No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M27 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M20 Mild Steel Plain Washers – Best Flat Washers for Industrial Durability

Product Overview

What Are M20 Mild Steel Plain Washers?

In the world of industrial fasteners, even the smallest component plays a pivotal role in ensuring structural integrity, load distribution, and operational safety. One such essential yet often overlooked element is the M20 Mild Steel Plain Washer. At Nafees Metal Industries, we understand the significance of using the right washer in the right setting—especially when it comes to heavy-duty applications. Our precision-engineered M20 Mild Steel Plain Washers are specifically designed to meet the dynamic needs of industries like construction, heavy machinery, automotive, infrastructure, and more.

So, what exactly makes the M20 Mild Steel Plain Washer a preferred choice across so many industries? The answer lies in its balanced combination of tensile strength, corrosion resistance, and cost-effectiveness. Unlike washers made from stainless steel or specialty alloys, M20 Mild Steel Plain Washers offer practical strength and durability without incurring high manufacturing costs. This makes them especially popular in high-volume installations where efficiency, reliability, and affordability are equally critical.

Our M20 Mild Steel Plain Washers are manufactured using premium-grade mild steel, known for its excellent machinability and ductility. These washers are used primarily to distribute the load of a threaded fastener like a bolt or nut, minimizing wear and preventing damage to the surface material. Whether you’re dealing with a bolted flange joint in a pipeline or securing structural beams, these washers serve as an ideal support element, ensuring a firm and long-lasting connection.

What sets M20 Mild Steel Plain Washers apart is their compatibility with a wide range of fastening assemblies. They come with standardized inner and outer diameters, ensuring seamless integration with M20 bolts. Moreover, they are available in a variety of surface finishes—including zinc-plated, black oxide, and self-colored—to cater to specific environmental and aesthetic needs.

We have seen growing demand for M20 Mild Steel Plain Washers from sectors requiring both large-volume availability and consistent performance. Whether it’s assembling industrial machinery or creating foundation anchoring systems, our clients rely on the performance of these washers in both static and dynamic conditions. The popularity of M20 Mild Steel Plain Washers is not just due to their size specifications, but because they serve as a cost-effective and practical alternative to expensive solutions without compromising performance.

In recent years, increased awareness around fastener performance and joint reliability has led many manufacturers and contractors to reconsider their choice of washers. Gone are the days when washers were selected merely based on size. Today, professionals evaluate washers based on their load-bearing capabilities, compatibility with bolt materials, and long-term wear resistance. It is in this refined selection process that M20 Mild Steel Plain Washers have consistently proven their worth.

From bolted assemblies in structural steelworks to high-torque industrial machines, M20 Mild Steel Plain Washers provide that critical layer of strength and protection between the fastener and the base material. Their usage results in longer service life, reduced maintenance, and improved safety across installations.

As a reputed manufacturer and supplier, we are committed to delivering M20 Mild Steel Plain Washers that meet stringent quality standards and are dimensionally accurate to meet global application requirements. Backed by in-house testing and quality inspection protocols, every washer we ship reflects our dedication to excellence.

If you’re searching for robust, scalable, and economical fastening components, you’ll find that M20 Mild Steel Plain Washers from Nafees Metal Industries are a superior choice. Whether you are an OEM, a contractor, or an engineering consultant, integrating our M20 Mild Steel Plain Washers into your assembly systems ensures better performance with peace of mind.

In this comprehensive guide, we will explore everything you need to know about M20 Mild Steel Plain Washers—their specifications, benefits, applications, technical properties, installation tips, and even a real-world case study. By the end, you’ll understand why these washers are more than just flat metal rings—they are an integral part of industrial success stories.

Key Features of M20 Mild Steel Plain Washers

Load Distribution

One of the most essential features of M20 Mild Steel Plain Washers is their ability to evenly distribute load across the surface of the material being fastened. When a bolt is tightened against a surface without a washer, it may cause indentation or warping. M20 washers spread the pressure over a broader area, reducing the stress on the component and increasing overall assembly integrity.

Vibration Resistance

M20 Mild Steel Plain Washers serve as mechanical buffers between the bolt/nut and the surface, helping absorb shock and vibration during operation. This feature becomes critical in automotive, railway, and mechanical systems where repetitive motion or shaking could otherwise cause fastener loosening or material fatigue.

Surface Protection

Mild steel washers help prevent metal-to-metal contact, which is often the cause of corrosion, scratching, or galling. By introducing a washer, the contact area is controlled and protected, prolonging the life of the mating parts.

Long-Term Durability

By reducing stress concentration, preventing wear, and maintaining joint tension over time, these washers extend the overall service life of machinery and assemblies. Using M20 Mild Steel Plain Washers results in lower maintenance costs and fewer replacements over time.

Material-Specific Advantages

Mild steel is known for its excellent machinability, weldability, and cost-effectiveness. These qualities make M20 Mild Steel Plain Washers highly attractive for industries requiring large quantities without compromising performance. Additionally, mild steel washers can be easily coated or plated for improved corrosion resistance.

Dimensions and Standards

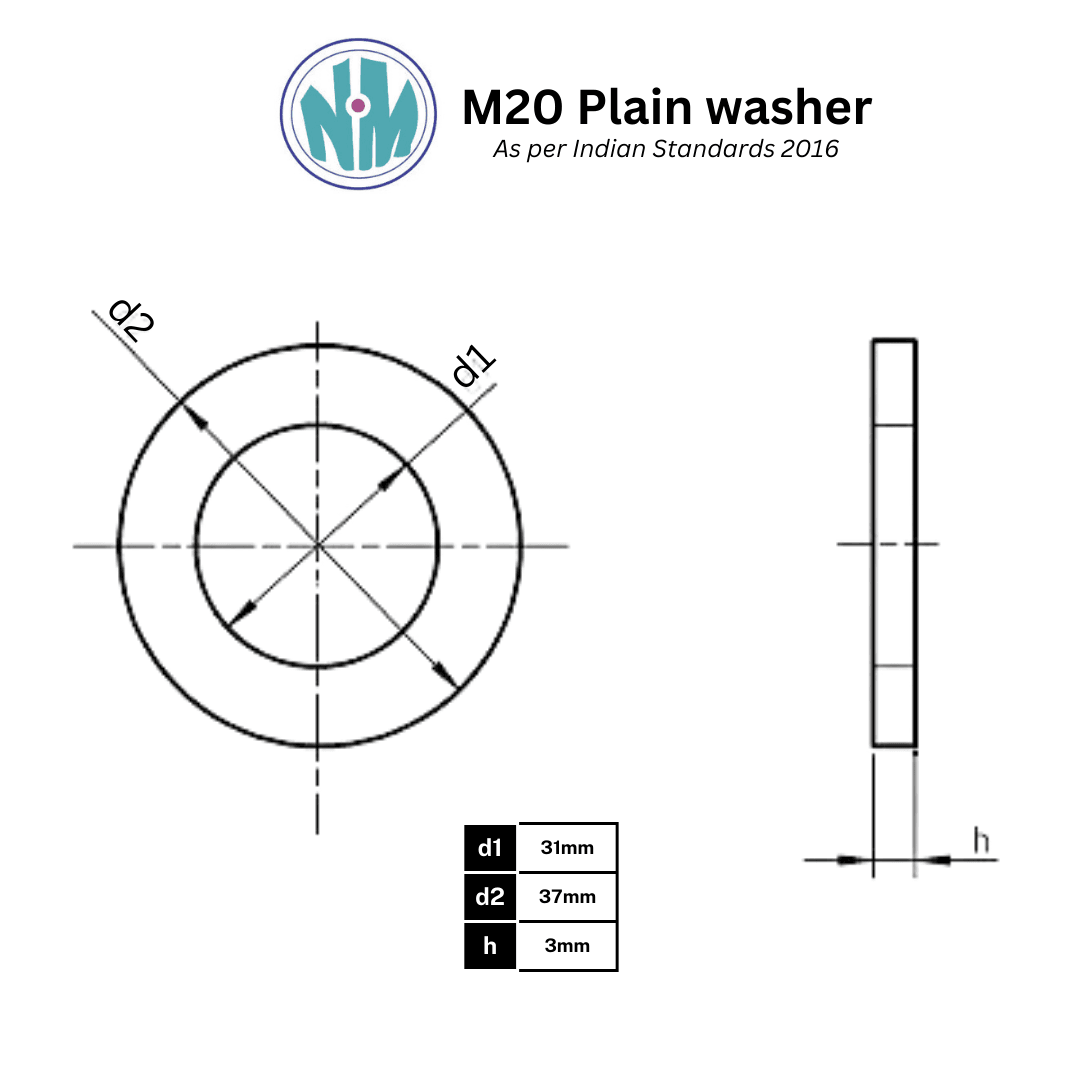

M20 Mild Steel Plain Washers generally adhere to standardized dimensions under IS 2016, DIN 125, and ISO 7089 specifications:

Inner Diameter (ID): 21 mm

Outer Diameter (OD): 37 mm

Thickness: 3 mm (may vary)

Material: Low carbon mild steel

Finish: Self-colored, zinc-plated, hot-dip galvanized (customizable)

These dimensions ensure interchangeability and compatibility with M20 bolts and nuts, making them suitable for global use in diverse projects.

Case Study: Enhancing Structural Integrity in a Heavy-Duty Machinery Project

Background

A renowned heavy engineering company specializing in large-scale industrial equipment faced recurring issues with bolt loosening and structural fatigue in their hydraulic press assemblies. These machines, operating under intense load cycles and environmental stress, demanded superior fastening reliability without excessive cost. Their earlier fastening solution involved plain washers that failed to distribute load uniformly or protect the surface integrity over prolonged use.

Challenge

The primary challenge was multifaceted:

High Vibration Environment: Machines experienced repetitive vibrations and shocks during press operations, causing conventional washers to fail in retaining the bolt tension.

Material Wear and Deformation: Direct metal-to-metal contact in the bolted joints caused scarring and deformation, reducing the lifecycle of the joint assembly.

Frequent Maintenance Downtime: Regular washer failures led to frequent shutdowns, increasing operational costs and reducing machine availability.

Cost Constraints: The client needed a cost-effective yet highly reliable washer solution to avoid shifting to high-cost alloys like stainless steel or specialized materials.

Solution Implementation

After analyzing the problem, our technical team recommended a transition to M20 Mild Steel Plain Washers, known for their optimal balance of durability, formability, and economic value. The strategy involved:

Customized Thickness & Tolerances: We tailored the washers to precise thicknesses for better fit in tight assemblies.

Surface Treated Mild Steel: The washers were given a light zinc-phosphate finish to improve corrosion resistance while retaining affordability.

Increased Outer Diameter (OD): A slightly larger OD was used to enhance load distribution without modifying the existing fastener holes.

These M20 Mild Steel Plain Washers were deployed across 60+ joint points in the hydraulic press assembly.

Results

The shift to M20 Mild Steel Plain Washers led to remarkable improvements within 4 months:

Reduced Bolt Loosening: 70% drop in bolt-related maintenance calls due to better vibration absorption and load distribution.

Improved Equipment Uptime: Downtime was cut by 45%, significantly boosting production cycles and ROI.

Surface Protection: Post-maintenance inspections showed no significant scarring or galling around the bolt interface.

Cost Optimization: Compared to high-grade stainless steel alternatives, the company achieved 38% cost savings while maintaining structural performance.

Key Learnings

This case proves the value of selecting the right washer material and dimension for critical mechanical systems. While it may seem minor, the washer plays a major role in long-term structural performance. M20 Mild Steel Plain Washers offer a practical, high-performing, and budget-conscious solution for vibration-prone applications in heavy machinery and construction setups.

Applications of M20 Mild Steel Plain Washers

M20 Mild Steel Plain Washers are an essential component in countless mechanical, structural, and industrial assemblies. Their role, while often understated, significantly enhances the efficiency, durability, and performance of the overall bolted system. These washers are especially crucial in applications where bolt sizes are M20, typically requiring enhanced load distribution, protection against wear, and vibration mitigation. Below is a detailed breakdown of where and how M20 Mild Steel Plain Washers are applied across various industries:

1. Heavy Machinery and Equipment Assemblies

In sectors like mining, construction, and earthmoving, machinery is subject to extreme forces and continuous vibrations. M20 Mild Steel Plain Washers play a critical role in:

Distributing the load under the head of large M20 bolts, preventing damage to softer metal or painted surfaces.

Reducing stress concentration in areas subject to constant mechanical pressure.

Enhancing the overall reliability of bolted joints in heavy-duty equipment like bulldozers, excavators, cranes, and hydraulic presses.

2. Automotive and Transportation Sector

While M6 to M12 washers are commonly used in light vehicles, larger bolts such as M20 are often required in commercial vehicles, trailers, and industrial transport applications. In this context, M20 Mild Steel Plain Washers are used to:

Support load-bearing parts like suspension assemblies, engine mounts, and chassis joints.

Prevent loosening caused by engine and road-induced vibrations.

Ensure consistent clamping force in areas experiencing thermal expansion or contraction.

3. Construction and Structural Engineering

M20 bolts and their corresponding washers are standard in the construction of large-scale infrastructure projects. Mild Steel Plain Washers in this size are vital in:

Steel beam-to-column connections in high-rise buildings.

Bridge decks, expansion joints, and structural bracings.

Precast concrete panel anchoring, where load distribution is key to preventing cracking or deformation.

Because Mild Steel is cost-effective and easy to fabricate, M20 Mild Steel Plain Washers become a logical choice for mass usage across projects that demand scale without compromising performance.

4. Oil and Gas Industry

Pipelines, pressure vessels, and offshore platforms often use large diameter bolts like M20 to secure flanges, valves, and pipe fittings. M20 Mild Steel Plain Washers provide:

Surface protection between flange faces and bolt heads or nuts.

Consistent bolt pre-load maintenance in high-temperature and corrosive conditions (especially when zinc-coated or treated).

Prevention of galling or scarring during bolt tightening, ensuring reusability of surfaces and easier maintenance access.

5. Electrical and Utility Infrastructure

M20 Mild Steel Plain Washers are used extensively in installations like:

High-voltage transmission towers.

Utility pole assemblies and grounding systems.

Electrical switchgear frames and cable tray supports.

In these setups, the washers ensure electrical conductivity (where necessary), corrosion resistance (with additional coating), and mechanical reliability in outdoor or semi-exposed conditions.

6. Renewable Energy Installations

Solar farms, wind turbine towers, and hydroelectric stations require robust mechanical fasteners to withstand weathering, vibrations, and dynamic loading. M20 Mild Steel Plain Washers find application in:

Turbine base plate connections.

Solar panel tracking system assemblies.

Hydro gate or dam infrastructure securing.

Their ability to distribute heavy loads and resist deformation under fluctuating forces makes them an ideal fit for renewable energy setups that operate continuously with minimal downtime.

7. Railway and Metro Infrastructure

Railway sleepers, track connectors, and signaling equipment often employ M20 bolts paired with Mild Steel Washers. Here, the washers provide:

Durability against constant vibration and dynamic loading from passing trains.

Better torque control during assembly and rework of railway fastening systems.

Cost-effective fastening in large quantities for long rail networks.

8. Agricultural Machinery

Tractors, threshers, harvesters, and irrigation pumps all utilize M20 bolt systems in their frame structures and mechanical joints. M20 Mild Steel Plain Washers ensure:

Protection of softer material surfaces.

Absorption of shocks during plowing or harvesting operations.

Longer life of bolts and surrounding components by reducing surface abrasion.

9. Fabrication and Metalworking

In general metalworking industries, where metal sheets, channels, or custom profiles are joined together, M20 Mild Steel Plain Washers are used to:

Protect component surfaces from scratches or paint damage during tightening.

Act as spacers in jigs, frames, or modular assemblies.

Enable torque control and consistent bolt engagement in variable setups.

10. Water Treatment and Piping Systems

In municipal waterworks or industrial effluent plants, M20 Mild Steel Plain Washers are employed in:

Flange connections between large-diameter pipes.

Pump and valve installations.

Securing structural members in water treatment plants.

These washers are often coated or hot-dip galvanized to provide corrosion resistance in moisture-prone environments.

Why Choose M20 Mild Steel Plain Washers?

Uniform and Accurate Sizing for precise fit with M20 fasteners

Cost-Effective Bulk Pricing for large-scale industrial projects

Versatile Coating Options – Zinc, Black Oxide, Galvanized

High Load-Bearing Capacity

Custom Manufacturing Support (thickness, diameter, coating)

Whether you’re sourcing for small assembly work or major infrastructural projects, M20 Mild Steel Plain Washers offer dependability and performance across sectors.

Why Mild Steel is Ideal for Flat Washers

Mild steel, despite being a basic alloy of iron and carbon, offers significant functional advantages for washer applications:

Easily Formable and Cut into precise flat washer dimensions

Weld-Friendly, if needed for permanent setups

Supports Post-Processing (coating, plating, bending)

Budget-Friendly for large-volume applications

Offers moderate tensile strength suitable for general fastening jobs

How to Source Quality M20 Mild Steel Plain Washers

When sourcing M20 Mild Steel Plain Washers, it’s important to consider:

Dimensional Accuracy – Ensure tolerances match the desired standard

Surface Finish – Choose coated washers for corrosive environments

Batch Consistency – Uniformity across bulk orders

Reliable Manufacturer – Verify industry experience and certifications

For industries looking to Buy M20 Mild Steel Plain Washers in Bulk, partnering with the Best M20 MS Flat Washers Manufacturer ensures you receive durable, tested, and value-optimized solutions.

Packaging and Delivery

Our M20 Mild Steel Plain Washers are:

Packed in moisture-proof, labeled containers

Available in poly bags, carton boxes, or wooden crates

Custom packaging available for exports

Delivered with full inspection certificates

Frequently Asked Questions (FAQs)

Q1. What is the weight of one M20 Mild Steel Plain Washer?

The weight can vary slightly based on thickness and coating, but on average, one washer weighs approximately 20 to 25 grams.

Q2. Can M20 Mild Steel Plain Washers be customized?

Yes. You can customize thickness, OD, ID, and finish depending on application needs. Custom stamping or lot numbers can also be added.

Q3. Are these washers rust-proof?

Standard mild steel is prone to corrosion, but coatings like zinc plating or hot-dip galvanizing offer effective protection against rust.

Q4. Are these suitable for outdoor use?

Yes, if coated properly (zinc or HDG), M20 Mild Steel Plain Washers perform well in outdoor environments and resist weathering.

Q5. Can I use these with stainless steel bolts?

It is technically possible, but galvanic corrosion may occur when dissimilar metals are paired. Prefer using them with mild steel bolts unless isolated properly.

Q6. What’s the lead time for bulk orders?

Lead time depends on quantity and customization, but standard orders are usually dispatched within 5–10 working days.

Q7. How do I ensure I’m buying genuine M20 Mild Steel Plain Washers?

Buy only from certified manufacturers who offer testing reports, standard compliance documents, and reliable packaging.

Q8. How many washers come in a standard box?

Typically, a standard box may contain 100 to 500 pieces, depending on washer thickness and weight constraints. Bulk packaging is customizable.

Q9. Do you provide delivery across India?

Yes, we provide PAN India delivery with logistics partners and also ship internationally on request.

Q10. What industries commonly use M20 Mild Steel Plain Washers?

Industries include construction, railways, manufacturing, automotive, heavy machinery, energy, and shipbuilding.

Conclusion

M20 Mild Steel Plain Washers stand out as a cost-effective, versatile, and high-performance solution for industrial bolting needs. Their load distribution, shock absorption, corrosion prevention, and mechanical reliability make them indispensable across industries.

When looking to Buy M20 Mild Steel Plain Washers in Bulk, always ensure you’re working with a supplier who understands your application needs and offers consistency, quality, and support.

Whether you are an OEM, contractor, or project procurement lead, integrating these washers into your builds will ensure long-term stability and reduced maintenance costs.

Why Choose Nafees Metal industries?

When you choose us as your M20 Mild Steel Plain Washers Manufacturer, you get more than just washers — you get a partner who cares about your success. We’re known for:

✔️ Bulk supply capabilities with consistent quality

✔️ Customization options for sizes, finishes, and coatings

✔️ Transparent pricing with no hidden fees

✔️ Strict quality control and on-time delivery

✔️ Expert support before, during, and after your purchase

We take pride in building lasting relationships with our clients by delivering products that meet the toughest industry standards.

Visit Us or Order Now

Experience the difference our precision-made washers can make in your projects. Visit our modern manufacturing unit at Reay Road, Mumbai, or get in touch with our team to discuss your bulk order requirements. We’re ready to help you find the best fastening solutions for your business.

M20 Mild Steel Plain Washers

24 people are viewing this product right now

₹2.64 Original price was: ₹2.64.₹2.20Current price is: ₹2.20. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M20

Inner Diameter (ID): 21 mm

Outer Diameter (OD): 37 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M20 Mild Steel Plain Washers – Best Flat Washers for Industrial Durability

Product Overview

What Are M20 Mild Steel Plain Washers?

In the world of industrial fasteners, even the smallest component plays a pivotal role in ensuring structural integrity, load distribution, and operational safety. One such essential yet often overlooked element is the M20 Mild Steel Plain Washer. At Nafees Metal Industries, we understand the significance of using the right washer in the right setting—especially when it comes to heavy-duty applications. Our precision-engineered M20 Mild Steel Plain Washers are specifically designed to meet the dynamic needs of industries like construction, heavy machinery, automotive, infrastructure, and more.

So, what exactly makes the M20 Mild Steel Plain Washer a preferred choice across so many industries? The answer lies in its balanced combination of tensile strength, corrosion resistance, and cost-effectiveness. Unlike washers made from stainless steel or specialty alloys, M20 Mild Steel Plain Washers offer practical strength and durability without incurring high manufacturing costs. This makes them especially popular in high-volume installations where efficiency, reliability, and affordability are equally critical.

Our M20 Mild Steel Plain Washers are manufactured using premium-grade mild steel, known for its excellent machinability and ductility. These washers are used primarily to distribute the load of a threaded fastener like a bolt or nut, minimizing wear and preventing damage to the surface material. Whether you’re dealing with a bolted flange joint in a pipeline or securing structural beams, these washers serve as an ideal support element, ensuring a firm and long-lasting connection.

What sets M20 Mild Steel Plain Washers apart is their compatibility with a wide range of fastening assemblies. They come with standardized inner and outer diameters, ensuring seamless integration with M20 bolts. Moreover, they are available in a variety of surface finishes—including zinc-plated, black oxide, and self-colored—to cater to specific environmental and aesthetic needs.

We have seen growing demand for M20 Mild Steel Plain Washers from sectors requiring both large-volume availability and consistent performance. Whether it’s assembling industrial machinery or creating foundation anchoring systems, our clients rely on the performance of these washers in both static and dynamic conditions. The popularity of M20 Mild Steel Plain Washers is not just due to their size specifications, but because they serve as a cost-effective and practical alternative to expensive solutions without compromising performance.

In recent years, increased awareness around fastener performance and joint reliability has led many manufacturers and contractors to reconsider their choice of washers. Gone are the days when washers were selected merely based on size. Today, professionals evaluate washers based on their load-bearing capabilities, compatibility with bolt materials, and long-term wear resistance. It is in this refined selection process that M20 Mild Steel Plain Washers have consistently proven their worth.

From bolted assemblies in structural steelworks to high-torque industrial machines, M20 Mild Steel Plain Washers provide that critical layer of strength and protection between the fastener and the base material. Their usage results in longer service life, reduced maintenance, and improved safety across installations.

As a reputed manufacturer and supplier, we are committed to delivering M20 Mild Steel Plain Washers that meet stringent quality standards and are dimensionally accurate to meet global application requirements. Backed by in-house testing and quality inspection protocols, every washer we ship reflects our dedication to excellence.

If you’re searching for robust, scalable, and economical fastening components, you’ll find that M20 Mild Steel Plain Washers from Nafees Metal Industries are a superior choice. Whether you are an OEM, a contractor, or an engineering consultant, integrating our M20 Mild Steel Plain Washers into your assembly systems ensures better performance with peace of mind.

In this comprehensive guide, we will explore everything you need to know about M20 Mild Steel Plain Washers—their specifications, benefits, applications, technical properties, installation tips, and even a real-world case study. By the end, you’ll understand why these washers are more than just flat metal rings—they are an integral part of industrial success stories.

Key Features of M20 Mild Steel Plain Washers

Load Distribution

One of the most essential features of M20 Mild Steel Plain Washers is their ability to evenly distribute load across the surface of the material being fastened. When a bolt is tightened against a surface without a washer, it may cause indentation or warping. M20 washers spread the pressure over a broader area, reducing the stress on the component and increasing overall assembly integrity.

Vibration Resistance

M20 Mild Steel Plain Washers serve as mechanical buffers between the bolt/nut and the surface, helping absorb shock and vibration during operation. This feature becomes critical in automotive, railway, and mechanical systems where repetitive motion or shaking could otherwise cause fastener loosening or material fatigue.

Surface Protection

Mild steel washers help prevent metal-to-metal contact, which is often the cause of corrosion, scratching, or galling. By introducing a washer, the contact area is controlled and protected, prolonging the life of the mating parts.

Long-Term Durability

By reducing stress concentration, preventing wear, and maintaining joint tension over time, these washers extend the overall service life of machinery and assemblies. Using M20 Mild Steel Plain Washers results in lower maintenance costs and fewer replacements over time.

Material-Specific Advantages

Mild steel is known for its excellent machinability, weldability, and cost-effectiveness. These qualities make M20 Mild Steel Plain Washers highly attractive for industries requiring large quantities without compromising performance. Additionally, mild steel washers can be easily coated or plated for improved corrosion resistance.

Dimensions and Standards

M20 Mild Steel Plain Washers generally adhere to standardized dimensions under IS 2016, DIN 125, and ISO 7089 specifications:

Inner Diameter (ID): 21 mm

Outer Diameter (OD): 37 mm

Thickness: 3 mm (may vary)

Material: Low carbon mild steel

Finish: Self-colored, zinc-plated, hot-dip galvanized (customizable)

These dimensions ensure interchangeability and compatibility with M20 bolts and nuts, making them suitable for global use in diverse projects.

Case Study: Enhancing Structural Integrity in a Heavy-Duty Machinery Project

Background

A renowned heavy engineering company specializing in large-scale industrial equipment faced recurring issues with bolt loosening and structural fatigue in their hydraulic press assemblies. These machines, operating under intense load cycles and environmental stress, demanded superior fastening reliability without excessive cost. Their earlier fastening solution involved plain washers that failed to distribute load uniformly or protect the surface integrity over prolonged use.

Challenge

The primary challenge was multifaceted:

High Vibration Environment: Machines experienced repetitive vibrations and shocks during press operations, causing conventional washers to fail in retaining the bolt tension.

Material Wear and Deformation: Direct metal-to-metal contact in the bolted joints caused scarring and deformation, reducing the lifecycle of the joint assembly.

Frequent Maintenance Downtime: Regular washer failures led to frequent shutdowns, increasing operational costs and reducing machine availability.

Cost Constraints: The client needed a cost-effective yet highly reliable washer solution to avoid shifting to high-cost alloys like stainless steel or specialized materials.

Solution Implementation

After analyzing the problem, our technical team recommended a transition to M20 Mild Steel Plain Washers, known for their optimal balance of durability, formability, and economic value. The strategy involved:

Customized Thickness & Tolerances: We tailored the washers to precise thicknesses for better fit in tight assemblies.

Surface Treated Mild Steel: The washers were given a light zinc-phosphate finish to improve corrosion resistance while retaining affordability.

Increased Outer Diameter (OD): A slightly larger OD was used to enhance load distribution without modifying the existing fastener holes.

These M20 Mild Steel Plain Washers were deployed across 60+ joint points in the hydraulic press assembly.

Results

The shift to M20 Mild Steel Plain Washers led to remarkable improvements within 4 months:

Reduced Bolt Loosening: 70% drop in bolt-related maintenance calls due to better vibration absorption and load distribution.

Improved Equipment Uptime: Downtime was cut by 45%, significantly boosting production cycles and ROI.

Surface Protection: Post-maintenance inspections showed no significant scarring or galling around the bolt interface.

Cost Optimization: Compared to high-grade stainless steel alternatives, the company achieved 38% cost savings while maintaining structural performance.

Key Learnings

This case proves the value of selecting the right washer material and dimension for critical mechanical systems. While it may seem minor, the washer plays a major role in long-term structural performance. M20 Mild Steel Plain Washers offer a practical, high-performing, and budget-conscious solution for vibration-prone applications in heavy machinery and construction setups.

Applications of M20 Mild Steel Plain Washers

M20 Mild Steel Plain Washers are an essential component in countless mechanical, structural, and industrial assemblies. Their role, while often understated, significantly enhances the efficiency, durability, and performance of the overall bolted system. These washers are especially crucial in applications where bolt sizes are M20, typically requiring enhanced load distribution, protection against wear, and vibration mitigation. Below is a detailed breakdown of where and how M20 Mild Steel Plain Washers are applied across various industries:

1. Heavy Machinery and Equipment Assemblies

In sectors like mining, construction, and earthmoving, machinery is subject to extreme forces and continuous vibrations. M20 Mild Steel Plain Washers play a critical role in:

Distributing the load under the head of large M20 bolts, preventing damage to softer metal or painted surfaces.

Reducing stress concentration in areas subject to constant mechanical pressure.

Enhancing the overall reliability of bolted joints in heavy-duty equipment like bulldozers, excavators, cranes, and hydraulic presses.

2. Automotive and Transportation Sector

While M6 to M12 washers are commonly used in light vehicles, larger bolts such as M20 are often required in commercial vehicles, trailers, and industrial transport applications. In this context, M20 Mild Steel Plain Washers are used to:

Support load-bearing parts like suspension assemblies, engine mounts, and chassis joints.

Prevent loosening caused by engine and road-induced vibrations.

Ensure consistent clamping force in areas experiencing thermal expansion or contraction.

3. Construction and Structural Engineering

M20 bolts and their corresponding washers are standard in the construction of large-scale infrastructure projects. Mild Steel Plain Washers in this size are vital in:

Steel beam-to-column connections in high-rise buildings.

Bridge decks, expansion joints, and structural bracings.

Precast concrete panel anchoring, where load distribution is key to preventing cracking or deformation.

Because Mild Steel is cost-effective and easy to fabricate, M20 Mild Steel Plain Washers become a logical choice for mass usage across projects that demand scale without compromising performance.

4. Oil and Gas Industry

Pipelines, pressure vessels, and offshore platforms often use large diameter bolts like M20 to secure flanges, valves, and pipe fittings. M20 Mild Steel Plain Washers provide:

Surface protection between flange faces and bolt heads or nuts.

Consistent bolt pre-load maintenance in high-temperature and corrosive conditions (especially when zinc-coated or treated).

Prevention of galling or scarring during bolt tightening, ensuring reusability of surfaces and easier maintenance access.

5. Electrical and Utility Infrastructure

M20 Mild Steel Plain Washers are used extensively in installations like:

High-voltage transmission towers.

Utility pole assemblies and grounding systems.

Electrical switchgear frames and cable tray supports.

In these setups, the washers ensure electrical conductivity (where necessary), corrosion resistance (with additional coating), and mechanical reliability in outdoor or semi-exposed conditions.

6. Renewable Energy Installations

Solar farms, wind turbine towers, and hydroelectric stations require robust mechanical fasteners to withstand weathering, vibrations, and dynamic loading. M20 Mild Steel Plain Washers find application in:

Turbine base plate connections.

Solar panel tracking system assemblies.

Hydro gate or dam infrastructure securing.

Their ability to distribute heavy loads and resist deformation under fluctuating forces makes them an ideal fit for renewable energy setups that operate continuously with minimal downtime.

7. Railway and Metro Infrastructure

Railway sleepers, track connectors, and signaling equipment often employ M20 bolts paired with Mild Steel Washers. Here, the washers provide:

Durability against constant vibration and dynamic loading from passing trains.

Better torque control during assembly and rework of railway fastening systems.

Cost-effective fastening in large quantities for long rail networks.

8. Agricultural Machinery

Tractors, threshers, harvesters, and irrigation pumps all utilize M20 bolt systems in their frame structures and mechanical joints. M20 Mild Steel Plain Washers ensure:

Protection of softer material surfaces.

Absorption of shocks during plowing or harvesting operations.

Longer life of bolts and surrounding components by reducing surface abrasion.

9. Fabrication and Metalworking

In general metalworking industries, where metal sheets, channels, or custom profiles are joined together, M20 Mild Steel Plain Washers are used to:

Protect component surfaces from scratches or paint damage during tightening.

Act as spacers in jigs, frames, or modular assemblies.

Enable torque control and consistent bolt engagement in variable setups.

10. Water Treatment and Piping Systems

In municipal waterworks or industrial effluent plants, M20 Mild Steel Plain Washers are employed in:

Flange connections between large-diameter pipes.

Pump and valve installations.

Securing structural members in water treatment plants.

These washers are often coated or hot-dip galvanized to provide corrosion resistance in moisture-prone environments.

Why Choose M20 Mild Steel Plain Washers?

Uniform and Accurate Sizing for precise fit with M20 fasteners

Cost-Effective Bulk Pricing for large-scale industrial projects

Versatile Coating Options – Zinc, Black Oxide, Galvanized

High Load-Bearing Capacity

Custom Manufacturing Support (thickness, diameter, coating)

Whether you’re sourcing for small assembly work or major infrastructural projects, M20 Mild Steel Plain Washers offer dependability and performance across sectors.

Why Mild Steel is Ideal for Flat Washers

Mild steel, despite being a basic alloy of iron and carbon, offers significant functional advantages for washer applications:

Easily Formable and Cut into precise flat washer dimensions

Weld-Friendly, if needed for permanent setups

Supports Post-Processing (coating, plating, bending)

Budget-Friendly for large-volume applications

Offers moderate tensile strength suitable for general fastening jobs

How to Source Quality M20 Mild Steel Plain Washers

When sourcing M20 Mild Steel Plain Washers, it’s important to consider:

Dimensional Accuracy – Ensure tolerances match the desired standard

Surface Finish – Choose coated washers for corrosive environments

Batch Consistency – Uniformity across bulk orders

Reliable Manufacturer – Verify industry experience and certifications

For industries looking to Buy M20 Mild Steel Plain Washers in Bulk, partnering with the Best M20 MS Flat Washers Manufacturer ensures you receive durable, tested, and value-optimized solutions.

Packaging and Delivery

Our M20 Mild Steel Plain Washers are:

Packed in moisture-proof, labeled containers

Available in poly bags, carton boxes, or wooden crates

Custom packaging available for exports

Delivered with full inspection certificates

Frequently Asked Questions (FAQs)

Q1. What is the weight of one M20 Mild Steel Plain Washer?

The weight can vary slightly based on thickness and coating, but on average, one washer weighs approximately 20 to 25 grams.

Q2. Can M20 Mild Steel Plain Washers be customized?

Yes. You can customize thickness, OD, ID, and finish depending on application needs. Custom stamping or lot numbers can also be added.

Q3. Are these washers rust-proof?

Standard mild steel is prone to corrosion, but coatings like zinc plating or hot-dip galvanizing offer effective protection against rust.

Q4. Are these suitable for outdoor use?

Yes, if coated properly (zinc or HDG), M20 Mild Steel Plain Washers perform well in outdoor environments and resist weathering.

Q5. Can I use these with stainless steel bolts?

It is technically possible, but galvanic corrosion may occur when dissimilar metals are paired. Prefer using them with mild steel bolts unless isolated properly.

Q6. What’s the lead time for bulk orders?

Lead time depends on quantity and customization, but standard orders are usually dispatched within 5–10 working days.

Q7. How do I ensure I’m buying genuine M20 Mild Steel Plain Washers?

Buy only from certified manufacturers who offer testing reports, standard compliance documents, and reliable packaging.

Q8. How many washers come in a standard box?

Typically, a standard box may contain 100 to 500 pieces, depending on washer thickness and weight constraints. Bulk packaging is customizable.

Q9. Do you provide delivery across India?

Yes, we provide PAN India delivery with logistics partners and also ship internationally on request.

Q10. What industries commonly use M20 Mild Steel Plain Washers?

Industries include construction, railways, manufacturing, automotive, heavy machinery, energy, and shipbuilding.

Conclusion

M20 Mild Steel Plain Washers stand out as a cost-effective, versatile, and high-performance solution for industrial bolting needs. Their load distribution, shock absorption, corrosion prevention, and mechanical reliability make them indispensable across industries.

When looking to Buy M20 Mild Steel Plain Washers in Bulk, always ensure you’re working with a supplier who understands your application needs and offers consistency, quality, and support.

Whether you are an OEM, contractor, or project procurement lead, integrating these washers into your builds will ensure long-term stability and reduced maintenance costs.

Why Choose Nafees Metal industries?

When you choose us as your M20 Mild Steel Plain Washers Manufacturer, you get more than just washers — you get a partner who cares about your success. We’re known for:

✔️ Bulk supply capabilities with consistent quality

✔️ Customization options for sizes, finishes, and coatings

✔️ Transparent pricing with no hidden fees

✔️ Strict quality control and on-time delivery

✔️ Expert support before, during, and after your purchase

We take pride in building lasting relationships with our clients by delivering products that meet the toughest industry standards.

Visit Us or Order Now

Experience the difference our precision-made washers can make in your projects. Visit our modern manufacturing unit at Reay Road, Mumbai, or get in touch with our team to discuss your bulk order requirements. We’re ready to help you find the best fastening solutions for your business.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch