No products in the cart.

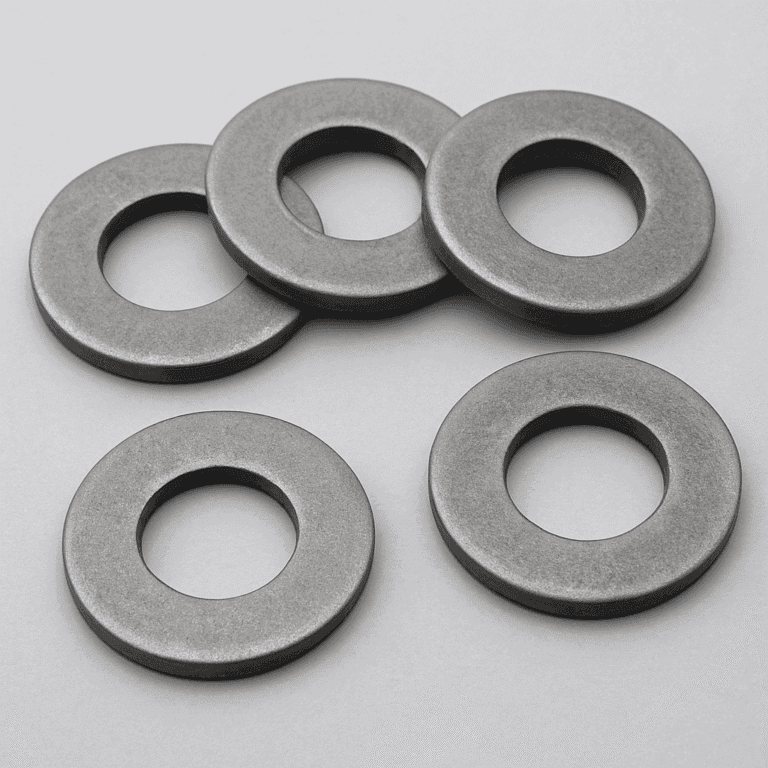

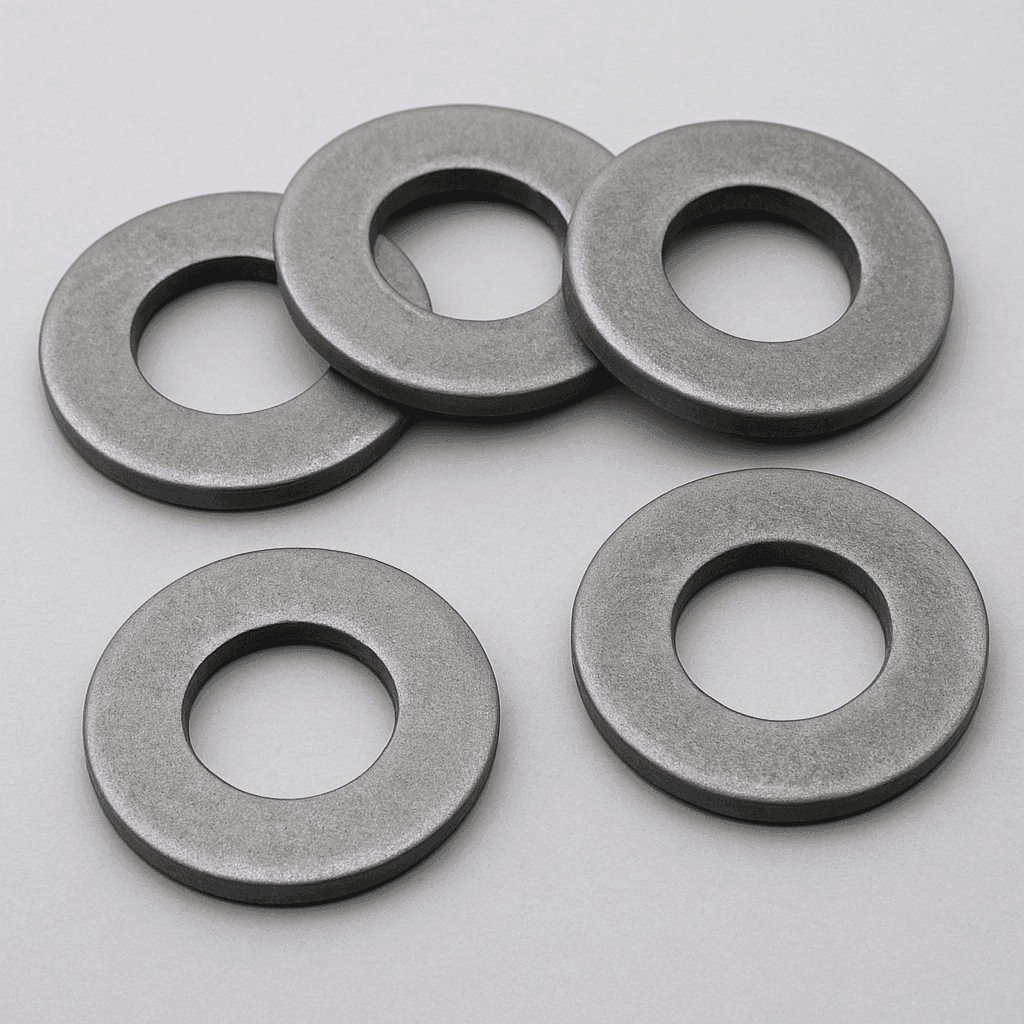

Mild Steel Plain Washers – Durable Support for Heavy-Duty Industrial Fastening

Introduction - Mild Steel Plain Washers

Mild steel plain washers may be small in size, but they hold enormous importance in ensuring the strength and stability of fastened joints in machinery and structures. Among the many types available, mild steel plain washers are one of the most versatile and cost-effective choices for everyday industrial applications.

At Nafees Metal Industries, we specialize in manufacturing and supplying punched mild steel plain washers that provide a stable surface area for nuts and bolts, reducing wear, pressure, and vibration on fastened assemblies.

What Are Mild Steel Plain Washers?

Plain washers are flat, round metal disks with a hole in the center, typically used to distribute load over a larger surface area. Mild steel as a material offers a balance of durability, affordability, and workability—making it a popular choice across industries.

Our punched mild steel washers are produced using high-speed punching machines for precise dimensions and uniform thickness.

What Are Stainless Steel Spring Washers?

Spring washers, also known as split lock washers, are circular washers with a cut and a slight twist, allowing them to exert a spring force between the fastener’s head and the surface. This design helps:

Alt Tag: Mild steel plain washers for industrial punched fastener applications

Prevent bolt loosening from vibration

Maintain tension in dynamic loads

Resist corrosion and environmental wear (especially in stainless steel variants)

Our stainless steel spring washers are available in SS202, SS304, and SS316 grades, offering excellent anti-vibration and corrosion-resistant performance.

Applications of Industrial Mild Steel Washers

Plain washers made of mild steel are used wherever nuts and bolts are tightened against surfaces. Their role is to protect surfaces, prevent loosening, and maintain the integrity of the joint.

Widely used in:

Heavy machinery and equipment

Electrical panel installations

Automobile and railway components

Structural steel frameworks

Home appliance manufacturing

Agricultural machinery

Whether you’re building a bridge or assembling an engine, industrial washers play a key role in your assembly’s long-term success.

Why Use Mild Steel Plain Washers?

1. Load Distribution:

Prevents damage to the surface material by distributing the pressure evenly around the bolt head.

2. Bolt Protection:

Reduces friction during tightening and loosening, which increases bolt life.

3. Anti-Loosening Support:

Minimizes loosening of fasteners due to vibration and thermal expansion.

4. Cost-Effective:

Mild steel is significantly more affordable than stainless steel or high-tensile materials, making it ideal for mass production and cost-sensitive projects.

Types of Mild Steel Plain Washers We Offer

We manufacture punched washers in various shapes and thicknesses depending on the requirement:

| Type | Details |

|---|---|

| Punched Plain Washers | Economical and precise; ideal for general applications |

| Machined Plain Washers | CNC-machined for critical dimensions and surface finishes |

| Special Flat Washers | Customized OD/ID as per drawing or load requirements |

| Galvanized/MS Black Finish | For enhanced rust resistance or aesthetic use |

All washers are tested for concentricity, flatness, and inner diameter tolerance.

Technical Details

Spring washers, also known as split lock washers, are circular washers with a cut and a slight twist, allowing them to exert a spring force between the fastener’s head and the surface. This design helps:

| Specification | Details |

|---|---|

| Material | Mild Steel (IS 2062, CR Sheets) |

| Size Range | M3 to M72 |

| Thickness | 1mm to 10mm (or as required) |

| Tolerance | +/- 0.05mm |

| Surface Finish | Natural, Blackodised, Zinc Plated, Hot Dip Galvanized |

Why Punched Washers Are Preferred in Industry

Punched washers are produced using die-cutting or punching presses that ensure:

- Quick mass production

- Uniform finish

- Minimal wastage

- Cost efficiency

For bulk buyers looking to buy industrial punched washers in bulk, punched mild steel washers are the best solution in terms of time and cost savings.

Best Mild Steel Plain Washers for Heavy Machinery

When used in heavy-duty industrial machinery, plain washers play a huge role in:

- Preventing component fatigue

- Withstanding thermal and vibratory loads

- Improving lifespan of bolted joints

- Reducing need for frequent maintenance

At Nafees Metal Industries, we supply the best mild steel plain washers for heavy machinery that are built to endure such challenging environments.

🛒 Bulk Ordering & Customization

We supply to OEMs, contractors, equipment manufacturers, and exporters with:

- Ready stock for common sizes

- Custom orders for unique washer sizes and thickness

- Bulk dispatch options with packaging to prevent rust

- Third-party inspection and lab certification (if required)

You can also buy industrial punched washers in bulk directly from us by contacting our sales team or using our website inquiry form.

🏭 Why Choose Nafees Metal Industries?

We are known for consistency, quality, and prompt service. With decades of experience in metal washer manufacturing, we understand the demands of industries that rely on dependable fasteners.

What Sets Us Apart:

In-house die setup and punching facility

Capacity to fulfill high-volume orders

Export-ready packaging

Competitive pricing and bulk discounts

Commitment to on-time delivery

If you’re searching for a reliable and cost-efficient washer for your structural or mechanical assembly, mild steel plain washers offer the perfect balance. They’re robust, affordable, and easy to work with—especially when sourced from a trusted manufacturer like Nafees Metal Industries.

Tags: Buy Washers in Bulk, custom washers manufacturer, fasteners for machinery, heavy duty washers, Industrial Washers, low cost washers, mild steel plain washers, MS flat washers, Nafees Metal Industries, punched washers

Related posts

Introduction Heavy machinery, structural assemblies, and industrial-grade equipment rely on the strength and stability of every fastened joint. A crucial but often overlooked component that... Continue reading

In the realm of industrial assembly and manufacturing, attention to detail often defines the difference between failure and flawless performance. One such critical component—though often... Continue reading

Introduction In industrial settings where exposure to moisture, chemicals, and harsh environments is common, phosphated washers play a critical role in ensuring the longevity and... Continue reading

Introduction When it comes to choosing washers that offer both corrosion resistance and electrical insulation, brass washers are an unmatched choice. These high-performance components are... Continue reading

In the world of industrial fasteners, sometimes it’s the simplest components that perform the most critical roles. One such unsung hero is the mild steel... Continue reading

Leave a reply