No products in the cart.

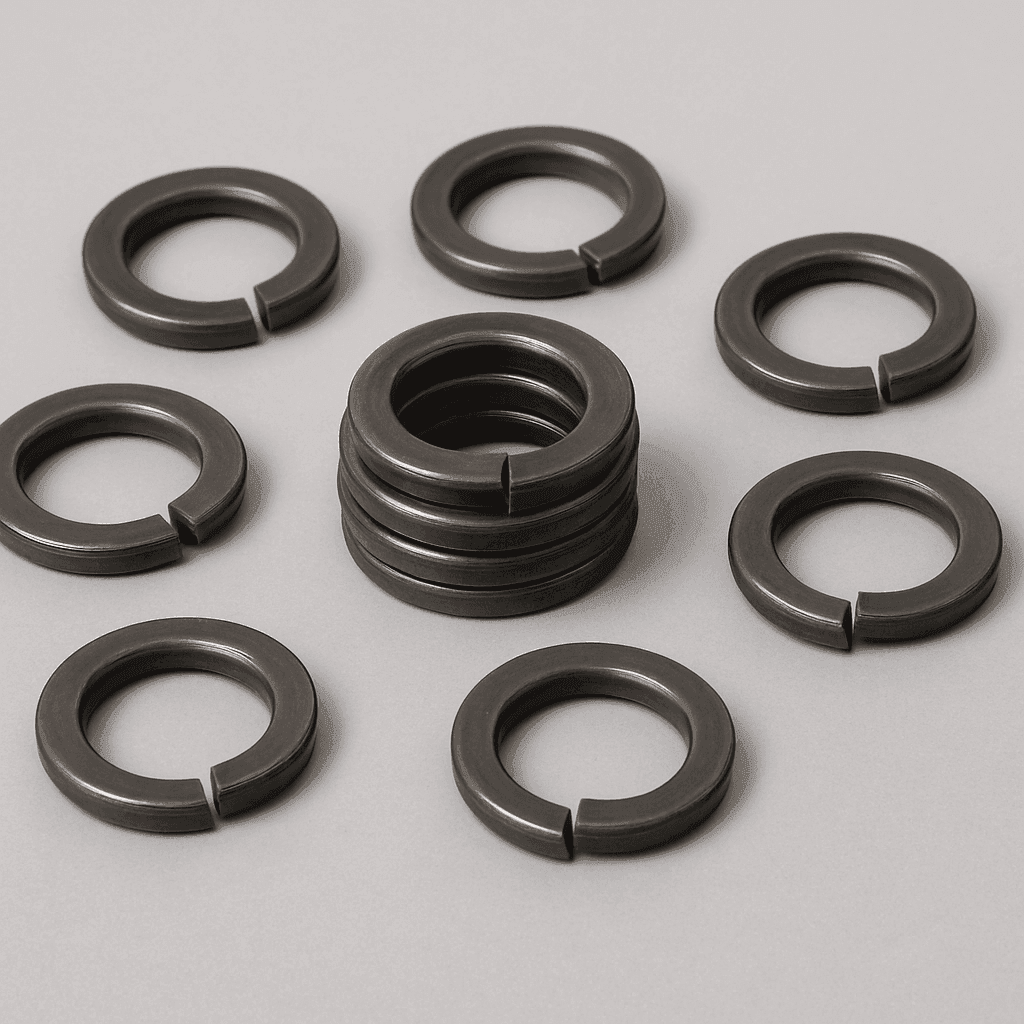

Phosphated Washers – Best Rust-Resistant Washers for Industrial Use

Introduction

In industrial settings where exposure to moisture, chemicals, and harsh environments is common, phosphated washers play a critical role in ensuring the longevity and efficiency of fastener assemblies. These washers undergo a special phosphate treatment, giving them excellent resistance against corrosion and a rough surface that improves paint or coating adhesion.

Whether you’re assembling machinery, structures, or equipment, phosphated washers offer a durable, cost-effective solution to common issues like rust and surface degradation. In this blog, we’ll explore their unique properties, advantages, and why they’re among the best rust-resistant washers for industrial use.

What Are Phosphated Washers?

Phosphated washers are standard metal washers treated with a phosphate chemical solution, typically manganese or zinc-based. This chemical conversion coating offers a protective layer that inhibits rust formation and prepares the surface for secondary coatings, such as paint or oil.

The phosphate treatment also enhances wear resistance, adds mild lubricity, and extends the service life of the washer, especially in corrosive conditions with industrial fasteners.

Key Features of Phosphated Washers

Corrosion Resistance

The phosphate layer acts as a barrier, protecting the metal underneath from oxidation and environmental damage.Improved Paint Adhesion

Phosphated washers provide a suitable surface for coatings to bond better, making them ideal for painted assemblies.Lubricity for Assembly

The slightly porous phosphate coating adds dry lubricity, reducing friction during assembly and improving torque performance.Cost-Effective Surface Treatment

Compared to other surface protection methods, phosphate coating is relatively inexpensive and highly effective for most industrial uses.

Applications of Phosphated Washers

Phosphated washers are widely used in sectors where corrosion protection is vital:

Automotive Industry – Common in engine assemblies, body fastenings, and chassis.

Construction – Used in steel frame structures and outdoor joints.

Electrical Equipment – Offers rust protection in cable trays and switchboards.

Heavy Equipment – Ideal for exposed assemblies on machinery and tools.

Phosphated vs. Other Coated Washers

While there are several coating options available like zinc plating, galvanizing, and black oxide, phosphated washers strike a perfect balance between performance and affordability.

Zinc-plated washers offer higher corrosion resistance but may lack the paint adhesion properties of phosphated ones.

Galvanized washers are best for outdoor use but are thicker and less suitable for precision assemblies.

Black oxide washers improve aesthetics but offer limited corrosion protection compared to phosphate-coated washers.

Phosphated washers provide optimal rust resistance, surface prep, and ease of assembly – making them ideal for large-scale manufacturing.

Benefits of Using Phosphated Washers in Industrial Assemblies

Maintains integrity of joints in humid or chemically aggressive environments

Reduces the likelihood of fastener failure due to rust

Ensures secure torque values during installation

Enhances finish quality in painted or coated assemblies

Environmentally safer than many plating options

How to Choose the Right Phosphated Washer?

Material Compatibility

Ensure the washer base material matches your assembly’s mechanical needs – common options include carbon steel and mild steel.Type of Phosphate Coating

Zinc phosphate offers enhanced corrosion resistance, while manganese phosphate adds wear protection.Washer Thickness and Diameter

Select based on bolt size and load-bearing requirements.Environmental Conditions

Consider the operating conditions—wet, hot, chemically exposed—to determine the ideal coating type.

🛒 Buy Phosphated Washers in Bulk from Nafees Metal Industries

At Nafees Metal Industries, we specialize in the manufacturing and supply of high-quality best phosphated washers for corrosion protection for industrial applications. Our washers are chemically treated under controlled processes to ensure even coating, consistent surface finish, and long-lasting protection.

Whether you’re looking for small quantities for prototype development or want to buy phosphated washers in bulk for large production runs, we offer fast delivery and reliable quality across the board.

Conclusion

In a world where rust and corrosion can undermine the reliability of fasteners and machinery, phosphated washers provide an effective, economical solution. With their excellent adhesion characteristics, dry lubricity, and superior corrosion resistance, they serve as the best rust-resistant washers for industrial use.

Upgrade your fastener game with the right surface treatment—choose phosphated washers for a dependable, corrosion-proof connection.

Tags: anti-corrosion washers, best phosphated washers, industrial fasteners, phosphate coating, phosphated washers, rust-resistant washers

Related posts

Introduction Heavy machinery, structural assemblies, and industrial-grade equipment rely on the strength and stability of every fastened joint. A crucial but often overlooked component that... Continue reading

In the realm of industrial assembly and manufacturing, attention to detail often defines the difference between failure and flawless performance. One such critical component—though often... Continue reading

Introduction When it comes to choosing washers that offer both corrosion resistance and electrical insulation, brass washers are an unmatched choice. These high-performance components are... Continue reading

In the world of industrial fasteners, sometimes it’s the simplest components that perform the most critical roles. One such unsung hero is the mild steel... Continue reading

When it comes to high-performance industrial components, the smallest parts often play the biggest roles. Among them, stainless steel flat washers are a quiet force... Continue reading

Leave a reply