No products in the cart.

High-Stress Application Washers – How to Choose the Right Washer for High-stress

Introduction

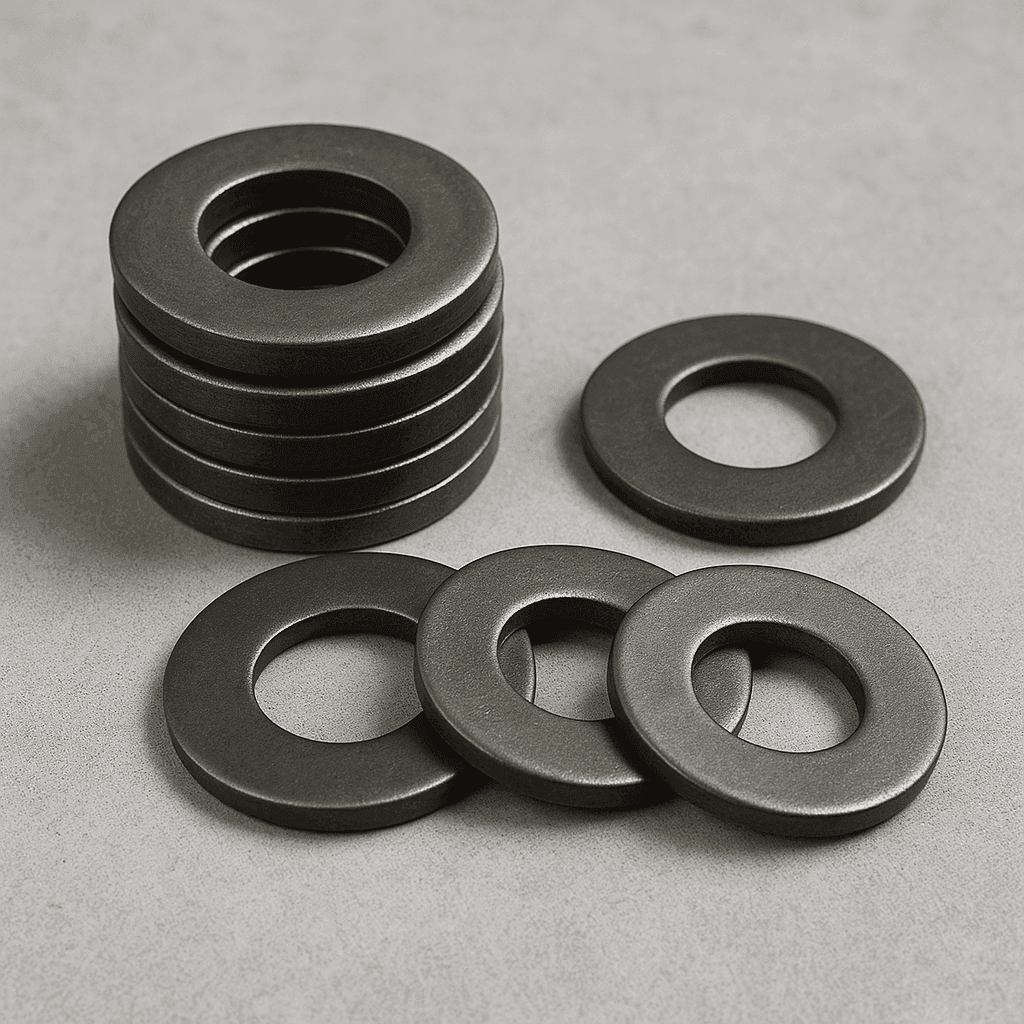

In the world of heavy-duty machinery and critical equipment, every component counts — especially the small ones like washers. While they may seem insignificant, washers play a pivotal role in maintaining stability, load distribution, and vibration reduction. When it comes to high-load environments, choosing the right high-stress application washer becomes a crucial decision that can impact safety, performance, and equipment longevity.

This blog will guide you through how to choose a washer for high-stress conditions and help you find the best washer for heavy load machinery.

Understanding High-Stress Applications

High-stress applications involve machinery or structural systems that undergo immense pressure, torque, temperature fluctuations, or repeated mechanical impact. Examples include:

Construction and mining equipment

Power press machines

Automotive engines and heavy trucks

Rail and aerospace assemblies

Oil rigs and marine engineering

Each of these environments demands specialized washers engineered to perform under extreme stress.

Why Regular Washers Fail?

A typical flat washer made from standard steel might suffice for light-duty tasks. However, in high-stress environments, regular washers may:

Flatten or deform under pressure

Loosen due to vibration

Fail to distribute load evenly

Corrode due to temperature or environmental exposure

This failure leads to compromised bolt tension, equipment wear, or even structural damage — making washer selection a serious engineering decision.

Key Factors for Selecting High-Stress Application Washers

Let’s break down the important parameters when choosing washers for industrial strength and reliability:

1. Material Composition

Material determines how much stress a washer can endure. Look for:

Hardened Steel: Excellent for shock loads and repetitive impact.

Stainless Steel (SS304/SS316): Corrosion-resistant and moderately strong — ideal for marine or chemical settings.

Alloy Steel: Exceptional tensile strength and fatigue resistance.

Spring Steel: Great for washers designed to absorb movement and shock, like Belleville or disc springs.

2. Washer Type and Design

Different industrial washer types are engineered to handle specific challenges:

Spring Washers: Absorb shock and resist vibration.

Belleville Washers: Ideal for cyclic loading.

Disc Spring Washers: Support dynamic axial loads.

Punched or Machined Washers: Offer tight tolerances for custom fits.

Thick Flat Washers: Distribute load across a wide area.

Each has unique benefits depending on the load condition and system requirement.

Matching Washer to Load Type

Match the washer to the type of stress your application generates:

| Load Type | Recommended Washer |

|---|---|

| Static Load | Thick Flat Washer / Hardened Washer |

| Cyclic or Dynamic | Belleville / Disc Spring Washer |

| Vibrational Load | Spring Lock Washer / Wave Washer |

| Thermal Expansion | Stainless Steel Flat Washer |

Coating and Finish

Surface treatment improves life and function in tough conditions:

Zinc Plating: Prevents corrosion in mild outdoor exposure.

Phosphating: Enhances wear resistance and friction control.

Black Oxide: Improves rust resistance and appearance.

Hot-Dip Galvanized: Heavy-duty rust protection for outdoor use.

Always choose the coating based on environmental exposure and chemical contact.

Why Custom Washers Are Best for High-Stress Jobs?

In many heavy-duty cases, off-the-shelf washers may not meet precision or load requirements. Custom punched or machined washers, tailored to your bolt size, torque value, and material needs, are often the best solution. These washers can be manufactured in-house by quality-driven suppliers like Nafees Metal Industries, ensuring tight tolerances and exact dimensions.

Common Industries Using High-Stress Application Washers

Oil & Gas

Power Transmission

Heavy Engineering

Automobile & Trucking

Construction Equipment Manufacturing

These industries prioritize safety and performance, making advanced washer selection crucial.

Conclusion

Washer selection is more than a mechanical afterthought — it’s an essential part of building reliable, high-performing systems. If you’re working with heavy load machinery or involved in a high-pressure industrial setup, choose the best washer for high-stress conditions.

With options like disc spring washers, Belleville types, or custom heavy-duty flat washers, manufacturers can ensure durability, reduced maintenance, and consistent performance.

Tags: best washer for heavy load machinery, custom industrial washers, high-stress application washer, how to choose a washer for high-stress conditions, industrial washer types, Nafees Metal Industries, washer selection

Related posts

Pipelines form the backbone of fluid and gas distribution in industries, residential systems, and large-scale infrastructure projects. While their functionality often draws the most attention,... Continue reading

Introduction Industrial machinery and high-heat environments demand components that won’t fail under pressure—and that’s where high-temperature washers come into play. Built to endure extreme heat... Continue reading

Leave a reply