage to structural components by evenly distributing load

Withstand outdoor exposure due to their excellent weather and rust resistance

Enhance the life of fasteners in critical load-bearing joints

Their M20 size is ideal for large structural bolts used in high-stress environments.

2. Shipbuilding & Marine Applications

SS304’s resistance to chlorides and salt spray makes these washers indispensable in:

Ship hull assembly

Offshore platforms and docking systems

Boating equipment and propeller mountings

Marine pipelines and underwater systems

The non-corrosive nature of SS304 ensures long service life in saltwater environments, reducing the need for frequent replacements.

3. Oil & Gas Industry

In the oil refining, drilling rigs, and petrochemical sectors, M20 SS304 Plain Washers serve the following purposes:

Secure flange connections in pipeline systems

Reinforce bolted joints in pressure vessels and storage tanks

Resist corrosion in hydrocarbon-rich or chemically active environments

Provide sealing support where tight fastening is critical to prevent leaks or vibrations

4. Power Plants & Energy Infrastructure

From thermal and hydroelectric plants to nuclear and solar facilities, M20 SS304 Plain Washers are used to:

Withstand high-temperature zones without deforming

Ensure strong, vibration-resistant fastening of turbine assemblies, support brackets, and frames

Maintain bolt alignment under heavy loads in high-pressure systems

Offer resistance to thermal fatigue in constantly fluctuating heat conditions

5. Automotive Industry

Within engine assemblies, suspension systems, chassis frameworks, and braking mechanisms, these washers serve critical functions:

Provide vibration dampening and shock absorption

Prevent metal-on-metal contact between bolt heads and sensitive components

Withstand exposure to engine heat, road moisture, and oils

Enable durable fastening that meets ISO and automotive-grade specifications

6. Food & Beverage Processing Equipment

In industries where hygiene, corrosion resistance, and non-contaminating materials are essential, M20 SS304 Plain Washers are used in:

Bottling machines and conveyors

Meat and dairy processing units

Commercial kitchen equipment

Brewing and fermentation systems

SS304’s non-reactive surface and ability to resist microbial buildup make it a preferred choice for applications requiring FDA compliance or food-grade fasteners.

7. Heavy Machinery & Industrial Equipment

For applications involving dynamic loads, vibrations, and mechanical shocks, these washers are used in:

Earthmoving and construction equipment

Mining tools and conveyor systems

Press machines and hydraulic assemblies

Agricultural and textile machinery

M20 SS304 Plain Washers act as load-distributing buffer elements, protecting bolts from excessive stress and reducing chances of loosening under vibration.

8. Chemical Processing Industry

Due to their chemical inertness and oxidation resistance, these washers are ideal for:

Acidic and alkaline processing equipment

Storage tanks and piping systems

Valves and instrumentation panels

Flange and clamp connections in corrosive settings

SS304 ensures longevity and operational safety in environments exposed to harsh chemicals.

At Nafees Metal Industries, we specialize in supplying M20 SS304 Plain Washers that meet demanding applications across these industries. Whether it’s structural durability, marine-grade corrosion protection, or precision in critical machinery, our washers are trusted by OEMs, contractors, and industrial users throughout India and internationally.

We offer bulk supply, customized packaging, and size specifications to meet your project requirements. Partner with one of the best manufacturers of stainless steel plain washers in India and experience reliability in every fastening solution.

Advantages of Using M20 SS304 Plain Washers

- Enhanced load distribution reduces stress on fasteners.

- Ideal for both static and dynamic mechanical loads.

- Longer service life compared to mild steel washers.

- Non-corrosive and maintenance-free under most conditions.

- Suitable for professional, industrial, and commercial installations.

Buy M20 SS304 Stainless Steel Plain Washers in Bulk, Best M20 SS304 Plain Washers Manufacturer Nafees Metal Industries is trusted as one of the Best M20 SS304 Plain Washers Manufacturers in India. We support bulk orders for industries across sectors with:

- Competitive pricing for bulk procurement

- Quality assurance with every dispatch

- Customization in dimensions and surface finishes

- Export-ready documentation and packaging

- PAN India delivery and OEM support

Case Study: Marine Engineering Firm Reduces Corrosion Failures with M20 SS304 Plain Washers from Nafees Metal Industries

A prominent marine construction company operating along India’s western coast was experiencing premature washer failures in its critical dock installations. The company had been using standard zinc-coated mild steel washers, which could not withstand the aggressive saltwater environment and intense humidity associated with coastal infrastructure.

The Challenge

The client faced several recurring issues:

Frequent corrosion of washers within 3–5 months of installation

High maintenance cycles, with the need for re-fastening bolts due to washer degradation

Structural instability concerns in load-bearing dock components

Customer dissatisfaction and operational delays due to constant repairs

These problems were not only increasing their material costs but also threatening their reputation for delivering long-lasting marine structures.

The Solution: Transition to M20 SS304 Plain Washers from Nafees Metal Industries

After evaluating various material options, the engineering firm approached Nafees Metal Industries, one of the best manufacturers of SS plain washers in India, for a long-term solution. We recommended our M20 SS304 Plain Washers due to their proven performance in harsh marine environments, outstanding resistance to chloride-induced corrosion, and load-bearing reliability.

Our washers were:

Manufactured using high-grade cold-rolled SS304 stainless steel

Engineered with tight dimensional tolerances for perfect bolt fit

Surface-polished for enhanced resistance to pitting and crevice corrosion

Inspected thoroughly under ISO-certified quality assurance systems

We supplied a batch of 10,000 M20 SS304 Plain Washers for use in their jetty support structures, bridge reinforcement plates, and underwater dock fasteners.

The Results: Dramatic Performance Improvements

Within just 8 months of implementation, the client reported significant improvements across multiple parameters:

Equipment Longevity Improved by 45%

The upgraded fastening system exhibited exceptional durability. The SS304 Plain Washers maintained their structural integrity and resisted metal fatigue, even under constant tidal movement and salty air.

Re-Fastening Requirements Dropped by 30%

The washers prevented bolt loosening and maintained clamp load effectively, reducing the need for routine torque checks and manual tightening—saving both labor time and costs.

Zero Corrosion Found in Field Inspections

Post-installation inspections conducted after 8 months revealed no visible signs of rust, discoloration, or surface corrosion, validating the superior anti-corrosive performance of our washers compared to previous alternatives.

Client Satisfaction and Re-Order Volume Doubled

Impressed by the results, the company not only placed a repeat order within the same quarter but also adopted SS304 Plain Washers as a standard across all their marine engineering projects. Their procurement team cited “Nafees’ technical expertise and product reliability” as a key driver behind this decision.

Conclusion

This case study highlights how Nafees Metal Industries’ M20 SS304 Plain Washers provided a critical engineering advantage for the marine construction industry. By switching to our stainless steel washers, the client achieved:

Reduced operational disruptions

Higher return on infrastructure investment

Increased customer satisfaction and project delivery efficiency

We continue to serve clients in the marine, offshore, and coastal infrastructure sectors, delivering long-lasting fastening solutions that stand up to the harshest environments.

Why Choose Nafees Metal Industries?

- Decades of Excellence: Trusted manufacturer of stainless steel washers in India

- Consistent Quality: Tolerance-verified washers meeting ISO, DIN, and IS standards

- Scalable Capacity: High-volume manufacturing with short lead times

- Transparent Supply: Real-time order tracking and dedicated customer support

- Made in India Brand: Focused on quality, affordability, and local job creation

When you choose Nafees Metal Industries, you’re partnering with one of India’s trusted M20 SS304 Stainless Steel Plain Washers manufacturers. We combine modern production technology, high-grade raw materials, and strict quality checks to deliver washers that exceed industry standards.

Frequently Asked Questions (FAQs)

- What is the standard size of M20 SS304 Plain Washers?

- M20 SS304 Plain Washers typically have a 21 mm inner diameter with 2–4 mm thickness, as per DIN 125 or ISO 7089 standards.

- M20 SS304 Plain Washers typically have a 21 mm inner diameter with 2–4 mm thickness, as per DIN 125 or ISO 7089 standards.

- Can M20 SS304 Plain Washers be used in outdoor environments?

- Yes, SS304 offers excellent corrosion resistance and is ideal for outdoor or marine applications.

- Yes, SS304 offers excellent corrosion resistance and is ideal for outdoor or marine applications.

- Are these washers compatible with galvanized bolts?

- Yes, M20 SS304 Plain Washers are compatible with galvanized or stainless bolts

- Yes, M20 SS304 Plain Washers are compatible with galvanized or stainless bolts

- Do you provide surface treatments?

- Yes, we offer plain, mirror polished, and brushed finishes.

- Yes, we offer plain, mirror polished, and brushed finishes.

- Can I get M20 SS304 Plain Washers in bulk?

- Absolutely. We specialize in bulk supply for OEMs and industrial contractors.

- Absolutely. We specialize in bulk supply for OEMs and industrial contractors.

- Are these washers available in custom sizes?

- Yes, we manufacture custom dimensions upon request.

- Yes, we manufacture custom dimensions upon request.

- What standards do your washers comply with?

- Our M20 SS304 Plain Washers comply with DIN 125, IS 2016, and ISO 7089.

- Our M20 SS304 Plain Washers comply with DIN 125, IS 2016, and ISO 7089.

- What is the weight of one M20 SS304 Plain Washer?

- Approx. 20–25 grams depending on thickness and OD.

- Approx. 20–25 grams depending on thickness and OD.

- What is the typical lead time for bulk orders?

- Generally 3–7 working days for stocked items; customized orders may take longer.

- Generally 3–7 working days for stocked items; customized orders may take longer.

- How are the washers packaged?

- We offer polybags, cartons, or customized industrial packaging as per client needs.

- Is SS304 suitable for chemical industries?

- Yes, SS304 has good chemical resistance for general industrial use.

- Do you export M20 SS304 Plain Washers?

- Yes, we export across the Middle East, Southeast Asia, and Africa.

- Can I request material test certificates?

- Yes, MTCs are available upon request.

- Are these washers magnetic?

- SS304 is generally non-magnetic in the annealed condition.

- Why choose Nafees Metal Industries for SS304 Washers?

- Our commitment to precision, durability, customer support, and affordable pricing makes us a preferred choice across industries.

Visit Us

Discover the difference with a supplier who puts your needs first. Visit our fully equipped manufacturing unit at Reay Road, Mumbai, or contact our team for a free quote or custom order.

Nafees Metal industries — your trusted partner for high-performance SS304 Plain Washers.

M20 SS304 Plain Washers

25 people are viewing this product right now

₹10.20 Original price was: ₹10.20.₹8.50Current price is: ₹8.50. /per piece

Specification:

Material: Stainless Steel – SS304

Nominal Size (g): M20

Inner Diameter (ID): 21 mm

Outer Diameter (OD): 37 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M20 SS304 Plain Washers – Precision Stainless Steel Flat Washers for Heavy-Duty Applications

At Nafees Metal Industries, we proudly manufacture and supply premium M20 SS304 Plain Washers, meticulously engineered for demanding industrial environments where strength, corrosion resistance, and long-term reliability are non-negotiable. Designed for compatibility with M20 bolts and fasteners, these plain washers serve as critical components in load-bearing assemblies across sectors such as construction, machinery, heavy equipment manufacturing, marine engineering, and infrastructure development.

Each M20 SS304 Plain Washer is fabricated from high-grade AISI 304 stainless steel, renowned for its excellent resistance to rust, oxidation, and chemical exposure. Whether it’s a heavy structural connection or a high-vibration mechanical setup, these washers act as a protective barrier—distributing load, minimizing bolt loosening, and protecting surfaces from damage. Their non-magnetic, heat-resistant nature makes them suitable for applications in harsh and high-temperature conditions.

As one of the best plain washer manufacturers in India, Nafees Metal Industries ensures every washer adheres to international standards such as IS 2016, DIN 125, and ISO 7089. We maintain strict dimensional accuracy, uniform thickness, and a clean finish to enable hassle-free assembly and extended service life. With a modern manufacturing setup in Mumbai and bulk inventory support, we deliver customized solutions and packaging tailored to OEMs, distributors, and exporters across India and abroad.

Whether you’re sourcing for critical infrastructure projects, marine equipment, or industrial installations, our M20 SS304 Plain Washers are the ideal choice when performance matters.

What Are M20 SS304 Plain Washers?

M20 SS304 Plain Washers are flat, disc-shaped components designed to be used with M20-size bolts and fasteners. These washers are manufactured from stainless steel grade 304 (SS304)—an austenitic, corrosion-resistant steel known for its excellent strength, ductility, and durability. The primary role of these washers is to distribute the load of a threaded fastener evenly across the surface, prevent bolt loosening due to vibration, and protect the mating surfaces from damage.

The designation “M20” refers to the inner diameter of the washer, which is precisely crafted to accommodate M20 bolts or threaded rods. Typically used in mechanical assemblies, structural frameworks, heavy-duty equipment, and marine or corrosive environments, these washers are favored for their non-rusting, heat-resistant, and long-lasting properties.

Here are the key characteristics that define M20 SS304 Plain Washers:

Material: AISI 304 Stainless Steel, which includes chromium and nickel for enhanced corrosion resistance

Compatibility: Fits perfectly with M20 bolts (20mm nominal diameter)

Form: Flat, smooth washer with a round shape and a central hole

Functionality: Distributes pressure, protects surfaces, ensures tight fastening, and prevents damage due to high torque

Compliance: Manufactured in line with international standards like DIN 125 / ISO 7089 / IS 2016

Because of their excellent strength-to-weight ratio, resistance to rust and oxidation, and ability to perform under high stress, M20 SS304 Plain Washers are essential in industrial, commercial, and architectural applications where reliability and longevity are key. These washers also provide electrical insulation in assemblies and are highly preferred in hygienic or outdoor environments, including food processing, marine, and chemical processing sectors.

When sourced from reputed manufacturers like Nafees Metal Industries, buyers are assured of precision-engineered, defect-free washers that can be supplied in custom finishes, bulk quantities, and varied sizes depending on project needs.

Why SS304 Stainless Steel for M20 Washers?

When it comes to selecting the ideal material for flat washers like M20 Plain Washers, SS304 stainless steel stands out as the industry standard for a wide range of demanding applications. The choice of SS304 is not incidental—it’s backed by decades of proven performance in mechanical, structural, marine, and industrial use cases.

Here’s why SS304 stainless steel is the preferred material for manufacturing M20 plain washers:

1. Superior Corrosion Resistance

SS304 contains approximately 18% chromium and 8% nickel, forming a protective oxide layer on its surface that prevents rust and oxidation—even in moist, humid, or chemically aggressive environments. This makes SS304 ideal for washers used outdoors, in marine applications, or in industrial zones exposed to oils, acids, or salts.

2. High Strength and Durability

M20 SS304 Plain Washers must withstand high clamping forces and torque pressures when used in heavy machinery or structural assemblies. SS304 offers excellent tensile strength and wear resistance, ensuring that the washers do not crack, deform, or fatigue under pressure.

3. Excellent Fabrication and Machinability

SS304 allows for easy punching, cutting, and forming, which is critical for achieving precise tolerances in washer dimensions. Whether standard or custom washers are needed, SS304 offers manufacturing flexibility without compromising quality.

4. Temperature Resistance

SS304 performs well in high-temperature environments, withstanding temperatures up to 870°C (or more under specific conditions). This makes M20 SS304 Plain Washers reliable in engines, exhaust systems, and other heat-intensive applications.

5. Hygienic and Non-Magnetic Properties

In addition to mechanical performance, SS304 is known for its non-reactive surface, making it safe for use in food processing, pharmaceutical, and cleanroom applications. Moreover, it is non-magnetic in its annealed state, which is essential for applications where magnetic interference must be avoided.

6. Long-Term Value

Though SS304 washers might have a higher initial cost than carbon steel or mild steel alternatives, they offer significantly lower lifecycle costs due to their durability, minimal maintenance, and long service life. This ensures long-term savings and reduces the need for frequent replacements.

7. Global Availability and Standardization

SS304 is one of the most widely used and internationally standardized grades of stainless steel. Its availability across global markets ensures that M20 SS304 Plain Washers conform to leading norms like DIN, ASTM, IS, and ISO standards, offering consistency in quality and fitment.

How Are M20 SS304 Plain Washers Manufactured?

At Nafees Metal Industries, we follow a precise, quality-driven, and ISO-certified manufacturing process to produce premium-grade M20 SS304 Plain Washers. Every washer that leaves our facility is a result of meticulous engineering, advanced machinery, and strict quality control.

Here’s a detailed look at how our M20 SS304 Plain Washers are manufactured:

1. Selection of Raw Material – SS304 Cold Rolled Stainless Steel Sheets

The process begins with sourcing high-quality cold-rolled SS304 stainless steel sheets, known for their uniformity, mechanical strength, and corrosion resistance. Only certified and traceable SS304 grade sheets are used to ensure compliance with international standards such as ASTM A240 / A276 and DIN 125.

These sheets are selected based on the required thickness, grain orientation, and flatness, ensuring consistency across every washer batch.

2. CNC-Based Precision Punching

Once the raw material is ready, it is fed into automated CNC punching machines. Using customized dies and tools, we accurately punch the washers to meet the M20 internal diameter specifications (typically around 21 mm ID) and precise outer diameters and thicknesses according to client requirements.

CNC punching offers:

Tight tolerances for flawless fit

High repeatability across large volumes

Minimal material wastage

Speed and accuracy, even in bulk production

3. Deburring, Polishing & Cleaning

After punching, washers often have micro-burrs or sharp edges. These are removed through a controlled deburring process using tumbling or vibratory finishing.

This is followed by:

Polishing to smoothen the surface

Degreasing and cleaning to remove oil, metal particles, or dust

Ultrasonic cleaning (if required) for specialty applications such as food-grade or pharma usage

The result is a smooth, burr-free washer with excellent surface integrity.

4. Optional Surface Treatment or Passivation

Although SS304 is naturally corrosion-resistant, we offer additional surface treatments based on application needs:

Electropolishing for enhanced brightness and corrosion resistance

Passivation to remove free iron and improve oxide layer formation

Pickling for applications requiring ultra-clean surfaces

Coating or PTFE finish (on request) for added protection or low-friction needs

These treatments further enhance aesthetic appeal, chemical resistance, and durability, especially in marine, chemical, or high-humidity environments.

5. Quality Inspection and Dimensional Verification

Every batch of M20 SS304 Plain Washers undergoes rigorous quality checks as part of our ISO-certified QC protocol. This includes:

Inner Diameter (ID) Measurement: To ensure M20 bolt compatibility

Outer Diameter (OD) Check: Based on DIN or custom specs

Thickness Verification: Using calibrated micrometers

Visual Inspection: For scratches, burrs, or surface defects

Hardness Testing: As per application (optional)

Salt Spray or Corrosion Test Reports: Available on request

We provide inspection certificates, batch traceability, and even third-party testing (if required) to ensure customer confidence.

6. Packaging and Dispatch

Once approved, the washers are packed in moisture-resistant, labeled cartons with clear batch markings. For bulk orders or export, we provide:

Wooden palletized packing

Custom labeling and barcoding

Tamper-proof sealing

This guarantees that M20 SS304 Plain Washers reach customers in perfect, corrosion-free condition, ready for immediate use. At Nafees Metal Industries, we don’t just manufacture washers—we deliver precision-engineered solutions trusted by industries worldwide. Our commitment to quality, customization, and timely delivery makes us one of the leading manufacturers of plain washers in India, especially for clients seeking durable, corrosion-resistant, and ISO-compliant stainless steel flat washers.

Key Features of M20 SS304 Plain Washers

- Designed for M20 Bolts: Precise inner diameter fits securely around M20 fasteners.

- Flat Load Distribution: Prevents bolt head damage and surface indentation.

- Superior Corrosion Resistance: Withstands moisture, chemicals, and industrial conditions.

- Non-Magnetic & Hygienic: Suitable for cleanroom, medical, and food equipment installations.

- Available in Bulk: Ready stock for industrial procurement and OEM supply.

- Surface Options: Available in plain, mirror polished, or brushed finishes.

- Made in India: Manufactured with advanced tools and skilled labor in our Mumbai facility.

Technical Specifications

| Property | Specification |

|---|---|

| Product Name | M20 SS304 Plain Washer |

| Material | SS304 Stainless Steel |

| Inner Diameter (ID) | Approx. 21.0 mm (fits M20 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 |

| Thickness | 2.0 mm – 4.0 mm (Customizable) |

| Surface Finish | Plain / Polished / Brushed |

| Standard Compliance | DIN 125 / ISO 7089 / IS 2016 |

| Application Category | Heavy-Duty Industrial, Marine, Automotive |

| Packaging | Bulk / Polybag / Carton / Custom Labeling |

Applications of M20 SS304 Plain Washers

M20 SS304 Plain Washers are highly valued across industries due to their corrosion resistance, durability, dimensional accuracy, and ability to distribute load uniformly. As trusted components in high-performance fastening systems, they serve a crucial role in enhancing the integrity, longevity, and safety of bolted joints.

Here’s a detailed overview of where M20 SS304 Plain Washers are commonly used:

1. Structural Engineering

In the construction of bridges, buildings, towers, and metal frameworks, M20 SS304 Plain Washers are used to:

Provide a stable surface for nuts and bolts on steel beams and plates

Prevent damage to structural components by evenly distributing load

Withstand outdoor exposure due to their excellent weather and rust resistance

Enhance the life of fasteners in critical load-bearing joints

Their M20 size is ideal for large structural bolts used in high-stress environments.

2. Shipbuilding & Marine Applications

SS304’s resistance to chlorides and salt spray makes these washers indispensable in:

Ship hull assembly

Offshore platforms and docking systems

Boating equipment and propeller mountings

Marine pipelines and underwater systems

The non-corrosive nature of SS304 ensures long service life in saltwater environments, reducing the need for frequent replacements.

3. Oil & Gas Industry

In the oil refining, drilling rigs, and petrochemical sectors, M20 SS304 Plain Washers serve the following purposes:

Secure flange connections in pipeline systems

Reinforce bolted joints in pressure vessels and storage tanks

Resist corrosion in hydrocarbon-rich or chemically active environments

Provide sealing support where tight fastening is critical to prevent leaks or vibrations

4. Power Plants & Energy Infrastructure

From thermal and hydroelectric plants to nuclear and solar facilities, M20 SS304 Plain Washers are used to:

Withstand high-temperature zones without deforming

Ensure strong, vibration-resistant fastening of turbine assemblies, support brackets, and frames

Maintain bolt alignment under heavy loads in high-pressure systems

Offer resistance to thermal fatigue in constantly fluctuating heat conditions

5. Automotive Industry

Within engine assemblies, suspension systems, chassis frameworks, and braking mechanisms, these washers serve critical functions:

Provide vibration dampening and shock absorption

Prevent metal-on-metal contact between bolt heads and sensitive components

Withstand exposure to engine heat, road moisture, and oils

Enable durable fastening that meets ISO and automotive-grade specifications

6. Food & Beverage Processing Equipment

In industries where hygiene, corrosion resistance, and non-contaminating materials are essential, M20 SS304 Plain Washers are used in:

Bottling machines and conveyors

Meat and dairy processing units

Commercial kitchen equipment

Brewing and fermentation systems

SS304’s non-reactive surface and ability to resist microbial buildup make it a preferred choice for applications requiring FDA compliance or food-grade fasteners.

7. Heavy Machinery & Industrial Equipment

For applications involving dynamic loads, vibrations, and mechanical shocks, these washers are used in:

Earthmoving and construction equipment

Mining tools and conveyor systems

Press machines and hydraulic assemblies

Agricultural and textile machinery

M20 SS304 Plain Washers act as load-distributing buffer elements, protecting bolts from excessive stress and reducing chances of loosening under vibration.

8. Chemical Processing Industry

Due to their chemical inertness and oxidation resistance, these washers are ideal for:

Acidic and alkaline processing equipment

Storage tanks and piping systems

Valves and instrumentation panels

Flange and clamp connections in corrosive settings

SS304 ensures longevity and operational safety in environments exposed to harsh chemicals.

At Nafees Metal Industries, we specialize in supplying M20 SS304 Plain Washers that meet demanding applications across these industries. Whether it’s structural durability, marine-grade corrosion protection, or precision in critical machinery, our washers are trusted by OEMs, contractors, and industrial users throughout India and internationally.

We offer bulk supply, customized packaging, and size specifications to meet your project requirements. Partner with one of the best manufacturers of stainless steel plain washers in India and experience reliability in every fastening solution.

Advantages of Using M20 SS304 Plain Washers

- Enhanced load distribution reduces stress on fasteners.

- Ideal for both static and dynamic mechanical loads.

- Longer service life compared to mild steel washers.

- Non-corrosive and maintenance-free under most conditions.

- Suitable for professional, industrial, and commercial installations.

Buy M20 SS304 Stainless Steel Plain Washers in Bulk, Best M20 SS304 Plain Washers Manufacturer Nafees Metal Industries is trusted as one of the Best M20 SS304 Plain Washers Manufacturers in India. We support bulk orders for industries across sectors with:

- Competitive pricing for bulk procurement

- Quality assurance with every dispatch

- Customization in dimensions and surface finishes

- Export-ready documentation and packaging

- PAN India delivery and OEM support

Case Study: Marine Engineering Firm Reduces Corrosion Failures with M20 SS304 Plain Washers from Nafees Metal Industries

A prominent marine construction company operating along India’s western coast was experiencing premature washer failures in its critical dock installations. The company had been using standard zinc-coated mild steel washers, which could not withstand the aggressive saltwater environment and intense humidity associated with coastal infrastructure.

The Challenge

The client faced several recurring issues:

Frequent corrosion of washers within 3–5 months of installation

High maintenance cycles, with the need for re-fastening bolts due to washer degradation

Structural instability concerns in load-bearing dock components

Customer dissatisfaction and operational delays due to constant repairs

These problems were not only increasing their material costs but also threatening their reputation for delivering long-lasting marine structures.

The Solution: Transition to M20 SS304 Plain Washers from Nafees Metal Industries

After evaluating various material options, the engineering firm approached Nafees Metal Industries, one of the best manufacturers of SS plain washers in India, for a long-term solution. We recommended our M20 SS304 Plain Washers due to their proven performance in harsh marine environments, outstanding resistance to chloride-induced corrosion, and load-bearing reliability.

Our washers were:

Manufactured using high-grade cold-rolled SS304 stainless steel

Engineered with tight dimensional tolerances for perfect bolt fit

Surface-polished for enhanced resistance to pitting and crevice corrosion

Inspected thoroughly under ISO-certified quality assurance systems

We supplied a batch of 10,000 M20 SS304 Plain Washers for use in their jetty support structures, bridge reinforcement plates, and underwater dock fasteners.

The Results: Dramatic Performance Improvements

Within just 8 months of implementation, the client reported significant improvements across multiple parameters:

Equipment Longevity Improved by 45%

The upgraded fastening system exhibited exceptional durability. The SS304 Plain Washers maintained their structural integrity and resisted metal fatigue, even under constant tidal movement and salty air.

Re-Fastening Requirements Dropped by 30%

The washers prevented bolt loosening and maintained clamp load effectively, reducing the need for routine torque checks and manual tightening—saving both labor time and costs.

Zero Corrosion Found in Field Inspections

Post-installation inspections conducted after 8 months revealed no visible signs of rust, discoloration, or surface corrosion, validating the superior anti-corrosive performance of our washers compared to previous alternatives.

Client Satisfaction and Re-Order Volume Doubled

Impressed by the results, the company not only placed a repeat order within the same quarter but also adopted SS304 Plain Washers as a standard across all their marine engineering projects. Their procurement team cited “Nafees’ technical expertise and product reliability” as a key driver behind this decision.

Conclusion

This case study highlights how Nafees Metal Industries’ M20 SS304 Plain Washers provided a critical engineering advantage for the marine construction industry. By switching to our stainless steel washers, the client achieved:

Reduced operational disruptions

Higher return on infrastructure investment

Increased customer satisfaction and project delivery efficiency

We continue to serve clients in the marine, offshore, and coastal infrastructure sectors, delivering long-lasting fastening solutions that stand up to the harshest environments.

Why Choose Nafees Metal Industries?

- Decades of Excellence: Trusted manufacturer of stainless steel washers in India

- Consistent Quality: Tolerance-verified washers meeting ISO, DIN, and IS standards

- Scalable Capacity: High-volume manufacturing with short lead times

- Transparent Supply: Real-time order tracking and dedicated customer support

- Made in India Brand: Focused on quality, affordability, and local job creation

When you choose Nafees Metal Industries, you’re partnering with one of India’s trusted M20 SS304 Stainless Steel Plain Washers manufacturers. We combine modern production technology, high-grade raw materials, and strict quality checks to deliver washers that exceed industry standards.

Frequently Asked Questions (FAQs)

- What is the standard size of M20 SS304 Plain Washers?

- M20 SS304 Plain Washers typically have a 21 mm inner diameter with 2–4 mm thickness, as per DIN 125 or ISO 7089 standards.

- M20 SS304 Plain Washers typically have a 21 mm inner diameter with 2–4 mm thickness, as per DIN 125 or ISO 7089 standards.

- Can M20 SS304 Plain Washers be used in outdoor environments?

- Yes, SS304 offers excellent corrosion resistance and is ideal for outdoor or marine applications.

- Yes, SS304 offers excellent corrosion resistance and is ideal for outdoor or marine applications.

- Are these washers compatible with galvanized bolts?

- Yes, M20 SS304 Plain Washers are compatible with galvanized or stainless bolts

- Yes, M20 SS304 Plain Washers are compatible with galvanized or stainless bolts

- Do you provide surface treatments?

- Yes, we offer plain, mirror polished, and brushed finishes.

- Yes, we offer plain, mirror polished, and brushed finishes.

- Can I get M20 SS304 Plain Washers in bulk?

- Absolutely. We specialize in bulk supply for OEMs and industrial contractors.

- Absolutely. We specialize in bulk supply for OEMs and industrial contractors.

- Are these washers available in custom sizes?

- Yes, we manufacture custom dimensions upon request.

- Yes, we manufacture custom dimensions upon request.

- What standards do your washers comply with?

- Our M20 SS304 Plain Washers comply with DIN 125, IS 2016, and ISO 7089.

- Our M20 SS304 Plain Washers comply with DIN 125, IS 2016, and ISO 7089.

- What is the weight of one M20 SS304 Plain Washer?

- Approx. 20–25 grams depending on thickness and OD.

- Approx. 20–25 grams depending on thickness and OD.

- What is the typical lead time for bulk orders?

- Generally 3–7 working days for stocked items; customized orders may take longer.

- Generally 3–7 working days for stocked items; customized orders may take longer.

- How are the washers packaged?

- We offer polybags, cartons, or customized industrial packaging as per client needs.

- Is SS304 suitable for chemical industries?

- Yes, SS304 has good chemical resistance for general industrial use.

- Do you export M20 SS304 Plain Washers?

- Yes, we export across the Middle East, Southeast Asia, and Africa.

- Can I request material test certificates?

- Yes, MTCs are available upon request.

- Are these washers magnetic?

- SS304 is generally non-magnetic in the annealed condition.

- Why choose Nafees Metal Industries for SS304 Washers?

- Our commitment to precision, durability, customer support, and affordable pricing makes us a preferred choice across industries.

Visit Us

Discover the difference with a supplier who puts your needs first. Visit our fully equipped manufacturing unit at Reay Road, Mumbai, or contact our team for a free quote or custom order.

Nafees Metal industries — your trusted partner for high-performance SS304 Plain Washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS304 Stainless Steel Plain Washers, Washers

Tag: SS304 Stainless Steel

Got Questions?

Feel free to

Get in touch