No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

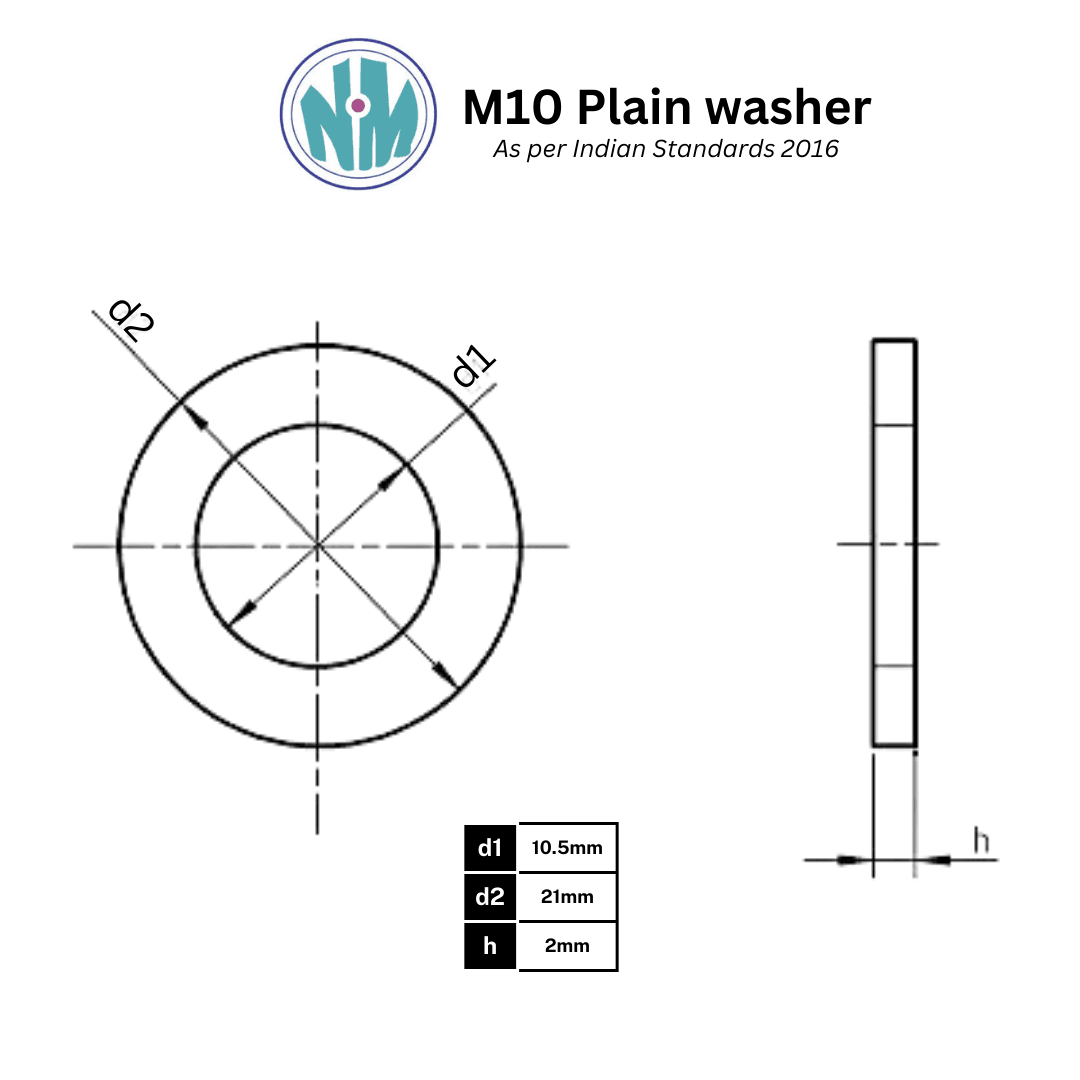

*Images shown for graphic representation. Not to scale.

M10 SS202 Plain Washers – Precision Engineering for Secure Fastening

Introduction

In the world of mechanical fastening, washers often go unnoticed despite their essential role in maintaining joint stability, distributing loads, and extending the life of connected components. Among the many variants available, M10 SS202 Plain Washers offer a unique balance of strength, corrosion resistance, and affordability. These washers are designed to work seamlessly with M10 bolts, making them a go-to choice for industries ranging from automotive to construction.

Choosing the right washer is about more than just size—it’s about matching the correct material, shape, and specification to your environment and mechanical stress conditions. M10 SS202 Plain Washers are manufactured using SS202 stainless steel, offering moderate corrosion resistance at a significantly lower cost than other stainless steel grades like SS304 or SS316.

Our brand is a trusted supplier of high-quality washers tailored to industrial-grade performance. With advanced manufacturing capabilities and a stringent quality control process, we are dedicated to delivering the Best M10 SS202 Washers for Industrial Use.

What Are M10 SS202 Plain Washers?

M10 SS202 Plain Washers are flat, circular components with a center hole sized for M10 bolts. Their primary function is to distribute the load of a bolt or screw evenly over a larger area, thereby reducing stress, preventing surface damage, and enhancing the stability of the fastening system.

In high-vibration or high-load environments, these washers play an integral role in minimizing wear and loosening of fasteners. They are essential in applications where the integrity of bolted joints directly impacts safety and performance.

The key roles performed by M10 SS202 Plain Washers include:

Load Distribution: Prevents material damage under bolt heads and nuts.

Vibration Resistance: Acts as a buffer to reduce loosening caused by dynamic loads.

Surface Protection: Prevents scratches, galling, and metal indentation.

As part of the SS202 Washers family, these components combine reliable performance with a cost-effective material choice, suitable for indoor and semi-outdoor environments.

Material Details: Why SS202?

SS202 is a chromium-nickel-manganese austenitic stainless steel. It is known for its good mechanical properties, excellent formability, and reasonable corrosion resistance, making it ideal for moderately demanding environments.

Composition of SS202 Stainless Steel:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: ≤ 0.08%

Comparison with Other Grades:

SS202 vs SS304: SS304 offers superior corrosion resistance, but SS202 provides nearly equivalent strength at a lower cost.

SS202 vs SS316: SS316 is used for marine and chemical exposure, but SS202 suffices for general industrial use at a fraction of the cost.

Advantages for M10 Washers:

More economical for medium-duty applications

Acceptable resistance in semi-corrosive environments

Good weldability and formability

Consistent strength in high-load fastenings

For projects that need both performance and budget-consciousness, M10 SS202 Plain Washers offer an ideal solution.

Manufacturing and Technical Specifications

M10 SS202 Plain Washers are produced under controlled environments to ensure dimensional accuracy and mechanical reliability. The manufacturing process emphasizes consistency, surface quality, and precise tolerances, enabling seamless integration with M10 fasteners.

Processes Involved:

CNC Machining for precision

Deburring for smooth edges

Surface finishing (Bright/Matte)

Dimensional and hardness inspection

Packaging per client specification

Technical Specifications:

| Specification | Value |

|---|---|

| Inner Diameter | 10.5 mm ± 0.2 mm |

| Outer Diameter | 21.0 mm ± 0.3 mm |

| Thickness | 2.0 mm ± 0.15 mm |

| Finish | Bright / Matte |

| Material | SS202 Stainless Steel |

| Shape | Flat Circular |

These specifications ensure compatibility with ISO-standard M10 bolts in a wide range of fastening applications.

Key Features of M10 SS202 Plain Washers

M10 SS202 Plain Washers are precision-engineered components designed to enhance the durability, stability, and performance of bolted joints. Below are the detailed features that make them a preferred choice for industrial and general-purpose applications:

1. Superior Load Distribution

These washers effectively distribute the compressive force from bolts and nuts over a larger surface area. This prevents localized stress on softer or thinner materials and significantly reduces the risk of material deformation or structural damage.

2. Accurate Fit for M10 Bolts

Manufactured with a precise inner diameter (~10.5 mm ± 0.3 mm), these washers fit snugly with M10 fasteners. The precision fit ensures stability in the joint and prevents shifting or slippage during installation or operation.

3. Vibration Dampening

M10 SS202 Plain Washers act as cushions that absorb minor shocks and vibrations, especially in dynamic environments like automotive or mechanical assemblies. This reduces the likelihood of fastener loosening and improves joint retention over time.

4. Moderate Corrosion Resistance

Constructed from SS202 stainless steel, these washers offer reasonable protection against corrosion in semi-corrosive environments. Ideal for indoor and protected outdoor use, they are suitable for most non-marine industrial conditions.

5. Durable and Long-Lasting

SS202 offers high tensile strength and resistance to wear, making these washers ideal for repeated tightening and long service cycles. Even under frequent mechanical stress, they maintain their form and performance.

6. Excellent Surface Finish

Available in bright, matte, or polished finishes, the smooth surfaces of these washers reduce friction, minimize galling, and enhance the aesthetic and functional quality of the assembly.

7. Low Maintenance Requirement

M10 SS202 Plain Washers require minimal upkeep when installed properly. Their material composition resists scaling, rusting, and other forms of degradation, especially in standard industrial settings.

8. Dimensional Accuracy

Each washer is CNC-machined or laser-cut to strict tolerances, ensuring consistency in thickness, inner and outer diameters. This precision allows for compatibility with automated and manual assembly systems.

9. Versatile Use Cases

Whether it’s for electronics, automotive, fabrication, or civil projects, these washers can be used across a wide spectrum of applications thanks to their universal design and robust material properties.

10. Bulk Availability & Custom Packaging

M10 SS202 Plain Washers are available in bulk quantities with custom packaging options—ideal for OEMs, wholesalers, and construction contractors. This ensures inventory continuity and storage efficiency.

Applications & Use Cases

M10 SS202 Plain Washers are utilized in a wide variety of sectors due to their versatility, durability, and efficient load management. Below is a breakdown of prominent use cases across different industries:

Automotive Industry:

Employed in engine compartments and brake systems

Assists in reducing vibration and metal fatigue

Construction and Infrastructure:

Structural bolting for steel frames, bridges, and panels

Reliable in high-load bearing joints

Machinery and Equipment:

Prevents loosening in high-speed rotating equipment

Used in compressors, gearboxes, and production lines

Electrical and Electronics:

As spacers in circuit boards or control panels

Prevents direct metal-to-metal contact for safety

DIY & General Fabrication:

Commonly used in furniture assembly and minor fixings

Provides enhanced grip in wooden and plastic surfaces

These varied applications reflect the multifunctional role of M10 SS202 Plain Washers in enhancing assembly safety and mechanical reliability.

Why Buy M10 SS202 Plain Washers in Bulk

M10 SS202 Plain Washers are widely used across industries, which makes bulk purchasing a strategic choice. Here’s why engineers, OEMs, and project managers choose to Buy M10 SS202 Plain Washers in Bulk:

Cost Efficiency: Unit cost decreases significantly with volume-based pricing.

Consistent Supply: Ensures washers are available during time-sensitive assembly or construction phases.

Custom Packaging: Options for labeled, boxed, or palletized packs for organized storage.

Inventory Planning: Allows for structured inventory control and batch tracking.

Quality Consistency: Uniform quality across a large number of units reduces rejection rates and rework.

We provide flexible minimum order quantities, fast turnaround times, and reliable logistics support for national and international bulk shipments.

Why Choose the Best M10 SS202 Plain Washers Manufacturer

Selecting the Best M10 SS202 Washers for Industrial Use involves more than just price—it’s about trust, reliability, and performance consistency. Here’s what sets our manufacturing apart:

ISO-Certified Facilities: Guaranteeing top-quality standards and traceability.

In-House Production: Complete control over sourcing, processing, and inspection.

Customization Capability: Made-to-order washer dimensions, finishes, and packaging.

Batch Certification: Test reports and compliance documents provided on request.

Global Clientele: Trusted by manufacturers, builders, and resellers worldwide.

Our commitment is to help you scale your project with dependable supply and engineering-grade quality in every batch.

Installation Tips for M10 SS202 Plain Washers

Proper installation of M10 SS202 Plain Washers is essential to maximize their performance and longevity. Follow these best practices to ensure secure fastening, minimal wear, and enhanced joint reliability:

1. Clean the Surface and Washer Before Installation

Ensure both the washer and the mating surfaces are free from oil, dust, rust, and debris. This prevents slippage and ensures better contact, load distribution, and joint integrity.

2. Correct Placement Under Bolt Head or Nut

Always place the washer directly under the head of the bolt or the nut, depending on the direction of the applied load. For critical applications, use washers on both ends (bolt head and nut) to ensure uniform stress distribution.

3. Avoid Over-Tightening the Bolt

While torque is essential for joint strength, over-tightening can deform the washer and reduce its effectiveness. Use a calibrated torque wrench and follow recommended torque values for M10 fasteners in your application.

4. Check for Flatness Before Use

Inspect each washer before installation. A warped or uneven washer may cause improper clamping force and damage the joint. Replace any washer that is bent, scratched, or visibly deformed.

5. Pair With Compatible Materials

For optimal results, use M10 SS202 Plain Washers with stainless steel bolts of compatible grades. Mismatched materials may lead to galvanic corrosion or fastener failure over time.

6. Apply Protective Coatings When Needed

In environments with elevated moisture, chemicals, or temperature variation, consider using protective coatings (such as anti-seize lubricants or zinc sprays) to further safeguard both the washer and the joint.

7. Use in Conjunction with Locking Elements (If Required)

In high-vibration settings, combine M10 SS202 Plain Washers with locking washers, thread lockers, or lock nuts to ensure enhanced vibration resistance and fastening security.

Maintenance Guidelines for M10 SS202 Plain Washers

Although M10 SS202 Plain Washers are known for their durability and low upkeep, proper maintenance ensures they continue to perform efficiently over extended periods. Here’s how to maintain them effectively:

1. Proper Storage

Store the washers in a dry, sealed container or cabinet to prevent exposure to moisture or corrosive substances. Avoid leaving them in open or humid environments, especially near chemicals or oils.

2. Regular Inspection Intervals

Establish a schedule to inspect fastened assemblies that use M10 SS202 Plain Washers. Focus on critical equipment every 3 to 6 months or more frequently in high-load or high-vibration environments.

3. Signs to Watch For

Look for surface corrosion, loss of shape, pitting, wear marks, or cracking. Any of these signs indicate that the washer needs replacement to maintain assembly integrity.

4. Cleaning Process

When necessary, clean the washers using a mild solvent or warm soapy water and a soft brush. Avoid abrasive tools that could scratch or damage the surface finish. After cleaning, dry the washer thoroughly before reinstallation.

5. Timely Replacement

Replace washers that show visible deformation, excessive corrosion, or wear—even if the fastener remains intact. A compromised washer reduces the overall effectiveness of the joint.

6. Document Maintenance Logs

For industrial or critical applications, maintain logs that document inspection dates, replacement intervals, and batch numbers. This enhances traceability and improves quality control.

7. Lubrication Checks

If your application requires lubrication, periodically check that protective lubricants (if used) are intact and reapply as needed, especially in high-temperature or corrosive conditions.

Case Study: Performance Improvement Using M10 SS202 Plain Washers

A mid-scale manufacturing facility involved in the assembly of compact industrial pumps faced frequent issues with fastener loosening and premature surface damage on aluminum components. The client had been using generic washers that failed to withstand the vibration levels and dynamic pressure within their equipment.

Challenge

Fasteners loosened due to vibration within 3 months of operation

Surface damage on lightweight pump housing due to poor load distribution

Increased maintenance cycles and downtime

Our Solution

We supplied M10 SS202 Plain Washers in customized packaging, along with a dimensional accuracy report and material certification. These washers were placed under both bolt heads and nuts to maximize load distribution and surface protection.

Execution

Supplied 18,000 pieces over 2 weeks

Delivered pre-cleaned and batch-labeled washers

Included technical support and on-site consultation

Outcome

| Metric | Before | After Using M10 SS202 Plain Washers |

|---|---|---|

| Maintenance Frequency | Every 3 Months | Every 10 Months |

| Bolt Loosening Incidents | 12 per Quarter | 1 per Quarter |

| Component Surface Damage | Visible Dents & Scratches | None |

| Assembly Efficiency | Moderate | Improved by 20% |

Client Feedback

“The difference was instantly noticeable in vibration resistance and assembly ease. These washers have improved both our product quality and maintenance intervals.”

Related Products or Variants

SS202 Washers in sizes ranging from M6 to M36

Stainless Steel Flat Washers (also available in SS304 and SS316 grades)

Metric Coated Washers for enhanced corrosion resistance

Custom Fabricated Washers for special dimension requirements

Sample Packs available for quality trials prior to bulk orders

Final Words

Choosing M10 SS202 Plain Washers is a step toward enhancing the structural integrity and performance of your assemblies. These washers offer a winning combination of cost-efficiency, durability, and compliance for industrial applications. Whether you’re in manufacturing, infrastructure, automotive, or general engineering, these washers deliver reliability you can count on.

Trust our team for consistent quality and professional support. Start your project right—Buy M10 SS202 Plain Washers in Bulk today.

Frequently Asked Questions (FAQs)

1. What do M10 SS202 Plain Washers do?

They distribute load, reduce wear, and prevent fastener loosening in bolted joints.

2. Can they be reused?

Yes, if they show no signs of deformation, corrosion, or fatigue.

3. Are they suitable for outdoor applications?

SS202 is moderately corrosion-resistant and best suited for indoor or semi-outdoor environments.

4. Do you supply with test reports?

Yes, we provide dimensional and material test certifications upon request.

5. Can I request different finishes?

Absolutely. We offer bright, matte, and polished surface finishes.

6. What’s the usual lead time?

Standard lead time is 7–10 working days depending on order size.

7. What’s the exact inner diameter?

Approximately 10.5 mm ± 0.3 mm for M10 compatibility.

8. Do you offer international shipping?

Yes, we deliver worldwide via trusted freight partners.

9. Can I order small quantities for trials?

Yes, we support sample orders before full-scale production runs.

10. Is SS202 better than SS304?

SS202 is more cost-effective; SS304 offers superior corrosion resistance for harsh environments.

11. Do these washers support electrical conductivity?

They do, though performance may vary based on application and finish.

12. What’s the maximum load they can withstand?

Typically suitable for moderate-load industrial use; detailed specs available upon request.

13. Do you offer packaging customization?

Yes—zip locks, carton boxes, labeled bags, or bulk packaging options are available.

14. Can I pair these with high-tensile bolts?

Yes, they are compatible with high-strength M10 bolts.

15. How do I choose the right washer size?

Base your choice on bolt diameter, surface requirements, and load conditions. We’re happy to assist.

Why Choose Nafees Metal Industries

When you choose Nafees Metal Industries, you choose a partner that values precision and quality. Every batch of M10 SS202 Plain Washers undergoes strict quality checks and is produced using advanced manufacturing techniques. Our experienced team guarantees consistent dimensions and performance every time.

We offer competitive pricing, flexible order quantities, and the option to buy bulk M10 stainless steel washers for larger projects. Plus, our dedicated support team is ready to help you choose the best SS202 plain washers for industrial use based on your needs.

Get Started with the Best M10 SS202 Plain Washers

Ready to improve the reliability and longevity of your fastening systems? Order M10 SS202 Plain Washers from Nafees Metal industries today. Visit our manufacturing unit at Reay Road, Mumbai, or reach out to our team to discuss your requirements for stainless steel washers that won’t let you down.

M10 SS202 Plain Washers

17 people are viewing this product right now

₹1.32 Original price was: ₹1.32.₹1.10Current price is: ₹1.10. /per piece

Specification:

Material: Stainless Steel – SS202

Nominal Size (g): M10

Inner Diameter (ID): 10.5 mm

Outer Diameter (OD): 20 mm

Thickness (t): 2 mm

Minimum order quantity: 5000 pieces

Pricing will be based on the customisations. Please use Request Quote or Call us buttons below to connect with us

Estimated delivery:13 days

M10 SS202 Plain Washers – Precision Engineering for Secure Fastening

Introduction

In the world of mechanical fastening, washers often go unnoticed despite their essential role in maintaining joint stability, distributing loads, and extending the life of connected components. Among the many variants available, M10 SS202 Plain Washers offer a unique balance of strength, corrosion resistance, and affordability. These washers are designed to work seamlessly with M10 bolts, making them a go-to choice for industries ranging from automotive to construction.

Choosing the right washer is about more than just size—it’s about matching the correct material, shape, and specification to your environment and mechanical stress conditions. M10 SS202 Plain Washers are manufactured using SS202 stainless steel, offering moderate corrosion resistance at a significantly lower cost than other stainless steel grades like SS304 or SS316.

Our brand is a trusted supplier of high-quality washers tailored to industrial-grade performance. With advanced manufacturing capabilities and a stringent quality control process, we are dedicated to delivering the Best M10 SS202 Washers for Industrial Use.

What Are M10 SS202 Plain Washers?

M10 SS202 Plain Washers are flat, circular components with a center hole sized for M10 bolts. Their primary function is to distribute the load of a bolt or screw evenly over a larger area, thereby reducing stress, preventing surface damage, and enhancing the stability of the fastening system.

In high-vibration or high-load environments, these washers play an integral role in minimizing wear and loosening of fasteners. They are essential in applications where the integrity of bolted joints directly impacts safety and performance.

The key roles performed by M10 SS202 Plain Washers include:

Load Distribution: Prevents material damage under bolt heads and nuts.

Vibration Resistance: Acts as a buffer to reduce loosening caused by dynamic loads.

Surface Protection: Prevents scratches, galling, and metal indentation.

As part of the SS202 Washers family, these components combine reliable performance with a cost-effective material choice, suitable for indoor and semi-outdoor environments.

Material Details: Why SS202?

SS202 is a chromium-nickel-manganese austenitic stainless steel. It is known for its good mechanical properties, excellent formability, and reasonable corrosion resistance, making it ideal for moderately demanding environments.

Composition of SS202 Stainless Steel:

Chromium: 17–19%

Nickel: 4–6%

Manganese: 7.5–10%

Carbon: ≤ 0.08%

Comparison with Other Grades:

SS202 vs SS304: SS304 offers superior corrosion resistance, but SS202 provides nearly equivalent strength at a lower cost.

SS202 vs SS316: SS316 is used for marine and chemical exposure, but SS202 suffices for general industrial use at a fraction of the cost.

Advantages for M10 Washers:

More economical for medium-duty applications

Acceptable resistance in semi-corrosive environments

Good weldability and formability

Consistent strength in high-load fastenings

For projects that need both performance and budget-consciousness, M10 SS202 Plain Washers offer an ideal solution.

Manufacturing and Technical Specifications

M10 SS202 Plain Washers are produced under controlled environments to ensure dimensional accuracy and mechanical reliability. The manufacturing process emphasizes consistency, surface quality, and precise tolerances, enabling seamless integration with M10 fasteners.

Processes Involved:

CNC Machining for precision

Deburring for smooth edges

Surface finishing (Bright/Matte)

Dimensional and hardness inspection

Packaging per client specification

Technical Specifications:

| Specification | Value |

|---|---|

| Inner Diameter | 10.5 mm ± 0.2 mm |

| Outer Diameter | 21.0 mm ± 0.3 mm |

| Thickness | 2.0 mm ± 0.15 mm |

| Finish | Bright / Matte |

| Material | SS202 Stainless Steel |

| Shape | Flat Circular |

These specifications ensure compatibility with ISO-standard M10 bolts in a wide range of fastening applications.

Key Features of M10 SS202 Plain Washers

M10 SS202 Plain Washers are precision-engineered components designed to enhance the durability, stability, and performance of bolted joints. Below are the detailed features that make them a preferred choice for industrial and general-purpose applications:

1. Superior Load Distribution

These washers effectively distribute the compressive force from bolts and nuts over a larger surface area. This prevents localized stress on softer or thinner materials and significantly reduces the risk of material deformation or structural damage.

2. Accurate Fit for M10 Bolts

Manufactured with a precise inner diameter (~10.5 mm ± 0.3 mm), these washers fit snugly with M10 fasteners. The precision fit ensures stability in the joint and prevents shifting or slippage during installation or operation.

3. Vibration Dampening

M10 SS202 Plain Washers act as cushions that absorb minor shocks and vibrations, especially in dynamic environments like automotive or mechanical assemblies. This reduces the likelihood of fastener loosening and improves joint retention over time.

4. Moderate Corrosion Resistance

Constructed from SS202 stainless steel, these washers offer reasonable protection against corrosion in semi-corrosive environments. Ideal for indoor and protected outdoor use, they are suitable for most non-marine industrial conditions.

5. Durable and Long-Lasting

SS202 offers high tensile strength and resistance to wear, making these washers ideal for repeated tightening and long service cycles. Even under frequent mechanical stress, they maintain their form and performance.

6. Excellent Surface Finish

Available in bright, matte, or polished finishes, the smooth surfaces of these washers reduce friction, minimize galling, and enhance the aesthetic and functional quality of the assembly.

7. Low Maintenance Requirement

M10 SS202 Plain Washers require minimal upkeep when installed properly. Their material composition resists scaling, rusting, and other forms of degradation, especially in standard industrial settings.

8. Dimensional Accuracy

Each washer is CNC-machined or laser-cut to strict tolerances, ensuring consistency in thickness, inner and outer diameters. This precision allows for compatibility with automated and manual assembly systems.

9. Versatile Use Cases

Whether it’s for electronics, automotive, fabrication, or civil projects, these washers can be used across a wide spectrum of applications thanks to their universal design and robust material properties.

10. Bulk Availability & Custom Packaging

M10 SS202 Plain Washers are available in bulk quantities with custom packaging options—ideal for OEMs, wholesalers, and construction contractors. This ensures inventory continuity and storage efficiency.

Applications & Use Cases

M10 SS202 Plain Washers are utilized in a wide variety of sectors due to their versatility, durability, and efficient load management. Below is a breakdown of prominent use cases across different industries:

Automotive Industry:

Employed in engine compartments and brake systems

Assists in reducing vibration and metal fatigue

Construction and Infrastructure:

Structural bolting for steel frames, bridges, and panels

Reliable in high-load bearing joints

Machinery and Equipment:

Prevents loosening in high-speed rotating equipment

Used in compressors, gearboxes, and production lines

Electrical and Electronics:

As spacers in circuit boards or control panels

Prevents direct metal-to-metal contact for safety

DIY & General Fabrication:

Commonly used in furniture assembly and minor fixings

Provides enhanced grip in wooden and plastic surfaces

These varied applications reflect the multifunctional role of M10 SS202 Plain Washers in enhancing assembly safety and mechanical reliability.

Why Buy M10 SS202 Plain Washers in Bulk

M10 SS202 Plain Washers are widely used across industries, which makes bulk purchasing a strategic choice. Here’s why engineers, OEMs, and project managers choose to Buy M10 SS202 Plain Washers in Bulk:

Cost Efficiency: Unit cost decreases significantly with volume-based pricing.

Consistent Supply: Ensures washers are available during time-sensitive assembly or construction phases.

Custom Packaging: Options for labeled, boxed, or palletized packs for organized storage.

Inventory Planning: Allows for structured inventory control and batch tracking.

Quality Consistency: Uniform quality across a large number of units reduces rejection rates and rework.

We provide flexible minimum order quantities, fast turnaround times, and reliable logistics support for national and international bulk shipments.

Why Choose the Best M10 SS202 Plain Washers Manufacturer

Selecting the Best M10 SS202 Washers for Industrial Use involves more than just price—it’s about trust, reliability, and performance consistency. Here’s what sets our manufacturing apart:

ISO-Certified Facilities: Guaranteeing top-quality standards and traceability.

In-House Production: Complete control over sourcing, processing, and inspection.

Customization Capability: Made-to-order washer dimensions, finishes, and packaging.

Batch Certification: Test reports and compliance documents provided on request.

Global Clientele: Trusted by manufacturers, builders, and resellers worldwide.

Our commitment is to help you scale your project with dependable supply and engineering-grade quality in every batch.

Installation Tips for M10 SS202 Plain Washers

Proper installation of M10 SS202 Plain Washers is essential to maximize their performance and longevity. Follow these best practices to ensure secure fastening, minimal wear, and enhanced joint reliability:

1. Clean the Surface and Washer Before Installation

Ensure both the washer and the mating surfaces are free from oil, dust, rust, and debris. This prevents slippage and ensures better contact, load distribution, and joint integrity.

2. Correct Placement Under Bolt Head or Nut

Always place the washer directly under the head of the bolt or the nut, depending on the direction of the applied load. For critical applications, use washers on both ends (bolt head and nut) to ensure uniform stress distribution.

3. Avoid Over-Tightening the Bolt

While torque is essential for joint strength, over-tightening can deform the washer and reduce its effectiveness. Use a calibrated torque wrench and follow recommended torque values for M10 fasteners in your application.

4. Check for Flatness Before Use

Inspect each washer before installation. A warped or uneven washer may cause improper clamping force and damage the joint. Replace any washer that is bent, scratched, or visibly deformed.

5. Pair With Compatible Materials

For optimal results, use M10 SS202 Plain Washers with stainless steel bolts of compatible grades. Mismatched materials may lead to galvanic corrosion or fastener failure over time.

6. Apply Protective Coatings When Needed

In environments with elevated moisture, chemicals, or temperature variation, consider using protective coatings (such as anti-seize lubricants or zinc sprays) to further safeguard both the washer and the joint.

7. Use in Conjunction with Locking Elements (If Required)

In high-vibration settings, combine M10 SS202 Plain Washers with locking washers, thread lockers, or lock nuts to ensure enhanced vibration resistance and fastening security.

Maintenance Guidelines for M10 SS202 Plain Washers

Although M10 SS202 Plain Washers are known for their durability and low upkeep, proper maintenance ensures they continue to perform efficiently over extended periods. Here’s how to maintain them effectively:

1. Proper Storage

Store the washers in a dry, sealed container or cabinet to prevent exposure to moisture or corrosive substances. Avoid leaving them in open or humid environments, especially near chemicals or oils.

2. Regular Inspection Intervals

Establish a schedule to inspect fastened assemblies that use M10 SS202 Plain Washers. Focus on critical equipment every 3 to 6 months or more frequently in high-load or high-vibration environments.

3. Signs to Watch For

Look for surface corrosion, loss of shape, pitting, wear marks, or cracking. Any of these signs indicate that the washer needs replacement to maintain assembly integrity.

4. Cleaning Process

When necessary, clean the washers using a mild solvent or warm soapy water and a soft brush. Avoid abrasive tools that could scratch or damage the surface finish. After cleaning, dry the washer thoroughly before reinstallation.

5. Timely Replacement

Replace washers that show visible deformation, excessive corrosion, or wear—even if the fastener remains intact. A compromised washer reduces the overall effectiveness of the joint.

6. Document Maintenance Logs

For industrial or critical applications, maintain logs that document inspection dates, replacement intervals, and batch numbers. This enhances traceability and improves quality control.

7. Lubrication Checks

If your application requires lubrication, periodically check that protective lubricants (if used) are intact and reapply as needed, especially in high-temperature or corrosive conditions.

Case Study: Performance Improvement Using M10 SS202 Plain Washers

A mid-scale manufacturing facility involved in the assembly of compact industrial pumps faced frequent issues with fastener loosening and premature surface damage on aluminum components. The client had been using generic washers that failed to withstand the vibration levels and dynamic pressure within their equipment.

Challenge

Fasteners loosened due to vibration within 3 months of operation

Surface damage on lightweight pump housing due to poor load distribution

Increased maintenance cycles and downtime

Our Solution

We supplied M10 SS202 Plain Washers in customized packaging, along with a dimensional accuracy report and material certification. These washers were placed under both bolt heads and nuts to maximize load distribution and surface protection.

Execution

Supplied 18,000 pieces over 2 weeks

Delivered pre-cleaned and batch-labeled washers

Included technical support and on-site consultation

Outcome

| Metric | Before | After Using M10 SS202 Plain Washers |

|---|---|---|

| Maintenance Frequency | Every 3 Months | Every 10 Months |

| Bolt Loosening Incidents | 12 per Quarter | 1 per Quarter |

| Component Surface Damage | Visible Dents & Scratches | None |

| Assembly Efficiency | Moderate | Improved by 20% |

Client Feedback

“The difference was instantly noticeable in vibration resistance and assembly ease. These washers have improved both our product quality and maintenance intervals.”

Related Products or Variants

SS202 Washers in sizes ranging from M6 to M36

Stainless Steel Flat Washers (also available in SS304 and SS316 grades)

Metric Coated Washers for enhanced corrosion resistance

Custom Fabricated Washers for special dimension requirements

Sample Packs available for quality trials prior to bulk orders

Final Words

Choosing M10 SS202 Plain Washers is a step toward enhancing the structural integrity and performance of your assemblies. These washers offer a winning combination of cost-efficiency, durability, and compliance for industrial applications. Whether you’re in manufacturing, infrastructure, automotive, or general engineering, these washers deliver reliability you can count on.

Trust our team for consistent quality and professional support. Start your project right—Buy M10 SS202 Plain Washers in Bulk today.

Frequently Asked Questions (FAQs)

1. What do M10 SS202 Plain Washers do?

They distribute load, reduce wear, and prevent fastener loosening in bolted joints.

2. Can they be reused?

Yes, if they show no signs of deformation, corrosion, or fatigue.

3. Are they suitable for outdoor applications?

SS202 is moderately corrosion-resistant and best suited for indoor or semi-outdoor environments.

4. Do you supply with test reports?

Yes, we provide dimensional and material test certifications upon request.

5. Can I request different finishes?

Absolutely. We offer bright, matte, and polished surface finishes.

6. What’s the usual lead time?

Standard lead time is 7–10 working days depending on order size.

7. What’s the exact inner diameter?

Approximately 10.5 mm ± 0.3 mm for M10 compatibility.

8. Do you offer international shipping?

Yes, we deliver worldwide via trusted freight partners.

9. Can I order small quantities for trials?

Yes, we support sample orders before full-scale production runs.

10. Is SS202 better than SS304?

SS202 is more cost-effective; SS304 offers superior corrosion resistance for harsh environments.

11. Do these washers support electrical conductivity?

They do, though performance may vary based on application and finish.

12. What’s the maximum load they can withstand?

Typically suitable for moderate-load industrial use; detailed specs available upon request.

13. Do you offer packaging customization?

Yes—zip locks, carton boxes, labeled bags, or bulk packaging options are available.

14. Can I pair these with high-tensile bolts?

Yes, they are compatible with high-strength M10 bolts.

15. How do I choose the right washer size?

Base your choice on bolt diameter, surface requirements, and load conditions. We’re happy to assist.

Why Choose Nafees Metal Industries

When you choose Nafees Metal Industries, you choose a partner that values precision and quality. Every batch of M10 SS202 Plain Washers undergoes strict quality checks and is produced using advanced manufacturing techniques. Our experienced team guarantees consistent dimensions and performance every time.

We offer competitive pricing, flexible order quantities, and the option to buy bulk M10 stainless steel washers for larger projects. Plus, our dedicated support team is ready to help you choose the best SS202 plain washers for industrial use based on your needs.

Get Started with the Best M10 SS202 Plain Washers

Ready to improve the reliability and longevity of your fastening systems? Order M10 SS202 Plain Washers from Nafees Metal industries today. Visit our manufacturing unit at Reay Road, Mumbai, or reach out to our team to discuss your requirements for stainless steel washers that won’t let you down.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Plain Washers, SS202 Stainless Steel Plain Washers, Washers

Tag: SS202 Stainless Steel

Got Questions?

Feel free to

Get in touch