No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

*Images shown for graphic representation. Not to scale.

M10 Mild Steel Plain Washers – Best M10 MS Flat Washers Manufacturer

Introduction

In modern industrial fastening, sometimes the smallest component makes the biggest difference. That’s the role played by M10 Mild Steel Plain Washers — small, flat discs that protect your assemblies, distribute load, and ensure your bolts perform reliably, even under stress.

Whether you’re securing structural brackets, mounting heavy machinery, or working with precision panels, using high-quality M10 Mild Steel Plain Washers can prevent surface damage, increase joint stability, and significantly cut maintenance costs. At Nafees Metal Industries, we’re proud to be recognized as the Best M10 MS Flat Washers Manufacturer, trusted by contractors, OEMs, and MRO teams nationwide.

This guide will show you exactly why these washers matter, how they’re made, where to use them, and how to order them in bulk for your next big project.

Role of M10 Mild Steel Plain Washers in Industrial Applications

Bolts and nuts clamp components together — but the force they apply is highly localized. For M10 bolts, which are often used for medium-to-heavy load applications, this concentrated pressure can damage softer materials or thin surfaces.

Adding M10 Mild Steel Plain Washers under the bolt head or nut helps by:

Spreading the load across a wider area

Preventing surface dents, cracks, or pull-through failures

Protecting painted or coated finishes from scratches

Improving vibration resistance and reducing loosening

Maintaining consistent bolt torque over time

Extending the lifespan of your entire assembly

From factory floor brackets to highway guardrails and heavy equipment, the humble washer keeps your fasteners working as intended.

What Are M10 Mild Steel Plain Washers

In simple terms, an M10 Mild Steel Plain Washer is a flat, circular disc with a precisely punched inner hole to fit an M10 bolt or screw. This design ensures that when you tighten the fastener, the force is evenly spread — instead of being focused directly under the bolt head or nut.

A practical example: mounting a structural steel beam with M10 bolts directly onto a painted support bracket. Without washers, the bolt can chip the paint, expose bare metal, and open the door to rust. With a washer, the paint stays intact and the bracket retains its strength and finish.

That’s why industries like construction, manufacturing, automotive, and MRO always stock M10 Mild Steel Plain Washers for safe, durable fastening.

Material Details: Why Use Mild Steel Washers

There’s a good reason why mild steel remains the standard material for most general-purpose washers.

Balanced Strength:

Mild steel has the perfect mix of strength and ductility. It can handle high clamping forces without cracking or deforming. This makes it ideal for washers that need to spread loads under moderate to heavy torque.

Cost-Effective:

Compared to stainless steel or specialty alloys, mild steel is more budget-friendly — making it practical for high-volume orders without compromising performance.

Easy to Manufacture:

Mild steel is easy to punch and shape with precision, ensuring tight tolerances for inner and outer diameters. This means your washers always fit your bolts properly.

Adaptable:

Mild steel washers can be supplied plain or coated with zinc, black oxide, or phosphate finishes to add corrosion resistance for specific environments.

Sustainable:

Mild steel is 100% recyclable, supporting your sustainability goals and lowering your overall project footprint.

When you order Mild Steel Washers, you get high performance and consistent quality at a cost that makes sense for bulk supply.

Manufacturing and Technical Specifications

At Nafees Metal Industries, our production process for M10 Mild Steel Plain Washers uses CNC punching, automated inspection, and rigorous quality control to ensure dimensional consistency and a clean, burr-free finish.

Our process includes:

Certified raw material sourcing

Precision punching for tight inner and outer diameter tolerances

Deburring and smoothing of edges for safer handling

Optional protective coating (zinc-plated, black oxide, etc.)

Random batch checks for dimensional accuracy

Typical specs for M10 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | ~10.5 mm (standard M10 bolt clearance) |

| Outer Diameter | ~20–30 mm depending on standard |

| Thickness | 2–3 mm |

| Finish | Plain or coated (zinc, phosphate, black oxide) |

| Material | Mild Steel |

| Shape | Flat round disc |

Whether you’re ordering a few thousand or several million, our production line delivers high repeatability so you can confidently Buy M10 Mild Steel Plain Washers in Bulk and keep your operations running without surprises.

Key Features of M10 Mild Steel Plain Washers

Accurate Load Distribution

One of the most important features of M10 Mild Steel Plain Washers is their ability to spread the clamping load applied by bolts or nuts evenly over a larger surface area.

Imagine you’re securing a mild steel bracket to a beam using an M10 bolt. Without a washer, the entire clamping force focuses on the small ring of metal directly under the bolt head. Over time, this concentrated force can punch into the bracket’s surface, creating dents or even cracks — especially if the material underneath is softer or thin.

When you place an M10 Mild Steel Plain Washer between the bolt head and the bracket, that same force is distributed across the wider surface of the washer. This prevents the underlying material from deforming and maintains the structural integrity of the entire assembly.

This feature is especially critical in applications involving dynamic loads, where bolts are exposed to vibrations, impacts, or shifting forces — like in structural steel, railings, mezzanine floors, or large shelving units.

Surface Protection

M10 Mild Steel Plain Washers act like a protective shield for the surfaces being clamped. Every bolt or nut has a rough underside that can scratch painted, coated, or plated finishes. Over time, these scratches expose bare metal, which can lead to corrosion and structural weaknesses.

When you use a washer, the rough bolt underside contacts the washer instead of the painted beam or bracket. The washer absorbs any friction, leaving the surface finish intact. This is particularly valuable in outdoor installations like guardrails, metal fences, or painted steel structures, where rust can quickly spread if protective coatings are damaged.

Many contractors rely on M10 Mild Steel Plain Washers to maintain both function and appearance of their metalwork — it’s a small investment that protects larger, more expensive structural elements.

Vibration Resistance

Vibration is one of the biggest enemies of bolted joints. When machinery runs, or vehicles move along structures, they generate vibrations that can gradually loosen bolts and nuts.

By adding M10 Mild Steel Plain Washers, you introduce an extra layer of friction under the fastener. This helps resist rotation caused by vibration. While plain washers alone don’t fully lock a bolt in place like a spring washer does, they still play an important role in helping the bolt maintain its tension longer.

In industries like manufacturing, heavy equipment, or construction sites near roads and railways, this added vibration resistance keeps structures safer and reduces the need for constant retightening.

Corrosion Resistance with Coatings

Basic M10 Mild Steel Plain Washers can be supplied plain for indoor or dry conditions. However, mild steel is highly adaptable — and it’s easy to add protective coatings for better corrosion resistance.

For example, zinc plating adds a layer of rust protection and gives the washer a shiny finish. Phosphate coatings add mild rust protection and help paint adhere. Black oxide offers a sleek appearance for indoor fixtures.

This means you can match your washers to the environment: plain for indoor structural steel, zinc-plated for moderate outdoor exposure, or painted/black oxide for decorative metalwork. This adaptability makes mild steel washers practical for large projects with mixed exposure conditions.

Reusable and Cost-Effective

A high-quality M10 Mild Steel Plain Washer doesn’t warp or deform under proper torque. This means it can be reused during maintenance, disassembly, or equipment upgrades.

For large maintenance teams or contractors managing hundreds of fastener points, reusable washers reduce replacement costs. Over time, this adds up to significant savings — all while ensuring you don’t compromise on safety or quality.

Plus, mild steel as a material is affordable, widely available, and easy to manufacture. That means bulk orders of M10 Mild Steel Plain Washers are cost-effective and help keep overall project costs in check, especially when compared to using more expensive specialty metals.

Easy to Handle and Install

Unlike some specialty washers with locking tabs or complex shapes, M10 Mild Steel Plain Washers are simple, flat, and easy to handle. Workers don’t need special training to install them. Just slip the washer onto the bolt or screw before tightening — it’s that simple.

In high-volume assembly lines, this simplicity helps maintain speed without compromising on fastening quality. For large construction crews, it reduces errors during installation and ensures every joint gets the protective benefits a washer provides.

Compatibility with Standard Bolts and Nuts

M10 Mild Steel Plain Washers are designed to perfectly match standard M10 bolts and nuts. The inner diameter is precisely punched to allow smooth installation without excessive play, while the outer diameter is wide enough to spread load effectively.

This tight dimensional control means you don’t have to worry about washers slipping out of place during tightening — they seat securely under the bolt head or nut.

Available in Bulk for Large Projects

Big projects demand big quantities. Whether you’re building multi-story frameworks, retrofitting industrial plants, or installing kilometers of guardrails, you need a consistent supply of washers that match your bolt specs.

That’s why we always recommend you Buy M10 Mild Steel Plain Washers in Bulk. Large orders ensure you have consistent quality across your entire project, avoid unexpected shortages, and benefit from competitive bulk pricing.

As the Best M10 MS Flat Washers Manufacturer, we at Nafees Metal Industries guarantee reliable supply and custom packing options to keep your site running smoothly.

Applications of M10 Mild Steel Plain Washers

Construction and Infrastructure

M10 fasteners are common in structural steel frameworks, bridge supports, and guardrails. Washers prevent damage to galvanized beams and brackets, keeping protective coatings intact for longer life.

Automotive and Heavy Vehicles

From mounting chassis components to securing engine parts, M10 Mild Steel Plain Washers protect thin panels and resist vibration loosening.

Industrial Machinery

Machinery frames, conveyor systems, and equipment brackets rely on these washers to maintain tight, stable joints that can withstand dynamic loads.

HVAC Systems

In ducting and mounting large HVAC units, M10 bolts and washers keep flanges secure without deforming the sheet metal.

Furniture and Metal Fixtures

Metal furniture frames, modular shelving, and fixtures often use M10 bolts and washers to protect painted surfaces and maintain joint strength.

DIY Projects and General Repairs

MRO teams and DIY enthusiasts keep MS Flat Washers in stock for general fastening tasks like mounting fences, repairing gates, or building metal structures.

Case Study: How M10 Mild Steel Plain Washers Saved ₹5 Lakhs in Costly Beam Repairs

Background

In early 2024, a well-known industrial storage solutions company was contracted to retrofit a large logistics warehouse for a major e-commerce brand in Western India. The retrofit involved building mezzanine floors to increase vertical storage space — requiring heavy-duty mild steel beams connected by M10 bolts.

Due to tight deadlines and cost pressure, the contractor initially decided to skip using washers altogether, believing that the M10 bolts alone would provide enough clamping force on the flanged beams.

The installation involved over 2,000 bolted joints across multiple beam segments. The fasteners were tightened directly against painted mild steel flanges, holding up pallet racks and floor decking above.

The Problem

For the first two months, everything appeared normal. But as pallet loads increased and the mezzanine saw daily forklift traffic, the maintenance team began noticing small issues:

Bolt heads were digging into the painted steel flanges, causing the paint to crack and flake away.

Exposed bare steel started rusting at multiple contact points.

Local deformation around bolt holes was visible in several flanges.

Bolts in high-load areas gradually lost tension due to the flanges bending under the focused pressure.

This seemingly minor oversight led to serious structural concerns. A third-party safety inspection flagged 75+ flanges that had bent to a point where load integrity was at risk.

Without a fix, the company faced:

✅ Structural reinforcement expenses estimated at over ₹5 lakhs.

✅ Disruption of warehouse operations for several days.

✅ A potential safety hazard that could damage inventory or injure workers.

The Solution

The contractor consulted Nafees Metal Industries, known as the Best M10 MS Flat Washers Manufacturer, for expert advice. After reviewing the problem on-site, our technical team confirmed that the absence of washers had allowed the bolts’ localized force to damage the flanges.

Our immediate recommendation was to retrofit every connection with high-quality M10 Mild Steel Plain Washers — manufactured to precise tolerances and zinc-plated for added corrosion resistance.

Why washers made sense:

✔ Load Distribution: The washers would spread the clamping force over a larger area, preventing further deformation.

✔ Surface Protection: They would shield the beam flanges from direct contact with bolt heads, keeping the paint intact and rust at bay.

✔ Maintaining Tension: By preventing local bending, the bolts would hold their torque longer, reducing loosening under vibration.

✔ Cost-Effective: Replacing washers was far cheaper than cutting and replacing beams.

Our team provided a detailed retrofit plan: unbolt each connection, inspect the flange, realign the beam if needed, add the M10 Mild Steel Plain Washers, and retighten to the correct torque. We also supplied 3,000 washers on priority, ensuring zero project downtime.

Implementation

The warehouse’s maintenance team worked overnight shifts to avoid disrupting daily operations. In phases, they:

Removed bolts from each beam flange.

Slipped on the M10 Mild Steel Plain Washers under each bolt head and nut.

Re-torqued the bolts to the correct clamping force.

Repainted any exposed spots where paint had flaked off.

Even in high-vibration areas (near conveyor tracks and forklift pathways), the washers immediately stabilized the joints. The flanges showed no additional bending, and periodic inspections confirmed that bolt tension held steady.

Results

✅ Structural integrity restored: Zero bent flanges reported after the retrofit, and no new rust spots formed under the bolts.

✅ Maintenance savings: The company avoided an estimated ₹5 lakhs in costly beam replacements and welding reinforcements.

✅ Downtime avoided: The phased installation allowed the warehouse to stay operational, fulfilling the client’s orders without disruption.

✅ Long-term durability: The contractor updated its SOP to mandate M10 Mild Steel Plain Washers for all future beam connections — no exceptions.

Client Feedback

The contractor’s project manager said it best:

“We thought we were saving money by skipping washers. But it almost cost us lakhs in repairs and safety fines. Adding M10 Mild Steel Plain Washers fixed the problem for a fraction of the cost. Nafees Metal Industries didn’t just sell us washers — they saved our project.”

Key Takeaways

This case shows exactly why even a small component like a washer plays a big role in structural projects:

✅ Without M10 Mild Steel Plain Washers, the localized bolt pressure damages painted mild steel flanges, leading to corrosion, bending, and loss of tension.

✅ With washers, the load is distributed evenly, surfaces stay protected, and joints stay secure under vibration and shifting loads.

✅ The upfront cost of bulk washers is negligible compared to the cost of replacing structural beams, losing production time, or failing safety inspections.

How This Applies to You

If your project involves:

Structural beams, channels, or brackets

Painted or coated steel sections

Medium-load bolts like M10

Heavy vibration from machinery or vehicle movement

then investing in bulk M10 Mild Steel Plain Washers is the smartest, most cost-effective insurance you can buy for your structure’s long-term integrity.

It’s a tiny piece that protects your biggest assets — your materials, your time, and your budget.

Why Choose the Best M10 MS Flat Washers Manufacturer

When you order from Nafees Metal Industries, you get:

ISO-aligned manufacturing and QC

Consistent batches for bulk orders

Custom coatings and sizes on request

Technical support for the right specs

Fast lead times and reliable dispatch

It’s why we’re trusted as the Best M10 MS Flat Washers Manufacturer for projects that can’t afford rework.

Installation Tips

Always use a washer under both bolt head and nut if possible.

Tighten to specified torque to prevent overtightening.

Store washers properly to avoid moisture damage.

Maintenance Guidelines

Inspect washers during scheduled maintenance.

Replace bent or corroded washers immediately.

Store extras sealed and dry to prevent rust.

Related Products

Explore our range:

Mild Steel Washers in all standard sizes

Spring and lock washers for anti-vibration

Stainless Steel Flat Washers for corrosive environments

Final Words

From high-rise construction to factory lines, every bolt deserves the right washer. Trust M10 Mild Steel Plain Washers to protect your structures, prevent damage, and deliver maximum value. It’s the small detail that keeps your biggest projects secure.

FAQs

What are M10 Mild Steel Plain Washers used for?

Distributing load, protecting surfaces, and preventing vibration loosening.Are they reusable?

Yes, if undamaged and rust-free.What finishes do you offer?

Plain, zinc-plated, black oxide, and more.Are they suitable for outdoor use?

Yes, with proper coatings.What standards do you follow?

IS/ISO/DIN, as required.Can I get test certificates?

Yes, on request.What sizes do you stock?

From M4 to M40.Do you ship globally?

Yes, worldwide.Can I get samples?

Of course.What is the MOQ?

Flexible — contact us.Do you offer custom packaging?

Yes.How should I store them?

In a dry, sealed container.What’s your lead time?

7–14 days for most orders.Do you offer bulk discounts?

Yes, volume pricing available.Why choose you?

Consistency, reliability, and trusted support.

Why Choose Nafees Metal Industries?

With decades of expertise, Nafees Metal Industries stands out as the Best M10 Mild Steel Plain Washers Manufacturer trusted by clients across automotive, construction, and industrial sectors. We combine high-quality materials, precise engineering, and modern manufacturing processes to deliver washers that exceed industry expectations.

When you choose us, you benefit from:

Reliable bulk supply for large or small orders.

Custom sizing and coating options to match unique project requirements.

Competitive pricing with no compromise on quality.

Timely delivery and responsive customer service.

Whether you’re searching for the Best M10 MS Flat Washers Manufacturer or looking to Buy M10 Mild Steel Plain Washers in Bulk, we’re here to support you every step of the way.

Visit Us Today

Explore our full range of Mild Steel Washers and other precision fasteners by visiting our advanced manufacturing unit at Reay Road, Mumbai. Reach out to our team for quotes, customization options, or to place bulk orders — and experience the quality and trust that define Nafees Metal industries.

M10 Mild Steel Plain Washers

12 people are viewing this product right now

₹0.66 Original price was: ₹0.66.₹0.55Current price is: ₹0.55. /per piece

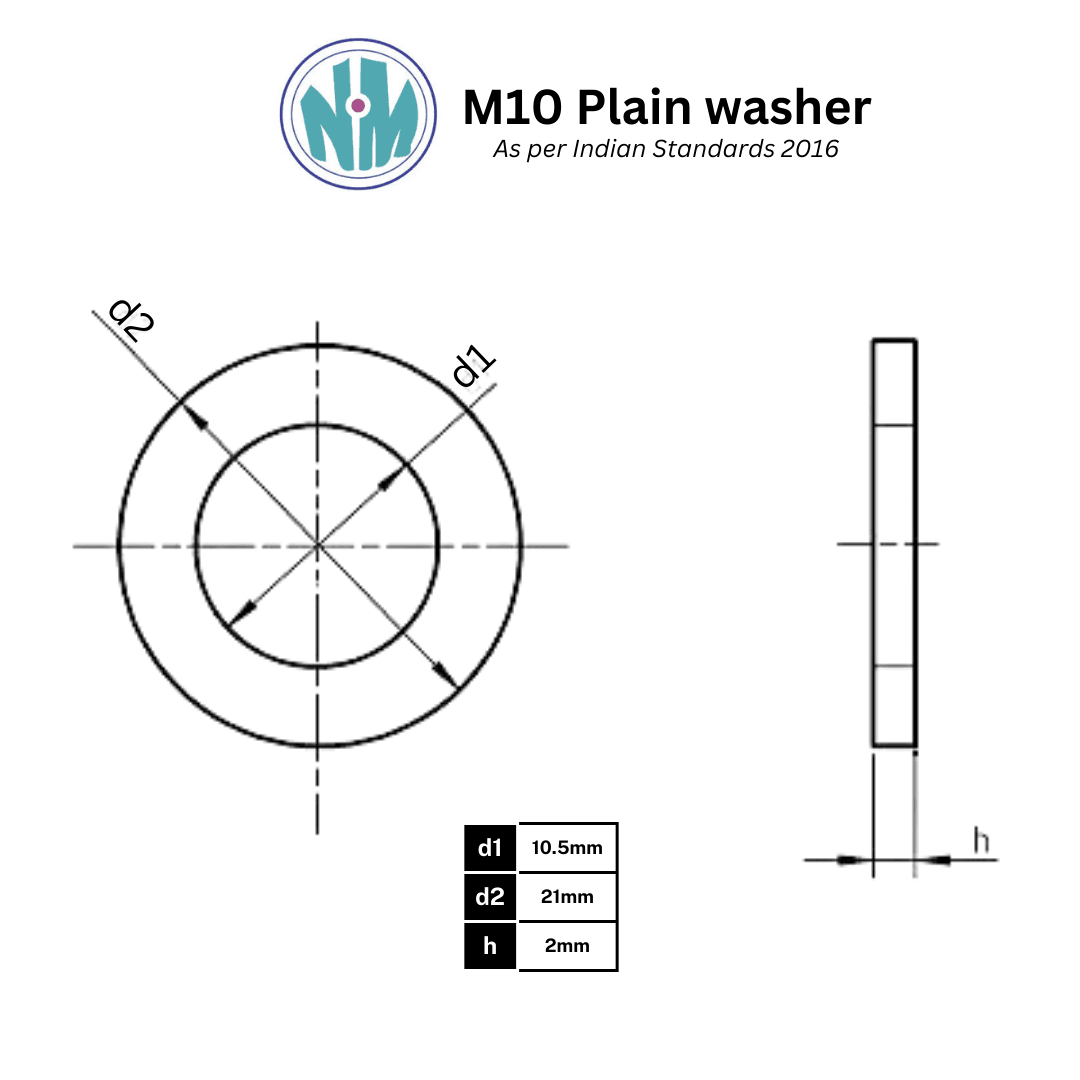

Specification:

Material: Mild Steel

Nominal Size (g): M10

Inner Diameter (ID): 10.5 mm

Outer Diameter (OD): 21 mm

Thickness (t): 2 mm

Minimum order quantity: 5000 pieces

Estimated delivery:14 days

M10 Mild Steel Plain Washers – Best M10 MS Flat Washers Manufacturer

Introduction

In modern industrial fastening, sometimes the smallest component makes the biggest difference. That’s the role played by M10 Mild Steel Plain Washers — small, flat discs that protect your assemblies, distribute load, and ensure your bolts perform reliably, even under stress.

Whether you’re securing structural brackets, mounting heavy machinery, or working with precision panels, using high-quality M10 Mild Steel Plain Washers can prevent surface damage, increase joint stability, and significantly cut maintenance costs. At Nafees Metal Industries, we’re proud to be recognized as the Best M10 MS Flat Washers Manufacturer, trusted by contractors, OEMs, and MRO teams nationwide.

This guide will show you exactly why these washers matter, how they’re made, where to use them, and how to order them in bulk for your next big project.

Role of M10 Mild Steel Plain Washers in Industrial Applications

Bolts and nuts clamp components together — but the force they apply is highly localized. For M10 bolts, which are often used for medium-to-heavy load applications, this concentrated pressure can damage softer materials or thin surfaces.

Adding M10 Mild Steel Plain Washers under the bolt head or nut helps by:

Spreading the load across a wider area

Preventing surface dents, cracks, or pull-through failures

Protecting painted or coated finishes from scratches

Improving vibration resistance and reducing loosening

Maintaining consistent bolt torque over time

Extending the lifespan of your entire assembly

From factory floor brackets to highway guardrails and heavy equipment, the humble washer keeps your fasteners working as intended.

What Are M10 Mild Steel Plain Washers

In simple terms, an M10 Mild Steel Plain Washer is a flat, circular disc with a precisely punched inner hole to fit an M10 bolt or screw. This design ensures that when you tighten the fastener, the force is evenly spread — instead of being focused directly under the bolt head or nut.

A practical example: mounting a structural steel beam with M10 bolts directly onto a painted support bracket. Without washers, the bolt can chip the paint, expose bare metal, and open the door to rust. With a washer, the paint stays intact and the bracket retains its strength and finish.

That’s why industries like construction, manufacturing, automotive, and MRO always stock M10 Mild Steel Plain Washers for safe, durable fastening.

Material Details: Why Use Mild Steel Washers

There’s a good reason why mild steel remains the standard material for most general-purpose washers.

Balanced Strength:

Mild steel has the perfect mix of strength and ductility. It can handle high clamping forces without cracking or deforming. This makes it ideal for washers that need to spread loads under moderate to heavy torque.

Cost-Effective:

Compared to stainless steel or specialty alloys, mild steel is more budget-friendly — making it practical for high-volume orders without compromising performance.

Easy to Manufacture:

Mild steel is easy to punch and shape with precision, ensuring tight tolerances for inner and outer diameters. This means your washers always fit your bolts properly.

Adaptable:

Mild steel washers can be supplied plain or coated with zinc, black oxide, or phosphate finishes to add corrosion resistance for specific environments.

Sustainable:

Mild steel is 100% recyclable, supporting your sustainability goals and lowering your overall project footprint.

When you order Mild Steel Washers, you get high performance and consistent quality at a cost that makes sense for bulk supply.

Manufacturing and Technical Specifications

At Nafees Metal Industries, our production process for M10 Mild Steel Plain Washers uses CNC punching, automated inspection, and rigorous quality control to ensure dimensional consistency and a clean, burr-free finish.

Our process includes:

Certified raw material sourcing

Precision punching for tight inner and outer diameter tolerances

Deburring and smoothing of edges for safer handling

Optional protective coating (zinc-plated, black oxide, etc.)

Random batch checks for dimensional accuracy

Typical specs for M10 Mild Steel Plain Washers:

| Parameter | Specification |

|---|---|

| Inner Diameter | ~10.5 mm (standard M10 bolt clearance) |

| Outer Diameter | ~20–30 mm depending on standard |

| Thickness | 2–3 mm |

| Finish | Plain or coated (zinc, phosphate, black oxide) |

| Material | Mild Steel |

| Shape | Flat round disc |

Whether you’re ordering a few thousand or several million, our production line delivers high repeatability so you can confidently Buy M10 Mild Steel Plain Washers in Bulk and keep your operations running without surprises.

Key Features of M10 Mild Steel Plain Washers

Accurate Load Distribution

One of the most important features of M10 Mild Steel Plain Washers is their ability to spread the clamping load applied by bolts or nuts evenly over a larger surface area.

Imagine you’re securing a mild steel bracket to a beam using an M10 bolt. Without a washer, the entire clamping force focuses on the small ring of metal directly under the bolt head. Over time, this concentrated force can punch into the bracket’s surface, creating dents or even cracks — especially if the material underneath is softer or thin.

When you place an M10 Mild Steel Plain Washer between the bolt head and the bracket, that same force is distributed across the wider surface of the washer. This prevents the underlying material from deforming and maintains the structural integrity of the entire assembly.

This feature is especially critical in applications involving dynamic loads, where bolts are exposed to vibrations, impacts, or shifting forces — like in structural steel, railings, mezzanine floors, or large shelving units.

Surface Protection

M10 Mild Steel Plain Washers act like a protective shield for the surfaces being clamped. Every bolt or nut has a rough underside that can scratch painted, coated, or plated finishes. Over time, these scratches expose bare metal, which can lead to corrosion and structural weaknesses.

When you use a washer, the rough bolt underside contacts the washer instead of the painted beam or bracket. The washer absorbs any friction, leaving the surface finish intact. This is particularly valuable in outdoor installations like guardrails, metal fences, or painted steel structures, where rust can quickly spread if protective coatings are damaged.

Many contractors rely on M10 Mild Steel Plain Washers to maintain both function and appearance of their metalwork — it’s a small investment that protects larger, more expensive structural elements.

Vibration Resistance

Vibration is one of the biggest enemies of bolted joints. When machinery runs, or vehicles move along structures, they generate vibrations that can gradually loosen bolts and nuts.

By adding M10 Mild Steel Plain Washers, you introduce an extra layer of friction under the fastener. This helps resist rotation caused by vibration. While plain washers alone don’t fully lock a bolt in place like a spring washer does, they still play an important role in helping the bolt maintain its tension longer.

In industries like manufacturing, heavy equipment, or construction sites near roads and railways, this added vibration resistance keeps structures safer and reduces the need for constant retightening.

Corrosion Resistance with Coatings

Basic M10 Mild Steel Plain Washers can be supplied plain for indoor or dry conditions. However, mild steel is highly adaptable — and it’s easy to add protective coatings for better corrosion resistance.

For example, zinc plating adds a layer of rust protection and gives the washer a shiny finish. Phosphate coatings add mild rust protection and help paint adhere. Black oxide offers a sleek appearance for indoor fixtures.

This means you can match your washers to the environment: plain for indoor structural steel, zinc-plated for moderate outdoor exposure, or painted/black oxide for decorative metalwork. This adaptability makes mild steel washers practical for large projects with mixed exposure conditions.

Reusable and Cost-Effective

A high-quality M10 Mild Steel Plain Washer doesn’t warp or deform under proper torque. This means it can be reused during maintenance, disassembly, or equipment upgrades.

For large maintenance teams or contractors managing hundreds of fastener points, reusable washers reduce replacement costs. Over time, this adds up to significant savings — all while ensuring you don’t compromise on safety or quality.

Plus, mild steel as a material is affordable, widely available, and easy to manufacture. That means bulk orders of M10 Mild Steel Plain Washers are cost-effective and help keep overall project costs in check, especially when compared to using more expensive specialty metals.

Easy to Handle and Install

Unlike some specialty washers with locking tabs or complex shapes, M10 Mild Steel Plain Washers are simple, flat, and easy to handle. Workers don’t need special training to install them. Just slip the washer onto the bolt or screw before tightening — it’s that simple.

In high-volume assembly lines, this simplicity helps maintain speed without compromising on fastening quality. For large construction crews, it reduces errors during installation and ensures every joint gets the protective benefits a washer provides.

Compatibility with Standard Bolts and Nuts

M10 Mild Steel Plain Washers are designed to perfectly match standard M10 bolts and nuts. The inner diameter is precisely punched to allow smooth installation without excessive play, while the outer diameter is wide enough to spread load effectively.

This tight dimensional control means you don’t have to worry about washers slipping out of place during tightening — they seat securely under the bolt head or nut.

Available in Bulk for Large Projects

Big projects demand big quantities. Whether you’re building multi-story frameworks, retrofitting industrial plants, or installing kilometers of guardrails, you need a consistent supply of washers that match your bolt specs.

That’s why we always recommend you Buy M10 Mild Steel Plain Washers in Bulk. Large orders ensure you have consistent quality across your entire project, avoid unexpected shortages, and benefit from competitive bulk pricing.

As the Best M10 MS Flat Washers Manufacturer, we at Nafees Metal Industries guarantee reliable supply and custom packing options to keep your site running smoothly.

Applications of M10 Mild Steel Plain Washers

Construction and Infrastructure

M10 fasteners are common in structural steel frameworks, bridge supports, and guardrails. Washers prevent damage to galvanized beams and brackets, keeping protective coatings intact for longer life.

Automotive and Heavy Vehicles

From mounting chassis components to securing engine parts, M10 Mild Steel Plain Washers protect thin panels and resist vibration loosening.

Industrial Machinery

Machinery frames, conveyor systems, and equipment brackets rely on these washers to maintain tight, stable joints that can withstand dynamic loads.

HVAC Systems

In ducting and mounting large HVAC units, M10 bolts and washers keep flanges secure without deforming the sheet metal.

Furniture and Metal Fixtures

Metal furniture frames, modular shelving, and fixtures often use M10 bolts and washers to protect painted surfaces and maintain joint strength.

DIY Projects and General Repairs

MRO teams and DIY enthusiasts keep MS Flat Washers in stock for general fastening tasks like mounting fences, repairing gates, or building metal structures.

Case Study: How M10 Mild Steel Plain Washers Saved ₹5 Lakhs in Costly Beam Repairs

Background

In early 2024, a well-known industrial storage solutions company was contracted to retrofit a large logistics warehouse for a major e-commerce brand in Western India. The retrofit involved building mezzanine floors to increase vertical storage space — requiring heavy-duty mild steel beams connected by M10 bolts.

Due to tight deadlines and cost pressure, the contractor initially decided to skip using washers altogether, believing that the M10 bolts alone would provide enough clamping force on the flanged beams.

The installation involved over 2,000 bolted joints across multiple beam segments. The fasteners were tightened directly against painted mild steel flanges, holding up pallet racks and floor decking above.

The Problem

For the first two months, everything appeared normal. But as pallet loads increased and the mezzanine saw daily forklift traffic, the maintenance team began noticing small issues:

Bolt heads were digging into the painted steel flanges, causing the paint to crack and flake away.

Exposed bare steel started rusting at multiple contact points.

Local deformation around bolt holes was visible in several flanges.

Bolts in high-load areas gradually lost tension due to the flanges bending under the focused pressure.

This seemingly minor oversight led to serious structural concerns. A third-party safety inspection flagged 75+ flanges that had bent to a point where load integrity was at risk.

Without a fix, the company faced:

✅ Structural reinforcement expenses estimated at over ₹5 lakhs.

✅ Disruption of warehouse operations for several days.

✅ A potential safety hazard that could damage inventory or injure workers.

The Solution

The contractor consulted Nafees Metal Industries, known as the Best M10 MS Flat Washers Manufacturer, for expert advice. After reviewing the problem on-site, our technical team confirmed that the absence of washers had allowed the bolts’ localized force to damage the flanges.

Our immediate recommendation was to retrofit every connection with high-quality M10 Mild Steel Plain Washers — manufactured to precise tolerances and zinc-plated for added corrosion resistance.

Why washers made sense:

✔ Load Distribution: The washers would spread the clamping force over a larger area, preventing further deformation.

✔ Surface Protection: They would shield the beam flanges from direct contact with bolt heads, keeping the paint intact and rust at bay.

✔ Maintaining Tension: By preventing local bending, the bolts would hold their torque longer, reducing loosening under vibration.

✔ Cost-Effective: Replacing washers was far cheaper than cutting and replacing beams.

Our team provided a detailed retrofit plan: unbolt each connection, inspect the flange, realign the beam if needed, add the M10 Mild Steel Plain Washers, and retighten to the correct torque. We also supplied 3,000 washers on priority, ensuring zero project downtime.

Implementation

The warehouse’s maintenance team worked overnight shifts to avoid disrupting daily operations. In phases, they:

Removed bolts from each beam flange.

Slipped on the M10 Mild Steel Plain Washers under each bolt head and nut.

Re-torqued the bolts to the correct clamping force.

Repainted any exposed spots where paint had flaked off.

Even in high-vibration areas (near conveyor tracks and forklift pathways), the washers immediately stabilized the joints. The flanges showed no additional bending, and periodic inspections confirmed that bolt tension held steady.

Results

✅ Structural integrity restored: Zero bent flanges reported after the retrofit, and no new rust spots formed under the bolts.

✅ Maintenance savings: The company avoided an estimated ₹5 lakhs in costly beam replacements and welding reinforcements.

✅ Downtime avoided: The phased installation allowed the warehouse to stay operational, fulfilling the client’s orders without disruption.

✅ Long-term durability: The contractor updated its SOP to mandate M10 Mild Steel Plain Washers for all future beam connections — no exceptions.

Client Feedback

The contractor’s project manager said it best:

“We thought we were saving money by skipping washers. But it almost cost us lakhs in repairs and safety fines. Adding M10 Mild Steel Plain Washers fixed the problem for a fraction of the cost. Nafees Metal Industries didn’t just sell us washers — they saved our project.”

Key Takeaways

This case shows exactly why even a small component like a washer plays a big role in structural projects:

✅ Without M10 Mild Steel Plain Washers, the localized bolt pressure damages painted mild steel flanges, leading to corrosion, bending, and loss of tension.

✅ With washers, the load is distributed evenly, surfaces stay protected, and joints stay secure under vibration and shifting loads.

✅ The upfront cost of bulk washers is negligible compared to the cost of replacing structural beams, losing production time, or failing safety inspections.

How This Applies to You

If your project involves:

Structural beams, channels, or brackets

Painted or coated steel sections

Medium-load bolts like M10

Heavy vibration from machinery or vehicle movement

then investing in bulk M10 Mild Steel Plain Washers is the smartest, most cost-effective insurance you can buy for your structure’s long-term integrity.

It’s a tiny piece that protects your biggest assets — your materials, your time, and your budget.

Why Choose the Best M10 MS Flat Washers Manufacturer

When you order from Nafees Metal Industries, you get:

ISO-aligned manufacturing and QC

Consistent batches for bulk orders

Custom coatings and sizes on request

Technical support for the right specs

Fast lead times and reliable dispatch

It’s why we’re trusted as the Best M10 MS Flat Washers Manufacturer for projects that can’t afford rework.

Installation Tips

Always use a washer under both bolt head and nut if possible.

Tighten to specified torque to prevent overtightening.

Store washers properly to avoid moisture damage.

Maintenance Guidelines

Inspect washers during scheduled maintenance.

Replace bent or corroded washers immediately.

Store extras sealed and dry to prevent rust.

Related Products

Explore our range:

Mild Steel Washers in all standard sizes

Spring and lock washers for anti-vibration

Stainless Steel Flat Washers for corrosive environments

Final Words

From high-rise construction to factory lines, every bolt deserves the right washer. Trust M10 Mild Steel Plain Washers to protect your structures, prevent damage, and deliver maximum value. It’s the small detail that keeps your biggest projects secure.

FAQs

What are M10 Mild Steel Plain Washers used for?

Distributing load, protecting surfaces, and preventing vibration loosening.Are they reusable?

Yes, if undamaged and rust-free.What finishes do you offer?

Plain, zinc-plated, black oxide, and more.Are they suitable for outdoor use?

Yes, with proper coatings.What standards do you follow?

IS/ISO/DIN, as required.Can I get test certificates?

Yes, on request.What sizes do you stock?

From M4 to M40.Do you ship globally?

Yes, worldwide.Can I get samples?

Of course.What is the MOQ?

Flexible — contact us.Do you offer custom packaging?

Yes.How should I store them?

In a dry, sealed container.What’s your lead time?

7–14 days for most orders.Do you offer bulk discounts?

Yes, volume pricing available.Why choose you?

Consistency, reliability, and trusted support.

Why Choose Nafees Metal Industries?

With decades of expertise, Nafees Metal Industries stands out as the Best M10 Mild Steel Plain Washers Manufacturer trusted by clients across automotive, construction, and industrial sectors. We combine high-quality materials, precise engineering, and modern manufacturing processes to deliver washers that exceed industry expectations.

When you choose us, you benefit from:

Reliable bulk supply for large or small orders.

Custom sizing and coating options to match unique project requirements.

Competitive pricing with no compromise on quality.

Timely delivery and responsive customer service.

Whether you’re searching for the Best M10 MS Flat Washers Manufacturer or looking to Buy M10 Mild Steel Plain Washers in Bulk, we’re here to support you every step of the way.

Visit Us Today

Explore our full range of Mild Steel Washers and other precision fasteners by visiting our advanced manufacturing unit at Reay Road, Mumbai. Reach out to our team for quotes, customization options, or to place bulk orders — and experience the quality and trust that define Nafees Metal industries.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch