No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

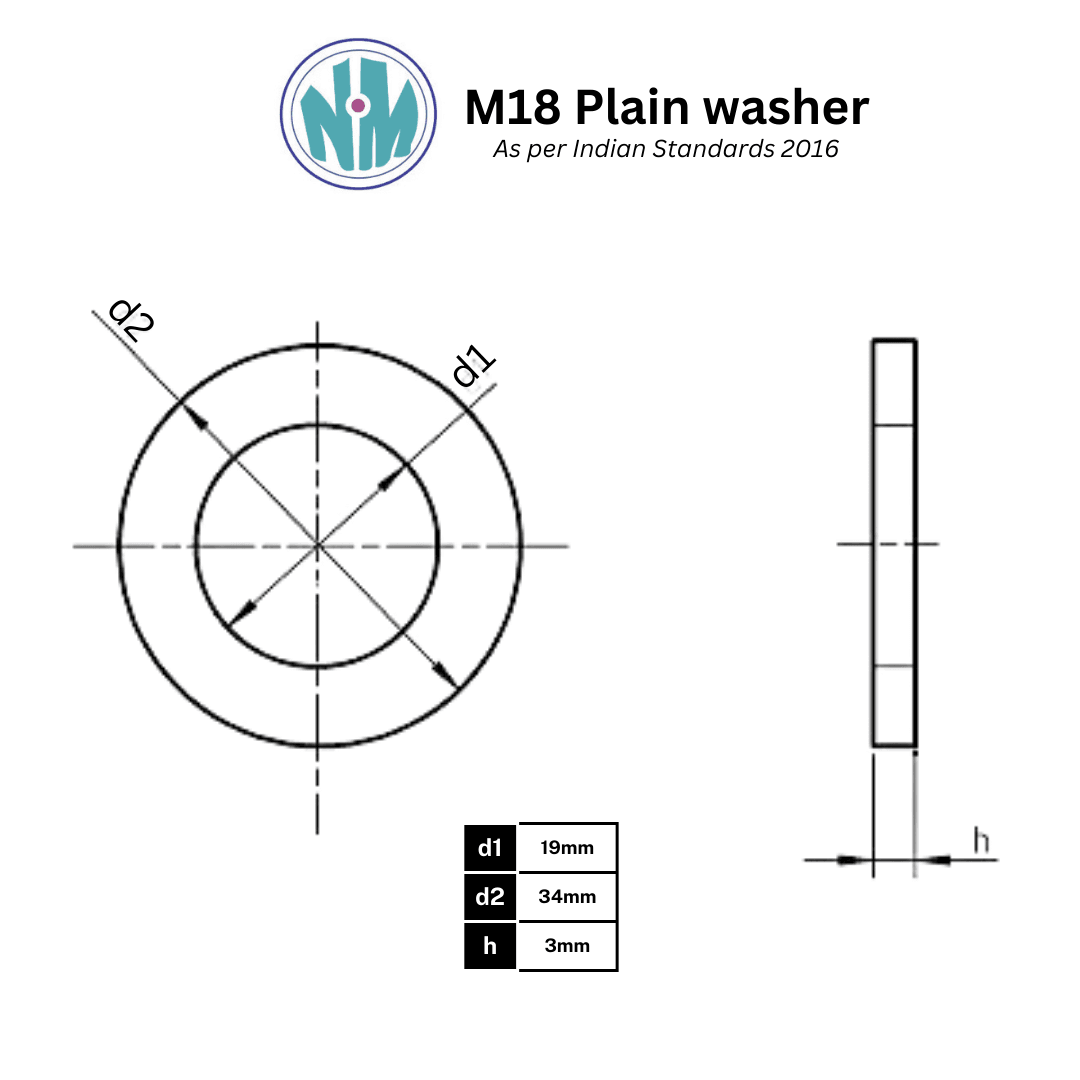

*Images shown for graphic representation. Not to scale.

M18 SS202 Plain Washers – Engineered for Reliable Load Distribution in Precision Assemblies

Introduction

In the world of precision engineering and structural fastening, even the smallest component plays a critical role. Washers, especially those tailored to specific bolt sizes, are essential for ensuring reliable, long-lasting mechanical connections. Among these, M18 SS202 Plain Washers are a widely preferred solution for industrial assemblies that demand consistent performance, accurate load distribution, and surface protection.

These washers are specifically designed to support M18 bolts, offering an optimal interface between the bolt head or nut and the underlying surface. Manufactured using SS202 stainless steel—a reliable material offering strength and moderate corrosion resistance—M18 SS202 Plain Washers are the perfect blend of durability and cost-effectiveness.

Used in industries ranging from automotive and construction to machinery and fabrication, these washers serve to prevent loosening under vibration, protect surfaces from deformation, and enhance the longevity of bolted joints. Our premium-quality M18 SS202 Plain Washers are engineered for performance, manufactured to precision, and available in bulk with customizable packaging options.

What Are M18 SS202 Plain Washers?

M18 SS202 Plain Washers are flat, round metallic discs with a central hole designed to fit around M18 bolts. Their core function is to distribute the bolt load evenly across the fastened surface to avoid localized stress. In addition to load distribution, they act as protective layers between fastening components and the surface they secure, reducing wear and preventing damage.

Core Functions:

Load Distribution – Prevents bolt heads or nuts from damaging the surface by evenly spreading the tightening force

Vibration Resistance – Reduces the risk of fastener loosening in machines or assemblies subjected to dynamic motion

Surface Preservation – Minimizes galling, scoring, or cracking on sensitive or softer surfaces

What sets M18 SS202 Plain Washers apart is the use of SS202 stainless steel—a practical choice for applications where full marine-grade resistance is not required, yet mechanical strength and moderate corrosion protection are essential.

Material Details: Why SS202?

SS202 stainless steel belongs to the austenitic family of stainless steels. It is known for its affordability, strength, and acceptable corrosion resistance in general industrial environments.

Composition of SS202:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: ≤ 0.08%

Benefits of SS202 in Washers:

Mechanical Strength – Withstands torque and compression without deforming

Corrosion Resistance – Ideal for mildly corrosive or semi-outdoor conditions

Formability & Weldability – Easily machined and integrated into custom assemblies

Economic Advantage – More cost-effective than SS304 or SS316 without significant compromise

For industries needing washers that balance performance and budget, M18 SS202 Plain Washers offer an optimal solution.

Manufacturing and Technical Specifications

All M18 SS202 Plain Washers are produced under strict quality assurance protocols. Our facilities employ CNC-controlled processes to ensure consistent dimensions, reliable performance, and batch-wise traceability.

Manufacturing Process:

CNC-machining for dimension precision

Deburring for safety and clean handling

Surface finishing options: matte, polished, or bright

Degreasing and rust-proof packaging

Final QC inspection and certification

Standard Specifications:

| Parameter | Specification |

|---|---|

| Inner Diameter | 18.5 mm ± 0.3 mm |

| Outer Diameter | 36.0 mm ± 0.5 mm |

| Thickness | 2.5 mm ± 0.2 mm |

| Material | SS202 Stainless Steel |

| Surface Finish | Matte / Bright / Polished |

| Shape | Flat Circular Disc |

These specifications ensure that M18 SS202 Plain Washers fit precisely with M18 bolts and function optimally across various applications.

Key Features

M18 SS202 Plain Washers are specifically designed to enhance the performance, reliability, and durability of fastened joints in industrial and structural applications. Their features are tailored to meet the demands of environments where precision, strength, and long-term consistency are essential.

1. Uniform Load Distribution

These washers play a critical role in distributing the clamping force applied by M18 bolts. Without them, bolt heads or nuts can concentrate pressure on a single point, potentially damaging the surface or causing structural failure. M18 SS202 Plain Washers evenly spread the load, protecting both the bolt and the surface material—especially important in assemblies involving softer metals, composites, or coated finishes.

2. Exact Fit for M18 Bolts

Precision is non-negotiable in critical fastening systems. Each M18 SS202 Plain Washer is manufactured with tight dimensional tolerances to ensure a snug and accurate fit around M18 bolts. This prevents side movement, reduces installation error, and ensures consistent torque application across the entire assembly.

3. Effective Vibration Resistance

Vibration is a major cause of fastener failure in industrial equipment, transport vehicles, and rotating machinery. These washers serve as a buffer that absorbs and distributes kinetic energy, helping bolts remain tight and minimizing the need for frequent re-torqueing. This leads to reduced downtime and enhanced operational safety.

4. Moderate Corrosion Protection

Constructed from SS202 stainless steel, these washers offer a reliable level of corrosion resistance for indoor and semi-exposed applications. They resist oxidation in moist and mildly corrosive environments, making them ideal for facilities with varying humidity levels or intermittent outdoor exposure.

5. Enhanced Surface Protection

A smooth, burr-free surface finish prevents scoring or scratching of adjacent components, which is particularly beneficial in precision assemblies, electrical panels, or when securing painted or coated surfaces. The washers act as a protective barrier that preserves component integrity and finish.

6. Long-Lasting Performance

Due to their material composition and quality manufacturing process, M18 SS202 Plain Washers maintain structural integrity even after repeated tightening and loosening cycles. They are less likely to deform, crack, or fatigue over time, resulting in a longer service life and fewer replacements.

7. High Mechanical Strength

Compared to washers made from mild steel or carbon steel, SS202 offers superior tensile strength and compressive load capacity. This makes these washers especially suitable for medium to heavy-duty fastening requirements across mechanical and structural systems.

8. Dimensional Accuracy and Consistency

The washers are CNC-machined to ensure every piece in a batch has uniform inner diameter, outer diameter, and thickness. This accuracy is essential for automated assembly lines, robotic fastening systems, or precision bolt-torque applications where consistency is critical.

9. Minimal Maintenance Requirements

Once installed, these washers require very little attention. Their stainless steel structure resists corrosion and wear, and their long-lasting surface finish eliminates the need for recoating or protective treatments in most environments.

10. Versatile Packaging Options

Depending on the application—whether it’s for mass production, field installation, or retail—M18 SS202 Plain Washers can be supplied in bulk boxes, individually labeled bags, or custom kits. This flexibility streamlines inventory, improves site logistics, and supports private labeling.

Applications & Use Cases

M18 SS202 Plain Washers are used in a wide range of industries and projects that require dependable fastening solutions. Thanks to their precise engineering and material resilience, they are a trusted component in everything from infrastructure and machinery to electronics and fabrication.

1. Industrial Machinery and Equipment

In machine assemblies, these washers are used to secure bolts in motors, gearboxes, frames, and rotating systems. They protect structural surfaces, prevent bolt loosening due to vibration, and maintain alignment under load. Whether it’s a CNC machine, a conveyor system, or a packaging unit, M18 SS202 Plain Washers help maintain operational stability.

2. Construction and Structural Steelwork

From structural beams and columns to baseplates and anchor bolts, these washers are commonly used in construction projects. They provide load-bearing support in connections subject to axial loads and shear forces. Their ability to distribute force reduces the risk of concrete crushing or steel deformation in high-load zones.

3. Automotive and Heavy Vehicles

M18 SS202 Plain Washers are used in the assembly of trucks, trailers, agricultural vehicles, and off-road machinery. They are placed under suspension bolts, frame joints, and engine mounts, ensuring bolt tension is maintained even under intense road vibrations and thermal expansion.

4. Renewable Energy Systems

In solar farms and wind turbine installations, these washers support M18 fasteners used to mount panel brackets, frames, and support arms. Their stainless steel composition helps them withstand the environmental conditions commonly found in outdoor energy applications, including temperature swings and exposure to moisture.

5. Electrical Panels and Control Boxes

Used beneath terminal bolts and mounting hardware, these washers provide secure connections in electrical cabinets and power distribution panels. They ensure grounding continuity, protect component surfaces, and maintain tightness in high-cycle installations.

6. Rail and Transportation Infrastructure

Rail fastening systems, signal mounts, and structural supports within train stations or depots all rely on washers to keep bolts tight and loads balanced. In such dynamic, high-impact environments, M18 SS202 Plain Washers offer the mechanical strength needed for safety-critical joints.

7. Fabrication Workshops and OEM Assemblies

These washers are regularly used in equipment manufactured by Original Equipment Manufacturers (OEMs). Applications range from shop-floor welding jigs and storage systems to commercial-grade furniture and industrial racks.

8. HVAC and Mechanical Installations

Heating, ventilation, and cooling systems use M18 bolts to mount ductwork, pipe flanges, and equipment brackets. Washers help prevent surface warping, ensure flat mounting, and reduce the risk of vibration-related loosening.

9. Marine and Port Facilities (Non-Submerged Use)

Although SS202 is not marine-grade, it performs reliably in above-deck port infrastructure or shoreline storage sheds where water exposure is moderate. The washers resist rusting from salt-laden air and are often used in fasteners for fences, railings, and equipment shelters.

10. Agricultural Machinery and Equipment

Used in tractors, tillers, harvesters, and irrigation systems, these washers reinforce M18 bolt connections on moving or load-bearing parts. Their strength and resistance to vibration are critical in rough terrain and high-cycle operations.

These diverse applications highlight the adaptability and reliability of M18 SS202 Plain Washers. Whether you’re securing a solar panel frame or bolting a heavy industrial motor, these washers provide the performance and protection your assembly needs.

Why Buy M18 SS202 Plain Washers in Bulk

Bulk purchasing is ideal for OEMs, distributors, and contractors who require volume, consistency, and efficiency.

Cost Savings: Reduced per-piece cost through volume pricing

Operational Readiness: Stock availability avoids work delays

Custom Packaging: Sorted, labeled, and barcoded packaging options

Batch Consistency: Uniform dimensions across entire supply

Convenient Logistics: Streamlined dispatch and tracking for large orders

Looking to Buy M18 SS202 Plain Washers in Bulk? We’re equipped to handle high-volume orders with global shipping support.

Why Choose the Best M18 SS202 Washers for Industrial Use

We stand out as the Best M18 SS202 Washers for Industrial Use because of:

In-House Production – Total control over quality, tolerances, and timelines

Certified Materials – ISO-certified, RoHS-compliant, with MTCs on request

Responsive Support – Engineering consultation, CAD validation, and RFQ assistance

Scalable Supply – From trial orders to full container loads

Reputation – Trusted by manufacturers, fabricators, and EPC contractors worldwide

Installation Tips

To ensure optimal performance:

Clean the surface and washer before installation

Place the washer flat beneath the bolt head or nut

Use a calibrated torque wrench for consistent fastening

Inspect for flatness—replace any deformed washers

Consider dual washers (under bolt and nut) for critical applications

Store unused washers in dry conditions to prevent premature rusting

Maintenance Guidelines

Inspection: Check periodically for signs of corrosion, warping, or cracking

Storage: Keep in sealed containers in a low-humidity environment

Cleaning: Wipe with a clean cloth and mild solvent—avoid abrasives

Replacement: Replace washers showing deformation or significant discoloration

Track Usage: Maintain records for scheduled replacements during equipment servicing

Case Study: Structural Retrofitting with M18 SS202 Plain Washers

During a large-scale retrofitting project for an industrial plant, the engineering team faced recurring issues with bolt loosening in vibration-prone zones. The existing washers were made from basic carbon steel, which deformed under stress and showed early signs of rust.

The Challenge

Frequent torque loss in structural connections

Washer cracking and bolt head embedment

Time-consuming maintenance cycles

The Solution

The engineering team replaced all carbon steel washers with M18 SS202 Plain Washers across 2,000+ structural joints.

Execution Highlights:

25,000 washers delivered in three phases

Matte finish to reduce reflection in inspection zones

Packaging in 1,000-piece labeled boxes

Certificate of conformity and inspection report provided

Results:

| Metric | Before (Carbon Steel) | After (M18 SS202 Plain Washers) |

|---|---|---|

| Torque Retention Rate | 77% | 98.9% |

| Washer Replacement Rate | 30% within 3 months | <2% within 6 months |

| Maintenance Intervals | Monthly | Quarterly |

| Bolt Loosening Reports | Frequent | Rare |

The team confirmed that M18 SS202 Plain Washers significantly improved structural integrity, reduced bolt fatigue, and streamlined maintenance schedules.

Related Products or Variants

SS202 Washers – Available in sizes from M6 to M36

Stainless Steel Flat Washers – For wider load distribution in soft materials

Hot-Dip Galvanized Washers – For highly corrosive or marine applications

Custom Washers – OD/ID/thickness tailored to your requirements

Trial Packs – Test before bulk commitment

Final Words

M18 SS202 Plain Washers are more than just flat pieces of metal—they are integral to the safety, durability, and reliability of every fastened connection. Whether you’re building bridges, manufacturing equipment, or managing routine maintenance, these washers deliver the performance you need.

Backed by precision engineering, competitive pricing, and scalable availability, our washers are the trusted choice across industries.

Choose reliability. Choose performance. Choose M18 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

1. What are M18 SS202 Plain Washers used for?

They’re used to distribute load, prevent surface damage, and resist vibration in fastened joints using M18 bolts.

2. Can I reuse these washers?

Yes, if they are not deformed or corroded.

3. Are these part of the SS202 Washers range?

Yes, they are a standard size in our SS202 Washers lineup.

4. Do you provide Stainless Steel Flat Washers too?

Absolutely. We offer a complete range including flat, spring, and special-purpose washers.

5. What makes them better than mild steel washers?

Superior strength, better fatigue resistance, and moderate corrosion protection.

6. Do you offer certifications with bulk orders?

Yes, including ISO, RoHS, and material test certificates.

7. Can I get a trial pack?

Yes, sample packs are available before placing a large order.

8. Do you offer custom dimensions?

Yes. We manufacture washers to client-supplied drawings and tolerances.

9. How do I Buy M18 SS202 Plain Washers in Bulk?

Submit an inquiry via our website or RFQ form, and our sales team will assist you.

10. Are these suitable for marine environments?

For marine use, we recommend SS316. SS202 works best in non-marine environments.

11. How long do they last in semi-outdoor use?

Typically several years, depending on environmental exposure and load cycles.

12. What packaging options do you offer?

Bulk sacks, labeled boxes, or custom retail packs based on your needs.

13. Do you ship internationally?

Yes, with full export documentation and support.

14. What is your MOQ for bulk orders?

Minimum order quantities typically start at 500 units.

15. Are you the Best M18 SS202 Washers for Industrial Use?

Yes, thanks to our proven quality, reliable delivery, and global customer base.

Why Choose Nafees Metal Industries

At Nafees Metal industries, we’re committed to manufacturing M18 SS202 Plain Washers that meet the highest standards for performance, reliability, and customer satisfaction. We use state-of-the-art equipment and top-grade SS202 stainless steel to produce washers trusted across multiple industries.

Whether you need standard sizes or custom solutions, our stainless steel washers are competitively priced, delivered on time, and backed by friendly, responsive support.

Order the Best M18 SS202 Plain Washers Today!

Get high-quality M18 SS202 Plain Washers direct from the manufacturer. Buy bulk M18 stainless steel washers for your next project and experience the difference in strength and reliability.

Visit our modern manufacturing unit at Reay Road, Mumbai, or order online for fast dispatch.

M18 SS202 Plain Washers

12 people are viewing this product right now

₹4.20 Original price was: ₹4.20.₹3.50Current price is: ₹3.50. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M18

Inner Diameter (ID): 19 mm

Outer Diameter (OD): 34 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M18 SS202 Plain Washers – Engineered for Reliable Load Distribution in Precision Assemblies

Introduction

In the world of precision engineering and structural fastening, even the smallest component plays a critical role. Washers, especially those tailored to specific bolt sizes, are essential for ensuring reliable, long-lasting mechanical connections. Among these, M18 SS202 Plain Washers are a widely preferred solution for industrial assemblies that demand consistent performance, accurate load distribution, and surface protection.

These washers are specifically designed to support M18 bolts, offering an optimal interface between the bolt head or nut and the underlying surface. Manufactured using SS202 stainless steel—a reliable material offering strength and moderate corrosion resistance—M18 SS202 Plain Washers are the perfect blend of durability and cost-effectiveness.

Used in industries ranging from automotive and construction to machinery and fabrication, these washers serve to prevent loosening under vibration, protect surfaces from deformation, and enhance the longevity of bolted joints. Our premium-quality M18 SS202 Plain Washers are engineered for performance, manufactured to precision, and available in bulk with customizable packaging options.

What Are M18 SS202 Plain Washers?

M18 SS202 Plain Washers are flat, round metallic discs with a central hole designed to fit around M18 bolts. Their core function is to distribute the bolt load evenly across the fastened surface to avoid localized stress. In addition to load distribution, they act as protective layers between fastening components and the surface they secure, reducing wear and preventing damage.

Core Functions:

Load Distribution – Prevents bolt heads or nuts from damaging the surface by evenly spreading the tightening force

Vibration Resistance – Reduces the risk of fastener loosening in machines or assemblies subjected to dynamic motion

Surface Preservation – Minimizes galling, scoring, or cracking on sensitive or softer surfaces

What sets M18 SS202 Plain Washers apart is the use of SS202 stainless steel—a practical choice for applications where full marine-grade resistance is not required, yet mechanical strength and moderate corrosion protection are essential.

Material Details: Why SS202?

SS202 stainless steel belongs to the austenitic family of stainless steels. It is known for its affordability, strength, and acceptable corrosion resistance in general industrial environments.

Composition of SS202:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: ≤ 0.08%

Benefits of SS202 in Washers:

Mechanical Strength – Withstands torque and compression without deforming

Corrosion Resistance – Ideal for mildly corrosive or semi-outdoor conditions

Formability & Weldability – Easily machined and integrated into custom assemblies

Economic Advantage – More cost-effective than SS304 or SS316 without significant compromise

For industries needing washers that balance performance and budget, M18 SS202 Plain Washers offer an optimal solution.

Manufacturing and Technical Specifications

All M18 SS202 Plain Washers are produced under strict quality assurance protocols. Our facilities employ CNC-controlled processes to ensure consistent dimensions, reliable performance, and batch-wise traceability.

Manufacturing Process:

CNC-machining for dimension precision

Deburring for safety and clean handling

Surface finishing options: matte, polished, or bright

Degreasing and rust-proof packaging

Final QC inspection and certification

Standard Specifications:

| Parameter | Specification |

|---|---|

| Inner Diameter | 18.5 mm ± 0.3 mm |

| Outer Diameter | 36.0 mm ± 0.5 mm |

| Thickness | 2.5 mm ± 0.2 mm |

| Material | SS202 Stainless Steel |

| Surface Finish | Matte / Bright / Polished |

| Shape | Flat Circular Disc |

These specifications ensure that M18 SS202 Plain Washers fit precisely with M18 bolts and function optimally across various applications.

Key Features

M18 SS202 Plain Washers are specifically designed to enhance the performance, reliability, and durability of fastened joints in industrial and structural applications. Their features are tailored to meet the demands of environments where precision, strength, and long-term consistency are essential.

1. Uniform Load Distribution

These washers play a critical role in distributing the clamping force applied by M18 bolts. Without them, bolt heads or nuts can concentrate pressure on a single point, potentially damaging the surface or causing structural failure. M18 SS202 Plain Washers evenly spread the load, protecting both the bolt and the surface material—especially important in assemblies involving softer metals, composites, or coated finishes.

2. Exact Fit for M18 Bolts

Precision is non-negotiable in critical fastening systems. Each M18 SS202 Plain Washer is manufactured with tight dimensional tolerances to ensure a snug and accurate fit around M18 bolts. This prevents side movement, reduces installation error, and ensures consistent torque application across the entire assembly.

3. Effective Vibration Resistance

Vibration is a major cause of fastener failure in industrial equipment, transport vehicles, and rotating machinery. These washers serve as a buffer that absorbs and distributes kinetic energy, helping bolts remain tight and minimizing the need for frequent re-torqueing. This leads to reduced downtime and enhanced operational safety.

4. Moderate Corrosion Protection

Constructed from SS202 stainless steel, these washers offer a reliable level of corrosion resistance for indoor and semi-exposed applications. They resist oxidation in moist and mildly corrosive environments, making them ideal for facilities with varying humidity levels or intermittent outdoor exposure.

5. Enhanced Surface Protection

A smooth, burr-free surface finish prevents scoring or scratching of adjacent components, which is particularly beneficial in precision assemblies, electrical panels, or when securing painted or coated surfaces. The washers act as a protective barrier that preserves component integrity and finish.

6. Long-Lasting Performance

Due to their material composition and quality manufacturing process, M18 SS202 Plain Washers maintain structural integrity even after repeated tightening and loosening cycles. They are less likely to deform, crack, or fatigue over time, resulting in a longer service life and fewer replacements.

7. High Mechanical Strength

Compared to washers made from mild steel or carbon steel, SS202 offers superior tensile strength and compressive load capacity. This makes these washers especially suitable for medium to heavy-duty fastening requirements across mechanical and structural systems.

8. Dimensional Accuracy and Consistency

The washers are CNC-machined to ensure every piece in a batch has uniform inner diameter, outer diameter, and thickness. This accuracy is essential for automated assembly lines, robotic fastening systems, or precision bolt-torque applications where consistency is critical.

9. Minimal Maintenance Requirements

Once installed, these washers require very little attention. Their stainless steel structure resists corrosion and wear, and their long-lasting surface finish eliminates the need for recoating or protective treatments in most environments.

10. Versatile Packaging Options

Depending on the application—whether it’s for mass production, field installation, or retail—M18 SS202 Plain Washers can be supplied in bulk boxes, individually labeled bags, or custom kits. This flexibility streamlines inventory, improves site logistics, and supports private labeling.

Applications & Use Cases

M18 SS202 Plain Washers are used in a wide range of industries and projects that require dependable fastening solutions. Thanks to their precise engineering and material resilience, they are a trusted component in everything from infrastructure and machinery to electronics and fabrication.

1. Industrial Machinery and Equipment

In machine assemblies, these washers are used to secure bolts in motors, gearboxes, frames, and rotating systems. They protect structural surfaces, prevent bolt loosening due to vibration, and maintain alignment under load. Whether it’s a CNC machine, a conveyor system, or a packaging unit, M18 SS202 Plain Washers help maintain operational stability.

2. Construction and Structural Steelwork

From structural beams and columns to baseplates and anchor bolts, these washers are commonly used in construction projects. They provide load-bearing support in connections subject to axial loads and shear forces. Their ability to distribute force reduces the risk of concrete crushing or steel deformation in high-load zones.

3. Automotive and Heavy Vehicles

M18 SS202 Plain Washers are used in the assembly of trucks, trailers, agricultural vehicles, and off-road machinery. They are placed under suspension bolts, frame joints, and engine mounts, ensuring bolt tension is maintained even under intense road vibrations and thermal expansion.

4. Renewable Energy Systems

In solar farms and wind turbine installations, these washers support M18 fasteners used to mount panel brackets, frames, and support arms. Their stainless steel composition helps them withstand the environmental conditions commonly found in outdoor energy applications, including temperature swings and exposure to moisture.

5. Electrical Panels and Control Boxes

Used beneath terminal bolts and mounting hardware, these washers provide secure connections in electrical cabinets and power distribution panels. They ensure grounding continuity, protect component surfaces, and maintain tightness in high-cycle installations.

6. Rail and Transportation Infrastructure

Rail fastening systems, signal mounts, and structural supports within train stations or depots all rely on washers to keep bolts tight and loads balanced. In such dynamic, high-impact environments, M18 SS202 Plain Washers offer the mechanical strength needed for safety-critical joints.

7. Fabrication Workshops and OEM Assemblies

These washers are regularly used in equipment manufactured by Original Equipment Manufacturers (OEMs). Applications range from shop-floor welding jigs and storage systems to commercial-grade furniture and industrial racks.

8. HVAC and Mechanical Installations

Heating, ventilation, and cooling systems use M18 bolts to mount ductwork, pipe flanges, and equipment brackets. Washers help prevent surface warping, ensure flat mounting, and reduce the risk of vibration-related loosening.

9. Marine and Port Facilities (Non-Submerged Use)

Although SS202 is not marine-grade, it performs reliably in above-deck port infrastructure or shoreline storage sheds where water exposure is moderate. The washers resist rusting from salt-laden air and are often used in fasteners for fences, railings, and equipment shelters.

10. Agricultural Machinery and Equipment

Used in tractors, tillers, harvesters, and irrigation systems, these washers reinforce M18 bolt connections on moving or load-bearing parts. Their strength and resistance to vibration are critical in rough terrain and high-cycle operations.

These diverse applications highlight the adaptability and reliability of M18 SS202 Plain Washers. Whether you’re securing a solar panel frame or bolting a heavy industrial motor, these washers provide the performance and protection your assembly needs.

Why Buy M18 SS202 Plain Washers in Bulk

Bulk purchasing is ideal for OEMs, distributors, and contractors who require volume, consistency, and efficiency.

Cost Savings: Reduced per-piece cost through volume pricing

Operational Readiness: Stock availability avoids work delays

Custom Packaging: Sorted, labeled, and barcoded packaging options

Batch Consistency: Uniform dimensions across entire supply

Convenient Logistics: Streamlined dispatch and tracking for large orders

Looking to Buy M18 SS202 Plain Washers in Bulk? We’re equipped to handle high-volume orders with global shipping support.

Why Choose the Best M18 SS202 Washers for Industrial Use

We stand out as the Best M18 SS202 Washers for Industrial Use because of:

In-House Production – Total control over quality, tolerances, and timelines

Certified Materials – ISO-certified, RoHS-compliant, with MTCs on request

Responsive Support – Engineering consultation, CAD validation, and RFQ assistance

Scalable Supply – From trial orders to full container loads

Reputation – Trusted by manufacturers, fabricators, and EPC contractors worldwide

Installation Tips

To ensure optimal performance:

Clean the surface and washer before installation

Place the washer flat beneath the bolt head or nut

Use a calibrated torque wrench for consistent fastening

Inspect for flatness—replace any deformed washers

Consider dual washers (under bolt and nut) for critical applications

Store unused washers in dry conditions to prevent premature rusting

Maintenance Guidelines

Inspection: Check periodically for signs of corrosion, warping, or cracking

Storage: Keep in sealed containers in a low-humidity environment

Cleaning: Wipe with a clean cloth and mild solvent—avoid abrasives

Replacement: Replace washers showing deformation or significant discoloration

Track Usage: Maintain records for scheduled replacements during equipment servicing

Case Study: Structural Retrofitting with M18 SS202 Plain Washers

During a large-scale retrofitting project for an industrial plant, the engineering team faced recurring issues with bolt loosening in vibration-prone zones. The existing washers were made from basic carbon steel, which deformed under stress and showed early signs of rust.

The Challenge

Frequent torque loss in structural connections

Washer cracking and bolt head embedment

Time-consuming maintenance cycles

The Solution

The engineering team replaced all carbon steel washers with M18 SS202 Plain Washers across 2,000+ structural joints.

Execution Highlights:

25,000 washers delivered in three phases

Matte finish to reduce reflection in inspection zones

Packaging in 1,000-piece labeled boxes

Certificate of conformity and inspection report provided

Results:

| Metric | Before (Carbon Steel) | After (M18 SS202 Plain Washers) |

|---|---|---|

| Torque Retention Rate | 77% | 98.9% |

| Washer Replacement Rate | 30% within 3 months | <2% within 6 months |

| Maintenance Intervals | Monthly | Quarterly |

| Bolt Loosening Reports | Frequent | Rare |

The team confirmed that M18 SS202 Plain Washers significantly improved structural integrity, reduced bolt fatigue, and streamlined maintenance schedules.

Related Products or Variants

SS202 Washers – Available in sizes from M6 to M36

Stainless Steel Flat Washers – For wider load distribution in soft materials

Hot-Dip Galvanized Washers – For highly corrosive or marine applications

Custom Washers – OD/ID/thickness tailored to your requirements

Trial Packs – Test before bulk commitment

Final Words

M18 SS202 Plain Washers are more than just flat pieces of metal—they are integral to the safety, durability, and reliability of every fastened connection. Whether you’re building bridges, manufacturing equipment, or managing routine maintenance, these washers deliver the performance you need.

Backed by precision engineering, competitive pricing, and scalable availability, our washers are the trusted choice across industries.

Choose reliability. Choose performance. Choose M18 SS202 Plain Washers.

Frequently Asked Questions (FAQs)

1. What are M18 SS202 Plain Washers used for?

They’re used to distribute load, prevent surface damage, and resist vibration in fastened joints using M18 bolts.

2. Can I reuse these washers?

Yes, if they are not deformed or corroded.

3. Are these part of the SS202 Washers range?

Yes, they are a standard size in our SS202 Washers lineup.

4. Do you provide Stainless Steel Flat Washers too?

Absolutely. We offer a complete range including flat, spring, and special-purpose washers.

5. What makes them better than mild steel washers?

Superior strength, better fatigue resistance, and moderate corrosion protection.

6. Do you offer certifications with bulk orders?

Yes, including ISO, RoHS, and material test certificates.

7. Can I get a trial pack?

Yes, sample packs are available before placing a large order.

8. Do you offer custom dimensions?

Yes. We manufacture washers to client-supplied drawings and tolerances.

9. How do I Buy M18 SS202 Plain Washers in Bulk?

Submit an inquiry via our website or RFQ form, and our sales team will assist you.

10. Are these suitable for marine environments?

For marine use, we recommend SS316. SS202 works best in non-marine environments.

11. How long do they last in semi-outdoor use?

Typically several years, depending on environmental exposure and load cycles.

12. What packaging options do you offer?

Bulk sacks, labeled boxes, or custom retail packs based on your needs.

13. Do you ship internationally?

Yes, with full export documentation and support.

14. What is your MOQ for bulk orders?

Minimum order quantities typically start at 500 units.

15. Are you the Best M18 SS202 Washers for Industrial Use?

Yes, thanks to our proven quality, reliable delivery, and global customer base.

Why Choose Nafees Metal Industries

At Nafees Metal industries, we’re committed to manufacturing M18 SS202 Plain Washers that meet the highest standards for performance, reliability, and customer satisfaction. We use state-of-the-art equipment and top-grade SS202 stainless steel to produce washers trusted across multiple industries.

Whether you need standard sizes or custom solutions, our stainless steel washers are competitively priced, delivered on time, and backed by friendly, responsive support.

Order the Best M18 SS202 Plain Washers Today!

Get high-quality M18 SS202 Plain Washers direct from the manufacturer. Buy bulk M18 stainless steel washers for your next project and experience the difference in strength and reliability.

Visit our modern manufacturing unit at Reay Road, Mumbai, or order online for fast dispatch.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch