No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M12 Mild Steel Plain Washers"

*Images shown for graphic representation. Not to scale.

M18 Mild Steel Plain Washers – Best M18 MS Flat Washers Manufacturer for Industrial Applications

Product Overview

M18 Mild Steel Plain Washers are essential components used extensively in mechanical, industrial, and structural applications. These washers are flat, disc-shaped components with a hole in the center to accommodate M18-sized bolts or screws. As part of the broader family of Mild Steel Washers, these washers provide critical load distribution, protect surfaces, and enhance the integrity of bolted assemblies.

At Nafees Metal Industries, we specialize in manufacturing high-quality M18 Mild Steel Plain Washers with precision engineering and consistent performance. Our washers are known for their dimensional accuracy, smooth finish, and corrosion resistance, making us the Best M18 MS Flat Washers Manufacturer in the market.

Key Features of M18 Mild Steel Plain Washers

At Nafees Metal Industries, we take pride in offering industrial-grade components that perform reliably under high-stress applications. Our M18 Mild Steel Plain Washers are designed with precision and manufactured under stringent quality control standards. Below are the key features that make these washers ideal for a wide range of industrial and mechanical uses:

1. Perfect Inner and Outer Diameters

Our M18 Mild Steel Plain Washers are dimensioned to fit seamlessly with M18 bolts and nuts, ensuring snug placement without excess play or distortion.

The precise inner diameter prevents misalignment or slippage during torque application.

The wide outer diameter provides a larger bearing surface, which helps in evenly distributing the load across the bolted joint.

2. Durable Mild Steel Composition

Manufactured using high-quality low-carbon mild steel, these washers offer exceptional ductility and tensile strength.

Mild steel resists cracking under pressure, making it ideal for applications where vibrations, dynamic loads, or torque variations are frequent.

The material provides the ideal balance between strength and machinability, making it a top choice for large-scale industrial setups.

3. Load Distribution Excellence

One of the core benefits of our M18 Mild Steel Plain Washers is their ability to disperse the load uniformly across the surface beneath the bolt or nut.

This helps prevent localized stress, material deformation, and bolt pull-through—issues common in high-torque fastening environments.

Ensures longer life of both fastener and mating surface, reducing repair and maintenance costs.

4. Excellent Vibration Dampening

In mechanical assemblies exposed to movement or shaking, washers play a critical role in maintaining joint integrity.

Our M18 washers help dampen vibrations and prevent loosening of nuts and bolts, making them indispensable in machinery, automotive, rail, and construction sectors.

5. Corrosion Protection Options

Though mild steel on its own can be susceptible to rust, we offer multiple post-processing options like:

Zinc plating

Hot-dip galvanization

Black oxide coating

These finishes enhance resistance to corrosion, making the washer suitable even for outdoor and marine environments.

6. Optimized for High-Torque Applications

Designed to withstand high torque without warping or cracking, these washers are ideal for:

Structural bolting

Engine assembly

Equipment base installations

Heavy fabrication jobs

Maintains shape and functionality even under repetitive torque cycles, preserving the reliability of the bolted connection.

7. Consistent Surface Finish

Each washer is finished to provide a smooth, burr-free surface, reducing friction during tightening and preventing damage to the joint surface.

Ensures uniform friction coefficient across all units, which is critical for consistent torque readings during automated or manual assembly.

8. Versatile Applications

Used in various industries such as:

Automotive

Construction

Electrical panel fabrication

OEM parts assembly

Heavy engineering and structural frameworks

Whether you’re assembling a heavy-duty machine or securing steel columns, these washers offer unmatched reliability.

9. Bulk Availability for Industrial Buyers

We understand the needs of OEMs, distributors, and contractors who require large-scale, consistent washer supply.

Our M18 Mild Steel Plain Washers are available for bulk purchase with assured dimensional accuracy.

If you’re looking to Buy M18 Mild Steel Plain Washers in Bulk, we provide pan-India logistics support and export options for international clients.

10. Made by the Best M18 MS Flat Washers Manufacturer

As a trusted name in the industry, Nafees Metal Industries has established itself as one of the Best M18 MS Flat Washers Manufacturers in India.

We offer:

Custom production runs

Laser marking and packaging

Technical documentation and material test certificates (MTC)

Every washer is batch-tested, dimensionally verified, and quality-approved, ensuring that our clients receive only the best.

Specifications

| Parameter | Specification |

|---|---|

| Size | M18 |

| Outer Diameter | As per DIN 125 / ISO 7089 |

| Inner Diameter | Approx. 18.5 mm |

| Thickness | Standard – 1.6 to 3 mm |

| Material | Mild Steel (Low Carbon Steel) |

| Surface Finish | Self-Color, Zinc Plated, or Galvanized |

| Hardness | Customized upon request |

| Tolerance | As per IS/ISO standards |

Applications of M18 Mild Steel Plain Washers

M18 Mild Steel Plain Washers are highly versatile components used across a wide range of industries and mechanical assemblies. Their primary purpose is to distribute load evenly under bolts, nuts, or screws, ensuring mechanical stability, reducing wear, and extending the service life of assemblies. Below are key application domains and examples of how M18 Mild Steel Plain Washers provide reliability and performance:

dzx1. Automotive Industry

In automotive manufacturing and servicing, M18 Mild Steel Plain Washers play a vital role in securing engine mounts, suspension components, chassis connections, and frame assemblies. The washers help in:

Minimizing metal fatigue by evenly distributing torque.

Preventing bolt loosening under engine vibration.

Protecting painted or sensitive surfaces from fastener damage.

Because automotive components undergo continuous motion and stress, the use of durable mild steel washers improves safety and prolongs the mechanical integrity of the vehicle.

2. Construction and Structural Engineering

In large-scale construction projects, washers like these are indispensable. M18 Mild Steel Plain Washers are used in steel structures, prefabricated buildings, bridges, and roof trusses. Their presence ensures:

Proper force distribution across bolted joints in beams and plates.

Prevention of material deformation due to over-tightening.

Resistance against long-term environmental stresses.

For instance, when high-load bolts are used in steel beams, these washers safeguard both the bolt and the steel from localized stress points.

3. Machinery and Equipment Assembly

In both light and heavy industrial machinery, M18 Mild Steel Plain Washers are integral to stable fastener placement. They are used in machines such as hydraulic presses, CNC systems, compressors, and packaging equipment.

They allow for a balanced tightening force in rotating parts.

They prevent bolt heads from embedding into the machine’s softer base metal.

Their mild steel construction enables reusability in servicing cycles.

Washers improve maintenance cycles by allowing for easier bolt removal and reducing thread damage during disassembly.

4. Electrical and Electronics Installation

Though mild steel is not ideal for direct current insulation, it is widely used in the structural and casing components of electrical equipment where mechanical integrity is crucial. M18 Mild Steel Plain Washers support:

Rack mounting and switchgear assembly.

Panel enclosures and junction box installations.

Fastening of heavy transformers or motor housings.

In such installations, washers offer extra support, preventing warping or cracking of metal panels due to bolt stress.

5. Railways and Transport Infrastructure

In the railway sector, from coach fabrication to track fasteners, M18 Mild Steel Plain Washers find application in:

Bolting rail joints and securing sleeper plates.

Mounting air brake systems and undercarriage hardware.

Assembly of rail car interiors and chassis systems.

These washers resist loosening due to vibration, making them ideal for moving and high-impact environments like railways and metros.

6. Oil & Gas and Petrochemical Plants

In onshore and offshore platforms, safety is paramount. Even though stainless steel is often used due to corrosion resistance, M18 Mild Steel Plain Washers are still in demand for:

Non-corrosive zone installations.

Heavy-duty clamping assemblies in oil refineries.

Maintenance applications where cost-effectiveness is crucial.

Their ability to maintain joint integrity under pressure and temperature fluctuations makes them suitable for auxiliary structures and enclosures.

7. Agricultural Machinery

Modern farming equipment such as ploughs, harvesters, threshers, and irrigation systems involve heavy-duty fastening solutions. M18 Mild Steel Plain Washers:

Provide additional support in assemblies that encounter soil impact or vibration.

Prevent loosening of blade and wheel assemblies.

Assist in reducing damage during machine disassembly or re-torquing.

The mild steel’s machinability ensures compatibility with different types of agricultural fasteners.

8. Furniture and Modular Fixture Manufacturing

In the furniture and modular fixture domain, M18 Mild Steel Plain Washers are used in joints where design aesthetics and structural reliability must coexist.

They prevent wood or composite panels from being crushed under bolt pressure.

Ensure a tight fit in movable joints like adjustable beds, foldable tables, and workstations.

Offer clean, even support to fasteners, extending the life of both hardware and the product.

They are particularly useful where wooden panels are fixed with metal fasteners, requiring uniform pressure and protection from splitting.

9. Solar Panel Mounting Systems

The growing renewable energy sector has created demand for reliable, yet cost-effective components. M18 Mild Steel Plain Washers are used in the structural mounting of photovoltaic systems:

Supporting solar frames under wind load conditions.

Assisting in safe, vibration-free installations.

Helping to avoid concentrated stress on panel brackets or cross beams.

Their strength-to-cost ratio makes them ideal for high-scale deployments of solar farms.

10. Marine and Shipbuilding Applications (Non-Corrosive Zones)

Although marine applications prefer stainless steel due to corrosion concerns, M18 Mild Steel Plain Washers still find use in internal structures:

Bolting of cabin interiors, engines, or non-exposed mechanical compartments.

Maintenance kits and shipyard tooling.

Dry dock equipment and temporary assembly fastenings.

With proper coating or galvanization, mild steel washers can be adapted for temporary outdoor use as well.

11. General Industrial Use

Beyond specific industries, these washers serve a wide spectrum of general applications, such as:

HVAC installations

Water pump assemblies

Generators and motors

Temporary scaffolding setups

Storage racks and warehouse fixtures

In every scenario, M18 Mild Steel Plain Washers contribute by ensuring safety, structural balance, and reducing rework due to improper fastening.

Case Study: Optimizing Structural Stability in Heavy-Duty Fabrication Using M18 Mild Steel Plain Washers

Background and Industry Context

A leading fabrication company in the infrastructure sector was contracted to construct multiple high-load structural assemblies for a government project involving modular bridges and heavy steel framework in a seismic-prone zone. These assemblies required a high degree of vibration resistance, load distribution, and material compatibility, especially in the bolted joints.

The engineering team faced challenges such as:

Uneven stress distribution on fastening surfaces

Bolt loosening due to vibration

Corrosion risk from dissimilar metal contact

Tight deadlines requiring cost-effective and fast assembly methods

The company needed a washer solution that could provide long-term mechanical integrity without escalating costs or introducing additional complexity into the supply chain.

Solution: Implementation of M18 Mild Steel Plain Washers

After rigorous analysis and testing, the team standardized on M18 Mild Steel Plain Washers across all major bolted joints in their framework designs.

Key reasons for selection:

Perfect dimensional compatibility with M18 bolts and nuts used in steel girders and flange plates

Machinability and formability of mild steel, allowing for custom tolerances when needed

High surface area for even load distribution under bolt heads and nuts

Excellent shock absorption properties for reducing the risk of bolt loosening under repeated vibration

Affordability and availability, critical for a project with high-volume washer requirements

The washers were supplied in bulk, ensuring uniformity in finish and tolerance throughout the build cycle.

Implementation Highlights

Over 12,000 M18 Mild Steel Plain Washers were used across the entire structural project.

Laser-aligned torque application ensured washers were correctly seated beneath fasteners.

All washers were galvanized post-installation, enhancing corrosion resistance during long-term exposure to outdoor conditions.

Fastener assemblies were periodically tested for torque retention, and less than 1.8% required re-tightening over a 12-month monitoring period — significantly below the industry average.

Observed Benefits

Improved Structural Longevity: Load-bearing points showed no visible deformation or fatigue even after months of thermal and mechanical stress.

Reduced Maintenance Needs: Washer integrity prevented frequent bolt re-tightening, reducing labor time.

Zero Failures in Bolted Joints: No reports of failure or slippage, affirming the choice of using M18 Mild Steel Plain Washers as a critical structural safeguard.

Optimized Inventory Costs: Due to bulk purchasing and simplified specifications, procurement costs were reduced by 8.5%.

Conclusion

This real-world case reaffirms that M18 Mild Steel Plain Washers are not merely passive components but play an active role in structural safety, cost efficiency, and long-term performance. For manufacturers, civil contractors, or heavy-equipment designers, the use of these washers offers a measurable advantage in engineering outcomes.

If you’re looking for the Best M18 MS Flat Washers Manufacturer or planning to Buy M18 Mild Steel Plain Washers in Bulk, consider solutions that are tested under real-world industrial conditions like the one detailed here.

Why Choose Nafees Metal Industries?

- Precision Manufacturing: State-of-the-art machinery for consistent product quality

- Bulk Availability: Ready stock for large volume orders

- Custom Solutions: Surface treatment, thickness, and dimensions as per client requirement

- Certified Quality: Adherence to ISO and DIN standards

- Fast Delivery: Efficient logistics for nationwide and international shipping

Buy M18 Mild Steel Plain Washers in Bulk

If you’re looking to Buy M18 Mild Steel Plain Washers in Bulk, we offer the most competitive rates with assured quality. Our bulk packaging ensures safety during transportation, and each batch undergoes quality testing to meet your specifications.

FAQs

Q1: What are M18 Mild Steel Plain Washers used for?

A: These washers are used to distribute load, protect surfaces, and reduce bolt loosening in structural, mechanical, and automotive applications.

Q2: Are M18 Mild Steel Plain Washers corrosion resistant?

A: While mild steel is not inherently corrosion-resistant, we offer zinc-plated and galvanized versions for better protection.

Q3: Can I request a custom thickness for the washers?

A: Yes, Nafees Metal Industries offers customization in thickness and dimensions as per client requirements.

Q4: How can I ensure these washers will fit my M18 bolts?

A: All our washers adhere to DIN and ISO standards, ensuring perfect compatibility with M18 bolts.

Q5: Do you offer international shipping?

A: Yes, we supply our washers both domestically and internationally.

Q6: What are MS Flat Washers?

A: MS Flat Washers refer to flat washers made from Mild Steel. They are used for spacing and load distribution in bolted assemblies.

Q7: How can I place a bulk order?

A: You can contact our sales team via phone or email, or place an inquiry through our website.

Q8: Why should I choose Nafees Metal Industries?

A: We are recognized for precision manufacturing, high-quality standards, and prompt service, making us the Best M18 MS Flat Washers Manufacturer.

Conclusion

M18 Mild Steel Plain Washers are indispensable in applications that demand reliability, load distribution, and durability. Their role in preserving assembly integrity and minimizing maintenance makes them an essential component across industries.

With features such as excellent vibration resistance, surface protection, and long-term benefits, these washers offer high value at an affordable cost. Whether you’re a large industrial client or a distributor looking to Buy M18 Mild Steel Plain Washers in Bulk, Nafees Metal Industries ensures that you get the best product with consistent quality.

Choose Nafees Metal Industries – the Best M18 MS Flat Washers Manufacturer – for all your Mild Steel Washers requirements.

Why Choose Nafees Metal industries?

Choosing the right M18 Mild Steel Plain Washers Manufacturer means partnering with a supplier who values your time and trust. With decades of industry experience, advanced production facilities, and a dedicated team, we ensure you get washers that match your exact requirements — every time.

✔️ Bulk Supply, Always Consistent: Whether you need a few thousand or several lakh pieces, we manage bulk orders smoothly.

✔️ Customization Options: Need a special size, thickness, or coating? We offer tailored solutions to match your specific application.

✔️ Transparent Pricing: We believe in fair pricing with no hidden costs, so you get great value for your investment.

✔️ Timely Delivery: We stick to deadlines, ensuring your supply chain remains uninterrupted.

✔️ Expert Support: From order placement to after-sales service, our team is here to help you at every step.

Visit Us or Get in Touch

Experience our commitment to quality firsthand by visiting our fully equipped manufacturing facility at Reay Road, Mumbai. Ready to place your order or discuss custom requirements? Reach out today to get a free quote and discover why we’re a trusted name in mild steel washers.

M18 Mild Steel Plain Washers

12 people are viewing this product right now

₹2.10 Original price was: ₹2.10.₹1.75Current price is: ₹1.75. /per piece

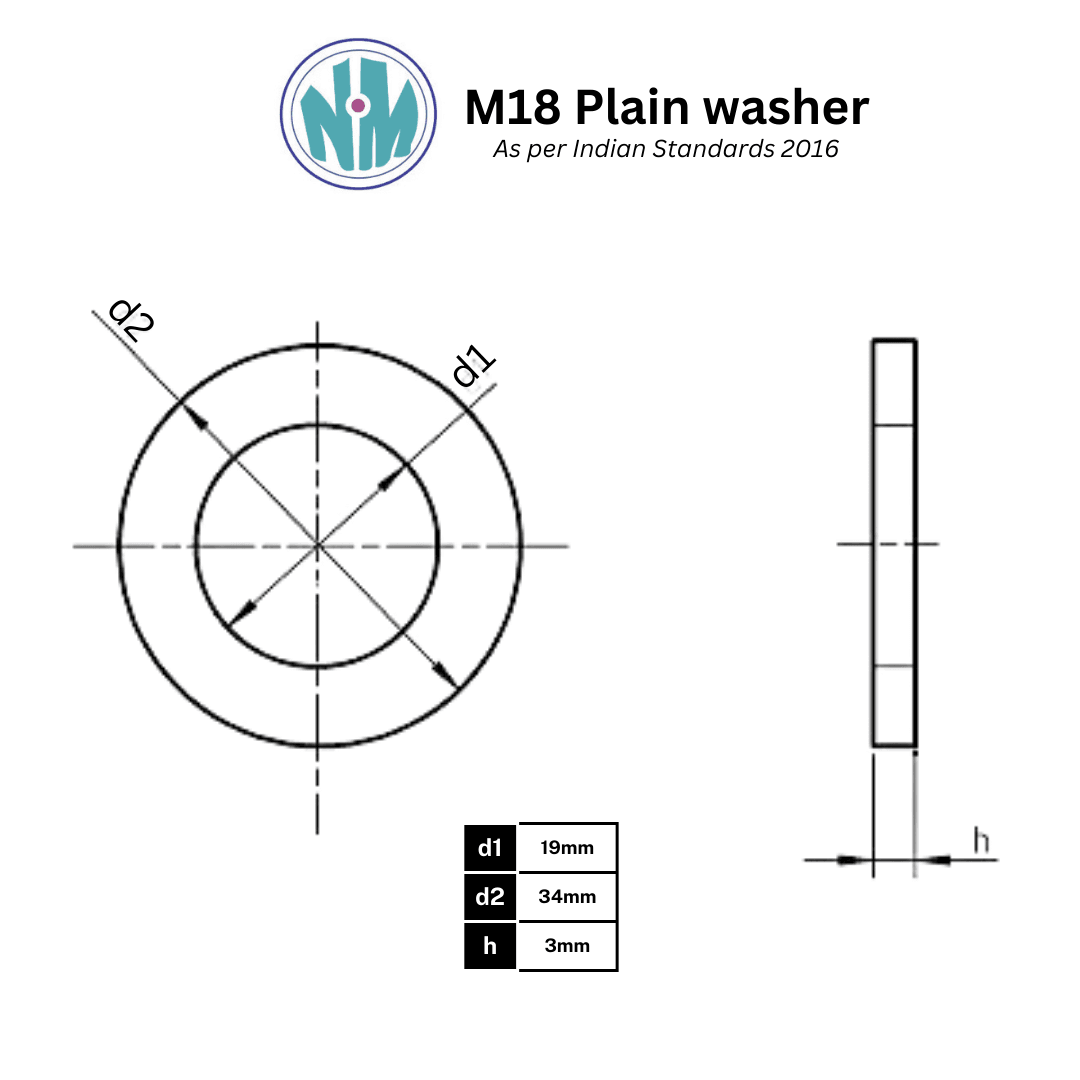

Specification:

Material: Mild Steel

Nominal Size (g): M18

Inner Diameter (ID): 19 mm

Outer Diameter (OD): 34 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M18 Mild Steel Plain Washers – Best M18 MS Flat Washers Manufacturer for Industrial Applications

Product Overview

M18 Mild Steel Plain Washers are essential components used extensively in mechanical, industrial, and structural applications. These washers are flat, disc-shaped components with a hole in the center to accommodate M18-sized bolts or screws. As part of the broader family of Mild Steel Washers, these washers provide critical load distribution, protect surfaces, and enhance the integrity of bolted assemblies.

At Nafees Metal Industries, we specialize in manufacturing high-quality M18 Mild Steel Plain Washers with precision engineering and consistent performance. Our washers are known for their dimensional accuracy, smooth finish, and corrosion resistance, making us the Best M18 MS Flat Washers Manufacturer in the market.

Key Features of M18 Mild Steel Plain Washers

At Nafees Metal Industries, we take pride in offering industrial-grade components that perform reliably under high-stress applications. Our M18 Mild Steel Plain Washers are designed with precision and manufactured under stringent quality control standards. Below are the key features that make these washers ideal for a wide range of industrial and mechanical uses:

1. Perfect Inner and Outer Diameters

Our M18 Mild Steel Plain Washers are dimensioned to fit seamlessly with M18 bolts and nuts, ensuring snug placement without excess play or distortion.

The precise inner diameter prevents misalignment or slippage during torque application.

The wide outer diameter provides a larger bearing surface, which helps in evenly distributing the load across the bolted joint.

2. Durable Mild Steel Composition

Manufactured using high-quality low-carbon mild steel, these washers offer exceptional ductility and tensile strength.

Mild steel resists cracking under pressure, making it ideal for applications where vibrations, dynamic loads, or torque variations are frequent.

The material provides the ideal balance between strength and machinability, making it a top choice for large-scale industrial setups.

3. Load Distribution Excellence

One of the core benefits of our M18 Mild Steel Plain Washers is their ability to disperse the load uniformly across the surface beneath the bolt or nut.

This helps prevent localized stress, material deformation, and bolt pull-through—issues common in high-torque fastening environments.

Ensures longer life of both fastener and mating surface, reducing repair and maintenance costs.

4. Excellent Vibration Dampening

In mechanical assemblies exposed to movement or shaking, washers play a critical role in maintaining joint integrity.

Our M18 washers help dampen vibrations and prevent loosening of nuts and bolts, making them indispensable in machinery, automotive, rail, and construction sectors.

5. Corrosion Protection Options

Though mild steel on its own can be susceptible to rust, we offer multiple post-processing options like:

Zinc plating

Hot-dip galvanization

Black oxide coating

These finishes enhance resistance to corrosion, making the washer suitable even for outdoor and marine environments.

6. Optimized for High-Torque Applications

Designed to withstand high torque without warping or cracking, these washers are ideal for:

Structural bolting

Engine assembly

Equipment base installations

Heavy fabrication jobs

Maintains shape and functionality even under repetitive torque cycles, preserving the reliability of the bolted connection.

7. Consistent Surface Finish

Each washer is finished to provide a smooth, burr-free surface, reducing friction during tightening and preventing damage to the joint surface.

Ensures uniform friction coefficient across all units, which is critical for consistent torque readings during automated or manual assembly.

8. Versatile Applications

Used in various industries such as:

Automotive

Construction

Electrical panel fabrication

OEM parts assembly

Heavy engineering and structural frameworks

Whether you’re assembling a heavy-duty machine or securing steel columns, these washers offer unmatched reliability.

9. Bulk Availability for Industrial Buyers

We understand the needs of OEMs, distributors, and contractors who require large-scale, consistent washer supply.

Our M18 Mild Steel Plain Washers are available for bulk purchase with assured dimensional accuracy.

If you’re looking to Buy M18 Mild Steel Plain Washers in Bulk, we provide pan-India logistics support and export options for international clients.

10. Made by the Best M18 MS Flat Washers Manufacturer

As a trusted name in the industry, Nafees Metal Industries has established itself as one of the Best M18 MS Flat Washers Manufacturers in India.

We offer:

Custom production runs

Laser marking and packaging

Technical documentation and material test certificates (MTC)

Every washer is batch-tested, dimensionally verified, and quality-approved, ensuring that our clients receive only the best.

Specifications

| Parameter | Specification |

|---|---|

| Size | M18 |

| Outer Diameter | As per DIN 125 / ISO 7089 |

| Inner Diameter | Approx. 18.5 mm |

| Thickness | Standard – 1.6 to 3 mm |

| Material | Mild Steel (Low Carbon Steel) |

| Surface Finish | Self-Color, Zinc Plated, or Galvanized |

| Hardness | Customized upon request |

| Tolerance | As per IS/ISO standards |

Applications of M18 Mild Steel Plain Washers

M18 Mild Steel Plain Washers are highly versatile components used across a wide range of industries and mechanical assemblies. Their primary purpose is to distribute load evenly under bolts, nuts, or screws, ensuring mechanical stability, reducing wear, and extending the service life of assemblies. Below are key application domains and examples of how M18 Mild Steel Plain Washers provide reliability and performance:

dzx1. Automotive Industry

In automotive manufacturing and servicing, M18 Mild Steel Plain Washers play a vital role in securing engine mounts, suspension components, chassis connections, and frame assemblies. The washers help in:

Minimizing metal fatigue by evenly distributing torque.

Preventing bolt loosening under engine vibration.

Protecting painted or sensitive surfaces from fastener damage.

Because automotive components undergo continuous motion and stress, the use of durable mild steel washers improves safety and prolongs the mechanical integrity of the vehicle.

2. Construction and Structural Engineering

In large-scale construction projects, washers like these are indispensable. M18 Mild Steel Plain Washers are used in steel structures, prefabricated buildings, bridges, and roof trusses. Their presence ensures:

Proper force distribution across bolted joints in beams and plates.

Prevention of material deformation due to over-tightening.

Resistance against long-term environmental stresses.

For instance, when high-load bolts are used in steel beams, these washers safeguard both the bolt and the steel from localized stress points.

3. Machinery and Equipment Assembly

In both light and heavy industrial machinery, M18 Mild Steel Plain Washers are integral to stable fastener placement. They are used in machines such as hydraulic presses, CNC systems, compressors, and packaging equipment.

They allow for a balanced tightening force in rotating parts.

They prevent bolt heads from embedding into the machine’s softer base metal.

Their mild steel construction enables reusability in servicing cycles.

Washers improve maintenance cycles by allowing for easier bolt removal and reducing thread damage during disassembly.

4. Electrical and Electronics Installation

Though mild steel is not ideal for direct current insulation, it is widely used in the structural and casing components of electrical equipment where mechanical integrity is crucial. M18 Mild Steel Plain Washers support:

Rack mounting and switchgear assembly.

Panel enclosures and junction box installations.

Fastening of heavy transformers or motor housings.

In such installations, washers offer extra support, preventing warping or cracking of metal panels due to bolt stress.

5. Railways and Transport Infrastructure

In the railway sector, from coach fabrication to track fasteners, M18 Mild Steel Plain Washers find application in:

Bolting rail joints and securing sleeper plates.

Mounting air brake systems and undercarriage hardware.

Assembly of rail car interiors and chassis systems.

These washers resist loosening due to vibration, making them ideal for moving and high-impact environments like railways and metros.

6. Oil & Gas and Petrochemical Plants

In onshore and offshore platforms, safety is paramount. Even though stainless steel is often used due to corrosion resistance, M18 Mild Steel Plain Washers are still in demand for:

Non-corrosive zone installations.

Heavy-duty clamping assemblies in oil refineries.

Maintenance applications where cost-effectiveness is crucial.

Their ability to maintain joint integrity under pressure and temperature fluctuations makes them suitable for auxiliary structures and enclosures.

7. Agricultural Machinery

Modern farming equipment such as ploughs, harvesters, threshers, and irrigation systems involve heavy-duty fastening solutions. M18 Mild Steel Plain Washers:

Provide additional support in assemblies that encounter soil impact or vibration.

Prevent loosening of blade and wheel assemblies.

Assist in reducing damage during machine disassembly or re-torquing.

The mild steel’s machinability ensures compatibility with different types of agricultural fasteners.

8. Furniture and Modular Fixture Manufacturing

In the furniture and modular fixture domain, M18 Mild Steel Plain Washers are used in joints where design aesthetics and structural reliability must coexist.

They prevent wood or composite panels from being crushed under bolt pressure.

Ensure a tight fit in movable joints like adjustable beds, foldable tables, and workstations.

Offer clean, even support to fasteners, extending the life of both hardware and the product.

They are particularly useful where wooden panels are fixed with metal fasteners, requiring uniform pressure and protection from splitting.

9. Solar Panel Mounting Systems

The growing renewable energy sector has created demand for reliable, yet cost-effective components. M18 Mild Steel Plain Washers are used in the structural mounting of photovoltaic systems:

Supporting solar frames under wind load conditions.

Assisting in safe, vibration-free installations.

Helping to avoid concentrated stress on panel brackets or cross beams.

Their strength-to-cost ratio makes them ideal for high-scale deployments of solar farms.

10. Marine and Shipbuilding Applications (Non-Corrosive Zones)

Although marine applications prefer stainless steel due to corrosion concerns, M18 Mild Steel Plain Washers still find use in internal structures:

Bolting of cabin interiors, engines, or non-exposed mechanical compartments.

Maintenance kits and shipyard tooling.

Dry dock equipment and temporary assembly fastenings.

With proper coating or galvanization, mild steel washers can be adapted for temporary outdoor use as well.

11. General Industrial Use

Beyond specific industries, these washers serve a wide spectrum of general applications, such as:

HVAC installations

Water pump assemblies

Generators and motors

Temporary scaffolding setups

Storage racks and warehouse fixtures

In every scenario, M18 Mild Steel Plain Washers contribute by ensuring safety, structural balance, and reducing rework due to improper fastening.

Case Study: Optimizing Structural Stability in Heavy-Duty Fabrication Using M18 Mild Steel Plain Washers

Background and Industry Context

A leading fabrication company in the infrastructure sector was contracted to construct multiple high-load structural assemblies for a government project involving modular bridges and heavy steel framework in a seismic-prone zone. These assemblies required a high degree of vibration resistance, load distribution, and material compatibility, especially in the bolted joints.

The engineering team faced challenges such as:

Uneven stress distribution on fastening surfaces

Bolt loosening due to vibration

Corrosion risk from dissimilar metal contact

Tight deadlines requiring cost-effective and fast assembly methods

The company needed a washer solution that could provide long-term mechanical integrity without escalating costs or introducing additional complexity into the supply chain.

Solution: Implementation of M18 Mild Steel Plain Washers

After rigorous analysis and testing, the team standardized on M18 Mild Steel Plain Washers across all major bolted joints in their framework designs.

Key reasons for selection:

Perfect dimensional compatibility with M18 bolts and nuts used in steel girders and flange plates

Machinability and formability of mild steel, allowing for custom tolerances when needed

High surface area for even load distribution under bolt heads and nuts

Excellent shock absorption properties for reducing the risk of bolt loosening under repeated vibration

Affordability and availability, critical for a project with high-volume washer requirements

The washers were supplied in bulk, ensuring uniformity in finish and tolerance throughout the build cycle.

Implementation Highlights

Over 12,000 M18 Mild Steel Plain Washers were used across the entire structural project.

Laser-aligned torque application ensured washers were correctly seated beneath fasteners.

All washers were galvanized post-installation, enhancing corrosion resistance during long-term exposure to outdoor conditions.

Fastener assemblies were periodically tested for torque retention, and less than 1.8% required re-tightening over a 12-month monitoring period — significantly below the industry average.

Observed Benefits

Improved Structural Longevity: Load-bearing points showed no visible deformation or fatigue even after months of thermal and mechanical stress.

Reduced Maintenance Needs: Washer integrity prevented frequent bolt re-tightening, reducing labor time.

Zero Failures in Bolted Joints: No reports of failure or slippage, affirming the choice of using M18 Mild Steel Plain Washers as a critical structural safeguard.

Optimized Inventory Costs: Due to bulk purchasing and simplified specifications, procurement costs were reduced by 8.5%.

Conclusion

This real-world case reaffirms that M18 Mild Steel Plain Washers are not merely passive components but play an active role in structural safety, cost efficiency, and long-term performance. For manufacturers, civil contractors, or heavy-equipment designers, the use of these washers offers a measurable advantage in engineering outcomes.

If you’re looking for the Best M18 MS Flat Washers Manufacturer or planning to Buy M18 Mild Steel Plain Washers in Bulk, consider solutions that are tested under real-world industrial conditions like the one detailed here.

Why Choose Nafees Metal Industries?

- Precision Manufacturing: State-of-the-art machinery for consistent product quality

- Bulk Availability: Ready stock for large volume orders

- Custom Solutions: Surface treatment, thickness, and dimensions as per client requirement

- Certified Quality: Adherence to ISO and DIN standards

- Fast Delivery: Efficient logistics for nationwide and international shipping

Buy M18 Mild Steel Plain Washers in Bulk

If you’re looking to Buy M18 Mild Steel Plain Washers in Bulk, we offer the most competitive rates with assured quality. Our bulk packaging ensures safety during transportation, and each batch undergoes quality testing to meet your specifications.

FAQs

Q1: What are M18 Mild Steel Plain Washers used for?

A: These washers are used to distribute load, protect surfaces, and reduce bolt loosening in structural, mechanical, and automotive applications.

Q2: Are M18 Mild Steel Plain Washers corrosion resistant?

A: While mild steel is not inherently corrosion-resistant, we offer zinc-plated and galvanized versions for better protection.

Q3: Can I request a custom thickness for the washers?

A: Yes, Nafees Metal Industries offers customization in thickness and dimensions as per client requirements.

Q4: How can I ensure these washers will fit my M18 bolts?

A: All our washers adhere to DIN and ISO standards, ensuring perfect compatibility with M18 bolts.

Q5: Do you offer international shipping?

A: Yes, we supply our washers both domestically and internationally.

Q6: What are MS Flat Washers?

A: MS Flat Washers refer to flat washers made from Mild Steel. They are used for spacing and load distribution in bolted assemblies.

Q7: How can I place a bulk order?

A: You can contact our sales team via phone or email, or place an inquiry through our website.

Q8: Why should I choose Nafees Metal Industries?

A: We are recognized for precision manufacturing, high-quality standards, and prompt service, making us the Best M18 MS Flat Washers Manufacturer.

Conclusion

M18 Mild Steel Plain Washers are indispensable in applications that demand reliability, load distribution, and durability. Their role in preserving assembly integrity and minimizing maintenance makes them an essential component across industries.

With features such as excellent vibration resistance, surface protection, and long-term benefits, these washers offer high value at an affordable cost. Whether you’re a large industrial client or a distributor looking to Buy M18 Mild Steel Plain Washers in Bulk, Nafees Metal Industries ensures that you get the best product with consistent quality.

Choose Nafees Metal Industries – the Best M18 MS Flat Washers Manufacturer – for all your Mild Steel Washers requirements.

Why Choose Nafees Metal industries?

Choosing the right M18 Mild Steel Plain Washers Manufacturer means partnering with a supplier who values your time and trust. With decades of industry experience, advanced production facilities, and a dedicated team, we ensure you get washers that match your exact requirements — every time.

✔️ Bulk Supply, Always Consistent: Whether you need a few thousand or several lakh pieces, we manage bulk orders smoothly.

✔️ Customization Options: Need a special size, thickness, or coating? We offer tailored solutions to match your specific application.

✔️ Transparent Pricing: We believe in fair pricing with no hidden costs, so you get great value for your investment.

✔️ Timely Delivery: We stick to deadlines, ensuring your supply chain remains uninterrupted.

✔️ Expert Support: From order placement to after-sales service, our team is here to help you at every step.

Visit Us or Get in Touch

Experience our commitment to quality firsthand by visiting our fully equipped manufacturing facility at Reay Road, Mumbai. Ready to place your order or discuss custom requirements? Reach out today to get a free quote and discover why we’re a trusted name in mild steel washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch