No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

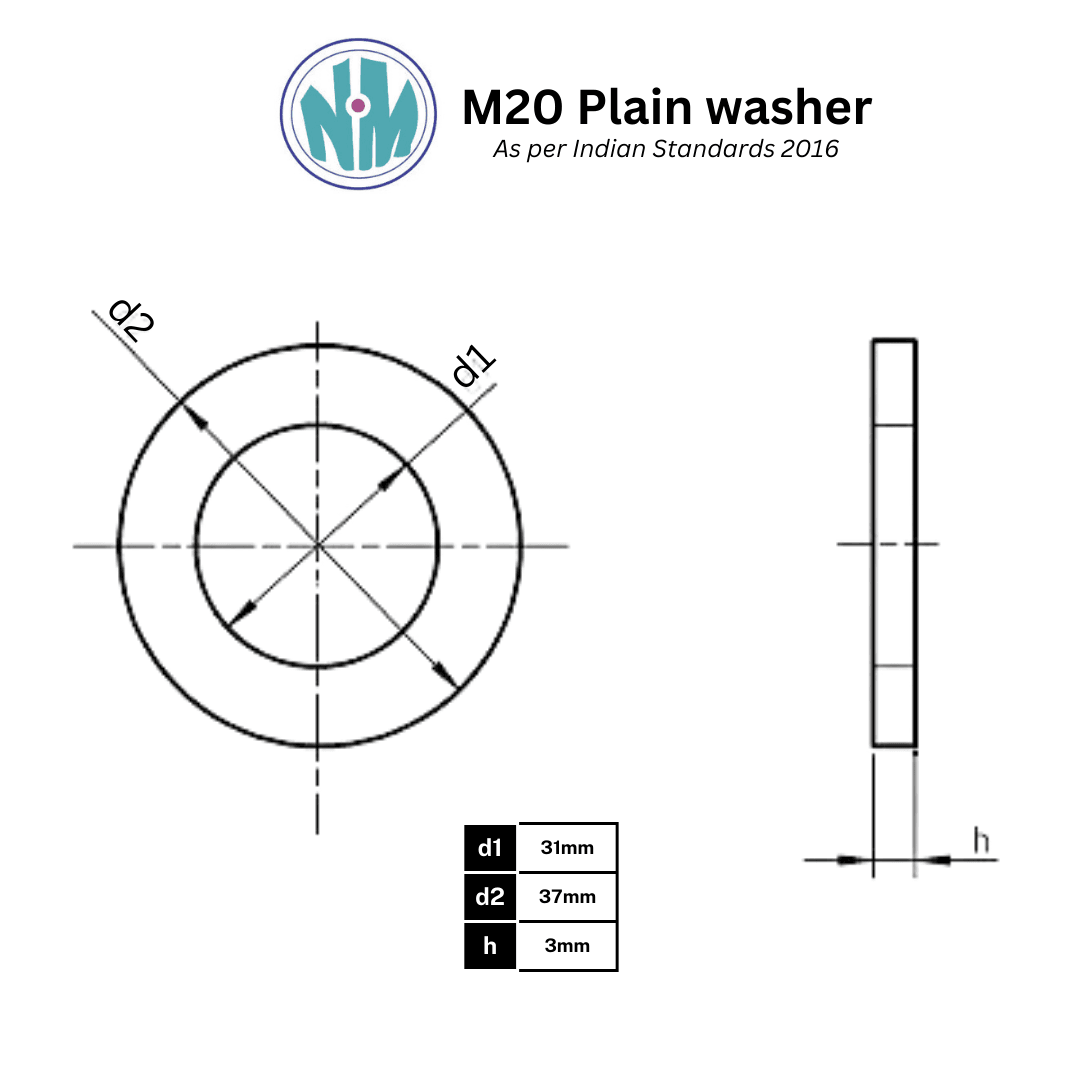

*Images shown for graphic representation. Not to scale.

M20 SS202 Plain Washers – Reliable Support for High-Performance Stainless Steel Fastening Applications

Introduction

In the world of industrial engineering, the smallest components often have the greatest impact on performance, safety, and longevity. Washers, though seemingly minor, play a critical role in the effectiveness of any bolted assembly. Their importance lies not just in their presence, but in their precision—ensuring even load distribution, surface protection, and joint stability. Among the various types available, M20 SS202 Plain Washers stand out as one of the most reliable and cost-effective options for general-purpose and industrial fastening needs.

Used across a broad spectrum of industries—from infrastructure and automotive to machinery and energy—M20 SS202 Plain Washers are engineered to enhance joint performance and prevent failures caused by uneven pressure, vibration, or material fatigue. They serve as the silent reinforcements that hold together thousands of structural and mechanical systems.

What makes these washers unique is the material they are crafted from: SS202 stainless steel. This grade offers a favorable blend of strength, corrosion resistance, and affordability—ideal for medium-duty industrial applications that demand reliability without driving up costs. With a standard inner diameter designed to fit M20 bolts precisely, these washers are both versatile and purpose-built.

When selecting fastening components, engineers and procurement teams must consider the bigger picture: performance under pressure, environmental factors, ease of installation, and long-term durability. M20 SS202 Plain Washers tick all the right boxes. They’re not just accessories to bolts and nuts—they are foundational to the integrity of the assembly itself.

As a leading manufacturer and supplier of stainless steel washers, our expertise lies in offering solutions that combine material science, manufacturing precision, and application-fit versatility. Whether you’re building a power plant, assembling a machine, or fastening a steel frame, our M20 Stainless steel Plain Washers provide the support, security, and performance your project demands.

What Are M20 SS202 Plain Washers?

M20 SS202 Plain Washers are flat, circular metal discs with a central hole sized specifically for M20 bolts. Their primary function is to distribute the clamping force of nuts or bolts evenly across the surface area of a fastened object. This simple yet crucial role helps protect the underlying material, maintain fastener tension, and reduce the risk of component loosening under stress.

From an engineering perspective, M20 SS202 Plain Washers offer multiple benefits:

Load Distribution: Spread clamping force over a wider area to prevent surface deformation or damage.

Vibration Resistance: Help maintain bolt tension by absorbing mechanical shock and vibration.

Surface Protection: Act as a buffer between metal parts to prevent galling, wear, and corrosion.

These washers are made from SS202 stainless steel, making them ideal for semi-corrosive environments and medium-duty industrial applications. Over time, using M20 SS202 Plain Washers contributes to higher reliability, fewer maintenance issues, and extended service life in both structural and machinery-based assemblies.

Material Details: Why SS202?

SS202 is a member of the austenitic family of stainless steels. It is known for its favorable blend of mechanical strength, moderate corrosion resistance, and cost-effectiveness—making it suitable for a wide range of fastening applications.

Composition of SS202:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: up to 0.08%

Comparison with Other Grades:

SS202 vs SS304: While SS304 offers higher corrosion resistance, SS202 provides comparable mechanical strength at a significantly lower cost. SS202 is ideal for inland, semi-outdoor, and lightly corrosive environments.

SS202 vs SS316: SS316 is used in highly corrosive environments like marine or chemical applications. For general industrial settings, SS202 offers better cost-performance.

Why Choose SS202 for M20 Washers:

Cost-effective alternative for industrial-grade applications

Offers sufficient corrosion resistance for most non-marine use cases

Easy to form, weld, and process

Strong and durable in load-bearing conditions

This combination of attributes makes M20 SS202 Plain Washers a smart choice for engineers and purchasing managers alike.

Manufacturing and Technical Specifications

We follow a meticulous manufacturing process to ensure dimensional accuracy, repeatability, and performance for each washer batch. Our production combines CNC machining, quality inspections, and client-specific customization.

Manufacturing Highlights:

Precision CNC machining

Degreasing and ultrasonic cleaning

Surface finishing (bright, matte, or polished)

Batch-level quality testing

Custom labeling and packaging

Product Specifications:

| Specification | Value |

|---|---|

| Inner Diameter | 21.5 mm ± 0.3 mm |

| Outer Diameter | 42.0 mm ± 0.5 mm |

| Thickness | 3.0 mm ± 0.2 mm |

| Finish | Matte, Bright, or Polished |

| Material | SS202 Stainless Steel |

| Shape | Flat Round Disc |

These technical specifications ensure that M20 SS202 Plain Washers meet the needs of precision assembly in heavy-duty settings.

Key Features

M20 SS202 Plain Washers are packed with performance advantages that make them a preferred choice in a variety of engineering, construction, and industrial applications. Each feature is designed to enhance the efficiency, safety, and longevity of fastening systems.

1. Optimized Load Distribution

One of the primary functions of these washers is to evenly distribute the load applied by the nut or bolt over a larger surface area. This prevents localized stress that can lead to cracking, deformation, or breakage in the surface material—especially important when working with softer metals, composites, or plastic housings.

2. Precision Fit for M20 Bolts

Manufactured to exact standards, these washers fit perfectly with M20 bolts, ensuring a snug, stable seating during fastening. The precise dimensions reduce play and minimize misalignment, which contributes to secure joints and long-term stability.

3. Moderate Corrosion Resistance

Made from SS202 stainless steel, these washers resist rusting and oxidation in semi-corrosive environments. While they may not be suited for marine or chemical environments, they are ideal for machinery, structures, or panels exposed to humidity, light chemicals, or outdoor weather.

4. Excellent Surface Finish

With options for bright, matte, or polished finishes, these washers offer more than just aesthetics. A smooth finish reduces friction during tightening, minimizes the risk of scoring or damaging mating surfaces, and ensures consistent torque application.

5. High Dimensional Accuracy

Advanced CNC manufacturing ensures every washer meets tight tolerances in inner diameter, outer diameter, and thickness. This accuracy allows for batch-to-batch consistency and easy compatibility with standard bolts and nuts used in industrial settings.

6. Extended Service Life

Because of their solid structural integrity and stainless steel composition, these washers stand up well to wear and tear. They can endure repeated fastening/unfastening cycles, vibration, and long-term mechanical stress without cracking, warping, or corroding.

7. Low Maintenance

These washers are designed for performance with minimal maintenance. No special cleaning or protection is required apart from regular visual inspection. In dry or indoor environments, they can last the lifetime of the assembly without any intervention.

8. Excellent Vibration Dampening

In dynamic systems—like motors, machinery, or transport applications—washers are crucial for absorbing vibration. M20 SS202 Plain Washers help maintain bolt tension under fluctuating conditions and reduce the risk of loosening due to movement.

9. SS202 Material Strength

SS202 offers a high yield strength compared to carbon steel or mild steel alternatives. It also provides moderate resistance to scaling and heat, making these washers suitable for environments with temperature variations or thermal expansion risks.

10. Flexible Packaging Options

Whether you need bulk supplies, pre-labeled boxes, or compartmentalized kits, these washers are available in custom packaging to suit warehouses, project sites, or retail distribution. We also offer private labeling and barcoding to support your supply chain.

Applications & Use Cases

M20 SS202 Plain Washers are utilized across a wide range of industries where fastening strength, long-term durability, and joint integrity are non-negotiable. Let’s explore their applications in more detail:

Automotive & Heavy Vehicles

Used in chassis frames, suspension arms, and engine mounts. These washers are key in maintaining bolt tension in dynamic environments, especially those exposed to continuous vibration and heat.

Civil Engineering & Infrastructure

Ideal for bolting in structural steel frames, bridge joints, heavy roofing systems, and load-bearing columns. They prevent surface crushing and ensure structural stability in critical applications.

Machinery & Equipment

Commonly used in motors, conveyor systems, pressure vessels, and industrial robots. M20 SS202 Plain Washers maintain fastener alignment and resist mechanical fatigue during operational stress.

Electrical Installations

Used in fastening panels, brackets, and electrical enclosures. Their corrosion resistance and dimensional stability help avoid arc flash risks and maintain enclosure integrity.

Renewable Energy

Applicable in wind turbines, solar mounting structures, and biomass plants. They provide longevity and strength for outdoor structures exposed to wind, vibration, and seasonal temperature shifts.

Railways & Transportation Infrastructure

Helps secure railway track fasteners, support frames, and transport vehicle assemblies. The washers’ vibration resistance makes them a top choice in this constantly moving environment.

DIY & Fabrication Shops

Used in repair work, furniture, custom fabrication, and agricultural machinery. Their compatibility with M20 bolts makes them a universal choice for general fastening purposes.

Why Buy M20 SS202 Plain Washers in Bulk

Buying in bulk is ideal for contractors, manufacturers, and distributors who require consistent washer performance at scale. Here’s why bulk ordering is beneficial:

Volume-Based Cost Advantage – Lower per-unit cost with bulk pricing

Reliable Inventory – Always have essential washers ready for project deadlines

Streamlined Packaging – Receive customized, labeled packaging suited to warehouse systems

Project Planning – Plan large-scale industrial rollouts with guaranteed washer availability

Reduced Procurement Cycles – Fewer purchase orders and streamlined vendor management

Whether you’re outfitting a production line or managing a high-rise build, you can confidently Buy M20 SS202 Plain Washers in Bulk with full traceability and technical documentation.

Why Choose the Best M20 SS202 Plain Washers Manufacturer

Choosing the right washer manufacturer isn’t just about pricing—it’s about trust, performance, and delivery. Here’s what sets us apart:

In-House Manufacturing – Total control over quality, timelines, and specifications

Global Certifications – ISO 9001:2015, RoHS compliance, and material traceability reports

Custom Engineering Support – Need an extra-thick washer or OD variation? We can deliver.

Bulk Logistics Expertise – Timely dispatch, tracking, and support for domestic and international clients

Client Portfolio – Trusted by EPC firms, OEMs, government contractors, and industrial traders

When looking for the Best M20 SS202 Washers for Industrial Use, count on us for quality, consistency, and technical assurance.

Installation Tips

Ensure proper installation to get the maximum value from M20 SS202 Plain Washers:

Clean contact surfaces to remove debris or oil

Place the washer flat under the bolt head or nut

Use calibrated torque wrenches for uniform tension

Avoid over-tightening which can deform the washer

Use washers on both sides (head and nut) for critical joints

Apply protective coatings if used in corrosive environments

Maintenance Guidelines

While these washers are low maintenance, best practices extend their life:

Store in sealed, moisture-free containers

Inspect periodically for rust, warping, or damage

Clean using mild detergent and soft cloth—avoid abrasives

Replace any washer showing signs of deformation or corrosion

Record washer replacement during machinery servicing cycles

Case Study: Structural Equipment Stability in Renewable Energy Plant

A renewable energy equipment supplier encountered fastening challenges during the installation of elevated platform assemblies for turbine access. These structures needed to handle both the static weight of personnel and maintenance gear as well as wind-induced vibrations.

Problem

The bolts securing the support structure were loosening within a few weeks of installation. The issue was traced back to poor load distribution and a lack of effective vibration damping. Basic mild steel washers had deformed under stress, leading to compromised joint integrity.

Solution

The engineering team decided to upgrade to M20 SS202 Plain Washers due to their better tensile strength, consistent flatness, and moderate corrosion resistance. These washers were installed in all key joints of the structure, especially where high load and vibration were expected.

Washers used: 18,000 units

Coating: Matte finish to minimize glare in open environments

Packaging: Supplied in 1,000-piece boxes with on-site delivery coordination

Certification: Provided dimensional and material test reports

Execution

The washers were installed as part of a phased maintenance and retrofitting plan across the facility. Installers noted immediate improvement in bolt seating and tension retention. Torque loss was significantly reduced, and visual inspections over time confirmed that joint integrity was sustained.

Results

| Performance Metric | Before (Old Washers) | After (M20 SS202 Plain Washers) |

|---|---|---|

| Bolt Loosening Rate | 3–4 per week | 0 per month |

| Assembly Time per Joint | 12–14 minutes | 8–9 minutes |

| Washer Failure Reports | Frequent (25%) | Rare (<1%) |

| Maintenance Cycle | Monthly | Bi-annual |

| Installer Satisfaction | Moderate | Excellent |

Feedback

Technicians and project managers reported improved confidence in structural safety and reduced rework. In the long run, switching to M20 SS202 Plain Washers helped minimize delays, material waste, and additional labor costs, thereby improving overall project profitability.

Related Products or Variants

SS202 Washers – Available in sizes M6 to M36

Stainless Steel Flat Washers – For high-load flat bearing surfaces

Metric Coated Washers – Zinc-coated, hot-dip galvanized options

Customized OD/ID Sizes – Built to client specs with technical drawings

Sample Packs – Test before bulk orders

Final Words

If your application requires strength, affordability, and consistency in fastening, then M20 SS202 Plain Washers are the perfect solution. Backed by a robust manufacturing process and years of technical expertise, our washers deliver optimal performance in critical industrial environments.

Choose long-term performance. Choose affordability. Choose M20 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

What are M20 SS202 Plain Washers used for?

They are used to distribute load, resist vibration, and protect surfaces in assemblies using M20 bolts.

Can I reuse M20 SS202 Plain Washers?

Yes, as long as they’re not warped or corroded, they can be reused.

Are these better than carbon steel washers?

Yes, especially for corrosion resistance and vibration-heavy applications.

Do you offer these washers with certifications?

Absolutely. We provide ISO and material test certificates with bulk orders.

What’s the lead time for 10,000 washers?

Typically 5–10 working days depending on customization.

Can I request a different finish?

Yes—polished, matte, or dull finish options are available.

Do you export M20 SS202 Plain Washers?

Yes, we ship globally with proper documentation.

Are they suitable for outdoor use?

Yes, in semi-corrosive environments. For marine or chemical exposure, SS316 is recommended.

What’s the minimum order quantity?

MOQ varies from 500 to 1,000 depending on packaging and custom needs.

Do you provide SS202 Washers in other sizes?

Yes, from M6 to M36 and beyond.

What makes SS202 better than mild steel?

Superior tensile strength, better corrosion resistance, and longer service life.

How thick are M20 SS202 Plain Washers?

Standard thickness is 3.0 mm, but can be customized.

Can I buy Stainless Steel Flat Washers instead?

Yes, we offer both flat and plain washers based on the application.

Do you offer trial packs before bulk order?

Yes, we can ship small sample lots for testing.

How do I order customized washers?

Share your dimensions, drawings, and finish preferences—we’ll produce accordingly.

Why Choose Nafees Metal Industries?

Trusted Manufacturer for Bulk M20 SS202 Plain Washers

For decades, we’ve supplied washers that stand up to the test of time and usage. Whether your order is large or small, you get consistent quality, competitive rates, and personalized service.

Custom Solutions & Finishes

Need something specific? Our team can help with custom dimensions, special coatings, and tailored packaging for your unique requirements.

Nationwide Reach & Excellent Support

We proudly serve industries across India with reliable lead times and transparent pricing. Our dedicated customer support team is always ready to assist with your queries, quotes, or technical needs.

Visit Us or Buy Online

Partner with Nafees Metal industries for all your fastening needs. Buy our M20 SS202 Plain Washers through our website or visit our manufacturing unit at Reay Road, Mumbai, to see our operations up close.

M20 SS202 Plain Washers

20 people are viewing this product right now

₹5.28 Original price was: ₹5.28.₹4.40Current price is: ₹4.40. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M20

Inner Diameter (ID): 21 mm

Outer Diameter (OD): 37 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M20 SS202 Plain Washers – Reliable Support for High-Performance Stainless Steel Fastening Applications

Introduction

In the world of industrial engineering, the smallest components often have the greatest impact on performance, safety, and longevity. Washers, though seemingly minor, play a critical role in the effectiveness of any bolted assembly. Their importance lies not just in their presence, but in their precision—ensuring even load distribution, surface protection, and joint stability. Among the various types available, M20 SS202 Plain Washers stand out as one of the most reliable and cost-effective options for general-purpose and industrial fastening needs.

Used across a broad spectrum of industries—from infrastructure and automotive to machinery and energy—M20 SS202 Plain Washers are engineered to enhance joint performance and prevent failures caused by uneven pressure, vibration, or material fatigue. They serve as the silent reinforcements that hold together thousands of structural and mechanical systems.

What makes these washers unique is the material they are crafted from: SS202 stainless steel. This grade offers a favorable blend of strength, corrosion resistance, and affordability—ideal for medium-duty industrial applications that demand reliability without driving up costs. With a standard inner diameter designed to fit M20 bolts precisely, these washers are both versatile and purpose-built.

When selecting fastening components, engineers and procurement teams must consider the bigger picture: performance under pressure, environmental factors, ease of installation, and long-term durability. M20 SS202 Plain Washers tick all the right boxes. They’re not just accessories to bolts and nuts—they are foundational to the integrity of the assembly itself.

As a leading manufacturer and supplier of stainless steel washers, our expertise lies in offering solutions that combine material science, manufacturing precision, and application-fit versatility. Whether you’re building a power plant, assembling a machine, or fastening a steel frame, our M20 Stainless steel Plain Washers provide the support, security, and performance your project demands.

What Are M20 SS202 Plain Washers?

M20 SS202 Plain Washers are flat, circular metal discs with a central hole sized specifically for M20 bolts. Their primary function is to distribute the clamping force of nuts or bolts evenly across the surface area of a fastened object. This simple yet crucial role helps protect the underlying material, maintain fastener tension, and reduce the risk of component loosening under stress.

From an engineering perspective, M20 SS202 Plain Washers offer multiple benefits:

Load Distribution: Spread clamping force over a wider area to prevent surface deformation or damage.

Vibration Resistance: Help maintain bolt tension by absorbing mechanical shock and vibration.

Surface Protection: Act as a buffer between metal parts to prevent galling, wear, and corrosion.

These washers are made from SS202 stainless steel, making them ideal for semi-corrosive environments and medium-duty industrial applications. Over time, using M20 SS202 Plain Washers contributes to higher reliability, fewer maintenance issues, and extended service life in both structural and machinery-based assemblies.

Material Details: Why SS202?

SS202 is a member of the austenitic family of stainless steels. It is known for its favorable blend of mechanical strength, moderate corrosion resistance, and cost-effectiveness—making it suitable for a wide range of fastening applications.

Composition of SS202:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: up to 0.08%

Comparison with Other Grades:

SS202 vs SS304: While SS304 offers higher corrosion resistance, SS202 provides comparable mechanical strength at a significantly lower cost. SS202 is ideal for inland, semi-outdoor, and lightly corrosive environments.

SS202 vs SS316: SS316 is used in highly corrosive environments like marine or chemical applications. For general industrial settings, SS202 offers better cost-performance.

Why Choose SS202 for M20 Washers:

Cost-effective alternative for industrial-grade applications

Offers sufficient corrosion resistance for most non-marine use cases

Easy to form, weld, and process

Strong and durable in load-bearing conditions

This combination of attributes makes M20 SS202 Plain Washers a smart choice for engineers and purchasing managers alike.

Manufacturing and Technical Specifications

We follow a meticulous manufacturing process to ensure dimensional accuracy, repeatability, and performance for each washer batch. Our production combines CNC machining, quality inspections, and client-specific customization.

Manufacturing Highlights:

Precision CNC machining

Degreasing and ultrasonic cleaning

Surface finishing (bright, matte, or polished)

Batch-level quality testing

Custom labeling and packaging

Product Specifications:

| Specification | Value |

|---|---|

| Inner Diameter | 21.5 mm ± 0.3 mm |

| Outer Diameter | 42.0 mm ± 0.5 mm |

| Thickness | 3.0 mm ± 0.2 mm |

| Finish | Matte, Bright, or Polished |

| Material | SS202 Stainless Steel |

| Shape | Flat Round Disc |

These technical specifications ensure that M20 SS202 Plain Washers meet the needs of precision assembly in heavy-duty settings.

Key Features

M20 SS202 Plain Washers are packed with performance advantages that make them a preferred choice in a variety of engineering, construction, and industrial applications. Each feature is designed to enhance the efficiency, safety, and longevity of fastening systems.

1. Optimized Load Distribution

One of the primary functions of these washers is to evenly distribute the load applied by the nut or bolt over a larger surface area. This prevents localized stress that can lead to cracking, deformation, or breakage in the surface material—especially important when working with softer metals, composites, or plastic housings.

2. Precision Fit for M20 Bolts

Manufactured to exact standards, these washers fit perfectly with M20 bolts, ensuring a snug, stable seating during fastening. The precise dimensions reduce play and minimize misalignment, which contributes to secure joints and long-term stability.

3. Moderate Corrosion Resistance

Made from SS202 stainless steel, these washers resist rusting and oxidation in semi-corrosive environments. While they may not be suited for marine or chemical environments, they are ideal for machinery, structures, or panels exposed to humidity, light chemicals, or outdoor weather.

4. Excellent Surface Finish

With options for bright, matte, or polished finishes, these washers offer more than just aesthetics. A smooth finish reduces friction during tightening, minimizes the risk of scoring or damaging mating surfaces, and ensures consistent torque application.

5. High Dimensional Accuracy

Advanced CNC manufacturing ensures every washer meets tight tolerances in inner diameter, outer diameter, and thickness. This accuracy allows for batch-to-batch consistency and easy compatibility with standard bolts and nuts used in industrial settings.

6. Extended Service Life

Because of their solid structural integrity and stainless steel composition, these washers stand up well to wear and tear. They can endure repeated fastening/unfastening cycles, vibration, and long-term mechanical stress without cracking, warping, or corroding.

7. Low Maintenance

These washers are designed for performance with minimal maintenance. No special cleaning or protection is required apart from regular visual inspection. In dry or indoor environments, they can last the lifetime of the assembly without any intervention.

8. Excellent Vibration Dampening

In dynamic systems—like motors, machinery, or transport applications—washers are crucial for absorbing vibration. M20 SS202 Plain Washers help maintain bolt tension under fluctuating conditions and reduce the risk of loosening due to movement.

9. SS202 Material Strength

SS202 offers a high yield strength compared to carbon steel or mild steel alternatives. It also provides moderate resistance to scaling and heat, making these washers suitable for environments with temperature variations or thermal expansion risks.

10. Flexible Packaging Options

Whether you need bulk supplies, pre-labeled boxes, or compartmentalized kits, these washers are available in custom packaging to suit warehouses, project sites, or retail distribution. We also offer private labeling and barcoding to support your supply chain.

Applications & Use Cases

M20 SS202 Plain Washers are utilized across a wide range of industries where fastening strength, long-term durability, and joint integrity are non-negotiable. Let’s explore their applications in more detail:

Automotive & Heavy Vehicles

Used in chassis frames, suspension arms, and engine mounts. These washers are key in maintaining bolt tension in dynamic environments, especially those exposed to continuous vibration and heat.

Civil Engineering & Infrastructure

Ideal for bolting in structural steel frames, bridge joints, heavy roofing systems, and load-bearing columns. They prevent surface crushing and ensure structural stability in critical applications.

Machinery & Equipment

Commonly used in motors, conveyor systems, pressure vessels, and industrial robots. M20 SS202 Plain Washers maintain fastener alignment and resist mechanical fatigue during operational stress.

Electrical Installations

Used in fastening panels, brackets, and electrical enclosures. Their corrosion resistance and dimensional stability help avoid arc flash risks and maintain enclosure integrity.

Renewable Energy

Applicable in wind turbines, solar mounting structures, and biomass plants. They provide longevity and strength for outdoor structures exposed to wind, vibration, and seasonal temperature shifts.

Railways & Transportation Infrastructure

Helps secure railway track fasteners, support frames, and transport vehicle assemblies. The washers’ vibration resistance makes them a top choice in this constantly moving environment.

DIY & Fabrication Shops

Used in repair work, furniture, custom fabrication, and agricultural machinery. Their compatibility with M20 bolts makes them a universal choice for general fastening purposes.

Why Buy M20 SS202 Plain Washers in Bulk

Buying in bulk is ideal for contractors, manufacturers, and distributors who require consistent washer performance at scale. Here’s why bulk ordering is beneficial:

Volume-Based Cost Advantage – Lower per-unit cost with bulk pricing

Reliable Inventory – Always have essential washers ready for project deadlines

Streamlined Packaging – Receive customized, labeled packaging suited to warehouse systems

Project Planning – Plan large-scale industrial rollouts with guaranteed washer availability

Reduced Procurement Cycles – Fewer purchase orders and streamlined vendor management

Whether you’re outfitting a production line or managing a high-rise build, you can confidently Buy M20 SS202 Plain Washers in Bulk with full traceability and technical documentation.

Why Choose the Best M20 SS202 Plain Washers Manufacturer

Choosing the right washer manufacturer isn’t just about pricing—it’s about trust, performance, and delivery. Here’s what sets us apart:

In-House Manufacturing – Total control over quality, timelines, and specifications

Global Certifications – ISO 9001:2015, RoHS compliance, and material traceability reports

Custom Engineering Support – Need an extra-thick washer or OD variation? We can deliver.

Bulk Logistics Expertise – Timely dispatch, tracking, and support for domestic and international clients

Client Portfolio – Trusted by EPC firms, OEMs, government contractors, and industrial traders

When looking for the Best M20 SS202 Washers for Industrial Use, count on us for quality, consistency, and technical assurance.

Installation Tips

Ensure proper installation to get the maximum value from M20 SS202 Plain Washers:

Clean contact surfaces to remove debris or oil

Place the washer flat under the bolt head or nut

Use calibrated torque wrenches for uniform tension

Avoid over-tightening which can deform the washer

Use washers on both sides (head and nut) for critical joints

Apply protective coatings if used in corrosive environments

Maintenance Guidelines

While these washers are low maintenance, best practices extend their life:

Store in sealed, moisture-free containers

Inspect periodically for rust, warping, or damage

Clean using mild detergent and soft cloth—avoid abrasives

Replace any washer showing signs of deformation or corrosion

Record washer replacement during machinery servicing cycles

Case Study: Structural Equipment Stability in Renewable Energy Plant

A renewable energy equipment supplier encountered fastening challenges during the installation of elevated platform assemblies for turbine access. These structures needed to handle both the static weight of personnel and maintenance gear as well as wind-induced vibrations.

Problem

The bolts securing the support structure were loosening within a few weeks of installation. The issue was traced back to poor load distribution and a lack of effective vibration damping. Basic mild steel washers had deformed under stress, leading to compromised joint integrity.

Solution

The engineering team decided to upgrade to M20 SS202 Plain Washers due to their better tensile strength, consistent flatness, and moderate corrosion resistance. These washers were installed in all key joints of the structure, especially where high load and vibration were expected.

Washers used: 18,000 units

Coating: Matte finish to minimize glare in open environments

Packaging: Supplied in 1,000-piece boxes with on-site delivery coordination

Certification: Provided dimensional and material test reports

Execution

The washers were installed as part of a phased maintenance and retrofitting plan across the facility. Installers noted immediate improvement in bolt seating and tension retention. Torque loss was significantly reduced, and visual inspections over time confirmed that joint integrity was sustained.

Results

| Performance Metric | Before (Old Washers) | After (M20 SS202 Plain Washers) |

|---|---|---|

| Bolt Loosening Rate | 3–4 per week | 0 per month |

| Assembly Time per Joint | 12–14 minutes | 8–9 minutes |

| Washer Failure Reports | Frequent (25%) | Rare (<1%) |

| Maintenance Cycle | Monthly | Bi-annual |

| Installer Satisfaction | Moderate | Excellent |

Feedback

Technicians and project managers reported improved confidence in structural safety and reduced rework. In the long run, switching to M20 SS202 Plain Washers helped minimize delays, material waste, and additional labor costs, thereby improving overall project profitability.

Related Products or Variants

SS202 Washers – Available in sizes M6 to M36

Stainless Steel Flat Washers – For high-load flat bearing surfaces

Metric Coated Washers – Zinc-coated, hot-dip galvanized options

Customized OD/ID Sizes – Built to client specs with technical drawings

Sample Packs – Test before bulk orders

Final Words

If your application requires strength, affordability, and consistency in fastening, then M20 SS202 Plain Washers are the perfect solution. Backed by a robust manufacturing process and years of technical expertise, our washers deliver optimal performance in critical industrial environments.

Choose long-term performance. Choose affordability. Choose M20 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

What are M20 SS202 Plain Washers used for?

They are used to distribute load, resist vibration, and protect surfaces in assemblies using M20 bolts.

Can I reuse M20 SS202 Plain Washers?

Yes, as long as they’re not warped or corroded, they can be reused.

Are these better than carbon steel washers?

Yes, especially for corrosion resistance and vibration-heavy applications.

Do you offer these washers with certifications?

Absolutely. We provide ISO and material test certificates with bulk orders.

What’s the lead time for 10,000 washers?

Typically 5–10 working days depending on customization.

Can I request a different finish?

Yes—polished, matte, or dull finish options are available.

Do you export M20 SS202 Plain Washers?

Yes, we ship globally with proper documentation.

Are they suitable for outdoor use?

Yes, in semi-corrosive environments. For marine or chemical exposure, SS316 is recommended.

What’s the minimum order quantity?

MOQ varies from 500 to 1,000 depending on packaging and custom needs.

Do you provide SS202 Washers in other sizes?

Yes, from M6 to M36 and beyond.

What makes SS202 better than mild steel?

Superior tensile strength, better corrosion resistance, and longer service life.

How thick are M20 SS202 Plain Washers?

Standard thickness is 3.0 mm, but can be customized.

Can I buy Stainless Steel Flat Washers instead?

Yes, we offer both flat and plain washers based on the application.

Do you offer trial packs before bulk order?

Yes, we can ship small sample lots for testing.

How do I order customized washers?

Share your dimensions, drawings, and finish preferences—we’ll produce accordingly.

Why Choose Nafees Metal Industries?

Trusted Manufacturer for Bulk M20 SS202 Plain Washers

For decades, we’ve supplied washers that stand up to the test of time and usage. Whether your order is large or small, you get consistent quality, competitive rates, and personalized service.

Custom Solutions & Finishes

Need something specific? Our team can help with custom dimensions, special coatings, and tailored packaging for your unique requirements.

Nationwide Reach & Excellent Support

We proudly serve industries across India with reliable lead times and transparent pricing. Our dedicated customer support team is always ready to assist with your queries, quotes, or technical needs.

Visit Us or Buy Online

Partner with Nafees Metal industries for all your fastening needs. Buy our M20 SS202 Plain Washers through our website or visit our manufacturing unit at Reay Road, Mumbai, to see our operations up close.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch