No products in the cart.

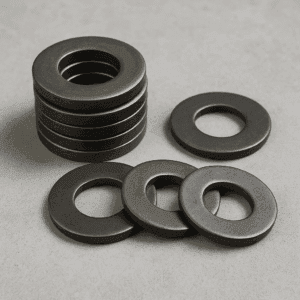

High-Temperature Washers – Designed for Extreme Heat and Heavy-Duty Performance

Introduction

Industrial machinery and high-heat environments demand components that won’t fail under pressure—and that’s where high-temperature washers come into play. Built to endure extreme heat and thermal cycling, these washers are essential in maintaining secure joints, preventing loosening, and prolonging the life of both the fastener and the material it joins.

Whether you operate in power generation, automotive engineering, or metallurgy, heat-resistant washers are your first line of defense against temperature-induced breakdowns.

What Makes High-Temperature Washers Different?

Regular washers fail to retain their shape and functionality under thermal stress. In contrast, high-temperature washers are engineered using specialized alloys or coatings that:

Resist deformation and thermal expansion

Maintain clamping force at high operating temperatures

Offer oxidation and corrosion resistance

Sustain performance in fluctuating thermal environments

These properties make them ideal for high-stakes industries where even a minor component failure can lead to costly downtime or hazardous conditions.

Common Materials Used in High-Temperature Washers

Inconel

A nickel-chromium-based alloy known for its extreme heat resistance, often used in aerospace and chemical processing industries.Stainless Steel Grades (304, 316, 321)

Widely used for their durability and resistance to both heat and corrosion.Titanium

Lightweight and thermally stable, suitable for high-end applications such as motorsports and defense equipment.Mica and Ceramic-Based

For electrical applications that require insulation alongside heat resistance.

Key Applications

Let’s look at how best washers for high-temperature environments support industrial operations:

Automotive Engines & Exhausts

With engine temperatures exceeding hundreds of degrees, high-temp washers ensure bolt stability in engine blocks and manifolds.Turbines and Generators

Used in power plants and aviation, these washers prevent thermal loosening in high RPM rotating equipment.Metal Processing Units

Furnaces, heat treatment plants, and casting systems utilize these washers to hold assemblies together despite high internal temperatures.Heavy Machinery

Bulldozers, cranes, and other industrial equipment operate in harsh climates where heat-resistant fasteners are essential.

Choosing the Right High-Temperature Washer

When selecting heat-resistant washers, keep the following in mind:

Operating Temperature Range

Match the washer’s capacity to your system’s max heat output.Washer Type

Choose between flat, lock, conical, or wave washers depending on load and thermal dynamics.Material Compatibility

Ensure the washer material aligns with the metals of your bolts and components to prevent galvanic corrosion.

Why Nafees Metal Industries?

At Nafees Metal Industries, we specialize in industrial-grade fasteners including high-temperature washers tailored to meet specific heat thresholds and mechanical load requirements.

✅ Quality Certified Manufacturing

✅ Custom Heat Ratings Available

✅ Tested for Thermal Durability

✅ Bulk Orders and On-Time Delivery

We ensure that each washer withstands high-performance conditions so that your operations never miss a beat.

How to Order

You can now buy heat-resistant washers online directly from our website or request a custom order for your specific requirements. We cater to a wide range of industries including manufacturing, mining, and energy.

Don’t let temperature extremes compromise your operations. Invest in high-temperature washers that offer reliability, safety, and long-term performance. From automotive engines to furnace plants, these washers act as silent sentinels that hold everything together.

Contact Nafees Metal Industries for your industrial washer needs and experience durability where it matters most.

Tags: best washers for high-temperature environments, buy heat-resistant washers online, extreme heat washers, heat-resistant washers, heavy duty washers, high-temperature washers, industrial-grade fasteners, thermal resistant washers

Related posts

Pipelines form the backbone of fluid and gas distribution in industries, residential systems, and large-scale infrastructure projects. While their functionality often draws the most attention,... Continue reading

Introduction In the world of heavy-duty machinery and critical equipment, every component counts — especially the small ones like washers. While they may seem insignificant,... Continue reading

Leave a reply