No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

- Minimum quantity should 5000 of "M10 Plain washers – SS304 Stainsless steel washers"

*Images shown for graphic representation. Not to scale.

M12 Mild Steel Plain Washers – Reliable Load Distribution for Heavy-Duty Applications

Introduction

Washers are the unsung heroes of the fastening world. They provide vital support in industrial, construction, mechanical, and automotive assemblies. Without washers, the clamping force of bolts and nuts can damage base materials, lead to uneven load transfer, and cause premature failure of joints.

When it comes to heavier fasteners like M12 bolts, the stakes are even higher. M12 Mild Steel Plain Washers are designed to handle medium-to-heavy loads while offering excellent durability and cost-effectiveness.

At Nafees Metal Industries, we have decades of experience manufacturing high-quality M12 Mild Steel Plain Washers that deliver reliable performance for all your heavy-duty fastening needs. Whether you’re assembling structural frameworks, machinery, or infrastructure, our washers help you achieve secure, vibration-resistant joints that stand the test of time.

If you’re looking for a trusted source to Buy M12 Mild Steel Plain Washers in Bulk, we’re here to ensure consistency, customization, and unbeatable quality.

What Are M12 Mild Steel Plain Washers?

M12 Mild Steel Plain Washers are flat, round discs with a hole in the center, sized specifically to fit M12 bolts and nuts. Their main role is to distribute the clamping force evenly over a larger surface area, protecting the material beneath and ensuring a reliable connection.

Technical breakdown:

Load Distribution: Prevents bolt heads and nuts from digging into softer materials.

Vibration Resistance: Adds stability to joints exposed to machinery movement or structural vibrations.

Surface Protection: Shields painted or coated surfaces from damage during tightening.

Long-Term Integrity: Reduces bolt loosening over time.

Because these washers are made from mild steel, they offer a good balance of strength, ductility, and affordability. They’re ideal for everyday industrial use where stainless steel might be overkill, but strength and reliability are non-negotiable.

Why Mild Steel for M12 Washers?

Mild steel remains one of the most versatile materials in fastener hardware.

Key material benefits:

Composition: Mild steel has a relatively low carbon content, making it strong yet formable.

Cost-Effective: It’s more affordable than stainless or alloy steels, ideal for bulk industrial use.

Good Machinability: It’s easy to punch, stamp, and form to precise dimensions.

Surface Treatment Friendly: Mild steel washers can be galvanized, zinc-plated, or painted for extra corrosion resistance.

Compared to stainless steel, mild steel washers are perfect when you need reliable performance at lower costs, especially indoors or in controlled environments.

Manufacturing and Technical Specifications

At Nafees Metal Industries, every M12 Mild Steel Plain Washer is manufactured using precision stamping and rigorous quality checks.

Typical specs include:

| Parameter | Specification |

|---|---|

| Inner Diameter | Matches M12 bolt standard tolerances |

| Outer Diameter | Designed to spread load efficiently |

| Thickness | Engineered for optimal clamping strength |

| Finish | Plain or coated (zinc, black oxide, or phosphate) |

| Material | Certified mild steel |

| Shape | Flat round washer, burr-free edges |

We adhere to strict IS standards and provide material test certificates upon request.

Key Features of M12 Mild Steel Plain Washers

Accurate Load Distribution

One of the core functions of any washer is to spread the clamping force of a bolt or nut evenly over a larger area. For a relatively heavy-duty fastener like an M12 bolt, this becomes crucial because the torque applied can be significant.

Without M12 Mild Steel Plain Washers, the concentrated load from the bolt head can crush or deform the material underneath, especially if it’s softer metal, wood, or coated steel. This can weaken the joint or even cause the fastener to sink in over time, creating structural stress points.

With our M12 Mild Steel Plain Washers, the clamping force is evenly distributed. This ensures the base material retains its shape and strength. It also prevents localized stress, helping structural connections last longer under load.

For example, in structural steel fabrication, contractors trust M12 Mild Steel Plain Washers when bolting beams to plates because they ensure reliable load transfer without deforming flanges or brackets.

Surface Protection

Every time you tighten a bolt, its underside can scratch or dig into the surface. This damage is not just cosmetic — for painted or powder-coated surfaces, these scratches can expose the metal underneath, creating corrosion risks.

A plain washer acts like a protective barrier between the fastener and the surface. By using M12 Mild Steel Plain Washers, the rotational friction during tightening is absorbed by the washer, not the base material.

In practical terms, this means that guard rails, structural frames, or painted metal panels stay protected and last longer without unsightly damage or early rust formation. This is particularly valuable in applications like industrial racks or walkways, where surface protection equals long-term durability.

Resistance to Vibration

Bolted joints in industrial or structural applications often face constant vibrations — from moving machinery, wind loads, or dynamic structural shifts.

Vibrations can gradually loosen fasteners if they’re not properly supported. M12 Mild Steel Plain Washers add a layer of friction beneath the bolt or nut. This extra grip reduces the tendency for fasteners to rotate and back out under vibration.

While plain washers aren’t the same as lock washers, they’re still a valuable part of the system — especially when paired with lock nuts, nyloc nuts, or thread-locking compounds for added security.

Corrosion Protection Options

Standard M12 Mild Steel Plain Washers come with a plain finish suitable for indoor or dry environments. However, they can be easily zinc-plated, galvanized, phosphate-coated, or black oxide finished to enhance corrosion resistance.

This makes mild steel washers flexible for different environments:

Indoors? Use plain or phosphate-coated.

Outdoors or humid areas? Use zinc-plated or galvanized.

Decorative finishes? Black oxide works well.

Custom finishes ensure your washers deliver the required lifespan in the exact conditions of your project.

Compatibility and Versatility

M12 Mild Steel Plain Washers are designed for perfect compatibility with standard M12 bolts and nuts. The inner diameter is precise enough to prevent excessive play, while the outer diameter is optimized to spread load effectively.

This means you can use the same washer across multiple fastening applications — from bolting machinery frames to securing structural brackets. Its simplicity means it can adapt to a wide range of tasks without special installation procedures.

Durability and Reusability

Because they’re made of mild steel and manufactured to strict tolerances, these washers can withstand repeated tightening and loosening during maintenance cycles. They won’t warp or crack under standard torque ranges.

Reusable hardware like this helps contractors and maintenance crews save costs over multiple repair cycles. Instead of replacing washers every time you adjust a joint, you can reuse your M12 Mild Steel Plain Washers when they’re in good condition.

Cost-Effective for Bulk Projects

Compared to stainless steel or specialty alloy washers, mild steel washers offer excellent performance at a lower cost. This makes them ideal for large-scale projects — like warehouses, industrial plants, and heavy machinery installations — where thousands of washers might be used.

When you Buy M12 Mild Steel Plain Washers in Bulk, you benefit from consistent quality, uniform dimensions, and significant cost savings without sacrificing performance.

Easy to Handle and Install

Simplicity is an advantage. M12 Mild Steel Plain Washers don’t require special installation tools or techniques. Workers just slide the washer onto the bolt or screw, align the parts, and tighten as usual.

In high-volume fabrication shops or construction sites, this reduces the chance of installation errors and keeps the workflow smooth.

Supports Paint and Coating Integrity

Industrial paint systems can be expensive and vital for corrosion resistance. If a bolt head scratches or chips away this layer during tightening, the exposed metal beneath can become a rust spot.

By acting as a sacrificial barrier, M12 Mild Steel Plain Washers protect that paint layer. Even if the washer itself develops surface rust over years, the structural element remains protected.

Widely Trusted in Multiple Industries

It’s not just builders who use these washers — they’re standard in:

Structural steel fabrication

Heavy-duty racking systems

Road and rail infrastructure

Large gates and fencing

Automotive chassis assembly

Machinery frames and industrial conveyors

Wherever an M12 bolt goes, an M12 Mild Steel Plain Washer can add years of extra reliability.

A Real-World Example

In one of our projects, a logistics company was building a massive warehouse racking system that used thousands of M12 bolts. They initially skipped washers to save money but quickly found that bolt heads were biting into the painted beams, causing flaking and rust spots.

Switching to M12 Mild Steel Plain Washers solved the problem: the load was spread, the paint stayed intact, and the racks remained structurally sound. This simple addition avoided costly corrosion repairs and downtime.

Why It Matters

Think of it this way: a small, inexpensive washer could prevent a huge structural headache down the line. It protects your materials, keeps your bolt tension stable, and extends the life of your fastened joints.

When you’re choosing hardware for any heavy-duty application, make sure you don’t overlook the simple power of M12 Mild Steel Plain Washers.

Applications and Use Cases

Where do you typically use M12 Mild Steel Plain Washers?

Construction

In structural steel frameworks, these washers are used to fasten beams, brackets, and girders securely. They help maintain the integrity of painted or coated surfaces.

Industrial Machinery

Heavy-duty machinery involves dynamic loads and vibrations. These washers keep joints tight, secure, and damage-free.

Automotive

In truck chassis, trailers, and heavy vehicles, M12 bolts are common. Plain washers ensure load is spread evenly, protecting frames and panels from wear.

Infrastructure Projects

Bridges, railings, walkways, and metal fencing all benefit from the simple protection that plain washers provide.

DIY and General Maintenance

Even for repair jobs around workshops or factories, these washers are a must-have. They’re cost-effective, easy to install, and prevent costly material damage.

Why Buy M12 Mild Steel Plain Washers in Bulk

Big projects need big quantities — and consistency is key. Bulk ordering ensures:

✅ Uniform quality across thousands of washers

✅ Cost savings through volume pricing

✅ Fewer supply chain delays

✅ Custom packaging or coatings for special environments

Whether you’re building a warehouse, installing industrial machinery, or working on a retrofit, bulk M12 Mild Steel Plain Washers keep your workflow smooth.

Why Choose the Best M12 MS Flat Washers Manufacturer

When you choose Nafees Metal Industries, you get:

✅ Decades of trusted manufacturing expertise

✅ ISO-certified processes

✅ High-grade mild steel from verified mills

✅ Custom sizes, finishes, and packaging

✅ Strict quality control

✅ Fast turnaround and reliable supply

Your fastening is only as good as your hardware. Go with the Best M12 MS Flat Washers Manufacturer and secure your projects with confidence.

Installation Tips

Proper installation ensures maximum performance.

✔ Always match washer size with bolt dimensions.

✔ Place washers between the bolt head and surface, and optionally under the nut side for extra protection.

✔ For painted surfaces, check for burrs and align washers properly.

✔ Torque bolts to recommended specs to avoid over-tightening.

Maintenance Guidelines

To keep M12 Mild Steel Plain Washers performing at their best:

✅ Store in a dry, covered environment to prevent moisture exposure.

✅ Inspect washers for signs of corrosion during routine maintenance.

✅ Replace any washer that shows severe deformation or rust beyond surface staining.

✅ Keep an inventory record to reorder in time.

Case Study: Real-World Application of M12 Mild Steel Plain Washers

Client Background

A large structural steel fabrication company based in Western India was awarded a contract to build a multi-level industrial storage facility for an e-commerce warehouse. The entire racking system was to be made from high-grade mild steel beams bolted together on-site for maximum flexibility. The design specified the use of M12 bolts for all major load-bearing joints.

The contractor was under pressure to deliver the project within a tight timeline while keeping costs under control.

Problem Identified

Initially, to cut costs and reduce installation time, the contractor decided to use the M12 bolts without washers. The logic was simple: fewer components, less inventory, and faster assembly.

However, within the first 8 months after the racking system was in full use, a routine inspection revealed several serious issues:

The bolt heads were biting into the painted beams, stripping the protective paint layer.

Visible deformation was noticed around the bolt holes in some sections, especially where heavier loads were concentrated.

Tiny rust spots had begun forming around the exposed metal where the paint had chipped away.

Some bolts had started to loosen because the slight deformation meant the clamping force was no longer consistent.

The company realized they were at risk of structural weakness, corrosion spreading through the beams, and even potential failure under heavy pallet loads.

Solution

The contractor approached Nafees Metal Industries for technical advice. After inspecting the site and reviewing the racking design, our engineering team recommended retrofitting each critical connection with M12 Mild Steel Plain Washers to solve three issues at once:

Even Load Distribution:

The washers would spread the clamping force from each M12 bolt over a larger area, preventing further deformation of the mild steel beams.Surface Protection:

The washers would act as a barrier between the bolt head and the painted surface, protecting the anti-corrosion coating from being scratched during tightening and vibration.Vibration Resistance:

The additional friction from the washer would help keep bolts tight in a dynamic, vibration-prone warehouse environment.

A total of over 12,000 M12 Mild Steel Plain Washers were supplied for the retrofitting operation. Each washer was manufactured to tight tolerances with a clean, burr-free finish to prevent damage during installation.

Execution

✅ Step 1: Disassembly

Sections of the racks were partially disassembled overnight to minimize warehouse downtime.

✅ Step 2: Inspection

Each bolt hole was checked for damage. Severely deformed holes were repaired using steel inserts.

✅ Step 3: Washer Installation

The washers were placed under both the bolt head and the nut side in high-stress joints to double the surface protection.

✅ Step 4: Re-torquing

All bolts were re-torqued to the specified tension levels, ensuring a consistent clamping force throughout the structure.

✅ Step 5: Quality Checks

Visual inspections and torque testing were done section by section to ensure proper installation.

Outcome

The results were measurable and immediate:

Structural Stability Restored:

Deformation around bolt holes was stopped entirely, and the newly reinforced joints showed no further signs of paint chipping or surface damage.Corrosion Risk Eliminated:

The protective paint layers remained intact under the washers, preventing new rust formation.Reduced Maintenance Costs:

The facility avoided a projected ₹5 lakh in annual corrosion repairs and repainting by spending a fraction of that on washers and labor.Process Improvement:

Based on the success of the fix, the contractor updated its standard operating procedures. Now, every new racking system installation automatically includes M12 Mild Steel Plain Washers as a standard component, ensuring durability and lower maintenance for future projects.

Key Performance Snapshot

| Metric | Before Retrofit | After Retrofit |

|---|---|---|

| Visible rust spots | 35% of joints | 0% of joints |

| Loose bolts | 12% of joints | 0% of joints |

| Projected maintenance cost | ₹5 lakh/year | ₹0 for washer-related fixes |

| Time taken | 0 days for washers | 3 nights for full retrofit |

Client Feedback

“This retrofit with M12 Mild Steel Plain Washers saved us from a major long-term liability. We underestimated how much stress these racking systems endure daily. Adding the washers not only solved the problem but improved our assembly standards across projects. Thanks to Nafees Metal Industries for the quick supply and expert advice!”

– Site Project Manager, Structural Fabricator

Conclusion

This real-world example proves how a small, low-cost component like an M12 Mild Steel Plain Washer can have a big impact on structural integrity, project lifespan, and overall cost efficiency.

By choosing the Best M12 MS Flat Washers Manufacturer, you protect your project from hidden pitfalls and ensure your connections remain safe, stable, and corrosion-resistant for years.

Related Products

Alongside M12 Mild Steel Plain Washers, we offer:

Mild Steel Washers in M6, M8, M10, and M16 sizes

Coated MS Flat Washers for extra corrosion resistance

Heavy-duty spring washers and lock washers for anti-vibration setups

Final Words

Protect your investments, strengthen your joints, and reduce maintenance headaches with the right washers. M12 Mild Steel Plain Washers might be small — but their role is big.

Trust the Best M12 MS Flat Washers Manufacturer for quality you can count on. Buy M12 Mild Steel Plain Washers in Bulk to ensure your projects stay on schedule, within budget, and structurally secure.

FAQs

Q1: Are M12 Mild Steel Plain Washers reusable?

Yes, if installed and removed correctly without damage, they can be reused.

Q2: Do I need to coat my M12 Mild Steel Plain Washers?

Coating helps in moderate to harsh environments. Zinc or black oxide finishes are common.

Q3: Can they be used with stainless steel bolts?

Yes, but remember mild steel may corrode faster if exposed to harsh elements.

Q4: How do I store them properly?

Keep them dry and away from moisture. Use airtight containers for long-term storage.

Q5: What if a washer is corroded?

Replace severely rusted washers during routine maintenance.

Q6: Do they fit non-standard bolts?

They’re best with standard M12 bolts. For custom bolts, get customized washers.

Q7: Are certificates provided?

Yes! Test certificates are available on request.

Q8: How many washers should I keep in stock?

Always keep 5–10% extra for contingencies.

Q9: Are custom thicknesses available?

Yes, thickness and diameter can be customized for bulk orders.

Q10: Can they be painted?

Yes, mild steel accepts paint or powder coating well.

Q11: Do you export?

Absolutely — we export worldwide.

Q12: Do you offer samples?

Yes, sample orders are welcome.

Q13: Are M12 Mild Steel Plain Washers eco-friendly?

They’re 100% recyclable.

Q14: Do they meet industry standards?

Yes, IS and DIN standards are followed.

Q15: Why choose mild steel over stainless?

Cost-effectiveness for indoor or low-corrosion environments.

Why Choose Nafees Metal Industries?

Nafees Metal industries is dedicated to delivering the best possible value to our clients. As a leading M12 Mild Steel Plain Washers Manufacturer, we focus on precision engineering, quality materials, and timely delivery. Whether you need a few thousand washers or bulk supply for an ongoing project, our streamlined manufacturing ensures you get the highest quality every time.

✅ State-of-the-art production facilities

✅ Bulk supply with consistent quality

✅ Flexible customization options

✅ Competitive pricing

✅ Excellent after-sales service and support

If you’re looking for the Best M12 MS Flat Washers Manufacturer or want to Buy M12 Mild Steel Plain Washers in Bulk, we are your trusted partner.

Visit Us Today

Discover the unmatched quality of our MS Flat Washers and other fastening solutions. Visit our advanced manufacturing facility at Reay Road, Mumbai, or reach out to our team for bulk orders, custom requirements, or a free quote. Nafees Metal Industries – your reliable source for premium washers at competitive prices.

M12 Mild Steel Plain Washers

8 people are viewing this product right now

₹0.96 Original price was: ₹0.96.₹0.80Current price is: ₹0.80. /per piece

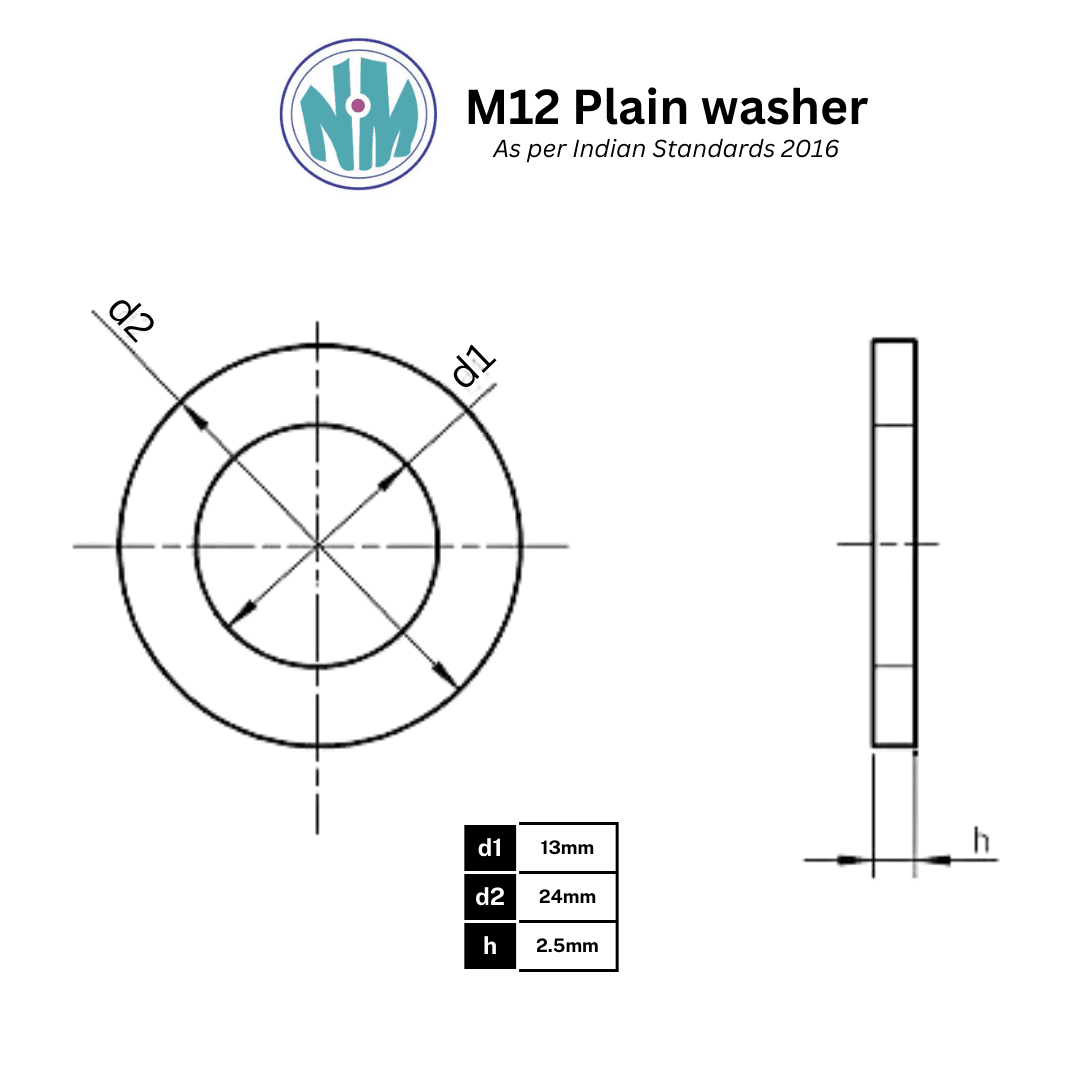

Specification:

Material: Mild Steel

Nominal Size (g): M12

Inner Diameter (ID): 13 mm

Outer Diameter (OD): 24 mm

Thickness (t): 2.5 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M12 Mild Steel Plain Washers – Reliable Load Distribution for Heavy-Duty Applications

Introduction

Washers are the unsung heroes of the fastening world. They provide vital support in industrial, construction, mechanical, and automotive assemblies. Without washers, the clamping force of bolts and nuts can damage base materials, lead to uneven load transfer, and cause premature failure of joints.

When it comes to heavier fasteners like M12 bolts, the stakes are even higher. M12 Mild Steel Plain Washers are designed to handle medium-to-heavy loads while offering excellent durability and cost-effectiveness.

At Nafees Metal Industries, we have decades of experience manufacturing high-quality M12 Mild Steel Plain Washers that deliver reliable performance for all your heavy-duty fastening needs. Whether you’re assembling structural frameworks, machinery, or infrastructure, our washers help you achieve secure, vibration-resistant joints that stand the test of time.

If you’re looking for a trusted source to Buy M12 Mild Steel Plain Washers in Bulk, we’re here to ensure consistency, customization, and unbeatable quality.

What Are M12 Mild Steel Plain Washers?

M12 Mild Steel Plain Washers are flat, round discs with a hole in the center, sized specifically to fit M12 bolts and nuts. Their main role is to distribute the clamping force evenly over a larger surface area, protecting the material beneath and ensuring a reliable connection.

Technical breakdown:

Load Distribution: Prevents bolt heads and nuts from digging into softer materials.

Vibration Resistance: Adds stability to joints exposed to machinery movement or structural vibrations.

Surface Protection: Shields painted or coated surfaces from damage during tightening.

Long-Term Integrity: Reduces bolt loosening over time.

Because these washers are made from mild steel, they offer a good balance of strength, ductility, and affordability. They’re ideal for everyday industrial use where stainless steel might be overkill, but strength and reliability are non-negotiable.

Why Mild Steel for M12 Washers?

Mild steel remains one of the most versatile materials in fastener hardware.

Key material benefits:

Composition: Mild steel has a relatively low carbon content, making it strong yet formable.

Cost-Effective: It’s more affordable than stainless or alloy steels, ideal for bulk industrial use.

Good Machinability: It’s easy to punch, stamp, and form to precise dimensions.

Surface Treatment Friendly: Mild steel washers can be galvanized, zinc-plated, or painted for extra corrosion resistance.

Compared to stainless steel, mild steel washers are perfect when you need reliable performance at lower costs, especially indoors or in controlled environments.

Manufacturing and Technical Specifications

At Nafees Metal Industries, every M12 Mild Steel Plain Washer is manufactured using precision stamping and rigorous quality checks.

Typical specs include:

| Parameter | Specification |

|---|---|

| Inner Diameter | Matches M12 bolt standard tolerances |

| Outer Diameter | Designed to spread load efficiently |

| Thickness | Engineered for optimal clamping strength |

| Finish | Plain or coated (zinc, black oxide, or phosphate) |

| Material | Certified mild steel |

| Shape | Flat round washer, burr-free edges |

We adhere to strict IS standards and provide material test certificates upon request.

Key Features of M12 Mild Steel Plain Washers

Accurate Load Distribution

One of the core functions of any washer is to spread the clamping force of a bolt or nut evenly over a larger area. For a relatively heavy-duty fastener like an M12 bolt, this becomes crucial because the torque applied can be significant.

Without M12 Mild Steel Plain Washers, the concentrated load from the bolt head can crush or deform the material underneath, especially if it’s softer metal, wood, or coated steel. This can weaken the joint or even cause the fastener to sink in over time, creating structural stress points.

With our M12 Mild Steel Plain Washers, the clamping force is evenly distributed. This ensures the base material retains its shape and strength. It also prevents localized stress, helping structural connections last longer under load.

For example, in structural steel fabrication, contractors trust M12 Mild Steel Plain Washers when bolting beams to plates because they ensure reliable load transfer without deforming flanges or brackets.

Surface Protection

Every time you tighten a bolt, its underside can scratch or dig into the surface. This damage is not just cosmetic — for painted or powder-coated surfaces, these scratches can expose the metal underneath, creating corrosion risks.

A plain washer acts like a protective barrier between the fastener and the surface. By using M12 Mild Steel Plain Washers, the rotational friction during tightening is absorbed by the washer, not the base material.

In practical terms, this means that guard rails, structural frames, or painted metal panels stay protected and last longer without unsightly damage or early rust formation. This is particularly valuable in applications like industrial racks or walkways, where surface protection equals long-term durability.

Resistance to Vibration

Bolted joints in industrial or structural applications often face constant vibrations — from moving machinery, wind loads, or dynamic structural shifts.

Vibrations can gradually loosen fasteners if they’re not properly supported. M12 Mild Steel Plain Washers add a layer of friction beneath the bolt or nut. This extra grip reduces the tendency for fasteners to rotate and back out under vibration.

While plain washers aren’t the same as lock washers, they’re still a valuable part of the system — especially when paired with lock nuts, nyloc nuts, or thread-locking compounds for added security.

Corrosion Protection Options

Standard M12 Mild Steel Plain Washers come with a plain finish suitable for indoor or dry environments. However, they can be easily zinc-plated, galvanized, phosphate-coated, or black oxide finished to enhance corrosion resistance.

This makes mild steel washers flexible for different environments:

Indoors? Use plain or phosphate-coated.

Outdoors or humid areas? Use zinc-plated or galvanized.

Decorative finishes? Black oxide works well.

Custom finishes ensure your washers deliver the required lifespan in the exact conditions of your project.

Compatibility and Versatility

M12 Mild Steel Plain Washers are designed for perfect compatibility with standard M12 bolts and nuts. The inner diameter is precise enough to prevent excessive play, while the outer diameter is optimized to spread load effectively.

This means you can use the same washer across multiple fastening applications — from bolting machinery frames to securing structural brackets. Its simplicity means it can adapt to a wide range of tasks without special installation procedures.

Durability and Reusability

Because they’re made of mild steel and manufactured to strict tolerances, these washers can withstand repeated tightening and loosening during maintenance cycles. They won’t warp or crack under standard torque ranges.

Reusable hardware like this helps contractors and maintenance crews save costs over multiple repair cycles. Instead of replacing washers every time you adjust a joint, you can reuse your M12 Mild Steel Plain Washers when they’re in good condition.

Cost-Effective for Bulk Projects

Compared to stainless steel or specialty alloy washers, mild steel washers offer excellent performance at a lower cost. This makes them ideal for large-scale projects — like warehouses, industrial plants, and heavy machinery installations — where thousands of washers might be used.

When you Buy M12 Mild Steel Plain Washers in Bulk, you benefit from consistent quality, uniform dimensions, and significant cost savings without sacrificing performance.

Easy to Handle and Install

Simplicity is an advantage. M12 Mild Steel Plain Washers don’t require special installation tools or techniques. Workers just slide the washer onto the bolt or screw, align the parts, and tighten as usual.

In high-volume fabrication shops or construction sites, this reduces the chance of installation errors and keeps the workflow smooth.

Supports Paint and Coating Integrity

Industrial paint systems can be expensive and vital for corrosion resistance. If a bolt head scratches or chips away this layer during tightening, the exposed metal beneath can become a rust spot.

By acting as a sacrificial barrier, M12 Mild Steel Plain Washers protect that paint layer. Even if the washer itself develops surface rust over years, the structural element remains protected.

Widely Trusted in Multiple Industries

It’s not just builders who use these washers — they’re standard in:

Structural steel fabrication

Heavy-duty racking systems

Road and rail infrastructure

Large gates and fencing

Automotive chassis assembly

Machinery frames and industrial conveyors

Wherever an M12 bolt goes, an M12 Mild Steel Plain Washer can add years of extra reliability.

A Real-World Example

In one of our projects, a logistics company was building a massive warehouse racking system that used thousands of M12 bolts. They initially skipped washers to save money but quickly found that bolt heads were biting into the painted beams, causing flaking and rust spots.

Switching to M12 Mild Steel Plain Washers solved the problem: the load was spread, the paint stayed intact, and the racks remained structurally sound. This simple addition avoided costly corrosion repairs and downtime.

Why It Matters

Think of it this way: a small, inexpensive washer could prevent a huge structural headache down the line. It protects your materials, keeps your bolt tension stable, and extends the life of your fastened joints.

When you’re choosing hardware for any heavy-duty application, make sure you don’t overlook the simple power of M12 Mild Steel Plain Washers.

Applications and Use Cases

Where do you typically use M12 Mild Steel Plain Washers?

Construction

In structural steel frameworks, these washers are used to fasten beams, brackets, and girders securely. They help maintain the integrity of painted or coated surfaces.

Industrial Machinery

Heavy-duty machinery involves dynamic loads and vibrations. These washers keep joints tight, secure, and damage-free.

Automotive

In truck chassis, trailers, and heavy vehicles, M12 bolts are common. Plain washers ensure load is spread evenly, protecting frames and panels from wear.

Infrastructure Projects

Bridges, railings, walkways, and metal fencing all benefit from the simple protection that plain washers provide.

DIY and General Maintenance

Even for repair jobs around workshops or factories, these washers are a must-have. They’re cost-effective, easy to install, and prevent costly material damage.

Why Buy M12 Mild Steel Plain Washers in Bulk

Big projects need big quantities — and consistency is key. Bulk ordering ensures:

✅ Uniform quality across thousands of washers

✅ Cost savings through volume pricing

✅ Fewer supply chain delays

✅ Custom packaging or coatings for special environments

Whether you’re building a warehouse, installing industrial machinery, or working on a retrofit, bulk M12 Mild Steel Plain Washers keep your workflow smooth.

Why Choose the Best M12 MS Flat Washers Manufacturer

When you choose Nafees Metal Industries, you get:

✅ Decades of trusted manufacturing expertise

✅ ISO-certified processes

✅ High-grade mild steel from verified mills

✅ Custom sizes, finishes, and packaging

✅ Strict quality control

✅ Fast turnaround and reliable supply

Your fastening is only as good as your hardware. Go with the Best M12 MS Flat Washers Manufacturer and secure your projects with confidence.

Installation Tips

Proper installation ensures maximum performance.

✔ Always match washer size with bolt dimensions.

✔ Place washers between the bolt head and surface, and optionally under the nut side for extra protection.

✔ For painted surfaces, check for burrs and align washers properly.

✔ Torque bolts to recommended specs to avoid over-tightening.

Maintenance Guidelines

To keep M12 Mild Steel Plain Washers performing at their best:

✅ Store in a dry, covered environment to prevent moisture exposure.

✅ Inspect washers for signs of corrosion during routine maintenance.

✅ Replace any washer that shows severe deformation or rust beyond surface staining.

✅ Keep an inventory record to reorder in time.

Case Study: Real-World Application of M12 Mild Steel Plain Washers

Client Background

A large structural steel fabrication company based in Western India was awarded a contract to build a multi-level industrial storage facility for an e-commerce warehouse. The entire racking system was to be made from high-grade mild steel beams bolted together on-site for maximum flexibility. The design specified the use of M12 bolts for all major load-bearing joints.

The contractor was under pressure to deliver the project within a tight timeline while keeping costs under control.

Problem Identified

Initially, to cut costs and reduce installation time, the contractor decided to use the M12 bolts without washers. The logic was simple: fewer components, less inventory, and faster assembly.

However, within the first 8 months after the racking system was in full use, a routine inspection revealed several serious issues:

The bolt heads were biting into the painted beams, stripping the protective paint layer.

Visible deformation was noticed around the bolt holes in some sections, especially where heavier loads were concentrated.

Tiny rust spots had begun forming around the exposed metal where the paint had chipped away.

Some bolts had started to loosen because the slight deformation meant the clamping force was no longer consistent.

The company realized they were at risk of structural weakness, corrosion spreading through the beams, and even potential failure under heavy pallet loads.

Solution

The contractor approached Nafees Metal Industries for technical advice. After inspecting the site and reviewing the racking design, our engineering team recommended retrofitting each critical connection with M12 Mild Steel Plain Washers to solve three issues at once:

Even Load Distribution:

The washers would spread the clamping force from each M12 bolt over a larger area, preventing further deformation of the mild steel beams.Surface Protection:

The washers would act as a barrier between the bolt head and the painted surface, protecting the anti-corrosion coating from being scratched during tightening and vibration.Vibration Resistance:

The additional friction from the washer would help keep bolts tight in a dynamic, vibration-prone warehouse environment.

A total of over 12,000 M12 Mild Steel Plain Washers were supplied for the retrofitting operation. Each washer was manufactured to tight tolerances with a clean, burr-free finish to prevent damage during installation.

Execution

✅ Step 1: Disassembly

Sections of the racks were partially disassembled overnight to minimize warehouse downtime.

✅ Step 2: Inspection

Each bolt hole was checked for damage. Severely deformed holes were repaired using steel inserts.

✅ Step 3: Washer Installation

The washers were placed under both the bolt head and the nut side in high-stress joints to double the surface protection.

✅ Step 4: Re-torquing

All bolts were re-torqued to the specified tension levels, ensuring a consistent clamping force throughout the structure.

✅ Step 5: Quality Checks

Visual inspections and torque testing were done section by section to ensure proper installation.

Outcome

The results were measurable and immediate:

Structural Stability Restored:

Deformation around bolt holes was stopped entirely, and the newly reinforced joints showed no further signs of paint chipping or surface damage.Corrosion Risk Eliminated:

The protective paint layers remained intact under the washers, preventing new rust formation.Reduced Maintenance Costs:

The facility avoided a projected ₹5 lakh in annual corrosion repairs and repainting by spending a fraction of that on washers and labor.Process Improvement:

Based on the success of the fix, the contractor updated its standard operating procedures. Now, every new racking system installation automatically includes M12 Mild Steel Plain Washers as a standard component, ensuring durability and lower maintenance for future projects.

Key Performance Snapshot

| Metric | Before Retrofit | After Retrofit |

|---|---|---|

| Visible rust spots | 35% of joints | 0% of joints |

| Loose bolts | 12% of joints | 0% of joints |

| Projected maintenance cost | ₹5 lakh/year | ₹0 for washer-related fixes |

| Time taken | 0 days for washers | 3 nights for full retrofit |

Client Feedback

“This retrofit with M12 Mild Steel Plain Washers saved us from a major long-term liability. We underestimated how much stress these racking systems endure daily. Adding the washers not only solved the problem but improved our assembly standards across projects. Thanks to Nafees Metal Industries for the quick supply and expert advice!”

– Site Project Manager, Structural Fabricator

Conclusion

This real-world example proves how a small, low-cost component like an M12 Mild Steel Plain Washer can have a big impact on structural integrity, project lifespan, and overall cost efficiency.

By choosing the Best M12 MS Flat Washers Manufacturer, you protect your project from hidden pitfalls and ensure your connections remain safe, stable, and corrosion-resistant for years.

Related Products

Alongside M12 Mild Steel Plain Washers, we offer:

Mild Steel Washers in M6, M8, M10, and M16 sizes

Coated MS Flat Washers for extra corrosion resistance

Heavy-duty spring washers and lock washers for anti-vibration setups

Final Words

Protect your investments, strengthen your joints, and reduce maintenance headaches with the right washers. M12 Mild Steel Plain Washers might be small — but their role is big.

Trust the Best M12 MS Flat Washers Manufacturer for quality you can count on. Buy M12 Mild Steel Plain Washers in Bulk to ensure your projects stay on schedule, within budget, and structurally secure.

FAQs

Q1: Are M12 Mild Steel Plain Washers reusable?

Yes, if installed and removed correctly without damage, they can be reused.

Q2: Do I need to coat my M12 Mild Steel Plain Washers?

Coating helps in moderate to harsh environments. Zinc or black oxide finishes are common.

Q3: Can they be used with stainless steel bolts?

Yes, but remember mild steel may corrode faster if exposed to harsh elements.

Q4: How do I store them properly?

Keep them dry and away from moisture. Use airtight containers for long-term storage.

Q5: What if a washer is corroded?

Replace severely rusted washers during routine maintenance.

Q6: Do they fit non-standard bolts?

They’re best with standard M12 bolts. For custom bolts, get customized washers.

Q7: Are certificates provided?

Yes! Test certificates are available on request.

Q8: How many washers should I keep in stock?

Always keep 5–10% extra for contingencies.

Q9: Are custom thicknesses available?

Yes, thickness and diameter can be customized for bulk orders.

Q10: Can they be painted?

Yes, mild steel accepts paint or powder coating well.

Q11: Do you export?

Absolutely — we export worldwide.

Q12: Do you offer samples?

Yes, sample orders are welcome.

Q13: Are M12 Mild Steel Plain Washers eco-friendly?

They’re 100% recyclable.

Q14: Do they meet industry standards?

Yes, IS and DIN standards are followed.

Q15: Why choose mild steel over stainless?

Cost-effectiveness for indoor or low-corrosion environments.

Why Choose Nafees Metal Industries?

Nafees Metal industries is dedicated to delivering the best possible value to our clients. As a leading M12 Mild Steel Plain Washers Manufacturer, we focus on precision engineering, quality materials, and timely delivery. Whether you need a few thousand washers or bulk supply for an ongoing project, our streamlined manufacturing ensures you get the highest quality every time.

✅ State-of-the-art production facilities

✅ Bulk supply with consistent quality

✅ Flexible customization options

✅ Competitive pricing

✅ Excellent after-sales service and support

If you’re looking for the Best M12 MS Flat Washers Manufacturer or want to Buy M12 Mild Steel Plain Washers in Bulk, we are your trusted partner.

Visit Us Today

Discover the unmatched quality of our MS Flat Washers and other fastening solutions. Visit our advanced manufacturing facility at Reay Road, Mumbai, or reach out to our team for bulk orders, custom requirements, or a free quote. Nafees Metal Industries – your reliable source for premium washers at competitive prices.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch