No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M12 Copper Plain Washer – Durable Copper Washers for Superior Conductivity and Sealing Performance

Nafees Metal Industries is proud to present the M12 Copper Plain Washer, engineered for high performance in demanding industrial, electrical, and thermal applications. Designed to deliver exceptional conductivity, sealing capability, and corrosion resistance, the Copper Washer stands out as a vital component in assemblies where both electrical and mechanical performance are crucial.

Crafted from high-grade copper, each M12 Copper Plain Washer we manufacture ensures a consistent fit, excellent load distribution, and long-lasting performance. Whether you require washers for high-current electrical terminals, hydraulic fittings, or machinery requiring leak-proof seals, our M12 Copper Plain Washer meets the mark with precision.

As one of the best copper washer manufacturers in India, Nafees Metal Industries brings years of experience and technical know-how to ensure that every washer meets the highest industry standards. From heat resistance to excellent malleability, this washer type is ideal for industries ranging from automotive and plumbing to electronics and aerospace.

The M12 Copper Plain Washer is specifically designed for bolts and fasteners with a 12 mm diameter, ensuring exact fitment and optimal clamping pressure. These washers are widely used in situations where electrical conductivity, thermal management, or fluid sealing is essential.

Key product features include:

Manufactured using premium copper alloy for consistent material quality

Designed to accommodate standard copper washer sizes for M12 bolts and fasteners

Ideal for use in high-heat environments, high-current electrical systems, and fluid-sealing mechanisms

Available in bulk, customized packaging options, and export-ready compliance

Whether you’re an OEM, maintenance contractor, or procurement officer looking for a reliable supplier of M12 Copper Plain Washers, our solutions are built to perform and last. Explore why countless industries rely on copper flat washer M12 size components from Nafees Metal Industries.

What is M12 Copper Plain Washer?

An M12 Copper Plain Washer is a flat, circular metallic disc made from high-quality copper, specifically designed to fit M12-sized bolts and screws. With an internal diameter slightly larger than 12 mm, it offers a snug yet smooth fit, ensuring optimal clamping without damaging the base material.

These washers serve multiple functional roles — from evenly distributing the fastener load to enhancing electrical conductivity and providing effective sealing in hydraulic or pneumatic systems. Unlike standard steel or stainless-steel washers, a copper washer offers superior malleability and corrosion resistance, making it an ideal choice for specialized environments.

The M12 Copper Plain Washer belongs to a wider category of copper washers, which come in various sizes and thicknesses. What distinguishes the M12 size is its common use in medium-load fastening applications such as automotive brake systems, thermal connectors, plumbing joints, and power distribution equipment.

Thanks to copper’s natural thermal and electrical conductivity, the M12 Copper Plain Washer is highly valued in industries where conductivity and sealing are priorities. It is non-magnetic, resists oxidation, and is gentle on softer metals, which helps prevent galling and surface damage during tightening.

Whether you’re working with delicate electrical assemblies or need a machined washer for precise, leak-proof joints in hydraulic systems, the M12 Copper Plain Washer provides a dependable, multi-functional solution.

Why Copper for M12 Washers?

Copper is a material of choice in engineering and industrial environments where conductivity, malleability, and corrosion resistance are crucial. Using copper for M12 washers offers several performance advantages that make the M12 Copper Plain Washer an ideal component for high-demand applications.

Here’s why copper is preferred:

1. Excellent Electrical Conductivity

Copper is one of the best conductors of electricity, second only to silver. When washers are used in electrical applications, especially grounding systems or connectors, copper washers allow uninterrupted electrical flow. The M12 Copper Plain Washer supports high-current applications without generating resistance or heat buildup at contact points.

2. Superior Thermal Conductivity

Copper dissipates heat quickly, making the M12 Copper Plain Washer perfect for assemblies exposed to high temperatures. It helps manage thermal stress in automotive engines, HVAC systems, and power transmission equipment.

3. Outstanding Corrosion Resistance

Copper forms a natural protective oxide layer when exposed to the atmosphere, shielding it from corrosion. This self-passivating nature makes the M12 Copper Plain Washer ideal for long-term use in damp, wet, or chemically reactive environments — including marine, plumbing, and chemical industries.

4. Excellent Sealing Capability

Thanks to its ductility and softness, copper creates tight seals even on uneven surfaces. The M12 Copper Plain Washer is widely used in sealing fuel lines, hydraulic connections, brake systems, and coolant lines where leak-proof performance is essential.

5. Non-Magnetic and Safe for Sensitive Equipment

Copper is non-ferromagnetic, meaning it does not interfere with sensitive instruments, sensors, or electrical signals. The M12 Copper Plain Washer is a reliable choice for precision electronics, medical devices, and instrumentation.

6. Easy Machinability and Recyclability

Copper is easy to form and machine, allowing the production of machined washers in custom dimensions and thicknesses. Additionally, copper is 100% recyclable without losing its properties, making it an environmentally responsible material choice.

These qualities make copper a far superior option compared to other common washer materials in specialized applications. When you choose the M12 Copper Plain Washer, you invest in durability, efficiency, and long-term reliability.

How Are M12 Copper Plain Washers Manufactured?

At Nafees Metal Industries, the manufacturing process of copper plain washers, especially in M12 size, follows stringent quality standards to ensure precision, performance, and durability. Each washer goes through a series of controlled steps to meet both national and international specifications.

1. Raw Material Selection

The process begins with selecting premium-grade copper sheets or coils with verified chemical composition and mechanical properties. The copper must exhibit excellent conductivity, malleability, and resistance to oxidation for optimal performance in technical environments.

2. Precision Blanking and Punching

Using high-tonnage power press machines, the copper sheet is stamped to form a flat washer with accurate inner and outer diameters. For an M12 washer, the internal diameter is typically sized to fit M12 bolts (around 13 mm), ensuring a snug fit. The outer diameter and thickness conform to DIN or IS standards or can be customized based on client requirements.

3. Deburring and Edge Finishing

Once punched, each washer undergoes deburring to remove sharp edges or residual burrs. This step ensures smooth handling and prevents scratching or damage to adjoining components during installation.

4. Surface Finishing

Depending on the application, the washers may be supplied in natural copper finish or with additional surface treatments like annealing, pickling, or passivation. These treatments can enhance oxidation resistance and improve visual appearance. Some clients prefer tumbled or polished finishes for specific aesthetic or operational reasons.

5. Dimensional and Quality Checks

Each batch is checked for inner diameter, outer diameter, and thickness using calibrated instruments. Flatness, roundness, and burr-free surfaces are also inspected. Our washers meet tolerances as per IS 2016, DIN 125, or ISO 7089 standards, ensuring interchangeability and consistency.

6. Customization (Optional)

We also manufacture copper flat washer M12 size variants with customized dimensions, hole profiles, or thicknesses based on application needs — be it for hydraulic sealing, electrical terminal clamping, or pressure-sensitive environments.

7. Packaging and Dispatch

Washers are packed in bulk quantities, poly bags, or custom cartons based on order volume and client preference. Each shipment is labeled for traceability and accompanied by inspection reports if required. Export orders include necessary compliance documentation for smooth customs clearance.

This rigorous process ensures that every washer delivers peak performance — whether it’s being used in automotive engines, electrical panels, plumbing systems, or custom assemblies.

Key Features of M12 Copper Plain Washers

The M12 copper plain washer is not just a simple component — it is a high-performance solution for industrial, automotive, and electrical applications. Below are the standout features that make this washer type reliable, efficient, and essential in a wide range of mechanical assemblies:

1. Exact Fit for M12 Bolts and Fasteners

Each washer is precisely dimensioned to accommodate standard M12 fasteners, ensuring reliable torque application and maintaining joint integrity without slippage.

2. High Electrical and Thermal Conductivity

Being made from pure copper, these washers enable excellent electrical current flow and effective heat dissipation. This makes them ideal for high-current connections and thermal management tasks.

3. Effective Load Distribution

The washer helps distribute the compressive load applied by the bolt head or nut across a wider surface area, preventing localized stress and reducing the risk of deformation or surface damage.

4. Exceptional Sealing Properties

Soft yet durable, the copper material deforms slightly under pressure to create an airtight and fluid-tight seal — a crucial feature for hydraulic, pneumatic, fuel line, and plumbing systems.

5. Corrosion Resistance

Copper resists oxidation and corrosion better than many other metals, especially in controlled or indoor environments. This extends the life of the washer even under harsh working conditions.

6. Non-Magnetic and Safe for Sensitive Equipment

Ideal for use near magnets or sensitive electronics, copper’s non-magnetic nature ensures there is no interference with electronic circuits or instruments.

7. Available in Various Thicknesses and Finishes

Standard and customized thickness options are available to suit different clamping and sealing needs. We also offer different surface finishes upon request, including annealed, polished, or raw copper finishes.

8. Custom Machined Washer Options

We provide machined washer variants for clients with highly specific dimensional tolerances or surface finish requirements, suitable for high-precision applications.

9. Lightweight and Easy to Handle

Despite its durability, copper is a relatively lightweight metal, making these washers easy to handle and assemble, even in tight or intricate installations.

10. Eco-Friendly and Recyclable

Copper is 100% recyclable, making these washers an environmentally responsible choice for manufacturers who value sustainability in their supply chain.

11. Bulk and Custom Packaging Options

Whether you’re an OEM, distributor, or contractor, we supply in bulk quantities with flexible packaging options tailored to your operational needs.

12. Made in India with Global Standards

All our copper washers are proudly manufactured at our ISO-certified facility in Mumbai, meeting global quality expectations and supporting the ‘Make in India’ initiative.

When you choose an M12 copper plain washer from Nafees Metal Industries, you’re choosing precision, performance, and durability — essential qualities for any fastener component used in mission-critical assemblies.

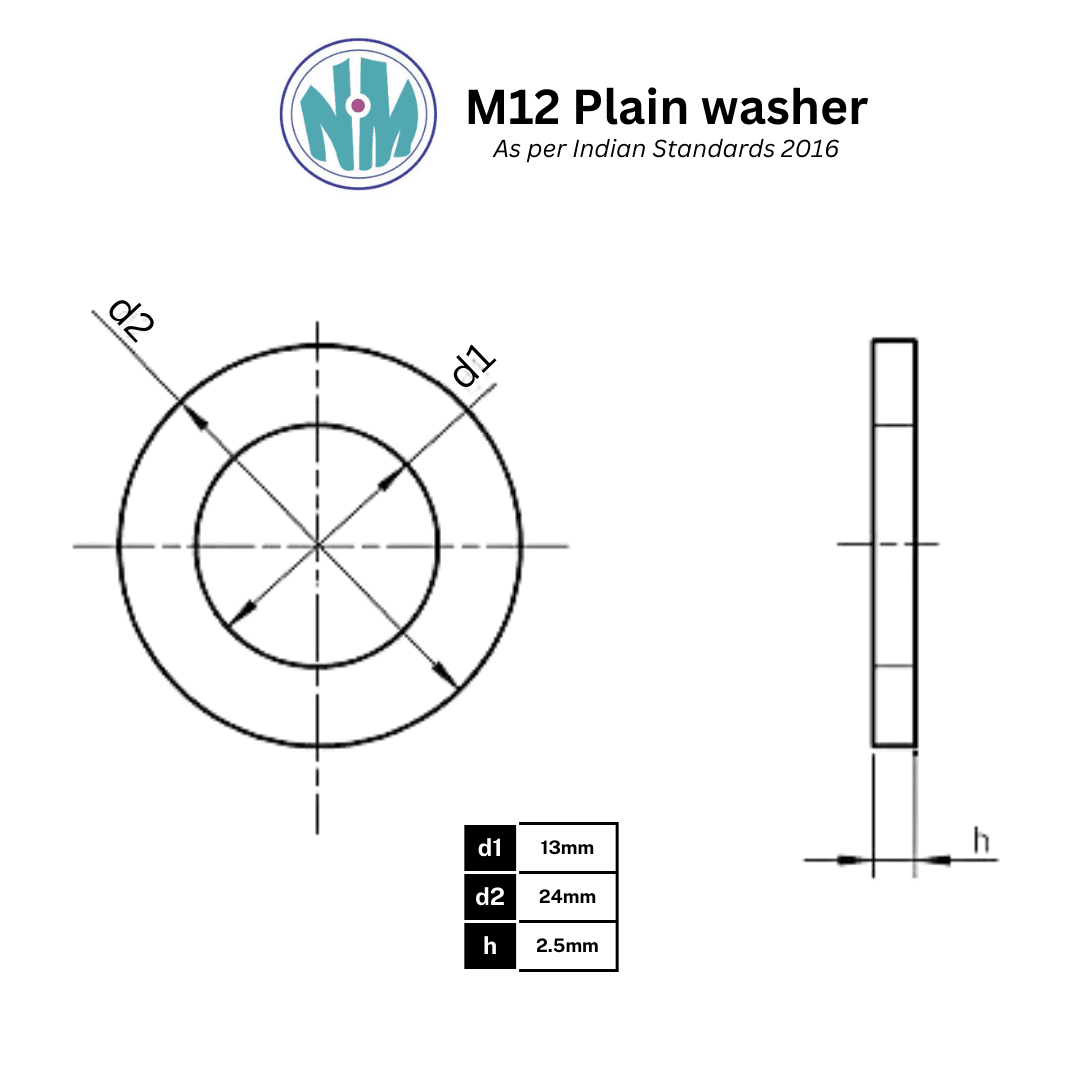

Technical Specifications of M12 Copper Plain Washers

Each M12 copper plain washer produced at Nafees Metal Industries is designed and manufactured to deliver precision fitment, long-lasting performance, and compliance with international quality standards. The technical specifications below offer a detailed look into the product’s design, material composition, and application suitability:

| Property | Specification |

|---|---|

| Product Name | M12 Copper Plain Washer |

| Material | Pure Copper / Electrolytic Grade Copper |

| Washer Type | Plain (Flat) Washer |

| Inner Diameter (ID) | Approx. 13.0 mm (suitable for M12 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 |

| Standard Thickness | 1.0 mm to 3.0 mm (custom thickness available) |

| Surface Finish Options | Natural Copper, Annealed, Pickled, Polished |

| Mechanical Properties | High conductivity, ductility, corrosion resistance |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Manufacturing Process | Precision stamping or CNC machining |

| Machined Washer Availability | Yes, on request |

| Corrosion Resistance | High, especially in indoor or dry environments |

| Thermal Conductivity | Excellent – suitable for heat-dissipating components |

| Electrical Conductivity | Excellent – suitable for grounding & electrical joints |

| Recyclability | 100% recyclable copper material |

| Country of Origin | India |

| Packaging | Bulk poly bags, corrugated boxes, or custom cartons |

| Applications | Electrical terminals, hydraulic fittings, sealing systems, automotive and industrial assemblies |

Whether you require standard copper flat washer M12 size dimensions or a custom solution for specialized installations, we deliver with unmatched accuracy and finish. All washers are quality-checked for tolerance, flatness, and material integrity to ensure smooth integration into your workflow.

Applications of M12 Copper Plain Washers

The M12 copper plain washer is a highly versatile component used across industries where electrical conductivity, fluid sealing, thermal resistance, or vibration absorption are essential. Due to its material properties and precision fit for M12 bolts, it finds application in both standard and mission-critical operations.

Below are some of the key industries and use cases where these washers are extensively used:

1. Automotive Industry

Copper washers are a staple in automotive assemblies. The M12 copper plain washer is commonly used in brake systems, oil drain plugs, engine manifolds, fuel lines, and exhaust systems. Its sealing capability and high heat resistance help prevent leaks and maintain joint integrity under high-temperature conditions.

2. Electrical and Power Systems

Copper’s unmatched electrical conductivity makes the washer ideal for use in power distribution panels, switchgear, grounding connections, and battery terminals. The M12 size fits mid-range connectors, ensuring secure and efficient current flow.

3. Plumbing and HVAC

In water and fluid systems, the M12 copper plain washer provides reliable sealing for pipe joints, valve assemblies, and heat exchangers. It forms a leak-proof interface even in high-pressure plumbing systems.

4. Renewable Energy Systems

These washers are used in solar panel mounting, wind turbine assemblies, and energy storage systems. Their corrosion resistance and conductivity ensure longevity in outdoor and harsh environments.

5. Aerospace and Defense

In aviation, spacecraft, and defense systems, where every component must deliver under extreme conditions, copper washers are trusted for their dimensional stability and sealing reliability.

6. Hydraulic and Pneumatic Assemblies

The M12 copper washer is a standard sealing component for hydraulic cylinders, pumps, and pneumatic lines. It maintains air and fluid pressure without deforming or losing its seal over time.

7. Electronics and Instrumentation

For circuit boards, control panels, and precision sensors, copper washers reduce electromagnetic interference (EMI) and provide shielding where required, especially in sensitive electronic assemblies.

8. Maintenance and Repair Kits (MRO)

Many fastener kits used by maintenance professionals across industries include M12 copper plain washers for use in sealing and assembly repairs. Their availability in various thicknesses ensures compatibility with diverse bolt-and-nut systems.

9. Marine and Offshore Applications

Copper resists saltwater corrosion, making these washers suitable for marine engines, pumps, and structural bolting in shipbuilding and offshore rigs.

10. Machinery and Heavy Equipment

In industrial equipment and agricultural machinery, copper washers help ensure leak-proof and vibration-resistant joints, especially in assemblies that deal with oil, fuel, or hydraulic pressure.

Due to their unique combination of conductivity, sealing strength, and corrosion resistance, these washers are indispensable in modern mechanical and electrical systems. Whether you are seeking standard M12 sizes or specific configurations, M12 copper plain washers provide long-term performance and operational assurance.

Advantages of Using M12 Copper Plain Washers

Choosing the right washer material is critical for the long-term success of any assembly. The M12 copper plain washer offers several functional and economic benefits, making it a preferred choice in industries that demand durability, conductivity, and reliability.

Below are the key advantages of using this washer type:

1. Excellent Conductivity

Copper is highly conductive, both thermally and electrically. Using copper washers ensures effective current transfer and heat dissipation, which is essential in electrical panels, battery terminals, and thermal control systems.

2. Reliable Sealing Capability

Copper’s malleable nature allows it to compress slightly under torque, forming a tight and leak-proof seal. This is particularly useful in high-pressure systems like hydraulic fittings, fuel lines, and cooling systems where standard washers might fail.

3. Corrosion Resistance in Tough Environments

Unlike carbon steel, copper resists rust and corrosion even in moisture-rich or mildly acidic environments. This extends the washer’s life, especially in marine, automotive, and HVAC applications.

4. Compatibility with Soft Metals

In assemblies involving softer metals such as aluminum, copper washers reduce the risk of galling or surface damage. Their compressibility allows them to conform without damaging the substrate.

5. High-Temperature Performance

Copper performs reliably under high-temperature conditions, maintaining its structural integrity where other materials might expand, warp, or degrade. This makes it suitable for engine components, exhaust systems, and thermal management assemblies.

6. Precision Fit for M12 Fasteners

Designed to match standard M12 bolt dimensions, these washers provide proper clamping force and minimize joint loosening. The accuracy of fit ensures uniform load distribution, reducing the risk of bolt failure.

7. Non-Magnetic and EMI Safe

Copper’s non-magnetic properties make these washers safe for use around sensors, compasses, and electronic devices where magnetic interference must be avoided.

8. Reusability and Recyclability

Depending on the application, copper washers can often be reused after inspection. Additionally, copper is a fully recyclable material, making it an eco-friendly choice for industries focusing on sustainability.

9. Ideal for Precision Assemblies

Whether in aerospace instrumentation or medical equipment, copper washers offer the reliability and fine tolerances required in precision-sensitive environments.

10. Wide Range of Availability

The M12 copper plain washer is available in standard sizes and thicknesses, and can be customized for specific requirements. This flexibility supports diverse industrial needs, from mass production to prototype development.

These advantages explain why copper washers, particularly in the M12 size, are preferred across sectors that value quality and consistency in performance. When you source from the best copper washer manufacturers in India, you ensure that every washer you use adds reliability to your final product.

Bulk Supply – Buy M12 Copper Plain Washers from Nafees Metal Industries

When your operations demand large volumes of dependable and precisely manufactured copper washers, Nafees Metal Industries is your trusted sourcing partner. We specialize in the production and bulk supply of high-quality M12 copper plain washers, catering to OEMs, industrial suppliers, exporters, and assembly-line manufacturers across India and international markets.

As one of the best copper washer manufacturers in India, we understand the importance of timely supply, dimensional consistency, and competitive pricing. Our manufacturing unit in Mumbai is equipped with advanced stamping and machining technology, allowing us to meet small to large-scale orders without compromising on quality or turnaround time.

Here’s why procurement teams, contractors, and sourcing professionals choose us:

1. Bulk-Ready Stock

We maintain ready inventory of standard copper washer sizes, including M12, to fulfill urgent requirements. Our warehouse supports large dispatches for both domestic and export shipments.

2. Competitive Pricing for High-Volume Orders

Our streamlined production process allows us to offer industry-best prices for bulk buyers. Volume-based discounts and long-term pricing agreements are available for regular clients.

3. Customization Support

Need a custom thickness, finish, or ID/OD ratio for your copper flat washer M12 size requirement? We provide machined and stamped washer options tailored to your drawings or technical specifications.

4. Wide Delivery Network

We ship across India and support international exports with proper documentation, HS codes, and certificates of origin. Whether you’re in automotive manufacturing, electronics, or plumbing systems, we ensure timely delivery of your washer requirements.

5. Flexible Packaging Solutions

Choose between standard bulk poly bags, sealed cartons, or customized packaging with your branding or part codes. This supports efficient warehousing and assembly-line integration at your end.

6. Quality Certification

All our washers are tested for mechanical properties, dimensional accuracy, and finish. We offer material test reports (MTR), inspection certificates, and compliance as per IS 2016, DIN 125, or ISO 7089.

7. End-to-End Customer Support

From helping you choose the right M12 copper plain washer variant to scheduling re-orders or managing exports, our support team ensures a smooth, transparent, and responsive experience.

Whether you’re a manufacturer of control panels, assembling hydraulic systems, or managing a distribution network for fasteners, Nafees Metal Industries provides consistent, certified, and cost-effective copper washer solutions built for performance.

Case Study – Improved Hydraulic Sealing Using M12 Copper Washers

Client Profile:

A mid-sized manufacturer of hydraulic equipment based in Pune, India, was experiencing recurring issues with fluid leaks in high-pressure pump assemblies. The existing setup used standard steel washers with M12 bolts to seal hydraulic joints, but over time, these washers failed to provide consistent sealing due to deformation and corrosion.

Problem Identified:

Frequent hydraulic oil leaks leading to production downtime

Increased maintenance costs due to washer replacements

Surface damage on aluminum housing caused by hard steel washers

Inconsistent sealing performance under fluctuating pressure and temperature

Solution Offered:

After an in-depth analysis, Nafees Metal Industries recommended switching to our precision-made M12 copper plain washers with annealed finish and a slightly thicker profile for improved sealing flexibility. The copper’s malleability and corrosion resistance made it ideal for high-pressure hydraulic environments.

Results Achieved:

Leak Elimination: 100% reduction in hydraulic fluid leaks after implementation

Surface Protection: No visible damage to housing or surrounding components after 6 months

Improved Efficiency: Faster assembly due to ease of washer installation and better torque consistency

Cost Savings: Reduced frequency of washer replacement lowered maintenance costs by 23%

Increased Output: The reduction in downtime resulted in an estimated 15% increase in production capacity

Client Feedback:

“We underestimated the role a washer plays in hydraulic sealing. Switching to copper washers from Nafees Metal Industries not only solved our leakage issue but also improved the overall reliability of our assemblies. The quality, support, and quick turnaround impressed our entire engineering team.”

This case study highlights the value of selecting the right material and size for your application. A small component like an M12 copper plain washer can deliver significant operational improvements when sourced from the right manufacturer. Whether it’s sealing, conductivity, or vibration resistance — copper washers deliver consistent results.

Frequently Asked Questions (FAQs)

1. What is an M12 copper plain washer used for?

An M12 copper plain washer is used to evenly distribute the load of an M12 bolt or screw while also offering excellent conductivity and sealing. It’s ideal for electrical connections, hydraulic joints, and high-temperature environments.

2. Is the M12 copper washer suitable for sealing hydraulic fluid?

Yes. Due to copper’s malleability, it conforms to uneven surfaces and creates a tight, leak-proof seal in hydraulic and pneumatic systems.

3. Can I use M12 copper washers in automotive brake lines?

Absolutely. Copper washers are commonly used in automotive applications, including brake lines and fuel systems, where sealing and heat resistance are essential.

4. What is the inner diameter of an M12 copper washer?

The inner diameter is typically around 13.0 mm to allow a precise fit over M12 bolts.

5. Do copper washers conduct electricity?

Yes, copper is one of the most conductive materials, making these washers suitable for grounding and electrical terminals.

6. Are M12 copper plain washers corrosion-resistant?

Yes. Copper naturally resists corrosion and oxidation, especially in indoor or controlled environments. For outdoor or marine use, additional treatment may be considered.

7. What is the standard thickness of a copper flat washer in M12 size?

Standard thickness ranges between 1.0 mm and 3.0 mm, but we offer custom thicknesses based on application needs.

8. Can I order custom dimensions or finishes for M12 copper washers?

Yes. At Nafees Metal Industries, we offer customized options for size, thickness, and finishes like annealed, polished, or tumbled.

9. What are the advantages of using copper over steel washers?

Copper washers provide better sealing, electrical conductivity, and corrosion resistance, and are gentler on softer materials like aluminum.

10. Are these washers suitable for high-temperature applications?

Yes. Copper can withstand high thermal loads, making it suitable for engines, exhaust systems, and industrial heat zones.

11. Do you supply machined washers for precision applications?

Yes, we manufacture machined washer variants of M12 copper washers for clients requiring tight tolerances or surface finish control.

12. Are M12 copper plain washers recyclable?

Yes, copper is 100% recyclable, making it a sustainable option for eco-conscious industries.

13. What are the packaging options available for bulk orders?

We offer bulk packaging in poly bags, corrugated cartons, and even custom-labeled packaging as per your logistical and storage requirements.

14. How do I place a bulk order for M12 copper washers?

You can reach out via our website https://nafeesmetalindustries.com, submit a product inquiry form, or contact us directly for pricing, lead time, and customization options.

15. Why choose Nafees Metal Industries for copper washer requirements?

We are one of the best copper washer manufacturers in India, known for quality, customization, prompt delivery, and expert support. Our products meet international standards and are made entirely in our ISO-certified facility in Mumbai.

M12 Copper Plain Washers (DIN 125)

3 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Copper

Nominal Size (g): M12

Inner Diameter (ID): 13 mm

Outer Diameter (OD): 24 mm

Thickness (t): 2.5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M12 Copper Plain Washer – Durable Copper Washers for Superior Conductivity and Sealing Performance

Nafees Metal Industries is proud to present the M12 Copper Plain Washer, engineered for high performance in demanding industrial, electrical, and thermal applications. Designed to deliver exceptional conductivity, sealing capability, and corrosion resistance, the Copper Washer stands out as a vital component in assemblies where both electrical and mechanical performance are crucial.

Crafted from high-grade copper, each M12 Copper Plain Washer we manufacture ensures a consistent fit, excellent load distribution, and long-lasting performance. Whether you require washers for high-current electrical terminals, hydraulic fittings, or machinery requiring leak-proof seals, our M12 Copper Plain Washer meets the mark with precision.

As one of the best copper washer manufacturers in India, Nafees Metal Industries brings years of experience and technical know-how to ensure that every washer meets the highest industry standards. From heat resistance to excellent malleability, this washer type is ideal for industries ranging from automotive and plumbing to electronics and aerospace.

The M12 Copper Plain Washer is specifically designed for bolts and fasteners with a 12 mm diameter, ensuring exact fitment and optimal clamping pressure. These washers are widely used in situations where electrical conductivity, thermal management, or fluid sealing is essential.

Key product features include:

Manufactured using premium copper alloy for consistent material quality

Designed to accommodate standard copper washer sizes for M12 bolts and fasteners

Ideal for use in high-heat environments, high-current electrical systems, and fluid-sealing mechanisms

Available in bulk, customized packaging options, and export-ready compliance

Whether you’re an OEM, maintenance contractor, or procurement officer looking for a reliable supplier of M12 Copper Plain Washers, our solutions are built to perform and last. Explore why countless industries rely on copper flat washer M12 size components from Nafees Metal Industries.

What is M12 Copper Plain Washer?

An M12 Copper Plain Washer is a flat, circular metallic disc made from high-quality copper, specifically designed to fit M12-sized bolts and screws. With an internal diameter slightly larger than 12 mm, it offers a snug yet smooth fit, ensuring optimal clamping without damaging the base material.

These washers serve multiple functional roles — from evenly distributing the fastener load to enhancing electrical conductivity and providing effective sealing in hydraulic or pneumatic systems. Unlike standard steel or stainless-steel washers, a copper washer offers superior malleability and corrosion resistance, making it an ideal choice for specialized environments.

The M12 Copper Plain Washer belongs to a wider category of copper washers, which come in various sizes and thicknesses. What distinguishes the M12 size is its common use in medium-load fastening applications such as automotive brake systems, thermal connectors, plumbing joints, and power distribution equipment.

Thanks to copper’s natural thermal and electrical conductivity, the M12 Copper Plain Washer is highly valued in industries where conductivity and sealing are priorities. It is non-magnetic, resists oxidation, and is gentle on softer metals, which helps prevent galling and surface damage during tightening.

Whether you’re working with delicate electrical assemblies or need a machined washer for precise, leak-proof joints in hydraulic systems, the M12 Copper Plain Washer provides a dependable, multi-functional solution.

Why Copper for M12 Washers?

Copper is a material of choice in engineering and industrial environments where conductivity, malleability, and corrosion resistance are crucial. Using copper for M12 washers offers several performance advantages that make the M12 Copper Plain Washer an ideal component for high-demand applications.

Here’s why copper is preferred:

1. Excellent Electrical Conductivity

Copper is one of the best conductors of electricity, second only to silver. When washers are used in electrical applications, especially grounding systems or connectors, copper washers allow uninterrupted electrical flow. The M12 Copper Plain Washer supports high-current applications without generating resistance or heat buildup at contact points.

2. Superior Thermal Conductivity

Copper dissipates heat quickly, making the M12 Copper Plain Washer perfect for assemblies exposed to high temperatures. It helps manage thermal stress in automotive engines, HVAC systems, and power transmission equipment.

3. Outstanding Corrosion Resistance

Copper forms a natural protective oxide layer when exposed to the atmosphere, shielding it from corrosion. This self-passivating nature makes the M12 Copper Plain Washer ideal for long-term use in damp, wet, or chemically reactive environments — including marine, plumbing, and chemical industries.

4. Excellent Sealing Capability

Thanks to its ductility and softness, copper creates tight seals even on uneven surfaces. The M12 Copper Plain Washer is widely used in sealing fuel lines, hydraulic connections, brake systems, and coolant lines where leak-proof performance is essential.

5. Non-Magnetic and Safe for Sensitive Equipment

Copper is non-ferromagnetic, meaning it does not interfere with sensitive instruments, sensors, or electrical signals. The M12 Copper Plain Washer is a reliable choice for precision electronics, medical devices, and instrumentation.

6. Easy Machinability and Recyclability

Copper is easy to form and machine, allowing the production of machined washers in custom dimensions and thicknesses. Additionally, copper is 100% recyclable without losing its properties, making it an environmentally responsible material choice.

These qualities make copper a far superior option compared to other common washer materials in specialized applications. When you choose the M12 Copper Plain Washer, you invest in durability, efficiency, and long-term reliability.

How Are M12 Copper Plain Washers Manufactured?

At Nafees Metal Industries, the manufacturing process of copper plain washers, especially in M12 size, follows stringent quality standards to ensure precision, performance, and durability. Each washer goes through a series of controlled steps to meet both national and international specifications.

1. Raw Material Selection

The process begins with selecting premium-grade copper sheets or coils with verified chemical composition and mechanical properties. The copper must exhibit excellent conductivity, malleability, and resistance to oxidation for optimal performance in technical environments.

2. Precision Blanking and Punching

Using high-tonnage power press machines, the copper sheet is stamped to form a flat washer with accurate inner and outer diameters. For an M12 washer, the internal diameter is typically sized to fit M12 bolts (around 13 mm), ensuring a snug fit. The outer diameter and thickness conform to DIN or IS standards or can be customized based on client requirements.

3. Deburring and Edge Finishing

Once punched, each washer undergoes deburring to remove sharp edges or residual burrs. This step ensures smooth handling and prevents scratching or damage to adjoining components during installation.

4. Surface Finishing

Depending on the application, the washers may be supplied in natural copper finish or with additional surface treatments like annealing, pickling, or passivation. These treatments can enhance oxidation resistance and improve visual appearance. Some clients prefer tumbled or polished finishes for specific aesthetic or operational reasons.

5. Dimensional and Quality Checks

Each batch is checked for inner diameter, outer diameter, and thickness using calibrated instruments. Flatness, roundness, and burr-free surfaces are also inspected. Our washers meet tolerances as per IS 2016, DIN 125, or ISO 7089 standards, ensuring interchangeability and consistency.

6. Customization (Optional)

We also manufacture copper flat washer M12 size variants with customized dimensions, hole profiles, or thicknesses based on application needs — be it for hydraulic sealing, electrical terminal clamping, or pressure-sensitive environments.

7. Packaging and Dispatch

Washers are packed in bulk quantities, poly bags, or custom cartons based on order volume and client preference. Each shipment is labeled for traceability and accompanied by inspection reports if required. Export orders include necessary compliance documentation for smooth customs clearance.

This rigorous process ensures that every washer delivers peak performance — whether it’s being used in automotive engines, electrical panels, plumbing systems, or custom assemblies.

Key Features of M12 Copper Plain Washers

The M12 copper plain washer is not just a simple component — it is a high-performance solution for industrial, automotive, and electrical applications. Below are the standout features that make this washer type reliable, efficient, and essential in a wide range of mechanical assemblies:

1. Exact Fit for M12 Bolts and Fasteners

Each washer is precisely dimensioned to accommodate standard M12 fasteners, ensuring reliable torque application and maintaining joint integrity without slippage.

2. High Electrical and Thermal Conductivity

Being made from pure copper, these washers enable excellent electrical current flow and effective heat dissipation. This makes them ideal for high-current connections and thermal management tasks.

3. Effective Load Distribution

The washer helps distribute the compressive load applied by the bolt head or nut across a wider surface area, preventing localized stress and reducing the risk of deformation or surface damage.

4. Exceptional Sealing Properties

Soft yet durable, the copper material deforms slightly under pressure to create an airtight and fluid-tight seal — a crucial feature for hydraulic, pneumatic, fuel line, and plumbing systems.

5. Corrosion Resistance

Copper resists oxidation and corrosion better than many other metals, especially in controlled or indoor environments. This extends the life of the washer even under harsh working conditions.

6. Non-Magnetic and Safe for Sensitive Equipment

Ideal for use near magnets or sensitive electronics, copper’s non-magnetic nature ensures there is no interference with electronic circuits or instruments.

7. Available in Various Thicknesses and Finishes

Standard and customized thickness options are available to suit different clamping and sealing needs. We also offer different surface finishes upon request, including annealed, polished, or raw copper finishes.

8. Custom Machined Washer Options

We provide machined washer variants for clients with highly specific dimensional tolerances or surface finish requirements, suitable for high-precision applications.

9. Lightweight and Easy to Handle

Despite its durability, copper is a relatively lightweight metal, making these washers easy to handle and assemble, even in tight or intricate installations.

10. Eco-Friendly and Recyclable

Copper is 100% recyclable, making these washers an environmentally responsible choice for manufacturers who value sustainability in their supply chain.

11. Bulk and Custom Packaging Options

Whether you’re an OEM, distributor, or contractor, we supply in bulk quantities with flexible packaging options tailored to your operational needs.

12. Made in India with Global Standards

All our copper washers are proudly manufactured at our ISO-certified facility in Mumbai, meeting global quality expectations and supporting the ‘Make in India’ initiative.

When you choose an M12 copper plain washer from Nafees Metal Industries, you’re choosing precision, performance, and durability — essential qualities for any fastener component used in mission-critical assemblies.

Technical Specifications of M12 Copper Plain Washers

Each M12 copper plain washer produced at Nafees Metal Industries is designed and manufactured to deliver precision fitment, long-lasting performance, and compliance with international quality standards. The technical specifications below offer a detailed look into the product’s design, material composition, and application suitability:

| Property | Specification |

|---|---|

| Product Name | M12 Copper Plain Washer |

| Material | Pure Copper / Electrolytic Grade Copper |

| Washer Type | Plain (Flat) Washer |

| Inner Diameter (ID) | Approx. 13.0 mm (suitable for M12 bolts) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 |

| Standard Thickness | 1.0 mm to 3.0 mm (custom thickness available) |

| Surface Finish Options | Natural Copper, Annealed, Pickled, Polished |

| Mechanical Properties | High conductivity, ductility, corrosion resistance |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Manufacturing Process | Precision stamping or CNC machining |

| Machined Washer Availability | Yes, on request |

| Corrosion Resistance | High, especially in indoor or dry environments |

| Thermal Conductivity | Excellent – suitable for heat-dissipating components |

| Electrical Conductivity | Excellent – suitable for grounding & electrical joints |

| Recyclability | 100% recyclable copper material |

| Country of Origin | India |

| Packaging | Bulk poly bags, corrugated boxes, or custom cartons |

| Applications | Electrical terminals, hydraulic fittings, sealing systems, automotive and industrial assemblies |

Whether you require standard copper flat washer M12 size dimensions or a custom solution for specialized installations, we deliver with unmatched accuracy and finish. All washers are quality-checked for tolerance, flatness, and material integrity to ensure smooth integration into your workflow.

Applications of M12 Copper Plain Washers

The M12 copper plain washer is a highly versatile component used across industries where electrical conductivity, fluid sealing, thermal resistance, or vibration absorption are essential. Due to its material properties and precision fit for M12 bolts, it finds application in both standard and mission-critical operations.

Below are some of the key industries and use cases where these washers are extensively used:

1. Automotive Industry

Copper washers are a staple in automotive assemblies. The M12 copper plain washer is commonly used in brake systems, oil drain plugs, engine manifolds, fuel lines, and exhaust systems. Its sealing capability and high heat resistance help prevent leaks and maintain joint integrity under high-temperature conditions.

2. Electrical and Power Systems

Copper’s unmatched electrical conductivity makes the washer ideal for use in power distribution panels, switchgear, grounding connections, and battery terminals. The M12 size fits mid-range connectors, ensuring secure and efficient current flow.

3. Plumbing and HVAC

In water and fluid systems, the M12 copper plain washer provides reliable sealing for pipe joints, valve assemblies, and heat exchangers. It forms a leak-proof interface even in high-pressure plumbing systems.

4. Renewable Energy Systems

These washers are used in solar panel mounting, wind turbine assemblies, and energy storage systems. Their corrosion resistance and conductivity ensure longevity in outdoor and harsh environments.

5. Aerospace and Defense

In aviation, spacecraft, and defense systems, where every component must deliver under extreme conditions, copper washers are trusted for their dimensional stability and sealing reliability.

6. Hydraulic and Pneumatic Assemblies

The M12 copper washer is a standard sealing component for hydraulic cylinders, pumps, and pneumatic lines. It maintains air and fluid pressure without deforming or losing its seal over time.

7. Electronics and Instrumentation

For circuit boards, control panels, and precision sensors, copper washers reduce electromagnetic interference (EMI) and provide shielding where required, especially in sensitive electronic assemblies.

8. Maintenance and Repair Kits (MRO)

Many fastener kits used by maintenance professionals across industries include M12 copper plain washers for use in sealing and assembly repairs. Their availability in various thicknesses ensures compatibility with diverse bolt-and-nut systems.

9. Marine and Offshore Applications

Copper resists saltwater corrosion, making these washers suitable for marine engines, pumps, and structural bolting in shipbuilding and offshore rigs.

10. Machinery and Heavy Equipment

In industrial equipment and agricultural machinery, copper washers help ensure leak-proof and vibration-resistant joints, especially in assemblies that deal with oil, fuel, or hydraulic pressure.

Due to their unique combination of conductivity, sealing strength, and corrosion resistance, these washers are indispensable in modern mechanical and electrical systems. Whether you are seeking standard M12 sizes or specific configurations, M12 copper plain washers provide long-term performance and operational assurance.

Advantages of Using M12 Copper Plain Washers

Choosing the right washer material is critical for the long-term success of any assembly. The M12 copper plain washer offers several functional and economic benefits, making it a preferred choice in industries that demand durability, conductivity, and reliability.

Below are the key advantages of using this washer type:

1. Excellent Conductivity

Copper is highly conductive, both thermally and electrically. Using copper washers ensures effective current transfer and heat dissipation, which is essential in electrical panels, battery terminals, and thermal control systems.

2. Reliable Sealing Capability

Copper’s malleable nature allows it to compress slightly under torque, forming a tight and leak-proof seal. This is particularly useful in high-pressure systems like hydraulic fittings, fuel lines, and cooling systems where standard washers might fail.

3. Corrosion Resistance in Tough Environments

Unlike carbon steel, copper resists rust and corrosion even in moisture-rich or mildly acidic environments. This extends the washer’s life, especially in marine, automotive, and HVAC applications.

4. Compatibility with Soft Metals

In assemblies involving softer metals such as aluminum, copper washers reduce the risk of galling or surface damage. Their compressibility allows them to conform without damaging the substrate.

5. High-Temperature Performance

Copper performs reliably under high-temperature conditions, maintaining its structural integrity where other materials might expand, warp, or degrade. This makes it suitable for engine components, exhaust systems, and thermal management assemblies.

6. Precision Fit for M12 Fasteners

Designed to match standard M12 bolt dimensions, these washers provide proper clamping force and minimize joint loosening. The accuracy of fit ensures uniform load distribution, reducing the risk of bolt failure.

7. Non-Magnetic and EMI Safe

Copper’s non-magnetic properties make these washers safe for use around sensors, compasses, and electronic devices where magnetic interference must be avoided.

8. Reusability and Recyclability

Depending on the application, copper washers can often be reused after inspection. Additionally, copper is a fully recyclable material, making it an eco-friendly choice for industries focusing on sustainability.

9. Ideal for Precision Assemblies

Whether in aerospace instrumentation or medical equipment, copper washers offer the reliability and fine tolerances required in precision-sensitive environments.

10. Wide Range of Availability

The M12 copper plain washer is available in standard sizes and thicknesses, and can be customized for specific requirements. This flexibility supports diverse industrial needs, from mass production to prototype development.

These advantages explain why copper washers, particularly in the M12 size, are preferred across sectors that value quality and consistency in performance. When you source from the best copper washer manufacturers in India, you ensure that every washer you use adds reliability to your final product.

Bulk Supply – Buy M12 Copper Plain Washers from Nafees Metal Industries

When your operations demand large volumes of dependable and precisely manufactured copper washers, Nafees Metal Industries is your trusted sourcing partner. We specialize in the production and bulk supply of high-quality M12 copper plain washers, catering to OEMs, industrial suppliers, exporters, and assembly-line manufacturers across India and international markets.

As one of the best copper washer manufacturers in India, we understand the importance of timely supply, dimensional consistency, and competitive pricing. Our manufacturing unit in Mumbai is equipped with advanced stamping and machining technology, allowing us to meet small to large-scale orders without compromising on quality or turnaround time.

Here’s why procurement teams, contractors, and sourcing professionals choose us:

1. Bulk-Ready Stock

We maintain ready inventory of standard copper washer sizes, including M12, to fulfill urgent requirements. Our warehouse supports large dispatches for both domestic and export shipments.

2. Competitive Pricing for High-Volume Orders

Our streamlined production process allows us to offer industry-best prices for bulk buyers. Volume-based discounts and long-term pricing agreements are available for regular clients.

3. Customization Support

Need a custom thickness, finish, or ID/OD ratio for your copper flat washer M12 size requirement? We provide machined and stamped washer options tailored to your drawings or technical specifications.

4. Wide Delivery Network

We ship across India and support international exports with proper documentation, HS codes, and certificates of origin. Whether you’re in automotive manufacturing, electronics, or plumbing systems, we ensure timely delivery of your washer requirements.

5. Flexible Packaging Solutions

Choose between standard bulk poly bags, sealed cartons, or customized packaging with your branding or part codes. This supports efficient warehousing and assembly-line integration at your end.

6. Quality Certification

All our washers are tested for mechanical properties, dimensional accuracy, and finish. We offer material test reports (MTR), inspection certificates, and compliance as per IS 2016, DIN 125, or ISO 7089.

7. End-to-End Customer Support

From helping you choose the right M12 copper plain washer variant to scheduling re-orders or managing exports, our support team ensures a smooth, transparent, and responsive experience.

Whether you’re a manufacturer of control panels, assembling hydraulic systems, or managing a distribution network for fasteners, Nafees Metal Industries provides consistent, certified, and cost-effective copper washer solutions built for performance.

Case Study – Improved Hydraulic Sealing Using M12 Copper Washers

Client Profile:

A mid-sized manufacturer of hydraulic equipment based in Pune, India, was experiencing recurring issues with fluid leaks in high-pressure pump assemblies. The existing setup used standard steel washers with M12 bolts to seal hydraulic joints, but over time, these washers failed to provide consistent sealing due to deformation and corrosion.

Problem Identified:

Frequent hydraulic oil leaks leading to production downtime

Increased maintenance costs due to washer replacements

Surface damage on aluminum housing caused by hard steel washers

Inconsistent sealing performance under fluctuating pressure and temperature

Solution Offered:

After an in-depth analysis, Nafees Metal Industries recommended switching to our precision-made M12 copper plain washers with annealed finish and a slightly thicker profile for improved sealing flexibility. The copper’s malleability and corrosion resistance made it ideal for high-pressure hydraulic environments.

Results Achieved:

Leak Elimination: 100% reduction in hydraulic fluid leaks after implementation

Surface Protection: No visible damage to housing or surrounding components after 6 months

Improved Efficiency: Faster assembly due to ease of washer installation and better torque consistency

Cost Savings: Reduced frequency of washer replacement lowered maintenance costs by 23%

Increased Output: The reduction in downtime resulted in an estimated 15% increase in production capacity

Client Feedback:

“We underestimated the role a washer plays in hydraulic sealing. Switching to copper washers from Nafees Metal Industries not only solved our leakage issue but also improved the overall reliability of our assemblies. The quality, support, and quick turnaround impressed our entire engineering team.”

This case study highlights the value of selecting the right material and size for your application. A small component like an M12 copper plain washer can deliver significant operational improvements when sourced from the right manufacturer. Whether it’s sealing, conductivity, or vibration resistance — copper washers deliver consistent results.

Frequently Asked Questions (FAQs)

1. What is an M12 copper plain washer used for?

An M12 copper plain washer is used to evenly distribute the load of an M12 bolt or screw while also offering excellent conductivity and sealing. It’s ideal for electrical connections, hydraulic joints, and high-temperature environments.

2. Is the M12 copper washer suitable for sealing hydraulic fluid?

Yes. Due to copper’s malleability, it conforms to uneven surfaces and creates a tight, leak-proof seal in hydraulic and pneumatic systems.

3. Can I use M12 copper washers in automotive brake lines?

Absolutely. Copper washers are commonly used in automotive applications, including brake lines and fuel systems, where sealing and heat resistance are essential.

4. What is the inner diameter of an M12 copper washer?

The inner diameter is typically around 13.0 mm to allow a precise fit over M12 bolts.

5. Do copper washers conduct electricity?

Yes, copper is one of the most conductive materials, making these washers suitable for grounding and electrical terminals.

6. Are M12 copper plain washers corrosion-resistant?

Yes. Copper naturally resists corrosion and oxidation, especially in indoor or controlled environments. For outdoor or marine use, additional treatment may be considered.

7. What is the standard thickness of a copper flat washer in M12 size?

Standard thickness ranges between 1.0 mm and 3.0 mm, but we offer custom thicknesses based on application needs.

8. Can I order custom dimensions or finishes for M12 copper washers?

Yes. At Nafees Metal Industries, we offer customized options for size, thickness, and finishes like annealed, polished, or tumbled.

9. What are the advantages of using copper over steel washers?

Copper washers provide better sealing, electrical conductivity, and corrosion resistance, and are gentler on softer materials like aluminum.

10. Are these washers suitable for high-temperature applications?

Yes. Copper can withstand high thermal loads, making it suitable for engines, exhaust systems, and industrial heat zones.

11. Do you supply machined washers for precision applications?

Yes, we manufacture machined washer variants of M12 copper washers for clients requiring tight tolerances or surface finish control.

12. Are M12 copper plain washers recyclable?

Yes, copper is 100% recyclable, making it a sustainable option for eco-conscious industries.

13. What are the packaging options available for bulk orders?

We offer bulk packaging in poly bags, corrugated cartons, and even custom-labeled packaging as per your logistical and storage requirements.

14. How do I place a bulk order for M12 copper washers?

You can reach out via our website https://nafeesmetalindustries.com, submit a product inquiry form, or contact us directly for pricing, lead time, and customization options.

15. Why choose Nafees Metal Industries for copper washer requirements?

We are one of the best copper washer manufacturers in India, known for quality, customization, prompt delivery, and expert support. Our products meet international standards and are made entirely in our ISO-certified facility in Mumbai.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Copper Plain Washers, Plain Washers, Washers

Tag: Copper

Got Questions?

Feel free to

Get in touch