No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M12 Brass Plain Washer – High-Performance Flat Washers for Industrial and Mechanical Applications

Nafees Metal Industries proudly presents the M12 Brass Plain Washer, a high-precision, corrosion-resistant washer designed for demanding mechanical and electrical fastening systems. As one of the leading brass plain washers manufacturers in India, we engineer these washers using premium-grade brass, ensuring superior conductivity, dimensional accuracy, and long-lasting performance. Whether it’s for electrical components, water fittings, or precision instruments, our M12 Brass Plain Washers are the ideal choice for industries that demand strength, reliability, and elegance in metal components.

These washers provide the perfect solution for spreading the load of threaded fasteners while protecting surfaces from damage. The M12 Brass Plain Washer is suitable for indoor, outdoor, and even semi-aggressive environments due to its natural corrosion resistance and aesthetic finish.

What is an M12 Brass Plain Washer?

The M12 Brass Plain Washer is a flat, circular disc with a central hole designed to fit M12 bolts, screws, or studs (12 mm in diameter). It is crafted from high-quality brass – an alloy of copper and zinc – known for its excellent corrosion resistance, conductivity, and non-magnetic properties. The primary role of this washer is to distribute the load of a threaded fastener evenly across a surface, preventing material deformation, wear, or damage, especially in softer substrates like plastic, wood, or aluminum.

The M12 size refers to the inner diameter that perfectly accommodates M12 fasteners, making it ideal for medium to heavy-duty assemblies where strength and aesthetics are essential. The M12 Brass Plain Washer acts as a barrier between the nut/bolt and the material surface, enhancing the clamping performance while extending the life of both the fastener and the material.

These washers are especially preferred in:

Electrical and electronics installations (due to brass’s conductivity)

Plumbing fixtures and sanitary fittings (thanks to corrosion resistance)

Decorative assemblies (where finish and aesthetics matter)

Non-magnetic and non-sparking environments (like explosive zones)

At Nafees Metal Industries, every M12 Brass Plain Washer is manufactured with exact tolerances and a smooth finish to ensure easy assembly, safe operation, and long-lasting performance in industrial environments.

Why Brass for M12 Washers?

Brass is a preferred material for manufacturing plain washers due to its unique combination of mechanical, electrical, and aesthetic properties. The M12 Brass Plain Washer leverages these properties to deliver superior performance across diverse applications – from electrical assemblies to fluid systems and decorative hardware.

Here’s why brass is the ideal material for M12 washers:

1. Excellent Corrosion Resistance

Brass naturally resists corrosion, especially in environments exposed to moisture, mild chemicals, or atmospheric elements. This makes the M12 Brass Plain Washer suitable for indoor and outdoor applications, including plumbing, marine, and electrical uses.

2. Superior Electrical Conductivity

Brass is highly conductive, second only to copper among commonly used metals. This makes it an excellent material for washers in electrical installations where conductivity and grounding are critical. The M12 Brass Plain Washer ensures minimal resistance and improved connectivity in such systems.

3. High Strength-to-Weight Ratio

Brass offers impressive mechanical strength while being relatively lightweight. This ensures the washer can withstand compressive loads without deformation, making it ideal for medium-load bearing applications.

4. Aesthetic Appeal

The golden-yellow sheen of brass adds a decorative appeal to the assembly. For industries where both form and function are important—such as architectural hardware, lighting fixtures, or custom instrumentation—the M12 Brass Plain Washer provides a clean, professional finish.

5. Non-Magnetic and Non-Sparking Properties

Brass is non-magnetic and non-sparking, which is vital in electronic assemblies or in explosive environments such as chemical plants and fuel handling units. The M12 Brass Plain Washer provides safe operation in these sensitive applications.

6. Dimensional Stability and Easy Machining

Brass allows for precise machining, enabling tight dimensional tolerances even in bulk production. At Nafees Metal Industries, we ensure each M12 Brass Plain Washer meets exacting standards for inner diameter, outer diameter, and thickness.

7. Eco-Friendly and Recyclable

Brass is fully recyclable, making the M12 Brass Plain Washer an environmentally responsible choice for industries that care about sustainability.

In conclusion, brass flat washers like the M12 variant combine beauty, durability, and versatility – a rare combination that makes them indispensable in numerous sectors. Choosing brass ensures long-term performance without compromising aesthetics or safety.

How Are M12 Brass Plain Washers Made?

At Nafees Metal Industries, the production of M12 Brass Plain Washers is a precision-driven, quality-controlled process that ensures consistent dimensions, durability, and surface finish. Each washer is crafted using high-grade brass raw material, processed through advanced manufacturing techniques at our state-of-the-art facility in Mumbai, India.

Here’s a step-by-step breakdown of how our M12 Brass Plain Washers are made:

1. Brass Sheet Selection

The process begins with the selection of premium-quality brass sheets. We use low-lead or lead-free brass grades that meet both Indian and international material standards for industrial washers. The brass sheets are chosen based on the required thickness and mechanical properties for the M12 washer.

2. Precision Punching

Using high-tonnage power press machines, circular discs are precisely punched from the brass sheet. The inner hole is accurately stamped to fit M12 bolts (approximately 12.5 mm ID) while maintaining tight tolerances on the outer diameter (as per DIN/IS standards). This step determines the dimensional integrity of the M12 Brass Plain Washer.

3. Deburring and Edge Smoothing

To ensure safe handling and easy assembly, each washer undergoes a deburring process to remove sharp edges or metal burrs. This step also ensures that the washers do not damage the surrounding surfaces during installation.

4. Surface Finishing

Depending on client requirements, the washers are either polished to retain their natural golden brass finish or undergo additional surface treatments like nickel-plating or lacquer coating. These finishes not only enhance aesthetics but also improve corrosion resistance and durability.

5. Dimensional Inspection

Our quality control team conducts rigorous inspection of each M12 Brass Plain Washer to ensure:

Correct inner and outer diameters

Uniform thickness

Flatness and smooth surface

Concentricity and roundness

No surface defects or discoloration

We follow international standards such as DIN 125, IS 2016, and ISO 7089 for production and quality control.

6. Packaging and Labelling

After passing inspection, the washers are counted and packed in bulk cartons, poly bags, or customized packaging as per client requirements. Each package is labeled with part specifications, batch number, and quantity for traceability.

7. Dispatch & Documentation

Orders are dispatched with all necessary documentation – including test reports, packing list, and tax invoices. For export orders, we provide certifications, HS codes, and custom clearance support.

Our advanced manufacturing process ensures that every M12 Brass Plain Washer we deliver is reliable, consistent, and ready for high-performance industrial use.

Key Features of M12 Brass Plain Washers

The M12 Brass Plain Washer offered by Nafees Metal Industries stands out due to its unmatched precision, durability, and compatibility with a wide range of applications. Engineered to meet both functional and aesthetic demands, our washers are ideal for professional use across industries like electrical, plumbing, instrumentation, and mechanical engineering.

Below are the standout features of our M12 Brass Plain Washers:

1. Perfect Fit for M12 Fasteners

Each washer is manufactured to precisely fit M12 bolts, screws, and threaded studs. The internal diameter is carefully calibrated for seamless installation, reducing slack and enhancing fastener performance.

2. Effective Load Distribution

Our M12 Brass Plain Washers distribute the clamping force of fasteners evenly across the surface. This minimizes surface damage and prevents material deformation, particularly in softer substrates like plastic, wood, and aluminum.

3. Premium Brass Construction

Made from high-quality brass, these washers offer an ideal balance of mechanical strength and corrosion resistance. Their non-magnetic and non-sparking nature makes them safe for use in electrical, electronic, and explosive environments.

4. Smooth Surface & Deburred Edges

Each washer undergoes polishing and deburring to eliminate sharp edges and burrs. This allows for safe handling and protects surrounding components from scratches or damage during assembly.

5. Uniform Thickness & Dimensional Accuracy

The washers are manufactured with consistent thickness and accurate dimensions as per DIN 125 / IS 2016 / ISO 7089 standards. This ensures reliability in automated and manual assembly operations.

6. Natural Aesthetic Finish

The signature golden finish of brass gives the M12 Brass Plain Washer a clean and professional appearance. It’s especially suitable for visible fastenings in decorative, architectural, and sanitary fittings.

7. Corrosion Resistance for Longevity

Brass offers strong resistance to rust and tarnish, especially in humid, wet, or chemically exposed environments. This extends the life of the washer and the components it supports.

8. Versatile Use

Compatible with a wide range of applications – from electrical panels and water fittings to structural assemblies and custom machinery.

9. Custom Coatings Available

Clients can request additional surface treatments like nickel-plating or lacquer coating for enhanced protection and visual appeal.

10. Available in Bulk & Custom Quantities

Ideal for large-scale industrial use, our M12 Brass Plain Washers are available in bulk supply with consistent quality and flexible packaging options.

11. Proudly Manufactured in India

Every washer is produced at our fully equipped facility in Mumbai, under strict quality protocols. As a trusted brass plain washers manufacturer, we support the Make in India initiative and deliver products that meet international standards.

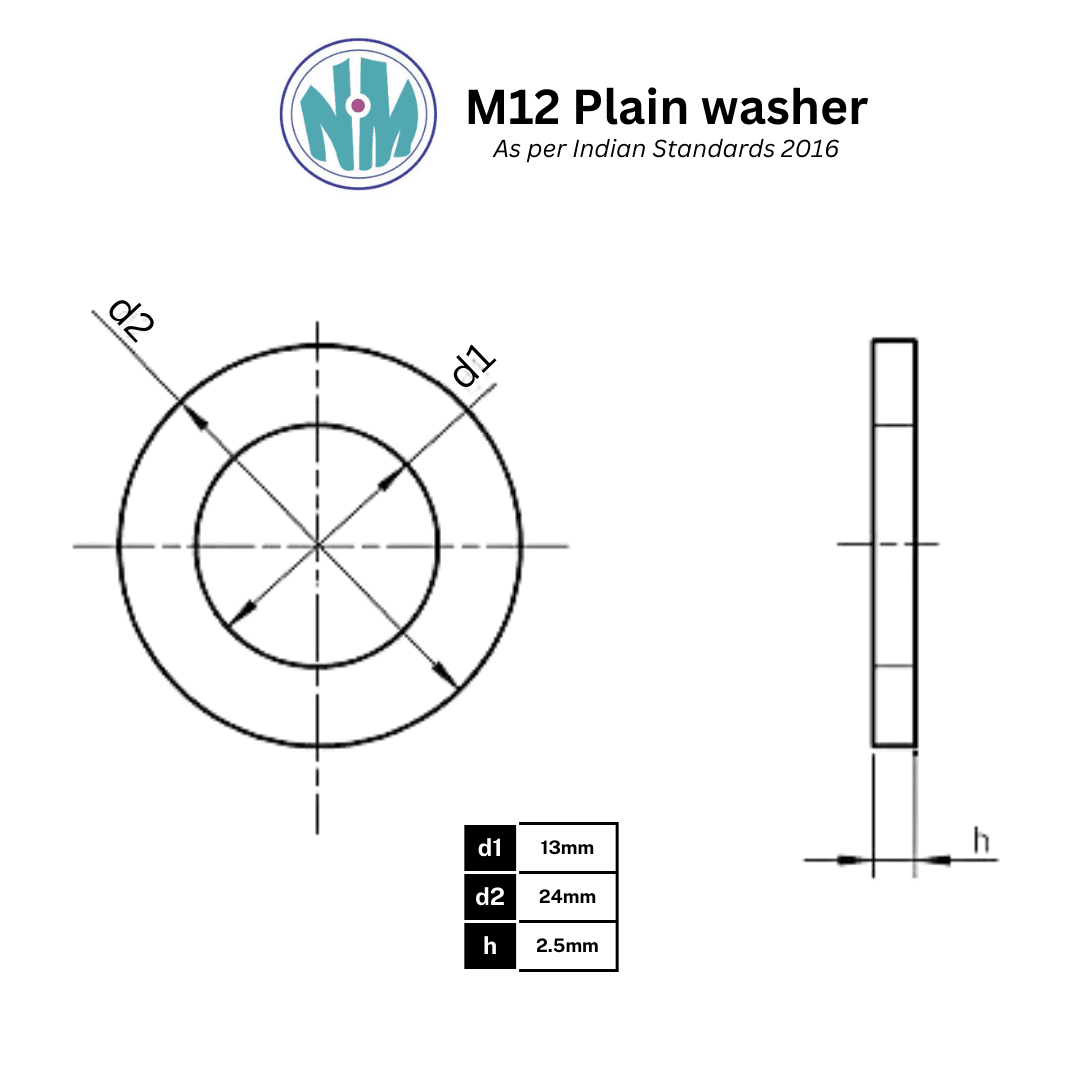

Technical Specifications of M12 Brass Plain Washer

At Nafees Metal Industries, we adhere to rigorous quality and dimensional standards while manufacturing the M12 Brass Plain Washer. Every washer is designed to deliver consistent performance under a variety of operating conditions – be it mechanical load, thermal exposure, or electrical conductivity.

Below is a detailed table of technical specifications for the M12 Brass Plain Washer:

| Property | Specification |

|---|---|

| Product Name | M12 Brass Plain Washer |

| Material | Premium-Grade Brass (Copper-Zinc Alloy) |

| Inner Diameter (ID) | Approx. 13 mm (to fit M12 bolts/screws precisely) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 standards (commonly ~24 mm) |

| Thickness | Standard 1.5 mm – 2.5 mm (customizable as per client requirement) |

| Surface Finish | Natural Brass Finish / Nickel-Plated / Lacquer Coated (on request) |

| Tensile Strength | 300–500 MPa (depending on brass grade) |

| Conductivity | 26–37% IACS (ideal for electrical applications) |

| Hardness | 50–90 HV (Vickers Hardness, depending on temper) |

| Corrosion Resistance | Excellent in moist or mildly corrosive environments |

| Thermal Conductivity | Approx. 109 W/m·K (suitable for heat-sensitive environments) |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Manufacturing Method | Cold Stamped / CNC Machined (for precision orders) |

| Application Category | Electrical, Plumbing, Mechanical Fastening, Automotive, Decorative Assemblies |

| Customization Options | ID/OD/Thickness variation, plating, finish, labeling, packaging |

| Packaging | Bulk in poly bags, corrugated boxes, or customized packs as per buyer requirement |

Note: If your application requires non-standard dimensions, specialized surface coatings, or high-performance custom brass grades, our team can develop tailored M12 Brass Plain Washers to your exact specifications.

With our advanced tooling and experienced workforce, we ensure that each washer conforms to the highest dimensional accuracy, finish quality, and durability standards.

Applications of M12 Brass Plain Washers

The M12 Brass Plain Washer is an essential component used in a variety of applications that demand high mechanical performance, corrosion resistance, and electrical conductivity. Thanks to its strength, aesthetic appeal, and non-magnetic properties, it finds use across multiple industries and environments – from power systems and plumbing to electronics and custom manufacturing.

Below are the major application areas where the M12 Brass Plain Washer plays a vital role:

1. Electrical and Electronics Industry

Brass being an excellent conductor of electricity, the M12 Brass Plain Washer is widely used in electrical panels, switchgear assemblies, and printed circuit board (PCB) fastenings. It ensures proper grounding, conductivity, and mechanical support without sparking or corrosion.

2. Plumbing and Water Fittings

Due to its anti-corrosive nature and compatibility with both hot and cold water systems, the M12 Brass Plain Washer is commonly used in bathroom fittings, pipe joints, tap installations, and sanitary fixtures. It helps prevent leakage and material stress on connection points.

3. Instrumentation and Precision Equipment

The washer’s uniform thickness and smooth finish make it suitable for delicate assemblies in gauges, meters, and test instruments. Its dimensional accuracy ensures perfect load distribution without damaging sensitive parts.

4. Mechanical Assemblies

In general mechanical fabrication and equipment manufacturing, the M12 Brass Plain Washer is used to prevent material deformation and to increase surface contact between bolts and substrates – especially in medium-load applications.

5. Automotive and Transport Systems

Automotive components, especially electronic modules, lighting systems, and dashboard fastenings, use M12 Brass Plain Washers for reliable assembly with minimal vibration and corrosion impact.

6. Decorative and Architectural Hardware

Thanks to its shiny golden appearance and resistance to tarnishing, this washer is ideal for visible fastening in premium furniture, custom lighting, and architectural fittings where visual appeal is essential.

7. Marine and Coastal Applications

In humid, salty environments such as docks, ports, or coastal installations, brass flat washers outperform steel by resisting rust and oxidation, making them reliable for long-term use.

8. Renewable Energy Installations

Solar panel mounts, wind turbine electronics, and battery storage systems benefit from brass’s conductivity and anti-corrosive properties, where the M12 Brass Plain Washer plays a supportive role in mechanical assembly.

9. Power Distribution Equipment

Used in switchboards, transformers, and conductors, M12 Brass Plain Washers provide a safe, conductive, and durable solution for high-performance electrical systems.

10. Chemical and Explosive Zones

Being non-sparking, brass is the material of choice in volatile environments. The M12 Brass Plain Washer ensures safe operation in fuel refineries, chemical plants, and mining areas.

Whether it’s for conductivity, aesthetics, or corrosion resistance, the M12 Brass Plain Washer is a highly adaptable component. At Nafees Metal Industries, we supply these washers to OEMs, contractors, maintenance engineers, and resellers across India and abroad, with the assurance of quality, consistency, and timely delivery.

Advantages of Using M12 Brass Washers

Choosing the M12 Brass Plain Washer from Nafees Metal Industries offers numerous advantages in terms of durability, performance, and aesthetic value. Whether you’re assembling electrical panels, plumbing fixtures, or precision equipment, brass washers bring specific benefits that outperform many other materials like mild steel, plastic, or even stainless steel in certain conditions.

Below are the key advantages of using M12 Brass Washers:

1. Excellent Corrosion Resistance

Brass naturally resists rust, oxidation, and most non-acidic chemical reactions. This makes the M12 Brass Plain Washer an ideal component in plumbing systems, marine environments, and outdoor installations.

2. Superior Electrical Conductivity

One of the top reasons to choose brass is its high electrical conductivity. The M12 Brass Plain Washer allows efficient current flow and grounding, which is vital in electrical assemblies, transformers, switchgear, and more.

3. Aesthetic Appearance

With its signature golden finish, the M12 Brass Plain Washer enhances the visual appeal of any assembly. This is especially beneficial in decorative applications such as lighting fixtures, designer furniture, and exposed bolts in architectural setups.

4. Non-Magnetic and Non-Sparking Properties

Brass is inherently non-magnetic and non-sparking, making it the safest material for environments with electromagnetic sensitivity (such as electronic devices) or potential explosive hazards (such as oil refineries or ammunition manufacturing).

5. Excellent Load Distribution

The washer effectively distributes the load from a fastener over a broader surface area. This prevents crushing, warping, or indenting of the base material – particularly important when working with softer surfaces like wood, plastic, or thin metal sheets.

6. Long Service Life

Thanks to its resistance to wear, corrosion, and tarnishing, the M12 Brass Plain Washer offers a longer operational lifespan compared to many other washer types, especially in aggressive or moist conditions.

7. Easy to Machine and Customize

Brass is an easily machinable metal, allowing us to create custom brass washers in terms of inner diameter, outer diameter, thickness, and finish. This ensures complete compatibility with client-specific applications.

8. Environmentally Friendly

Brass is 100% recyclable without any loss in quality. Using brass flat washers supports sustainable manufacturing and helps industries meet green compliance standards.

9. Vibration Dampening

The density and elasticity of brass make it moderately effective in absorbing vibration in assemblies, helping reduce loosening or wear caused by mechanical oscillation.

10. Bulk Availability and Cost-Efficiency

For applications where both quality and quantity matter, Nafees Metal Industries provides M12 Brass Plain Washers in bulk at competitive rates. With in-house production and stringent quality checks, we guarantee value for your investment.

Whether you’re a contractor, OEM, exporter, or maintenance engineer, incorporating M12 Brass Plain Washers into your operations ensures superior fastening support, enhanced aesthetics, and long-term reliability. With all these advantages, it’s no surprise that brass washers remain a trusted choice across industries.

Buy M12 Brass Plain Washers in Bulk – Best M12 Brass Plain Washers Manufacturer in India

When it comes to sourcing top-quality M12 Brass Plain Washers in bulk, Nafees Metal Industries stands as a trusted name among manufacturers and suppliers across India and global markets. With decades of experience in washer manufacturing, we are committed to delivering precision-engineered brass flat washers that meet the highest industrial standards.

As a reputed brass plain washers manufacturer, we specialize in meeting the diverse needs of OEMs, hardware distributors, fabrication units, electrical contractors, maintenance teams, and international buyers with speed, reliability, and customization.

Why Choose Nafees Metal Industries for M12 Brass Plain Washers?

1. Bulk Production Capacity

Our Mumbai-based facility is equipped with high-speed stamping and quality control systems that allow us to produce large volumes of M12 Brass Plain Washers without compromising quality. We maintain ready stock to meet urgent requirements and high-volume demands.

2. Customization Options

Whether you require a specific thickness, coating, outer diameter, or packaging configuration, we provide full customization. Our team works closely with clients to deliver washers tailored to their exact application needs.

3. Competitive Pricing with Transparent Quotations

We believe in providing high-quality products at affordable rates. Our pricing is structured for large-scale procurement without hidden charges. You get factory-direct value with full pricing transparency.

4. Export-Ready & Compliant

With all necessary compliance certifications, HS codes, and export documentation, Nafees Metal Industries is a trusted supplier for international buyers. Our M12 Brass Plain Washers are supplied to clients across the Middle East, Africa, Southeast Asia, and Europe.

5. Expert Technical Support

Our in-house engineering and sales team offer technical consultation to help you choose the right washer based on your project specifications, load-bearing requirements, or environmental conditions.

6. Custom Branding & Packaging

We offer OEM and white-label packaging solutions for brands and industrial buyers. Washers can be packed in poly bags, small boxes, or industrial cartons with custom labeling and barcoding as per your supply chain needs.

7. Timely Dispatch & Logistics Support

From order confirmation to dispatch, our team ensures smooth coordination and prompt delivery. We partner with reliable logistic providers to ensure your M12 Brass Plain Washers reach you safely and on time, whether in India or abroad.

Industries We Serve

Electrical and Electronics Manufacturing

Plumbing and Sanitary Ware

Power and Energy Systems

Precision Engineering and Instrumentation

Marine, Aviation, and Transportation

Architectural and Decorative Hardware

Government and Defense Contractors

Export Houses and Traders

Whether you’re looking to buy brass washers online, source from a brass plain washers manufacturer, or need an industrial brass washers partner who understands your volume and quality requirements, Nafees Metal Industries is here to support you with:

ISO-certified processes

Consistent product quality

End-to-end customer support

Nationwide and global delivery

Choose Nafees Metal Industries to experience reliability, precision, and professionalism in every washer you procure.

Case Study: Improving Fastening Performance with M12 Brass Plain Washers

Client Overview:

A reputed electrical switchgear manufacturer based in Pune was facing recurring issues with inconsistent clamping pressure, corrosion buildup around fasteners, and cosmetic damage to the final assembly. The products were meant for export to humid tropical regions, where rust and oxidation were a major concern.

Challenge:

The client previously used mild steel plain washers with zinc plating for their M12 bolts in panel assemblies. While the initial cost was lower, they began experiencing:

Surface rust within 3 weeks of shipment

Discoloration and flaking of the plated finish

Poor electrical conductivity across fastening points

Increased warranty claims from overseas clients

The company approached Nafees Metal Industries in search of a long-term, corrosion-resistant alternative that wouldn’t compromise on aesthetics or performance.

Solution: Use of M12 Brass Plain Washers

After understanding their application needs and installation environment, we recommended replacing the zinc-plated mild steel washers with our M12 Brass Plain Washers featuring a natural polished brass finish. The client conducted internal testing and approved the washers after evaluating the following parameters:

Dimensional consistency for automated torque-controlled fastening

Electrical conductivity to ensure proper grounding

Resistance to oxidation and discoloration

Enhanced visual finish for exported panels

We supplied the washers in custom packaging with printed batch numbers and QC tags for traceability.

Outcome & Results

Within three months of implementation, the client reported measurable improvements:

Eliminated Rust Issues: No signs of corrosion even after 60 days in high-humidity storage.

Improved Electrical Contact: Conductivity readings showed 30% improvement across M12 terminals.

Reduction in Assembly Defects: Flatness and edge finish improved torque control and reduced fastener loosening.

Enhanced Visual Finish: Customer satisfaction improved due to clean and professional-looking panel interiors.

Repeat Order Rate Increased: The client placed two additional bulk orders for M12 and M10 brass washers.

Conclusion

This case highlights the performance and quality advantages of the M12 Brass Plain Washer in real-world industrial applications. By replacing a low-cost, low-performance component with a precision-engineered brass washer, the client was able to achieve significant improvements in reliability, appearance, and long-term customer satisfaction.

Nafees Metal Industries continues to support them with timely deliveries, customization options, and ongoing product development for their international expansion.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we are committed to delivering high-performance washer solutions that align with the needs of modern industrial applications. Our M12 Brass Plain Washers are just one example of our dedication to quality, precision, and customer satisfaction. Here’s why industry leaders across India and abroad trust us as their preferred washer manufacturer:

1. Superior Material Sourcing

We use premium-grade brass alloys that conform to international standards. Our materials are chosen not only for strength and corrosion resistance but also for consistent machinability and surface finish. Every washer batch is produced from carefully selected raw materials to ensure uniform quality.

2. Precision Manufacturing

Our washers are manufactured using state-of-the-art power press machines and undergo rigorous dimensional checks. We maintain tight tolerances, precise inner and outer diameters, and uniform thickness in every washer we produce. The flatness and edge finish of our washers ensure optimal load distribution and reliable torque transfer.

3. Surface Finish Excellence

Our natural polished finish not only enhances the aesthetic appeal of the brass washers but also serves a functional purpose. The smooth surface reduces friction, prevents galling, and contributes to better sealing and grounding in mechanical and electrical assemblies.

4. Bulk and Custom Orders

We cater to both high-volume demands and custom size requirements. Whether you need thousands of standard-size washers or a unique design tailored to your specific project, our agile production team can deliver with efficiency and consistency.

5. Trusted Quality Assurance

Each washer batch undergoes multi-point quality checks including:

Dimensional verification

Surface inspection

Hardness testing

Batch-wise traceability

We follow strict internal QC protocols and can provide test reports and certificates of conformity upon request.

6. Competitive Pricing and Lead Times

We strike a balance between high quality and cost-effectiveness. Our optimized production processes and strategic sourcing allow us to offer competitive pricing without compromising on material or workmanship. Additionally, we are known for our fast turnaround times and on-time delivery for both domestic and export orders.

7. Strong Customer Relationships

We believe in building long-term partnerships through responsive communication, technical support, and reliable after-sales service. Our dedicated team is always available to assist with order queries, product selection, and any specific requirements.

Whether you are a wholesaler, OEM, or engineering consultant, Nafees Metal Industries is your trusted partner for brass, stainless steel, and mild steel washer solutions. Our M12 Brass Plain Washers are a testament to our manufacturing capabilities and the trust placed in us by industries across sectors.

Frequently Asked Questions (FAQs) – M12 Brass Plain Washers

1. What are M12 brass plain washers used for?

M12 brass plain washers are used to distribute load and prevent damage to surfaces during fastening. They are ideal for applications in plumbing, electrical assemblies, marine hardware, and automotive parts where corrosion resistance and conductivity are critical.

2. What does M12 mean in M12 brass washer?

M12 refers to the inner diameter of the washer, designed to fit around M12 bolts or screws (12 mm in diameter). This ensures proper alignment and fastening performance in industrial and commercial applications.

3. Are brass washers corrosion-resistant?

Yes, brass is naturally corrosion-resistant. M12 brass washers are suitable for use in humid, coastal, or chemically exposed environments due to their excellent resistance to tarnish, rust, and oxidation.

4. Can I use M12 brass washers in electrical applications?

Absolutely. Brass is an excellent conductor of electricity, making M12 brass washers a preferred choice in electrical panels, terminals, and grounding systems.

5. What are the benefits of choosing brass over stainless steel washers?

Brass washers offer better electrical conductivity, are non-magnetic, and resist corrosion in certain chemical environments better than stainless steel. They’re also softer, reducing the risk of damaging mating surfaces.

6. Do you offer bulk discounts for M12 brass plain washers?

Yes, at Nafees Metal Industries, we provide competitive bulk pricing for large orders. Contact our sales team for quantity-based quotations and tailored offers.

7. What are the standard dimensions of M12 brass plain washers?

Typical M12 brass washers have an inner diameter of 12 mm, outer diameter of around 24–26 mm, and thickness between 1.5–2.5 mm. We can also provide custom sizes upon request.

8. Are your brass washers manufactured as per any standards?

Yes, we manufacture brass plain washers according to DIN 125 and other applicable international standards, ensuring precision, durability, and compatibility.

9. Can M12 brass plain washers be used in plumbing systems?

Yes. Due to their non-reactive nature and resistance to water and moisture, M12 brass washers are widely used in plumbing fixtures and pipe fittings.

10. Do you supply M12 brass washers with specific coatings or finishes?

While brass washers have a naturally smooth finish, we can offer surface treatments like polishing or custom coatings based on your application requirements.

11. Can I request custom thickness or outer diameter for M12 washers?

Yes, we offer customization for thickness, outer diameter, and other specifications. Simply share your requirements with our team.

12. How do I know if M12 is the right washer size for my application?

If you’re using M12 bolts or screws (12 mm in diameter), M12 washers are the appropriate choice. However, our team can guide you based on your application if you’re unsure.

13. Are your brass washers RoHS compliant?

Yes, our brass washers are manufactured using RoHS-compliant materials, ensuring safety and environmental compliance for global markets.

14. Do you ship M12 brass washers across India and internationally?

Yes, we deliver pan-India and also export worldwide. Our logistics partners ensure timely and safe delivery to your location.

15. How can I place an order for M12 brass plain washers?

You can place an order by contacting us via phone, email, or our website’s contact form. We will confirm availability, pricing, and lead time as per your order quantity and delivery location.

M12 Brass Plain Washers (DIN 125)

25 people are viewing this product right now

₹1.20 /per piece

Specification:

Material: Brass

Nominal Size (g): M12

Inner Diameter (ID): 13 mm

Outer Diameter (OD): 24 mm

Thickness (t): 2.5 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M12 Brass Plain Washer – High-Performance Flat Washers for Industrial and Mechanical Applications

Nafees Metal Industries proudly presents the M12 Brass Plain Washer, a high-precision, corrosion-resistant washer designed for demanding mechanical and electrical fastening systems. As one of the leading brass plain washers manufacturers in India, we engineer these washers using premium-grade brass, ensuring superior conductivity, dimensional accuracy, and long-lasting performance. Whether it’s for electrical components, water fittings, or precision instruments, our M12 Brass Plain Washers are the ideal choice for industries that demand strength, reliability, and elegance in metal components.

These washers provide the perfect solution for spreading the load of threaded fasteners while protecting surfaces from damage. The M12 Brass Plain Washer is suitable for indoor, outdoor, and even semi-aggressive environments due to its natural corrosion resistance and aesthetic finish.

What is an M12 Brass Plain Washer?

The M12 Brass Plain Washer is a flat, circular disc with a central hole designed to fit M12 bolts, screws, or studs (12 mm in diameter). It is crafted from high-quality brass – an alloy of copper and zinc – known for its excellent corrosion resistance, conductivity, and non-magnetic properties. The primary role of this washer is to distribute the load of a threaded fastener evenly across a surface, preventing material deformation, wear, or damage, especially in softer substrates like plastic, wood, or aluminum.

The M12 size refers to the inner diameter that perfectly accommodates M12 fasteners, making it ideal for medium to heavy-duty assemblies where strength and aesthetics are essential. The M12 Brass Plain Washer acts as a barrier between the nut/bolt and the material surface, enhancing the clamping performance while extending the life of both the fastener and the material.

These washers are especially preferred in:

Electrical and electronics installations (due to brass’s conductivity)

Plumbing fixtures and sanitary fittings (thanks to corrosion resistance)

Decorative assemblies (where finish and aesthetics matter)

Non-magnetic and non-sparking environments (like explosive zones)

At Nafees Metal Industries, every M12 Brass Plain Washer is manufactured with exact tolerances and a smooth finish to ensure easy assembly, safe operation, and long-lasting performance in industrial environments.

Why Brass for M12 Washers?

Brass is a preferred material for manufacturing plain washers due to its unique combination of mechanical, electrical, and aesthetic properties. The M12 Brass Plain Washer leverages these properties to deliver superior performance across diverse applications – from electrical assemblies to fluid systems and decorative hardware.

Here’s why brass is the ideal material for M12 washers:

1. Excellent Corrosion Resistance

Brass naturally resists corrosion, especially in environments exposed to moisture, mild chemicals, or atmospheric elements. This makes the M12 Brass Plain Washer suitable for indoor and outdoor applications, including plumbing, marine, and electrical uses.

2. Superior Electrical Conductivity

Brass is highly conductive, second only to copper among commonly used metals. This makes it an excellent material for washers in electrical installations where conductivity and grounding are critical. The M12 Brass Plain Washer ensures minimal resistance and improved connectivity in such systems.

3. High Strength-to-Weight Ratio

Brass offers impressive mechanical strength while being relatively lightweight. This ensures the washer can withstand compressive loads without deformation, making it ideal for medium-load bearing applications.

4. Aesthetic Appeal

The golden-yellow sheen of brass adds a decorative appeal to the assembly. For industries where both form and function are important—such as architectural hardware, lighting fixtures, or custom instrumentation—the M12 Brass Plain Washer provides a clean, professional finish.

5. Non-Magnetic and Non-Sparking Properties

Brass is non-magnetic and non-sparking, which is vital in electronic assemblies or in explosive environments such as chemical plants and fuel handling units. The M12 Brass Plain Washer provides safe operation in these sensitive applications.

6. Dimensional Stability and Easy Machining

Brass allows for precise machining, enabling tight dimensional tolerances even in bulk production. At Nafees Metal Industries, we ensure each M12 Brass Plain Washer meets exacting standards for inner diameter, outer diameter, and thickness.

7. Eco-Friendly and Recyclable

Brass is fully recyclable, making the M12 Brass Plain Washer an environmentally responsible choice for industries that care about sustainability.

In conclusion, brass flat washers like the M12 variant combine beauty, durability, and versatility – a rare combination that makes them indispensable in numerous sectors. Choosing brass ensures long-term performance without compromising aesthetics or safety.

How Are M12 Brass Plain Washers Made?

At Nafees Metal Industries, the production of M12 Brass Plain Washers is a precision-driven, quality-controlled process that ensures consistent dimensions, durability, and surface finish. Each washer is crafted using high-grade brass raw material, processed through advanced manufacturing techniques at our state-of-the-art facility in Mumbai, India.

Here’s a step-by-step breakdown of how our M12 Brass Plain Washers are made:

1. Brass Sheet Selection

The process begins with the selection of premium-quality brass sheets. We use low-lead or lead-free brass grades that meet both Indian and international material standards for industrial washers. The brass sheets are chosen based on the required thickness and mechanical properties for the M12 washer.

2. Precision Punching

Using high-tonnage power press machines, circular discs are precisely punched from the brass sheet. The inner hole is accurately stamped to fit M12 bolts (approximately 12.5 mm ID) while maintaining tight tolerances on the outer diameter (as per DIN/IS standards). This step determines the dimensional integrity of the M12 Brass Plain Washer.

3. Deburring and Edge Smoothing

To ensure safe handling and easy assembly, each washer undergoes a deburring process to remove sharp edges or metal burrs. This step also ensures that the washers do not damage the surrounding surfaces during installation.

4. Surface Finishing

Depending on client requirements, the washers are either polished to retain their natural golden brass finish or undergo additional surface treatments like nickel-plating or lacquer coating. These finishes not only enhance aesthetics but also improve corrosion resistance and durability.

5. Dimensional Inspection

Our quality control team conducts rigorous inspection of each M12 Brass Plain Washer to ensure:

Correct inner and outer diameters

Uniform thickness

Flatness and smooth surface

Concentricity and roundness

No surface defects or discoloration

We follow international standards such as DIN 125, IS 2016, and ISO 7089 for production and quality control.

6. Packaging and Labelling

After passing inspection, the washers are counted and packed in bulk cartons, poly bags, or customized packaging as per client requirements. Each package is labeled with part specifications, batch number, and quantity for traceability.

7. Dispatch & Documentation

Orders are dispatched with all necessary documentation – including test reports, packing list, and tax invoices. For export orders, we provide certifications, HS codes, and custom clearance support.

Our advanced manufacturing process ensures that every M12 Brass Plain Washer we deliver is reliable, consistent, and ready for high-performance industrial use.

Key Features of M12 Brass Plain Washers

The M12 Brass Plain Washer offered by Nafees Metal Industries stands out due to its unmatched precision, durability, and compatibility with a wide range of applications. Engineered to meet both functional and aesthetic demands, our washers are ideal for professional use across industries like electrical, plumbing, instrumentation, and mechanical engineering.

Below are the standout features of our M12 Brass Plain Washers:

1. Perfect Fit for M12 Fasteners

Each washer is manufactured to precisely fit M12 bolts, screws, and threaded studs. The internal diameter is carefully calibrated for seamless installation, reducing slack and enhancing fastener performance.

2. Effective Load Distribution

Our M12 Brass Plain Washers distribute the clamping force of fasteners evenly across the surface. This minimizes surface damage and prevents material deformation, particularly in softer substrates like plastic, wood, and aluminum.

3. Premium Brass Construction

Made from high-quality brass, these washers offer an ideal balance of mechanical strength and corrosion resistance. Their non-magnetic and non-sparking nature makes them safe for use in electrical, electronic, and explosive environments.

4. Smooth Surface & Deburred Edges

Each washer undergoes polishing and deburring to eliminate sharp edges and burrs. This allows for safe handling and protects surrounding components from scratches or damage during assembly.

5. Uniform Thickness & Dimensional Accuracy

The washers are manufactured with consistent thickness and accurate dimensions as per DIN 125 / IS 2016 / ISO 7089 standards. This ensures reliability in automated and manual assembly operations.

6. Natural Aesthetic Finish

The signature golden finish of brass gives the M12 Brass Plain Washer a clean and professional appearance. It’s especially suitable for visible fastenings in decorative, architectural, and sanitary fittings.

7. Corrosion Resistance for Longevity

Brass offers strong resistance to rust and tarnish, especially in humid, wet, or chemically exposed environments. This extends the life of the washer and the components it supports.

8. Versatile Use

Compatible with a wide range of applications – from electrical panels and water fittings to structural assemblies and custom machinery.

9. Custom Coatings Available

Clients can request additional surface treatments like nickel-plating or lacquer coating for enhanced protection and visual appeal.

10. Available in Bulk & Custom Quantities

Ideal for large-scale industrial use, our M12 Brass Plain Washers are available in bulk supply with consistent quality and flexible packaging options.

11. Proudly Manufactured in India

Every washer is produced at our fully equipped facility in Mumbai, under strict quality protocols. As a trusted brass plain washers manufacturer, we support the Make in India initiative and deliver products that meet international standards.

Technical Specifications of M12 Brass Plain Washer

At Nafees Metal Industries, we adhere to rigorous quality and dimensional standards while manufacturing the M12 Brass Plain Washer. Every washer is designed to deliver consistent performance under a variety of operating conditions – be it mechanical load, thermal exposure, or electrical conductivity.

Below is a detailed table of technical specifications for the M12 Brass Plain Washer:

| Property | Specification |

|---|---|

| Product Name | M12 Brass Plain Washer |

| Material | Premium-Grade Brass (Copper-Zinc Alloy) |

| Inner Diameter (ID) | Approx. 13 mm (to fit M12 bolts/screws precisely) |

| Outer Diameter (OD) | As per DIN 125 / IS 2016 / ISO 7089 standards (commonly ~24 mm) |

| Thickness | Standard 1.5 mm – 2.5 mm (customizable as per client requirement) |

| Surface Finish | Natural Brass Finish / Nickel-Plated / Lacquer Coated (on request) |

| Tensile Strength | 300–500 MPa (depending on brass grade) |

| Conductivity | 26–37% IACS (ideal for electrical applications) |

| Hardness | 50–90 HV (Vickers Hardness, depending on temper) |

| Corrosion Resistance | Excellent in moist or mildly corrosive environments |

| Thermal Conductivity | Approx. 109 W/m·K (suitable for heat-sensitive environments) |

| Standard Compliance | IS 2016 / DIN 125 / ISO 7089 |

| Manufacturing Method | Cold Stamped / CNC Machined (for precision orders) |

| Application Category | Electrical, Plumbing, Mechanical Fastening, Automotive, Decorative Assemblies |

| Customization Options | ID/OD/Thickness variation, plating, finish, labeling, packaging |

| Packaging | Bulk in poly bags, corrugated boxes, or customized packs as per buyer requirement |

Note: If your application requires non-standard dimensions, specialized surface coatings, or high-performance custom brass grades, our team can develop tailored M12 Brass Plain Washers to your exact specifications.

With our advanced tooling and experienced workforce, we ensure that each washer conforms to the highest dimensional accuracy, finish quality, and durability standards.

Applications of M12 Brass Plain Washers

The M12 Brass Plain Washer is an essential component used in a variety of applications that demand high mechanical performance, corrosion resistance, and electrical conductivity. Thanks to its strength, aesthetic appeal, and non-magnetic properties, it finds use across multiple industries and environments – from power systems and plumbing to electronics and custom manufacturing.

Below are the major application areas where the M12 Brass Plain Washer plays a vital role:

1. Electrical and Electronics Industry

Brass being an excellent conductor of electricity, the M12 Brass Plain Washer is widely used in electrical panels, switchgear assemblies, and printed circuit board (PCB) fastenings. It ensures proper grounding, conductivity, and mechanical support without sparking or corrosion.

2. Plumbing and Water Fittings

Due to its anti-corrosive nature and compatibility with both hot and cold water systems, the M12 Brass Plain Washer is commonly used in bathroom fittings, pipe joints, tap installations, and sanitary fixtures. It helps prevent leakage and material stress on connection points.

3. Instrumentation and Precision Equipment

The washer’s uniform thickness and smooth finish make it suitable for delicate assemblies in gauges, meters, and test instruments. Its dimensional accuracy ensures perfect load distribution without damaging sensitive parts.

4. Mechanical Assemblies

In general mechanical fabrication and equipment manufacturing, the M12 Brass Plain Washer is used to prevent material deformation and to increase surface contact between bolts and substrates – especially in medium-load applications.

5. Automotive and Transport Systems

Automotive components, especially electronic modules, lighting systems, and dashboard fastenings, use M12 Brass Plain Washers for reliable assembly with minimal vibration and corrosion impact.

6. Decorative and Architectural Hardware

Thanks to its shiny golden appearance and resistance to tarnishing, this washer is ideal for visible fastening in premium furniture, custom lighting, and architectural fittings where visual appeal is essential.

7. Marine and Coastal Applications

In humid, salty environments such as docks, ports, or coastal installations, brass flat washers outperform steel by resisting rust and oxidation, making them reliable for long-term use.

8. Renewable Energy Installations

Solar panel mounts, wind turbine electronics, and battery storage systems benefit from brass’s conductivity and anti-corrosive properties, where the M12 Brass Plain Washer plays a supportive role in mechanical assembly.

9. Power Distribution Equipment

Used in switchboards, transformers, and conductors, M12 Brass Plain Washers provide a safe, conductive, and durable solution for high-performance electrical systems.

10. Chemical and Explosive Zones

Being non-sparking, brass is the material of choice in volatile environments. The M12 Brass Plain Washer ensures safe operation in fuel refineries, chemical plants, and mining areas.

Whether it’s for conductivity, aesthetics, or corrosion resistance, the M12 Brass Plain Washer is a highly adaptable component. At Nafees Metal Industries, we supply these washers to OEMs, contractors, maintenance engineers, and resellers across India and abroad, with the assurance of quality, consistency, and timely delivery.

Advantages of Using M12 Brass Washers

Choosing the M12 Brass Plain Washer from Nafees Metal Industries offers numerous advantages in terms of durability, performance, and aesthetic value. Whether you’re assembling electrical panels, plumbing fixtures, or precision equipment, brass washers bring specific benefits that outperform many other materials like mild steel, plastic, or even stainless steel in certain conditions.

Below are the key advantages of using M12 Brass Washers:

1. Excellent Corrosion Resistance

Brass naturally resists rust, oxidation, and most non-acidic chemical reactions. This makes the M12 Brass Plain Washer an ideal component in plumbing systems, marine environments, and outdoor installations.

2. Superior Electrical Conductivity

One of the top reasons to choose brass is its high electrical conductivity. The M12 Brass Plain Washer allows efficient current flow and grounding, which is vital in electrical assemblies, transformers, switchgear, and more.

3. Aesthetic Appearance

With its signature golden finish, the M12 Brass Plain Washer enhances the visual appeal of any assembly. This is especially beneficial in decorative applications such as lighting fixtures, designer furniture, and exposed bolts in architectural setups.

4. Non-Magnetic and Non-Sparking Properties

Brass is inherently non-magnetic and non-sparking, making it the safest material for environments with electromagnetic sensitivity (such as electronic devices) or potential explosive hazards (such as oil refineries or ammunition manufacturing).

5. Excellent Load Distribution

The washer effectively distributes the load from a fastener over a broader surface area. This prevents crushing, warping, or indenting of the base material – particularly important when working with softer surfaces like wood, plastic, or thin metal sheets.

6. Long Service Life

Thanks to its resistance to wear, corrosion, and tarnishing, the M12 Brass Plain Washer offers a longer operational lifespan compared to many other washer types, especially in aggressive or moist conditions.

7. Easy to Machine and Customize

Brass is an easily machinable metal, allowing us to create custom brass washers in terms of inner diameter, outer diameter, thickness, and finish. This ensures complete compatibility with client-specific applications.

8. Environmentally Friendly

Brass is 100% recyclable without any loss in quality. Using brass flat washers supports sustainable manufacturing and helps industries meet green compliance standards.

9. Vibration Dampening

The density and elasticity of brass make it moderately effective in absorbing vibration in assemblies, helping reduce loosening or wear caused by mechanical oscillation.

10. Bulk Availability and Cost-Efficiency

For applications where both quality and quantity matter, Nafees Metal Industries provides M12 Brass Plain Washers in bulk at competitive rates. With in-house production and stringent quality checks, we guarantee value for your investment.

Whether you’re a contractor, OEM, exporter, or maintenance engineer, incorporating M12 Brass Plain Washers into your operations ensures superior fastening support, enhanced aesthetics, and long-term reliability. With all these advantages, it’s no surprise that brass washers remain a trusted choice across industries.

Buy M12 Brass Plain Washers in Bulk – Best M12 Brass Plain Washers Manufacturer in India

When it comes to sourcing top-quality M12 Brass Plain Washers in bulk, Nafees Metal Industries stands as a trusted name among manufacturers and suppliers across India and global markets. With decades of experience in washer manufacturing, we are committed to delivering precision-engineered brass flat washers that meet the highest industrial standards.

As a reputed brass plain washers manufacturer, we specialize in meeting the diverse needs of OEMs, hardware distributors, fabrication units, electrical contractors, maintenance teams, and international buyers with speed, reliability, and customization.

Why Choose Nafees Metal Industries for M12 Brass Plain Washers?

1. Bulk Production Capacity

Our Mumbai-based facility is equipped with high-speed stamping and quality control systems that allow us to produce large volumes of M12 Brass Plain Washers without compromising quality. We maintain ready stock to meet urgent requirements and high-volume demands.

2. Customization Options

Whether you require a specific thickness, coating, outer diameter, or packaging configuration, we provide full customization. Our team works closely with clients to deliver washers tailored to their exact application needs.

3. Competitive Pricing with Transparent Quotations

We believe in providing high-quality products at affordable rates. Our pricing is structured for large-scale procurement without hidden charges. You get factory-direct value with full pricing transparency.

4. Export-Ready & Compliant

With all necessary compliance certifications, HS codes, and export documentation, Nafees Metal Industries is a trusted supplier for international buyers. Our M12 Brass Plain Washers are supplied to clients across the Middle East, Africa, Southeast Asia, and Europe.

5. Expert Technical Support

Our in-house engineering and sales team offer technical consultation to help you choose the right washer based on your project specifications, load-bearing requirements, or environmental conditions.

6. Custom Branding & Packaging

We offer OEM and white-label packaging solutions for brands and industrial buyers. Washers can be packed in poly bags, small boxes, or industrial cartons with custom labeling and barcoding as per your supply chain needs.

7. Timely Dispatch & Logistics Support

From order confirmation to dispatch, our team ensures smooth coordination and prompt delivery. We partner with reliable logistic providers to ensure your M12 Brass Plain Washers reach you safely and on time, whether in India or abroad.

Industries We Serve

Electrical and Electronics Manufacturing

Plumbing and Sanitary Ware

Power and Energy Systems

Precision Engineering and Instrumentation

Marine, Aviation, and Transportation

Architectural and Decorative Hardware

Government and Defense Contractors

Export Houses and Traders

Whether you’re looking to buy brass washers online, source from a brass plain washers manufacturer, or need an industrial brass washers partner who understands your volume and quality requirements, Nafees Metal Industries is here to support you with:

ISO-certified processes

Consistent product quality

End-to-end customer support

Nationwide and global delivery

Choose Nafees Metal Industries to experience reliability, precision, and professionalism in every washer you procure.

Case Study: Improving Fastening Performance with M12 Brass Plain Washers

Client Overview:

A reputed electrical switchgear manufacturer based in Pune was facing recurring issues with inconsistent clamping pressure, corrosion buildup around fasteners, and cosmetic damage to the final assembly. The products were meant for export to humid tropical regions, where rust and oxidation were a major concern.

Challenge:

The client previously used mild steel plain washers with zinc plating for their M12 bolts in panel assemblies. While the initial cost was lower, they began experiencing:

Surface rust within 3 weeks of shipment

Discoloration and flaking of the plated finish

Poor electrical conductivity across fastening points

Increased warranty claims from overseas clients

The company approached Nafees Metal Industries in search of a long-term, corrosion-resistant alternative that wouldn’t compromise on aesthetics or performance.

Solution: Use of M12 Brass Plain Washers

After understanding their application needs and installation environment, we recommended replacing the zinc-plated mild steel washers with our M12 Brass Plain Washers featuring a natural polished brass finish. The client conducted internal testing and approved the washers after evaluating the following parameters:

Dimensional consistency for automated torque-controlled fastening

Electrical conductivity to ensure proper grounding

Resistance to oxidation and discoloration

Enhanced visual finish for exported panels

We supplied the washers in custom packaging with printed batch numbers and QC tags for traceability.

Outcome & Results

Within three months of implementation, the client reported measurable improvements:

Eliminated Rust Issues: No signs of corrosion even after 60 days in high-humidity storage.

Improved Electrical Contact: Conductivity readings showed 30% improvement across M12 terminals.

Reduction in Assembly Defects: Flatness and edge finish improved torque control and reduced fastener loosening.

Enhanced Visual Finish: Customer satisfaction improved due to clean and professional-looking panel interiors.

Repeat Order Rate Increased: The client placed two additional bulk orders for M12 and M10 brass washers.

Conclusion

This case highlights the performance and quality advantages of the M12 Brass Plain Washer in real-world industrial applications. By replacing a low-cost, low-performance component with a precision-engineered brass washer, the client was able to achieve significant improvements in reliability, appearance, and long-term customer satisfaction.

Nafees Metal Industries continues to support them with timely deliveries, customization options, and ongoing product development for their international expansion.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we are committed to delivering high-performance washer solutions that align with the needs of modern industrial applications. Our M12 Brass Plain Washers are just one example of our dedication to quality, precision, and customer satisfaction. Here’s why industry leaders across India and abroad trust us as their preferred washer manufacturer:

1. Superior Material Sourcing

We use premium-grade brass alloys that conform to international standards. Our materials are chosen not only for strength and corrosion resistance but also for consistent machinability and surface finish. Every washer batch is produced from carefully selected raw materials to ensure uniform quality.

2. Precision Manufacturing

Our washers are manufactured using state-of-the-art power press machines and undergo rigorous dimensional checks. We maintain tight tolerances, precise inner and outer diameters, and uniform thickness in every washer we produce. The flatness and edge finish of our washers ensure optimal load distribution and reliable torque transfer.

3. Surface Finish Excellence

Our natural polished finish not only enhances the aesthetic appeal of the brass washers but also serves a functional purpose. The smooth surface reduces friction, prevents galling, and contributes to better sealing and grounding in mechanical and electrical assemblies.

4. Bulk and Custom Orders

We cater to both high-volume demands and custom size requirements. Whether you need thousands of standard-size washers or a unique design tailored to your specific project, our agile production team can deliver with efficiency and consistency.

5. Trusted Quality Assurance

Each washer batch undergoes multi-point quality checks including:

Dimensional verification

Surface inspection

Hardness testing

Batch-wise traceability

We follow strict internal QC protocols and can provide test reports and certificates of conformity upon request.

6. Competitive Pricing and Lead Times

We strike a balance between high quality and cost-effectiveness. Our optimized production processes and strategic sourcing allow us to offer competitive pricing without compromising on material or workmanship. Additionally, we are known for our fast turnaround times and on-time delivery for both domestic and export orders.

7. Strong Customer Relationships

We believe in building long-term partnerships through responsive communication, technical support, and reliable after-sales service. Our dedicated team is always available to assist with order queries, product selection, and any specific requirements.

Whether you are a wholesaler, OEM, or engineering consultant, Nafees Metal Industries is your trusted partner for brass, stainless steel, and mild steel washer solutions. Our M12 Brass Plain Washers are a testament to our manufacturing capabilities and the trust placed in us by industries across sectors.

Frequently Asked Questions (FAQs) – M12 Brass Plain Washers

1. What are M12 brass plain washers used for?

M12 brass plain washers are used to distribute load and prevent damage to surfaces during fastening. They are ideal for applications in plumbing, electrical assemblies, marine hardware, and automotive parts where corrosion resistance and conductivity are critical.

2. What does M12 mean in M12 brass washer?

M12 refers to the inner diameter of the washer, designed to fit around M12 bolts or screws (12 mm in diameter). This ensures proper alignment and fastening performance in industrial and commercial applications.

3. Are brass washers corrosion-resistant?

Yes, brass is naturally corrosion-resistant. M12 brass washers are suitable for use in humid, coastal, or chemically exposed environments due to their excellent resistance to tarnish, rust, and oxidation.

4. Can I use M12 brass washers in electrical applications?

Absolutely. Brass is an excellent conductor of electricity, making M12 brass washers a preferred choice in electrical panels, terminals, and grounding systems.

5. What are the benefits of choosing brass over stainless steel washers?

Brass washers offer better electrical conductivity, are non-magnetic, and resist corrosion in certain chemical environments better than stainless steel. They’re also softer, reducing the risk of damaging mating surfaces.

6. Do you offer bulk discounts for M12 brass plain washers?

Yes, at Nafees Metal Industries, we provide competitive bulk pricing for large orders. Contact our sales team for quantity-based quotations and tailored offers.

7. What are the standard dimensions of M12 brass plain washers?

Typical M12 brass washers have an inner diameter of 12 mm, outer diameter of around 24–26 mm, and thickness between 1.5–2.5 mm. We can also provide custom sizes upon request.

8. Are your brass washers manufactured as per any standards?

Yes, we manufacture brass plain washers according to DIN 125 and other applicable international standards, ensuring precision, durability, and compatibility.

9. Can M12 brass plain washers be used in plumbing systems?

Yes. Due to their non-reactive nature and resistance to water and moisture, M12 brass washers are widely used in plumbing fixtures and pipe fittings.

10. Do you supply M12 brass washers with specific coatings or finishes?

While brass washers have a naturally smooth finish, we can offer surface treatments like polishing or custom coatings based on your application requirements.

11. Can I request custom thickness or outer diameter for M12 washers?

Yes, we offer customization for thickness, outer diameter, and other specifications. Simply share your requirements with our team.

12. How do I know if M12 is the right washer size for my application?

If you’re using M12 bolts or screws (12 mm in diameter), M12 washers are the appropriate choice. However, our team can guide you based on your application if you’re unsure.

13. Are your brass washers RoHS compliant?

Yes, our brass washers are manufactured using RoHS-compliant materials, ensuring safety and environmental compliance for global markets.

14. Do you ship M12 brass washers across India and internationally?

Yes, we deliver pan-India and also export worldwide. Our logistics partners ensure timely and safe delivery to your location.

15. How can I place an order for M12 brass plain washers?

You can place an order by contacting us via phone, email, or our website’s contact form. We will confirm availability, pricing, and lead time as per your order quantity and delivery location.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Brass Plain Washers, Plain Washers, Washers

Tag: Brass

Got Questions?

Feel free to

Get in touch