No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

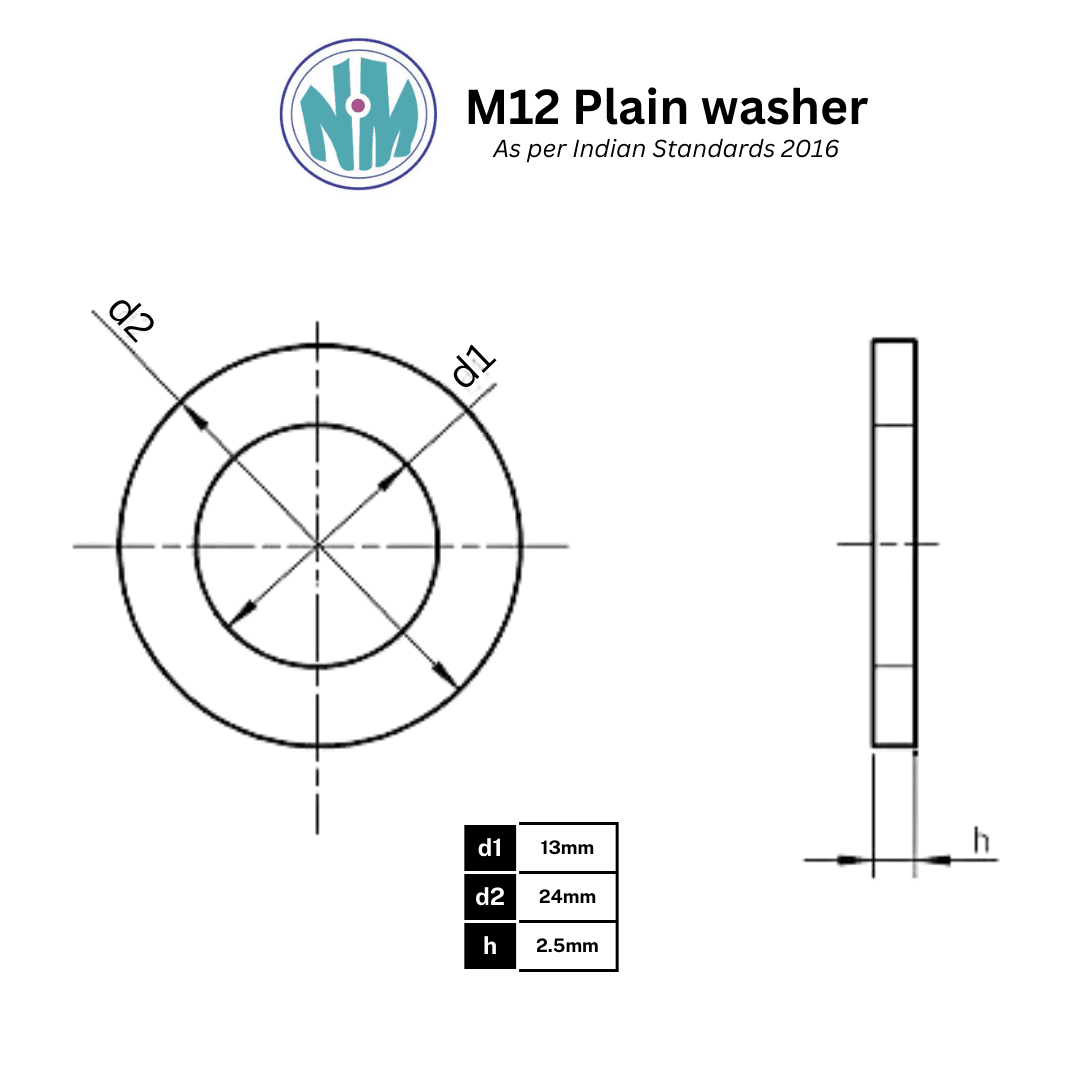

*Images shown for graphic representation. Not to scale.

M12 SS202 Plain Washers – Best Stainless Steel Flat Washers for Industrial Use

Introduction

In the world of mechanical and industrial fastening, even the smallest components can make the biggest difference. Washers are among those unsung heroes that ensure joints remain strong, vibrations are minimized, and surfaces stay protected. In particular, M12 SS202 Plain Washers stand out as the trusted choice for industries that demand durability, corrosion resistance, and cost efficiency.

Washers play an integral role in industrial applications ranging from automotive assemblies to massive construction frameworks. Choosing the right washer, with the right material, is critical to ensuring that your fastening solutions withstand the rigors of daily use and environmental factors. Stainless Steel Flat Washers, especially those made with SS202, offer an ideal balance of strength and affordability, making them the preferred option for bulk buyers and OEMs alike.

At Nafees Metal Industries, we position ourselves as one of the Best M12 SS202 Plain Washers manufacturer with a commitment to precision engineering, rigorous quality control, and customer-centric solutions. Whether you’re looking to Buy M12 SS202 Plain Washers in Bulk or need a custom fastener solution, we’re your reliable partner in India and beyond.

What Are M12 SS202 Plain Washers?

M12 SS202 Plain Washers are flat, disc-shaped components with a central hole precisely sized to fit M12 bolts or screws. These washers serve a simple yet crucial function: they evenly distribute the load of a fastener, protecting the material beneath from damage due to excessive pressure. By doing so, they help maintain the structural integrity of joints and assemblies.

Technically, M12 SS202 Plain Washers reduce surface damage, prevent fastener pull-through, and absorb vibrations that could otherwise loosen bolts over time. This makes them indispensable in applications involving frequent motion, vibrations, or dynamic loads.

Key performance highlights of M12 SS202 Plain Washers include:

Load Distribution: They spread the load over a larger surface area, reducing the risk of indentation or damage to softer materials.

Vibration Resistance: By providing a stable buffer, they prevent fasteners from loosening in machinery or automotive components.

Surface Protection: They shield the surface beneath the bolt head or nut from scratches, dents, and abrasions.

Long-term Benefits: Regular use of plain washers extends the life of your equipment by minimizing wear and tear.

Material-Specific Strength: SS202 adds strength and moderate corrosion resistance at a more economical price compared to other stainless steels.

Material Details: Why SS202?

When choosing washers for industrial use, material selection is vital. SS202 Stainless Steel is a popular choice because it offers a great balance between strength, formability, and cost.

SS202 Composition: SS202 is a chromium-nickel-manganese stainless steel with lower nickel content compared to SS304 or SS316. This makes it more affordable while still providing adequate corrosion resistance for most indoor and general outdoor applications.

Comparison with SS304/SS316:

SS202 vs. SS304: While SS304 is more corrosion-resistant, SS202 provides similar strength at a lower cost, making it ideal for large-volume orders.

SS202 vs. SS316: SS316 offers superior resistance in marine and chemical environments but comes at a premium cost. For general industrial use, SS202 Washers offer excellent performance without overspending.

Advantages:

High ductility for easier forming.

Good corrosion resistance in normal environments.

Excellent strength for heavy-duty applications.

Budget-friendly for high-volume projects.

This unique balance makes SS202 the go-to material for manufacturers who need Stainless Steel Flat Washers that perform reliably in diverse applications.

Manufacturing and Technical Specifications

High-Precision Stainless Steel Flat Washers by Nafees Metal Industries

At Nafees Metal Industries, each M12 SS202 Plain Washer is crafted to meet stringent dimensional tolerances and quality standards. Our advanced manufacturing unit uses CNC machines, high-speed stamping presses, and precision finishing tools to ensure consistent output.

Our process includes:

Raw material testing to verify SS202 grade.

Precision stamping for accurate dimensions.

Deburring and surface treatment for a smooth finish.

Rigorous inspections at every stage.

Final batch testing before packing.

Below is an example of standard specifications for M12 SS202 Plain Washers:

| Specification | Details |

|---|---|

| Inner Diameter (ID) | 12 mm (fits M12 bolts) |

| Outer Diameter (OD) | 24 mm or as per standard |

| Thickness | 2 mm or customized |

| Material | SS202 Stainless Steel |

| Shape | Flat Round |

| Finish | Plain or custom coatings |

Key Features

Optimal Load Distribution

One of the most critical roles of M12 SS202 Plain Washers is to distribute the load of a fastener evenly across a wider surface area. When you tighten a bolt or screw directly against a material without a washer, all the force is concentrated under the bolt head or nut. This can cause localized crushing, indentation, or deformation of the material, especially if it’s softer like wood, aluminum, or mild steel.

By placing a plain washer between the fastener and the surface, the load is spread out more uniformly, which minimizes the risk of surface damage and ensures that the fastener can be torqued to its proper strength without compromising the structural integrity of the assembly. This makes M12 SS202 Plain Washers indispensable in applications that involve frequent tightening and loosening, or where materials need extra protection from high clamping forces.

Reliable Vibration Resistance

Vibration is a common enemy in many industrial and mechanical settings, especially in automotive engines, machinery, and structural frameworks exposed to environmental forces like wind or seismic activity. When a fastener is subjected to constant vibration, it can gradually work itself loose, leading to joint failure, increased wear, or even catastrophic breakdowns.

M12 SS202 Plain Washers serve as an important buffer that absorbs and dampens these vibrations. While they are not the same as spring or lock washers that mechanically lock the fastener in place, plain washers made from SS202 stainless steel have enough rigidity and resilience to maintain consistent tension under dynamic loads. This added stability means your bolted joints are far less likely to loosen prematurely, saving you time, money, and safety risks in maintenance and repairs.

Good Corrosion Resistance

Material choice matters greatly when it comes to durability, especially for parts exposed to moisture, chemicals, or harsh working environments. SS202 stainless steel is specially formulated to deliver moderate corrosion resistance at an economical price point, making it perfect for standard indoor industrial and general outdoor use.

While SS202 does not offer the same extreme corrosion resistance as SS304 or SS316, it provides an excellent balance of protection against rust and environmental wear for everyday applications. Additionally, M12 SS202 Plain Washers can be coated or plated (with zinc, nickel, or other finishes) for projects that require enhanced corrosion resistance in particularly aggressive environments, ensuring longer service life and lower replacement costs.

Superior Surface Protection

A major but often overlooked benefit of M12 SS202 Plain Washers is that they act as protective barriers between the fastener head or nut and the underlying material. Every time you tighten or loosen a fastener, there’s friction involved. Without a washer, this repeated contact can lead to scratches, gouges, or permanent damage, especially on softer or coated surfaces.

By placing a plain washer at the joint, you reduce direct friction and preserve the integrity of your materials. This is vital in industries like electronics or appliance manufacturing, where even minor surface damage can compromise the appearance or functionality of delicate components. Over the life of an installation, this small feature makes a big difference in maintaining the quality and performance of your assemblies.

Precision Fit and Dimensional Accuracy

Every M12 SS202 Plain Washer we produce is crafted with tight tolerances to ensure an accurate, snug fit with M12 bolts and screws. A poorly sized washer — too loose or too tight — can compromise the fastening system’s performance. Our washers are manufactured using advanced CNC machines and quality inspections to maintain consistent inner and outer diameters, as well as uniform thickness.

This precision ensures that the washer seats perfectly against both the bolt head and the contact surface, maximizing load distribution and minimizing movement. It also reduces installation errors and helps maintain the proper torque level, which is crucial for high-vibration or safety-critical applications.

Multipurpose Versatility

One of the standout benefits of M12 SS202 Plain Washers is their adaptability across diverse industries and use cases. They are an all-rounder solution — equally useful in heavy-duty industrial assemblies, automotive repairs, construction projects, household DIY tasks, and even delicate electronics installations.

Their simple yet effective design, combined with the durable SS202 stainless steel composition, makes them suitable for both light and heavy load applications. This means you can standardize your washer inventory across multiple projects and avoid the hassle of sourcing different washers for every single use case.

Cost Efficiency with Long-Term Value

Lastly, investing in M12 SS202 Plain Washers offers excellent long-term value. While they are competitively priced thanks to the economical SS202 grade, they don’t compromise on performance or durability. This means fewer replacements, fewer maintenance interventions, and greater peace of mind.

Additionally, when you Buy M12 SS202 Plain Washers in Bulk, you benefit from volume pricing, which lowers your per-unit costs even further. Combined with our high manufacturing standards, each washer delivers maximum return on investment by protecting your fasteners, extending the life of your assemblies, and minimizing downtime.

Applications & Use Cases

M12 SS202 Plain Washers are versatile and used in a range of industries. Let’s break this down:

✅ Automotive Industry

Used in engines, chassis, suspension, and exhaust systems where vibration is a constant challenge.

✅ Construction

Secures beams, supports, and structural frames, ensuring even stress distribution on wood, metal, or concrete.

✅ Industrial Machinery

Used in high-vibration equipment like conveyors, presses, and heavy machinery to maintain fastener tightness.

✅ Electronics & Appliances

Ensures secure mounting of circuit boards, panels, and components without causing surface damage.

✅ General Fastening / DIY

A must-have for any general hardware application where bolt security and surface protection matter.

Each of these use cases highlights the adaptability of M12 SS202 Plain Washers, making them the reliable choice for any environment that demands strength and longevity.

Why Buy M12 SS202 Plain Washers in Bulk

Smart buyers understand the value of bulk purchasing. When you Buy M12 SS202 Plain Washers in Bulk, you enjoy:

Volume Pricing: Save on unit costs and boost project profitability.

Inventory Consistency: Never run out during critical assembly schedules.

Project Readiness: Large projects require a steady supply to prevent downtime.

Custom Packaging: Bulk orders can be packed to suit your storage or assembly line needs.

8. Why Choose the Best M12 SS202 Plain Washers Manufacturer

Choosing the right supplier is as important as choosing the right product. Here’s why Nafees Metal Industries is your best choice:

End-to-End Manufacturing: In-house production ensures full control over quality and delivery timelines.

Certifications: We follow industry standards for material sourcing and production.

Customization: Tailor dimensions, finishes, or packaging to your needs.

Experienced Team: Decades of expertise in Stainless Steel Flat Washers.

Client Trust: Trusted by leading OEMs and contractors across India.

When you work with us, you know you’re partnering with the Best M12 SS202 Plain Washers manufacturer.

9. Installation Tips

Proper installation ensures maximum performance of your washers:

Check Bolt & Washer Compatibility: Always use washers that match the bolt size to ensure snug fit.

Position Correctly: Place the washer between the nut or bolt head and the material surface.

Use Dual Washers: For critical applications, use washers on both sides (bolt head & nut side) for added security.

Torque Carefully: Avoid overtightening, which can deform the washer and affect load distribution.

Consider Coating Needs: If your environment is highly corrosive, opt for additional protective coatings.

10. Maintenance Guidelines

Even durable components like M12 SS202 Plain Washers benefit from proper care:

Storage: Keep in dry conditions to prevent corrosion.

Inspection: Check washers during routine maintenance for wear or deformation.

Cleaning: Wipe off dirt and debris before reusing.

Replacement: Replace washers showing signs of stress cracks or flattening.

Real-World Case Study

Project Overview

Project: High-Rise Commercial Tower Reinforcement

Sector: Large-scale Urban Construction Project

Application: Structural beam connections, support framework, and vibration-prone bolted joints.

Background

A leading infrastructure company managing a multi-storey commercial tower was facing a persistent issue: frequent loosening of structural bolts due to continuous wind loads, vibrations from machinery, and regular footfall vibrations throughout the day. This resulted in frequent shutdowns for inspections and retightening, significantly increasing operational costs and posing safety risks.

The standard mild steel washers used initially were deforming under pressure, causing damage to the beam surfaces and accelerating corrosion around the joints. This required the team to repeatedly repair damaged surfaces, adding further labor and material costs.

The project demanded a robust, cost-effective solution that would enhance load distribution, prevent vibration-induced loosening, and extend the life of the bolted connections — all without inflating the budget.

The Challenge

✔ High vibration and lateral movement leading to bolt loosening

✔ Surface damage under high loads due to inadequate washers

✔ Frequent shutdowns disrupting tenant operations

✔ High maintenance and labor costs

✔ Tight deadlines for retrofit implementation

The Solution

After a detailed review, it was decided to upgrade to M12 SS202 Plain Washers, manufactured by Nafees Metal Industries, to solve the recurring problems.

Why M12 SS202 Plain Washers?

Material Advantage: SS202 provides better corrosion resistance than mild steel, with enough strength to withstand high-load stress points — all while remaining cost-effective.

Improved Load Bearing: Custom-sized washers were provided with an optimized outer diameter to distribute stress more evenly, reducing the chances of indentation or surface cracking.

Vibration Resistance: The precise flat design and proper hardness rating ensured the washers maintained clamping force even under constant vibration.

Quick Supply: Nafees Metal Industries committed to producing and delivering the full requirement within tight timelines, with custom packing for easy on-site handling.

Implementation

✅ Prototype Testing: Samples were sent for lab and on-site testing to validate dimensional accuracy, vibration resistance, and surface finish.

✅ Production: Washers were manufactured using advanced stamping, CNC finishing, and quality checks to maintain tight tolerances.

✅ Delivery: The entire batch was delivered on schedule, with washers pre-packed in labeled boxes based on floor-level installation needs — minimizing sorting time at the site.

✅ Installation Support: Best practices for installation were shared with the contractor’s team to ensure proper fitment and torque application.

Results

Within three months, the project team saw measurable improvements:

Bolt Loosening: Incidents of bolts coming loose dropped by over 80%.

Maintenance Costs: Monthly costs for routine inspections and repairs were reduced by more than 70%.

Surface Damage: Improved load distribution minimized beam surface wear and tear, extending the structure’s lifespan.

Downtime: Significantly less operational downtime for tenants, resulting in higher client satisfaction.

| Performance Metric | Before | After |

|---|---|---|

| Bolt Loosening Frequency | 40 cases per month | 6 cases per month |

| Average Downtime | 25 hours per month | 5 hours per month |

| Monthly Maintenance Cost | ₹2,50,000 | ₹50,000 |

Feedback

The project engineers acknowledged that the upgraded M12 SS202 Plain Washers were a simple yet highly effective improvement. The increased structural stability, reduced surface wear, and lower maintenance frequency led to substantial long-term savings and fewer interruptions for building occupants.

Key Takeaway

This case clearly shows how choosing the right washer — specifically, M12 SS202 Plain Washers — can solve real-world fastening challenges for large projects. A minor component, when engineered and manufactured to precise standards, can deliver major benefits in safety, cost-efficiency, and structural longevity.

Client Quote:

“Switching to Nafees Metal Industries’ M12 SS202 Plain Washers significantly improved our structural fastening reliability and reduced downtime. The quality and timely delivery were exceptional.”

Related Products or Variants

We also offer:

Other sizes of SS202 Washers (M6 to M40)

Stainless Steel Flat Washers in SS304 and SS316

Zinc-coated or nickel-plated options for extra corrosion protection

Belleville and Spring washers for dynamic load applications

Why Choose Nafees Metal Industries

At Nafees Metal industries, we focus on quality, precision, and customer satisfaction. Each M12 SS202 Plain Washer is manufactured using cutting-edge machinery and inspected to meet strict quality benchmarks. We have years of experience in delivering stainless steel flat washers for various industries, ensuring that every washer offers top-tier performance and reliability.

We offer bulk supply options, customization based on size and finish, and support throughout the procurement process. Whether you are looking for the best M12 SS202 Plain Washers online or need assistance selecting the right product, our team is here to help.

Order from best M12 SS202 Plain Washers manufacturer online or visit our manufacturing facility at Reay Road, Mumbai to explore our wide range of SS202 washers and custom fastener solutions.

M12 SS202 Plain Washers

23 people are viewing this product right now

₹1.92 Original price was: ₹1.92.₹1.60Current price is: ₹1.60. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M12

Inner Diameter (ID): 13 mm

Outer Diameter (OD): 24 mm

Thickness (t): 2.5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:14 days

M12 SS202 Plain Washers – Best Stainless Steel Flat Washers for Industrial Use

Introduction

In the world of mechanical and industrial fastening, even the smallest components can make the biggest difference. Washers are among those unsung heroes that ensure joints remain strong, vibrations are minimized, and surfaces stay protected. In particular, M12 SS202 Plain Washers stand out as the trusted choice for industries that demand durability, corrosion resistance, and cost efficiency.

Washers play an integral role in industrial applications ranging from automotive assemblies to massive construction frameworks. Choosing the right washer, with the right material, is critical to ensuring that your fastening solutions withstand the rigors of daily use and environmental factors. Stainless Steel Flat Washers, especially those made with SS202, offer an ideal balance of strength and affordability, making them the preferred option for bulk buyers and OEMs alike.

At Nafees Metal Industries, we position ourselves as one of the Best M12 SS202 Plain Washers manufacturer with a commitment to precision engineering, rigorous quality control, and customer-centric solutions. Whether you’re looking to Buy M12 SS202 Plain Washers in Bulk or need a custom fastener solution, we’re your reliable partner in India and beyond.

What Are M12 SS202 Plain Washers?

M12 SS202 Plain Washers are flat, disc-shaped components with a central hole precisely sized to fit M12 bolts or screws. These washers serve a simple yet crucial function: they evenly distribute the load of a fastener, protecting the material beneath from damage due to excessive pressure. By doing so, they help maintain the structural integrity of joints and assemblies.

Technically, M12 SS202 Plain Washers reduce surface damage, prevent fastener pull-through, and absorb vibrations that could otherwise loosen bolts over time. This makes them indispensable in applications involving frequent motion, vibrations, or dynamic loads.

Key performance highlights of M12 SS202 Plain Washers include:

Load Distribution: They spread the load over a larger surface area, reducing the risk of indentation or damage to softer materials.

Vibration Resistance: By providing a stable buffer, they prevent fasteners from loosening in machinery or automotive components.

Surface Protection: They shield the surface beneath the bolt head or nut from scratches, dents, and abrasions.

Long-term Benefits: Regular use of plain washers extends the life of your equipment by minimizing wear and tear.

Material-Specific Strength: SS202 adds strength and moderate corrosion resistance at a more economical price compared to other stainless steels.

Material Details: Why SS202?

When choosing washers for industrial use, material selection is vital. SS202 Stainless Steel is a popular choice because it offers a great balance between strength, formability, and cost.

SS202 Composition: SS202 is a chromium-nickel-manganese stainless steel with lower nickel content compared to SS304 or SS316. This makes it more affordable while still providing adequate corrosion resistance for most indoor and general outdoor applications.

Comparison with SS304/SS316:

SS202 vs. SS304: While SS304 is more corrosion-resistant, SS202 provides similar strength at a lower cost, making it ideal for large-volume orders.

SS202 vs. SS316: SS316 offers superior resistance in marine and chemical environments but comes at a premium cost. For general industrial use, SS202 Washers offer excellent performance without overspending.

Advantages:

High ductility for easier forming.

Good corrosion resistance in normal environments.

Excellent strength for heavy-duty applications.

Budget-friendly for high-volume projects.

This unique balance makes SS202 the go-to material for manufacturers who need Stainless Steel Flat Washers that perform reliably in diverse applications.

Manufacturing and Technical Specifications

High-Precision Stainless Steel Flat Washers by Nafees Metal Industries

At Nafees Metal Industries, each M12 SS202 Plain Washer is crafted to meet stringent dimensional tolerances and quality standards. Our advanced manufacturing unit uses CNC machines, high-speed stamping presses, and precision finishing tools to ensure consistent output.

Our process includes:

Raw material testing to verify SS202 grade.

Precision stamping for accurate dimensions.

Deburring and surface treatment for a smooth finish.

Rigorous inspections at every stage.

Final batch testing before packing.

Below is an example of standard specifications for M12 SS202 Plain Washers:

| Specification | Details |

|---|---|

| Inner Diameter (ID) | 12 mm (fits M12 bolts) |

| Outer Diameter (OD) | 24 mm or as per standard |

| Thickness | 2 mm or customized |

| Material | SS202 Stainless Steel |

| Shape | Flat Round |

| Finish | Plain or custom coatings |

Key Features

Optimal Load Distribution

One of the most critical roles of M12 SS202 Plain Washers is to distribute the load of a fastener evenly across a wider surface area. When you tighten a bolt or screw directly against a material without a washer, all the force is concentrated under the bolt head or nut. This can cause localized crushing, indentation, or deformation of the material, especially if it’s softer like wood, aluminum, or mild steel.

By placing a plain washer between the fastener and the surface, the load is spread out more uniformly, which minimizes the risk of surface damage and ensures that the fastener can be torqued to its proper strength without compromising the structural integrity of the assembly. This makes M12 SS202 Plain Washers indispensable in applications that involve frequent tightening and loosening, or where materials need extra protection from high clamping forces.

Reliable Vibration Resistance

Vibration is a common enemy in many industrial and mechanical settings, especially in automotive engines, machinery, and structural frameworks exposed to environmental forces like wind or seismic activity. When a fastener is subjected to constant vibration, it can gradually work itself loose, leading to joint failure, increased wear, or even catastrophic breakdowns.

M12 SS202 Plain Washers serve as an important buffer that absorbs and dampens these vibrations. While they are not the same as spring or lock washers that mechanically lock the fastener in place, plain washers made from SS202 stainless steel have enough rigidity and resilience to maintain consistent tension under dynamic loads. This added stability means your bolted joints are far less likely to loosen prematurely, saving you time, money, and safety risks in maintenance and repairs.

Good Corrosion Resistance

Material choice matters greatly when it comes to durability, especially for parts exposed to moisture, chemicals, or harsh working environments. SS202 stainless steel is specially formulated to deliver moderate corrosion resistance at an economical price point, making it perfect for standard indoor industrial and general outdoor use.

While SS202 does not offer the same extreme corrosion resistance as SS304 or SS316, it provides an excellent balance of protection against rust and environmental wear for everyday applications. Additionally, M12 SS202 Plain Washers can be coated or plated (with zinc, nickel, or other finishes) for projects that require enhanced corrosion resistance in particularly aggressive environments, ensuring longer service life and lower replacement costs.

Superior Surface Protection

A major but often overlooked benefit of M12 SS202 Plain Washers is that they act as protective barriers between the fastener head or nut and the underlying material. Every time you tighten or loosen a fastener, there’s friction involved. Without a washer, this repeated contact can lead to scratches, gouges, or permanent damage, especially on softer or coated surfaces.

By placing a plain washer at the joint, you reduce direct friction and preserve the integrity of your materials. This is vital in industries like electronics or appliance manufacturing, where even minor surface damage can compromise the appearance or functionality of delicate components. Over the life of an installation, this small feature makes a big difference in maintaining the quality and performance of your assemblies.

Precision Fit and Dimensional Accuracy

Every M12 SS202 Plain Washer we produce is crafted with tight tolerances to ensure an accurate, snug fit with M12 bolts and screws. A poorly sized washer — too loose or too tight — can compromise the fastening system’s performance. Our washers are manufactured using advanced CNC machines and quality inspections to maintain consistent inner and outer diameters, as well as uniform thickness.

This precision ensures that the washer seats perfectly against both the bolt head and the contact surface, maximizing load distribution and minimizing movement. It also reduces installation errors and helps maintain the proper torque level, which is crucial for high-vibration or safety-critical applications.

Multipurpose Versatility

One of the standout benefits of M12 SS202 Plain Washers is their adaptability across diverse industries and use cases. They are an all-rounder solution — equally useful in heavy-duty industrial assemblies, automotive repairs, construction projects, household DIY tasks, and even delicate electronics installations.

Their simple yet effective design, combined with the durable SS202 stainless steel composition, makes them suitable for both light and heavy load applications. This means you can standardize your washer inventory across multiple projects and avoid the hassle of sourcing different washers for every single use case.

Cost Efficiency with Long-Term Value

Lastly, investing in M12 SS202 Plain Washers offers excellent long-term value. While they are competitively priced thanks to the economical SS202 grade, they don’t compromise on performance or durability. This means fewer replacements, fewer maintenance interventions, and greater peace of mind.

Additionally, when you Buy M12 SS202 Plain Washers in Bulk, you benefit from volume pricing, which lowers your per-unit costs even further. Combined with our high manufacturing standards, each washer delivers maximum return on investment by protecting your fasteners, extending the life of your assemblies, and minimizing downtime.

Applications & Use Cases

M12 SS202 Plain Washers are versatile and used in a range of industries. Let’s break this down:

✅ Automotive Industry

Used in engines, chassis, suspension, and exhaust systems where vibration is a constant challenge.

✅ Construction

Secures beams, supports, and structural frames, ensuring even stress distribution on wood, metal, or concrete.

✅ Industrial Machinery

Used in high-vibration equipment like conveyors, presses, and heavy machinery to maintain fastener tightness.

✅ Electronics & Appliances

Ensures secure mounting of circuit boards, panels, and components without causing surface damage.

✅ General Fastening / DIY

A must-have for any general hardware application where bolt security and surface protection matter.

Each of these use cases highlights the adaptability of M12 SS202 Plain Washers, making them the reliable choice for any environment that demands strength and longevity.

Why Buy M12 SS202 Plain Washers in Bulk

Smart buyers understand the value of bulk purchasing. When you Buy M12 SS202 Plain Washers in Bulk, you enjoy:

Volume Pricing: Save on unit costs and boost project profitability.

Inventory Consistency: Never run out during critical assembly schedules.

Project Readiness: Large projects require a steady supply to prevent downtime.

Custom Packaging: Bulk orders can be packed to suit your storage or assembly line needs.

8. Why Choose the Best M12 SS202 Plain Washers Manufacturer

Choosing the right supplier is as important as choosing the right product. Here’s why Nafees Metal Industries is your best choice:

End-to-End Manufacturing: In-house production ensures full control over quality and delivery timelines.

Certifications: We follow industry standards for material sourcing and production.

Customization: Tailor dimensions, finishes, or packaging to your needs.

Experienced Team: Decades of expertise in Stainless Steel Flat Washers.

Client Trust: Trusted by leading OEMs and contractors across India.

When you work with us, you know you’re partnering with the Best M12 SS202 Plain Washers manufacturer.

9. Installation Tips

Proper installation ensures maximum performance of your washers:

Check Bolt & Washer Compatibility: Always use washers that match the bolt size to ensure snug fit.

Position Correctly: Place the washer between the nut or bolt head and the material surface.

Use Dual Washers: For critical applications, use washers on both sides (bolt head & nut side) for added security.

Torque Carefully: Avoid overtightening, which can deform the washer and affect load distribution.

Consider Coating Needs: If your environment is highly corrosive, opt for additional protective coatings.

10. Maintenance Guidelines

Even durable components like M12 SS202 Plain Washers benefit from proper care:

Storage: Keep in dry conditions to prevent corrosion.

Inspection: Check washers during routine maintenance for wear or deformation.

Cleaning: Wipe off dirt and debris before reusing.

Replacement: Replace washers showing signs of stress cracks or flattening.

Real-World Case Study

Project Overview

Project: High-Rise Commercial Tower Reinforcement

Sector: Large-scale Urban Construction Project

Application: Structural beam connections, support framework, and vibration-prone bolted joints.

Background

A leading infrastructure company managing a multi-storey commercial tower was facing a persistent issue: frequent loosening of structural bolts due to continuous wind loads, vibrations from machinery, and regular footfall vibrations throughout the day. This resulted in frequent shutdowns for inspections and retightening, significantly increasing operational costs and posing safety risks.

The standard mild steel washers used initially were deforming under pressure, causing damage to the beam surfaces and accelerating corrosion around the joints. This required the team to repeatedly repair damaged surfaces, adding further labor and material costs.

The project demanded a robust, cost-effective solution that would enhance load distribution, prevent vibration-induced loosening, and extend the life of the bolted connections — all without inflating the budget.

The Challenge

✔ High vibration and lateral movement leading to bolt loosening

✔ Surface damage under high loads due to inadequate washers

✔ Frequent shutdowns disrupting tenant operations

✔ High maintenance and labor costs

✔ Tight deadlines for retrofit implementation

The Solution

After a detailed review, it was decided to upgrade to M12 SS202 Plain Washers, manufactured by Nafees Metal Industries, to solve the recurring problems.

Why M12 SS202 Plain Washers?

Material Advantage: SS202 provides better corrosion resistance than mild steel, with enough strength to withstand high-load stress points — all while remaining cost-effective.

Improved Load Bearing: Custom-sized washers were provided with an optimized outer diameter to distribute stress more evenly, reducing the chances of indentation or surface cracking.

Vibration Resistance: The precise flat design and proper hardness rating ensured the washers maintained clamping force even under constant vibration.

Quick Supply: Nafees Metal Industries committed to producing and delivering the full requirement within tight timelines, with custom packing for easy on-site handling.

Implementation

✅ Prototype Testing: Samples were sent for lab and on-site testing to validate dimensional accuracy, vibration resistance, and surface finish.

✅ Production: Washers were manufactured using advanced stamping, CNC finishing, and quality checks to maintain tight tolerances.

✅ Delivery: The entire batch was delivered on schedule, with washers pre-packed in labeled boxes based on floor-level installation needs — minimizing sorting time at the site.

✅ Installation Support: Best practices for installation were shared with the contractor’s team to ensure proper fitment and torque application.

Results

Within three months, the project team saw measurable improvements:

Bolt Loosening: Incidents of bolts coming loose dropped by over 80%.

Maintenance Costs: Monthly costs for routine inspections and repairs were reduced by more than 70%.

Surface Damage: Improved load distribution minimized beam surface wear and tear, extending the structure’s lifespan.

Downtime: Significantly less operational downtime for tenants, resulting in higher client satisfaction.

| Performance Metric | Before | After |

|---|---|---|

| Bolt Loosening Frequency | 40 cases per month | 6 cases per month |

| Average Downtime | 25 hours per month | 5 hours per month |

| Monthly Maintenance Cost | ₹2,50,000 | ₹50,000 |

Feedback

The project engineers acknowledged that the upgraded M12 SS202 Plain Washers were a simple yet highly effective improvement. The increased structural stability, reduced surface wear, and lower maintenance frequency led to substantial long-term savings and fewer interruptions for building occupants.

Key Takeaway

This case clearly shows how choosing the right washer — specifically, M12 SS202 Plain Washers — can solve real-world fastening challenges for large projects. A minor component, when engineered and manufactured to precise standards, can deliver major benefits in safety, cost-efficiency, and structural longevity.

Client Quote:

“Switching to Nafees Metal Industries’ M12 SS202 Plain Washers significantly improved our structural fastening reliability and reduced downtime. The quality and timely delivery were exceptional.”

Related Products or Variants

We also offer:

Other sizes of SS202 Washers (M6 to M40)

Stainless Steel Flat Washers in SS304 and SS316

Zinc-coated or nickel-plated options for extra corrosion protection

Belleville and Spring washers for dynamic load applications

Why Choose Nafees Metal Industries

At Nafees Metal industries, we focus on quality, precision, and customer satisfaction. Each M12 SS202 Plain Washer is manufactured using cutting-edge machinery and inspected to meet strict quality benchmarks. We have years of experience in delivering stainless steel flat washers for various industries, ensuring that every washer offers top-tier performance and reliability.

We offer bulk supply options, customization based on size and finish, and support throughout the procurement process. Whether you are looking for the best M12 SS202 Plain Washers online or need assistance selecting the right product, our team is here to help.

Order from best M12 SS202 Plain Washers manufacturer online or visit our manufacturing facility at Reay Road, Mumbai to explore our wide range of SS202 washers and custom fastener solutions.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch