No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M20 Copper Plain Washer – Durable Copper Flat Washers for High-Conductivity and Sealing Applications

Nafees Metal Industries introduces the M20 Copper Plain Washer, designed for applications that demand excellent thermal and electrical conductivity, high corrosion resistance, and long-lasting performance. Precision-machined to fit M20 bolts and fasteners, our copper washers are ideal for use in plumbing, automotive, electrical systems, instrumentation, and high-temperature environments. As one of the best copper washer manufacturers in India, we offer M20 copper washers that combine durability, performance, and cost-efficiency for a wide range of mechanical and electrical uses.

The M20 Copper Plain Washer is especially preferred where electrical grounding, sealing against fluid or gas leaks, and heat dissipation are crucial. Manufactured from high-purity copper, these washers maintain strength even under fluctuating loads and temperatures. Whether you’re sourcing for critical assemblies or looking for a high-performance substitute to traditional metal washers, our M20 copper washers offer unmatched functionality and precision.

What is an M20 Copper Plain Washer?

An M20 Copper Plain Washer is a flat, circular disc made from high-purity copper, engineered with a central hole precisely sized to fit M20 bolts, screws, or threaded rods. The term “M20” refers to a metric thread size of 20 mm diameter, making this washer suitable for heavy-duty bolting applications where a secure and durable fastener setup is essential.

Unlike other washer types, plain copper washers serve dual purposes — mechanical load distribution and sealing or conductivity enhancement. These washers are particularly beneficial in systems that involve high vibration, electrical conductivity requirements, or corrosion-sensitive environments.

Key uses of M20 Copper Plain Washers include:

Distributing the load of M20 bolts to prevent damage to soft or brittle materials.

Acting as a seal in fluid or gas pipelines, especially in plumbing and hydraulic systems.

Serving as a conductive interface in grounding or electrical connection applications.

Protecting the bolted joint from galvanic corrosion when used with dissimilar metals.

At Nafees Metal Industries, we manufacture M20 copper washers as per DIN 125 and IS 2016 standards, ensuring consistency in dimensions, smooth finishing, and flat surface contact for optimized performance.

Whether you’re dealing with high-pressure sealing, electrical continuity, or corrosion-resistant installations, M20 Copper Plain Washers provide a reliable and durable solution across industrial, automotive, and electrical sectors.

Why Copper for M20 Plain Washers?

Copper is a highly versatile and valuable material, especially in industries that require high conductivity, anti-corrosion properties, and temperature resilience. When used in the form of an M20 Copper Plain Washer, copper delivers multiple advantages that make it superior to many other metals for specific use cases.

Key Benefits of Using Copper in M20 Washers:

Exceptional Electrical Conductivity

Copper is one of the best conductors of electricity, making M20 copper washers ideal for grounding and bonding applications. They help maintain consistent electrical continuity in electrical panels, terminals, and circuits.Excellent Thermal Conductivity

In high-heat environments such as engines, heating systems, and heavy machinery, copper helps dissipate heat efficiently from the fastening area. This reduces thermal stress on fastened joints.Natural Corrosion Resistance

Copper forms a protective oxide layer when exposed to the environment. This makes M20 copper plain washers highly resistant to corrosion, even in marine or chemical exposure settings.High Malleability for Sealing

Copper’s softness allows it to deform under pressure, which makes it an ideal choice for sealing washers in plumbing, hydraulic, and pneumatic systems. It creates a tight, leak-proof seal when compressed between metal surfaces.Non-Magnetic and Non-Sparking

Copper is non-ferrous, which means M20 copper washers are suitable for sensitive electronic equipment and environments where magnetic interference or sparks could be hazardous.Compatibility with Dissimilar Metals

Copper washers can be used between dissimilar metals to prevent galvanic corrosion — especially in installations involving aluminum, steel, or brass components.Eco-Friendly and Recyclable

Copper is 100% recyclable without loss in performance. Choosing copper washers supports sustainability goals for manufacturers and contractors.

The M20 Copper Plain Washer is the optimal choice when your application demands high conductivity, effective sealing, corrosion resistance, and reliable mechanical support. Whether you’re installing a copper flat washer M20 size in an electric cabinet, a pump flange, or a high-vibration engine block, copper delivers long-term dependability.

How Are M20 Copper Plain Washers Manufactured?

At Nafees Metal Industries, every M20 Copper Plain Washer is manufactured with precision, consistency, and adherence to international quality standards. Our production process ensures that each washer delivers optimal performance in mechanical, electrical, and sealing applications.

Step-by-Step Manufacturing Process:

Raw Material Selection

We begin with high-grade, electrolytic copper sheets or coils that meet the required mechanical and chemical specifications. The copper used typically falls within C11000 or equivalent grades, known for their high conductivity and corrosion resistance.Blanking and Stamping

Using CNC-controlled stamping or power press machines, round blanks are punched with the precise inner diameter (ID) and outer diameter (OD). For an M20 copper plain washer, the inner diameter is designed to fit standard M20 bolts (approximately 21 mm), while the outer diameter and thickness conform to DIN 125 / IS 2016 standards.Deburring and Edge Finishing

After blanking, each washer undergoes a deburring process to remove sharp edges and surface irregularities. This ensures safe handling, easy assembly, and uniform contact surfaces.Annealing (Optional)

For washers that require higher malleability or sealing properties, an annealing step is performed. This heat treatment process softens the copper, making the washer more suitable for gasket-type applications.Surface Treatment or Cleaning

Although copper naturally resists corrosion, some washers undergo chemical cleaning or polishing to remove oxidation, oil residues, or surface discoloration. Bright polished or dull finishes can be offered based on customer requirements.Dimensional and Quality Inspection

Each batch of M20 copper plain washers is subjected to strict quality control. Parameters like ID, OD, thickness, flatness, and surface finish are measured to ensure compliance with dimensional tolerances and performance expectations.Packaging and Labelling

Depending on customer needs, washers are packed in polybags, corrugated boxes, or bulk cartons. Each package is labeled with size, quantity, batch number, and quality mark for traceability and order accuracy.

Customization Available:

Thickness options: Standard 1.5 mm to 3.0 mm (customizable on request)

Surface finishes: Natural, polished, or oxidized

Special packaging for retail or export

Custom washer ID/OD dimensions for non-standard M20 fasteners

Our machined washer variants are also available for critical tolerance applications where turned components are preferred over stamped ones.

By combining automation, skilled labor, and quality-first practices, Nafees Metal Industries ensures that every M20 Copper Plain Washer meets or exceeds customer expectations across industries.

Key Features of M20 Copper Plain Washers

The M20 Copper Plain Washer stands out as a high-performance, multipurpose component designed to deliver consistent results across a wide range of applications. At Nafees Metal Industries, each washer is engineered with features that enhance both mechanical and functional value, ensuring reliability in every fastening or sealing task.

1. Precision Fitment for M20 Bolts

Our washers are dimensioned precisely to accommodate M20 bolts, screws, and threaded rods. This ensures a tight, secure fit that enhances both fastening integrity and alignment.

2. Superior Load Distribution

M20 copper plain washers help evenly distribute the load exerted by the fastener head or nut, preventing localized damage to soft or uneven surfaces, especially in brass, aluminum, or plastic assemblies.

3. Exceptional Electrical and Thermal Conductivity

Copper’s conductivity ensures optimal electrical grounding and thermal transfer, making the washer suitable for high-performance electrical and mechanical systems.

4. Excellent Corrosion Resistance

Naturally corrosion-resistant, these washers perform reliably in humid, marine, or mildly acidic environments without the need for additional coatings.

5. High Malleability for Leak-Free Sealing

The softness of copper enables the washer to deform under pressure, creating a seal between metal surfaces. This is particularly useful in plumbing, hydraulic, and gas fittings.

6. Non-Magnetic and Spark-Free

Ideal for use in sensitive or hazardous environments, M20 copper washers do not interfere with magnetic equipment and do not generate sparks when struck.

7. Smooth Surface and Uniform Thickness

All washers are deburred and finished for smooth surfaces, reducing the risk of damage during assembly and improving contact consistency in electrical setups.

8. Machined and Stamped Options Available

We offer both stamped and machined washer versions for customers who require tighter tolerances or higher finish quality in precision applications.

9. Bulk Availability and Custom Packaging

Suitable for OEMs and industrial distributors, our washers are available in bulk with customizable packaging and labeling to meet specific procurement needs.

10. Compliance with Global Standards

Manufactured to conform to IS 2016 / DIN 125 / ISO 7089, ensuring dimensional accuracy and compatibility in global markets.

Each feature of the M20 Copper Plain Washer contributes to a high-value component that supports durable, efficient, and maintenance-free assembly operations.

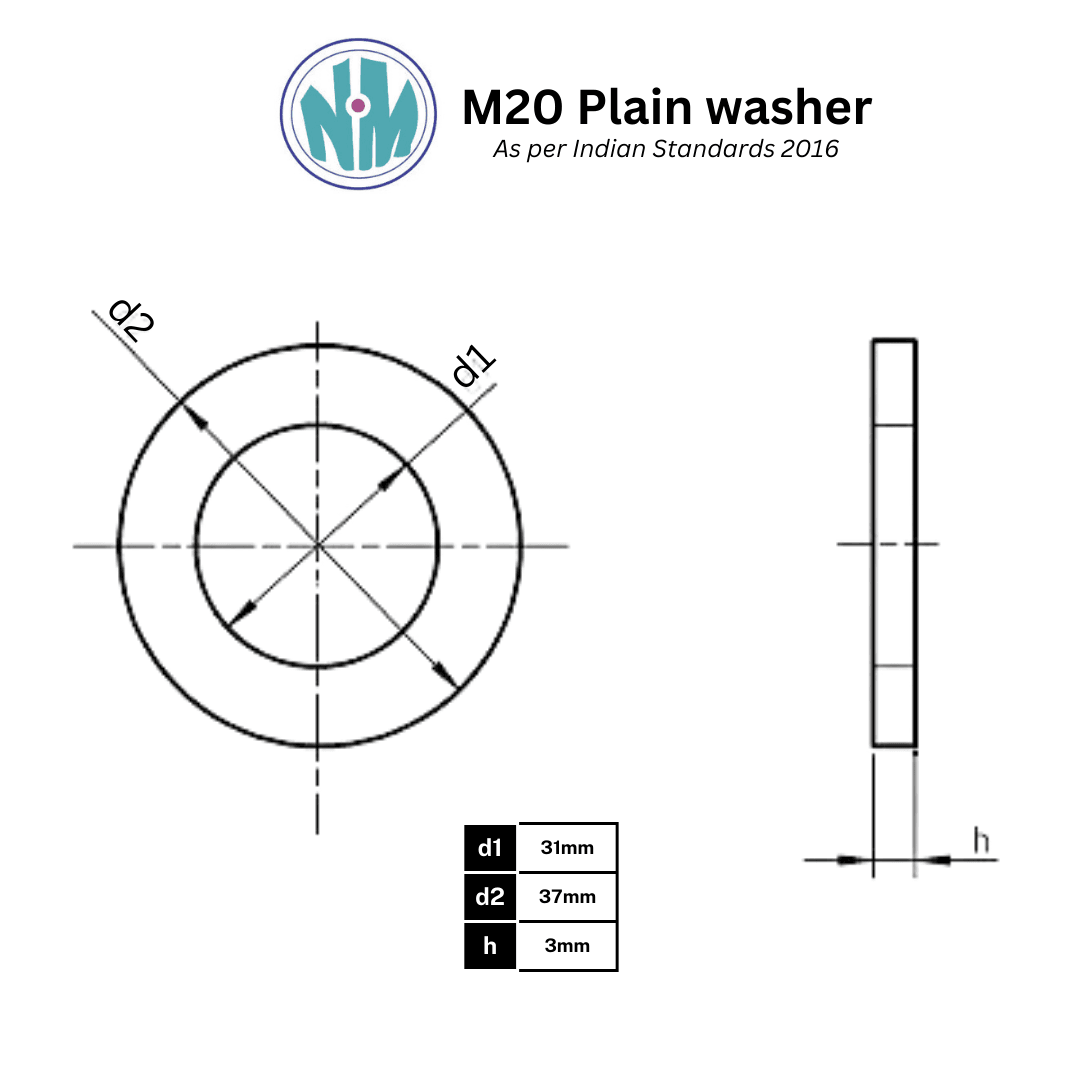

Technical Specifications

At Nafees Metal Industries, our M20 Copper Plain Washers are manufactured with strict adherence to international quality standards and dimensional accuracy. Below is the detailed specification table for the M20 size, covering all technical aspects relevant for design engineers, procurement teams, and industrial users.

| Property | Specification |

|---|---|

| Product Name | M20 Copper Plain Washer |

| Material | High-Purity Copper (Typically C11000 or equivalent) |

| Inner Diameter (ID) | Approx. 21 mm (Fits standard M20 bolts and fasteners) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 standards (typically 37–40 mm) |

| Thickness | Standard 1.5 mm to 3.0 mm (Custom thickness available) |

| Surface Finish | Natural, Polished, or Oxidized |

| Manufacturing Method | Cold Stamped or CNC Machined |

| Tolerances | ID/OD within ±0.1 mm (for stamped), ±0.05 mm (for machined) |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Electrical Conductivity | >97% IACS (International Annealed Copper Standard) |

| Tensile Strength | Approx. 210 MPa (annealed) – varies with temper |

| Temperature Resistance | Operates reliably up to 400°C in continuous applications |

| Magnetic Properties | Non-Magnetic |

| Packaging | Bulk poly bags, cartons, export-grade boxes – customizable |

| Application Categories | Electrical, Plumbing, Sealing, Industrial Fastening, Automotive, Instrumentation |

| Custom Options | ID/OD customization, branding, labeling, special packaging |

These specifications ensure the M20 copper flat washer is not only compatible with a wide range of fastener types but also adaptable to various industrial environments requiring mechanical support or sealing efficiency.

Applications of M20 Copper Plain Washers

The M20 Copper Plain Washer is a versatile and high-performance component widely used in sectors where sealing, conductivity, and corrosion resistance are critical. Its unique combination of mechanical stability and material properties makes it suitable for a range of demanding applications.

1. Electrical and Grounding Systems

Due to copper’s high electrical conductivity, M20 copper washers are frequently used in electrical panels, switchgear, busbars, battery terminals, and power distribution assemblies. They ensure secure fastening while maintaining reliable grounding and electrical flow.

2. Plumbing and Sealing Applications

Copper washers are known for their ability to deform slightly under pressure, making them ideal as sealing elements in plumbing joints, flanges, and pipe connections. They are used in both hot and cold water systems, gas fittings, and HVAC setups.

3. Automotive and Heavy Vehicles

In engine compartments, fuel injection systems, brake line connections, and gearboxes, M20 copper washers are used to provide leak-proof seals and absorb vibrations. They are compatible with high-temperature and oil-exposed environments.

4. Instrumentation and Sensors

For high-precision installations like pressure sensors, temperature probes, and control instruments, M20 copper washers help ensure tight sealing and prevent fluid or gas leakage, while also reducing electrical resistance in grounding points.

5. Hydraulic and Pneumatic Systems

Copper plain washers are commonly installed in hydraulic manifolds, actuators, pumps, and compressors to provide durable sealing under pressure without reacting with fluids or oils.

6. Renewable Energy Systems

Used in solar panels, wind turbines, and battery connections where corrosion resistance, electrical continuity, and thermal conductivity are essential.

7. Marine and Offshore Installations

Copper’s natural corrosion resistance makes M20 washers suitable for use in saltwater environments, such as shipbuilding, offshore platforms, and underwater fittings.

8. Manufacturing and Maintenance Operations

These washers are commonly stocked in maintenance toolkits for routine industrial servicing, machinery assembly, and retrofitting of old systems.

9. Electrical Enclosures and Panels

In electrical control panels and enclosures, copper washers support the fastening of terminals, conductors, or plates while reducing contact resistance and heat buildup.

10. Aerospace and Defense Applications

In aviation and defense-grade systems, copper washers are valued for their spark-resistant properties, sealing strength, and vibration absorption.

Whether for electrical grounding, fluid sealing, or thermal control, the M20 copper plain washer is indispensable in modern industrial systems where precision and performance matter.

Advantages of Using M20 Copper Washers

Choosing M20 Copper Plain Washers from Nafees Metal Industries provides more than just reliable fastening — it offers long-term functional benefits across electrical, mechanical, and sealing applications. Here are the core advantages that make these washers a preferred choice for engineers, manufacturers, and maintenance professionals:

1. High Electrical Conductivity

Copper is second only to silver in electrical conductivity. Using M20 copper washers ensures minimal resistance and consistent current flow in electrical joints, making them vital in grounding and power transmission assemblies.

2. Superior Thermal Conductivity

These washers efficiently transfer heat away from fastened joints, preventing thermal stress in high-temperature environments like engines, turbines, and electrical enclosures.

3. Reliable Sealing Under Pressure

Copper’s natural softness and malleability make it an ideal sealing washer. It conforms to mating surfaces when compressed, providing leak-free joints in hydraulic, gas, and plumbing systems.

4. Excellent Corrosion Resistance

Copper forms a passive oxide layer that protects it from rust and corrosion. This makes M20 copper washers highly durable even in marine, humid, and chemically active environments.

5. Vibration Dampening

By absorbing vibrations and minor movements at the joint, copper washers reduce loosening of fasteners over time — critical for engines, machinery, and mobile systems.

6. Compatible with Dissimilar Metals

Copper minimizes galvanic reactions when used between different metals, preventing long-term degradation at fastening points.

7. Non-Magnetic and Spark-Free

Ideal for use near sensitive equipment and in explosive environments where magnetic interference or sparks are unacceptable.

8. Dimensional Precision and Uniformity

Our washers are manufactured with tight tolerances, ensuring consistent fitment, reduced wear on mating parts, and easier installation.

9. Long Service Life

Because of their mechanical and chemical stability, M20 copper washers offer extended lifespan, reducing maintenance and replacement costs.

10. Environmentally Friendly

Copper is fully recyclable, and its long lifespan reduces waste. Choosing copper washers contributes to sustainable industrial practices.

Buy M20 Copper Plain Washers in Bulk, Best M20 Copper Washer Manufacturer

If you’re looking for high-quality, precision-engineered M20 copper plain washers, Nafees Metal Industries is your trusted partner. As one of the best copper washer manufacturers in India, we specialize in the design, production, and supply of a wide range of copper washers tailored to meet the diverse needs of industrial users, OEMs, maintenance contractors, and exporters.

Why Choose Nafees Metal Industries for M20 Copper Washers?

Specialized Washer Manufacturing

With years of expertise in plain, spring, disc, and machined washers, we understand the technical requirements across sectors. Our M20 copper flat washers are manufactured in line with international standards and are tested for critical tolerances.Bulk Stock Availability

We maintain ready-to-ship inventory of standard M20 copper washers and can fulfill urgent bulk orders with quick turnaround times.Custom Specifications Accepted

Need a non-standard OD, thickness, or finish? We offer custom machining and stamping services to manufacture washers exactly as per your technical drawing or requirement.Competitive Pricing

Whether you need 1,000 or 1,00,000 pieces, we provide industry-best pricing without compromising on quality. As a direct manufacturer, we eliminate unnecessary markups.Custom Coating & Packaging Options

While copper is often used in its natural state, we also provide oxidized or polished finishes. Packaging can be customized with labeling, poly bags, cartons, or export-friendly boxes.Pan-India Delivery & Export-Ready Logistics

Located in Mumbai, our manufacturing unit is well-connected to ports and transport hubs. We offer seamless delivery within India and support international buyers with necessary documentation for smooth export.Dedicated Customer Support

Our technical and commercial teams are available to assist you with the right washer size, type, and application advice — from quotation to after-sales support.

We Serve a Wide Range of Customers:

Electrical panel manufacturers

Plumbing and HVAC contractors

Hydraulic and pneumatic system integrators

Automotive component suppliers

Aerospace and defense suppliers

Maintenance and MRO companies

Engineering procurement departments

Our M20 copper plain washers are trusted across industries for their sealing efficiency, conductivity, and corrosion resistance.

Case Study: Improving Hydraulic Seal Integrity with M20 Copper Washers

Client: Hydraulic Equipment Manufacturer – Gujarat, India

Application: High-pressure hydraulic valve assemblies

Challenge: Persistent leakage in flange joints despite using fiber and rubber washers

Problem Overview:

A mid-sized hydraulic equipment manufacturer was experiencing sealing failures in their M20 flange bolts used in pump and valve assemblies. Despite repeated installations using synthetic sealing washers, minor leaks persisted after pressure buildup, especially during thermal expansion cycles. These leaks led to component downtime, increased maintenance, and client dissatisfaction.

Nafees Metal Industries’ Solution:

After a consultation and sample evaluation, the client switched to our M20 copper plain washers in the sealing joints. We provided:

Custom-sized copper washers with annealed finish for enhanced deformability

2 mm thickness for improved sealing under torque

5000 washers with export-grade polybag and carton packaging

Technical guidance on recommended torque settings during installation

Results After Implementation:

Leakage Eliminated: All sealing failures resolved within the first production batch

Enhanced Sealing: Copper washers formed tight, leak-free connections under dynamic pressures

Improved Torque Control: Uniform compression reduced the need for re-tightening

Cost Savings: Maintenance time reduced by 30%, improving production efficiency

Client Retention: Zero complaints from downstream clients over 3 months of deployment

The success of this transition demonstrated the superior sealing and performance value that M20 copper plain washers provide in hydraulic systems — where consistent pressure retention is critical.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we go beyond being just a washer supplier — we are a solutions partner for industries that demand performance, precision, and reliability. When it comes to sourcing M20 copper plain washers, here’s why manufacturers, OEMs, and procurement teams across India and beyond choose us with confidence.

1. Decades of Specialized Experience

With focused expertise in manufacturing washers of various materials including copper, stainless steel, brass, and mild steel, we understand application-specific demands across diverse sectors such as electrical, automotive, plumbing, and heavy machinery.

2. End-to-End Quality Control

Our copper washers are manufactured using best-in-class copper grades, precision-machined or stamped to size, and inspected for ID/OD accuracy, thickness, flatness, and surface finish. We follow IS 2016, DIN 125, and ISO 7089 standards to ensure consistency in every batch.

3. Customization Without Compromise

From standard bulk washers to machined washers for critical applications, we offer made-to-order solutions in terms of dimensions, hardness (annealed/non-annealed), finishes, and packaging.

4. Commitment to the ‘Make in India’ Mission

All our products are proudly manufactured in our facility in Mumbai, India — supporting local industries while delivering global-grade quality and performance.

5. Strong Supply Chain & On-Time Delivery

Our robust logistics network ensures fast and reliable delivery across India. For export buyers, we provide complete shipping documentation, HS codes, and secure packaging suited for international freight.

6. Transparent, Competitive Pricing

We believe in long-term partnerships. Our pricing is fair, consistent, and designed to deliver maximum value for quality-conscious buyers procuring copper washers in bulk or regular volumes.

7. Customer-First Approach

From technical consultations to post-sales support, we are always ready to guide you. Whether you need help selecting the right copper washer size, thickness, or coating option, our team offers practical insights based on real-world applications.

8. Trusted by Thousands of Clients

Our client base includes industrial OEMs, MEP contractors, automotive assemblers, renewable energy companies, and equipment manufacturers — a testament to the trust placed in our brand and product quality.

We believe our M20 copper plain washers can add lasting value to your fastening, sealing, or conductive systems. When you choose Nafees Metal Industries, you’re choosing unmatched product integrity backed by consistent service.

Frequently Asked Questions (FAQs) – M20 Copper Plain Washer

1. What is the outer and inner diameter of the M20 copper plain washer?

The M20 copper plain washer typically has an inner diameter (ID) of 21 mm and an outer diameter (OD) of 37 mm, as per standard DIN 125 dimensions. However, we also offer customized sizes based on your specific application requirements.

2. What is the primary use of an M20 copper plain washer?

M20 copper washers are primarily used in high-load, high-vibration applications to distribute the pressure of bolts or nuts evenly. Their electrical conductivity and corrosion resistance make them ideal for grounding, sealing, and high-temperature environments.

3. Are these washers annealed or non-annealed?

We offer both annealed (soft) and non-annealed (hard) versions. Annealed copper washers are preferred for better sealing and compression applications, while hard ones are used where firmness and rigidity are needed.

4. Is the M20 copper washer suitable for high-temperature applications?

Yes, copper has excellent thermal conductivity and a high melting point, making it suitable for use in high-temperature environments, such as engines, boilers, and HVAC systems.

5. Can M20 copper washers be used in electrical applications?

Absolutely. Copper’s high electrical conductivity makes these washers perfect for grounding, bonding, and current-carrying applications in electrical panels, transformers, and battery terminals.

6. What industries commonly use M20 copper washers?

Industries like electrical, automotive, oil & gas, chemical, HVAC, marine, and heavy equipment manufacturing regularly use M20 copper plain washers for various structural and conductive purposes.

7. Are these washers corrosion-resistant?

Yes, copper naturally resists corrosion and does not rust. It forms a stable oxide layer that protects the underlying metal, especially in marine and humid environments.

8. Do you offer customization for M20 copper plain washers?

Yes. We provide customization in terms of ID/OD, thickness, hardness, finish (bare, tinned, coated), and packaging. Share your drawing or specification sheet, and we will manufacture it accordingly.

9. How is the thickness of the M20 copper washer determined?

The standard thickness ranges between 1.5 mm to 3 mm depending on the requirement, but it can be customized based on load-bearing needs or sealing specifications.

10. What surface finishes are available for these washers?

We offer plain copper finish as well as tinned or nickel-plated options to enhance conductivity or corrosion resistance as per the application environment.

11. Do you provide material test certificates (MTC)?

Yes, we provide MTCs on request to ensure complete transparency. The certificate confirms the composition, hardness, and properties of the copper used.

12. What is the minimum order quantity (MOQ) for M20 copper plain washers?

Our MOQ is flexible depending on whether you’re purchasing for retail, industrial, or export purposes. We also cater to bulk orders with competitive pricing.

13. Can I buy M20 copper washers in bulk for export?

Yes, we are fully equipped to handle bulk export orders. We provide HS codes, country-specific packaging, and documentation as required for customs clearance.

14. Are these washers RoHS compliant?

Yes, the copper washers we supply are manufactured from RoHS-compliant raw material, ensuring safety and environmental compliance.

15. How soon can I receive my order?

Lead time depends on quantity and customization. Standard sizes like M20 are usually ready in stock or can be dispatched within 2–4 working days. For large or custom orders, delivery timelines will be communicated transparently.

M20 Copper Plain Washers (DIN 125)

3 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M20

Inner Diameter (ID): 21 mm

Outer Diameter (OD): 37 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:12 days

M20 Copper Plain Washer – Durable Copper Flat Washers for High-Conductivity and Sealing Applications

Nafees Metal Industries introduces the M20 Copper Plain Washer, designed for applications that demand excellent thermal and electrical conductivity, high corrosion resistance, and long-lasting performance. Precision-machined to fit M20 bolts and fasteners, our copper washers are ideal for use in plumbing, automotive, electrical systems, instrumentation, and high-temperature environments. As one of the best copper washer manufacturers in India, we offer M20 copper washers that combine durability, performance, and cost-efficiency for a wide range of mechanical and electrical uses.

The M20 Copper Plain Washer is especially preferred where electrical grounding, sealing against fluid or gas leaks, and heat dissipation are crucial. Manufactured from high-purity copper, these washers maintain strength even under fluctuating loads and temperatures. Whether you’re sourcing for critical assemblies or looking for a high-performance substitute to traditional metal washers, our M20 copper washers offer unmatched functionality and precision.

What is an M20 Copper Plain Washer?

An M20 Copper Plain Washer is a flat, circular disc made from high-purity copper, engineered with a central hole precisely sized to fit M20 bolts, screws, or threaded rods. The term “M20” refers to a metric thread size of 20 mm diameter, making this washer suitable for heavy-duty bolting applications where a secure and durable fastener setup is essential.

Unlike other washer types, plain copper washers serve dual purposes — mechanical load distribution and sealing or conductivity enhancement. These washers are particularly beneficial in systems that involve high vibration, electrical conductivity requirements, or corrosion-sensitive environments.

Key uses of M20 Copper Plain Washers include:

Distributing the load of M20 bolts to prevent damage to soft or brittle materials.

Acting as a seal in fluid or gas pipelines, especially in plumbing and hydraulic systems.

Serving as a conductive interface in grounding or electrical connection applications.

Protecting the bolted joint from galvanic corrosion when used with dissimilar metals.

At Nafees Metal Industries, we manufacture M20 copper washers as per DIN 125 and IS 2016 standards, ensuring consistency in dimensions, smooth finishing, and flat surface contact for optimized performance.

Whether you’re dealing with high-pressure sealing, electrical continuity, or corrosion-resistant installations, M20 Copper Plain Washers provide a reliable and durable solution across industrial, automotive, and electrical sectors.

Why Copper for M20 Plain Washers?

Copper is a highly versatile and valuable material, especially in industries that require high conductivity, anti-corrosion properties, and temperature resilience. When used in the form of an M20 Copper Plain Washer, copper delivers multiple advantages that make it superior to many other metals for specific use cases.

Key Benefits of Using Copper in M20 Washers:

Exceptional Electrical Conductivity

Copper is one of the best conductors of electricity, making M20 copper washers ideal for grounding and bonding applications. They help maintain consistent electrical continuity in electrical panels, terminals, and circuits.Excellent Thermal Conductivity

In high-heat environments such as engines, heating systems, and heavy machinery, copper helps dissipate heat efficiently from the fastening area. This reduces thermal stress on fastened joints.Natural Corrosion Resistance

Copper forms a protective oxide layer when exposed to the environment. This makes M20 copper plain washers highly resistant to corrosion, even in marine or chemical exposure settings.High Malleability for Sealing

Copper’s softness allows it to deform under pressure, which makes it an ideal choice for sealing washers in plumbing, hydraulic, and pneumatic systems. It creates a tight, leak-proof seal when compressed between metal surfaces.Non-Magnetic and Non-Sparking

Copper is non-ferrous, which means M20 copper washers are suitable for sensitive electronic equipment and environments where magnetic interference or sparks could be hazardous.Compatibility with Dissimilar Metals

Copper washers can be used between dissimilar metals to prevent galvanic corrosion — especially in installations involving aluminum, steel, or brass components.Eco-Friendly and Recyclable

Copper is 100% recyclable without loss in performance. Choosing copper washers supports sustainability goals for manufacturers and contractors.

The M20 Copper Plain Washer is the optimal choice when your application demands high conductivity, effective sealing, corrosion resistance, and reliable mechanical support. Whether you’re installing a copper flat washer M20 size in an electric cabinet, a pump flange, or a high-vibration engine block, copper delivers long-term dependability.

How Are M20 Copper Plain Washers Manufactured?

At Nafees Metal Industries, every M20 Copper Plain Washer is manufactured with precision, consistency, and adherence to international quality standards. Our production process ensures that each washer delivers optimal performance in mechanical, electrical, and sealing applications.

Step-by-Step Manufacturing Process:

Raw Material Selection

We begin with high-grade, electrolytic copper sheets or coils that meet the required mechanical and chemical specifications. The copper used typically falls within C11000 or equivalent grades, known for their high conductivity and corrosion resistance.Blanking and Stamping

Using CNC-controlled stamping or power press machines, round blanks are punched with the precise inner diameter (ID) and outer diameter (OD). For an M20 copper plain washer, the inner diameter is designed to fit standard M20 bolts (approximately 21 mm), while the outer diameter and thickness conform to DIN 125 / IS 2016 standards.Deburring and Edge Finishing

After blanking, each washer undergoes a deburring process to remove sharp edges and surface irregularities. This ensures safe handling, easy assembly, and uniform contact surfaces.Annealing (Optional)

For washers that require higher malleability or sealing properties, an annealing step is performed. This heat treatment process softens the copper, making the washer more suitable for gasket-type applications.Surface Treatment or Cleaning

Although copper naturally resists corrosion, some washers undergo chemical cleaning or polishing to remove oxidation, oil residues, or surface discoloration. Bright polished or dull finishes can be offered based on customer requirements.Dimensional and Quality Inspection

Each batch of M20 copper plain washers is subjected to strict quality control. Parameters like ID, OD, thickness, flatness, and surface finish are measured to ensure compliance with dimensional tolerances and performance expectations.Packaging and Labelling

Depending on customer needs, washers are packed in polybags, corrugated boxes, or bulk cartons. Each package is labeled with size, quantity, batch number, and quality mark for traceability and order accuracy.

Customization Available:

Thickness options: Standard 1.5 mm to 3.0 mm (customizable on request)

Surface finishes: Natural, polished, or oxidized

Special packaging for retail or export

Custom washer ID/OD dimensions for non-standard M20 fasteners

Our machined washer variants are also available for critical tolerance applications where turned components are preferred over stamped ones.

By combining automation, skilled labor, and quality-first practices, Nafees Metal Industries ensures that every M20 Copper Plain Washer meets or exceeds customer expectations across industries.

Key Features of M20 Copper Plain Washers

The M20 Copper Plain Washer stands out as a high-performance, multipurpose component designed to deliver consistent results across a wide range of applications. At Nafees Metal Industries, each washer is engineered with features that enhance both mechanical and functional value, ensuring reliability in every fastening or sealing task.

1. Precision Fitment for M20 Bolts

Our washers are dimensioned precisely to accommodate M20 bolts, screws, and threaded rods. This ensures a tight, secure fit that enhances both fastening integrity and alignment.

2. Superior Load Distribution

M20 copper plain washers help evenly distribute the load exerted by the fastener head or nut, preventing localized damage to soft or uneven surfaces, especially in brass, aluminum, or plastic assemblies.

3. Exceptional Electrical and Thermal Conductivity

Copper’s conductivity ensures optimal electrical grounding and thermal transfer, making the washer suitable for high-performance electrical and mechanical systems.

4. Excellent Corrosion Resistance

Naturally corrosion-resistant, these washers perform reliably in humid, marine, or mildly acidic environments without the need for additional coatings.

5. High Malleability for Leak-Free Sealing

The softness of copper enables the washer to deform under pressure, creating a seal between metal surfaces. This is particularly useful in plumbing, hydraulic, and gas fittings.

6. Non-Magnetic and Spark-Free

Ideal for use in sensitive or hazardous environments, M20 copper washers do not interfere with magnetic equipment and do not generate sparks when struck.

7. Smooth Surface and Uniform Thickness

All washers are deburred and finished for smooth surfaces, reducing the risk of damage during assembly and improving contact consistency in electrical setups.

8. Machined and Stamped Options Available

We offer both stamped and machined washer versions for customers who require tighter tolerances or higher finish quality in precision applications.

9. Bulk Availability and Custom Packaging

Suitable for OEMs and industrial distributors, our washers are available in bulk with customizable packaging and labeling to meet specific procurement needs.

10. Compliance with Global Standards

Manufactured to conform to IS 2016 / DIN 125 / ISO 7089, ensuring dimensional accuracy and compatibility in global markets.

Each feature of the M20 Copper Plain Washer contributes to a high-value component that supports durable, efficient, and maintenance-free assembly operations.

Technical Specifications

At Nafees Metal Industries, our M20 Copper Plain Washers are manufactured with strict adherence to international quality standards and dimensional accuracy. Below is the detailed specification table for the M20 size, covering all technical aspects relevant for design engineers, procurement teams, and industrial users.

| Property | Specification |

|---|---|

| Product Name | M20 Copper Plain Washer |

| Material | High-Purity Copper (Typically C11000 or equivalent) |

| Inner Diameter (ID) | Approx. 21 mm (Fits standard M20 bolts and fasteners) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 standards (typically 37–40 mm) |

| Thickness | Standard 1.5 mm to 3.0 mm (Custom thickness available) |

| Surface Finish | Natural, Polished, or Oxidized |

| Manufacturing Method | Cold Stamped or CNC Machined |

| Tolerances | ID/OD within ±0.1 mm (for stamped), ±0.05 mm (for machined) |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Electrical Conductivity | >97% IACS (International Annealed Copper Standard) |

| Tensile Strength | Approx. 210 MPa (annealed) – varies with temper |

| Temperature Resistance | Operates reliably up to 400°C in continuous applications |

| Magnetic Properties | Non-Magnetic |

| Packaging | Bulk poly bags, cartons, export-grade boxes – customizable |

| Application Categories | Electrical, Plumbing, Sealing, Industrial Fastening, Automotive, Instrumentation |

| Custom Options | ID/OD customization, branding, labeling, special packaging |

These specifications ensure the M20 copper flat washer is not only compatible with a wide range of fastener types but also adaptable to various industrial environments requiring mechanical support or sealing efficiency.

Applications of M20 Copper Plain Washers

The M20 Copper Plain Washer is a versatile and high-performance component widely used in sectors where sealing, conductivity, and corrosion resistance are critical. Its unique combination of mechanical stability and material properties makes it suitable for a range of demanding applications.

1. Electrical and Grounding Systems

Due to copper’s high electrical conductivity, M20 copper washers are frequently used in electrical panels, switchgear, busbars, battery terminals, and power distribution assemblies. They ensure secure fastening while maintaining reliable grounding and electrical flow.

2. Plumbing and Sealing Applications

Copper washers are known for their ability to deform slightly under pressure, making them ideal as sealing elements in plumbing joints, flanges, and pipe connections. They are used in both hot and cold water systems, gas fittings, and HVAC setups.

3. Automotive and Heavy Vehicles

In engine compartments, fuel injection systems, brake line connections, and gearboxes, M20 copper washers are used to provide leak-proof seals and absorb vibrations. They are compatible with high-temperature and oil-exposed environments.

4. Instrumentation and Sensors

For high-precision installations like pressure sensors, temperature probes, and control instruments, M20 copper washers help ensure tight sealing and prevent fluid or gas leakage, while also reducing electrical resistance in grounding points.

5. Hydraulic and Pneumatic Systems

Copper plain washers are commonly installed in hydraulic manifolds, actuators, pumps, and compressors to provide durable sealing under pressure without reacting with fluids or oils.

6. Renewable Energy Systems

Used in solar panels, wind turbines, and battery connections where corrosion resistance, electrical continuity, and thermal conductivity are essential.

7. Marine and Offshore Installations

Copper’s natural corrosion resistance makes M20 washers suitable for use in saltwater environments, such as shipbuilding, offshore platforms, and underwater fittings.

8. Manufacturing and Maintenance Operations

These washers are commonly stocked in maintenance toolkits for routine industrial servicing, machinery assembly, and retrofitting of old systems.

9. Electrical Enclosures and Panels

In electrical control panels and enclosures, copper washers support the fastening of terminals, conductors, or plates while reducing contact resistance and heat buildup.

10. Aerospace and Defense Applications

In aviation and defense-grade systems, copper washers are valued for their spark-resistant properties, sealing strength, and vibration absorption.

Whether for electrical grounding, fluid sealing, or thermal control, the M20 copper plain washer is indispensable in modern industrial systems where precision and performance matter.

Advantages of Using M20 Copper Washers

Choosing M20 Copper Plain Washers from Nafees Metal Industries provides more than just reliable fastening — it offers long-term functional benefits across electrical, mechanical, and sealing applications. Here are the core advantages that make these washers a preferred choice for engineers, manufacturers, and maintenance professionals:

1. High Electrical Conductivity

Copper is second only to silver in electrical conductivity. Using M20 copper washers ensures minimal resistance and consistent current flow in electrical joints, making them vital in grounding and power transmission assemblies.

2. Superior Thermal Conductivity

These washers efficiently transfer heat away from fastened joints, preventing thermal stress in high-temperature environments like engines, turbines, and electrical enclosures.

3. Reliable Sealing Under Pressure

Copper’s natural softness and malleability make it an ideal sealing washer. It conforms to mating surfaces when compressed, providing leak-free joints in hydraulic, gas, and plumbing systems.

4. Excellent Corrosion Resistance

Copper forms a passive oxide layer that protects it from rust and corrosion. This makes M20 copper washers highly durable even in marine, humid, and chemically active environments.

5. Vibration Dampening

By absorbing vibrations and minor movements at the joint, copper washers reduce loosening of fasteners over time — critical for engines, machinery, and mobile systems.

6. Compatible with Dissimilar Metals

Copper minimizes galvanic reactions when used between different metals, preventing long-term degradation at fastening points.

7. Non-Magnetic and Spark-Free

Ideal for use near sensitive equipment and in explosive environments where magnetic interference or sparks are unacceptable.

8. Dimensional Precision and Uniformity

Our washers are manufactured with tight tolerances, ensuring consistent fitment, reduced wear on mating parts, and easier installation.

9. Long Service Life

Because of their mechanical and chemical stability, M20 copper washers offer extended lifespan, reducing maintenance and replacement costs.

10. Environmentally Friendly

Copper is fully recyclable, and its long lifespan reduces waste. Choosing copper washers contributes to sustainable industrial practices.

Buy M20 Copper Plain Washers in Bulk, Best M20 Copper Washer Manufacturer

If you’re looking for high-quality, precision-engineered M20 copper plain washers, Nafees Metal Industries is your trusted partner. As one of the best copper washer manufacturers in India, we specialize in the design, production, and supply of a wide range of copper washers tailored to meet the diverse needs of industrial users, OEMs, maintenance contractors, and exporters.

Why Choose Nafees Metal Industries for M20 Copper Washers?

Specialized Washer Manufacturing

With years of expertise in plain, spring, disc, and machined washers, we understand the technical requirements across sectors. Our M20 copper flat washers are manufactured in line with international standards and are tested for critical tolerances.Bulk Stock Availability

We maintain ready-to-ship inventory of standard M20 copper washers and can fulfill urgent bulk orders with quick turnaround times.Custom Specifications Accepted

Need a non-standard OD, thickness, or finish? We offer custom machining and stamping services to manufacture washers exactly as per your technical drawing or requirement.Competitive Pricing

Whether you need 1,000 or 1,00,000 pieces, we provide industry-best pricing without compromising on quality. As a direct manufacturer, we eliminate unnecessary markups.Custom Coating & Packaging Options

While copper is often used in its natural state, we also provide oxidized or polished finishes. Packaging can be customized with labeling, poly bags, cartons, or export-friendly boxes.Pan-India Delivery & Export-Ready Logistics

Located in Mumbai, our manufacturing unit is well-connected to ports and transport hubs. We offer seamless delivery within India and support international buyers with necessary documentation for smooth export.Dedicated Customer Support

Our technical and commercial teams are available to assist you with the right washer size, type, and application advice — from quotation to after-sales support.

We Serve a Wide Range of Customers:

Electrical panel manufacturers

Plumbing and HVAC contractors

Hydraulic and pneumatic system integrators

Automotive component suppliers

Aerospace and defense suppliers

Maintenance and MRO companies

Engineering procurement departments

Our M20 copper plain washers are trusted across industries for their sealing efficiency, conductivity, and corrosion resistance.

Case Study: Improving Hydraulic Seal Integrity with M20 Copper Washers

Client: Hydraulic Equipment Manufacturer – Gujarat, India

Application: High-pressure hydraulic valve assemblies

Challenge: Persistent leakage in flange joints despite using fiber and rubber washers

Problem Overview:

A mid-sized hydraulic equipment manufacturer was experiencing sealing failures in their M20 flange bolts used in pump and valve assemblies. Despite repeated installations using synthetic sealing washers, minor leaks persisted after pressure buildup, especially during thermal expansion cycles. These leaks led to component downtime, increased maintenance, and client dissatisfaction.

Nafees Metal Industries’ Solution:

After a consultation and sample evaluation, the client switched to our M20 copper plain washers in the sealing joints. We provided:

Custom-sized copper washers with annealed finish for enhanced deformability

2 mm thickness for improved sealing under torque

5000 washers with export-grade polybag and carton packaging

Technical guidance on recommended torque settings during installation

Results After Implementation:

Leakage Eliminated: All sealing failures resolved within the first production batch

Enhanced Sealing: Copper washers formed tight, leak-free connections under dynamic pressures

Improved Torque Control: Uniform compression reduced the need for re-tightening

Cost Savings: Maintenance time reduced by 30%, improving production efficiency

Client Retention: Zero complaints from downstream clients over 3 months of deployment

The success of this transition demonstrated the superior sealing and performance value that M20 copper plain washers provide in hydraulic systems — where consistent pressure retention is critical.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we go beyond being just a washer supplier — we are a solutions partner for industries that demand performance, precision, and reliability. When it comes to sourcing M20 copper plain washers, here’s why manufacturers, OEMs, and procurement teams across India and beyond choose us with confidence.

1. Decades of Specialized Experience

With focused expertise in manufacturing washers of various materials including copper, stainless steel, brass, and mild steel, we understand application-specific demands across diverse sectors such as electrical, automotive, plumbing, and heavy machinery.

2. End-to-End Quality Control

Our copper washers are manufactured using best-in-class copper grades, precision-machined or stamped to size, and inspected for ID/OD accuracy, thickness, flatness, and surface finish. We follow IS 2016, DIN 125, and ISO 7089 standards to ensure consistency in every batch.

3. Customization Without Compromise

From standard bulk washers to machined washers for critical applications, we offer made-to-order solutions in terms of dimensions, hardness (annealed/non-annealed), finishes, and packaging.

4. Commitment to the ‘Make in India’ Mission

All our products are proudly manufactured in our facility in Mumbai, India — supporting local industries while delivering global-grade quality and performance.

5. Strong Supply Chain & On-Time Delivery

Our robust logistics network ensures fast and reliable delivery across India. For export buyers, we provide complete shipping documentation, HS codes, and secure packaging suited for international freight.

6. Transparent, Competitive Pricing

We believe in long-term partnerships. Our pricing is fair, consistent, and designed to deliver maximum value for quality-conscious buyers procuring copper washers in bulk or regular volumes.

7. Customer-First Approach

From technical consultations to post-sales support, we are always ready to guide you. Whether you need help selecting the right copper washer size, thickness, or coating option, our team offers practical insights based on real-world applications.

8. Trusted by Thousands of Clients

Our client base includes industrial OEMs, MEP contractors, automotive assemblers, renewable energy companies, and equipment manufacturers — a testament to the trust placed in our brand and product quality.

We believe our M20 copper plain washers can add lasting value to your fastening, sealing, or conductive systems. When you choose Nafees Metal Industries, you’re choosing unmatched product integrity backed by consistent service.

Frequently Asked Questions (FAQs) – M20 Copper Plain Washer

1. What is the outer and inner diameter of the M20 copper plain washer?

The M20 copper plain washer typically has an inner diameter (ID) of 21 mm and an outer diameter (OD) of 37 mm, as per standard DIN 125 dimensions. However, we also offer customized sizes based on your specific application requirements.

2. What is the primary use of an M20 copper plain washer?

M20 copper washers are primarily used in high-load, high-vibration applications to distribute the pressure of bolts or nuts evenly. Their electrical conductivity and corrosion resistance make them ideal for grounding, sealing, and high-temperature environments.

3. Are these washers annealed or non-annealed?

We offer both annealed (soft) and non-annealed (hard) versions. Annealed copper washers are preferred for better sealing and compression applications, while hard ones are used where firmness and rigidity are needed.

4. Is the M20 copper washer suitable for high-temperature applications?

Yes, copper has excellent thermal conductivity and a high melting point, making it suitable for use in high-temperature environments, such as engines, boilers, and HVAC systems.

5. Can M20 copper washers be used in electrical applications?

Absolutely. Copper’s high electrical conductivity makes these washers perfect for grounding, bonding, and current-carrying applications in electrical panels, transformers, and battery terminals.

6. What industries commonly use M20 copper washers?

Industries like electrical, automotive, oil & gas, chemical, HVAC, marine, and heavy equipment manufacturing regularly use M20 copper plain washers for various structural and conductive purposes.

7. Are these washers corrosion-resistant?

Yes, copper naturally resists corrosion and does not rust. It forms a stable oxide layer that protects the underlying metal, especially in marine and humid environments.

8. Do you offer customization for M20 copper plain washers?

Yes. We provide customization in terms of ID/OD, thickness, hardness, finish (bare, tinned, coated), and packaging. Share your drawing or specification sheet, and we will manufacture it accordingly.

9. How is the thickness of the M20 copper washer determined?

The standard thickness ranges between 1.5 mm to 3 mm depending on the requirement, but it can be customized based on load-bearing needs or sealing specifications.

10. What surface finishes are available for these washers?

We offer plain copper finish as well as tinned or nickel-plated options to enhance conductivity or corrosion resistance as per the application environment.

11. Do you provide material test certificates (MTC)?

Yes, we provide MTCs on request to ensure complete transparency. The certificate confirms the composition, hardness, and properties of the copper used.

12. What is the minimum order quantity (MOQ) for M20 copper plain washers?

Our MOQ is flexible depending on whether you’re purchasing for retail, industrial, or export purposes. We also cater to bulk orders with competitive pricing.

13. Can I buy M20 copper washers in bulk for export?

Yes, we are fully equipped to handle bulk export orders. We provide HS codes, country-specific packaging, and documentation as required for customs clearance.

14. Are these washers RoHS compliant?

Yes, the copper washers we supply are manufactured from RoHS-compliant raw material, ensuring safety and environmental compliance.

15. How soon can I receive my order?

Lead time depends on quantity and customization. Standard sizes like M20 are usually ready in stock or can be dispatched within 2–4 working days. For large or custom orders, delivery timelines will be communicated transparently.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch